An Experimental Study on Structural Concrete Containing Recycled Aggregates and Powder from Construction and Demolition Waste

Abstract

:1. Introduction

2. Materials and Methods

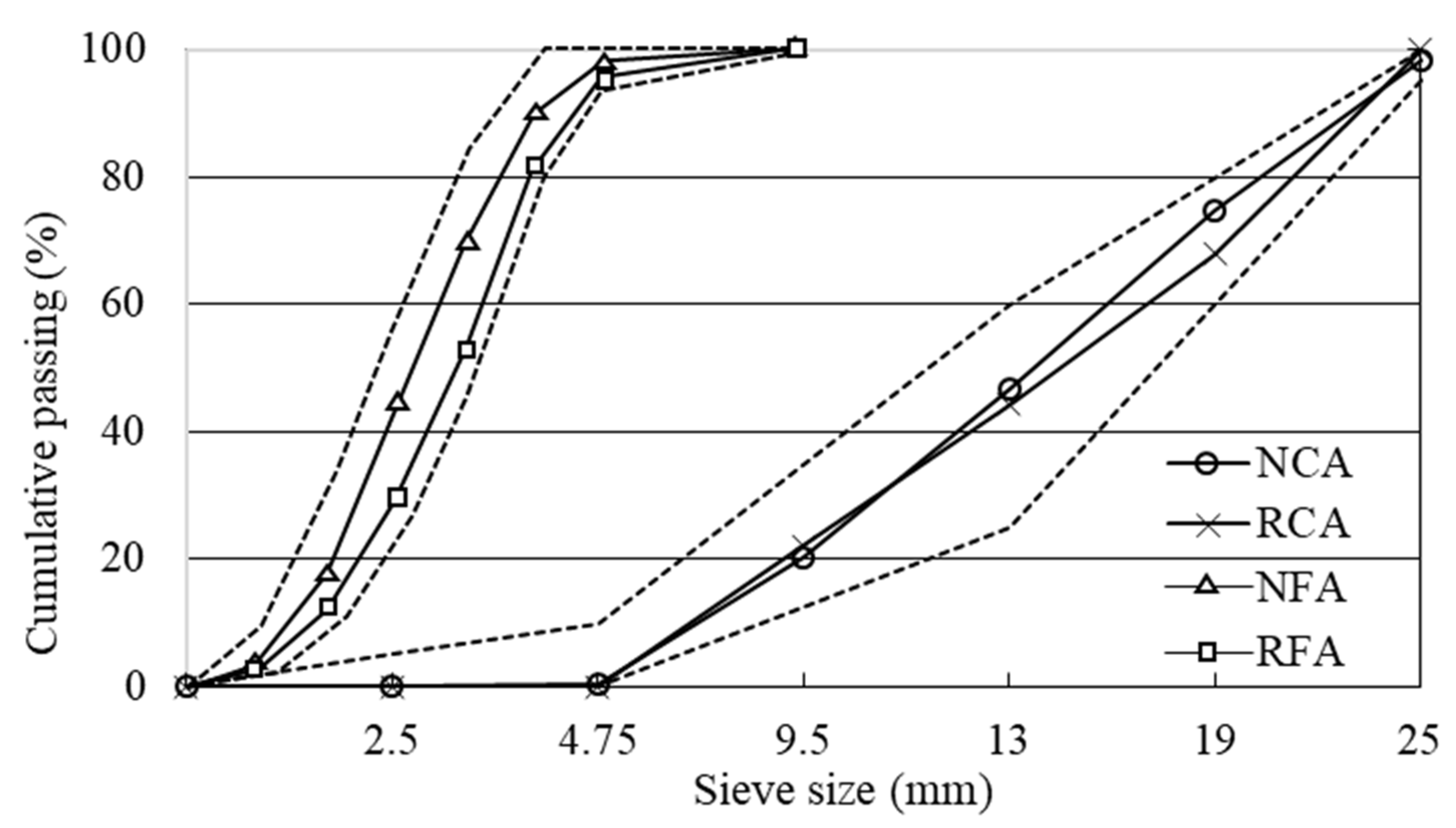

2.1. Materials

2.2. Mix Design and Testing Methods

- RCAC-replacement ratio: concrete made from NCA, NFA, OPC, and RCA that replaces NCA in a certain ratio (i.e., 30%, 60%, and 100%).

- RFAC-replacement ratio: concrete made from NCA, NFA, OPC, and RFA that replaces NFA in a certain ratio (30%, 60%, and 100%).

- RPC-replacement ratio: Concrete made with NCA, NFA, OPC, and RP that replaces OPC in a certain proportion (10%, 20%, and 30%). Test results for RPC were adopted from the previous study of the author [32].

- RCFAC-replacement ratio: Concrete made by replacing both NCA and NFA with RCA and RFA in a certain percentage (30%, 60%, and 100%). OPC was used as a binder.

| Test | Standard | Specimen Size (mm) | Test Age (Days) |

|---|---|---|---|

| Fresh state | |||

| Air content | [40] | n/a | Immediately after mixing |

| Consistency | [41] | n/a | Immediately after mixing |

| Hardened state | |||

| Compressive strength | [42] | Ø100 × 200 | 28 and 56 |

| Splitting tensile strength | [43] | Ø100 × 200 | 28 |

| Elastic modulus | [44] | Ø100 × 200 | 28 and 56 |

2.3. Cost and Environmental Impact Assessment

3. Results and Discussion

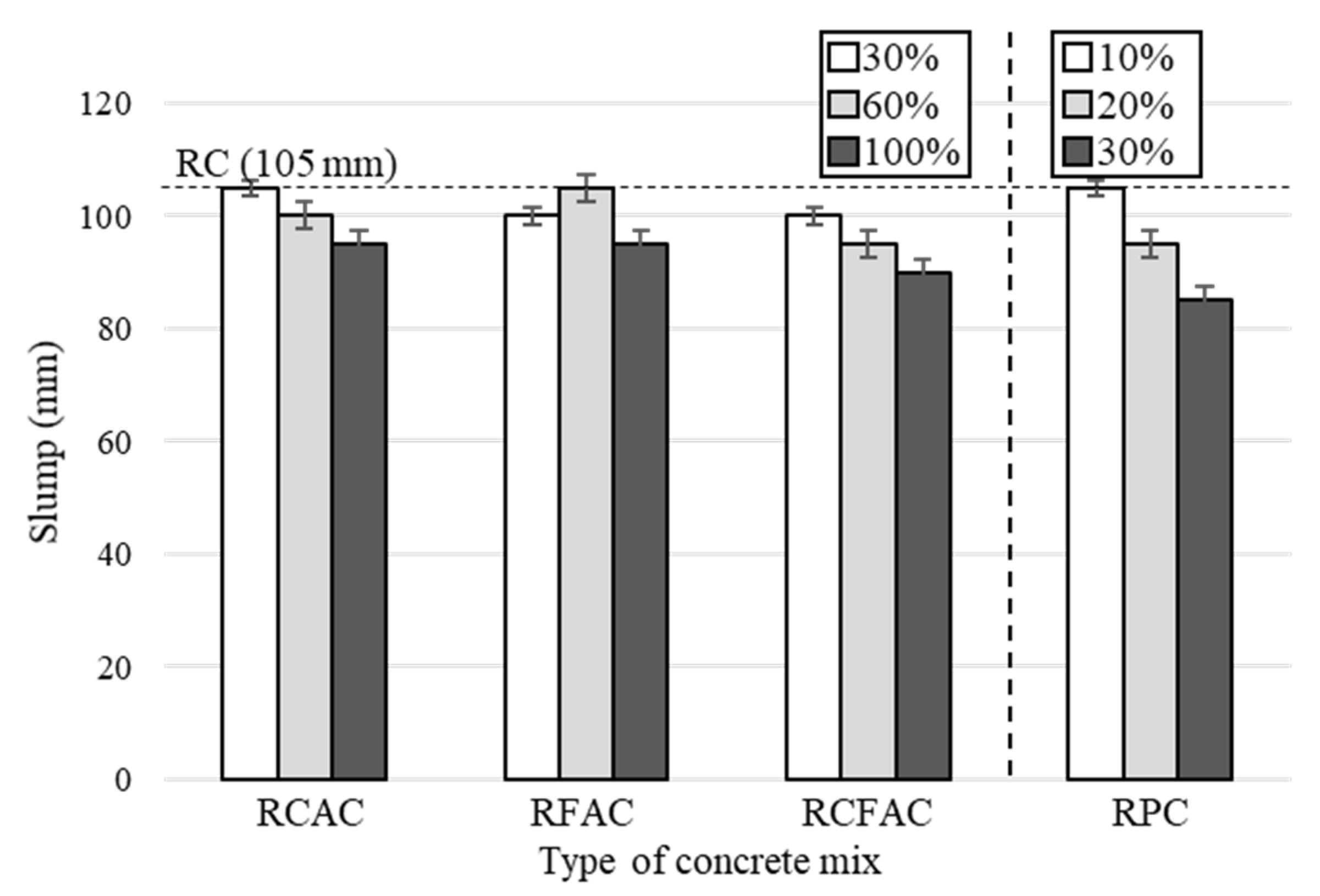

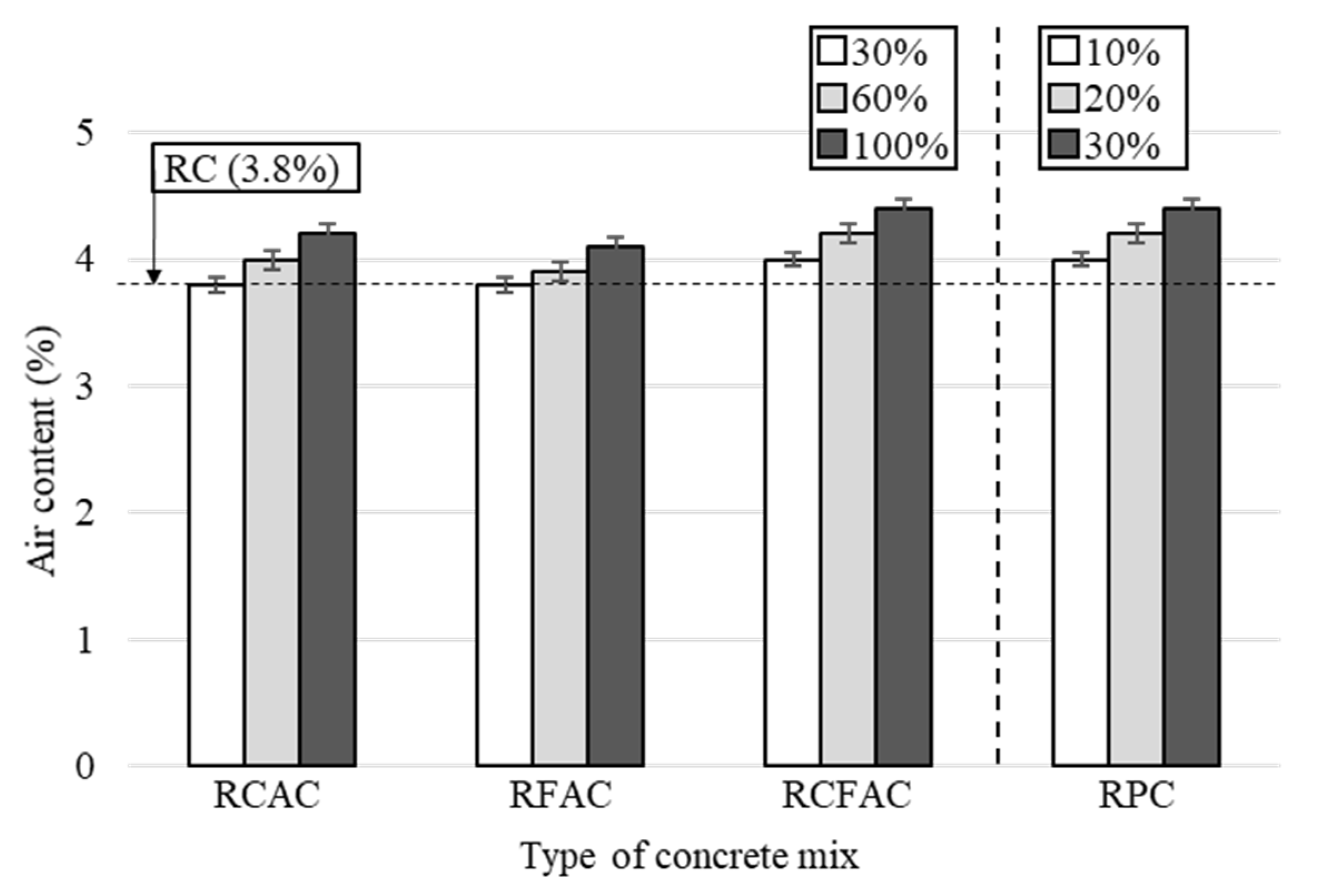

3.1. Fresh Properties

3.2. Hardened Properties

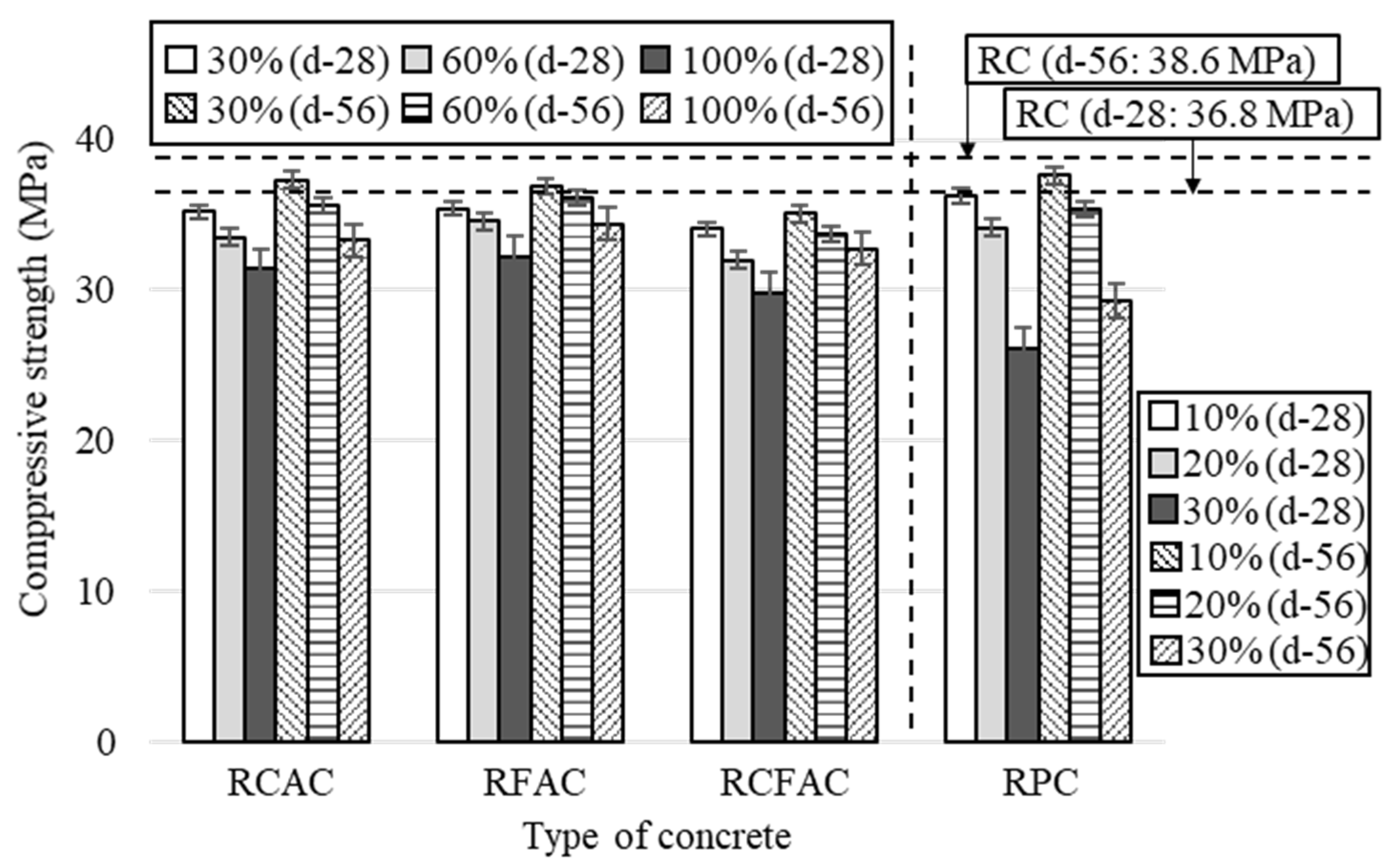

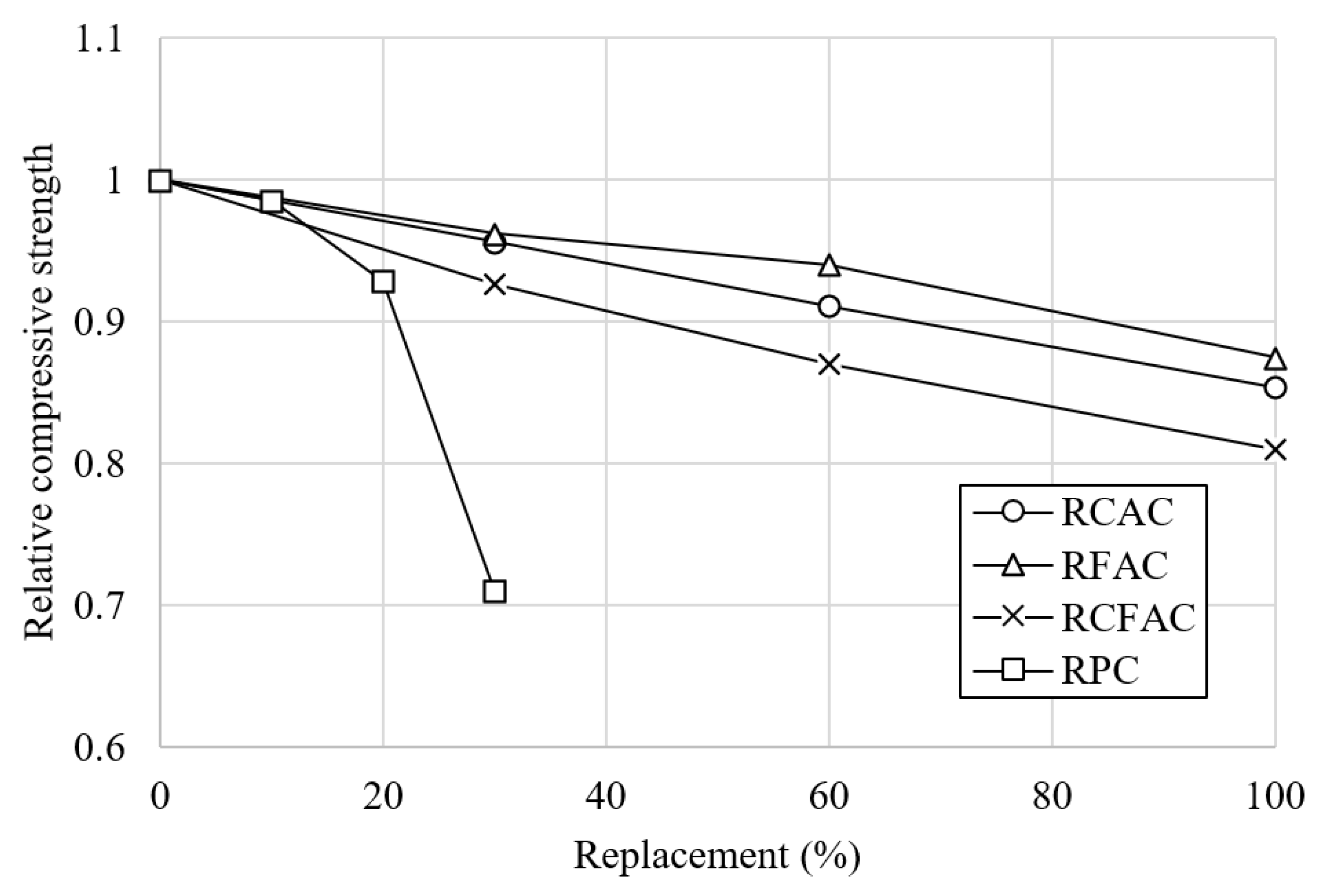

3.2.1. Compressive Strength

3.2.2. Splitting Tensile Strength

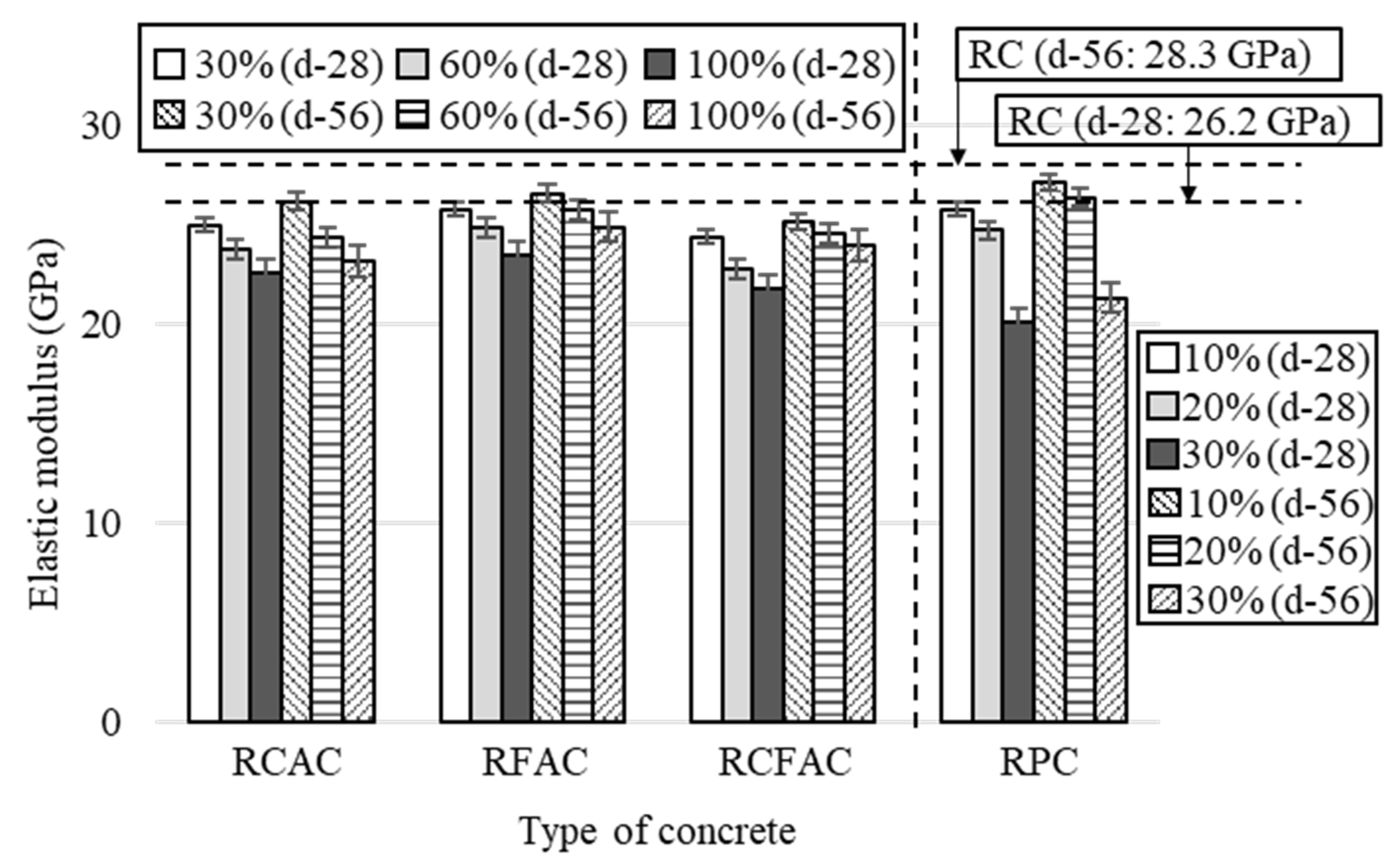

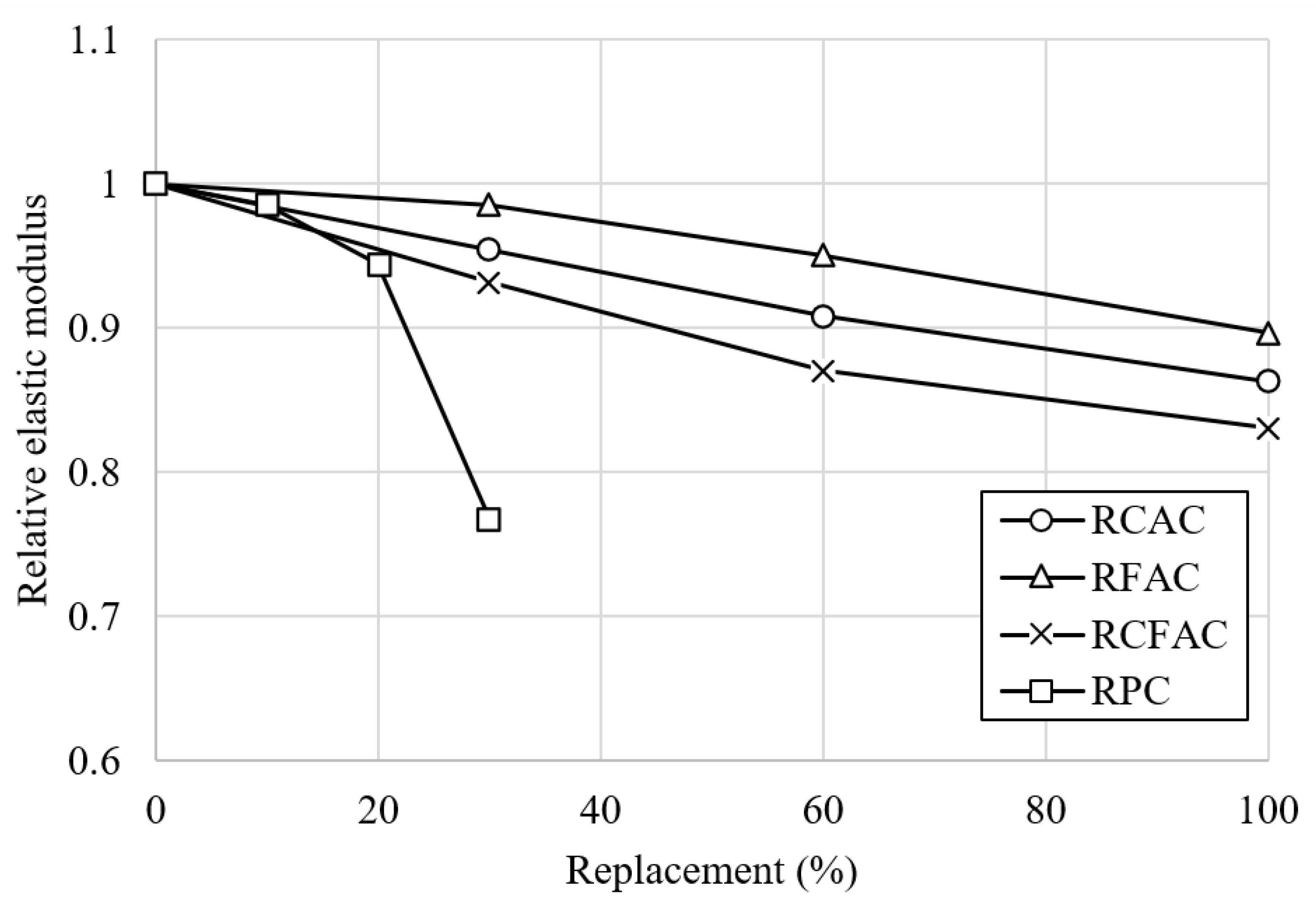

3.2.3. Elastic Modulus

4. Correlation between Properties of Concrete

4.1. Relationship between Compressive Strength and Density

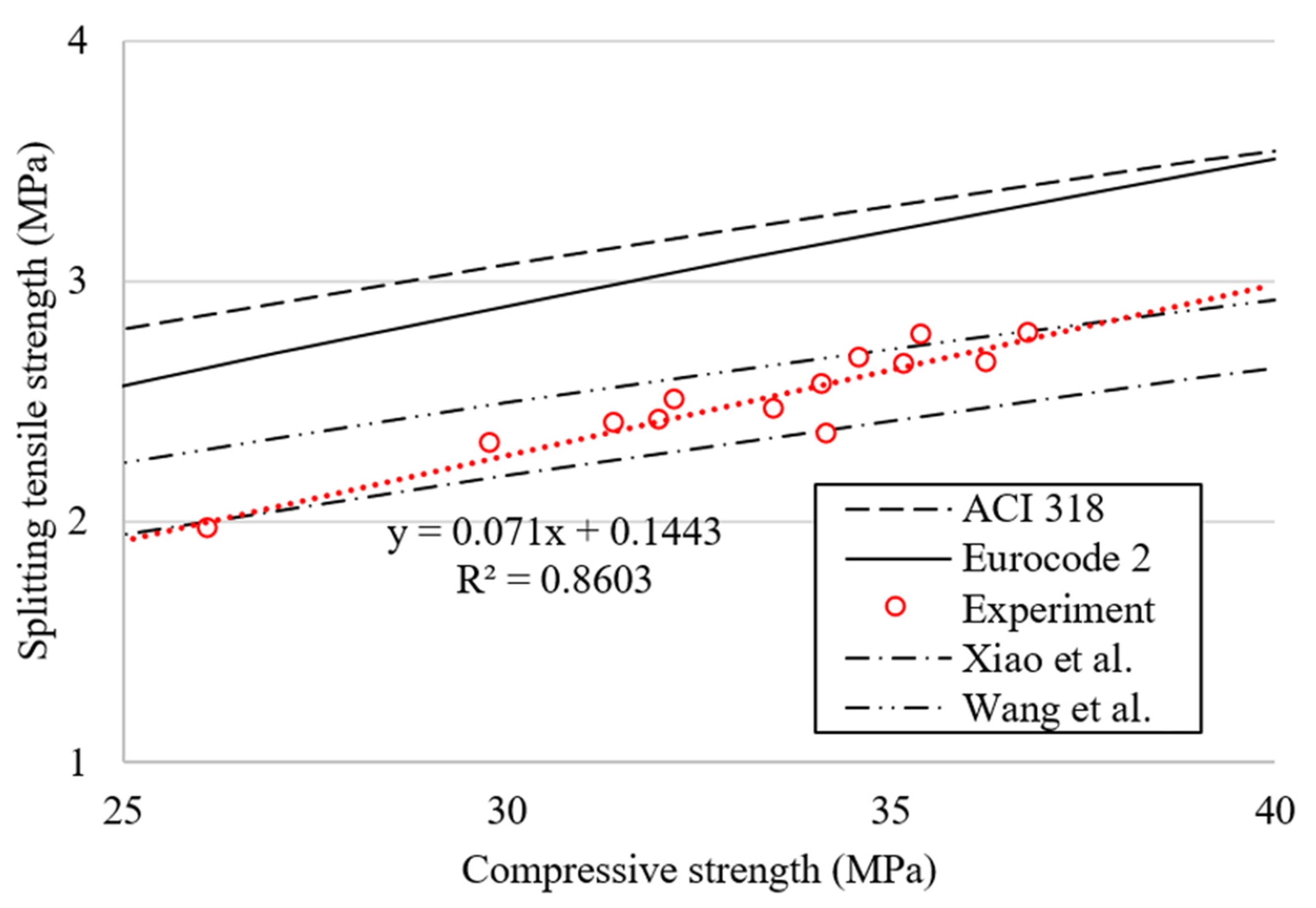

4.2. Relationship between Compressive Strength and Splitting Tensile Strength

4.3. Relationship between Compressive Strength and Elastic Modulus

5. Cost Analysis and Environmental Impact Assessment

6. Conclusions

- With the increased replacement ratios of natural materials by recycled materials, the slump of the concrete mixes was reduced (up to 19%) and the air content was increased (up to 0.6%) compared to the reference concrete, but the fresh properties were within the range required by the standard.

- As the replacement ratio increased, the mechanical properties of concrete decreased. The properties decreased in the order of RFAC, RCAC, and RCFAC at the same replacement ratio.

- The reduction of compressive strength and elastic modulus was only 1–4% for concrete with 10% RP and 6–8% for concrete with 20% RP. However, when 30% RP was added, the mechanical properties showed a rapid decrease of 23~29%, thus special attention is required for its use. Nevertheless, all mixtures could be applied as structural concretes under different environmental exposure conditions.

- The relationship between compressive strength, elastic modulus, and splitting tensile strength of concrete containing different size fractions of recycled concrete materials showed a strong correlation. However, for the relationship between compressive strength and density, RPC needs to be considered separately from RCAC, RFAC, and RCFAC.

- Replacing OPC with RP by up to 20%, cost value and eco-efficiency were superior to those of RC. Although the cost value and eco-efficiency of concrete incorporating RCA and RFA were lower, the production cost and GWP were lower than those of RC; thus, it can be considered economical and eco-friendly if the intended requirements are achieved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, K.; Xu, P.; Wang, F.; You, L.; Zhang, X.; Fu, C. Assessment of automatic induction self-healing treatment applied to steel deck asphalt pavement. Autom. Constr. 2022, 133, 104011. [Google Scholar] [CrossRef]

- Jayasinghe, A.; Orr, J.; Hawkins, W.; Ibell, T.; Boshoff, W.P. Comparing different strategies of minimising embodied carbon in concrete floors. J. Clean. Prod. 2022, 345, 131177. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef] [Green Version]

- Flower, D.J.M.; Sanjayan, J.G. Greenhouse Gas Emissions Due to Concrete Manufacture. In Handbook of Low Carbon Concrete; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–16. [Google Scholar]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Aslam, M.S.; Huang, B.; Cui, L. Review of construction and demolition waste management in China and USA. J. Environ. Manage. 2020, 264, 110445. [Google Scholar] [CrossRef]

- Qianzhan Industry Institute Market Status and Prospect Analysis of Construction and Demolition Waste Treatment Industry in China in 2019. Available online: https://bg.qianzhan.com/report/detail/300/190605-cb2ad101.html (accessed on 17 March 2022).

- Kim, J. Construction and demolition waste management in Korea: Recycled aggregate and its application. Clean Technol. Environ. Policy 2021, 23, 2223–2234. [Google Scholar] [CrossRef]

- Yang, H.; Xia, J.; Thompson, J.R.; Flower, R.J. Urban construction and demolition waste and landfill failure in Shenzhen, China. Waste Manag. 2017, 63, 393–396. [Google Scholar] [CrossRef]

- Salesa, Á.; Pérez-Benedicto, J.A.; Colorado-Aranguren, D.; López-Julián, P.L.; Esteban, L.M.; Sanz-Baldúz, L.J.; Sáez-Hostaled, J.L.; Ramis, J.; Olivares, D. Physico – mechanical properties of multi – recycled concrete from precast concrete industry. J. Clean. Prod. 2017, 141, 248–255. [Google Scholar] [CrossRef]

- Huda, S.B.; Alam, M.S. Mechanical behavior of three generations of 100% repeated recycled coarse aggregate concrete. Constr. Build. Mater. 2014, 65, 574–582. [Google Scholar] [CrossRef]

- Zhu, P.; Hao, Y.; Liu, H.; Wei, D.; Liu, S.; Gu, L. Durability evaluation of three generations of 100% repeatedly recycled coarse aggregate concrete. Constr. Build. Mater. 2019, 210, 442–450. [Google Scholar] [CrossRef]

- Xie, T.; Yang, G.; Zhao, X.; Xu, J.; Fang, C. A unified model for predicting the compressive strength of recycled aggregate concrete containing supplementary cementitious materials. J. Clean. Prod. 2020, 251, 119752. [Google Scholar] [CrossRef]

- Kim, J. Influence of quality of recycled aggregates on the mechanical properties of recycled aggregate concretes: An overview. Constr. Build. Mater. 2022, 328, 127071. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Grabiec, A.M.; Kim, J.; Ubysz, A.; Bilbao, P. Some Remarks towards a Better Understanding of the Use of Concrete Recycled Aggregate: A Review. Sustainability 2021, 13, 13336. [Google Scholar] [CrossRef]

- Singh, R.; Nayak, D.; Pandey, A.; Kumar, R.; Kumar, V. Effects of recycled fine aggregates on properties of concrete containing natural or recycled coarse aggregates: A comparative study. J. Build. Eng. 2022, 45, 103442. [Google Scholar] [CrossRef]

- Villagrán-Zaccardi, Y.A.; Marsh, A.T.M.; Sosa, M.E.; Zega, C.J.; De Belie, N.; Bernal, S.A. Complete re-utilization of waste concretes–Valorisation pathways and research needs. Resour. Conserv. Recycl. 2022, 177, 105955. [Google Scholar] [CrossRef]

- Rilem, T.C. 121-DRG. Specifications for concrete with recycled aggregates. Mater. Struct. 1994, 27, 557–559. [Google Scholar]

- Kirthika, S.K.; Singh, S.K. Durability studies on recycled fine aggregate concrete. Constr. Build. Mater. 2020, 250, 118850. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Behera, M.; Minocha, A.K.; Bhattacharyya, S.K. Flow behavior, microstructure, strength and shrinkage properties of self-compacting concrete incorporating recycled fine aggregate. Constr. Build. Mater. 2019, 228, 116819. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Structural concrete with simultaneous incorporation of fine and coarse recycled concrete aggregates: Mechanical, durability and long-term properties. Constr. Build. Mater. 2017, 154, 294–309. [Google Scholar] [CrossRef]

- Plaza, P.; Sáez del Bosque, I.F.; Frías, M.; Sánchez de Rojas, M.I.; Medina, C. Use of recycled coarse and fine aggregates in structural eco-concretes. Physical and mechanical properties and CO2 emissions. Constr. Build. Mater. 2021, 285, 122926. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Tam, V.W.Y. A closed-loop life cycle assessment of recycled aggregate concrete utilization in China. Waste Manag. 2016, 56, 367–375. [Google Scholar] [CrossRef] [PubMed]

- Pradhan, S.; Tiwari, B.R.; Kumar, S.; Barai, S.V. Comparative LCA of recycled and natural aggregate concrete using Particle Packing Method and conventional method of design mix. J. Clean. Prod. 2019, 228, 679–691. [Google Scholar] [CrossRef]

- Jiang, X.; Xiao, R.; Bai, Y.; Huang, B.; Ma, Y. Influence of waste glass powder as a supplementary cementitious material (SCM) on physical and mechanical properties of cement paste under high temperatures. J. Clean. Prod. 2022, 340, 130778. [Google Scholar] [CrossRef]

- Jiang, X.; Zhang, Y.; Xiao, R.; Polaczyk, P.; Zhang, M.; Hu, W.; Bai, Y.; Huang, B. A comparative study on geopolymers synthesized by different classes of fly ash after exposure to elevated temperatures. J. Clean. Prod. 2020, 270, 122500. [Google Scholar] [CrossRef]

- Ma, Z.; Yao, P.; Yang, D.; Shen, J. Effects of fire-damaged concrete waste on the properties of its preparing recycled aggregate, recycled powder and newmade concrete. J. Mater. Res. Technol. 2021, 15, 1030–1045. [Google Scholar] [CrossRef]

- Ma, Z.; Duan, Z.; Ba, G. Effects of an Applied Load on the Chloride Penetration of Concrete with Recycled Aggregates and Recycled Powder. Adv. Civ. Eng. 2019, 2019, 1–15. [Google Scholar] [CrossRef]

- Duan, Z.; Singh, A.; Xiao, J.; Hou, S. Combined use of recycled powder and recycled coarse aggregate derived from construction and demolition waste in self-compacting concrete. Constr. Build. Mater. 2020, 254, 119323. [Google Scholar] [CrossRef]

- Kim, J.; Jang, H. Closed-loop recycling of C&D waste: Mechanical properties of concrete with the repeatedly recycled C&D powder as partial cement replacement. J. Clean. Prod. 2022, 343, 130977. [Google Scholar] [CrossRef]

- ACI Committee 211; ACI 211.1-91 Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete: (ACI 211.1-91). American Concrete Institute: Farmington Hills, MI, USA, 1991.

- Poon, C.S.; Shui, Z.H.; Lam, L.; Fok, H.; Kou, S.C. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem. Concr. Res. 2004, 34, 31–36. [Google Scholar] [CrossRef]

- Brand, A.S.; Roesler, J.R.; Salas, A. Initial moisture and mixing effects on higher quality recycled coarse aggregate concrete. Constr. Build. Mater. 2015, 79, 83–89. [Google Scholar] [CrossRef]

- Zhuang, Y.; Liang, Y.; Nabizadeh, A.; Ng, Z.; Ji, T. Influence of the moisture state of recycled fine aggregate on the impermeability of concrete. Mater. Test. 2019, 61, 991–998. [Google Scholar] [CrossRef]

- Cuenca-Moyano, G.M.; Martín-Morales, M.; Valverde-Palacios, I.; Valverde-Espinosa, I.; Zamorano, M. Influence of pre-soaked recycled fine aggregate on the properties of masonry mortar. Constr. Build. Mater. 2014, 70. [Google Scholar] [CrossRef]

- Jang, H.; Kim, J.; Sicakova, A. Effect of Aggregate Size on Recycled Aggregate Concrete under Equivalent Mortar Volume Mix Design. Appl. Sci. 2021, 11, 11274. [Google Scholar] [CrossRef]

- ASTM International; ASTM C192/C192M-19 Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM International; ASTM C231/C231M-17a Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM International; ASTM C143/C143M-20 Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM International; ASTM C39/C39M-21 Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM International; ASTM C496/C496M-17 Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM International; ASTM C469/C469M-14e1 Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2014.

- Braga, A.M.; Silvestre, J.D.; de Brito, J. Compared environmental and economic impact from cradle to gate of concrete with natural and recycled coarse aggregates. J. Clean. Prod. 2017, 162, 529–543. [Google Scholar] [CrossRef]

- Tan, J.; Cai, J.; Li, X.; Pan, J.; Li, J. Development of eco-friendly geopolymers with ground mixed recycled aggregates and slag. J. Clean. Prod. 2020, 256, 120369. [Google Scholar] [CrossRef]

- Yang, S.; Lim, Y. Mechanical strength and drying shrinkage properties of RCA concretes produced from old railway concrete sleepers using by a modified EMV method. Constr. Build. Mater. 2018, 185, 499–507. [Google Scholar] [CrossRef]

- ASTM International; ASTM C94/C94M-21b Standard Specification for Ready-Mixed Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Kim, J. Properties of recycled aggregate concrete designed with equivalent mortar volume mix design. Constr. Build. Mater. 2021, 301, 124091. [Google Scholar] [CrossRef]

- Xiao, J.; Ma, Z.; Sui, T.; Akbarnezhad, A.; Duan, Z. Mechanical properties of concrete mixed with recycled powder produced from construction and demolition waste. J. Clean. Prod. 2018, 188, 720–731. [Google Scholar] [CrossRef]

- Li, X. Recycling and reuse of waste concrete in China: Part I. Material behaviour of recycled aggregate concrete. Resour. Conserv. Recycl. 2008, 53, 36–44. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Gholampour, A.; Xie, T. Mechanical and Durability Properties of Recycled Aggregate Concrete: Effect of Recycled Aggregate Properties and Content. J. Mater. Civ. Eng. 2018, 30. [Google Scholar] [CrossRef]

- Guo, Z.; Chen, C.; Lehman, D.E.; Xiao, W.; Zheng, S.; Fan, B. Mechanical and durability behaviours of concrete made with recycled coarse and fine aggregates. Eur. J. Environ. Civ. Eng. 2020, 24, 171–189. [Google Scholar] [CrossRef]

- Sérifou, M.; Sbartaï, Z.M.; Yotte, S.; Boffoué, M.O.; Emeruwa, E.; Bos, F. A Study of Concrete Made with Fine and Coarse Aggregates Recycled from Fresh Concrete Waste. J. Constr. Eng. 2013, 2013, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Cabral, A.E.B.; Schalch, V.; Molin, D.C.C.D.; Ribeiro, J.L.D. Mechanical properties modeling of recycled aggregate concrete. Constr. Build. Mater. 2010, 24, 421–430. [Google Scholar] [CrossRef]

- Salahuddin, H.; Qureshi, L.A.; Nawaz, A.; Raza, S.S. Effect of recycled fine aggregates on performance of Reactive Powder Concrete. Constr. Build. Mater. 2020, 243, 118223. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Cantero, B.; Bravo, M.; de Brito, J.; Sáez del Bosque, I.F.; Medina, C. Mechanical behaviour of structural concrete with ground recycled concrete cement and mixed recycled aggregate. J. Clean. Prod. 2020, 275, 122913. [Google Scholar] [CrossRef]

- PN-EN-206:2016; Concrete—Requirements, Properties and Conformity. Polish Committee for Standardization: Warsaw, Poland, 2016.

- Silva, R.V.; De Brito, J.; Dhir, R.K. Tensile strength behaviour of recycled aggregate concrete. Constr. Build. Mater. 2015, 83, 108–118. [Google Scholar] [CrossRef]

- Kim, Y.-J. Quality properties of self-consolidating concrete mixed with waste concrete powder. Constr. Build. Mater. 2017, 135. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2869–2876. [Google Scholar] [CrossRef]

- EN 1992-1-1:2004; Eurocode 2: Design of concrete structures-Part 1-1: General Rules and Rules for Buildings. British Standard Institution: London, UK, 2004.

- ACI Committee 318; ACI 318 Building Code Requirements for Structural Concrete (ACI 318-14): An ACI Standard. Commentary on Building Code Requirements for Structural Concrete (ACI 318R-14); American Concrete Institute: Farmington Hills, MI, USA, 2014.

- Xiao, J.-Z.; Li, J.-B.; Zhang, C. On relationships between the mechanical properties of recycled aggregate concrete: An overview. Mater. Struct. 2007, 39, 655–664. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, H.; Geng, Y.; Wang, Q.; Zhang, S. Prediction of the elastic modulus and the splitting tensile strength of concrete incorporating both fine and coarse recycled aggregate. Constr. Build. Mater. 2019, 215, 332–346. [Google Scholar] [CrossRef]

- Duan, Z.H.; Poon, C.S. Properties of recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mater. Des. 2014, 58, 19–29. [Google Scholar] [CrossRef]

| Mix | OPC (kg/m3) | Water (kg/m3) | w/c | NCA (kg/m3) | NFA (kg/m3) |

|---|---|---|---|---|---|

| RC | 389 | 175 | 0.45 | 1011 | 740 |

| Aggregates | Specific Gravity | Water Absorption (%) |

|---|---|---|

| NCA | 2.68 | 0.88 |

| RCA | 2.41 | 4.45 |

| NFA | 2.60 | 0.91 |

| RFA | 2.22 | 5.38 |

| Mix Designation | OPC (kg/m3) | RP (kg/m3) | Water (kg/m3) | w/c | NCA (kg/m3) | RCA (kg/m3) | NFA (kg/m3) | RFA (kg/m3) |

|---|---|---|---|---|---|---|---|---|

| RCAC-30 | 389 | 0 | 175 | 0.45 | 707 | 279 | 740 | 0 |

| RCAC-60 | 389 | 0 | 175 | 0.45 | 404 | 545 | 740 | 0 |

| RCAC-100 | 389 | 0 | 175 | 0.45 | 0 | 909 | 740 | 0 |

| RFAC-30 | 389 | 0 | 175 | 0.45 | 1011 | 0 | 518 | 189 |

| RFAC-60 | 389 | 0 | 175 | 0.45 | 1011 | 0 | 296 | 379 |

| RFAC-100 | 389 | 0 | 175 | 0.45 | 1011 | 0 | 0 | 632 |

| RPC-10 [32] | 350 | 39 | 175 | 0.45 | 1011 | 0 | 740 | 0 |

| RPC-20 [32] | 311 | 78 | 175 | 0.45 | 1011 | 0 | 740 | 0 |

| RPC-30 [32] | 272 | 117 | 175 | 0.45 | 1011 | 0 | 740 | 0 |

| RCFAC-30 | 389 | 0 | 175 | 0.45 | 707 | 279 | 518 | 189 |

| RCFAC-60 | 389 | 0 | 175 | 0.45 | 404 | 545 | 296 | 379 |

| RCFAC100 [32] | 389 | 0 | 175 | 0.45 | 0 | 909 | 0 | 632 |

| Concrete Grade | Exposure Class * | Applicable Mix |

|---|---|---|

| C8/10 | X0—no risk of corrosion | - |

| C16/20 | XC1—dry or permanent wet XC2—wet, rarely dry | - |

| C20/25 | XC3—moderate humidity XC4—cyclic wet and dry | - |

| C25/30 | XF2—moderate water absorption (saturation), water includes de-icing agent | RPC-30 RCFAC-100 |

| C30/37 | XD1—moderately wet XD2—wet, occasionally dry XS1—action of salts in air = atmosphere XF1—moderate water absorption (saturation) XF3—strong water absorption (saturation), water without de-icing agent XF4—strong water absorption (saturation), water includes de-icing agent XA1—weak chemical aggression XA2—moderate chemical aggression XM1—moderate risk of abrasion XM2—strong risk of abrasion | RCAC-60 RCAC-100 RFAC-60 RFAC-100 RPC-20 RCFAC-30 RCFAC-60 |

| C35/45 | XD3—moderately wet and dry XS2—permanent immersion in water XS3—tidal, splash and aerosol zones XA3—strong chemical aggression XM3—extreme risk of abrasion | RC RCAC-30 RFAC-30 RPC-10 |

| Mix | Cost (USD/m3) | GWP (kg CO2-eq./m3) | Compressive Strength (MPa) | Cost Value | Eco-Efficiency | Target Strength |

|---|---|---|---|---|---|---|

| RC | 56.20 | 405.22 | 36.8 | 1 | 1 | Pass |

| RCAC-30 | 54.73 | 399.88 | 35.2 | 0.98 | 0.97 | Pass |

| RCAC-60 | 53.20 | 394.47 | 33.5 | 0.96 | 0.93 | Pass |

| RCAC-100 | 51.21 | 387.32 | 31.4 | 0.94 | 0.89 | Pass |

| RFAC-30 | 55.33 | 401.94 | 35.4 | 0.98 | 0.97 | Pass |

| RFAC-60 | 54.47 | 398.67 | 34.6 | 0.97 | 0.96 | Pass |

| RFAC-100 | 53.31 | 394.31 | 32.2 | 0.92 | 0.90 | Pass |

| RPC-10 | 52.33 | 378.60 | 36.3 | 1.06 | 1.06 | Pass |

| RPC-20 | 48.45 | 351.87 | 34.2 | 1.08 | 1.07 | Pass |

| RPC-30 | 44.56 | 325.15 | 26.1 | 0.90 | 0.89 | Fail |

| RCFAC-30 | 53.85 | 396.60 | 34.1 | 0.97 | 0.95 | Pass |

| RCFAC-60 | 51.46 | 387.92 | 32.0 | 0.95 | 0.91 | Pass |

| RCFAC-100 | 48.32 | 376.40 | 29.8 | 0.94 | 0.87 | Fail |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Grabiec, A.M.; Ubysz, A. An Experimental Study on Structural Concrete Containing Recycled Aggregates and Powder from Construction and Demolition Waste. Materials 2022, 15, 2458. https://doi.org/10.3390/ma15072458

Kim J, Grabiec AM, Ubysz A. An Experimental Study on Structural Concrete Containing Recycled Aggregates and Powder from Construction and Demolition Waste. Materials. 2022; 15(7):2458. https://doi.org/10.3390/ma15072458

Chicago/Turabian StyleKim, Jeonghyun, Anna M. Grabiec, and Andrzej Ubysz. 2022. "An Experimental Study on Structural Concrete Containing Recycled Aggregates and Powder from Construction and Demolition Waste" Materials 15, no. 7: 2458. https://doi.org/10.3390/ma15072458

APA StyleKim, J., Grabiec, A. M., & Ubysz, A. (2022). An Experimental Study on Structural Concrete Containing Recycled Aggregates and Powder from Construction and Demolition Waste. Materials, 15(7), 2458. https://doi.org/10.3390/ma15072458