Fracture Load Predictions in Additively Manufactured ABS U-Notched Specimens Using Average Strain Energy Density Criteria

Abstract

:1. Introduction

2. Theoretical Background

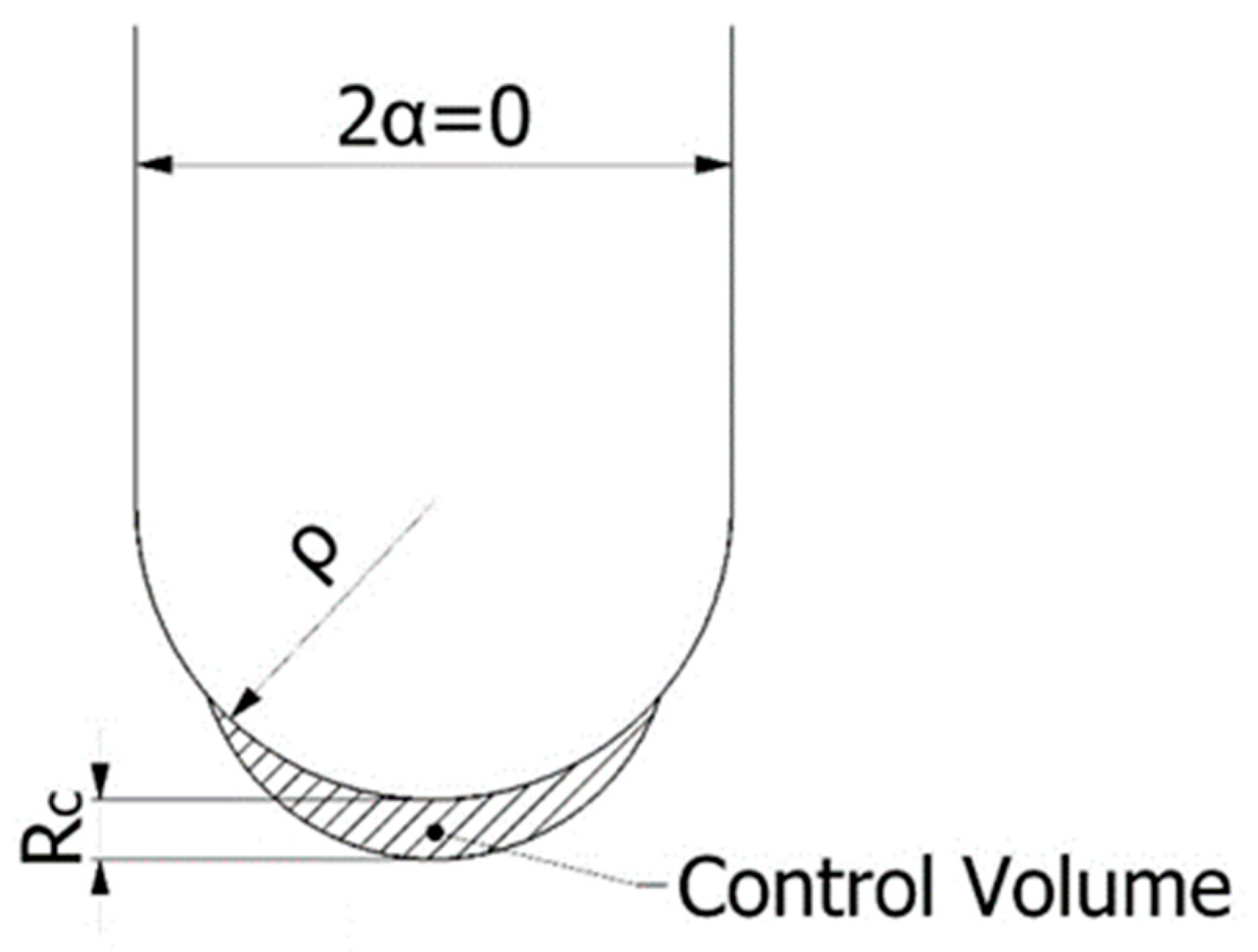

2.1. Average Strain Density Criterion

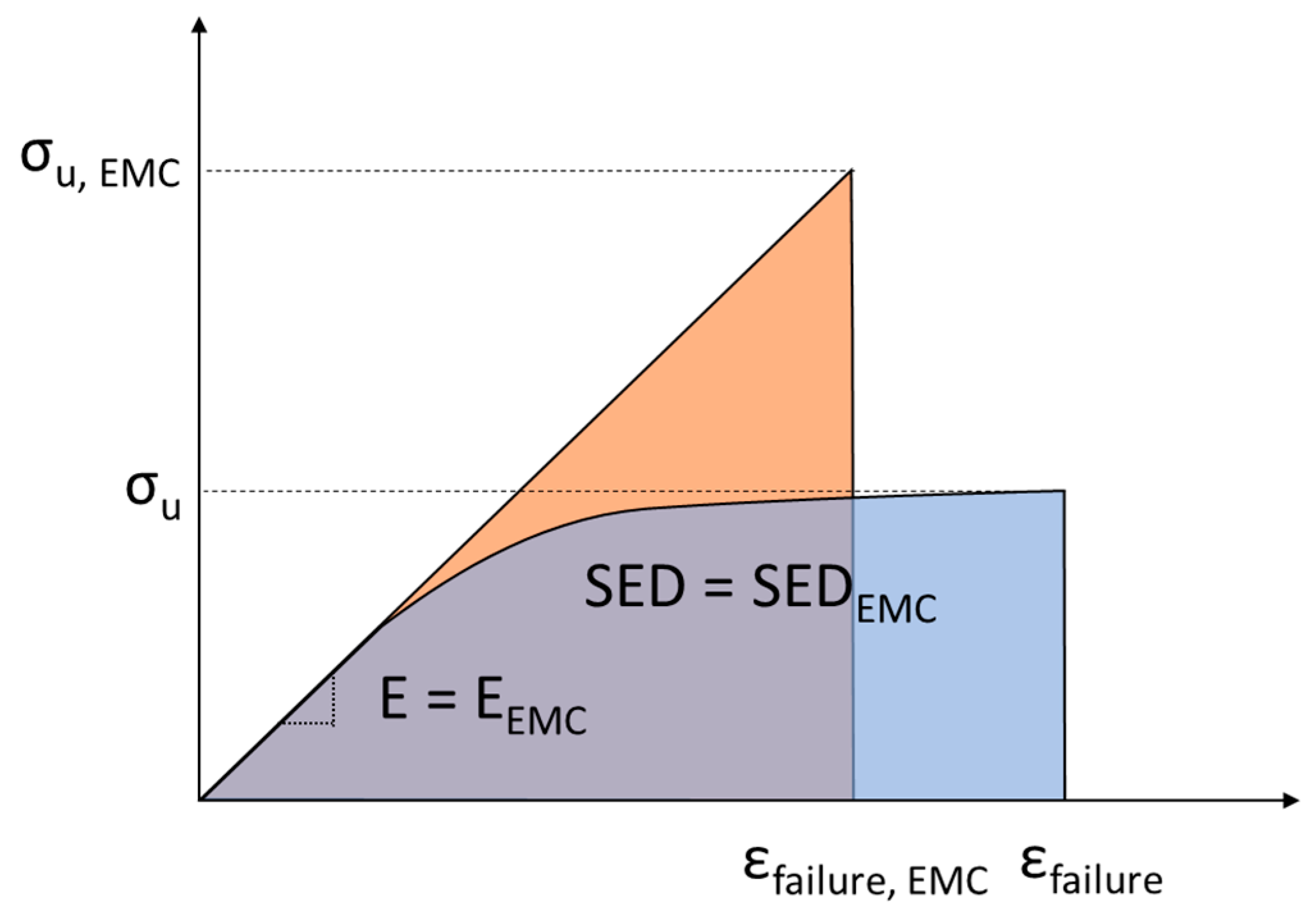

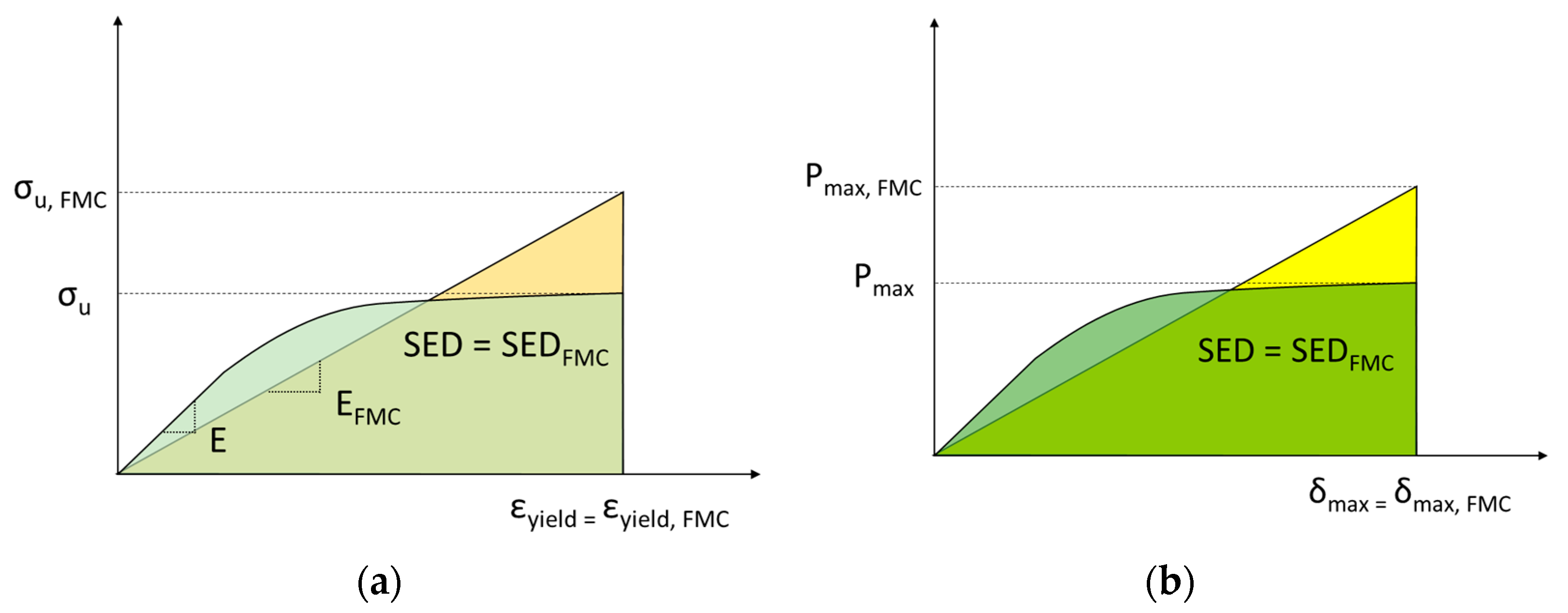

2.2. The Equivalent and Fictitious Material Concepts

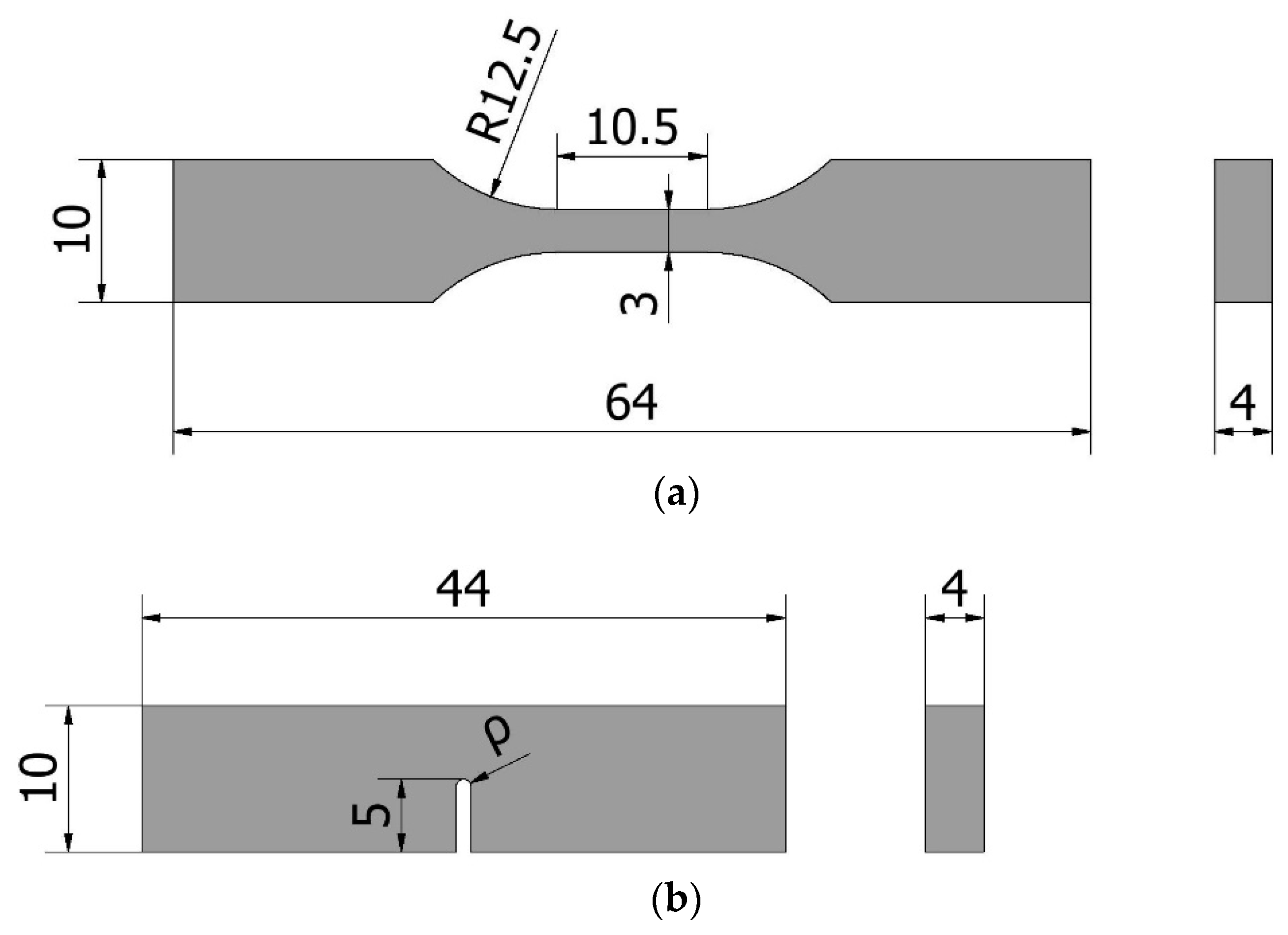

3. Materials and Methods

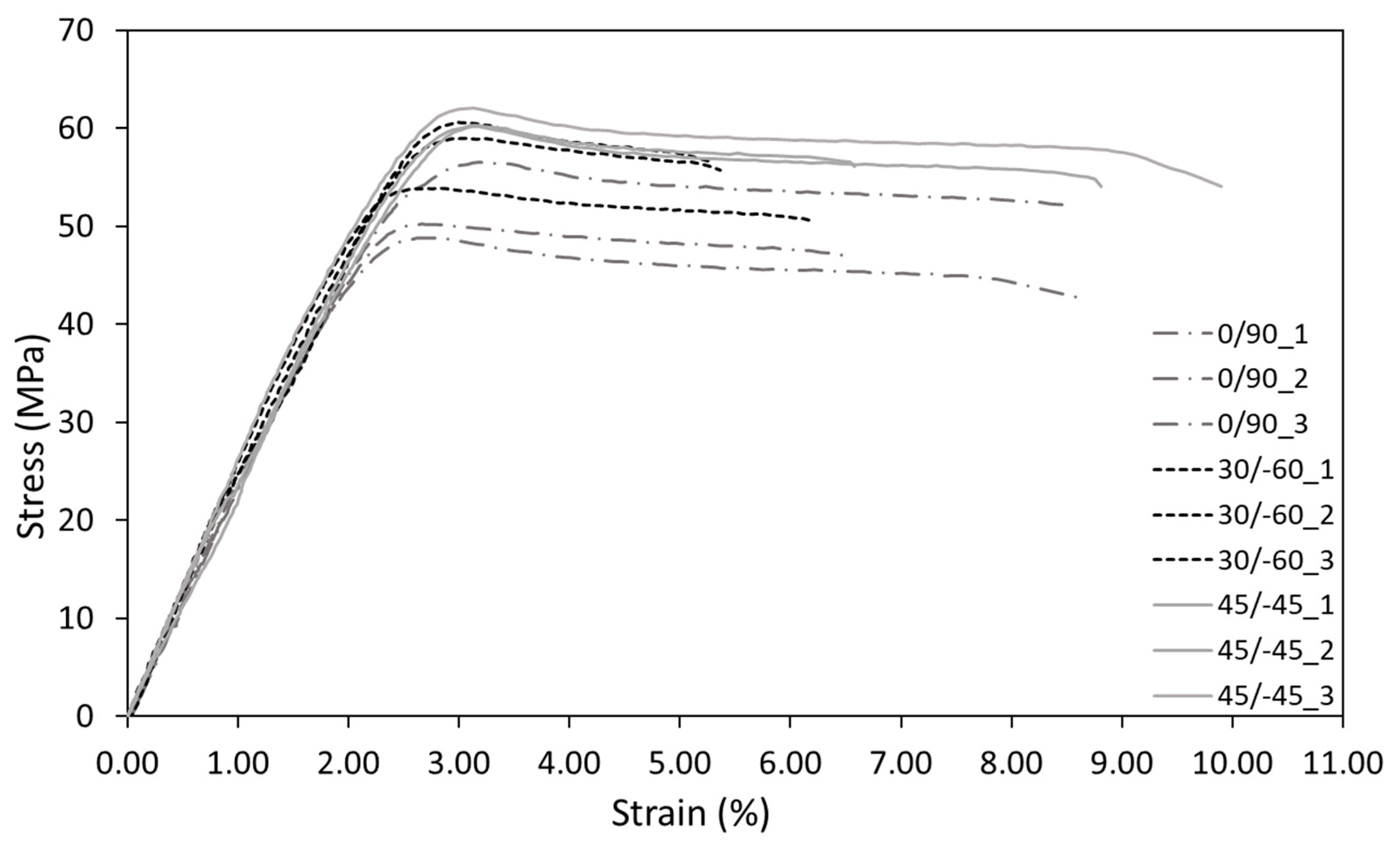

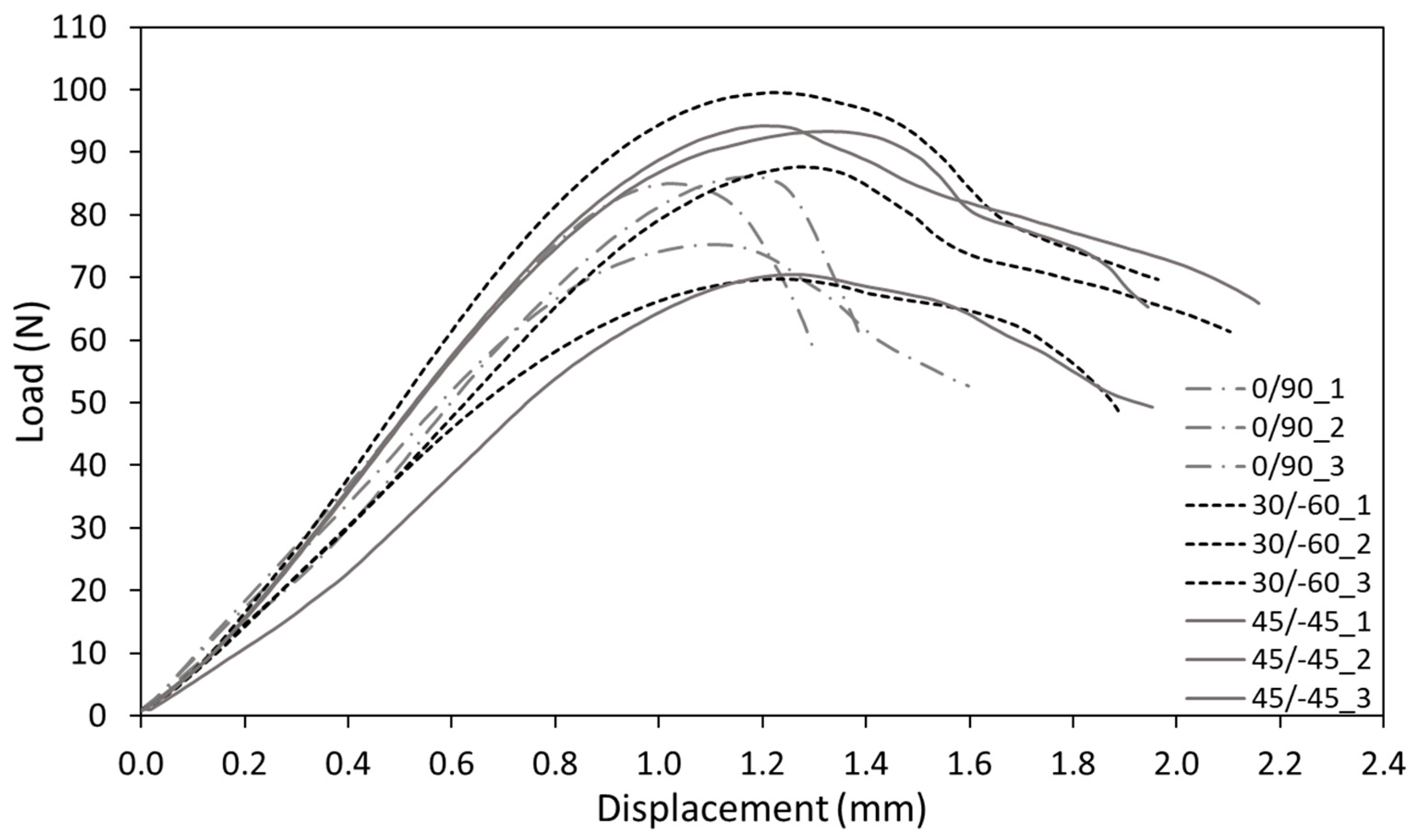

4. Results and Discussion

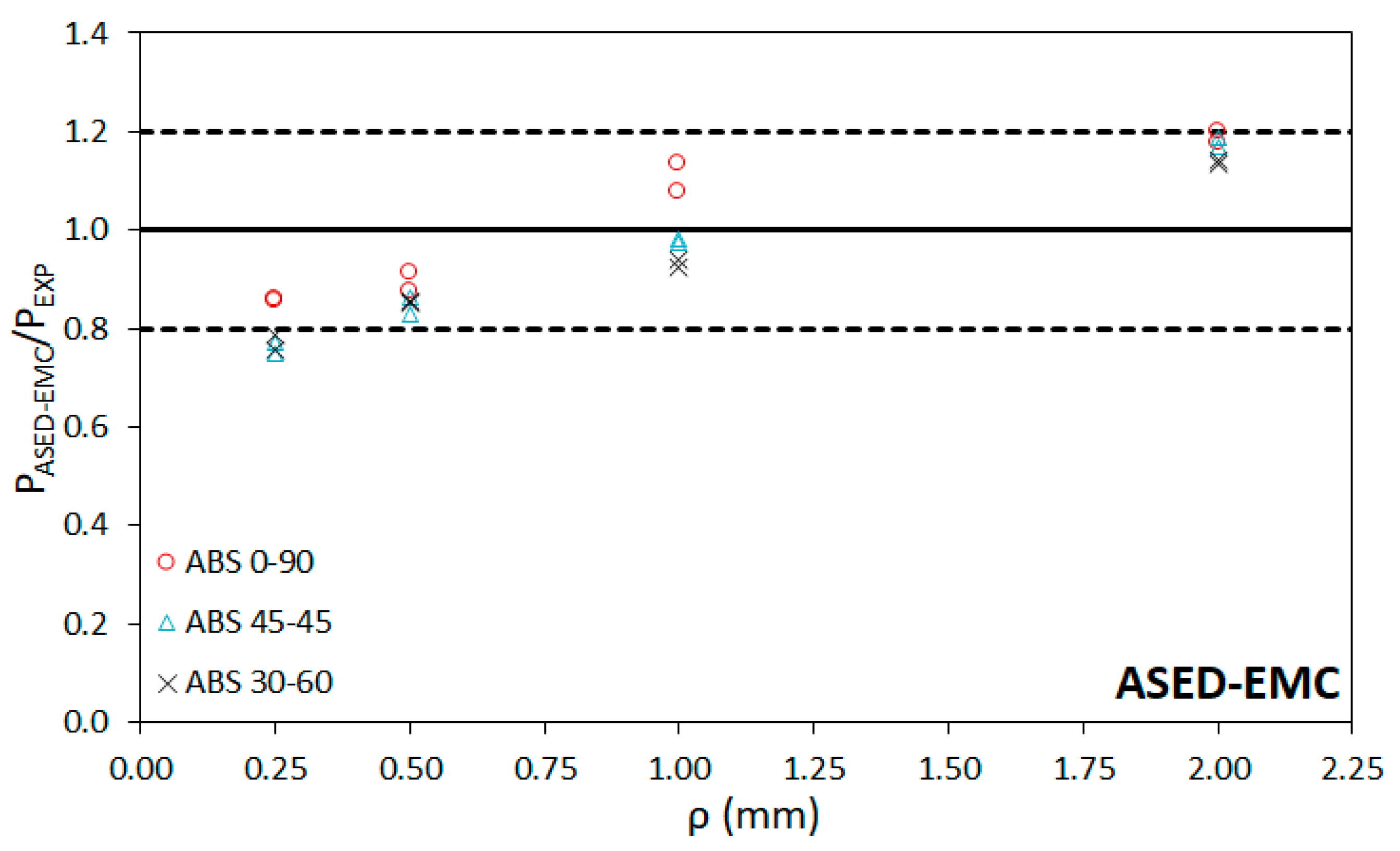

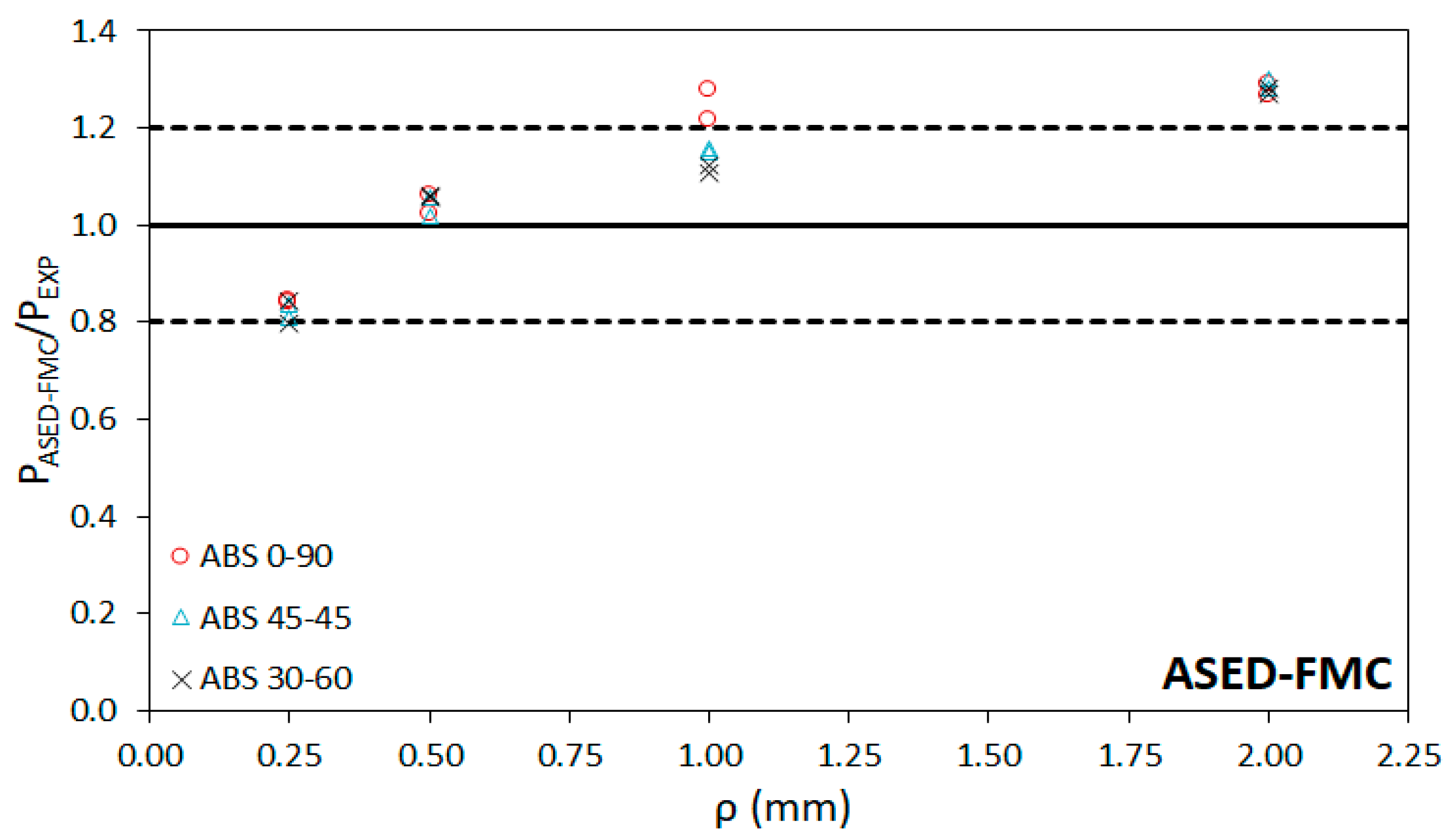

ASED-EMC and ASED-FMC Fracture Load Predictions

5. Conclusions

- The strict application of the ASED criterion provides the most conservative results, since it was formulated for brittle materials with linear elastic behavior.

- Both the ASED-EMC and the ASED-FMC criteria improves the accuracy of the predictions provided by the ASED approach.

- The ASED-EMC criterion has been the best approach to predict the failure loads in AM ABS material containing U-notches, generally combining accuracy and safety.

- Thus, a powerful engineering tool that may avoid time-consuming elastoplastic analyses has been validated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| ABS | Acrylonitrile Butadiene Styrene |

| PLA | Polylactic Acid |

| AM | Additive Manufacturing |

| ME | Material Extrusion |

| FDM | Fused Deposition Modeling |

| CAD | Computer-Aided Design |

| TDC | Theory of Critical Distances |

| ASED | Average Strain Energy Density |

| SED | Strain Energy Density |

| EMC | Equivalent Material Concept |

| FMC | Fictitious Material Concept |

| SENB | Single Edge Notched Bending (specimen) |

| mean value of the strain energy density | |

| Wc | critical strain energy density |

| Rc | critical radius |

| σu | ultimate tensile strength |

| σy | yield strength |

| σsy | tensile strength at yield |

| εyield | strain at yield |

| E | Young’s modulus |

| ν | Poisson´s ratio |

| Kc | material fracture toughness in stress intensity factor units |

| B | specimen thickness |

| KI | applied stress intensity factor |

| σmax | maximum principal stress at the notch tip |

| σu,EMC | equivalent tensile strength |

| σu,FMC | fictitious tensile strength |

| Kc,FMC | fictitious fracture toughness in stress intensity factor units |

| EFMC | fictitious Young´s modulus |

| Pmax,FMC | fictitious maximum load |

| Pcritical | predicted failure load |

| Pmax | maximum load |

| PQ | load provided by the intersection of the load-displacement curve and a line with a compliance 5% greater than the straight part of the load-displacement curve. |

| ρ | notch radius |

References

- Cantrell, J.T.; Rohde, S.; Damiani, D.; Gurnani, R.; DiSandro, L.; Anton, J.; Young, A.; Jerez, A.; Steinbach, D.; Kroese, C.; et al. Experimental characterization of the mechanical properties of 3D-printed ABS and polycarbonate parts. Rapid Prototyp. J. 2017, 23, 811–824. [Google Scholar] [CrossRef]

- Bamiduro, O.; Owolabi, G.; Haile, M.A.; Riddick, J.C. The influence of load direction, microstructure, raster orientation on the quasi-static response of fused deposition modeling ABS. Rapid Prototyp. J. 2019, 25, 462–472. [Google Scholar] [CrossRef]

- Ahn, S.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef] [Green Version]

- Ng, C.T.; Susmel, L. Notch static strength of additively manufactured acrylonitrile butadiene styrene (ABS). Addit. Manuf. 2020, 34, 101212. [Google Scholar] [CrossRef]

- Cicero, S.; Martínez-Mata, V.; Alonso-Estebanez, A.; Castanon-Jano, L.; Arroyo, B. Analysis of Notch Effect in 3D-Printed ABS Fracture Specimens Containing U-Notches. Materials 2020, 13, 4716. [Google Scholar] [CrossRef]

- Ameri, B.; Taheri-Behrooz, F.; Aliha, M.R.M. Fracture loads prediction of the modified 3D-printed ABS specimens under mixed-mode I/II loading. Eng. Fract. Mech. 2020, 235, 107181. [Google Scholar] [CrossRef]

- Isaac, J.P.; Dondeti, S.; Tippur, H.V. Fracture behavior of additively printed ABS: Effects of print architecture and loading rate. Int. J. Solids Struct. 2021, 212, 80–95. [Google Scholar] [CrossRef]

- McLouth, T.D.; Severino, J.V.; Adams, P.M.; Patel, D.N.; Zaldivar, R.J. The impact of print orientation and raster pattern on fracture toughness in additively manufactured ABS. Addit. Manuf. 2017, 18, 103–109. [Google Scholar] [CrossRef]

- Hart, K.R.; Wetzel, E.D. Fracture behavior of additively manufactured acrylonitrile butadiene styrene (ABS) materials. Eng. Fract. Mech. 2017, 177, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive manufacturing: Challenges, trends, and applications. Adv. Mech. Eng. 2019, 11, 1687814018822880. [Google Scholar] [CrossRef] [Green Version]

- Haidiezul, A.; Aiman, A.; Bakar, B. Surface Finish Effects Using Coating Method on 3D Printing (FDM) Parts. IOP Conf. Ser. Mater. Sci. Eng. 2018, 318, 012065. [Google Scholar] [CrossRef]

- Tang, Q.; Yin, S.; Zhang, Y.; Wu, J. A tool vector control for laser additive manufacturing in five-axis configuration. Int. J. Adv. Manuf. Technol. 2018, 98, 1671–1684. [Google Scholar] [CrossRef]

- Kousiatza, C.; Karalekas, D. In-situ monitoring of strain and temperature distributions during fused deposition modeling process. Mater. Des. 2016, 97, 400–406. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Zharylkassyn, B.; Seisekulova, A.; Akhmetov, M.; Perveen, A.; Talamona, D. Optimisation of Strength Properties of FDM Printed Parts—A Critical Review. Polymers 2021, 13, 1587. [Google Scholar] [CrossRef]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012, 2012, 208760. [Google Scholar] [CrossRef] [Green Version]

- Agron, D.J.S.; Nwakanma, C.I.; Lee, J.-M.; Kim, D.-S. Smart Monitoring for SLA-type 3D Printer using Artificial Neural Network. KICS 2020, 72, 1203–1204. [Google Scholar]

- Kadam, V.; Kumar, S.; Bongale, A.; Wazarkar, S.; Kamat, P.; Patil, S. Enhancing Surface Fault Detection Using Machine Learning for 3D Printed Products. Appl. Syst. Innov. 2021, 4, 34. [Google Scholar] [CrossRef]

- Ameri, B.; Taheri-Behrooz, F.; Aliha, M.R.M. Evaluation of the geometrical discontinuity effect on mixed-mode I/II fracture load of FDM 3D-printed parts. Theor. Appl. Fract. Mech. 2021, 113, 102953. [Google Scholar] [CrossRef]

- Beaumont, P.W.R. The failure of fibre composites: An overview. J. Strain Anal. Eng. Des. 1989, 24, 189–205. [Google Scholar] [CrossRef]

- Head, P. Advanced composite materials. Eng. Des. 1996, 22, 4–9. [Google Scholar] [CrossRef]

- Bäcklund, J.; Aronsson, C.G. Tensile Fracture of Laminates with Holes. J. Compos. Mater. 1986, 20, 259–286. [Google Scholar] [CrossRef]

- Taylor, D. The Theory of Critical Distances. Theory Crit. Distances 2007, 75, 1696–1705. [Google Scholar] [CrossRef]

- Berto, F.; Lazzarin, P.; Ayatollahi, M.R. Recent developments in brittle and quasi-brittle failure assessment of graphite by means of SED approach. In Proceedings of the 13th International Conference on Fracture, Beijing, China, 16–21 June 2013; Volume 2, pp. 854–861. [Google Scholar]

- Nguyen, B.N. Three-dimensional modeling of damage in laminated composites containing a central hole. J. Compos. Mater. 1997, 31, 1672–1693. [Google Scholar] [CrossRef]

- Chang, K.Y.; Llu, S.; Chang, F.K. Damage Tolerance of Laminated Composites Containing an Open Hole and Subjected to Tensile Loadings. J. Compos. Mater. 1991, 25, 274–301. [Google Scholar] [CrossRef]

- Lawcokc, G.; Lin, Y.; Mai, Y. Progressive Damage and Residual Strength of a Carbon Fibre Reinforced Metal Laminate. J. Compos. Mater. 1997, 31, 762–787. [Google Scholar]

- Justo, J.; Castro, J.; Cicero, S. Energy-based approach for fracture assessment of several rocks containing U-shaped notches through the application of the SED criterion. Int. J. Rock Mech. Min. Sci. 2018, 110, 306–315. [Google Scholar] [CrossRef]

- Ibáñez-Gutiérrez, F.T.; Cicero, S.; Madrazo, V.; Berto, F. Fracture Loads Prediction on Notched Short Glass Fibre Reinforced Polyamide 6 Using the Strain Energy Density. Phys. Mesomech. 2018, 21, 165–172. [Google Scholar] [CrossRef]

- Cicero, S.; Berto, F.; Ibáñez-Gutiérrez, F.T.; Procopio, I.; Madrazo, V. SED criterion estimations of fracture loads in structural steels operating at lower shelf temperatures and containing u-notches. Theor. Appl. Fract. Mech. 2017, 90, 234–243. [Google Scholar] [CrossRef]

- Seibert, P.; Susmel, L.; Berto, F.; Kästner, M.; Razavi, S.M.J. Applicability of strain energy density criterion for fracture prediction of notched PLA specimens produced via fused deposition modeling. Eng. Fract. Mech. 2021, 258, 108103. [Google Scholar] [CrossRef]

- Torabi, A.R. Estimation of tensile load-bearing capacity of ductile metallic materials weakened by a V-notch: The equivalent material concept. Mater. Sci. Eng. A 2012, 536, 249–255. [Google Scholar] [CrossRef]

- Fuentes, J.D.; Cicero, S.; Berto, F.; Torabi, A.R.; Madrazo, V.; Azizi, P. Estimation of fracture loads in AL7075-T651 notched specimens using the equivalent material concept combined with the strain energy density criterion and with the theory of critical distances. Metals 2018, 8, 87. [Google Scholar] [CrossRef] [Green Version]

- Cicero, S.; Fuentes, J.D.; Torabi, A.R. Using the equivalent material concept and the average strain energy density to analyse the fracture behaviour of structural materials. Appl. Sci. 2020, 10, 1601. [Google Scholar] [CrossRef] [Green Version]

- Torabi, A.R.; Hamidi, K.; Rahimi, A.S.; Cicero, S. Notch fracture in polymeric specimens under compressive stresses: The role of the equivalent material concept in estimating the critical stress of polymers. Appl. Sci. 2021, 11, 2104. [Google Scholar] [CrossRef]

- Torabi, A.R.; Kamyab, M. The fictitious material concept. Eng. Fract. Mech. 2019, 209, 17–31. [Google Scholar] [CrossRef]

- Torabi, A.R.; Rahimi, A.S.; Ayatollahi, M.R. Fracture study of a ductile polymer-based nanocomposite weakened by blunt V-notches under mode I loading: Application of the Equivalent Material Concept. Theor. Appl. Fract. Mech. 2018, 94, 26–33. [Google Scholar] [CrossRef]

- Cicero, S.; Torabi, A.R.; Majidi, H.R.; Gómez, F.J. On the use of the combined FMC-ASED criterion for fracture prediction of notched specimens with nonlinear behavior. Procedia Struct. Integr. 2020, 28, 84–92. [Google Scholar] [CrossRef]

- Torabi, A.R.; Majidi, H.R.; Cicero, S.; Ibáñez-Gutiérrez, F.T.; Fuentes, J.D. Experimental verification of the Fictitious Material Concept for tensile fracture in short glass fibre reinforced polyamide 6 notched specimens with variable moisture. Eng. Fract. Mech. 2019, 212, 95–105. [Google Scholar] [CrossRef]

- Cicero, S.; Torabi, A.R.; Madrazo, V.; Azizi, P. Prediction of fracture loads in PMMA U-notched specimens using the equivalent material concept and the theory of critical distances combined criterion. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 688–699. [Google Scholar] [CrossRef]

- Albinmousa, J.; Alsadah, J.; Hawwa, M.A.; Al-Qahtani, H.M. Estimation of mode I fracture of u-notched polycarbonate specimens using the equivalent material concept and strain energy density. Appl. Sci. 2021, 11, 3370. [Google Scholar] [CrossRef]

- Lazzarin, P.; Zambardi, R. A finite-volume-energy based approach to predict the static and fatigue behavior of components with sharp V-shaped notches. Int. J. Fract. 2001, 112, 275–298. [Google Scholar] [CrossRef]

- Berto, F.; Lazzarin, P. A review of the volume-based strain energy density approach applied to V-notches and welded structures. Theor. Appl. Fract. Mech. 2009, 52, 183–194. [Google Scholar] [CrossRef]

- Lazzarin, P.; Berto, F. Some expressions for the strain energy in a finite volume surrounding the root of blunt V-notches. Int. J. Fract. 2005, 135, 161–185. [Google Scholar] [CrossRef]

- Yosibash, Z. Failure Criteria for Brittle Elastic Materials. Interdiscip. Appl. Math. 2012, 37, 185–220. [Google Scholar] [CrossRef] [Green Version]

- ASTM International ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014; Volume 08.01.

- ASTM International ASTM D6068-10(2018); Standard Test Method for Determining J-R Curves of Plastic Materials. ASTM International: West Conshohocken, PA, USA, 2010; Volume 08.03.

- ASTM International ASTM D5045-14; Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials. ASTM International: West Conshohocken, PA, USA, 2014; Volume 08.02.

- Creager, M.; Paris, P.C. Elastic field equations for blunt cracks with reference to stress corrosion cracking. Int. J. Fract. Mech. 1967, 3, 247–252. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications, 4th ed.; CRC Press: Boca Raton, FL, USA, 2005; ISBN 1498728146. [Google Scholar]

- Samykano, M.; Selvamani, S.K.; Kadirgama, K.; Ngui, W.K.; Kanagaraj, G.; Sudhakar, K. Mechanical property of FDM printed ABS: Influence of printing parameters. Int J. Adv. Manuf. Technol. 2019, 102, 2779–2796. [Google Scholar] [CrossRef]

- Dwiyati, S.T.; Kholil, A.; Riyadi, R.; Putra, S.E. Influence of layer thickness and 3D printing direction on tensile properties of ABS material. J. Phys. Conf. Ser. 2019, 1402, 066014. [Google Scholar] [CrossRef]

| Rc/ρ | H | ||

|---|---|---|---|

| ν = 0.3 | ν = 0.35 | ν = 0.4 | |

| 0.01 | 0.5638 | 0.5432 | 0.5194 |

| 0.05 | 0.5086 | 0.4884 | 0.4652 |

| 0.1 | 0.4518 | 0.4322 | 0.4099 |

| 0.3 | 0.3069 | 0.2902 | 0.2713 |

| 0.5 | 0.2276 | 0.2135 | 0.1976 |

| 1 | 0.1314 | 0.1217 | 0.1110 |

| 0/90 | 30/−60 | 45/−45 | ||||

|---|---|---|---|---|---|---|

| Material Property | Mean | Std. Dev. | Mean | Std. Dev. | Mean | Std. Dev. |

| E (MPa) | 2241 | 169.34 | 2329 | 45.45 | 2388 | 181.67 |

| σsy (MPa) | 51.77 | 4.08 | 59.37 | 1.10 | 60.87 | 1.07 |

| εyield (%) | 2.90 | 0.30 | 2.92 | 0.22 | 3.14 | 0.02 |

| SED (MPa) | 0.91 | 0.15 | 1.01 | 0.06 | 1.13 | 0.04 |

| Kc (MPa·m0.5) | 2.05 | 0.16 | 1.99 | 0.35 | 2.03 | 0.16 |

| 0/90 | 30/−60 | 45/−45 | ||||

|---|---|---|---|---|---|---|

| Material Property | Mean | Std. Dev. | Mean | Std. Dev. | Mean | Std. Dev. |

| σu,EMC (MPa) | 62.67 | 4.36 | 68.54 | 1.26 | 71.62 | 2.88 |

| σu,FMC (MPa) | 63.64 | 5.15 | 68.64 | 2.18 | 73.34 | 1.34 |

| Kc,FMC (MPa·m0.5) | 2.55 | 0.15 | 2.75 | 0.48 | 2.80 | 0.47 |

| EFMC | 2176 | 59.80 | 2323 | 53.63 | 2276 | 100.93 |

| Raster Orientation | N° Test | ρ (mm) | PEXP (N) | PASED (N) | PASED-EMC (N) | PASED-FMC (N) | Deviation ASED (%) | Deviation ASED-EMC (%) | Deviation ASED-FMC (%) |

|---|---|---|---|---|---|---|---|---|---|

| 0/90 | 1 | 0.25 | 89.9 | 62.3 | 76.8 | 75.5 | −30.8 | −14.6 | −16.1 |

| 2 | 0.25 | 89.5 | 62.3 | 76.8 | 75.5 | −30.4 | −14.2 | −15.7 | |

| 3 | 0.50 | 98.2 | 80.3 | 85.8 | 100.4 | −18.2 | −12.6 | 2.3 | |

| 4 | 0.50 | 93.6 | 79.6 | 85.3 | 99.3 | −15.0 | −8.9 | 6.0 | |

| 5 | 1.00 | 85.9 | 89.2 | 97.4 | 109.9 | 3.7 | 13.4 | 28.0 | |

| 6 | 1.00 | 90.5 | 89.2 | 97.5 | 109.9 | −1.5 | 7.7 | 21.5 | |

| 7 | 2.00 | 101.3 | 106.4 | 121.3 | 130.5 | 5.0 | 19.7 | 28.8 | |

| 8 | 2.00 | 102.9 | 106.3 | 121.2 | 130.4 | 3.2 | 17.7 | 26.6 | |

| Average Error | −10.5 | 1.0 | 10.2 | ||||||

| 30/−60 | 1 | 0.25 | 103.4 | 71.4 | 78.2 | 82.9 | −30.9 | −24.4 | −20.2 |

| 2 | 0.25 | 97.8 | 71.4 | 77.0 | 82.9 | −27.0 | −21.3 | −15.6 | |

| 3 | 0.50 | 100.4 | 81.4 | 86.1 | 106.4 | −19.0 | −14.3 | 6.0 | |

| 4 | 0.50 | 101.1 | 81.5 | 86.2 | 106.8 | −19.4 | −14.8 | 5.6 | |

| 5 | 1.00 | 107.7 | 94.0 | 101.0 | 121.1 | −12.7 | −6.2 | 12.2 | |

| 6 | 1.00 | 110.2 | 94.8 | 101.7 | 122.2 | −14.0 | −7.7 | 10.7 | |

| 7 | 2.00 | 111.9 | 114.6 | 127.1 | 142.4 | 2.4 | 13.5 | 26.9 | |

| 8 | 2.00 | 111.6 | 115.1 | 127.5 | 143.3 | 3.2 | 14.2 | 28.1 | |

| Average Error | −14.7 | −7.6 | 6.7 | ||||||

| 45/−45 | 1 | 0.25 | 103.2 | 73.2 | 79.7 | 86.2 | −29.05 | −22.8 | −16.4 |

| 2 | 0.25 | 106.5 | 73.2 | 79.8 | 86.2 | −31.28 | −25.1 | −19.0 | |

| 3 | 0.50 | 108.2 | 83.7 | 89.9 | 110.3 | −22.66 | −16.9 | 1.9 | |

| 4 | 0.50 | 103.3 | 83.2 | 89.3 | 109.2 | −19.48 | −13.5 | 5.7 | |

| 5 | 1.00 | 108.8 | 96.2 | 105.8 | 124.9 | −11.56 | −2.8 | 14.8 | |

| 6 | 1.00 | 107.6 | 95.9 | 105.5 | 124.5 | −10.83 | −1.9 | 15.7 | |

| 7 | 2.00 | 112.9 | 117.2 | 134.1 | 147.0 | 3.81 | 18.8 | 30.2 | |

| 8 | 2.00 | 114.8 | 117.4 | 134.2 | 147.3 | 2.26 | 17.0 | 28.3 | |

| Average Error | −14.9 | −5.9 | 7.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez, M.; Cicero, S.; Arrieta, S.; Martínez, V. Fracture Load Predictions in Additively Manufactured ABS U-Notched Specimens Using Average Strain Energy Density Criteria. Materials 2022, 15, 2372. https://doi.org/10.3390/ma15072372

Sánchez M, Cicero S, Arrieta S, Martínez V. Fracture Load Predictions in Additively Manufactured ABS U-Notched Specimens Using Average Strain Energy Density Criteria. Materials. 2022; 15(7):2372. https://doi.org/10.3390/ma15072372

Chicago/Turabian StyleSánchez, Marcos, Sergio Cicero, Sergio Arrieta, and Victor Martínez. 2022. "Fracture Load Predictions in Additively Manufactured ABS U-Notched Specimens Using Average Strain Energy Density Criteria" Materials 15, no. 7: 2372. https://doi.org/10.3390/ma15072372

APA StyleSánchez, M., Cicero, S., Arrieta, S., & Martínez, V. (2022). Fracture Load Predictions in Additively Manufactured ABS U-Notched Specimens Using Average Strain Energy Density Criteria. Materials, 15(7), 2372. https://doi.org/10.3390/ma15072372