Research on the Mechanism and Prevention Methods of the Drying Shrinkage Effect of Earthen Sites

Abstract

:1. Introduction

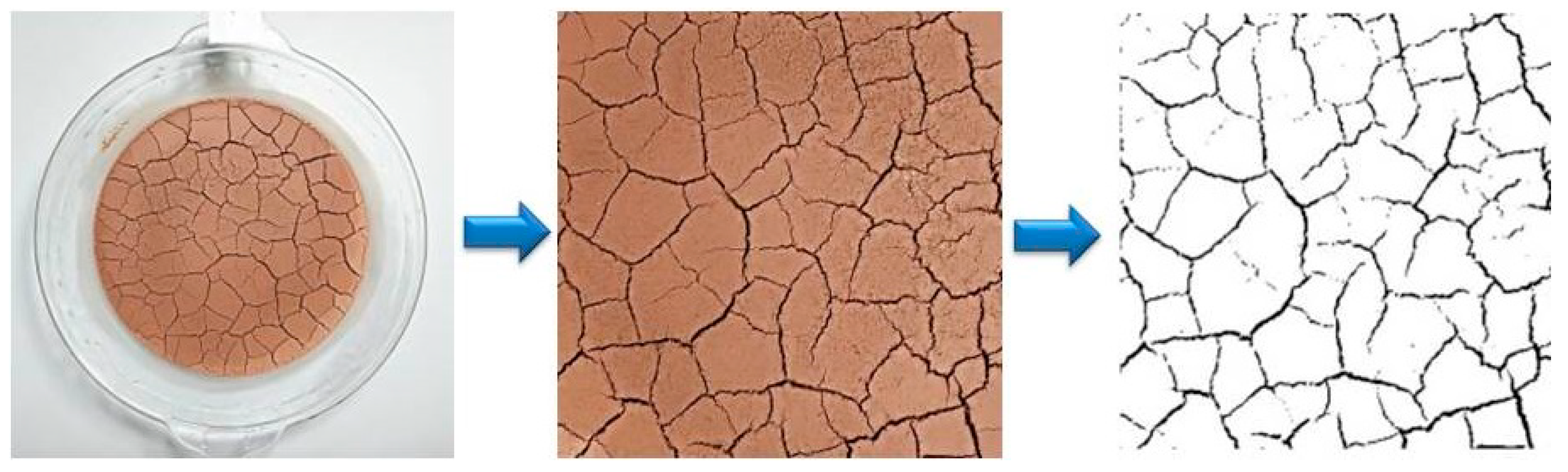

2. Soil Sample Preparation and Test Methods

2.1. Soil Sample Preparation

- (1)

- Sample preparation process for the plain soil group

- (2)

- Sample preparation process for improved groups

- (3)

- Dry and wet cycle test

2.2. Soil Sample Preparation

2.3. Effect of Particle Size on Dry Shrinkage Fissures

2.4. Effect of Dry and Wet Cycle on Dry Shrinkage Fissures

2.5. Effect of Soil Sample Thickness on Dry Shrinkage Fissure

2.6. Dry Shrinkage Fissure Test of Improved Soil

3. Results

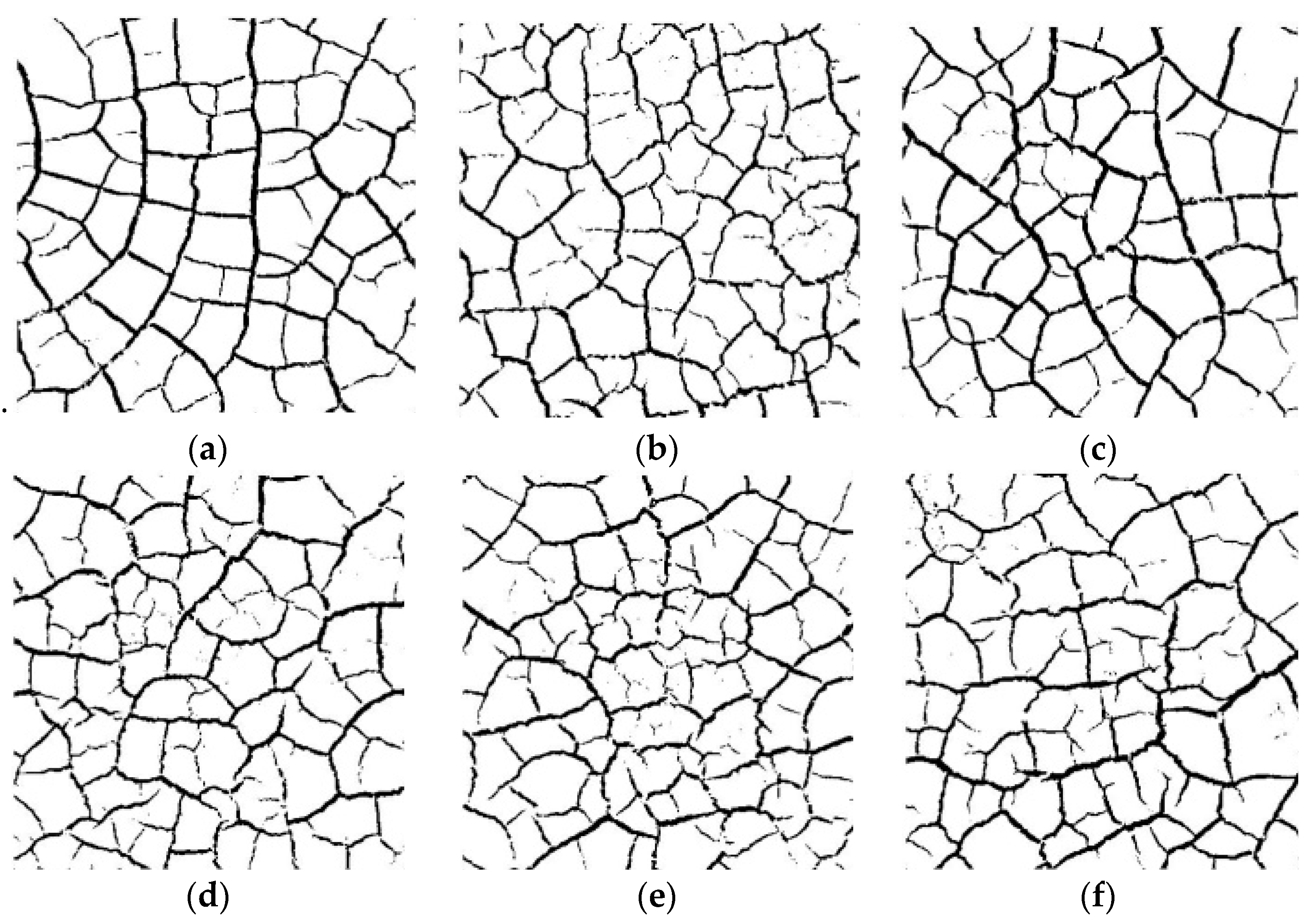

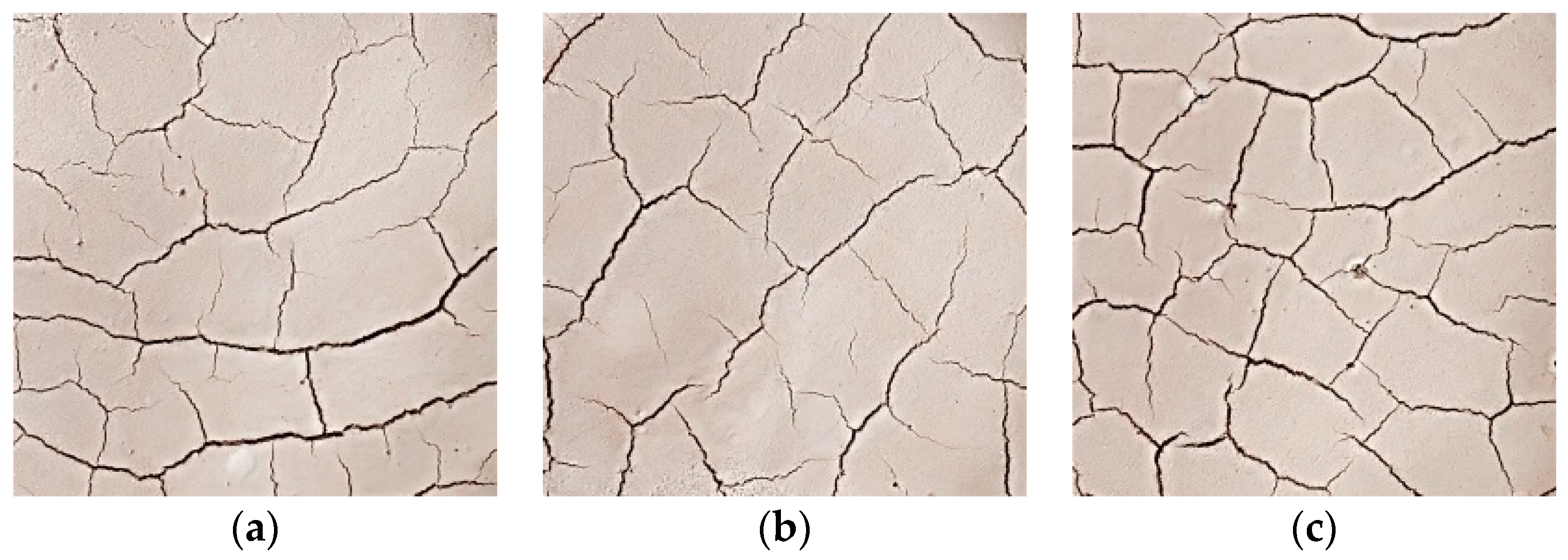

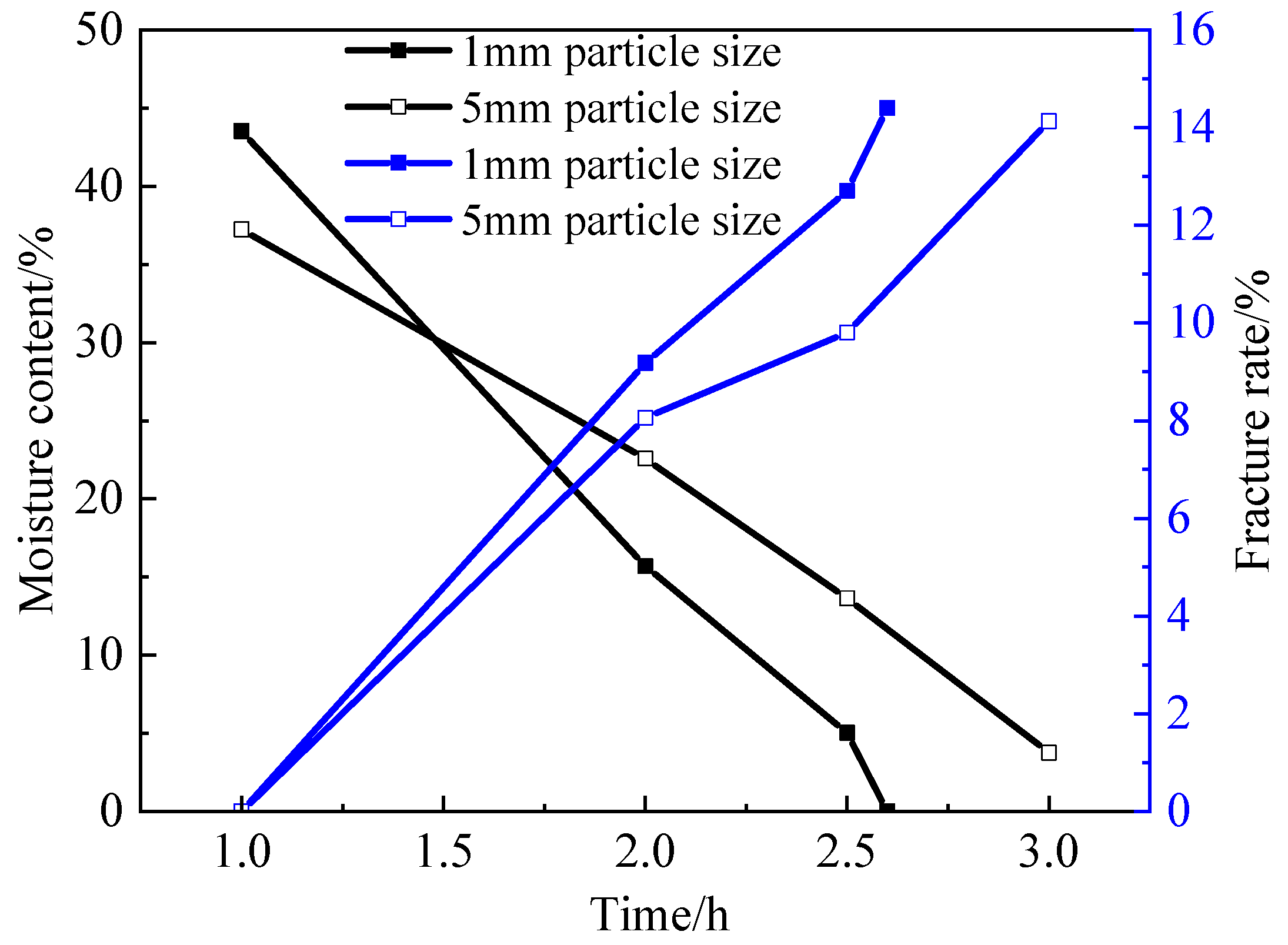

3.1. Effect of Particle Size on Dry Shrinkage Fissures

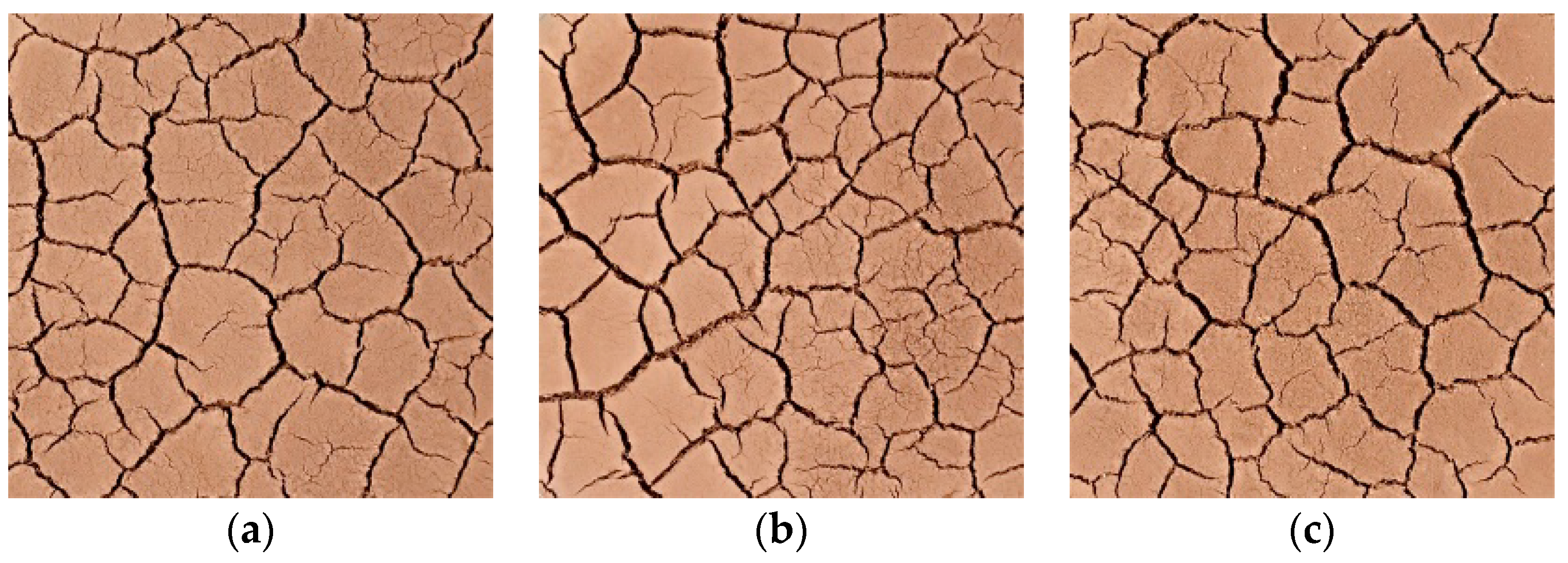

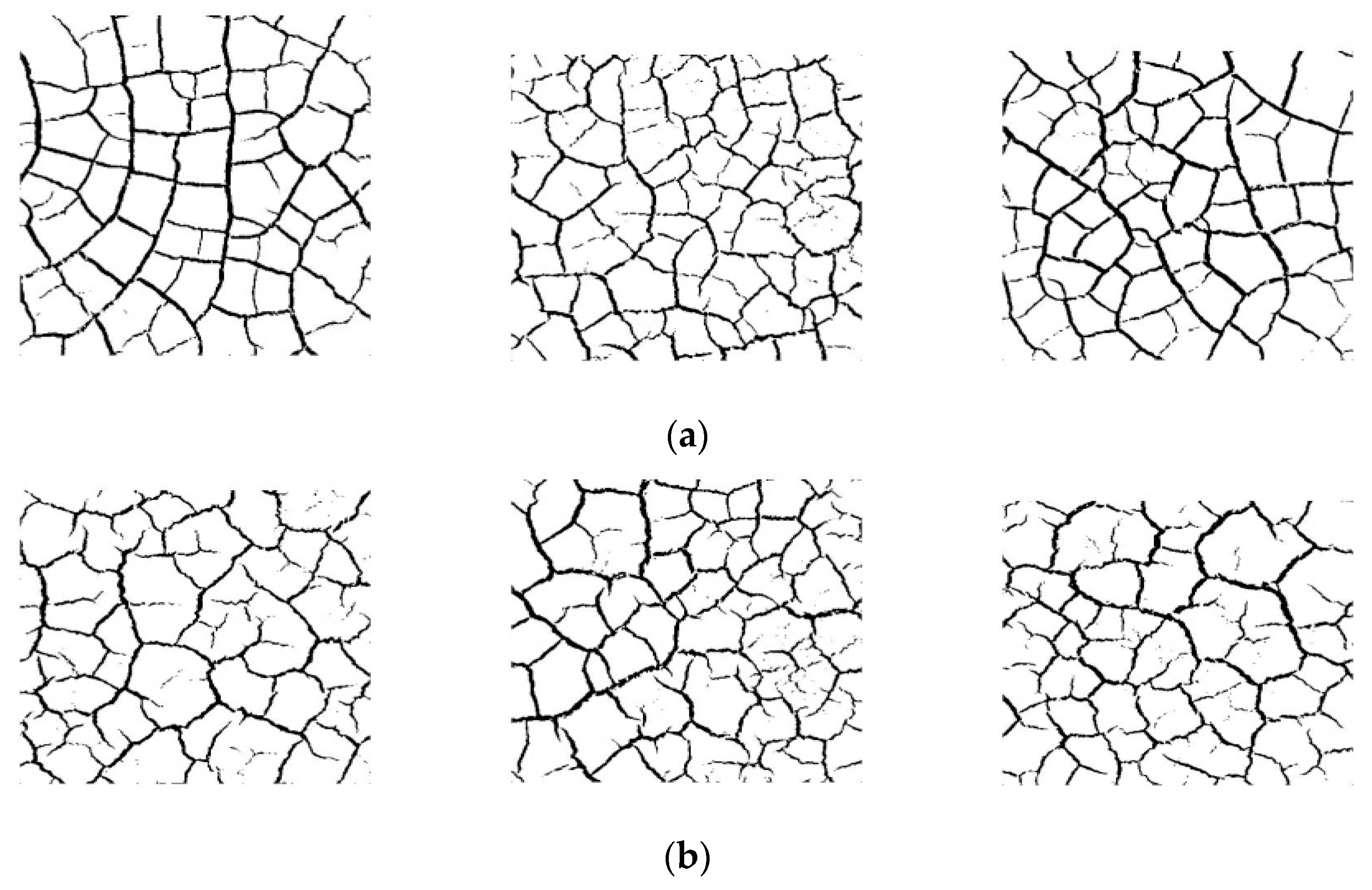

3.2. Effect of Dry and Wet Cycle on Dry Shrinkage Fissures

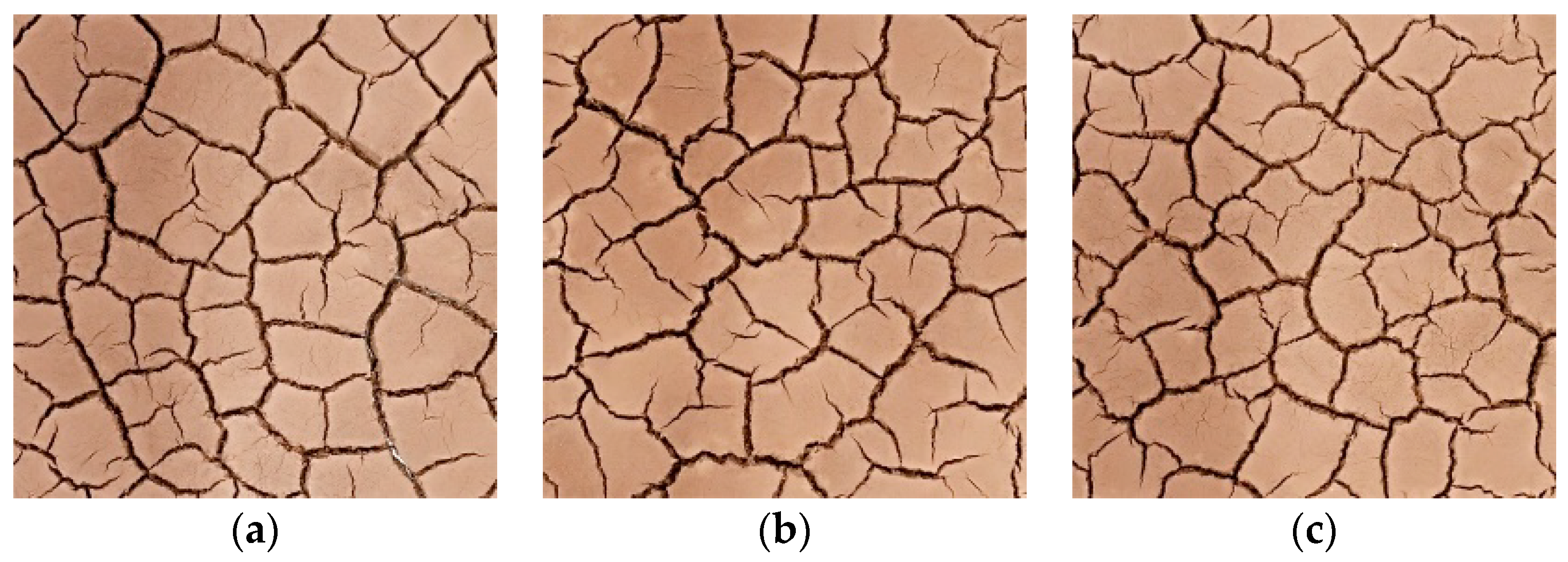

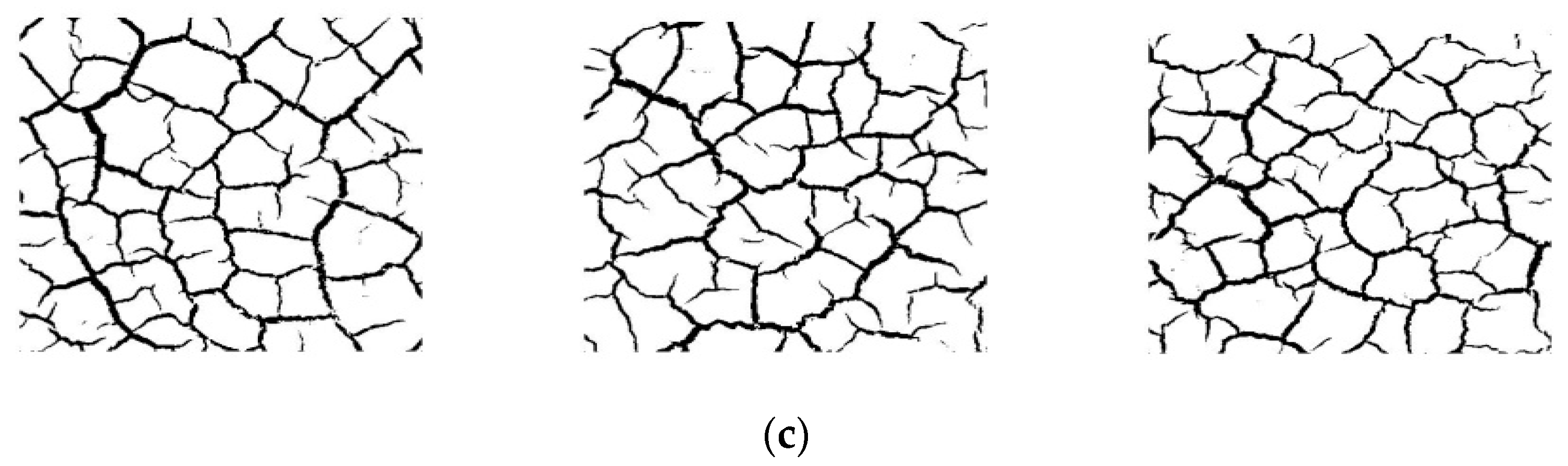

3.3. Effect of Thickness on Dry Shrinkage Fissures

3.4. Dry Shrinkage Fissure Test of Improved Soil

4. Discussion

5. Conclusions

- (1)

- The particle size of soil sample has a direct impact on the crack rate of expansive soil. In the process of drying, the larger the particle size of a soil sample is, the more cracks will be produced after drying shrinkage. Especially in the late stage of cracking, the cracking rate of soil samples from groups S1–S3 was 2.91% higher than that from groups S4–S6, and the water content of soil samples from groups S1–S3 was 8.59% lower than that from groups S4–S6. Both of these values are maximum values throughout the experiment, proving that the larger the soil sample particles, the more likely the soil sample will lose water and will be the first to experience cracking.

- (2)

- A comparison of 1, 2 and 3 dry and wet cycles of cracks shows that as the number of dry and wet cycles increases, the distance between the main cracks increases, the number of cracks from the cracks increases significantly and also develops gradually, and the distribution of cracks becomes more and more uniform.

- (3)

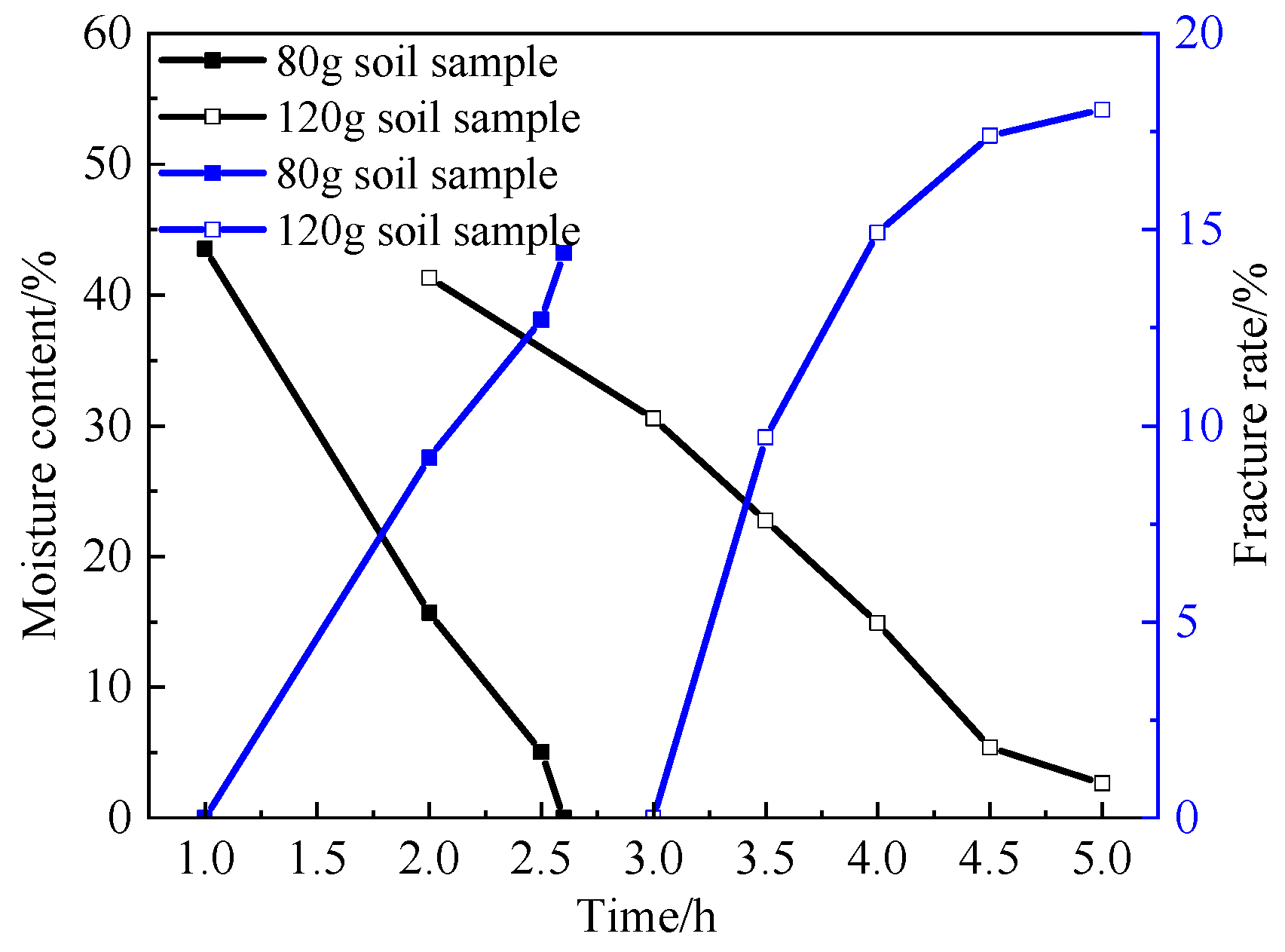

- Thickness has a significant effect on the moisture content, crack width and surface crack rate of the samples. The thicker the thickness is, the wider the crack width is, and there are many warps of different sizes on the edge of soil particles on the surface of soil sample. The soil samples with the low soil layer thickness (S1–S3 groups) will crack earlier than the soil samples with the large soil layer thickness (S4–S6 groups), but the crack rate of the soil samples with the large soil layer thickness is 2.95% higher than that of the soil samples with the small soil layer thickness. This shows that the thicker the soil sample is, the longer the time required for complete water evaporation and the greater the surface crack rate.

- (4)

- The improvement in the mixed admixture produces crystals between the soil particles, increases the compactness, improves the strength, effectively inhibits the generation of cracks, and makes the soil sample have good hydrophobicity, which weakens the adverse effect of water on the soil.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yue, J.W.; Huang, X.J.; Zhao, L.M.; Wang, Z.F. Study on the Factors Affecting Cracking of Earthen Soil under Dry Shrinkage and Freeze-Thaw Conditions. Sci. Rep. 2021, 12, 1816. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.Y.; Wang, S.J.; Yang, Z.B. Quantitative analysis of fracture evolution of expansive soils under wetting-drying cycles. Rock Soil Mech. 2020, 41, 2313–2323. [Google Scholar] [CrossRef]

- Wang, N.; Wang, J.N.; Zhang, X.M. Evolution Characteristics of Cracks in Benggang Soil Under Controlled Thickness. J. Soil Water Conserv. 2021, 35, 175–182. [Google Scholar] [CrossRef]

- Ma, P.H.; Peng, J.B.; Zhu, X.H.; Tong, X.; Meng, Z.J.; Duan, Z. Regularities of Rainfall Infiltration in Shallow Loess. Bull. Soil Water Conserv. 2017, 37, 248–253. [Google Scholar] [CrossRef]

- Guo, T.H.; Wang, W.W.; Cheng, Y.W.; Yi, Y.; Long, G. Experiment Study on Indoor Rainfall Infiltration of the Fractured Expansive Soil with Different Compaction Degrees or Initial Water Contents. Sci. Technol. Eng. 2018, 18, 295–302. [Google Scholar] [CrossRef]

- Yue, J.W.; Huang, X.J.; Zhao, L.M.; Kong, Q.M.; Chen, Y.; Wang, Z.F. Finite element method study on stress-strain relationship of site soil. Mech. Eng. 2021, 43, 921–932. [Google Scholar] [CrossRef]

- Ren, K.B.; Wang, B.; Li, X.M.; Yin, S. Strength properties and pore-size distribution of earthen archaeological site under dry-wet cycles of capillary water. Rock Soil Mech. 2019, 40, 962–970. [Google Scholar] [CrossRef]

- Ren, K.B.; Wang, B.; Li, X.M.; Yin, S. Effect of dry-wet cycles on the mechanical properties of earthen archaeological site under low stresses. Chin. J. Rock Mech. Eng. 2019, 38, 376–385. [Google Scholar] [CrossRef]

- Dai, M.Y.; Chen, Y.; Wang, Z.W. A fitting model for shrinkage of expansive soil in different initial states. Yangtze River 2018, 49, 83–87. [Google Scholar] [CrossRef]

- Wei, X.; Wang, G. Modeling swell-shrink behavior of compacted expansive clays subjected to cyclic drying and wetting. Chin. J. Geotech. Eng. 2014, 36, 1423–1431. [Google Scholar] [CrossRef]

- Huang, B.; Cheng, Z.L.; Xu, H. Expansion model of expansive soil and its application to slope engineering. Rock Soil Mech. 2014, 35, 3550–3555. [Google Scholar] [CrossRef]

- Li, Y.S. Research on the fissure development indoor test of expansive soil cracks under the action of dry-wet circulation. J. Hebei Univ. Eng. 2018, 35, 32–37. [Google Scholar] [CrossRef]

- Tang, C.S.; Cui, Y.J.; Anh-minh, T.; Shi, B. Shrinkage and desiccation cracking process of expansive soil and its temperature-dependent behaviour. Chin. J. Geotech. Eng. 2012, 34, 2181–2187. [Google Scholar]

- Yuan, M.Y.; Zhang, F.H.; Wang, Y.H. Experiments and mechanism of slag improving expansive soil. J. Hebei Univ. Eng. 2018, 35, 67–70. [Google Scholar] [CrossRef]

- Fu, N.Q.; Xu, H.Z.; Zhang, S.J. Unconfined compressive strength test on expansive soil reinforced with fiber and fly ash. J. Nanjing Tech. Univ. 2018, 40, 133–137. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Cui, Y.J. Behaviors and mechanisms of desiccation cracking of soils. Chin. J. Geotech. Eng. 2018, 40, 1415–1423. [Google Scholar] [CrossRef]

- Xu, Y.X.; Yao, X.; Zhuang, Y.; Duan, W.; Zhang, X.D.; Hu, S.L. The Effects of Fiber Inclusion on the Evolution of Desiccation Cracking in Soil-Cement. Materials 2021, 14, 4974. [Google Scholar] [CrossRef]

- Wang, W.W.; Li, W.; Yi, Y. Study on the Cracking Law of Nanyang Expansive Soil. Chin. J. Undergr. Space Eng. 2015, 11, 1437–1443. [Google Scholar]

- Sun, Y.J.; Sun, S.Q.; Bao, S.F. Cause of conventional vacuum consolidation technology failure to newly filled reclamation mud foundation. Port Waterw. Eng. 2012, 11, 148–154. [Google Scholar] [CrossRef]

- Cui, K.; Huang, J.J.; Chen, W.W.; Wang, D.H.; Han, N. Research on selection of anchor slurry and performance of mixed quick lime in earthen sites. Rock Soil Mech. 2019, 40, 2183–2191. [Google Scholar] [CrossRef]

- Chen, W.W.; Han, Q.Y.; Liu, H.W. Infiltration grouting diffusion law of SH agent in earthen sites. Rock Soil Mech. 2019, 40, 429–435. [Google Scholar] [CrossRef]

- Chen, W.W.; Han, Q.Y.; Liu, H.W.; Gao, F. Reinforcing Effect Of Relic Soil Sites Penetrated With High Polymer Material SH. J. Eng. Geol. 2017, 25, 1307–1313. [Google Scholar] [CrossRef]

- Lin, L.; Tang, C.S.; Cheng, Q.; Zeng, H.; Shi, B. Desiccation cracking bebavior of soils based on digital image correlation technique. Chin. J. Geotech. Eng. 2019, 41, 1311–1318. [Google Scholar] [CrossRef]

- Liu, J.D.; Tang, C.S.; Zeng, H.; Shi, B. Evolution of desiccation cracking behavior of clays under drying-wetting cycles. Rock Soil Mech. 2021, 42, 2763–2772. [Google Scholar] [CrossRef]

- Tang, C.S.; Cui, Y.J.; Tang, A.M.; Shi, B. Experiment evidence on the temperature dependence of desiccation cracking behavior of clayey soils. Eng. Geol. 2010, 114, 261–266. [Google Scholar] [CrossRef] [Green Version]

- Tang, C.S.; Shi, B.; Liu, C.; Zhao, L.; Wang, B. Influencing factors of geometrical structure of surface shrinkage cracks in clayey soils. Eng. Geol. 2008, 101, 204–217. [Google Scholar] [CrossRef]

- Albrecht, B.A.; Benson, C.H. Effect of Desiccation on Compacted Natural Clays. J. Geotech. Geoenviron. Eng. 2001, 128, 67–75. [Google Scholar] [CrossRef]

| Liquid Limit/% | Plastic Limit/% | Plasticity Index | Free Expansion Rate/% | Natural Moisture Content/% |

|---|---|---|---|---|

| 34.7 | 15.2 | 19.5 | 58 | 23.5 |

| Number | S1 | S2 | S3 | Average Value | |

|---|---|---|---|---|---|

| Time (h) | |||||

| 1 | 41.91% (0%) | 44.41% (0%) | 44.24% (0%) | 43.52% (0%) | |

| 2 | 15.10 (10.21%) | 16.19% (8.07%) | 15.82% (9.29%) | 15.70% (9.19%) | |

| 2.5 | 3.77% (14.32%) | 4.90% (11.46%) | 6.49% (12.36%) | 5.05% (12.71%) | |

| 2.6 | 0% (15.31%) | 0% (13.38%) | 0% (14.53%) | 0% (14.41%) | |

| Number | S4 | S5 | S6 | Average Value | |

|---|---|---|---|---|---|

| Time (h) | |||||

| 1 | 38.71% (0%) | 37.72% (0%) | 35.29% (0%) | 37.24% (0%) | |

| 2 | 24.25% (8.11%) | 23.48% (8.58%) | 19.99% (7.49%) | 22.57% (8.06%) | |

| 2.5 | 15.41% (9.55%) | 15.35% (9.66%) | 10.16% (10.18%) | 13.64% (9.80%) | |

| 3 | 5.53% (13.81%) | 2.87% (13.81%) | 2.91% (14.77%) | 3.77% (14.13%) | |

| Number | S7 | S8 | S9 | Average Value | |

|---|---|---|---|---|---|

| Time (h) | |||||

| 2 | 42.17% (0) | 41.26% (0%) | 40.56% (0%) | 41.33% (0%) | |

| 3 | 31.52% (0) | 29.99% (0%) | 30.55% (0%) | 30.55% (0%) | |

| 3.5 | 22.49% (7.45%) | 22.58% (12.79%) | 22.77% (8.90%) | 22.77% (9.8%) | |

| 4 | 14.24% (13.72%) | 14.46% (18.27%) | 14.92% (12.76%) | 14.92% (14.92%) | |

| 4.5 | 4.99% (16.11%) | 5.31% (19.83%) | 5.43% (16.28%) | 5.43% (17.40%) | |

| 5 | 2.47% (17.26%) | 2.60% (20.17%) | 2.68% (16.77%) | 2.68% (18.07%) | |

| Number | S10 | S11 | S12 | Average Value | |

|---|---|---|---|---|---|

| Time (h) | |||||

| 0.5 | 45.84% (2. 61%) | 41.54% (3.31%) | 43.81% (4.02%) | 43.73% (3.31%) | |

| 1 | 26.71% (2.74%) | 21.45% (3.38%) | 24.60% (4.19%) | 24.25% (3.44%) | |

| 1.5 | 11.62% (3.09%) | 7.23% (3.77%) | 8.59% (4.86%) | 9.15% (3.91%) | |

| 2 | 3.41% (3.47%) | 0.65% (4.10%) | 1.92% (5.16%) | 1.99% (4.24%) | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Yang, J.; Yue, J.; Li, W.; Gao, H. Research on the Mechanism and Prevention Methods of the Drying Shrinkage Effect of Earthen Sites. Materials 2022, 15, 2595. https://doi.org/10.3390/ma15072595

Zhang Z, Yang J, Yue J, Li W, Gao H. Research on the Mechanism and Prevention Methods of the Drying Shrinkage Effect of Earthen Sites. Materials. 2022; 15(7):2595. https://doi.org/10.3390/ma15072595

Chicago/Turabian StyleZhang, Zehuan, Jianzhong Yang, Jianwei Yue, Wenhao Li, and Huijie Gao. 2022. "Research on the Mechanism and Prevention Methods of the Drying Shrinkage Effect of Earthen Sites" Materials 15, no. 7: 2595. https://doi.org/10.3390/ma15072595

APA StyleZhang, Z., Yang, J., Yue, J., Li, W., & Gao, H. (2022). Research on the Mechanism and Prevention Methods of the Drying Shrinkage Effect of Earthen Sites. Materials, 15(7), 2595. https://doi.org/10.3390/ma15072595