Hot Isostatic Pressing for Fatigue Critical Additively Manufactured Ti-6Al-4V

Abstract

:1. Introduction

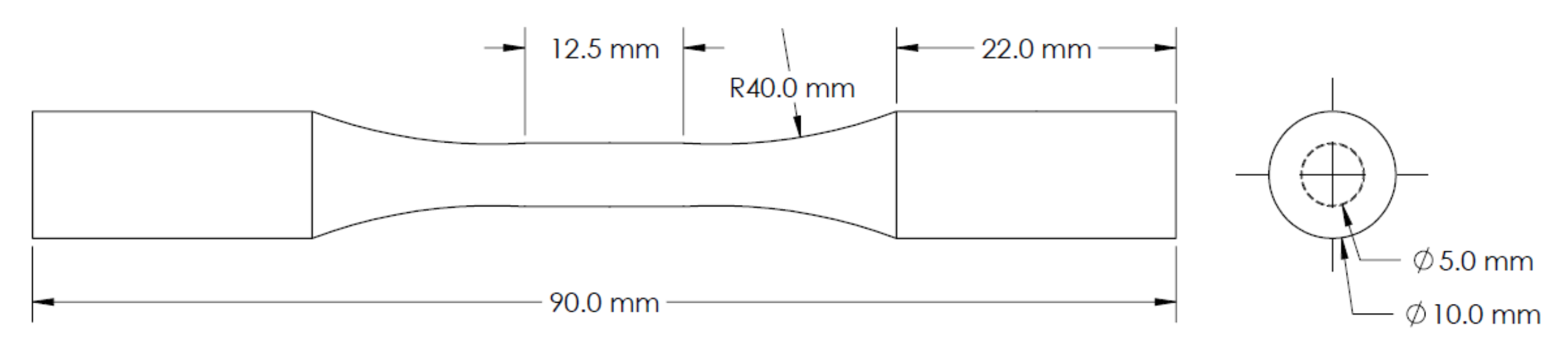

2. Material and Methods

2.1. Specimen Fabrication

2.2. X-ray Computed Tomography

2.3. HIP Treatment and Mechanical Testing

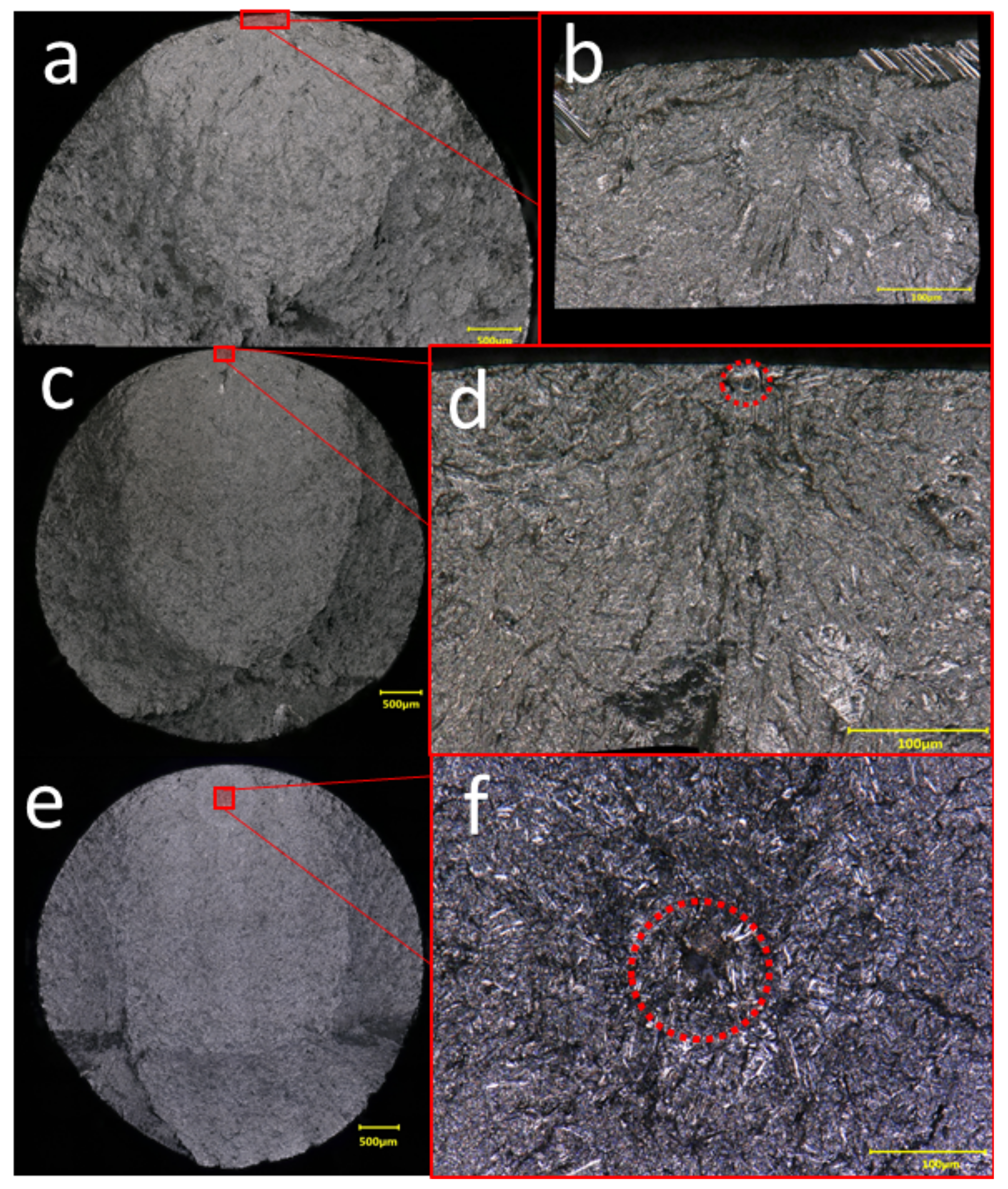

2.4. Microscopy

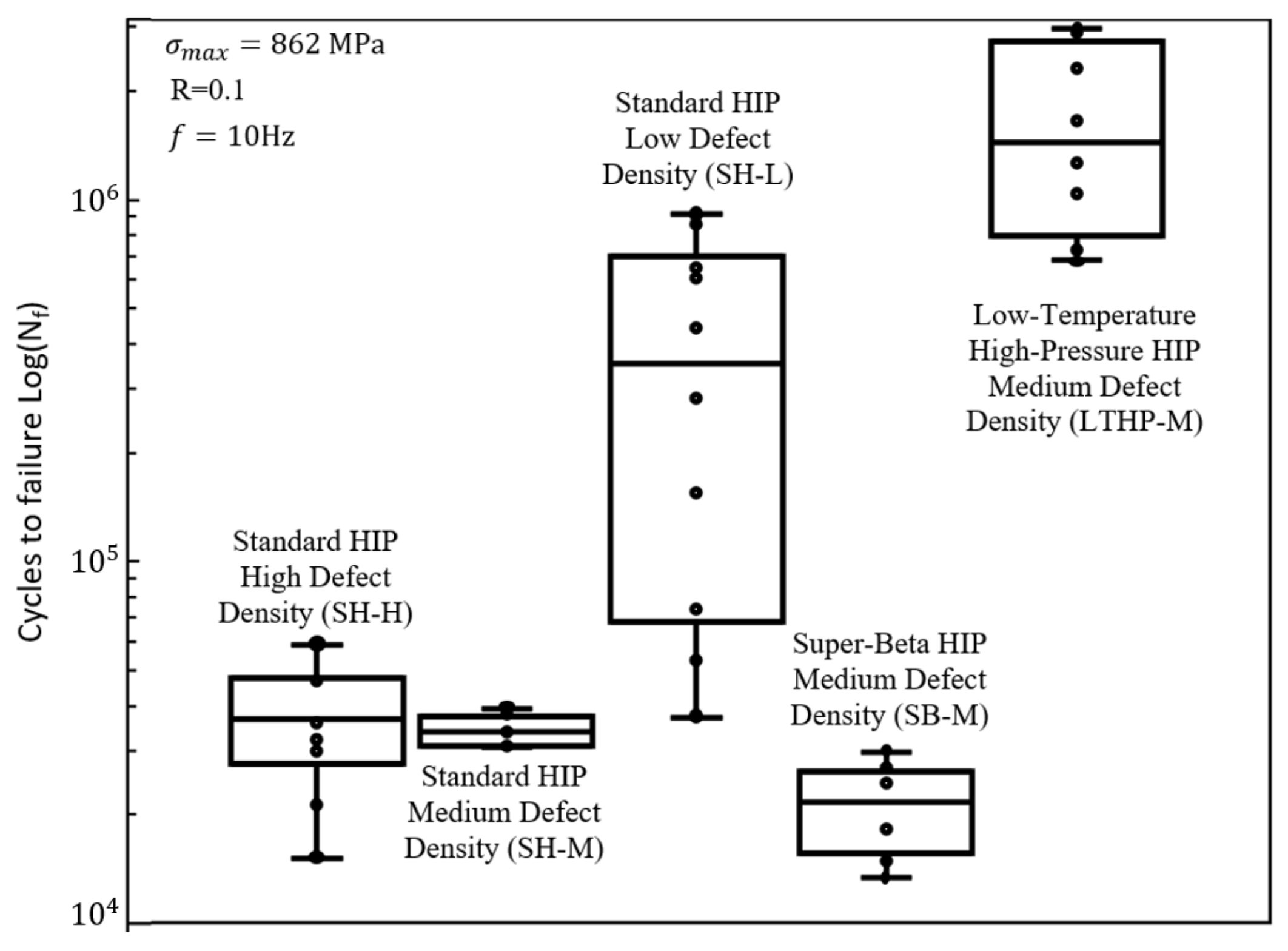

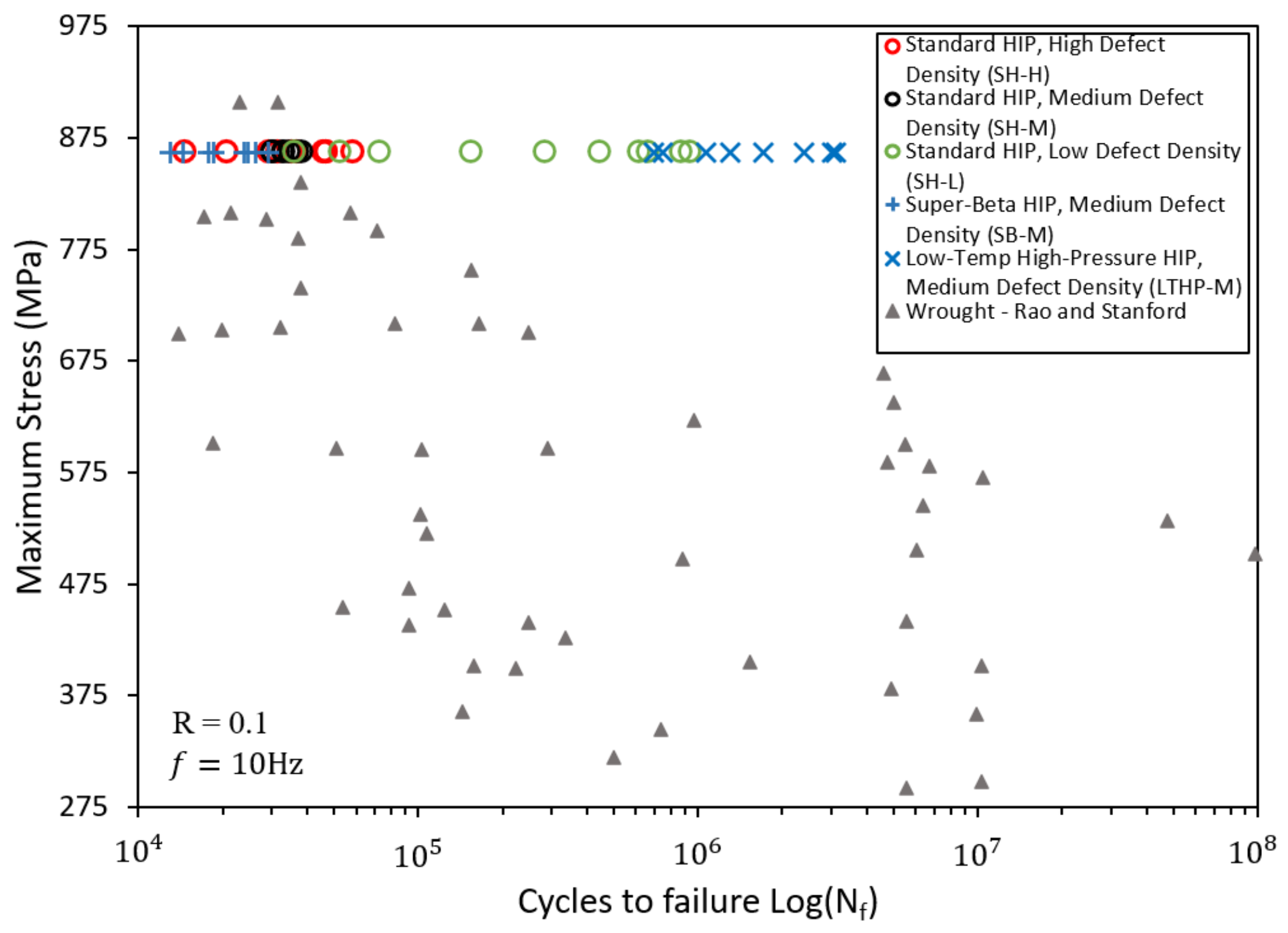

3. Results and Discussion

4. Conclusions

- (1)

- The fatigue life of HIP’d Ti-6Al-4V is dependent on the initial material state. AM Ti-6Al-4V materials with different initial material states exhibited significantly different fatigue performance despite have undergone identical HIP treatment.

- (2)

- Average microstructure morphology and defect population attributes do not govern fatigue performance in HIP’d AM Ti-6Al-4V. In direct contradiction to much of the literature, where defects were reportedly neutralized by HIP, crack initiation was observed both at and independent of defects. This suggests that initiation site type does not control failure. Popular models that employ extreme value statistics to map defect characteristics to fatigue performance are therefore not mechanistically supported for HIP’d Ti-6Al-4V.

- (3)

- Commonly examined material attributes (e.g., defect size/shape, and average grain morphology) were insufficient to explain the observed discrepancy in fatigue performance. This result implies that attributes beyond those commonly examined in AM materials, or local deviations from these average attributes, should be considered as mechanisms for both crack initiation and arrest.

- (4)

- Despite a relatively high defect density, a low-temperature high-pressure HIP treatment produced fatigue performance far superior to the ASTM recommended standard HIP. It is recommended that this new treatment be applied to fatigue critical applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, S.; Shin, Y.C. Additive manufacturing of ti6al4v alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Harun, W.S.W.; Manam, N.S.; Kamariah, M.S.I.N.; Sharif, S.; Zulkifly, A.H.; Ahmad, I.; Miura, H. A review of powdered additive manufacturing techniques for Ti-6Al-4V biomedical applications. Powder Technol. 2018, 331, 74–97. [Google Scholar] [CrossRef]

- Rawal, S.; Brantley, J.; Karabudak, N. Additive manufacturing of ti-6al-4v alloy components for spacecraft applications. In Proceedings of the 2013 6th International Conference on Recent Advances in Space Technologies (RAST), Istanbul, Turkey, 12–14 June 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 5–11. [Google Scholar]

- Inagaki, I.; Takechi, T.; Shirai, Y.; Ariyasu, N. Application and features of titanium for the aerospace industry. Nippon. Steel Sumitomo Met. Tech. Rep. 2014, 106, 22–27. [Google Scholar]

- Yadollahi, A.; Shamsaei, N. Additive manufacturing of fatigue resistant materials: Challenges and opportunities. Int. J. Fatigue 2017, 98, 14–31. [Google Scholar] [CrossRef] [Green Version]

- Carrion, P.E.; Soltani-Tehrani, A.; Phan, N.; Shamsaei, N. Powder recycling effects on the tensile and fatigue behavior of additively manufactured Ti-6Al-4V parts. JOM 2019, 71, 963–973. [Google Scholar] [CrossRef] [Green Version]

- Kasperovich, G.; Hausmann, J. Improvement of fatigue resistance and ductility of ti-6al-4v processed by selective laser melting. J. Mater. Process. Technol. 2015, 220, 202–214. [Google Scholar] [CrossRef]

- Shunmugavel, M.; Polishetty, A.; Goldberg, M.; Singh, R.; Littlefair, G. A comparative study of mechanical properties and machinability of wrought and additive manufactured (selective laser melting) titanium alloy–Ti–6Al–4V. Rapid Prototyp. J. 2017, 23, 1051–1056. [Google Scholar] [CrossRef]

- Li, P.; Warner, D.H.; Fatemi, A.; Phan, N. Critical assessment of the fatigue performance of additively manufactured ti–6al–4v and perspective for future research. Int. J. Fatigue 2016, 85, 130–143. [Google Scholar] [CrossRef]

- Sanaei, N.; Fatemi, A. Defect-based fatigue life prediction of l-pbf additive manufactured metals. Eng. Fract. Mech. 2021, 244, 107541. [Google Scholar] [CrossRef]

- Tian, C.; Li, T.; Bustillos, J.; Bhattacharya, S.; Turnham, T.; Yeo, J.; Moridi, A. Data-driven approaches toward smarter additive manufacturing. Adv. Intell. Syst. 2021, 3, 2100014. [Google Scholar] [CrossRef]

- Waddell, M.; Walker, K.; Bandyopadhyay, R.; Kapoor, K.; Mallory, A.; Xiao, X.; Chuang, A.C.; Liu, Q.; Phan, N.; Sangid, M. Small fatigue crack growth behavior of ti–6al–4v produced via selective laser melting: In Situ characterization of a 3d crack tip interactions with defects. Int. J. Fatigue 2020, 137, 105638. [Google Scholar] [CrossRef]

- Sheridan, L.; Gockel, J.; Scott-Emuakpor, O.E. Primary processing parameters, porosity production, and fatigue prediction for additively manufactured alloy 718. J. Mater. Eng. Perform. 2019, 28, 5387–5397. [Google Scholar] [CrossRef]

- Moran, T.P.; Warner, D.H.; Phan, N. Scan-by-scan part-scale thermal modelling for defect prediction in metal additive manufacturing. Addit. Manuf. 2021, 37, 101667. [Google Scholar] [CrossRef]

- Bertoli, U.S.; Wolfer, A.J.; Matthews, M.J.; Delplanque, J.R.; Schoenung, J.M. On the limitations of volumetric energy density as a design parameter for selective laser melting. Mater. Des. 2017, 113, 331–340. [Google Scholar] [CrossRef] [Green Version]

- Moran, T.P.; Li, P.; Warner, D.H.; Phan, N. Utility of superposition-based finite element approach for part-scale thermal simulation in additive manufacturing. Addit. Manuf. 2018, 21, 215–219. [Google Scholar] [CrossRef]

- Liu, Q.C.; Elambasseril, J.; Sun, S.J.; Leary, M.; Brandt, M.; Sharp, P.K. The effect of manufacturing defects on the fatigue behaviour of ti-6al-4v specimens fabricated using selective laser melting. Adv. Mater. Res. 2014, 891, 1519–1524. [Google Scholar] [CrossRef]

- Moran, T.P.; Warner, D.H.; Soltani-Tehrani, A.; Shamsaei, N.; Phan, N. Spatial inhomogeneity of build defects across the build plate in laser powder bed fusion. Addit. Manuf. 2021, 47, 102333. [Google Scholar] [CrossRef]

- Scime, L.; Beuth, J. Anomaly detection and classification in a laser powder bed additive manufacturing process using a trained computer vision algorithm. Addit. Manuf. 2018, 19, 114–126. [Google Scholar] [CrossRef]

- Bustillos, J.; Kim, J.; Moridi, A. Exploiting lack of fusion defects for microstructural engineering in additive manufacturing. Addit. Manuf. 2021, 48, 102399. [Google Scholar] [CrossRef]

- Leuders, S.; Lieneke, T.; Lammers, S.; Tröster, T.; Niendorf, T. On the fatigue properties of metals manufactured by selective laser Melting—The role of ductility. J. Mater. Res. 2014, 29, 1911–1919. [Google Scholar] [CrossRef]

- Li, P.; Warner, D.H.; Pegues, J.W.; Roach, M.D.; Shamsaei, N.; Phan, N. Investigation of the mechanisms by which hot isostatic pressing improves the fatigue performance of powder bed fused Ti–6Al–4V. Int. J. Fatigue 2019, 120, 342–352. [Google Scholar] [CrossRef] [PubMed]

- Molaei, R.; Fatemi, A.; Phan, N. Significance of hot isostatic pressing (hip) on multiaxial deformation and fatigue behaviors of additive manufactured ti–6al–4v including build orientation and surface roughness effects. Int. J. Fatigue 2018, 117, 352–370. [Google Scholar] [CrossRef]

- Seifi, M.; Salem, A.; Satko, D.; Shaffer, J.; Lewandowski, J.J. Defect distribution and microstructure heterogeneity effects on fracture resistance and fatigue behavior of ebm Ti–6Al–4V. Int. J. Fatigue 2017, 94, 263–287. [Google Scholar] [CrossRef]

- Wu, M.W.; Lai, P.H. The positive effect of hot isostatic pressing on improving the anisotropies of bending and impact properties in selective laser melted ti–6al–4v alloy. Mater. Sci. Eng. A 2016, 658, 429–438. [Google Scholar] [CrossRef]

- Qiu, C.; Adkins, N.; Attallah, M. Microstructure and tensile properties of selectively laser-melted and of hiped laser-melted ti–6al–4v. Mater. Sci. Eng. A 2013, 578, 230–239. [Google Scholar] [CrossRef]

- Leuders, S.; Vollmer, M.; Brenne, F.; Tröster, T.; Niendorf, T. Fatigue strength prediction for titanium alloy TiAl6V4 manufactured by selective laser melting. Metall. Mater. Trans. A 2015, 46, 3816–3823. [Google Scholar] [CrossRef]

- Shao, S.; Mahtabi, M.J.; Shamsaei, N.; Thompson, S.M. Solubility of argon in laser additive manufactured α-titanium under hot isostatic pressing condition. Comput. Mater. Sci. 2017, 131, 209–219. [Google Scholar] [CrossRef]

- Günther, J.; Krewerth, D.; Lippmann, T.; Leuders, S.; Tröster, T.; Weidner, A.; Biermann, H.; Niendorf, T. Fatigue life of additively manufactured Ti–6Al–4V in the very high cycle fatigue regime. Int. J. Fatigue 2017, 94, 236–245. [Google Scholar] [CrossRef]

- Rao, J.H.; Stanford, N. A survey of fatigue properties from wrought and additively manufactured Ti–6Al–4V. Mater. Lett. 2021, 283, 128800. [Google Scholar] [CrossRef]

- Greitemeier, D.; Palm, F.; Syassen, F.; Melz, T. Fatigue performance of additive manufactured tial6v4 using electron and laser beam melting. Int. J. Fatigue 2017, 94, 211–217. [Google Scholar] [CrossRef]

- Zhao, X.; Li, S.; Zhang, M.; Liu, Y.; Sercombe, T.B.; Wang, S.; Hao, Y.; Yang, R.; Murr, L.E. Comparison of the microstructures and mechanical properties of ti–6al–4v fabricated by selective laser melting and electron beam melting. Mater. Des. 2016, 95, 21–31. [Google Scholar] [CrossRef]

- Molaei, R.; Fatemi, A.; Sanaei, N.; Pegues, J.; Shamsaei, N.; Shao, S.; Li, P.; Warner, D.H.; Phan, N. Fatigue of additive manufactured ti–6al–4v, part ii: The relationship between microstructure, material cyclic properties, and component performance. Int. J. Fatigue 2020, 132, 105363. [Google Scholar] [CrossRef]

- Tammas-Williams, S.; Withers, P.J.; Todd, I.; Prangnell, P.B. The effectiveness of hot isostatic pressing for closing porosity in titanium parts manufactured by selective electron beam melting. Metall. Mater. Trans. A 2016, 47, 1939–1946. [Google Scholar] [CrossRef] [Green Version]

- Soltani-Tehrani, A.; Pegues, J.; Shamsaei, N. Fatigue behavior of additively manufactured 17-4 PH stainless steel: The effects of part location and powder re-use. Addit. Manuf. 2020, 36, 101398. [Google Scholar] [CrossRef]

- MSFC-SPEC-3717; Specification for Control and Quantification of Laser Powder Bed Fusion Metallurgical Processes. Standard, National Aeronautics and Space Administration, Marshall Space Flight Center: Huntsville, AL, USA, 2017.

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef] [Green Version]

- Tammas-Williams, S.; Withers, P.J.; Todd, I.; Prangnell, P.B. The influence of porosity on fatigue crack initiation in additively manufactured titanium components. Sci. Rep. 2017, 7, 7308. [Google Scholar] [CrossRef]

- Murakami, Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Mukherjee, T.; DebRoy, T. Mitigation of lack of fusion defects in powder bed fusion additive manufacturing. J. Manuf. Process. 2018, 36, 442–449. [Google Scholar] [CrossRef]

- Li, P.; Warner, D.H.; Pegues, J.W.; Roach, M.D.; Shamsaei, N.; Phan, N. Towards predicting differences in fatigue performance of laser powder bed fused ti–6al–4v coupons from the same build. Int. J. Fatigue 2019, 126, 284–296. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, D.; Wang, P.; Yan, M.; Yang, C.; Chen, Z.; Lu, J.; Lu, Z. Additive manufacturing of metals: Microstructure evolution and multistage control. J. Mater. Sci. Technol. 2021, 100, 224–236. [Google Scholar] [CrossRef]

- Zerbst, U.; Bruno, G.; Buffiere, J.; Wegener, T.; Niendorf, T.; Wu, T.; Zhang, X.; Kashaev, N.; Meneghetti, G.; Hrabe, N.; et al. Damage tolerant design of additively manufactured metallic components subjected to cyclic loading: State of the art and challenges. Prog. Mater. Sci. 2021, 121, 100786. [Google Scholar] [CrossRef]

- Zerbst, U.; Madia, M.; Bruno, G.; Hilgenberg, K. Towards a methodology for component design of metallic am parts subjected to cyclic loading. Metals 2021, 11, 709. [Google Scholar] [CrossRef]

- Brenne, F.; Niendorf, T. Damage tolerant design by microstructural gradation—Influence of processing parameters and build orientation on crack growth within additively processed 316l. Mater. Sci. Eng. A 2019, 764, 138186. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

| Group | Laser Power (W) | Scan Speed (mm/s) | Hatch Distance (µm) | Layer Thickness (µm) | Beam Diameter (µm) | Energy Density (J/mm3) |

|---|---|---|---|---|---|---|

| DMP:SH-M,SB-M,LTHP-M | 245 | 1250 | 82 | 60 | 85 | 39.8 |

| EOS:SH-H | 160 | 1200 | 140 | 30 | 100 | 31.7 |

| EOS:SH-L 3 | 280 | 1200 | 140 | 30 | 100 | 55.6 |

| Group | Description | Temperature (C) | Pressure (MPa) | Soak Time (h) |

|---|---|---|---|---|

| SH | Standard HIP | 920 | 100 | 2 |

| SB | Super-Beta HIP | 1050 | 100 | 2 |

| LTHP | Low-T/High-P | 800 | 200 | 2 |

| HIP Treatment | Defect Level | Defect Diameter | Defect Density | Porosity |

|---|---|---|---|---|

| Group Label | (H/M/L) | (m) | (Defects/mm) | (%) |

| Standard HIP (SH-H) | High | 58.7 | 265.85 | 3.96 |

| Standard Hip (SH-M) | ||||

| Low-Temperature High-Pressure (LTHP-M) | Medium | 41.2 | 7.27 | 0.036 |

| Super-Beta (SB-M) | ||||

| Standard HIP (SH-L) | Low | 49.3 | 0.35 | 0.00264 |

| Group Label | SH-H | SH-M | SH-L | SB-M | LTHP-M |

|---|---|---|---|---|---|

| HIP Treatment | Standard HIP | Standard HIP | Standard HIP | Super-Beta HIP | Low-Temp High-Pressure HIP |

| Defect Level | High | Medium | Low | Medium | Medium |

| Length (m) | 45.0 | 49.5 | 46.4 | 85.3 | 40.4 |

| Width (m) | 4.3 | 4.4 | 4.2 | 12.9 | 3.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moran, T.P.; Carrion, P.E.; Lee, S.; Shamsaei, N.; Phan, N.; Warner, D.H. Hot Isostatic Pressing for Fatigue Critical Additively Manufactured Ti-6Al-4V. Materials 2022, 15, 2051. https://doi.org/10.3390/ma15062051

Moran TP, Carrion PE, Lee S, Shamsaei N, Phan N, Warner DH. Hot Isostatic Pressing for Fatigue Critical Additively Manufactured Ti-6Al-4V. Materials. 2022; 15(6):2051. https://doi.org/10.3390/ma15062051

Chicago/Turabian StyleMoran, Terrence P., Patricio E. Carrion, Seungjong Lee, Nima Shamsaei, Nam Phan, and Derek H. Warner. 2022. "Hot Isostatic Pressing for Fatigue Critical Additively Manufactured Ti-6Al-4V" Materials 15, no. 6: 2051. https://doi.org/10.3390/ma15062051

APA StyleMoran, T. P., Carrion, P. E., Lee, S., Shamsaei, N., Phan, N., & Warner, D. H. (2022). Hot Isostatic Pressing for Fatigue Critical Additively Manufactured Ti-6Al-4V. Materials, 15(6), 2051. https://doi.org/10.3390/ma15062051