Smart Graphite–Cement Composites with Low Percolation Threshold

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of Exfoliated Graphite

2.3. Preparation of Cement Composites with Exfoliated Graphite

2.4. Experimental Method and Equipment

2.4.1. Characterization of Exfoliated Graphite and Its Dispersion in Matrix

2.4.2. Mechanical Properties of Composites

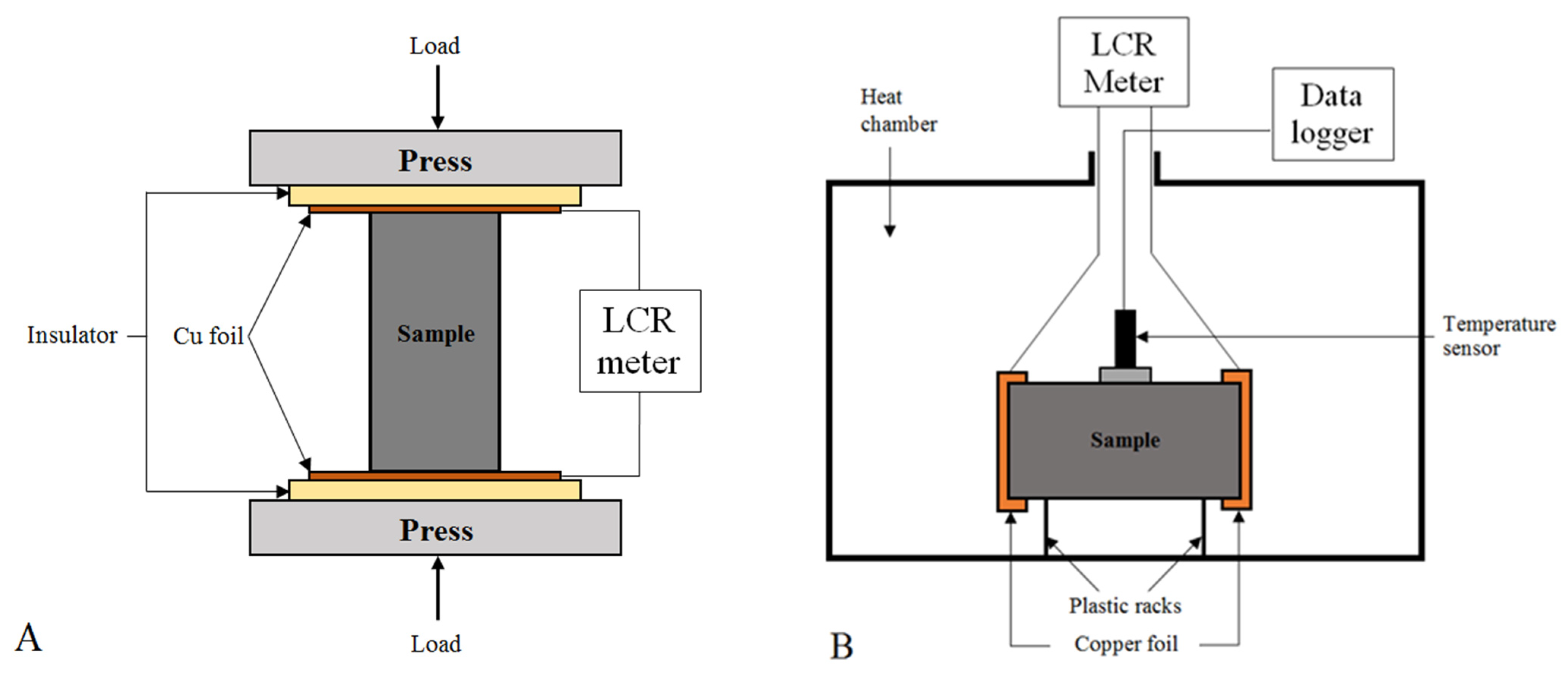

2.4.3. Electrical Conductivity of Composites

2.4.4. Piezoresistive Properties of Composites

2.4.5. Temperature–Resistivity Properties of Composites

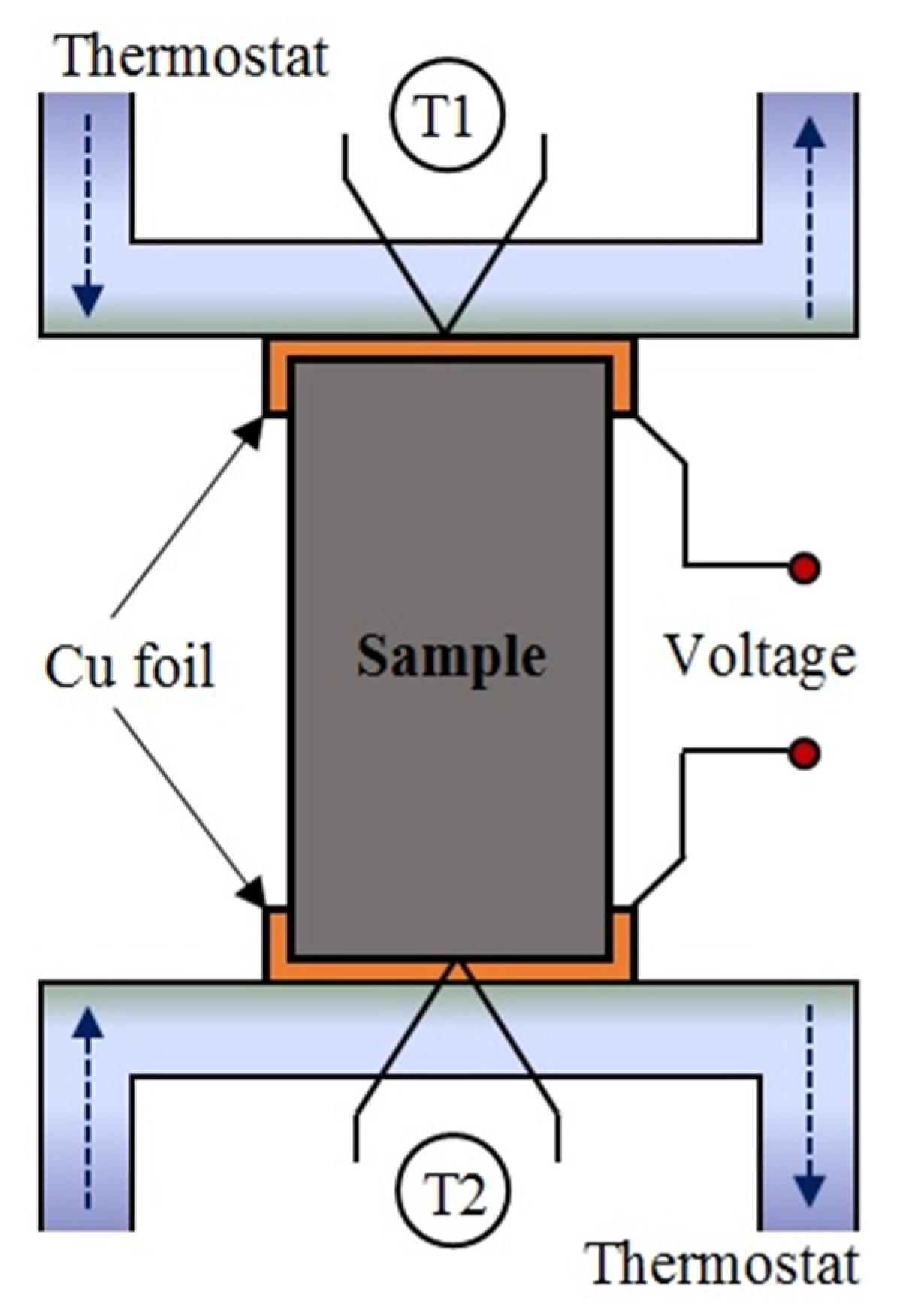

2.4.6. Thermoelectric Properties of Composites

3. Results and Discussion

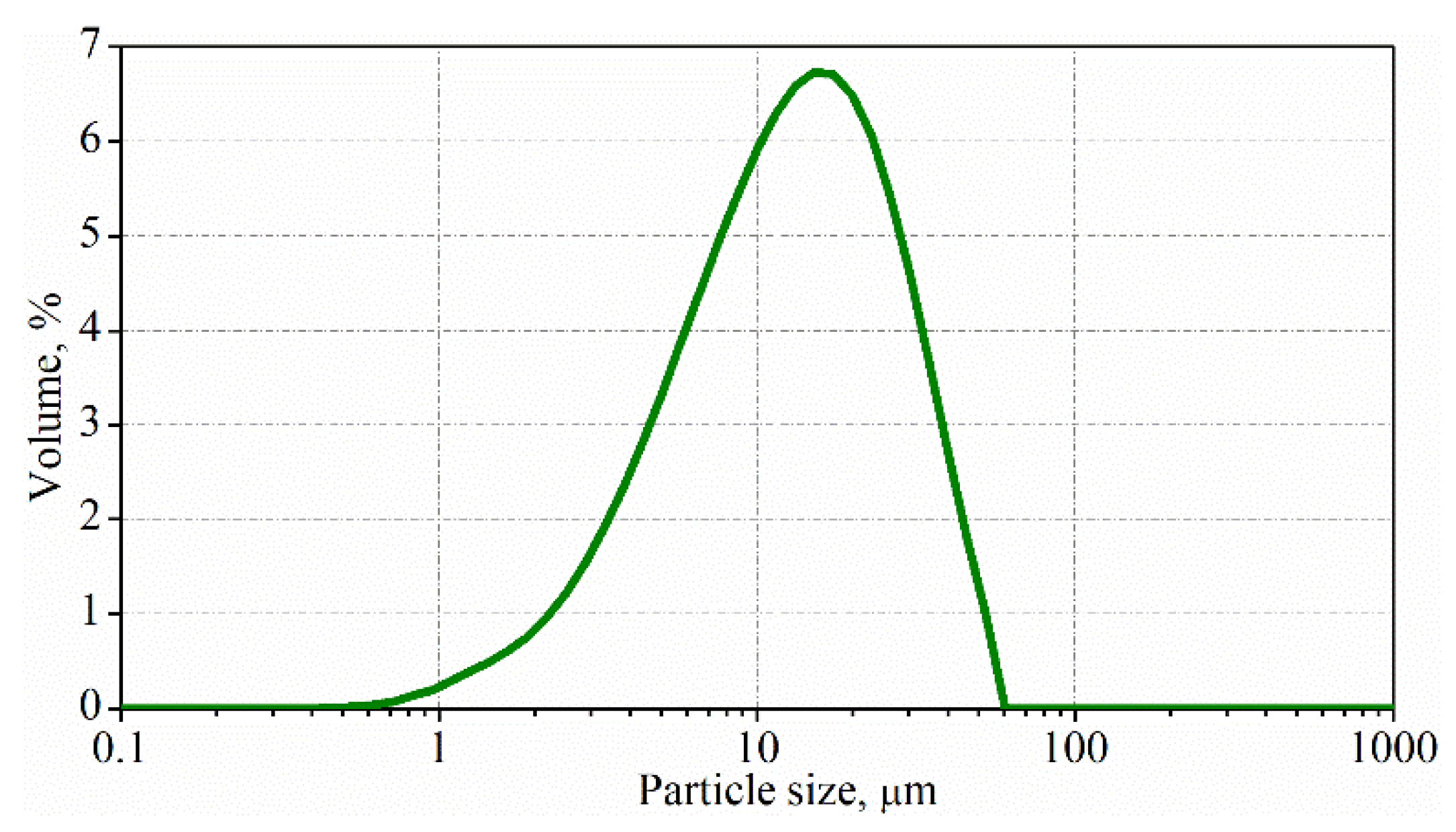

3.1. Characterization of the Particle Size of Exfoliated Graphite

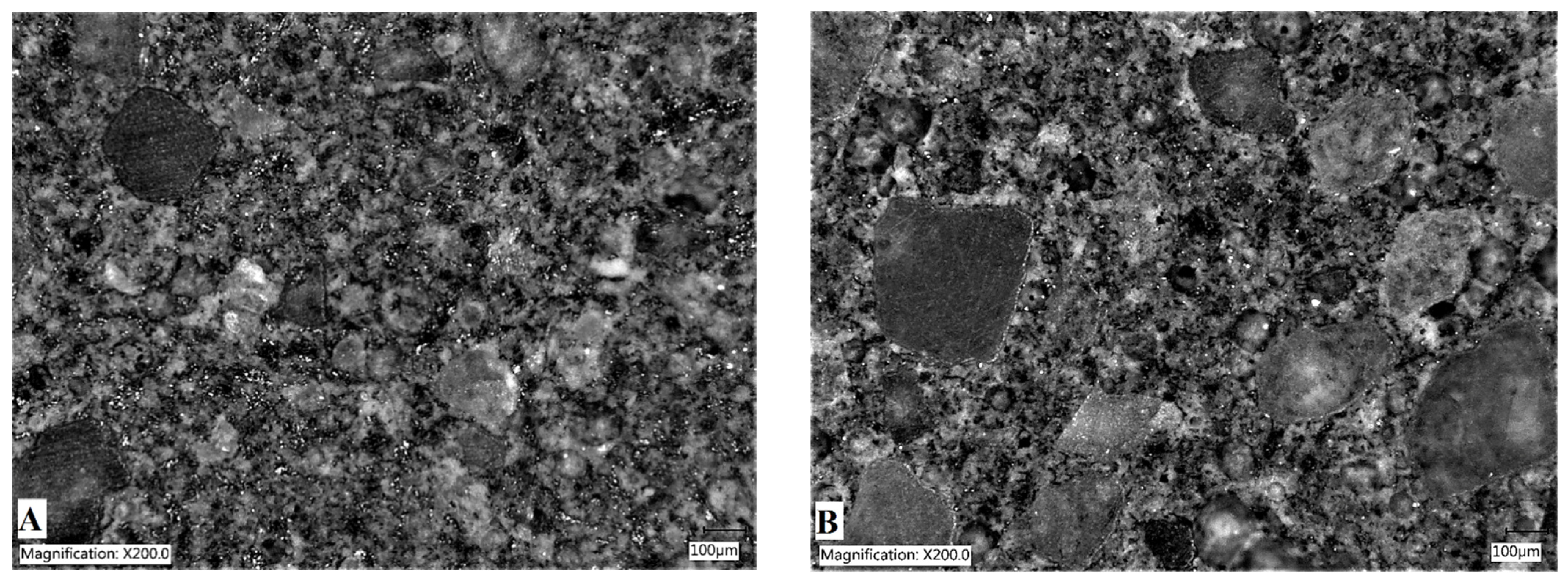

3.2. Dispersion of Exfoliated Graphite in Cement Matrix

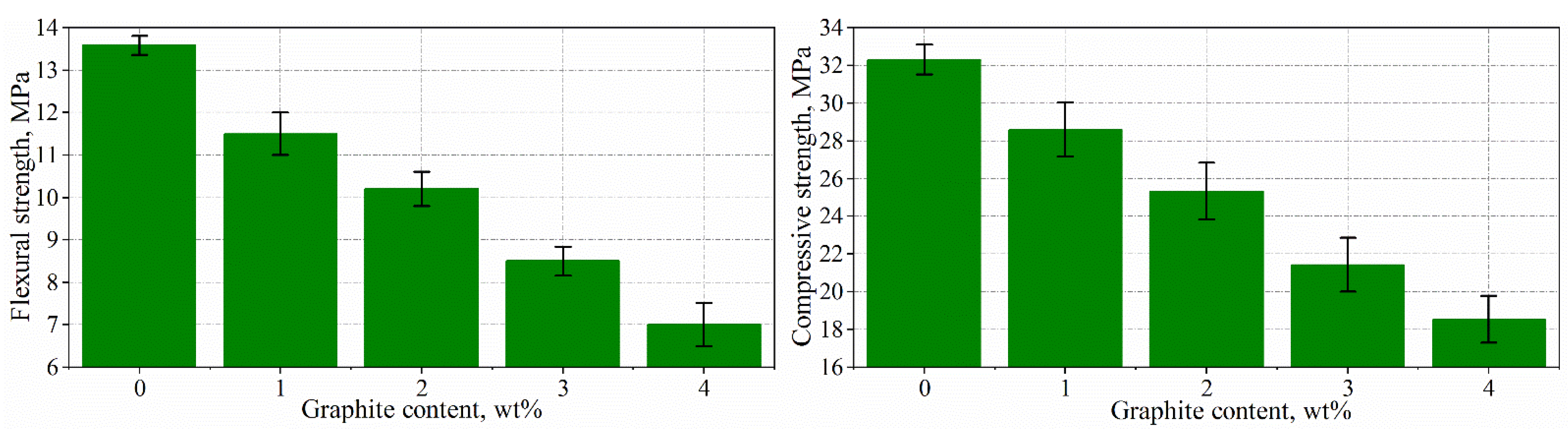

3.3. Mechanical Properties of Composites

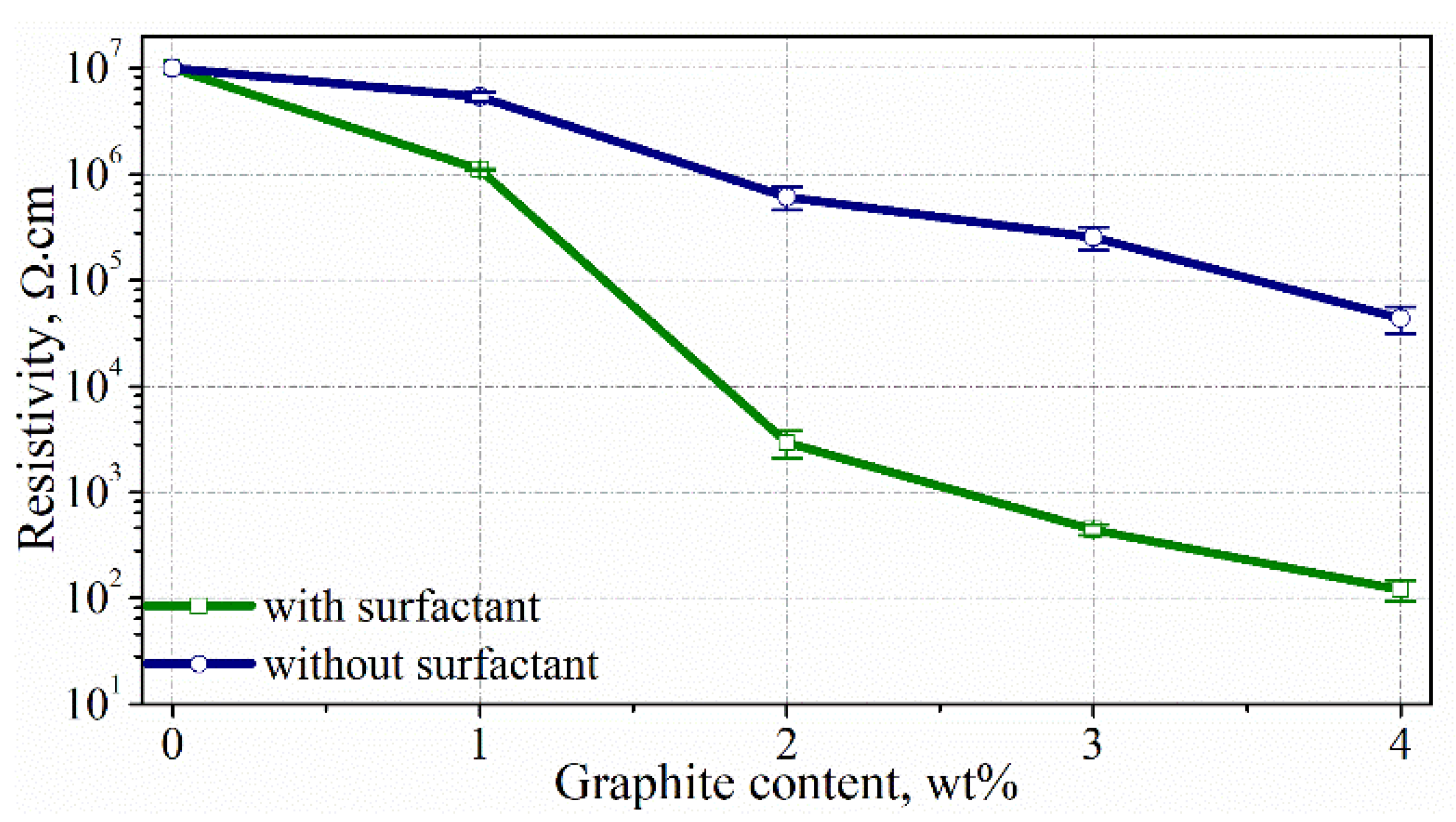

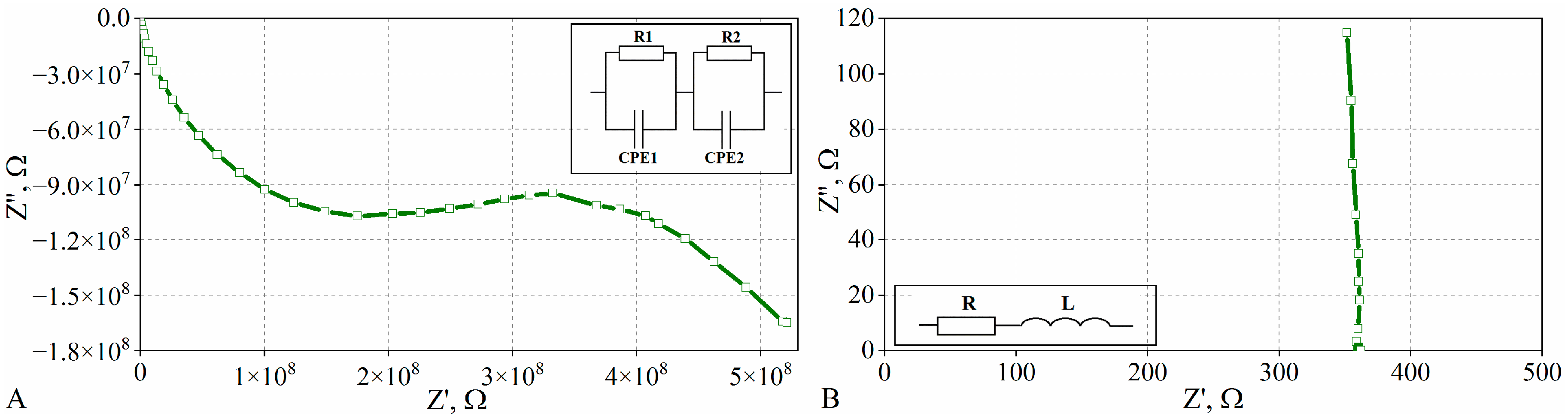

3.4. Electric Conductivity of Composites

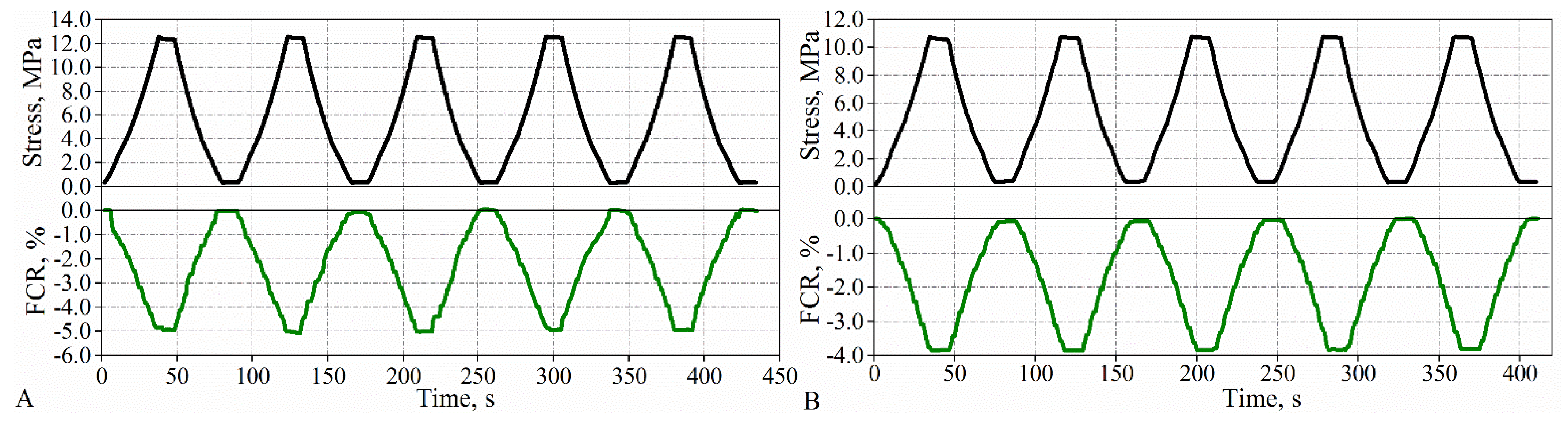

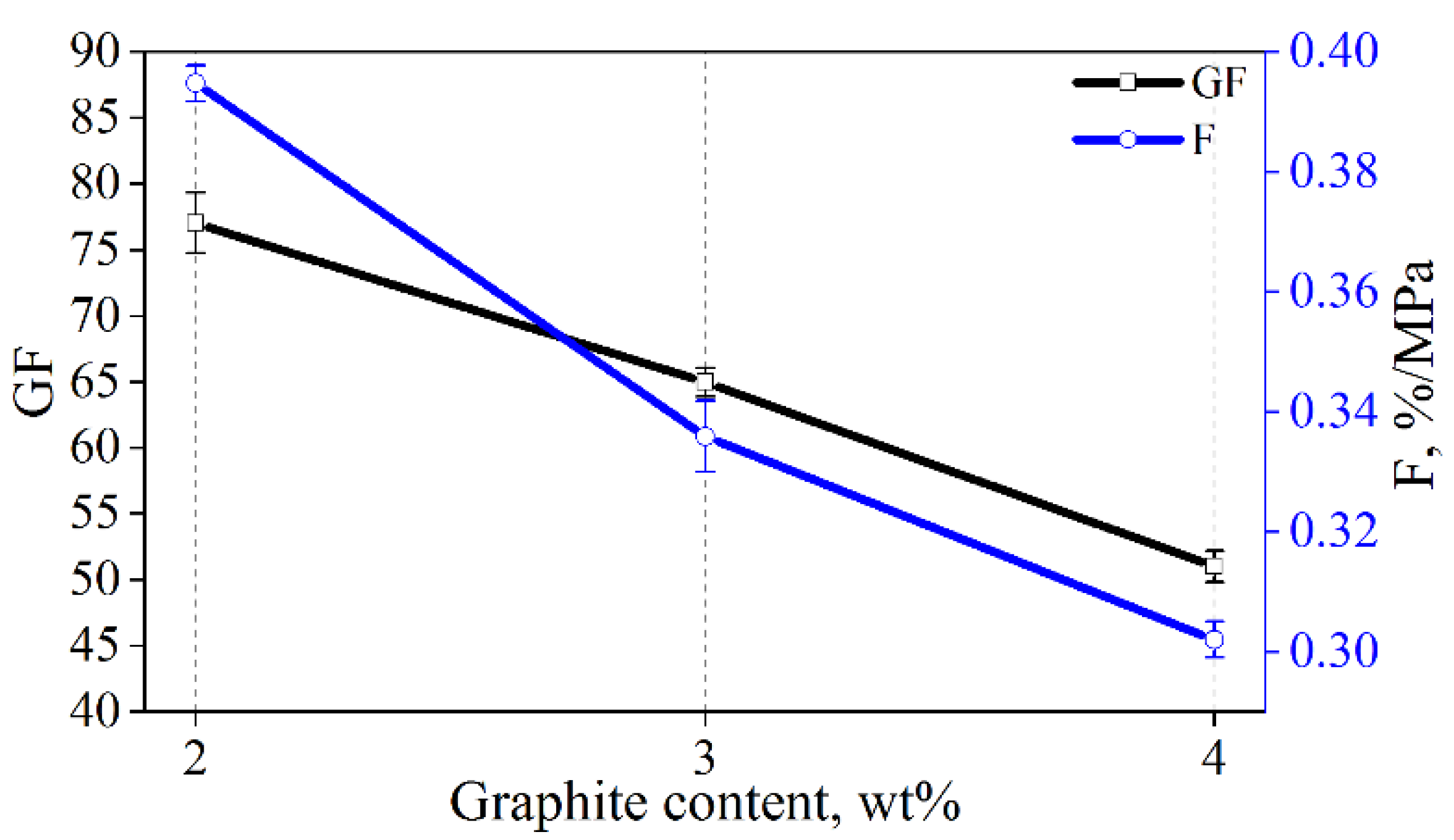

3.5. Piezoresistive Properties of Composites

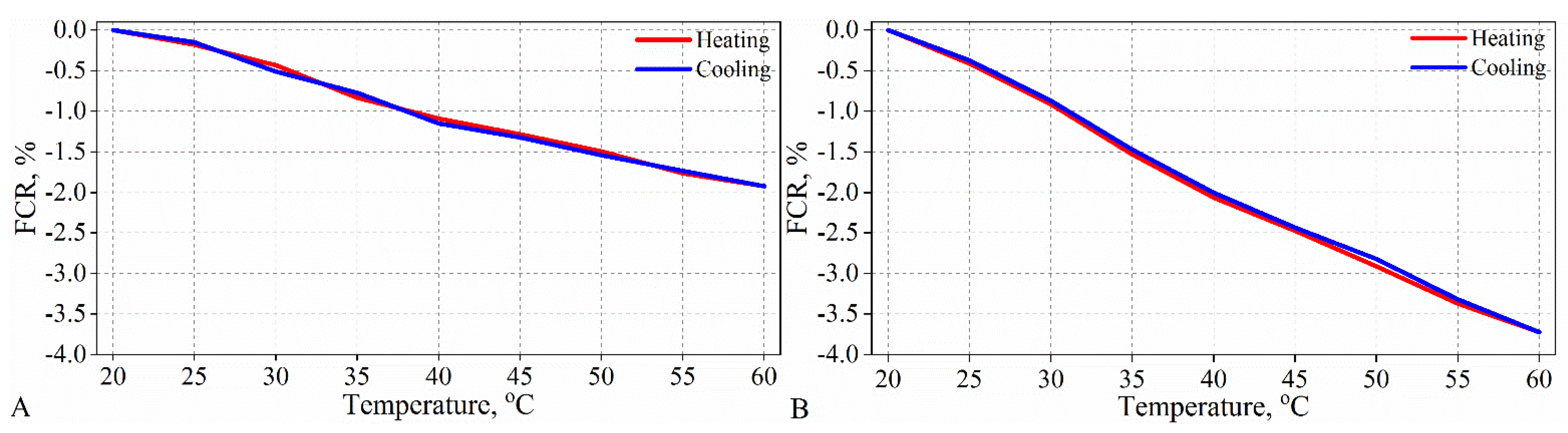

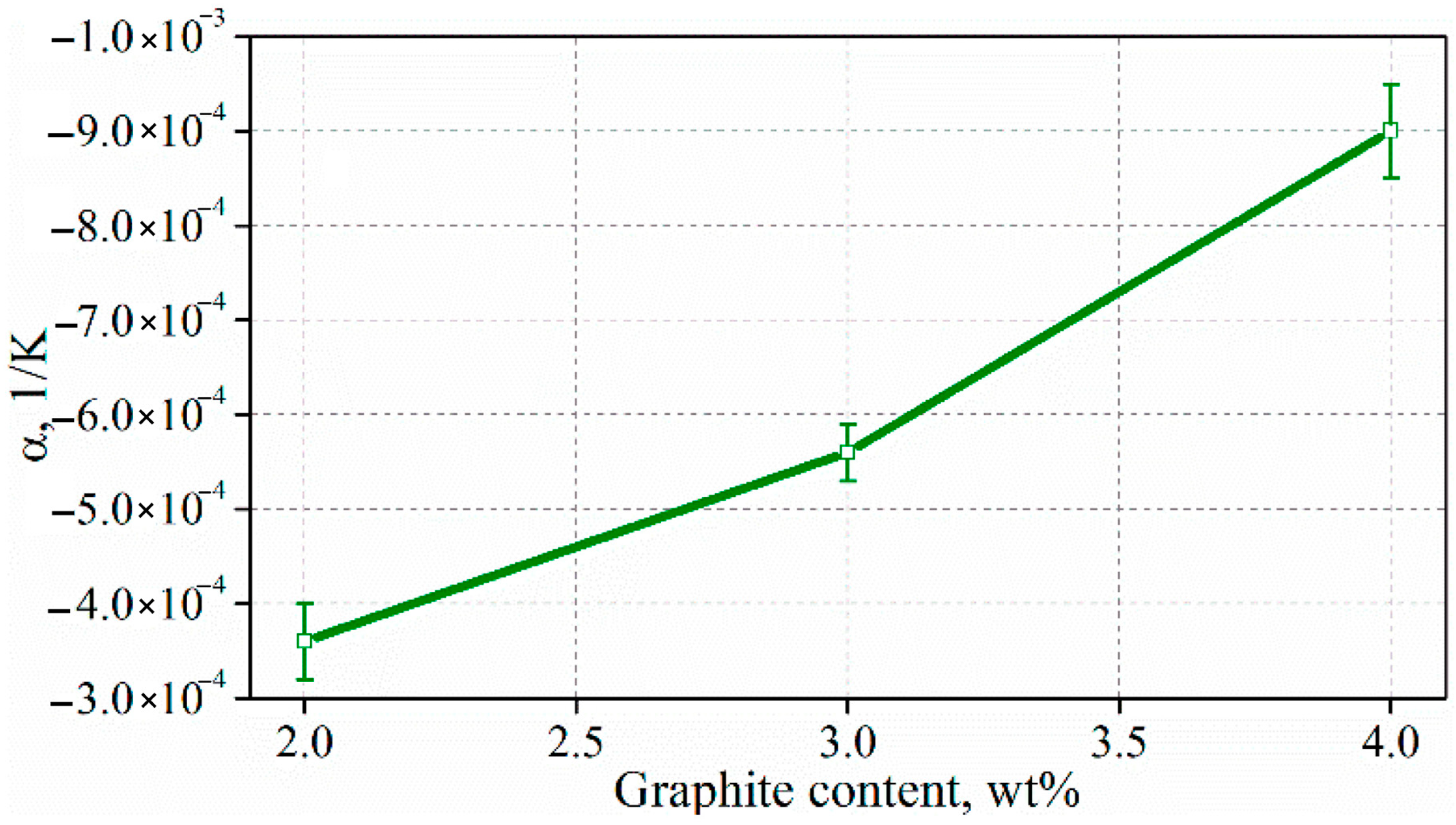

3.6. Temperature–Resistivity Properties of Composites

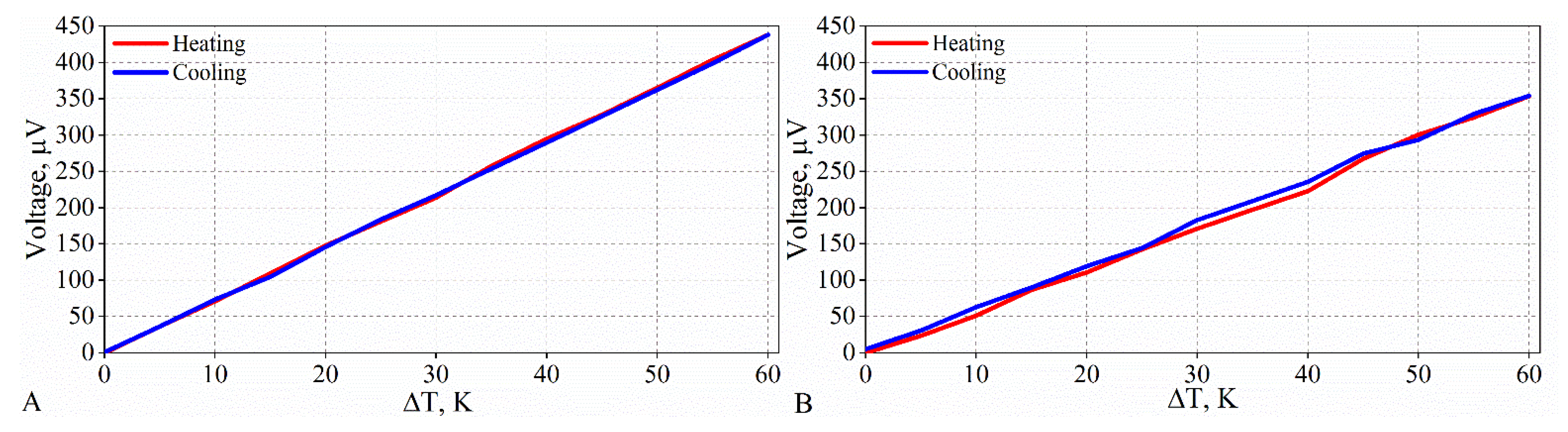

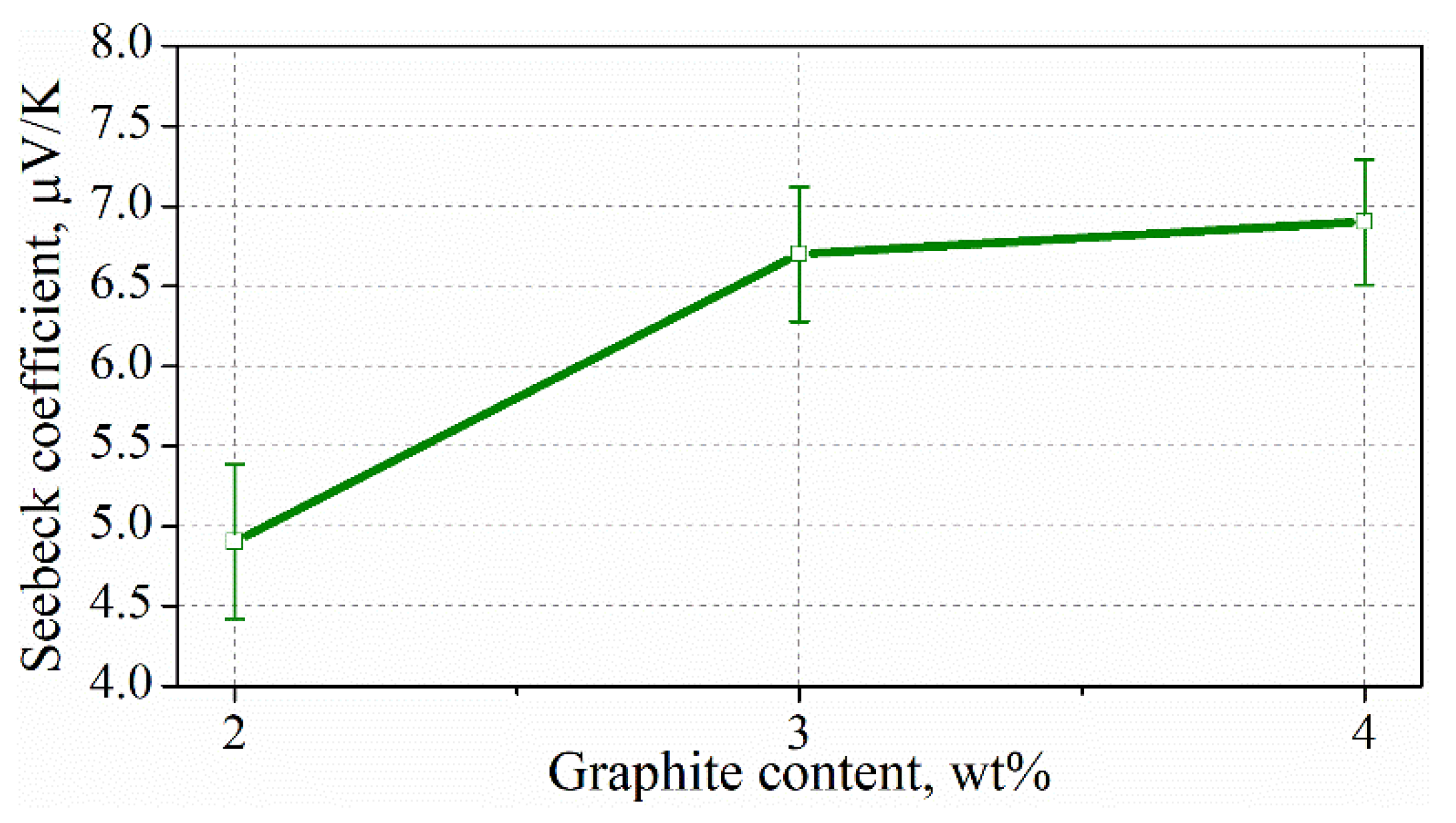

3.7. Thermoelectric Properties of Composites

4. Conclusions

- Exfoliation of expanded graphite in water with surfactant by ultrasonic irradiation is an effective method to obtain smaller graphite particles with a size of less than 40 µm.

- The addition of the surfactant remaining after exfoliation to the exfoliated graphite during the preparation of the composite allows for a good dispersion of the exfoliated graphite into the composites.

- The addition of exfoliated graphite to the cement matrix allows the percolation threshold with a low graphite addition of 0.96 vol% of the total volume of composite (2 wt% cement) to be reached.

- The incorporation of exfoliated graphite reduces the mechanical strength of the composites. However, the mechanical properties are satisfactory for practical application. The flexural and compressive strength values of the composites with a graphite addition of 0.96 vol% (above the percolation threshold) are 10.2 and 25.3 MPa, respectively.

- The cement composites with exfoliated graphite have good synchronization and repeatability of resistivity changes with variations in stress and possess relatively high values of sensitivity.

- The cement composites with the addition of exfoliated graphite above the percolation threshold exhibit a relatively high temperature coefficient of resistivity (−9 × 104 1/K), and the changes in resistivity with temperature variation are linear and repeatable.

- The cement composites with the addition of exfoliated graphite greater than 1.43 vol% (of the total volume of composite) show linear and repeatable changes in thermoelectric voltage during heating and cooling, and the highest Seebeck coefficient is 6.9 μV/K.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Larsen, C. Electrical Resistivity of Concrete-Part II: Influence of Moisture Content and Temperature. In Proceedings of the 2nd International RILEM Symposium on Advances in Concrete through Science and Engineering 2006, Quebec City, QC, Canada, 11–13 September 2006. [Google Scholar] [CrossRef]

- Tumidajski, P.J. Electrical Conductivity of Portland Cement Mortars. Cem. Concr. Res. 1996, 26, 529–534. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Uygunoğlu, T.; Hocaoğlu, İ. Electrical Conductivity of Setting Cement Paste with Different Mineral Admixtures. Constr. Build. Mater. 2012, 28, 414–420. [Google Scholar] [CrossRef]

- Wei, J.; Nie, Z.; He, G.; Hao, L.; Zhao, L.; Zhang, Q. Energy Harvesting from Solar Irradiation in Cities by Thermoelectric Behavior of Carbon Fiber Reinforced Cement Composites. RSC Adv. 2014, 4, 48128–48134. [Google Scholar] [CrossRef]

- Donnini, J.; Bellezze, T.; Corinaldesi, V. Mechanical, Electrical and Self-Sensing Properties of Cementitious Mortars Containing Short Carbon Fibers. J. Build. Eng. 2018, 20, 8–14. [Google Scholar] [CrossRef]

- Baeza, F.J.; Galao, O.; Zornoza, E.; Garcés, P. Effect of Aspect Ratio on Strain Sensing Capacity of Carbon Fiber Reinforced Cement Composites. Mater. Des. 2013, 51, 1085–1094. [Google Scholar] [CrossRef]

- Galao, O.; Baeza, F.J.; Zornoza, E.; Garcés, P. Strain and Damage Sensing Properties on Multifunctional Cement Composites with CNF Admixture. Cem. Concr. Compos. 2014, 46, 90–98. [Google Scholar] [CrossRef]

- Ślosarczyk, A.; Pichór, W.; Frąc, M. Thermal and Electrical Characterization of the Carbon Nanofibers Based Cement Composites. Mater. Sci. 2017, 23, 156–160. [Google Scholar] [CrossRef][Green Version]

- Sun, M.; Li, Z.; Mao, Q.; Shen, D. Thermoelectric Percolation Phenomena in Carbon Fiber-Reinforced Concrete. Cem. Concr. Res. 1998, 28, 1707–1712. [Google Scholar] [CrossRef]

- Xu, J.; Yin, T.; Wang, Y.; Liu, L. Anisotropic Electrical and Piezoresistive Sensing Properties of Cement-Based Sensors with Aligned Carbon Fibers. Cem. Concr. Compos. 2021, 116, 103873. [Google Scholar] [CrossRef]

- Wei, J.; Fan, Y.; Zhao, L.; Xue, F.; Hao, L.; Zhang, Q. Thermoelectric Properties of Carbon Nanotube Reinforced Cement-Based Composites Fabricated by Compression Shear. Ceram. Int. 2018, 44, 5829–5833. [Google Scholar] [CrossRef]

- Sasmal, S.; Ravivarman, N.; Sindu, B.S.; Vignesh, K. Electrical Conductivity and Piezo-Resistive Characteristics of CNT and CNF Incorporated Cementitious Nanocomposites under Static and Dynamic Loading. Compos. Part A Appl. Sci. Manuf. 2017, 100, 227–243. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Rallini, M.; Ubertini, F.; Materazzi, A.L.; Kenny, J.M. Investigations on Scalable Fabrication Procedures for Self-Sensing Carbon Nanotube Cement-Matrix Composites for SHM Applications. Cem. Concr. Compos. 2016, 65, 200–213. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; You, I.; Lee, S.-J. Electrical and Piezoresistive Sensing Capacities of Cement Paste with Multi-Walled Carbon Nanotubes. Arch. Civ. Mech. Eng. 2018, 18, 371–384. [Google Scholar] [CrossRef]

- Le, J.-L.; Du, H.; Pang, S.D. Use of 2D Graphene Nanoplatelets (GNP) in Cement Composites for Structural Health Evaluation. Compos. Part B Eng. 2014, 67, 555–563. [Google Scholar] [CrossRef]

- Dang, N.; Tao, J.; Zeng, Q.; Zhao, W. May the Piezoresistivity of GNP-Modified Cement Mortar Be Related to Its Fractal Structure? Fractal Fract. 2021, 5, 148. [Google Scholar] [CrossRef]

- Ghosh, S.; Harish, S.; Rocky, K.A.; Ohtaki, M.; Saha, B.B. Graphene Enhanced Thermoelectric Properties of Cement Based Composites for Building Energy Harvesting. Energy Build. 2019, 202, 109419. [Google Scholar] [CrossRef]

- Wei, J.; Jia, Z.; Wang, Y.; Jiang, Y.; Miao, Z.; Zhou, Y.; Zhang, H. Enhanced Thermoelectric Performance of Low Carbon Cement-Based Composites by Reduced Graphene Oxide. Energy Build. 2021, 250, 111279. [Google Scholar] [CrossRef]

- Sun, S.; Han, B.; Shan, J.; Yu, X.; Wang, Y.; Li, H.; Ou, J. Nano Graphite Platelets-Enabled Piezoresistive Cementitious Composites for Structural Health Monitoring. Constr. Build. Mater. 2017, 136, 314–328. [Google Scholar] [CrossRef]

- Pichór, W.; Frąc, M.; Radecka, M. Determination of Percolation Threshold in Cement Composites with Expanded Graphite by Impedance Spectroscopy. Cem. Concr. Compos. 2022, 125, 104328. [Google Scholar] [CrossRef]

- Frąc, M.; Pichór, W. Piezoresistive Properties of Cement Composites with Expanded Graphite. Compos. Commun. 2020, 19, 99–102. [Google Scholar] [CrossRef]

- Pichór, W.; Frąc, M. Multifunctional Cement Composites with Expanded Graphite for Temperature Monitoring of Buildings. Adv. Cem. Res. 2020, 32, 413–420. [Google Scholar] [CrossRef]

- Wei, J.; Zhao, L.; Zhang, Q.; Nie, Z.; Hao, L. Enhanced Thermoelectric Properties of Cement-Based Composites with Expanded Graphite for Climate Adaptation and Large-Scale Energy Harvesting. Energy Build. 2018, 159, 66–74. [Google Scholar] [CrossRef]

- Pichor, W. Dynamic electrical properties of lightweight cement mortars with waste graphite additive. Compos. Theory Pract. 2010, 10, 175–180. [Google Scholar]

- Li, H.; Xiao, H.; Ou, J. Effect of Compressive Strain on Electrical Resistivity of Carbon Black-Filled Cement-Based Composites. Cem. Concr. Compos. 2006, 28, 824–828. [Google Scholar] [CrossRef]

- Monteiro, A.O.; Cachim, P.B.; Costa, P.M.F.J. Self-Sensing Piezoresistive Cement Composite Loaded with Carbon Black Particles. Cem. Concr. Compos. 2017, 81, 59–65. [Google Scholar] [CrossRef]

- Dong, S.; Han, B.; Ou, J.; Li, Z.; Han, L.; Yu, X. Electrically Conductive Behaviors and Mechanisms of Short-Cut Super-Fine Stainless Wire Reinforced Reactive Powder Concrete. Cem. Concr. Compos. 2016, 72, 48–65. [Google Scholar] [CrossRef]

- Demircilioğlu, E.; Teomete, E.; Ozbulut, O. Strain Sensitivity of Steel-Fiber-Reinforced Industrial Smart Concrete. J. Intell. Mater. Syst. Struct. 2019, 31, 127–136. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D.L. Seebeck Effect in Steel Fiber Reinforced Cement. Cem. Concr. Res. 2000, 30, 661–664. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D. A Comparative Study of Steel- and Carbon-Fiber Cement as Piezoresistive Strain Sensors. Adv. Cem. Res. 2003, 15, 119–128. [Google Scholar] [CrossRef]

- Frąc, M.; Szudek, W.; Szołdra, P.; Pichór, W. The Applicability of Shungite as an Electrically Conductive Additive in Cement Composites. J. Build. Eng. 2022, 45, 103469. [Google Scholar] [CrossRef]

- Han, B.; Han, B.; Yu, X. Effects of the Content Level and Particle Size of Nickel Powder on the Piezoresistivity of Cement-Based Composites/Sensors. Smart Mater. Struct. 2010, 19, 065012. [Google Scholar] [CrossRef]

- Teomete, E.; Kolatar, Ö.; Demircilioğlu, E.; Kahraman, S. The Strain Sensitivity of Copper Powder Reinforced Concrete. Chall. J. Struct. Mech. 2017, 3, 96. [Google Scholar] [CrossRef]

- Kim, G.M.; Naeem, F.; Kim, H.K.; Lee, H.K. Heating and Heat-Dependent Mechanical Characteristics of CNT-Embedded Cementitious Composites. Compos. Struct. 2016, 136, 162–170. [Google Scholar] [CrossRef]

- Mingqing, S.; Xinying, M.; Xiaoying, W.; Zuofu, H.; Zhuoqiu, L. Experimental Studies on the Indoor Electrical Floor Heating System with Carbon Black Mortar Slabs. Energy Build. 2008, 40, 1094–1100. [Google Scholar] [CrossRef]

- Frąc, M.; Pichór, W.; Szołdra, P. Cement Composites with Expanded Graphite as Resistance Heating Elements. J. Compos. Mater. 2020, 54, 3821–3831. [Google Scholar] [CrossRef]

- Mu, S.; Yue, J.; Wang, Y.; Feng, C. Electrical, Piezoresistive and Electromagnetic Properties of Graphene Reinforced Cement Composites: A Review. Nanomaterials 2021, 11, 3220. [Google Scholar] [CrossRef]

- Goldmann, E.; Górski, M.; Klemczak, B. Recent Advancements in Carbon Nano-Infused Cementitious Composites. Materials 2021, 14, 5176. [Google Scholar] [CrossRef]

- Lin, Y.; Du, H. Graphene Reinforced Cement Composites: A Review. Constr. Build. Mater. 2020, 265, 120312. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Q.; Huang, Z. Investigation on the Poor Fluidity of Electrically Conductive Cement-Graphite Paste: Experiment and Simulation. Mater. Des. 2019, 169, 107679. [Google Scholar] [CrossRef]

- Chuang, W.; Geng-sheng, J.; Bing-liang, L.; Lei, P.; Ying, F.; Ni, G.; Ke-zhi, L. Dispersion of Carbon Fibers and Conductivity of Carbon Fiber-Reinforced Cement-Based Composites. Ceram. Int. 2017, 43, 15122–15132. [Google Scholar] [CrossRef]

- Zou, B.; Chen, S.J.; Korayem, A.H.; Collins, F.; Wang, C.M.; Duan, W.H. Effect of Ultrasonication Energy on Engineering Properties of Carbon Nanotube Reinforced Cement Pastes. Carbon 2015, 85, 212–220. [Google Scholar] [CrossRef]

- Bai, S.; Jiang, L.; Xu, N.; Jin, M.; Jiang, S. Enhancement of Mechanical and Electrical Properties of Graphene/Cement Composite Due to Improved Dispersion of Graphene by Addition of Silica Fume. Constr. Build. Mater. 2018, 164, 433–441. [Google Scholar] [CrossRef]

- Chung, D. Dispersion of Short Fibers in Cement. J. Mater. Civ. Eng. 2005, 17, 379–383. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. Combined Effect of Silica Fume and Steel Fibers on the Impact Resistance and Mechanical Properties of Concrete. Int. J. Impact Eng. 2010, 37, 879–886. [Google Scholar] [CrossRef]

- Giner, V.T.; Baeza, F.J.; Ivorra, S.; Zornoza, E.; Galao, Ó. Effect of Steel and Carbon Fiber Additions on the Dynamic Properties of Concrete Containing Silica Fume. Mater. Des. 2012, 34, 332–339. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical Behavior and Microstructure of Cement Composites Incorporating Surface-Treated Multi-Walled Carbon Nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Li, K.; Wang, C.; Li, H.; Li, X.; Ouyang, H.; Wei, J. Effect of Chemical Vapor Deposition Treatment of Carbon Fibers on the Reflectivity of Carbon Fiber-Reinforced Cement-Based Composites. Compos. Sci. Technol. 2008, 68, 1105–1114. [Google Scholar] [CrossRef]

- Janowska, I.; Bégin, D.; Ersen, O.; Moldovan, S.; Chizari, K.; Ledoux, M.; Pham-Huu, C. High Yield Graphene and Few-Layer Graphene Synthesis Assisted by Microwaves. Phys. E-Low-Dimens. Syst. Nanostructures 2012, 44, 1009–1011. [Google Scholar] [CrossRef]

- Chen, G.; Wu, C.; Weng, W.; Wu, D.; Yan, W. Preparation of Polystyrene/Graphite Nanosheet Composite. Polymer 2003, 44, 1781–1784. [Google Scholar] [CrossRef]

- Yasmin, A.; Luo, J.-J.; Daniel, I.M. Processing of Expanded Graphite Reinforced Polymer Nanocomposites. Compos. Sci. Technol. 2006, 66, 1182–1189. [Google Scholar] [CrossRef]

- Song, S.H.; Jeong, H.K.; Kang, Y.G. Preparation and Characterization of Exfoliated Graphite and Its Styrene Butadiene Rubber Nanocomposites. J. Ind. Eng. Chem. 2010, 16, 1059–1065. [Google Scholar] [CrossRef]

- Mo, Z.; Zuo, D.; Chen, H.; Sun, Y.; Zhang, P. Synthesis of Graphite Nanosheets/AgCl/Polypyrrole Composites via Two-Step Inverse Microemulsion Method. Eur. Polym. J. 2007, 43, 300–306. [Google Scholar] [CrossRef]

- Afanasov, I.M.; Morozov, V.A.; Kepman, A.V.; Ionov, S.G.; Seleznev, A.N.; Tendeloo, G.V.; Avdeev, V.V. Preparation, Electrical and Thermal Properties of New Exfoliated Graphite-Based Composites. Carbon 2009, 47, 263–270. [Google Scholar] [CrossRef]

- Kalaitzidou, K.; Fukushima, H.; Drzal, L.T. A New Compounding Method for Exfoliated Graphite–Polypropylene Nanocomposites with Enhanced Flexural Properties and Lower Percolation Threshold. Compos. Sci. Technol. 2007, 67, 2045–2051. [Google Scholar] [CrossRef]

- Rehman, S.K.U.; Ibrahim, Z.; Memon, S.A.; Javed, M.F.; Khushnood, R.A. A Sustainable Graphene Based Cement Composite. Sustainability 2017, 9, 1229. [Google Scholar] [CrossRef]

- Rehman, S.K.U.; Ibrahim, Z.; Memon, S.A.; Aunkor, M.T.H.; Faisal Javed, M.; Mehmood, K.; Shah, S.M.A. Influence of Graphene Nanosheets on Rheology, Microstructure, Strength Development and Self-Sensing Properties of Cement Based Composites. Sustainability 2018, 10, 822. [Google Scholar] [CrossRef]

- Luo, J.; Duan, Z.; Zhao, T.; Li, Q. Hybrid Effect of Carbon Fiber on Piezoresistivity of Carbon Nanotube Cement-Based Composite. Adv. Mater. Res. 2010, 143–144, 639–643. [Google Scholar] [CrossRef]

| Content of Exfoliated Graphite, by Weight of Cement, % | Content of Exfoliated Graphite in Relation to the Total of the Composite, % | w/c Ratio | s/c Ratio |

|---|---|---|---|

| 0 | - | 0.40 | 0.75 |

| 1 | 0.49 | ||

| 2 | 0.96 | ||

| 3 | 1.43 | ||

| 4 | 1.90 |

| Conductive Additive | Percolation Threshold | Reference | |

|---|---|---|---|

| Exfoliated graphite | 2 wt% of cement (0.96 vol% of composite) | In this study | |

| Carbon black | 7.22–11.4 vol% of composite | [25] | |

| Carbon fibers | 3 mm—length 7.2 µm—diameter | 0.28 vol% of composite | [6] |

| 12 mm—length 7.2 µm—diameter | 0.09 vol% of composite | [6] | |

| 5 mm—length 7.0 µm—diameter | 1.2 wt% of cement | [9] | |

| Carbon nanotubes | 1 wt% of cement | [13] | |

| 0.6 wt% of cement | [34] | ||

| Expanded graphite | 5 wt% of cement | [20] | |

| Graphene nanoplatelets | 2.4 vol% of composite | [15] | |

| 2 vol% of composite | [19] | ||

| 1.2 wt% of cement | [16] | ||

| Shungite | 16.2 vol% of composite | [31] | |

| Conductive Additive | Content | GF | Stress Sensitivity, %/MPa | Reference | |

|---|---|---|---|---|---|

| Cement composites | Exfoliated graphite | 2 wt% of cement (0.96 vol% of composite) | 77 | 0.38 | In this study |

| Carbon black | 7 wt% of cement | 30 | - | [26] | |

| Carbon fibers | 0.28 vol% of composite | 31 | - | [6] | |

| Carbon nanofibers | 2 wt% of cement | 50 | - | [7] | |

| Carbon nanotubes | 1.1 vol% of cement | 220 | - | [14] | |

| Carbon nanotubes and carbon fibers | 0.6 wt% of cement | 64 | 0.54 | [58] | |

| Copper powder | 0.35 vol% of composite | 44 | - | [33] | |

| Expanded graphite | 5 wt% of cement | 68 | - | [21] | |

| Nanographite | 5 vol% of cement | 156 | 0.78 | [19] | |

| Shungite | 31 vol% of composite | 29 | 0.38 | [31] | |

| Steel fibers | 0.8 vol% of composite | 127 | - | [28] | |

| Metal foil strain gauge | - | 2–5 | - | - | |

| Conductive Additive | Content | Seebeck Coefficient, μV/K | Reference | |

|---|---|---|---|---|

| Cement composites | Exfoliated graphite | 3 wt% of cement (1.43 vol% of composite) | 6.9 | In this study |

| Carbon fibers | 0.97 vol% of composite (w/c = 0.44) | 19.7 | [4] | |

| 3 wt% of cement (w/c = 0.5) | 8.5 | [8] | ||

| 1 wt% of cement (w/c = 0.3) | 17.8 | [9] | ||

| 1.2 wt% of cement (w/c = 0.3) | 5.5 | [9] | ||

| Carbon nanotubes | 15 wt% of cement | 57.9 | [11] | |

| Expanded graphite obtained at 500 °C | 6 wt% of cement (w/c = 0.5; s/c = 0.75) | 13.7 | [22] | |

| Expanded graphite obtained at 1000 °C | 4 wt% of cement (w/c = 0.5; s/c = 0.75) | 3.0 | [22] | |

| Graphene nanoplates | 15 wt% of cement (w/c = 0.1; compressed samples) | 34 | [17] | |

| Graphite powder | 30 wt% of cement (w/c = 0.5; s/c = 0.75) | 18 | [24] | |

| Reduced graphene oxide | 5 vol% of cement (w/c = 0.2; compressed samples) | 32.7 | [18] | |

| Shungite | 20 vol% of composite (w/c = 0.76; c/s = 0.75) | 4.1 | [31] | |

| Steel fibers | 0.2 vol% of composite (w/c = 0.35) | 59 | [29] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frąc, M.; Szołdra, P.; Pichór, W. Smart Graphite–Cement Composites with Low Percolation Threshold. Materials 2022, 15, 2770. https://doi.org/10.3390/ma15082770

Frąc M, Szołdra P, Pichór W. Smart Graphite–Cement Composites with Low Percolation Threshold. Materials. 2022; 15(8):2770. https://doi.org/10.3390/ma15082770

Chicago/Turabian StyleFrąc, Maksymilian, Paulina Szołdra, and Waldemar Pichór. 2022. "Smart Graphite–Cement Composites with Low Percolation Threshold" Materials 15, no. 8: 2770. https://doi.org/10.3390/ma15082770

APA StyleFrąc, M., Szołdra, P., & Pichór, W. (2022). Smart Graphite–Cement Composites with Low Percolation Threshold. Materials, 15(8), 2770. https://doi.org/10.3390/ma15082770