Microstructural Parameters for Modelling of Superconducting Foams

Abstract

1. Introduction

2. Experimental Procedures

2.1. Sample Preparation

- (i)

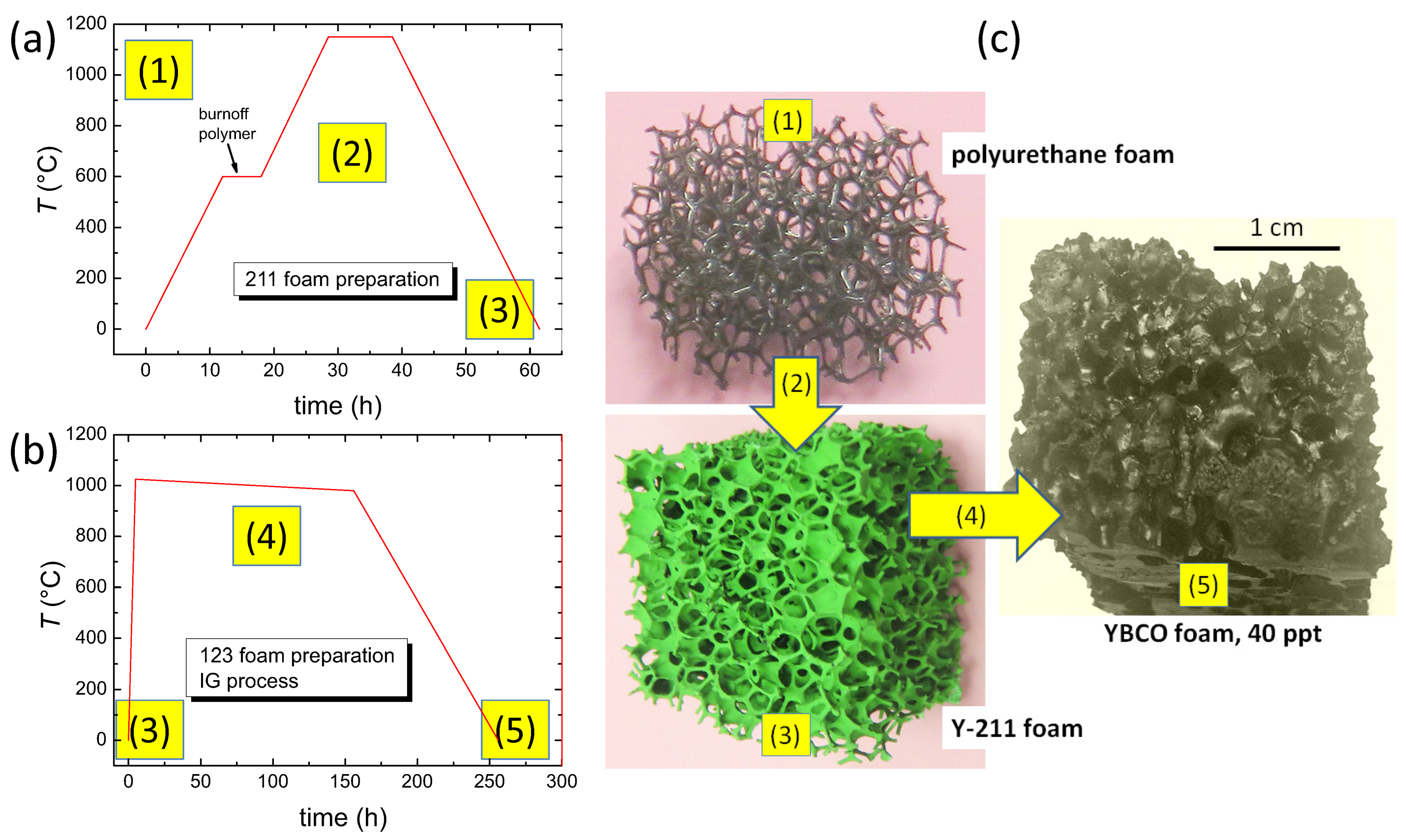

- Starting from commercially available polyurethane foams (1) [35], which define the porosity and other structural parameters of the final product, the sample is covered with a slurry of Y-211 powder dissolved in polyvinyalcohol (PVA) and water. To form ceramic Y-211 foams, a heat treatment is required to burn off the polyurethane and to compact the Y-211 ceramic (2). This is illustrated in the temperature program shown in Figure 1a.

- (ii)

- The green Y-211 foam (3) is then converted into the YBCO superconductor using the IG process [32,33] using a Nd-123 seed crystal on top and a liquid source consisting of a 1:1 mixture of Ba and Cu oxides with an overall stoichiometry of BaCuO and additional 123 powder placed beneath the Y-211 foam. When being heated above the eutectic temperature (1010 C, (4)), the liquid phase infiltrates the Y-211 foam by capillary action [36]. The seed crystal ensures an overall texture of the superconducting foam sample like in the case of bulk superconductors. Finally, the Y-211 foam is fully converted to the 123-phase (5) in a slow-cooling process.

2.2. Microscopy Investigations

3. Results and Discussion

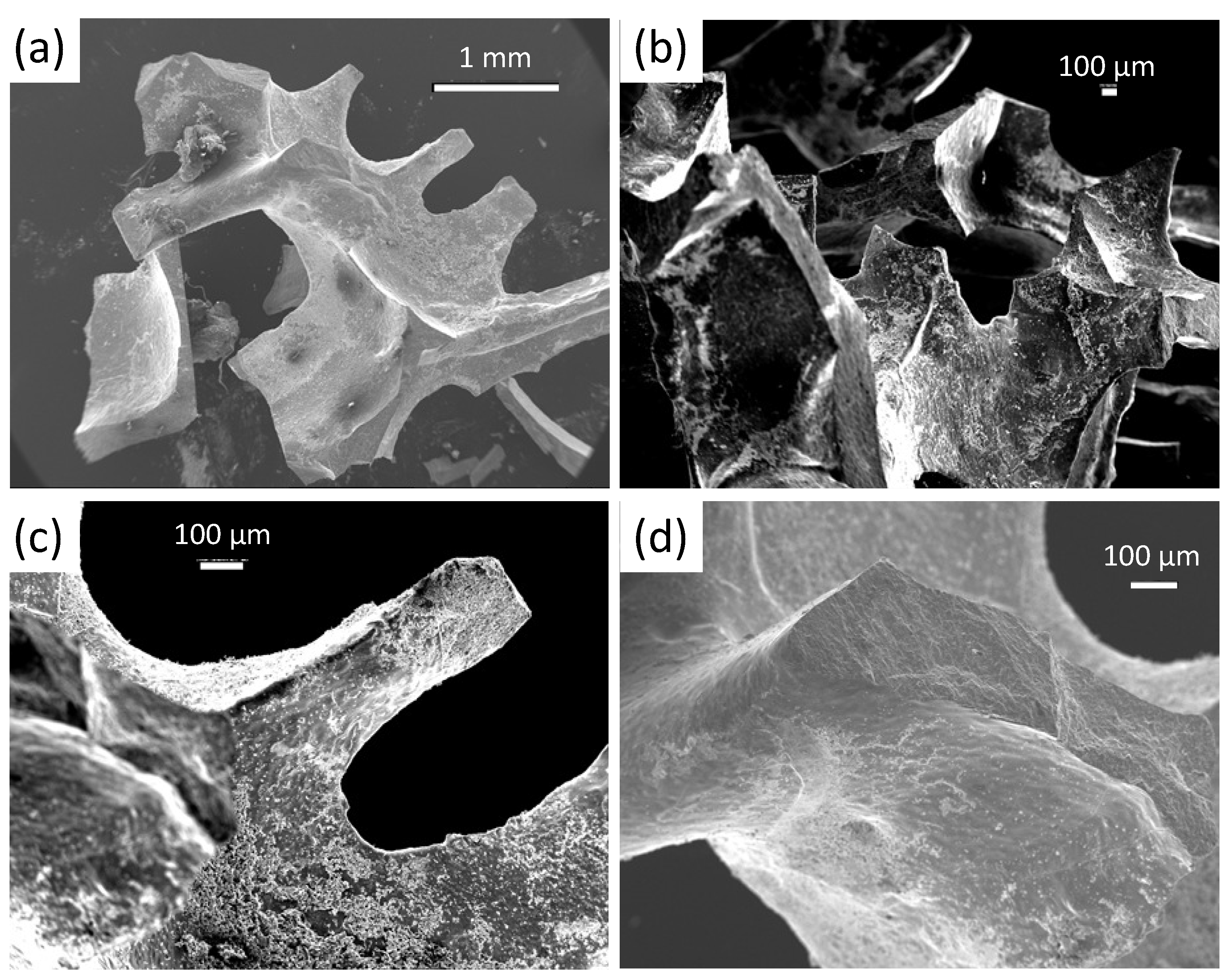

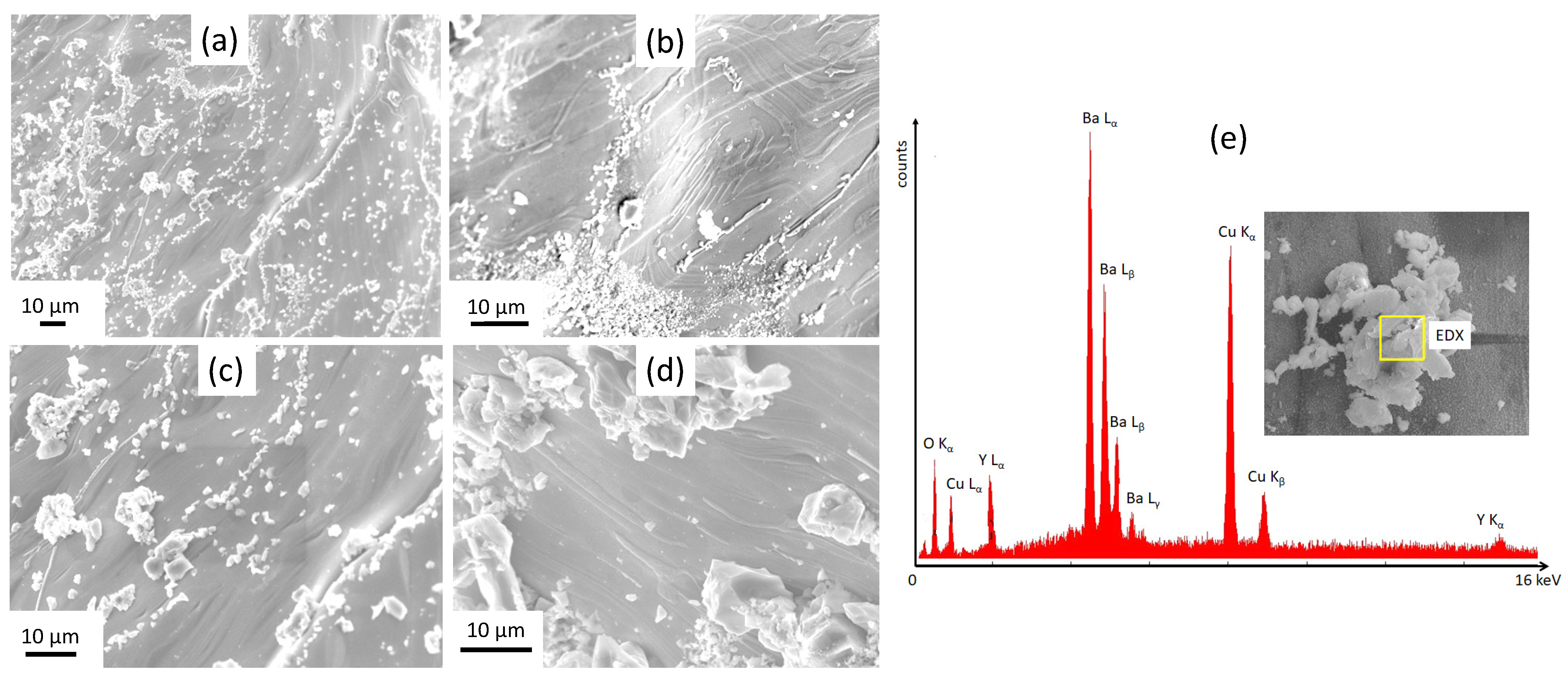

3.1. Scanning Electron Microscopy

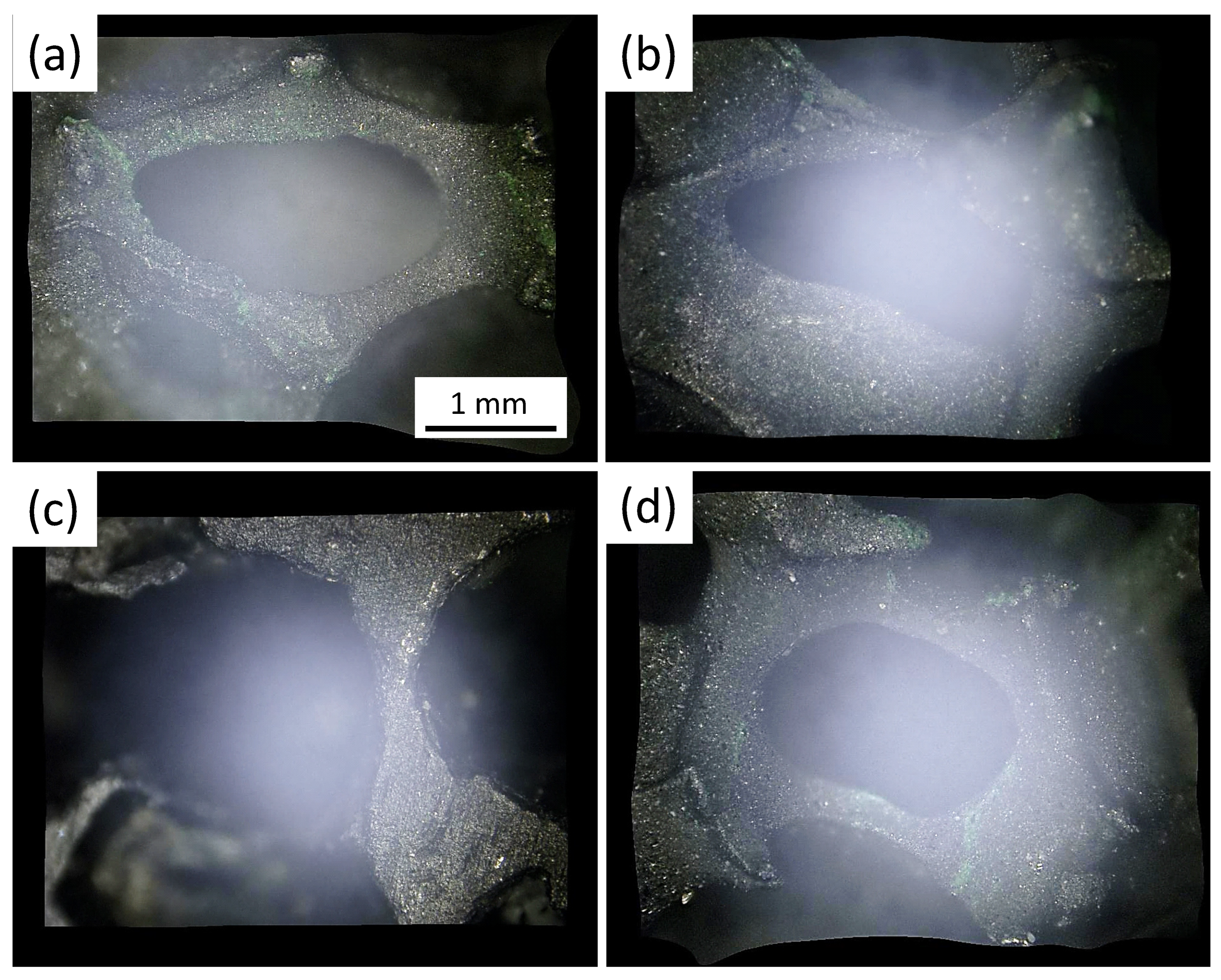

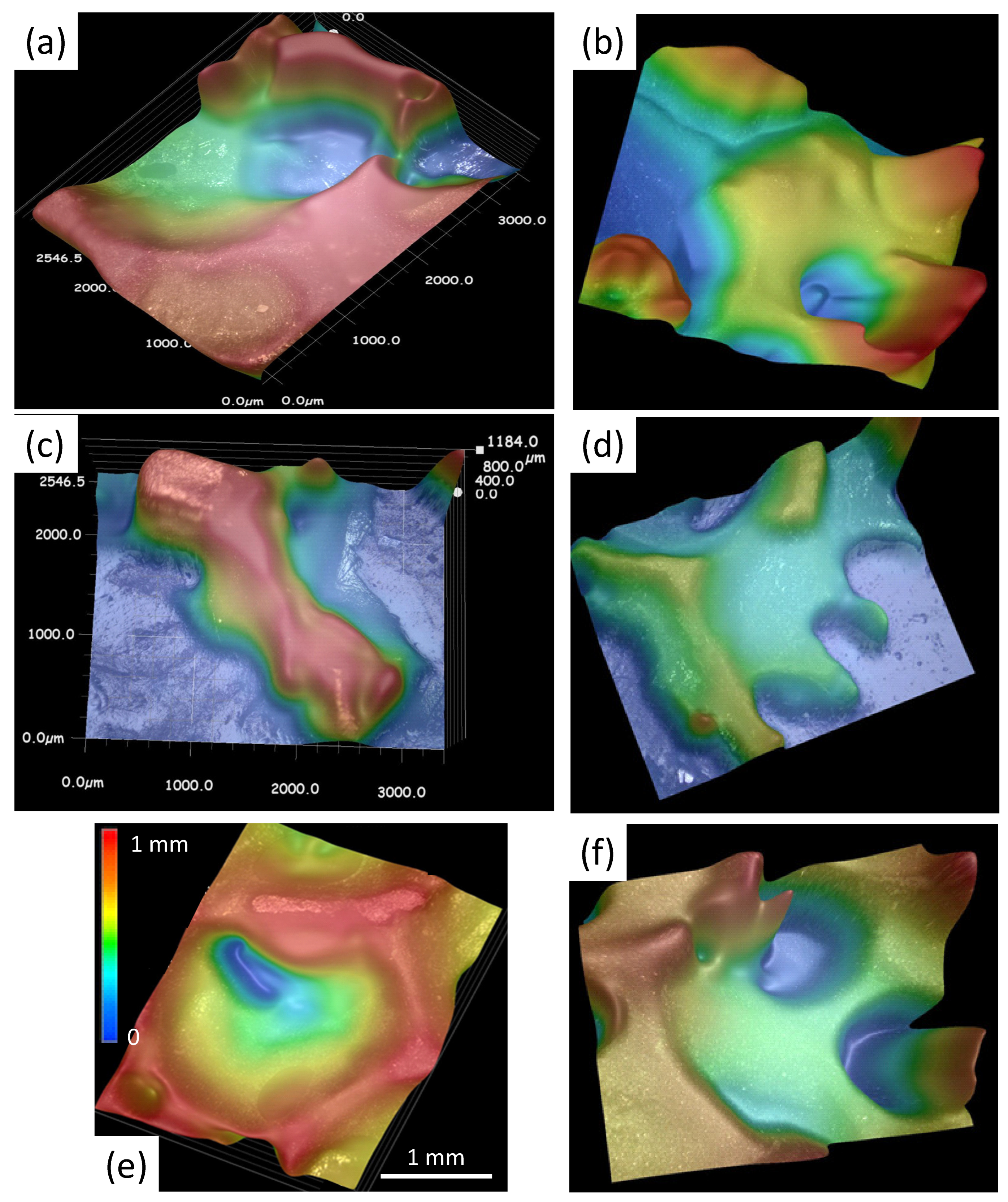

3.2. Digital Optical Microscopy

3.3. Discussion of Modelling Approaches and Parameters

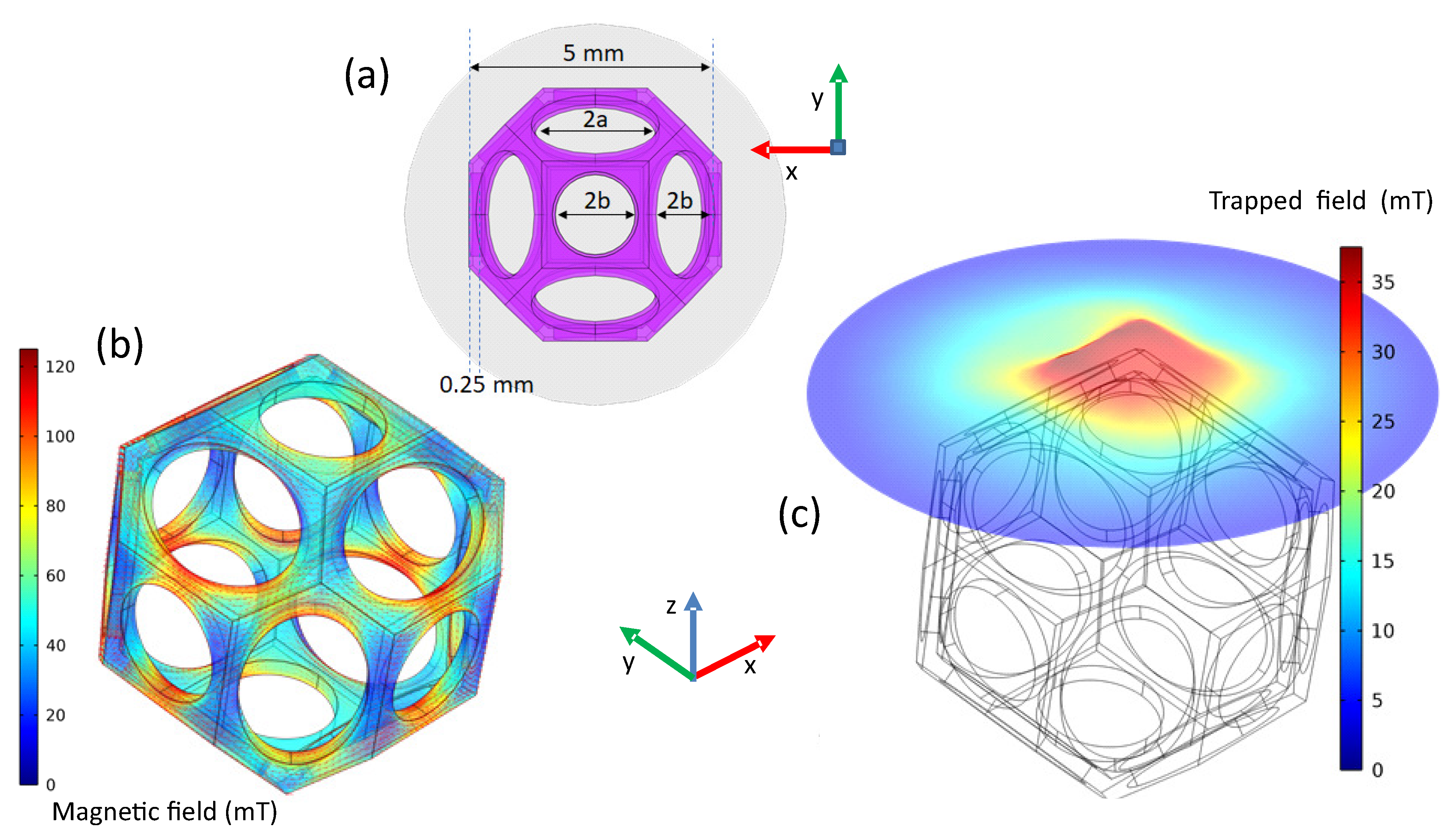

3.4. First Modelling of Field Cooling and Trapping

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reddy, E.S.; Schmitz, G.J. Superconducting foams. Supercond. Sci. Technol. 2002, 15, L21–L24. [Google Scholar] [CrossRef]

- Reddy, E.S.; Schmitz, G.J. Ceramic foams. Am. Ceram. Soc. Bull. 2002, 81, 35–37. [Google Scholar]

- Reddy, E.S.; Herweg, M.; Schmitz, G.J. Processing of Y2BaCuO5 foams. Supercond. Sci. Technol. 2003, 16, 608–612. [Google Scholar] [CrossRef]

- Patel, A.; Giunchi, G.; Figini Albisetti, A.; Shi, Y.; Hopkins, S.C.; Palka, R.; Cardwell, D.A.; Glowacki, B.A. High Force Magnetic Levitation Using Magnetized Superconducting Bulks as a Field Source for Bearing Applications. Phys. Proc. 2012, 36, 937–942. [Google Scholar] [CrossRef]

- Werfel, F.N.; Floegel-Delor, U.; Riedel, T.; Goebel, B.; Rothfeld, R.; Schirrmeister, P.; Wippich, D. Large-scale HTS bulks for magnetic application. Phys. C Supercond. 2013, 484, 6–11. [Google Scholar] [CrossRef]

- Ogata, M.; Matsue, H.; Yamashita, T.; Hasegawa, H.; Nagashima, K.; Maeda, T.; Matsuoka, T.; Mukoyama, S.; Shimizu, H.; Horiuchi, S. Test equipment for a flywheel energy storage system using a magnetic bearing composed of superconducting coils and superconducting bulks. Supercond. Sci. Technol. 2016, 29, 054002. [Google Scholar] [CrossRef]

- Durrell, J.H.; Ainslie, M.D.; Zhou, D.; Vanderbemden, P.; Bradshaw, T.; Speller, S.; Filipenko, M.; Cardwell, D.A. Bulk superconductors: A roadmap to applications. Supercond. Sci. Technol. 2018, 31, 103501. [Google Scholar] [CrossRef]

- Yang, W.; Liao, D.; Yao, L. Effects of magnetization conditions on dynamic characteristics of spacecrafts with superconducting flux pinning docking interfaces. J. Appl. Phys. 2018, 124, 213901. [Google Scholar] [CrossRef]

- Dorget, R.; Nouailhetas, Q.; Colle, A.; Berger, K.; Sudo, K.; Ayat, S.; Lévêque, J.; Koblischka, M.R.; Sakai, N.; Oka, T.; et al. Review on the Use of Superconducting Bulks for Magnetic Screening in Electrical Machines for Aircraft Applications. Materials 2021, 14, 2847. [Google Scholar] [CrossRef]

- Tang, R.; Song, Y.; He, J.; Liu, X.; Ren, Y.; Zhou, D.; Li, J.; Den, Z. Correlation Between Density and Levitation Performance of YBCO Bulk Superconductor Over Halbach NdFeB Guideway. IEEE Trans. Appl. Supercond. 2022, 32, 3600504. [Google Scholar] [CrossRef]

- Koblischka, M.R.; Koblischka-Veneva, A.; Gohkfeld, D.; Pavan Kumar Naik, S.; Nouailhetas, Q.; Berger, K.; Douine, B. Flux Pinning Docking Interfaces in Satellites Using Superconducting Foams as Trapped Field Magnets. IEEE Trans. Appl. Supercond. 2022, 32, 4900105. [Google Scholar] [CrossRef]

- Noudem, J.G. Developing of shaping textured superconductors. J. Supercond. 2011, 24, 105–110. [Google Scholar] [CrossRef]

- Koblischka, M.R.; Pavan Kumar Naik, S.; Koblischka-Veneva, A.; Murakami, M.; Gohkfeld, D.; Reddy, E.S.; Schmitz, G.J. Superconducting YBCO foams as trapped field magnets. Materials 2019, 12, 853. [Google Scholar] [CrossRef] [PubMed]

- Bartolomé, E.; Granados, X.; Puig, T.; Obradors, X.; Reddy, E.S.; Schmitz, G.J. Critical state in superconducting single-crystalline YBa2Cu3O7 foams: Local versus long-range currents. Phys. Rev. B 2004, 70, 144514. [Google Scholar] [CrossRef]

- Carrera, M.; Amoros, J.; Carrillo, A.E.; Obradors, X.; Fontcuberta, J. Current distribution maps in large YBCO melt-textured blocks. Phys. C 2003, 385, 539–543. [Google Scholar] [CrossRef]

- Johansen, T.H. Flux-pinning-induced stress and magnetostriction in bulk superconductors. Supercond. Sci. Technol. 2000, 13, R121–R137. [Google Scholar] [CrossRef]

- Yong, H.-D.; Zhou, Y.-E. Effect of nonsuperconducting particles on the effective magnetostriction of bulk superconductors. J. Appl. Phys. 2008, 104, 043907. [Google Scholar] [CrossRef]

- Diko, P. Cracking in melt-grown RE-Ba-Cu-O single-grain bulk superconductors. Supercond. Sci. Technol. 2004, 17, R45–R58. [Google Scholar] [CrossRef]

- Diko, P.; Chaud, X.; Antal, V.; Kaňuchová, M.; Šefčíková, M.; Šuster, D.; Kováč, J. Elimination of Oxygenation Cracking in YBCO Bulk Superconductors. In Key Engineering Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2009; Volume 409, pp. 216–222. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Montminy, M.D.; Tannenbaum, A.R.; Macosko, C.W. The 3D structure of real polymer foams. J. Colloid Interface Sci. 2004, 280, 202–211. [Google Scholar] [CrossRef]

- Jang, W.-Y.; Kraynik, A.M.; Kyriakides, S. On the microstructure of open-cell foams and its effect on elastic properties. Int. J. Solids Struct. 2008, 45, 1845–1875. [Google Scholar] [CrossRef]

- Buffel, B.; Desplentere, F.; Bracke, K.; Verpoest, I. Modelling open cell-foams based on the Weaire–Phelan unit cell with a minimal surface energy approach. Int. J. Solids Struct. 2014, 51, 3461–3470. [Google Scholar] [CrossRef]

- Nie, Z.; Lin, Y.; Tong, Q. Modeling structures of open cell foams. Comput. Mater. Sci. 2017, 131, 160–169. [Google Scholar] [CrossRef]

- Fanelli, P.; Evangelisti, A.; Salvini, P.; Vivio, F. Modelling and characterization of structural behaviour of Al open-cell foams. Mater. Des. 2017, 114, 167–175. [Google Scholar] [CrossRef]

- Banhart, J. Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Onck, P.R.; van Merkerk, R.; Raaijmakers, A.; de Hoss, R.T.M. Fracture of open- and closed-cell metal foams. J. Mater. Sci. 2005, 40, 5821–5828. [Google Scholar] [CrossRef]

- Lefebvre, L.-P.; Banhart, J.; Dunand, D.C. Porous Metals and Metallic Foams: Current Status and Recent Developments. Adv. Eng. Mater. 2008, 10, 775–787. [Google Scholar] [CrossRef]

- Kaya, A.C.; Fleck, C. Deformation behavior of open-cell stainless steel foams. Mater. Sci. Eng. A 2014, 615, 447–456. [Google Scholar] [CrossRef]

- Jung, A.; Wocker, M.; Chen, Z.; Seibert, H. Microtensile testing of open-cell metal foams—Experimental setup, micromechanical properties. Mater. Des. 2015, 88, 1021–1030. [Google Scholar] [CrossRef]

- Jung, A.; Diebels, S. Modelling of metal foams by a modified elastic law. Mech. Mater. 2016, 101, 61–70. [Google Scholar] [CrossRef]

- Devendra Kumar, N.; Shi, Y.-H.; Cardwell, D.A. Fabrication of bulk (RE)BCO superconductors by the infiltration and growth process: Past, present and future. In Superconductivity Applications Today and Tomorrow; Muralidhar, M., Ed.; Nova Science Publishers: Commack, NY, USA, 2017; pp. 1–35. [Google Scholar]

- Namburi, D.K.; Shi, Y.-H.; Cardwell, D.A. The processing and properties of bulk (RE)BCO high temperature superconductors: Current status and future perspectives. Supercond. Sci. Technol. 2021, 34, 053002. [Google Scholar] [CrossRef]

- Koblischka, M.R.; Koblischka-Veneva, A.; Reddy, E.S.; Schmitz, G.J. Analysis of the microstructure of superconducting YBCO foams by means of AFM and EBSD. J. Adv. Ceram. 2014, 3, 317–325. [Google Scholar] [CrossRef]

- Filteron AG, Solingen, Germany. Available online: https://filteron.de/produkte/filterschaum_ppi (accessed on 31 January 2022).

- Reddy, E.S.; Rajasekharan, T. Fabrication of textured REBa2Cu3O7/RE2BaCuO5 (RE = Y, Gd) composites by infiltration and growth of RE2BaCuO5 preforms by liquid phases. Supercond. Sci. Technol. 1998, 11, 523–534. [Google Scholar] [CrossRef]

- Keyence Corp. Optical Microscopes. Available online: https://www.keyence.com/products/microscope/digital-microscope/vhx-7000/ (accessed on 31 January 2022).

- ImageJ. Image Processing and Analysis in Java. Available online: https://imagej.nih.gov/ij/index.html (accessed on 31 January 2022).

- Horcas, I.; Fernández, R.; Gómez-Rodríguez, J.M.; Colchero, J.; Gómez-Herrero, J.; Baro, A.M. WSXM: A software for scanning probe microscopy and a tool for nanotechnology. Rev. Sci. Instrum. 2007, 78, 013705. [Google Scholar] [CrossRef]

- TexSEM Laboratories (TSL). Orientation Imaging Microscopy Software V7.2, User Manual; TexSEM Laboratories (TSL): Draper, UT, USA, 2015. [Google Scholar]

- Reimer, L. Scanning Electron Microscopy: Physics of Image Formation and Microanalysis; Springer Science: Berlin/Heidelberg, Germany, 1985. [Google Scholar]

- Koblischka, M.R.; Koblischka-Veneva, A. Applications of the electron backscatter diffraction technique to ceramic materials. Phase Trans. 2013, 86, 651–660. [Google Scholar] [CrossRef]

- Koblischka-Veneva, A.; Koblischka, M.R.; Schmauch, J. The surface structure of YBCO foam struts and the effect on flux pinning. Unpublished work.

- Guilmeau, E.; Lambert, S.; Chateigner, D.; Ouladdiaf, B.; Noudem, J.G. Quantitative texture analysis of polyphased oxides by diffraction: Example of Bi2223 sinter-forged ceramic and Y123 foam superconductors. Mater. Sci. Eng. B 2003, 104, 107–112. [Google Scholar] [CrossRef][Green Version]

- Noudem, J.G.; Guilmeau, E.; Chateigner, D.; Lambert, S.; Reddy, E.S.; Ouladdiaf, B.; Schmitz, G.J. Properties of YBa2Cu3Oy-textured superconductor foams. Physica C 2004, 408–410, 655–656. [Google Scholar] [CrossRef]

- Koblischka-Veneva, A.; Koblischka, M.R.; Schmauch, J.; Murakami, M. Secondary phase particles in bulk, infiltration-growth processed YBCO investigated by transmission Kikuchi diffraction and TEM. Supercond. Sci. Technol. 2020, 33, 034010. [Google Scholar] [CrossRef]

- Koblischka-Veneva, A.; Koblischka, M.R.; Ide, N.; Inoue, K.; Muralidhar, M.; Hauet, T.; Murakami, M. Microstructural and magnetic analysis of a superconducting foam and comparison with IG-processed bulk samples. J. Phys. Conf. Ser. 2016, 695, 012002. [Google Scholar] [CrossRef]

- Koblischka, M.R.; Pavan Kumar Naik, S.; Koblischka-Veneva, A.; Gokhfeld, D.; Murakami, M. Flux creep after field trapping in YBa2Cu3Oy foams. Supercond. Sci. Technol. 2020, 33, 044008. [Google Scholar] [CrossRef]

- Almonti, D.; Baiocco, G.; Tagliaferri, V.; Ucciardello, N. Design and mechanical characterization of Voronoi structures manufactured by indirect additive manufacturing. Materials 2020, 13, 1085. [Google Scholar] [CrossRef]

- Almonti, D.; Ucciardello, N. Design and thermal comparison of random structures realized by indirect additive manufacturing. Materials 2019, 12, 2261. [Google Scholar] [CrossRef] [PubMed]

- Al-Ethari, H.; Haleem, A.H.; Ali, O.I. Optimization of Manufacturing Parameters Affecting on Characterization of Porous Sintered Tin-Bronze Alloy. Int. J. Eng. Technol. 2019, 8, 299–307. [Google Scholar] [CrossRef]

- Koblischka, M.R.; Koblischka-Veneva, A.; Berger, K.; Nouailhetas, Q.; Douine, B.; Reddy, E.S.; Schmitz, G.J. Current flow and flux pinning properties of YBCO foam struts. IEEE Trans. Appl. Supercond. 2019, 29, 8001405. [Google Scholar] [CrossRef]

- Koblischka, M.R.; Koblischka-Veneva, A.; Chang, C.; Hauet, T.; Reddy, E.S.; Schmitz, G.J. Flux pinning analysis of superconducting YBCO foam struts. IEEE Trans. Appl. Supercond. 2019, 29, 8001905. [Google Scholar] [CrossRef]

- Kapek, J.; Berger, K.; Koblischka, M.R.; Trillaud, F.; Lévêque, J. 2-D Numerical Modeling of a Bulk HTS Magnetization Based on H Formulation Coupled With Electrical Circuit. IEEE Trans. Appl. Supercond. 2019, 29, 6801405. [Google Scholar] [CrossRef]

- Kapek, J.; Berger, K.; Lévêque, J. 2D and 3D validation of a hybrid method based on A and H formulations for Pulsed Field Magnetization. In Proceedings of the 7th International Workshop on Numerical Modelling of High Temperature Superconductors (HTS 2020), Online. 22–23 June 2021; Available online: https://hal.univ-lorraine.fr/HTS2020/hal-03273940v1 (accessed on 31 January 2022).

- Wei, X.; Nagarajan, R.S.; Peng, E.; Xue, J.; Wang, J.; Ding, J. Fabrication of YBa2Cu3O7−x (YBCO) superconductor bulk structures by extrusion freeforming. Ceram. Int. 2016, 42, 15836–15842. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, Q.; He, P.; Ma, Y.; Shen, L.; Zhang, X.; Zhou, Y. Efficient Fabrication of Ultralight YBa2Cu3O7−x Superconductors with Programmable Shape and Structure. Adv. Funct. Mater. 2021, 31, 2100680. [Google Scholar] [CrossRef]

- Mendes, D.; Sousa, D.; Cerdeira, A.C.; Pereira, L.C.J.; Marques, A.; Murta-Pina, J.; Pronto, A.; Ferreira, I. Low-cost and high-performance 3D printed YBCO superconductors. Ceram. Int. 2021, 47, 381–387. [Google Scholar] [CrossRef]

- Koblischka, M.R.; Koblischka-Veneva, A. Porous high-Tc superconductors and their applications. AIMS Mater. Sci. 2018, 5, 1199–1213. [Google Scholar] [CrossRef]

- Gokhfeld, D.; Koblischka, M.R.; Koblischka-Veneva, A. ВЫСОКОПОРИСТЫЕ СВЕРХПРОВОДНИКИ: СИНТЕЗ, ИССЛЕДОВАНИЯ И ПЕРСПЕКТИВЫ. Fiz. Met. I Met. 2020, 121, 1026–1038. (In Russian) [Google Scholar]

- Gokhfeld, D.; Koblischka, M.R.; Koblischka-Veneva, A. Highly Porous Superconductors: Synthesis, Research, and Prospects. Phys. Met. Metallogr. 2020, 121, 936–948. [Google Scholar] [CrossRef]

- Lozanovski, B.; Leary, M.; Tran, P.; Shidid, D.; Qian, M.; Choong, P.; Brandt, M. Computational modelling of strut defects in SLM manufactured lattice structures. Mater. Des. 2019, 171, 107671. [Google Scholar] [CrossRef]

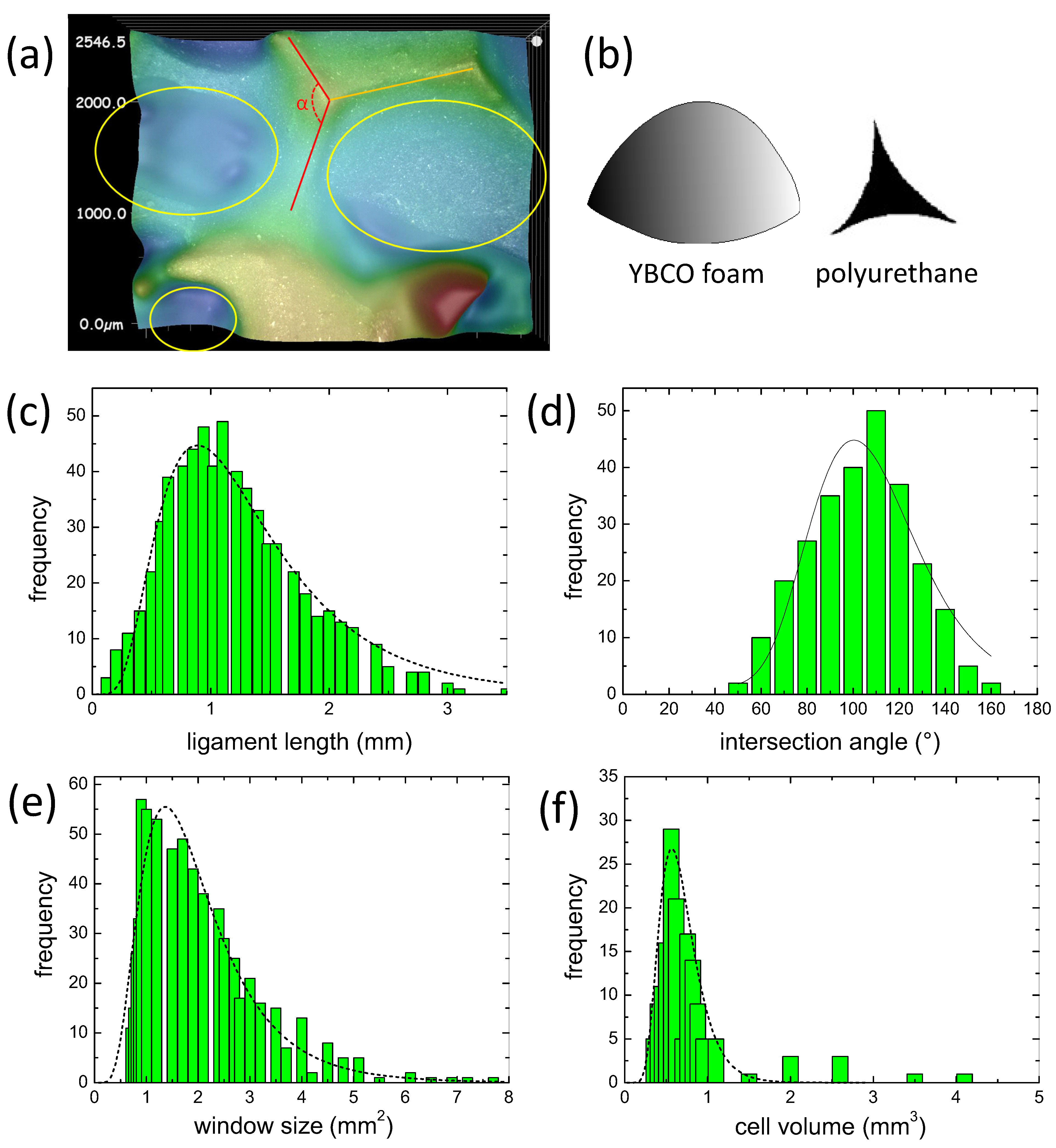

), the intersection angle (

), the intersection angle ( ) and the window size (yellow ellipses). (b) presents the typical cross section found by profile analysis for the YBCO foam (left) compared to a sketch of the cross section following Jang et al. [22]. (c–f) Statistical distribution analysis of the ligament (strut) lengths, the window size, the intersection angles and the cell size. The black dashed lines indicate log-normal fits to the data, and a normal fit in (d).

) and the window size (yellow ellipses). (b) presents the typical cross section found by profile analysis for the YBCO foam (left) compared to a sketch of the cross section following Jang et al. [22]. (c–f) Statistical distribution analysis of the ligament (strut) lengths, the window size, the intersection angles and the cell size. The black dashed lines indicate log-normal fits to the data, and a normal fit in (d).

), the intersection angle (

), the intersection angle ( ) and the window size (yellow ellipses). (b) presents the typical cross section found by profile analysis for the YBCO foam (left) compared to a sketch of the cross section following Jang et al. [22]. (c–f) Statistical distribution analysis of the ligament (strut) lengths, the window size, the intersection angles and the cell size. The black dashed lines indicate log-normal fits to the data, and a normal fit in (d).

) and the window size (yellow ellipses). (b) presents the typical cross section found by profile analysis for the YBCO foam (left) compared to a sketch of the cross section following Jang et al. [22]. (c–f) Statistical distribution analysis of the ligament (strut) lengths, the window size, the intersection angles and the cell size. The black dashed lines indicate log-normal fits to the data, and a normal fit in (d).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koblischka, M.R.; Koblischka-Veneva, A.; Nouailhetas, Q.; Hajiri, G.; Berger, K.; Douine, B.; Gokhfeld, D. Microstructural Parameters for Modelling of Superconducting Foams. Materials 2022, 15, 2303. https://doi.org/10.3390/ma15062303

Koblischka MR, Koblischka-Veneva A, Nouailhetas Q, Hajiri G, Berger K, Douine B, Gokhfeld D. Microstructural Parameters for Modelling of Superconducting Foams. Materials. 2022; 15(6):2303. https://doi.org/10.3390/ma15062303

Chicago/Turabian StyleKoblischka, Michael Rudolf, Anjela Koblischka-Veneva, Quentin Nouailhetas, Ghazi Hajiri, Kévin Berger, Bruno Douine, and Denis Gokhfeld. 2022. "Microstructural Parameters for Modelling of Superconducting Foams" Materials 15, no. 6: 2303. https://doi.org/10.3390/ma15062303

APA StyleKoblischka, M. R., Koblischka-Veneva, A., Nouailhetas, Q., Hajiri, G., Berger, K., Douine, B., & Gokhfeld, D. (2022). Microstructural Parameters for Modelling of Superconducting Foams. Materials, 15(6), 2303. https://doi.org/10.3390/ma15062303