Design, Fabrication, and Mechanical Properties of T-700TM Multiaxial-Warp-Knitting–Needled–C/SiC Composite and Pin

Abstract

:1. Introduction

2. Fabrication of 12k T-700TM MWK–N–C/SiC Composite and Pin and Mechanical Experimental Procedure

2.1. Fabrication of C/SiC Composite and Pins

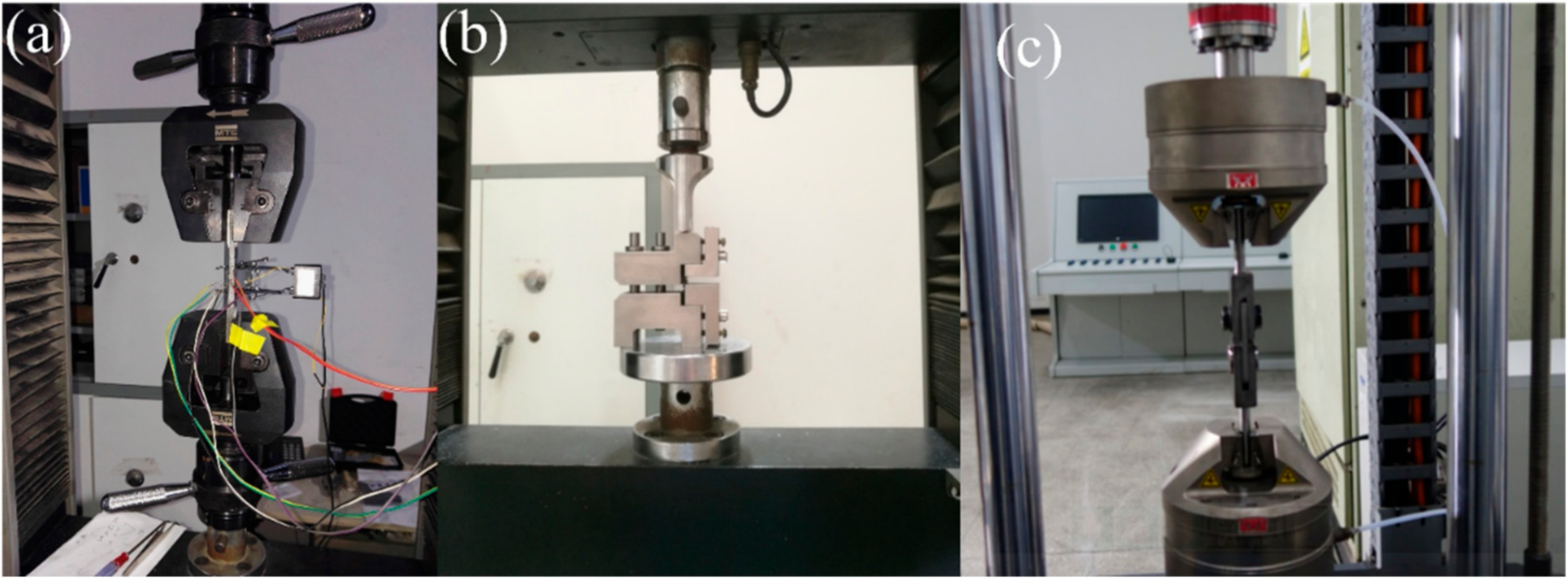

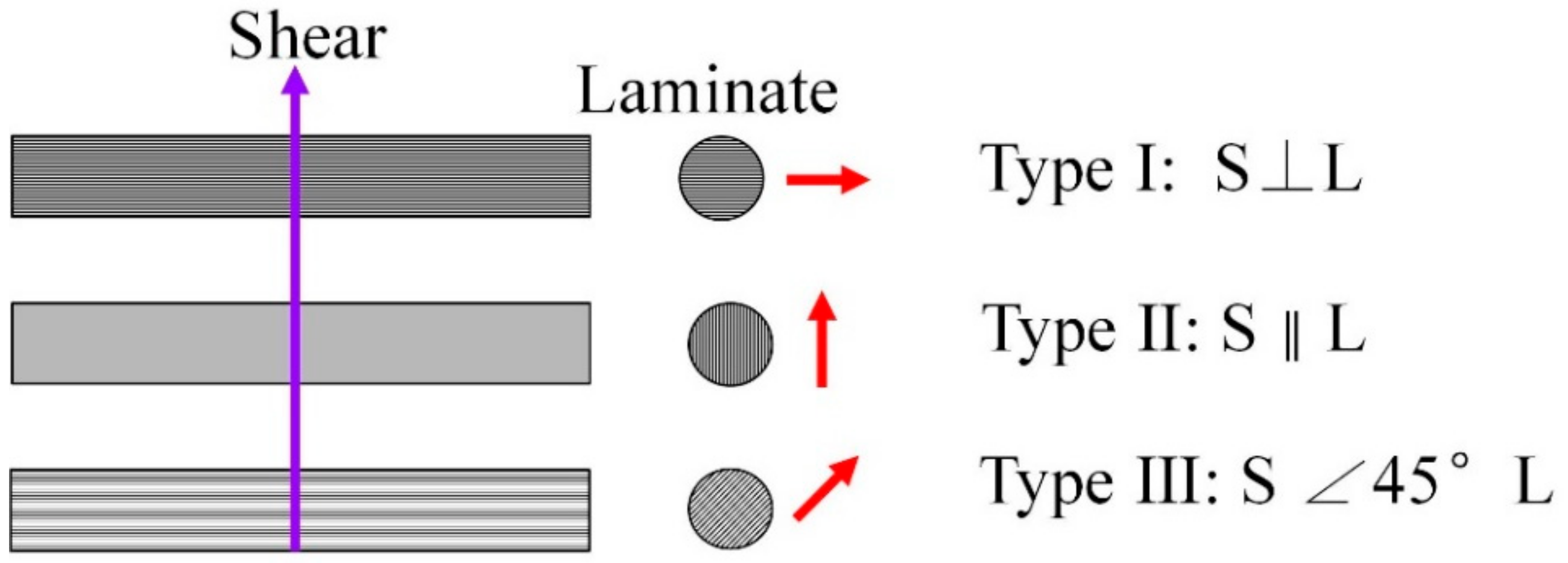

2.2. Mechanical Test Procedures

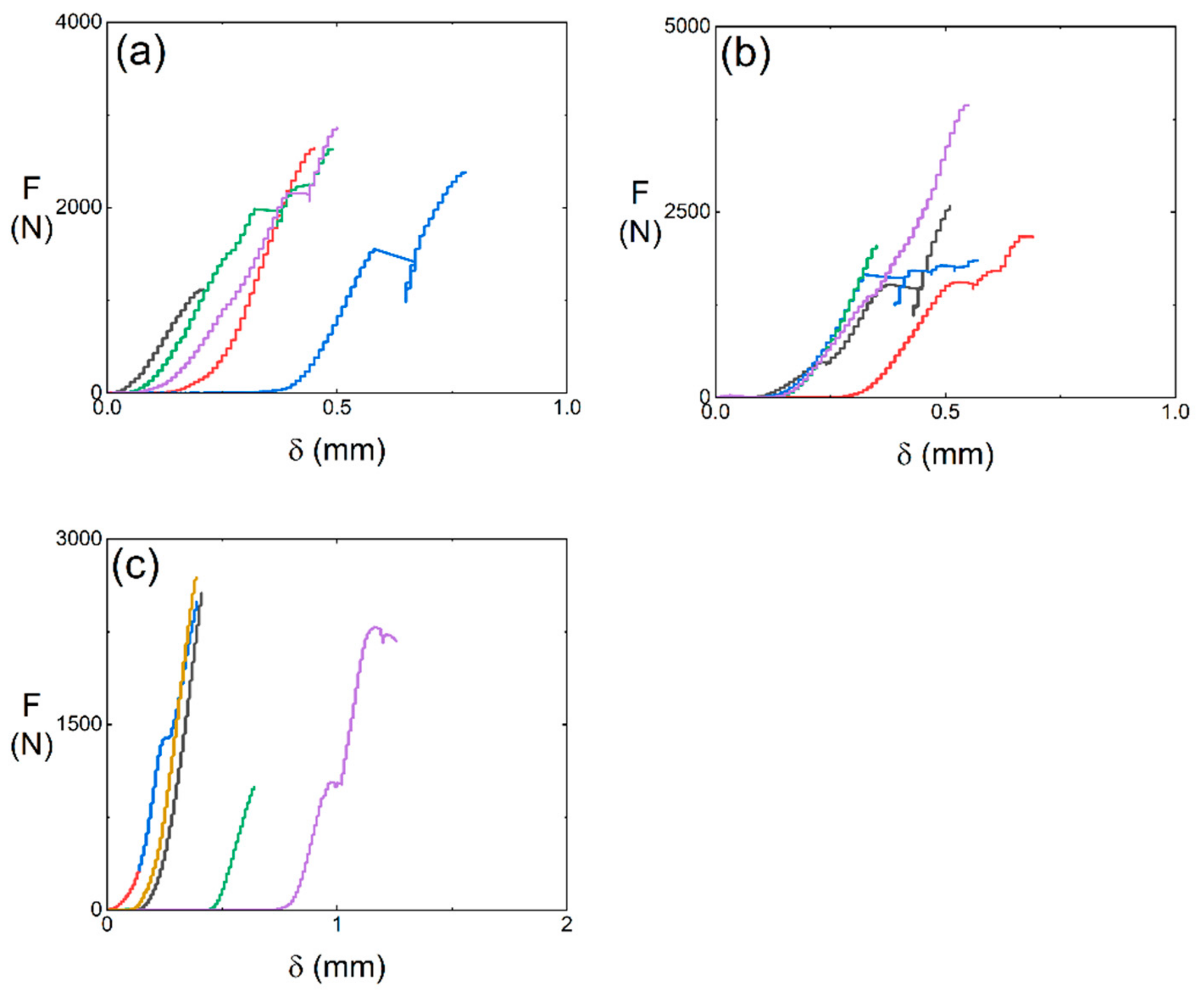

- Type I, the shear loading is perpendicular to the lamination.

- Type II, the shear loading is along the lamination.

- Type III, 45° off-axial shear loading.

3. Experimental Results and Discussion

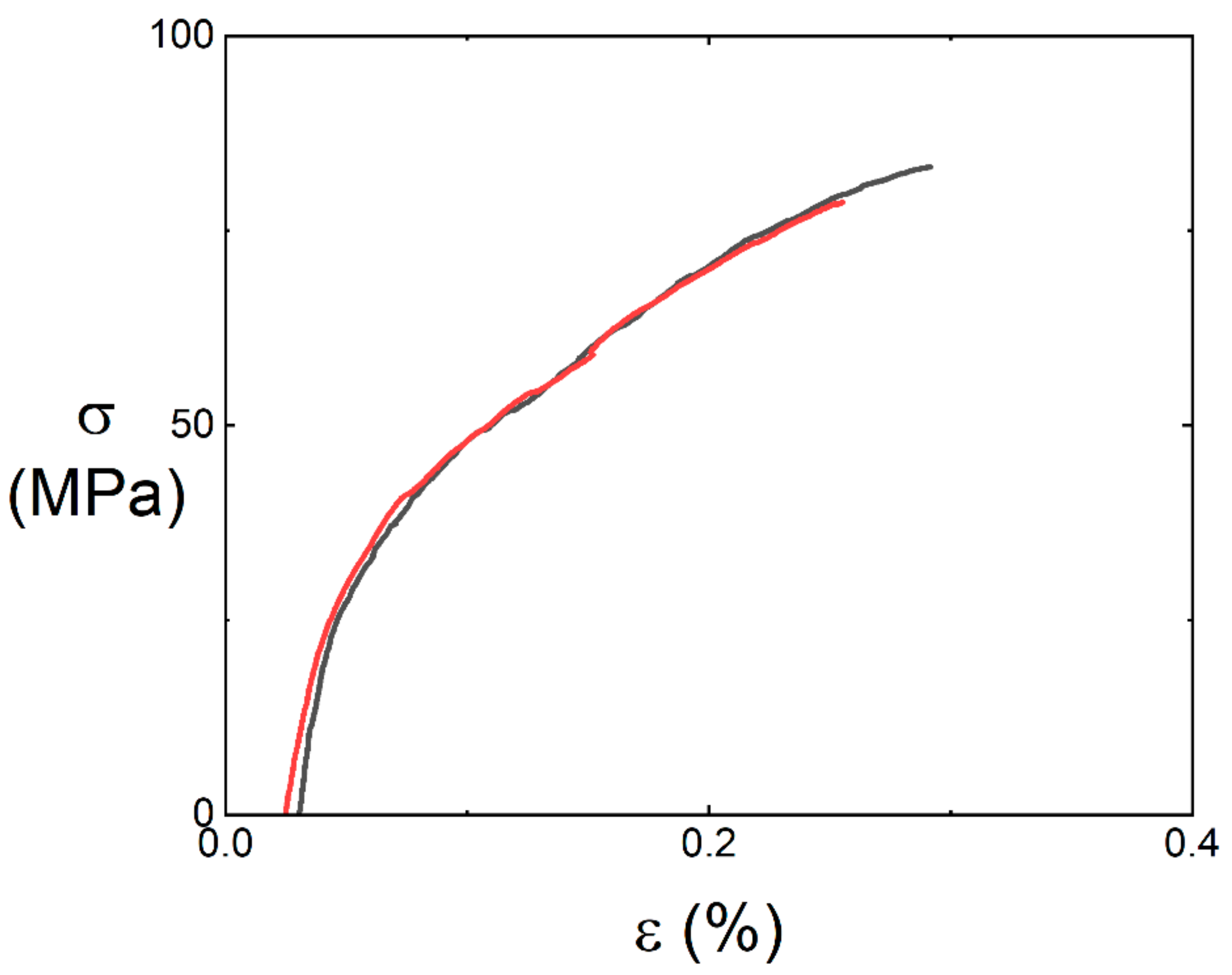

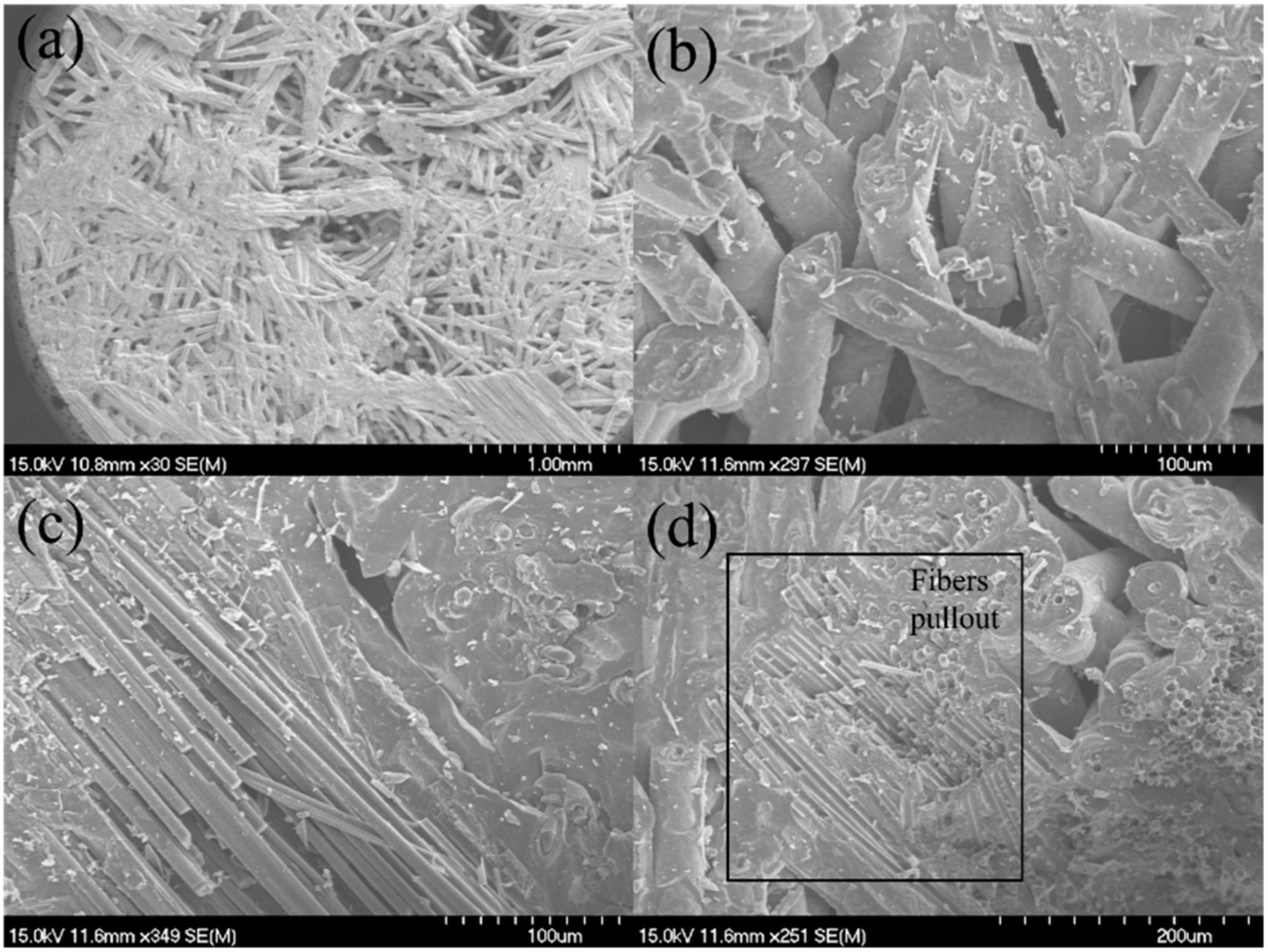

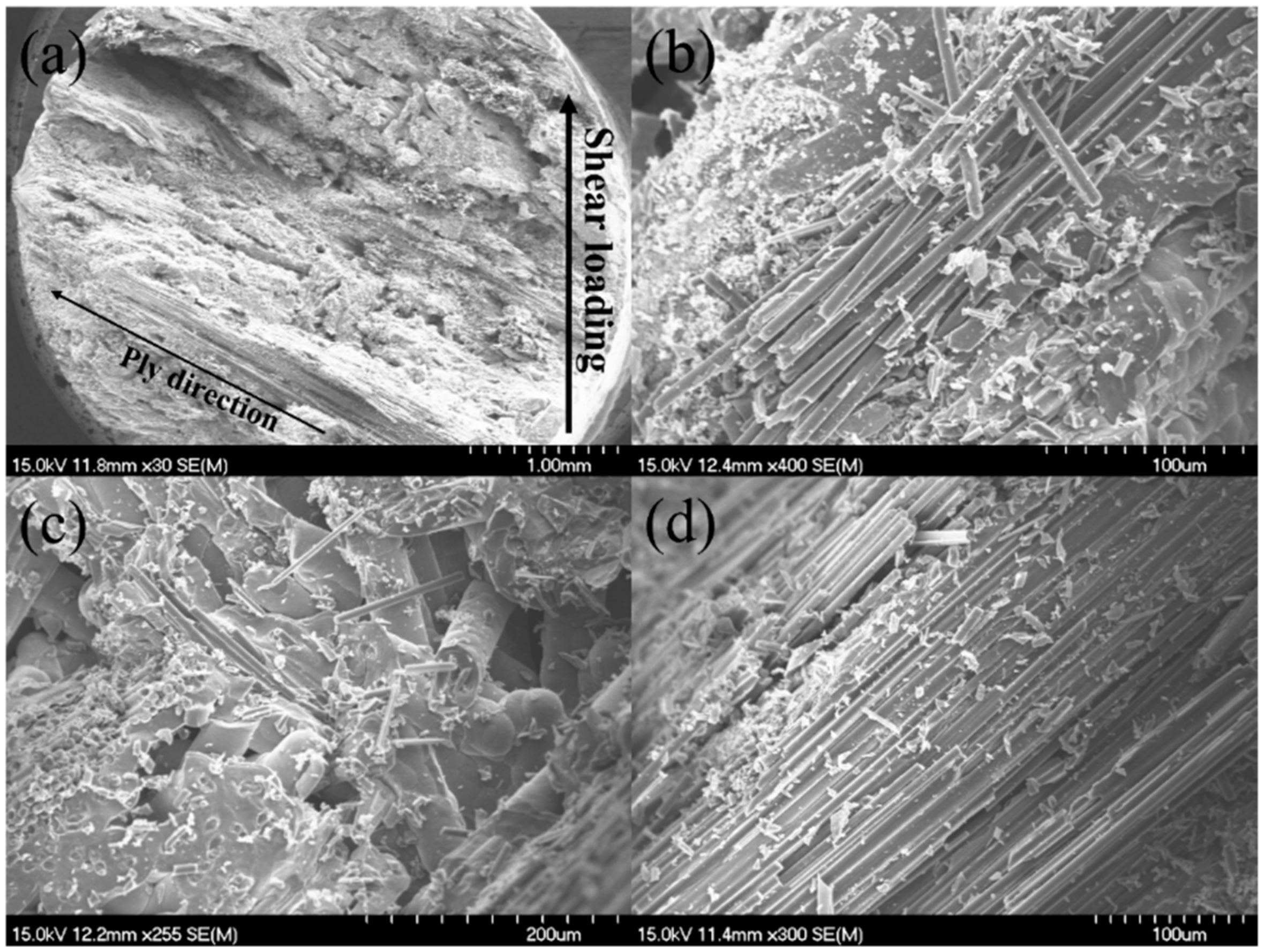

3.1. Tensile Behavior of 12k T-700TM MWK–N–C/SiC Composite

3.2. Interlaminar Shear Behavior of the 12k T-700TM MWK–N–C/SiC Composite

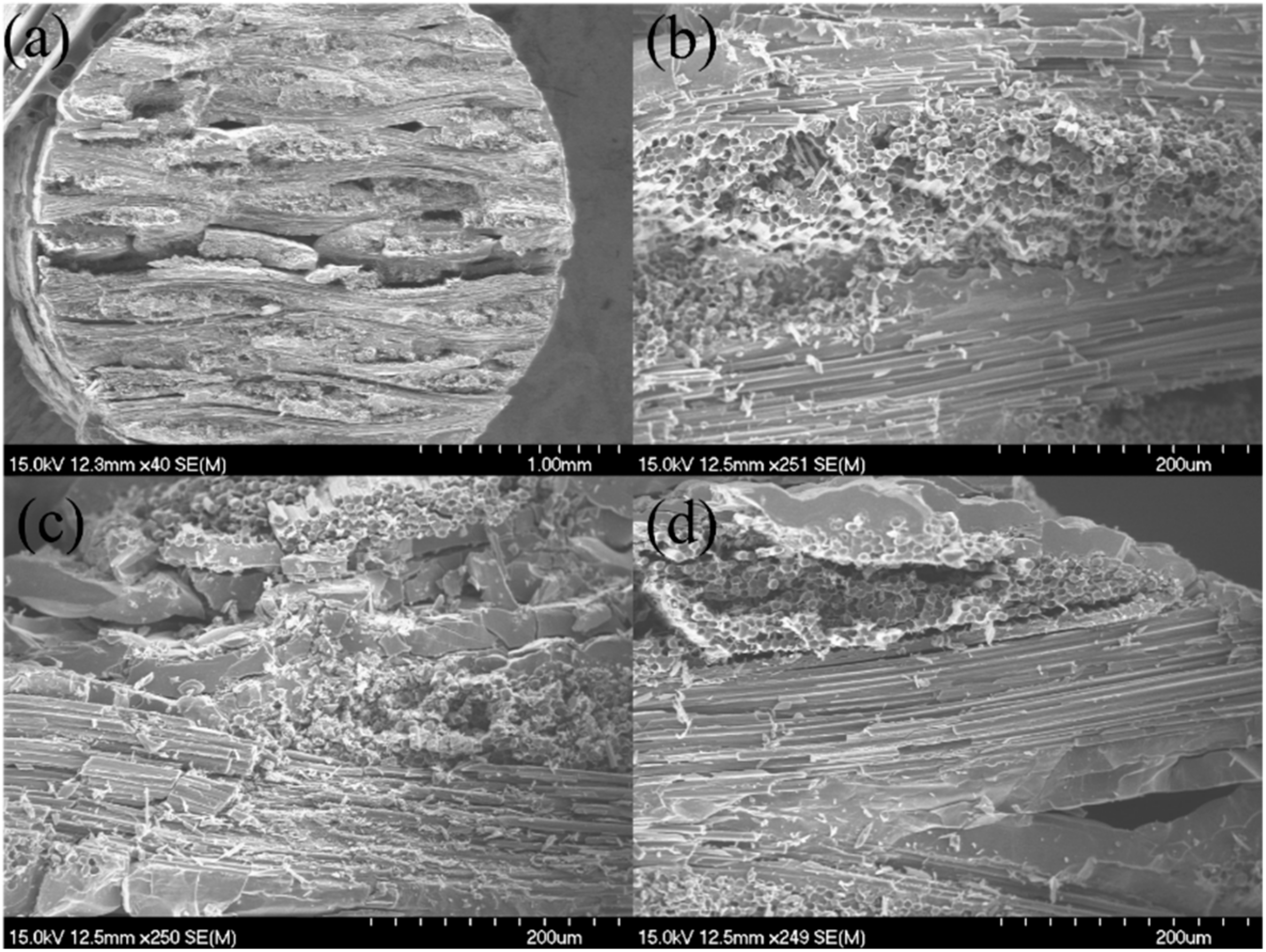

3.3. Double-Shear Mechanical Behavior of the 12k T-700TM MWK–N–C/SiC Pins

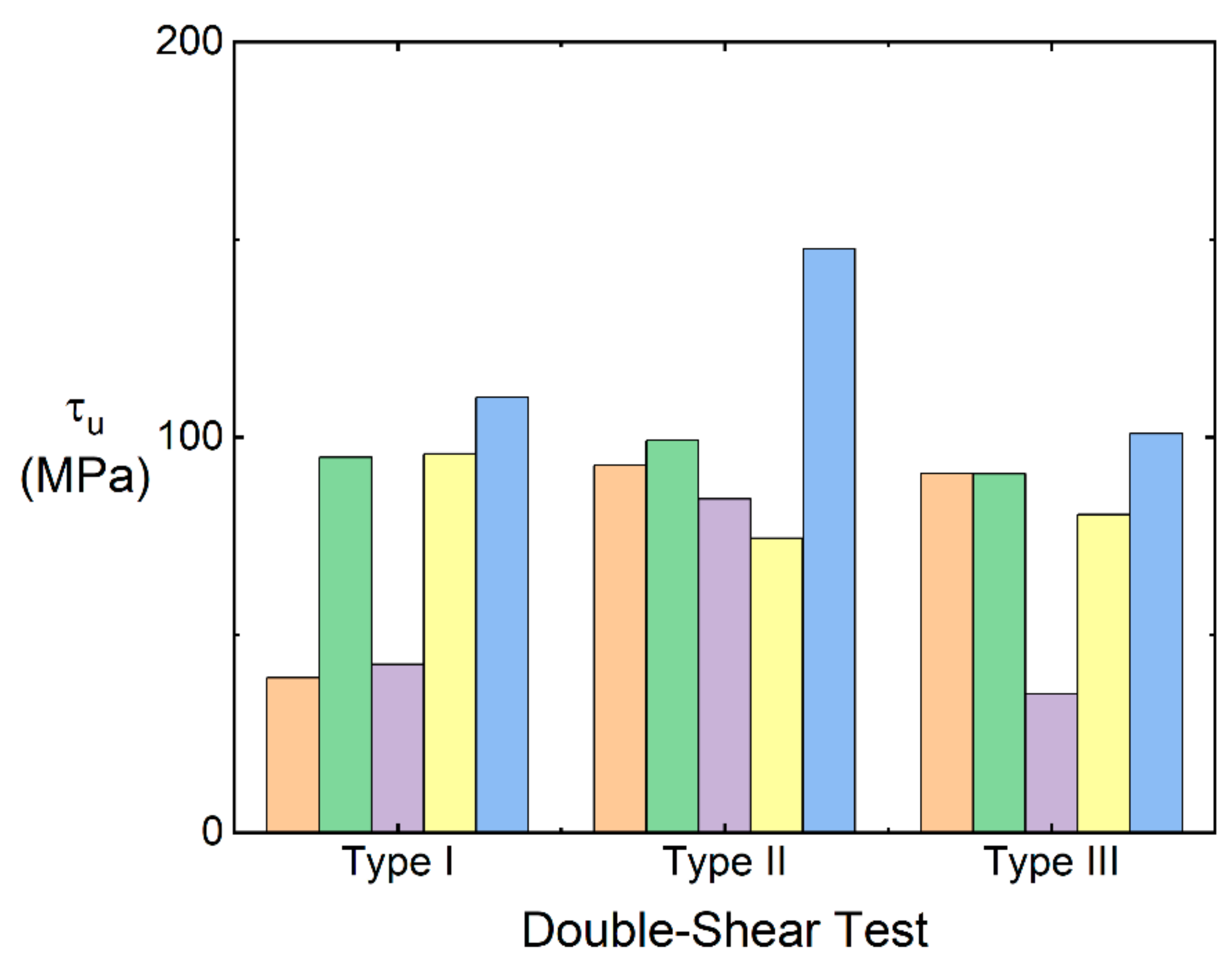

- For test type I, five samples (i.e., #1~#5) were conducted for the double-shear test. The average double-shear strength is τu = 76.5 MPa.

- For test type II, five samples (i.e., #6~#10) were conducted for the double-shear test. The average double-shear strength is τu = 99.7 MPa.

- For test type III, five samples (i.e., #11~#15) were conducted for the double-shear test. The average double-shear strength is τu = 79.6 MPa.

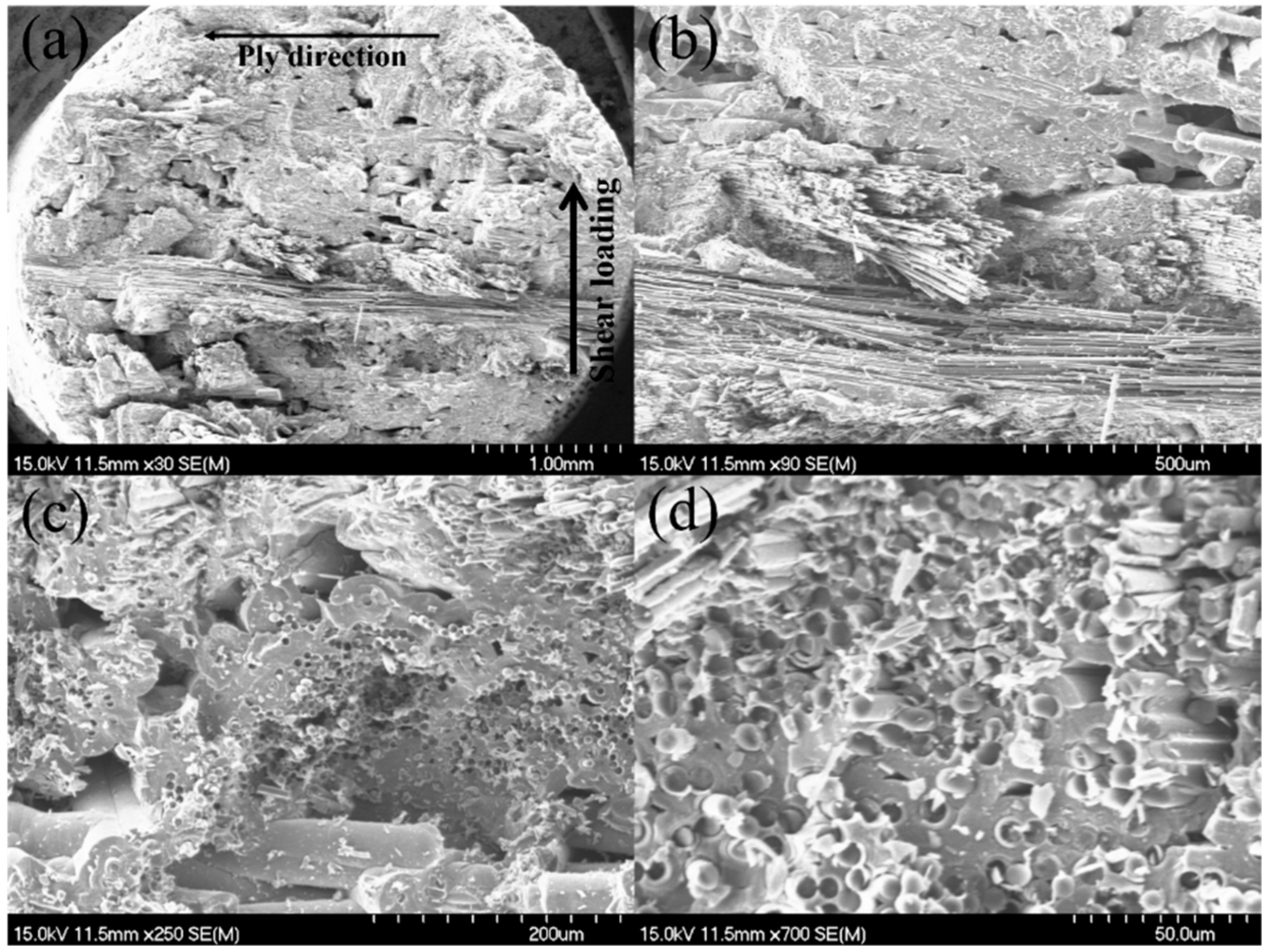

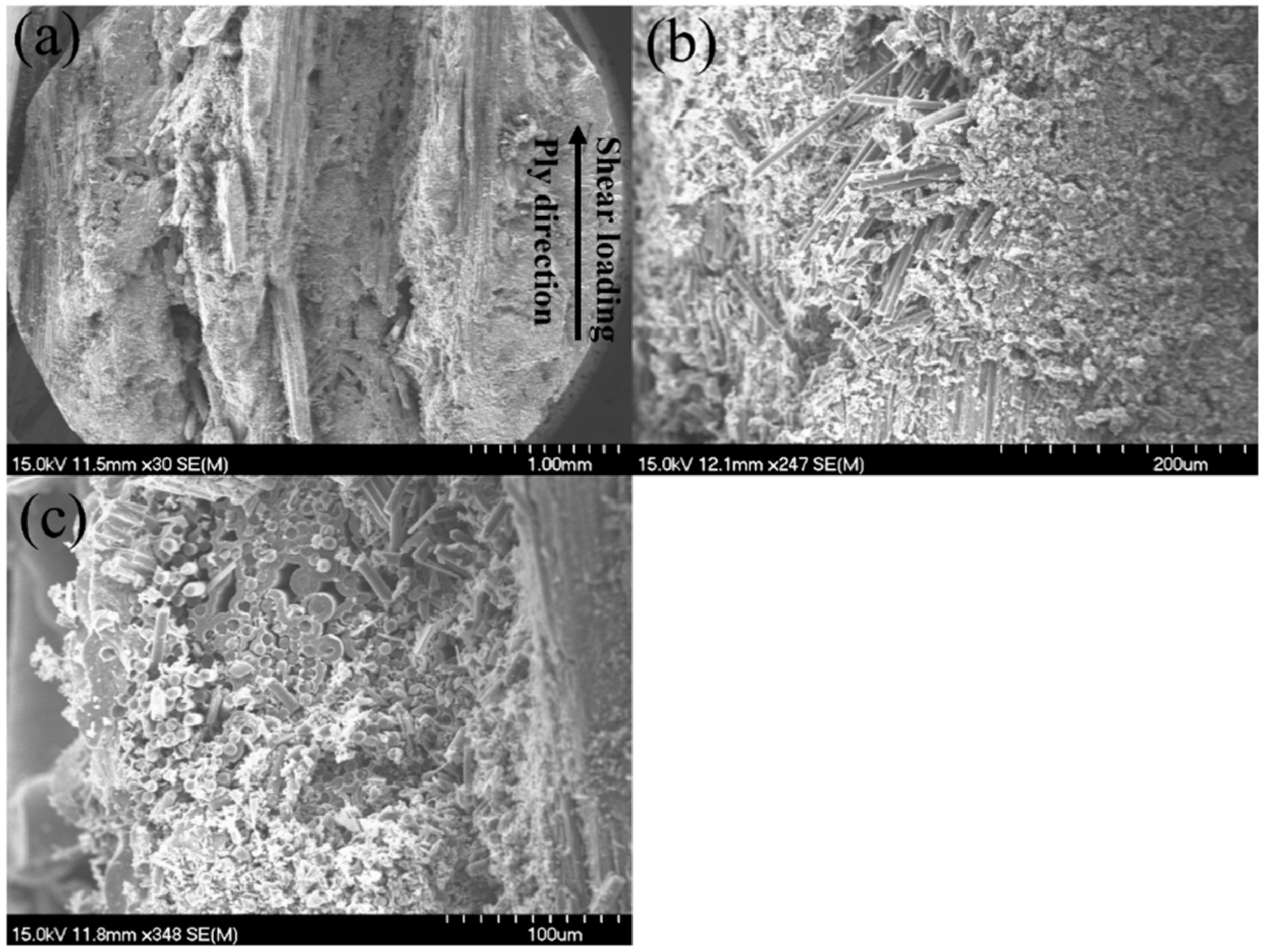

3.4. Discussion

4. Summary and Conclusions

- The average composite tensile strength was σuts = 68.3 MPa and the average composite tensile modulus was E = 195.3 GPa. At the fracture surface, long fiber pullout existed in the 0° and ±45° plies, and the needled fibers along the Z direction appeared in the pullout fibers in the 0° and ±45° fibers.

- The average interlaminar shear strength was τu = 38.7 MPa. Compared with the MWK–C/SiC composite, needled fiber fracture and pullout appeared in the Z direction.

- For the MWK–N–C/SiC pins, the double-shear strength was τu = 76.5 MPa, 99.7 MPa, and 79.6 MPa for test types I, II, and III, respectively. Compared with the MWK–C/SiC pins, the double-shear strength of the MWK–N–C/SiC pins all decreased, i.e., 26.7%, 50.8%, and 8% for test types I, II, and III, respectively.

- The tensile strength of the MWK–N–C/SiC composite possessed low tensile strength compared with those C/SiC composites with (0°/90°) plain-woven (PW) fiber preform, due to the low fiber volume content along the tensile loading direction. The Young’s modulus and interlaminar shear strength of the MWK–N–C/SiC composite were higher than those of the PW–C/SiC composite, due to the needled fiber in the thickness direction, low porosity (10–15%), and high composite density (2.0 g/cm3).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Naslain, R. Design, Preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: An overview. Compos. Sci. Technol. 2004, 64, 155–170. [Google Scholar] [CrossRef]

- Li, L.B. Modeling temperature-dependent vibration damping in C/SiC fiber-reinforced ceramic-matrix composites. Materials 2020, 13, 1633. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, L.B.; Reynaud, P.; Fantozzi, G. Mechanical hysteresis and damage evolution in C/SiC composites under fatigue loading at room and elevated temperatures. Int. J. Appl. Ceram. Technol. 2019, 16, 2214–2228. [Google Scholar] [CrossRef]

- Li, L.B. High Temperature Mechanical Behavior of Ceramic-Matrix Composites; Wiley-VCH: Weinheim, Germany, 2021. [Google Scholar]

- Yang, X.; Feng, C.; Wang, Y.; Li, G.; Cao, J. Study on mechanical behavior of CVD-SiC coated C/SiC composites under simulated space environments. Appl. Compos. Mater. 2018, 25, 1093–1101. [Google Scholar] [CrossRef]

- Li, L.B. Durability of Ceramic Matrix Composites; Elsevier: Oxford, UK, 2020. [Google Scholar]

- Li, L.B. Tension-tension fatigue beahvior of unidirectional C/SiC ceramic-matrix composite at room temperature and 800 °C in air atmosphere. Materials 2015, 8, 3316–3333. [Google Scholar] [CrossRef] [Green Version]

- Li, L.B. Fatigue hysteresis behavior of cross-ply C/SiC ceramic matrix composites at room and elevated temperatures. Mater. Sci. Eng. A 2013, 586, 160–170. [Google Scholar] [CrossRef]

- Liu, X.C.; Guo, X.J.; Xu, Y.L.; Li, L.B.; Zhu, W.; Zeng, Y.Q.; Li, J.; Luo, X.; Hu, X. Cyclic Thermal shock damage behavior in CVI SiC/SiC high-pressure turbine twin guide vanes. Materials 2021, 14, 6104. [Google Scholar] [CrossRef]

- Krenkel, W. Carbon fibre reinforced silicon carbide composites (C/SiC, C/C-SiC). In Handbook of Ceramic Composites; Bansal, N.P., Ed.; Springer: Boston, MA, USA, 2005. [Google Scholar]

- Sygulla, D.; Sabath, D.; Püttmann, N.; Schmid, V.; Caporicci, M.; Anderson, B. The US-European Cooperation in the X-38 and CRV Programs. In Proceedings of the IAF Abstracts, 34th COSPAR Scientific Assembly, the Second World Space Congress, Houston, TX, USA, 10–19 October 2002. [Google Scholar]

- Christin, F. Design, fabrication and application of thermostructural composites (TSC) like C/C, C/SiC and SiC/SiC composites. Adv. Eng. Mater. 2002, 4, 903–912. [Google Scholar] [CrossRef]

- Hald, H.; Weihs, H.; Benitsch, B.; Fischer, I.; Reimer, T.; Winkelmann, P.; Gülhan, A. Development of a Nose Cap System for X-38. In Proceedings of the International Symposium Atmospheric Reentry Vehicles and Systems, Arcachon, France, 18–21 October 1999. [Google Scholar]

- Nicholas, M.G.; Peteves, S.D. Reactive joining: Chemical effects on the formation and properties of brazed and diffusion bonded interfaces. Scr. Mater. 1994, 31, 1091–1096. [Google Scholar] [CrossRef]

- Loehman, R.E. Recent progress in ceramic joining. Key Eng. Mater. 1999, 161–163, 657–662. [Google Scholar] [CrossRef] [Green Version]

- Ferraris, M.; Casalegno, V. Integration and joining of ceramic matrix composites. In Ceramic Matrix Composites: Materials, Modeling and Technology; Bansal, N.P., Lamon, J., Eds.; Wiley: Weinheim, Germany, 2015. [Google Scholar]

- Kang, S.; Dunn, E.M. Issue in ceramic-to-metal joining: An investigation of brazing a silicon nitride-based ceramic to a low expansion superalloy. Am. Ceram. Soc. Bull. 1989, 68, 1608–1617. [Google Scholar]

- Asthana, R.; Singh, M. Joining of partially sintered alumina to alumina, titanium, hastealloy and C-SiC composite using Ag-Cu brazes. J. Eur. Ceram. Soc. 2008, 28, 617–631. [Google Scholar] [CrossRef]

- Dano, M.L.; Gendron, G.; Picard, A. Stress and failure analysis of mechanically fastened joints in composite laminates. Compos. Struct. 2000, 50, 287–296. [Google Scholar] [CrossRef]

- Li, G.; Zhang, Y.; Zhang, C.; Hu, H.; Chen, S.; Zhang, Z. Design, preparation and properties of online-joints of C/SiC-C/SiC with pins. Compos. Part B 2013, 48, 134–139. [Google Scholar] [CrossRef]

- Li, G.; Wu, X.; Zhang, C.; Hu, H.; Zhang, Y.; Zhang, Z. Theoretical simulation and experimental verification of C/SiC joints with pins and bolts. Mater. Des. 2014, 53, 1071–1076. [Google Scholar] [CrossRef]

- Li, G.; Zhang, C.; Hu, H.; Zhang, Y. Preparation and mechanical properties of C/SiC nuts and bolts. Mater. Sci. Eng. A 2012, 547, 1–5. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Zhang, J.; Yin, X.; Liu, C. Effects of z-pin’s porosity on shear properties of 2D C/SiC z-pinned joint. Compos. Struct. 2017, 173, 106–114. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.; Chen, J.; Jiang, W.; Zhang, Y.; Chen, C. Fabrication and tensile behavior of plain woven C/SiC z-pinned joint. J. Chin. Ceram. Soc. 2021, 49, 1206–1212. [Google Scholar]

- Liu, Y.; Hu, C.; Wang, Q.; Cheng, L.; Zhang, L. Numerical simulation and experimental validation of stress in C/SiC riveting joints under tensile load. Acta Mater. Compos. Sin. 2013, 30, 205–210. [Google Scholar]

- Chun, H.-J.; Kim, H.-W.; Byun, J.-H. Effects of through-the-thickness stitches on the elastic beahvior of multi-axial warp knit fabric composites. Compos. Struct. 2006, 74, 484–494. [Google Scholar] [CrossRef]

- Gao, X.P.; Li, D.X.; Wu, W.; Chen, S. Experimental investigation of the tensile and bending behavior of multi-axial warp knitted fabric composites. Text. Res. J. 2018, 88, 333–344. [Google Scholar] [CrossRef]

- Li, D.-S.; Yang, Y.; Wang, Z.; Jiang, L. Experimental investigation on mechanical response and failure analysis of 3D multi-axial warp knitted hybrid composites. Compos. Struct. 2020, 246, 112340. [Google Scholar] [CrossRef]

- Kamiya, R.; Cheeseman, B.A.; Popper, P.; Chou, T.-W. Some recent advances in the fabrication and design of three-dimensional textile preforms: A review. Compos. Sci. Technol. 2000, 60, 33–47. [Google Scholar] [CrossRef]

- ASTM-C1275; Standard Test Method for Monotonic Tensile Behavior of Continuous Fiber-Reinforced Advanced Ceramics with Solid Rectangular Cross-Section Test Specimens at Ambient Temperature. ASTM: West Conshohocken, PA, USA, 2018.

- ASTM-C1292; Standard Test Method for Shear Strength of Continuous Fiber-Reinforced Advanced Ceramics at Ambient Temperatures. ASTM: West Conshohocken, PA, USA, 2022.

- Li, L.B. A time-dependent tensile constitutive model for long-fiber-reinforced unidirectional ceramic-matrix minicomposites considering interface and fiber oxidation. Int. J. Damage Mech. 2020, 29, 1138–1166. [Google Scholar]

- Li, L.B. Effect of stochastic loading on tensile damage and fracture of fiber-reinforced ceramic-matrix composites. Materials 2020, 13, 2469. [Google Scholar] [CrossRef]

- Galizia, P.; Sciti, D.; Jain, N. Insight into microstructure and flexural strength of ultra-high temperature ceramics enriched SICARBONTM composite. Mater. Des. 2021, 208, 109888. [Google Scholar] [CrossRef]

- Chao, W.; Xiangxin, X.; Xiaozhou, C.; He, Y.; Gongjin, C. The effect of Ti addition on the microstructure and fracture toughness of Bn-Al composite materials synthesized by vacuum infiltration. Arch. Metall. Mater. 2013, 58, 509–512. [Google Scholar] [CrossRef] [Green Version]

- Du, Q.; Gao, Y.; Ren, Z.H.; Cao, X.M.; Wang, C.; Zhang, J.S. Preparation and erosion performance for co-continuous phase composites of Si3N4/1Cr18Ni9Ti. Chin. J. Mater. Res. 2019, 33, 34–42. [Google Scholar]

| No. | Length/(mm) | Width/(mm) | Thickness/(mm) | σuts/(MPa) | E/(GPa) |

|---|---|---|---|---|---|

| #1 | 130.2 | 11.6 | 3.2 | 82.8 | 161.9 |

| #2 | 130.4 | 11.7 | 3.1 | 52.7 | 200.7 |

| #3 | 130.2 | 11.6 | 3.1 | 57.5 | 154.2 |

| #4 | 130.1 | 11.6 | 3.3 | 84.3 | 253.1 |

| #5 | 130.2 | 11.6 | 3.2 | 54.1 | 277.4 |

| #6 | 130.2 | 11.6 | 3.2 | 78.7 | 124.6 |

| No. | Width/(mm) | Notch Space/(mm) | Area/(mm2) | Fmax/(N) | τu/(MPa) |

|---|---|---|---|---|---|

| #1 | 10.07 | 6.75 | 67.97 | 2522 | 37.1 |

| #2 | 10.15 | 6.84 | 69.42 | 3254 | 46.8 |

| #3 | 10.12 | 6.12 | 61.93 | 1616 | 26.1 |

| #4 | 10.15 | 6.51 | 66.07 | 2773 | 41.9 |

| #5 | 10.06 | 6.84 | 68.81 | 2882 | 41.8 |

| No. | Diameter/(mm) | Density/(cm3) | Test Type | Ultimate Load/(N) | τu/(MPa) |

|---|---|---|---|---|---|

| #1 | 4.24 | 2.44 | I | 1107 | 39.2 |

| #2 | 4.21 | 2.42 | I | 2639 | 94.9 |

| #3 | 4.15 | 2.47 | I | 1153 | 42.6 |

| #4 | 4.17 | 2.47 | I | 2612 | 95.8 |

| #5 | 4.04 | 2.47 | I | 2824 | 110.1 |

| #6 | 4.17 | 2.48 | II | 2542 | 92.9 |

| #7 | 3.73 | 2.51 | II | 2168 | 99.2 |

| #8 | 3.73 | 2.51 | II | 1845 | 84.4 |

| #9 | 4.16 | 2.56 | II | 2023 | 74.5 |

| #10 | 4.11 | 2.49 | II | 3924 | 147.6 |

| #11 | 4.21 | 2.52 | III | 2531 | 90.9 |

| #12 | 4.17 | 2.49 | III | 2480 | 90.8 |

| #13 | 4.17 | 2.53 | III | 958 | 35.1 |

| #14 | 4.17 | 2.49 | III | 2199 | 80.5 |

| #15 | 4.10 | 2.45 | III | 2668 | 100.9 |

| Property | Unit | Gasphase Infiltration (CVI) Process | Liquid Infiltration Process | ||||

|---|---|---|---|---|---|---|---|

| CVI (Isothermal) | CVI (p, T-Gradient) | Liquid Polymer Infiltration (LPI) | Liquid Silicon Infiltration (LSI) | ||||

| C/SiC | C/SiC | C/SiC | C/SiC | C/SiC | C/C–SiC | ||

| Tensile strength | MPa | 52.7–84.3 | 350 | 300–320 | 250 | 240–270 | 80–190 |

| Young’s modulus | GPa | 124.6–253.1 | 90–100 | 90–100 | 65 | 60–80 | 50–70 |

| Interlaminar shear strength | MPa | 26.1–46.8 | 35 | 45–48 | 10 | 35 | 28–33 |

| Porosity | % | 10–15 | 10 | 10-15 | 10 | 15–20 | 2–5 |

| Fiber content | Vol.% | 30–45 | 45 | 42–47 | 46 | 42–47 | 55–65 |

| Density | g/cm3 | 2.0 | 2.1 | 2.1–2.2 | 1.8 | 1.7–1.8 | 1.9–2.0 |

| Fiber preform | MWK–N | (0°/90°) PW | (0°/90°) PW | (0°/90°) PW | (0°/90°) PW | (0°/90°) PW | |

| Manufacturer | NWPU | SNECMA [10] | MAN [10] | Dornier [10] | MAN [10] | DLR [10] | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, X.; He, J.; Liu, X.; Xu, Y.; Li, J.; Guo, X.; Wang, Q.; Li, L. Design, Fabrication, and Mechanical Properties of T-700TM Multiaxial-Warp-Knitting–Needled–C/SiC Composite and Pin. Materials 2022, 15, 2338. https://doi.org/10.3390/ma15062338

Luo X, He J, Liu X, Xu Y, Li J, Guo X, Wang Q, Li L. Design, Fabrication, and Mechanical Properties of T-700TM Multiaxial-Warp-Knitting–Needled–C/SiC Composite and Pin. Materials. 2022; 15(6):2338. https://doi.org/10.3390/ma15062338

Chicago/Turabian StyleLuo, Xiao, Jiangyi He, Xiaochong Liu, Youliang Xu, Jian Li, Xiaojun Guo, Qianru Wang, and Longbiao Li. 2022. "Design, Fabrication, and Mechanical Properties of T-700TM Multiaxial-Warp-Knitting–Needled–C/SiC Composite and Pin" Materials 15, no. 6: 2338. https://doi.org/10.3390/ma15062338

APA StyleLuo, X., He, J., Liu, X., Xu, Y., Li, J., Guo, X., Wang, Q., & Li, L. (2022). Design, Fabrication, and Mechanical Properties of T-700TM Multiaxial-Warp-Knitting–Needled–C/SiC Composite and Pin. Materials, 15(6), 2338. https://doi.org/10.3390/ma15062338