Effects of Annealing and Solution Treatments on the Microstructure and Mechanical Properties of Ti6Al4V Manufactured by Selective Laser Melting

Abstract

:1. Introduction

2. Materials and Methods

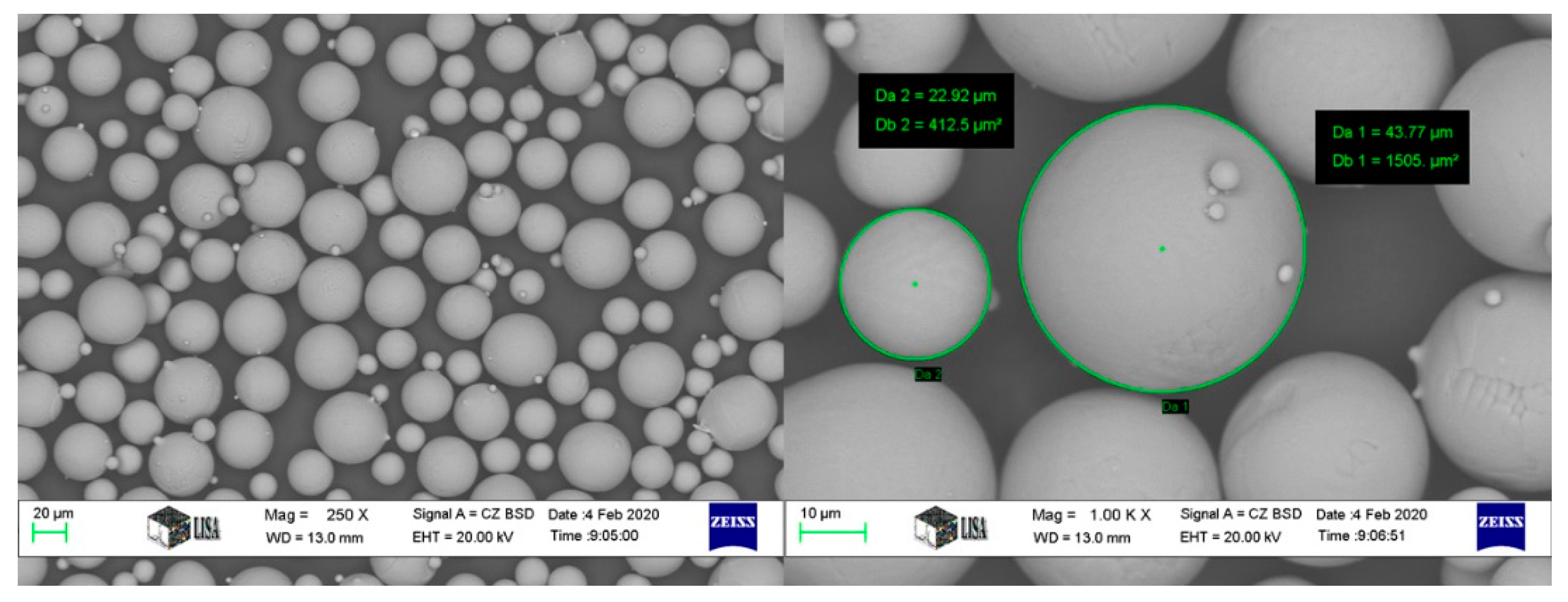

2.1. Materials Preparation

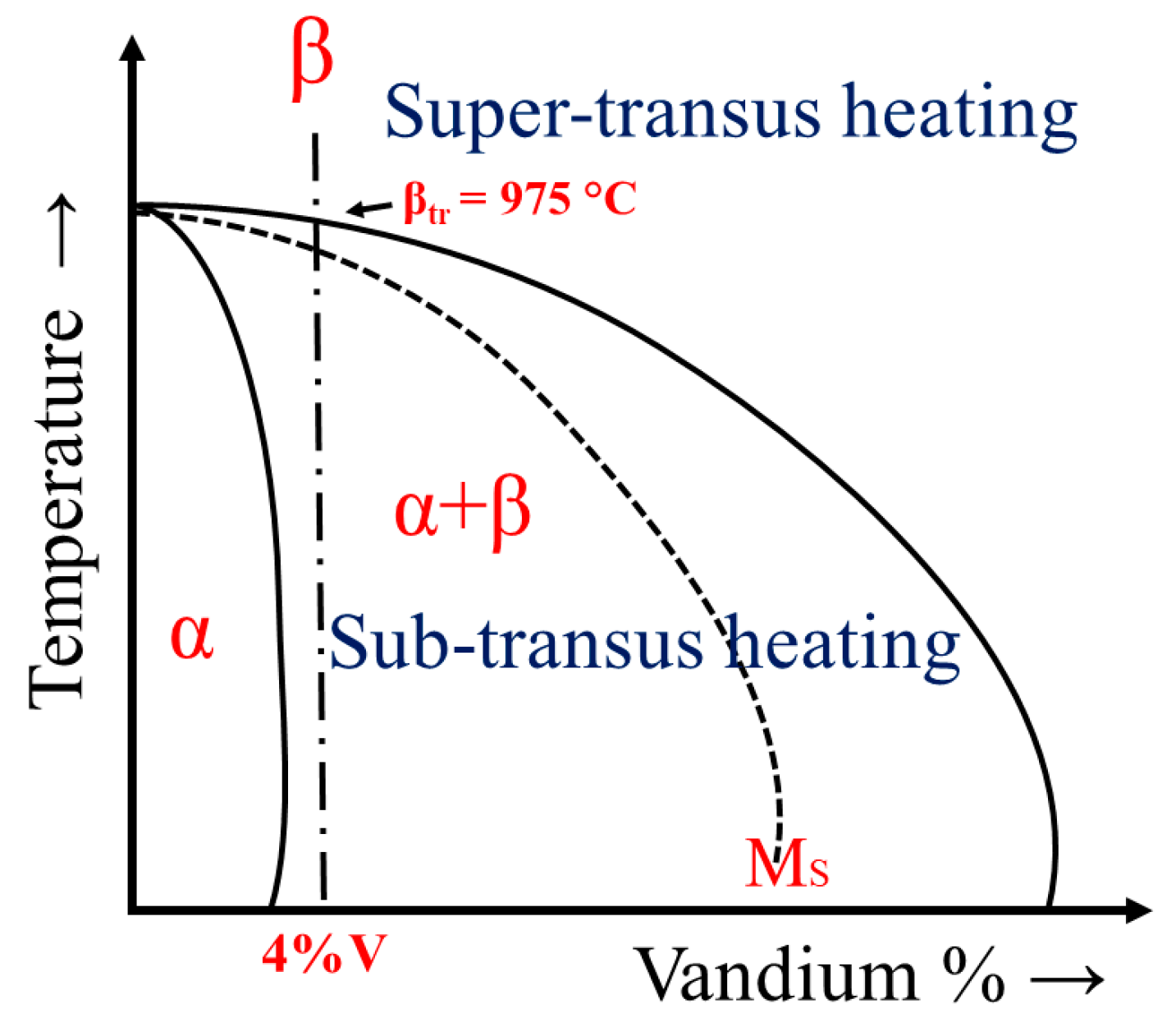

2.2. Heat Treatments

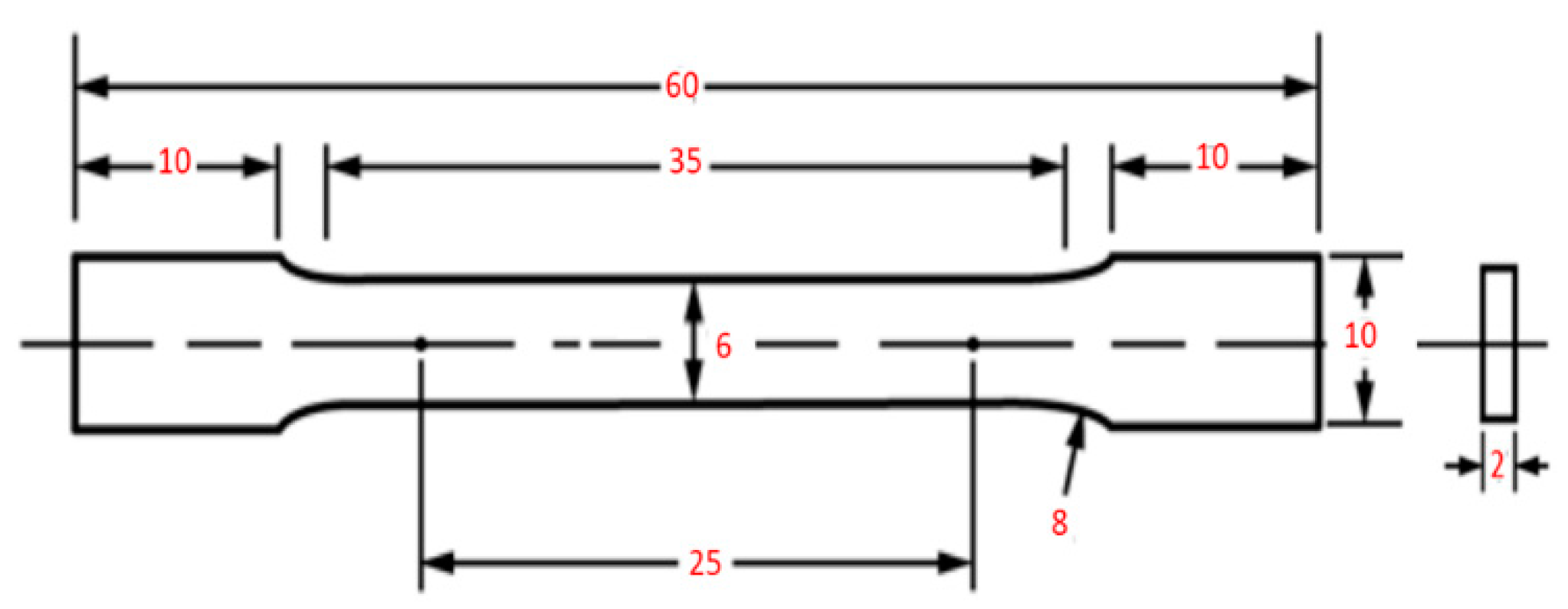

2.3. Materials Characterization

3. Results and Discussion

3.1. Microstructure Investigation

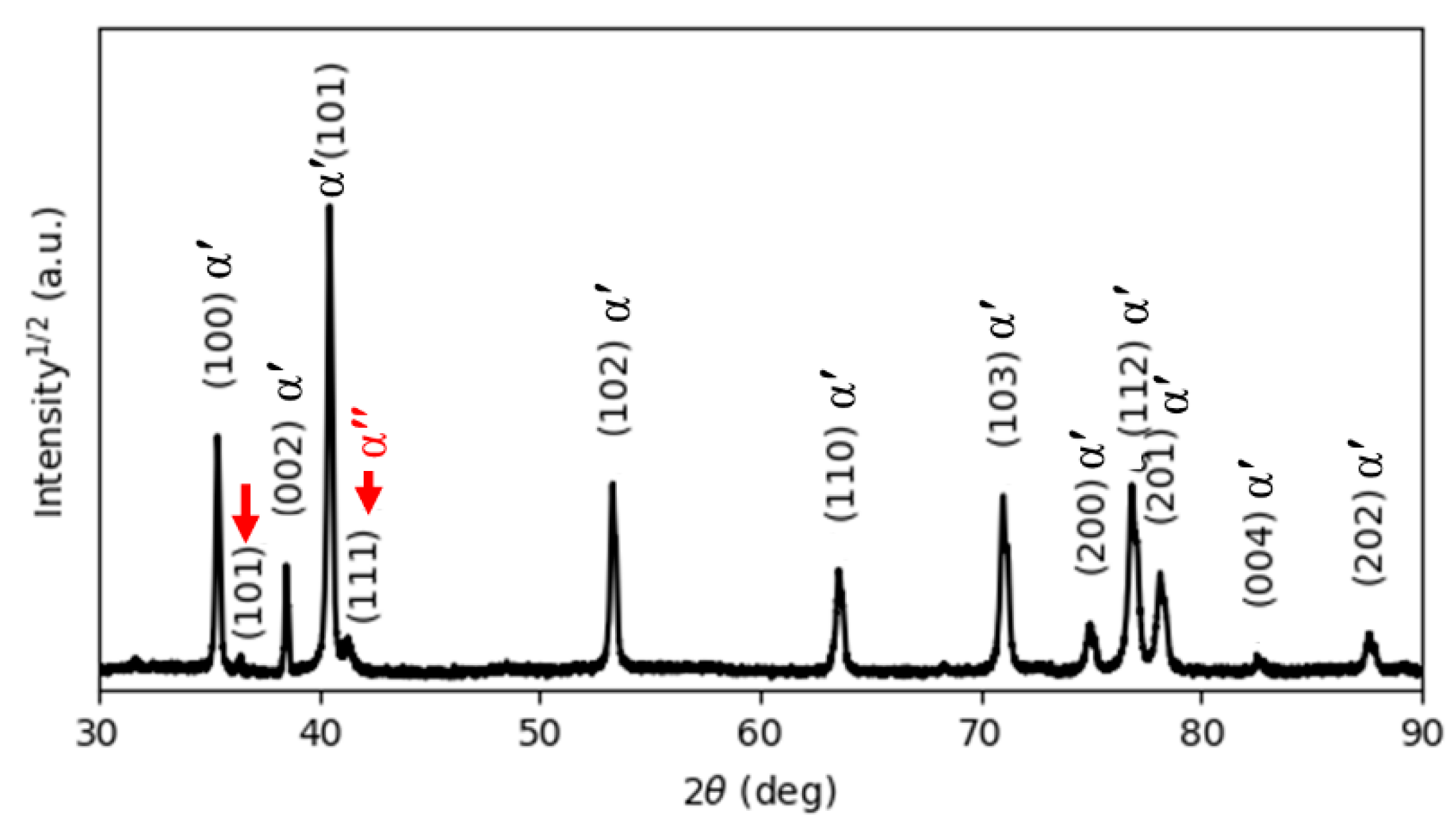

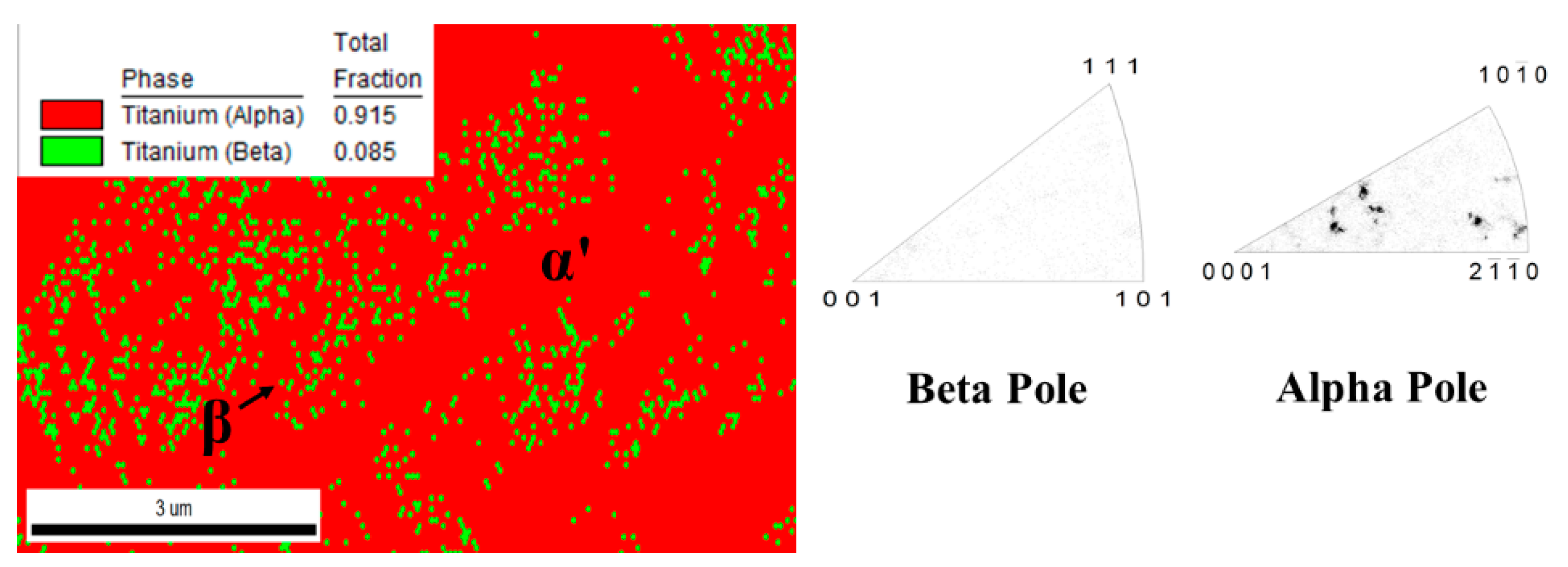

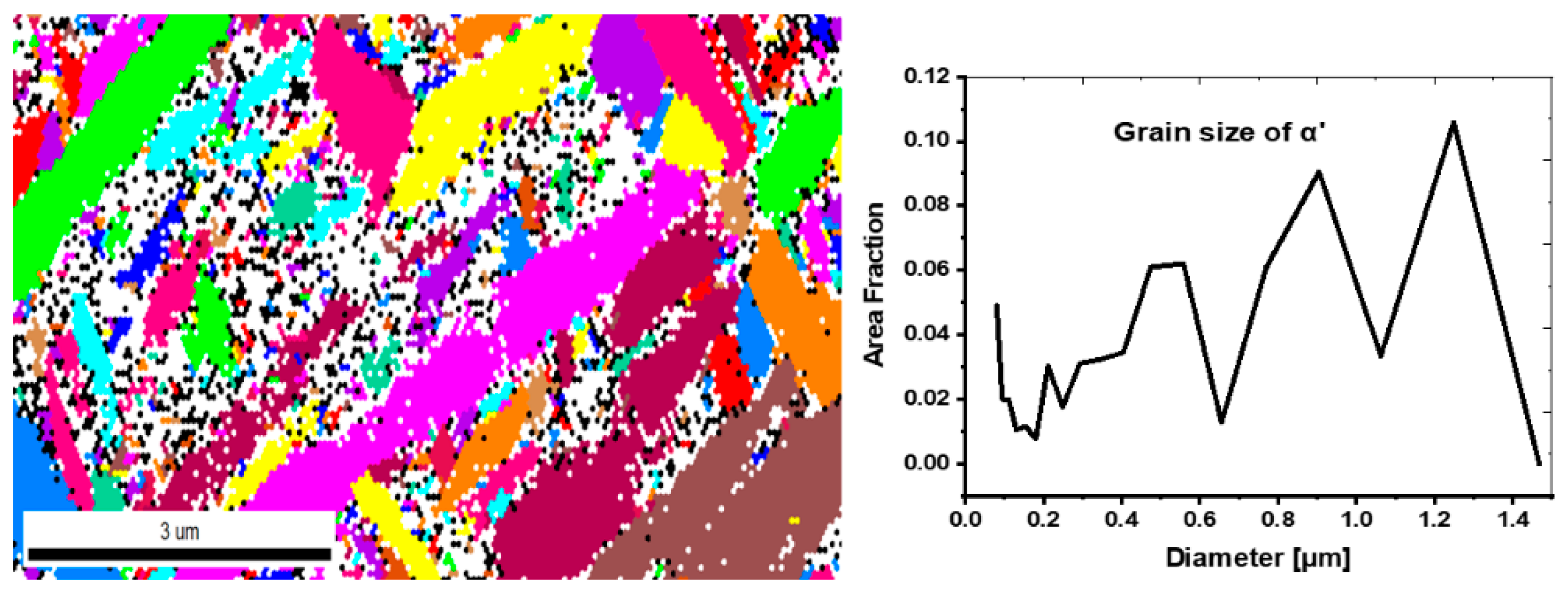

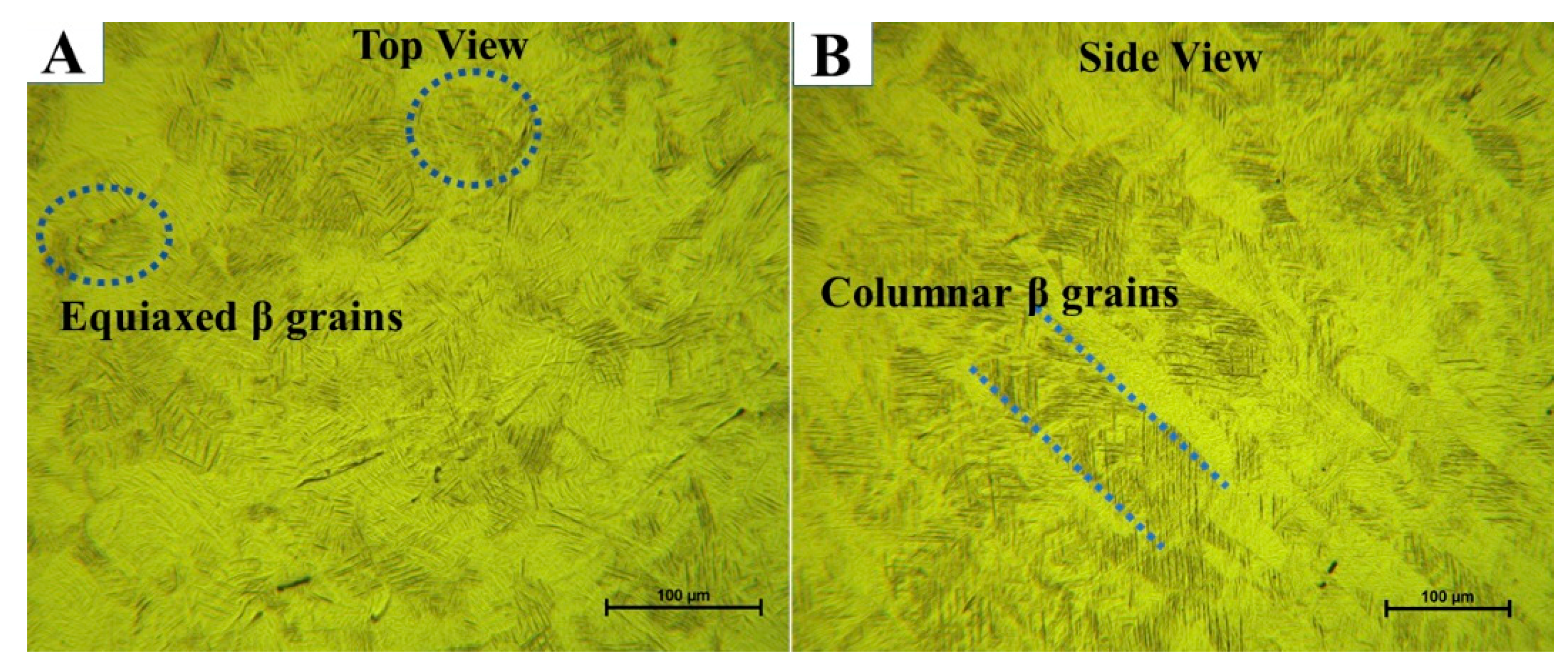

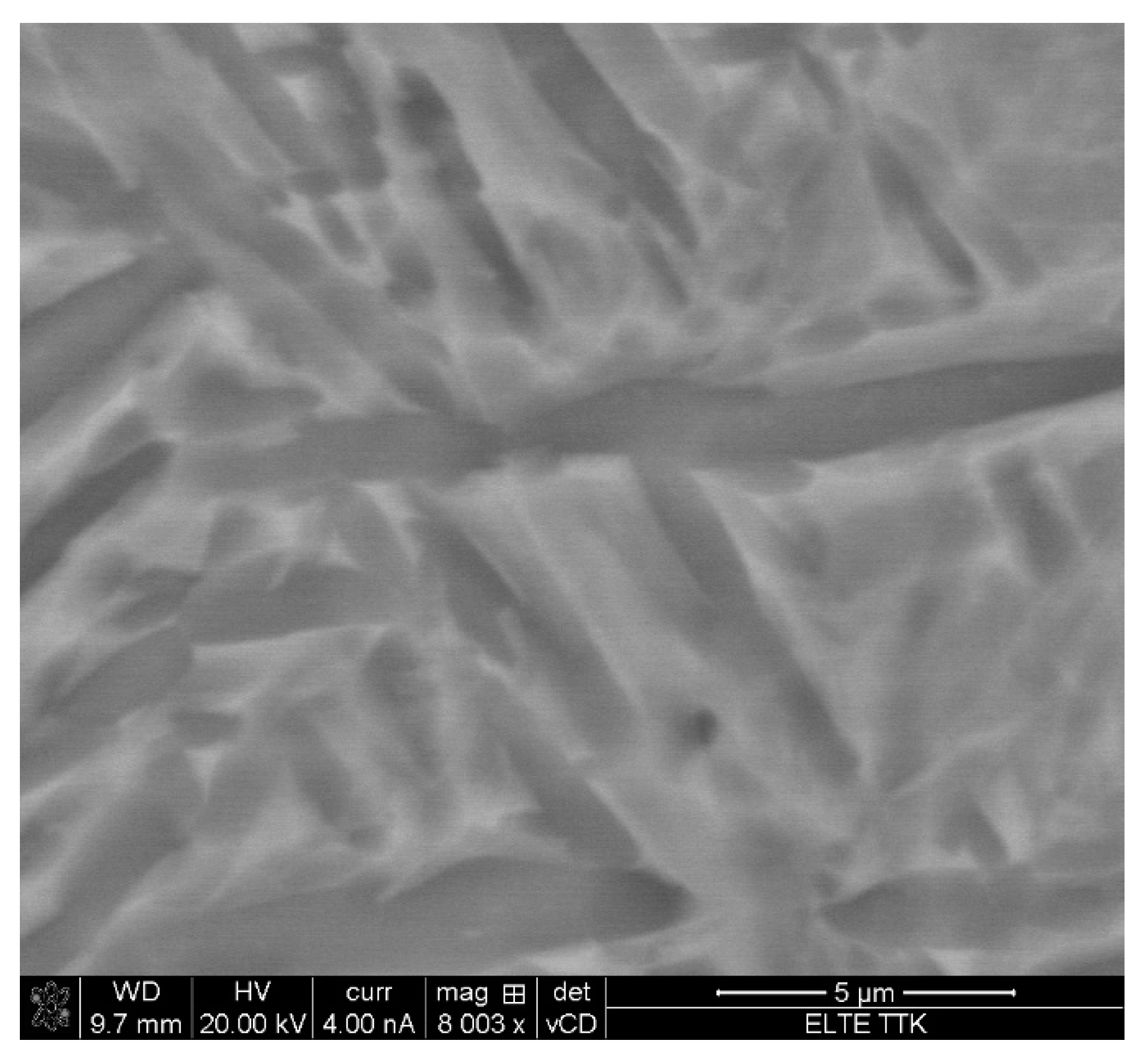

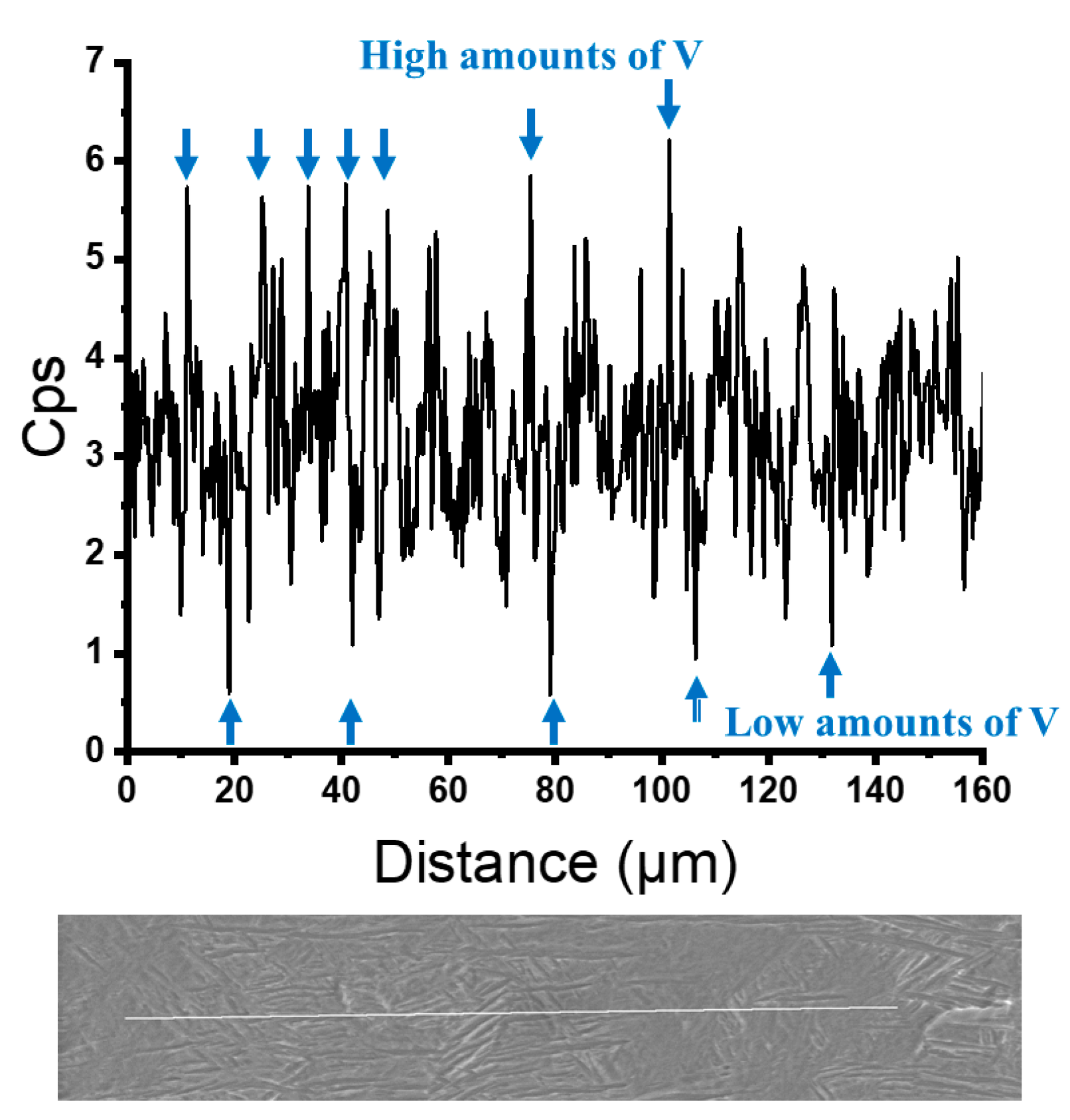

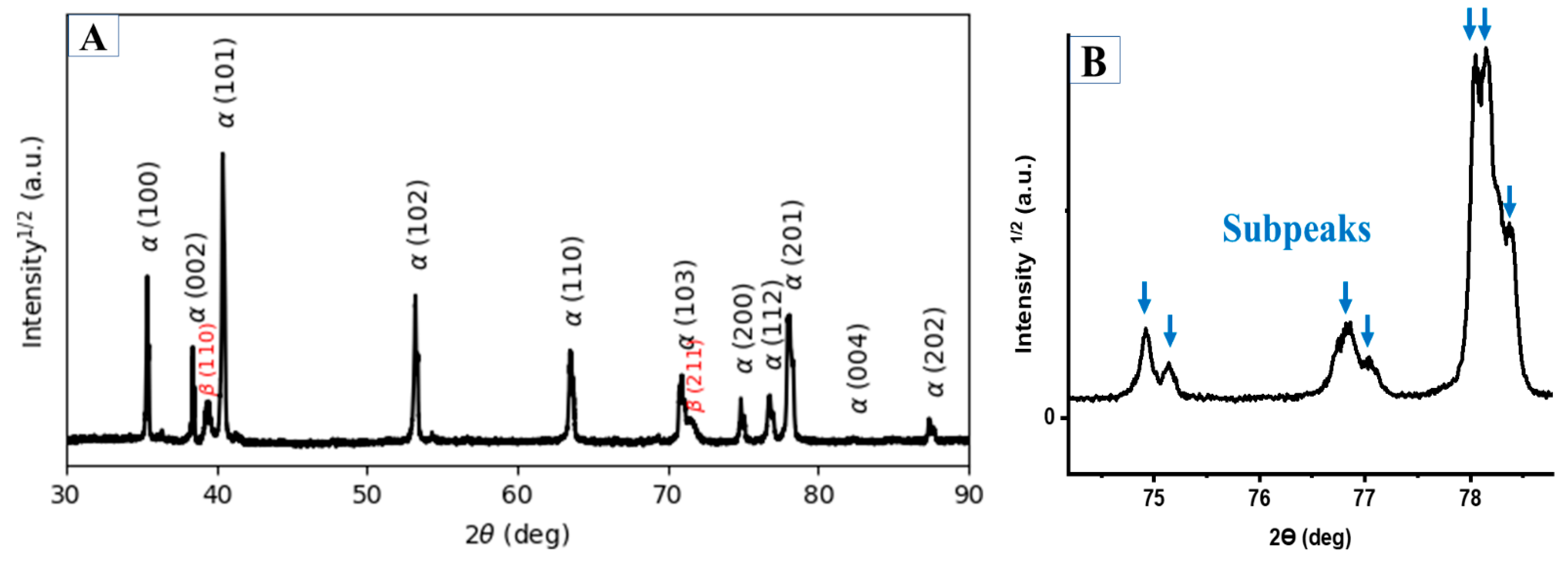

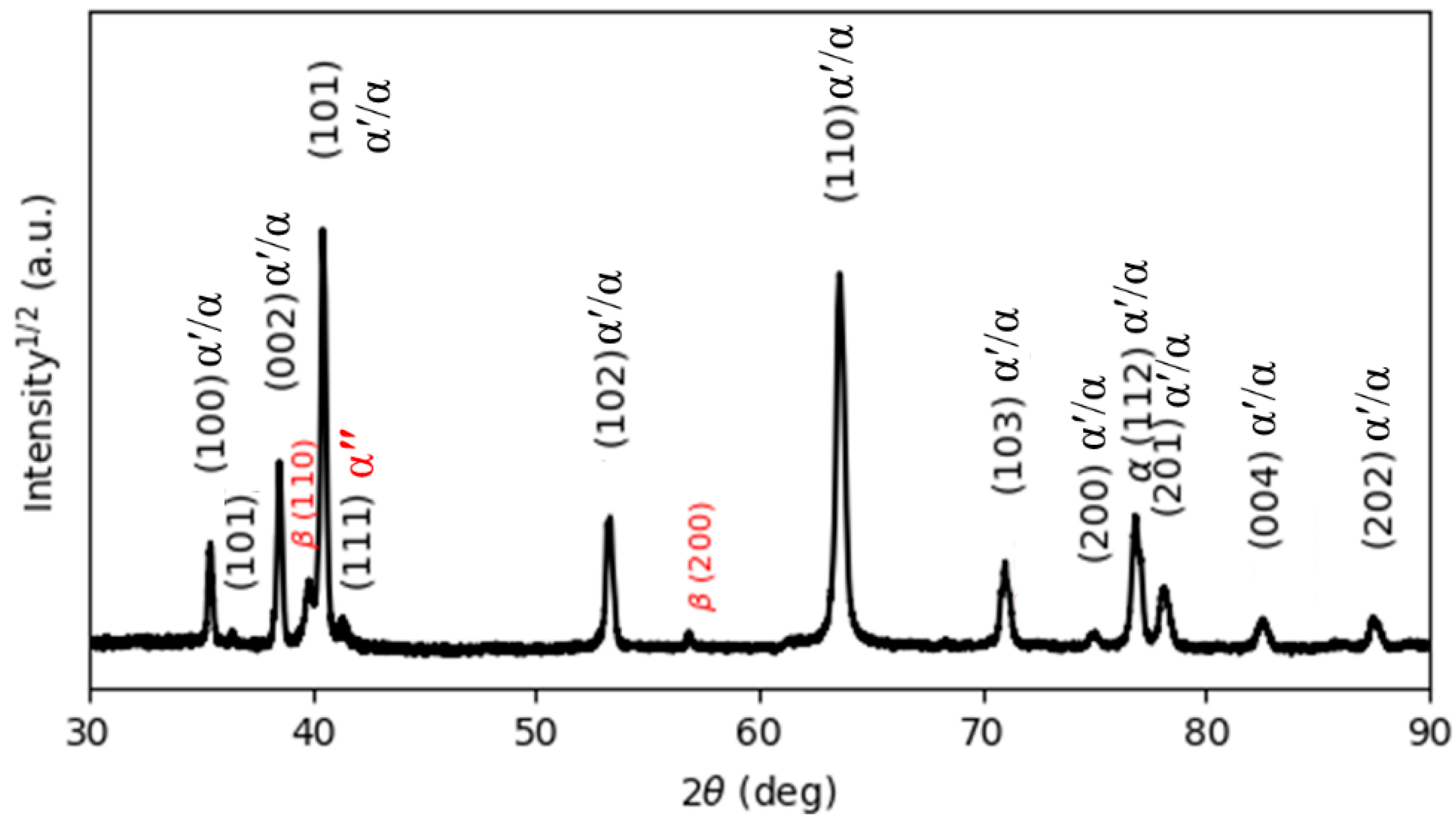

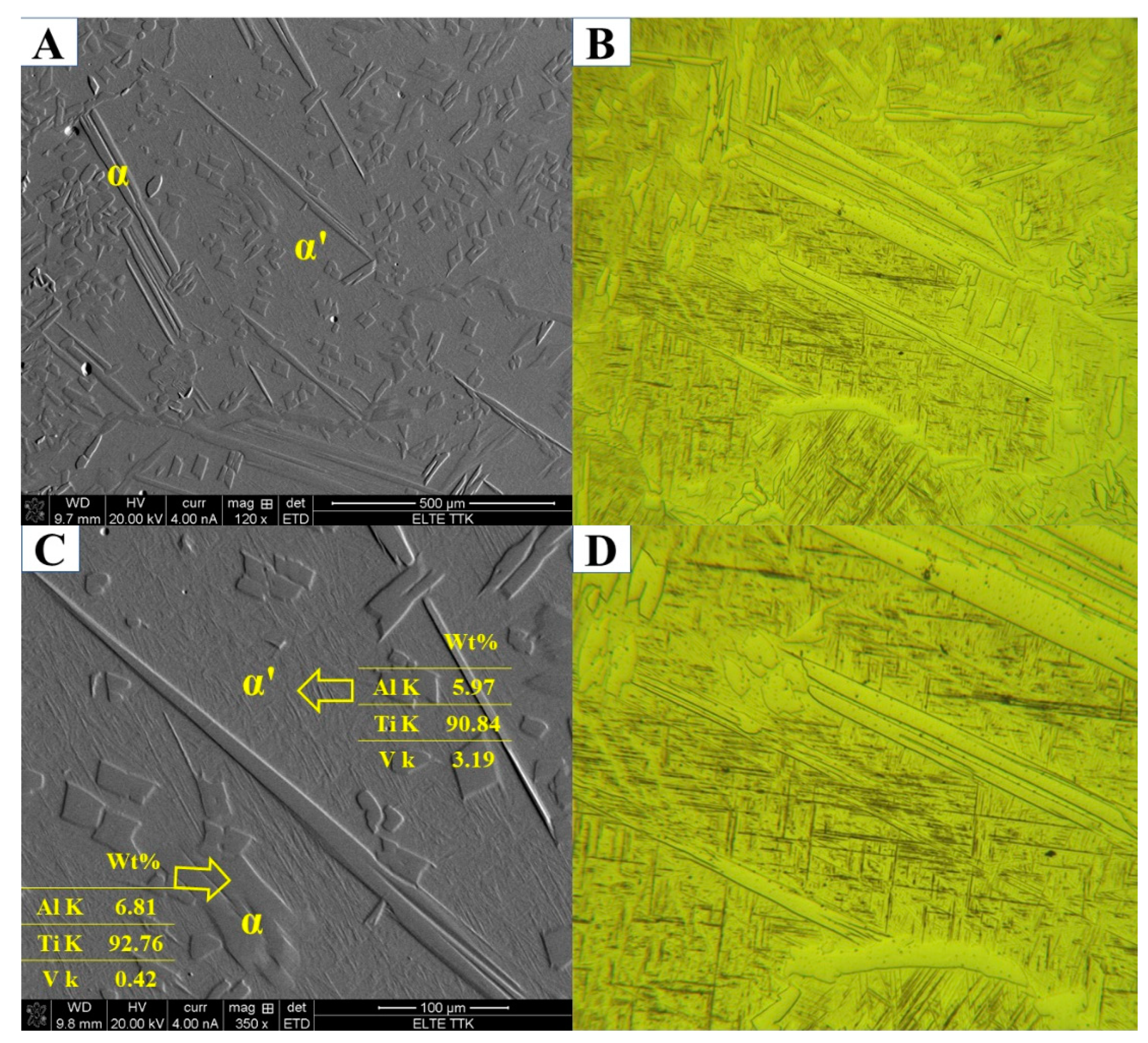

3.1.1. Microstructure of As-Manufactured Ti6Al4V

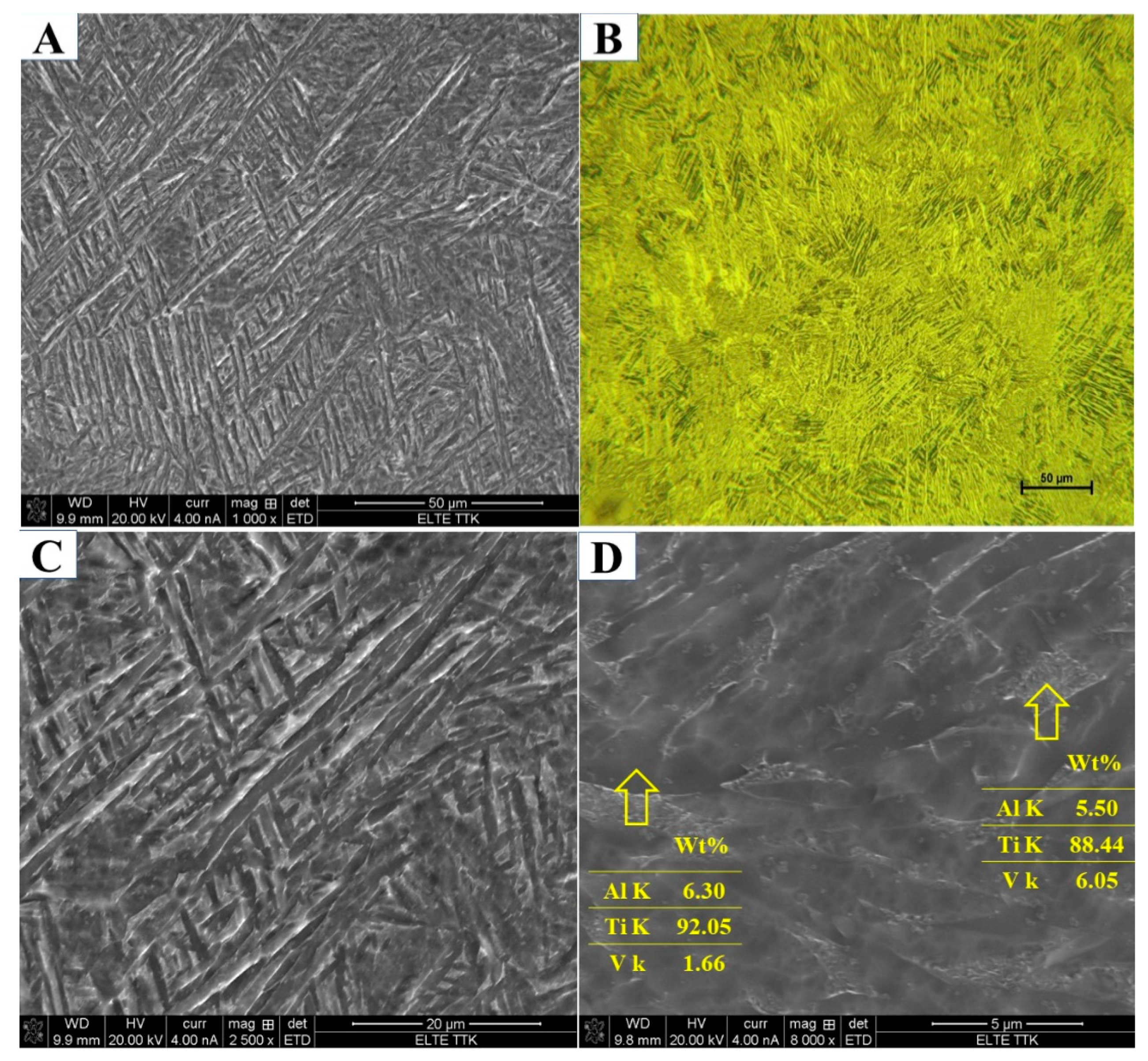

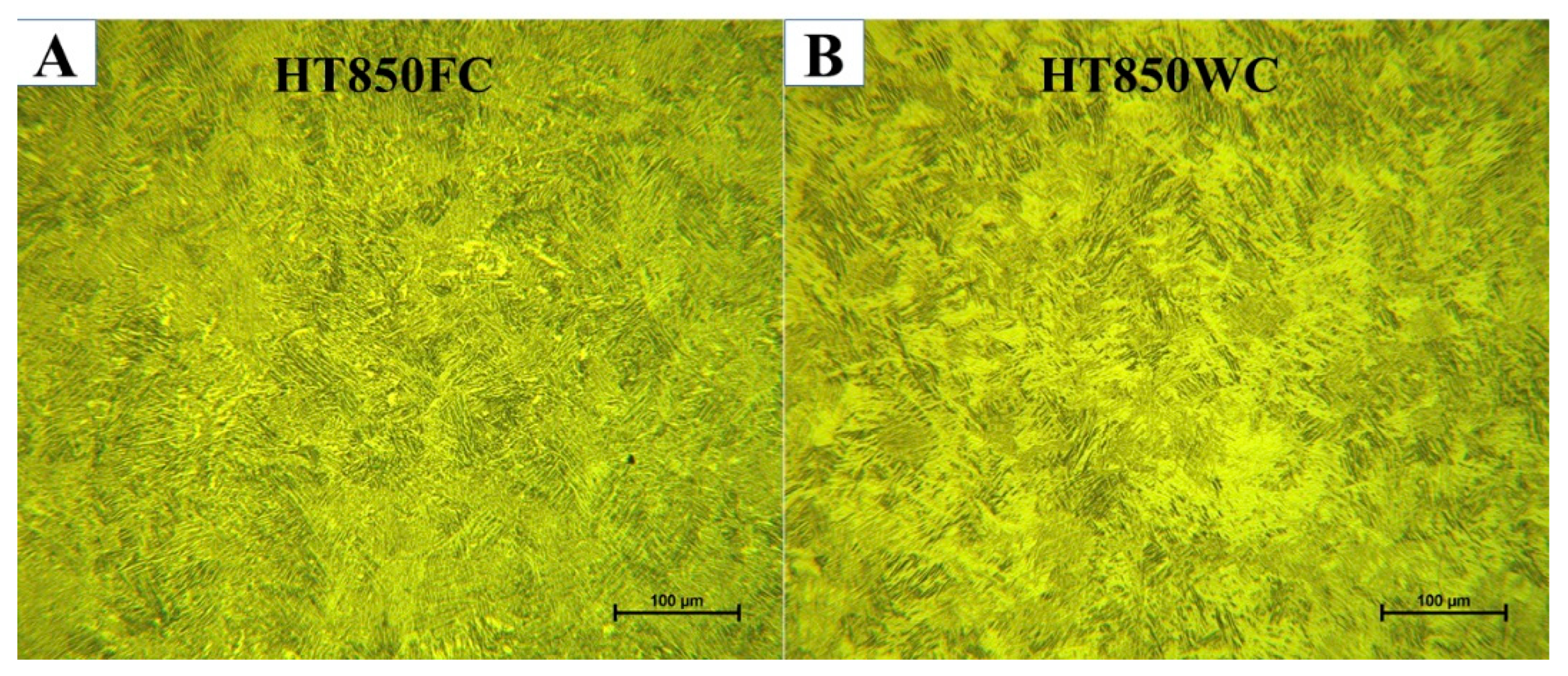

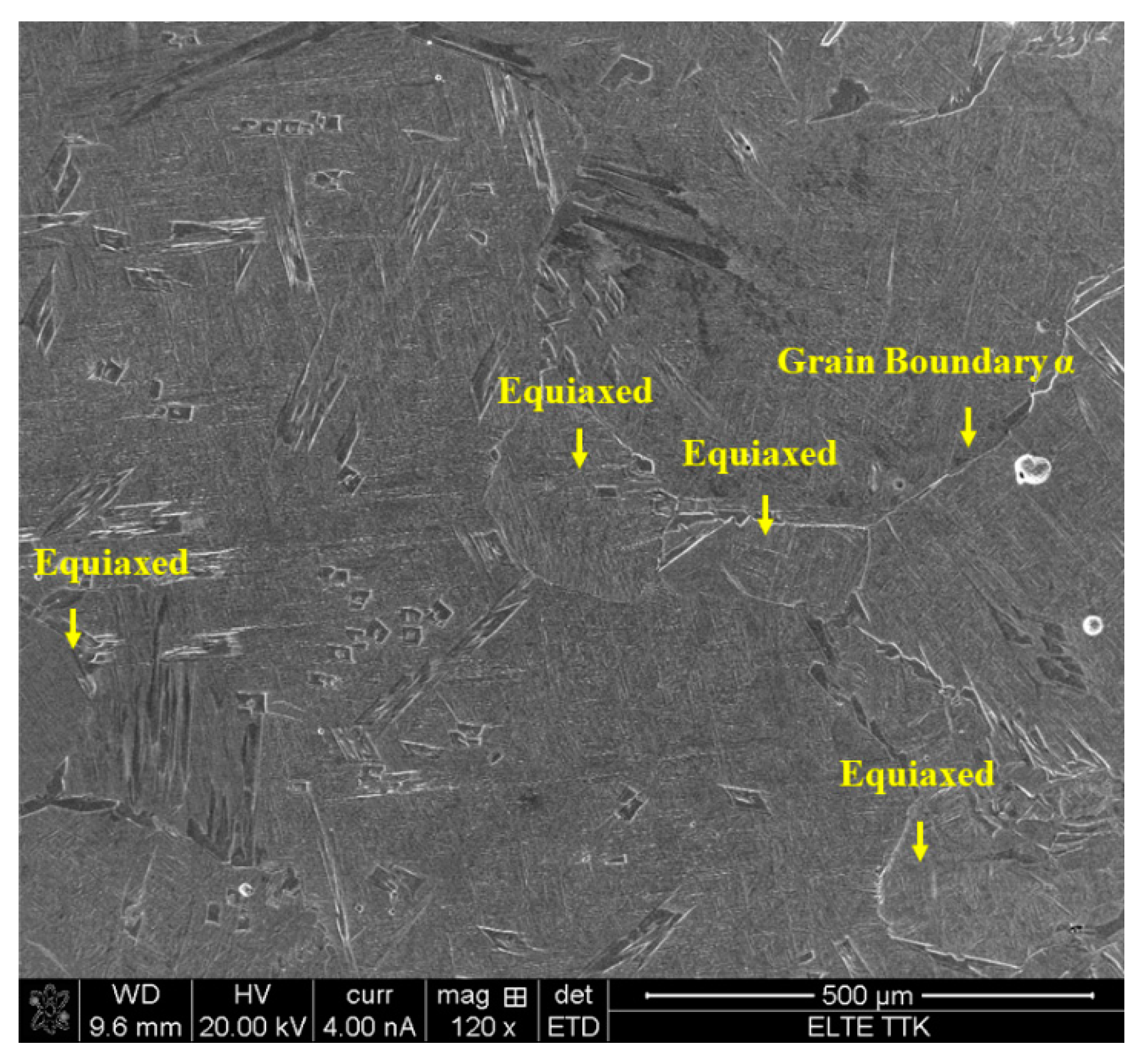

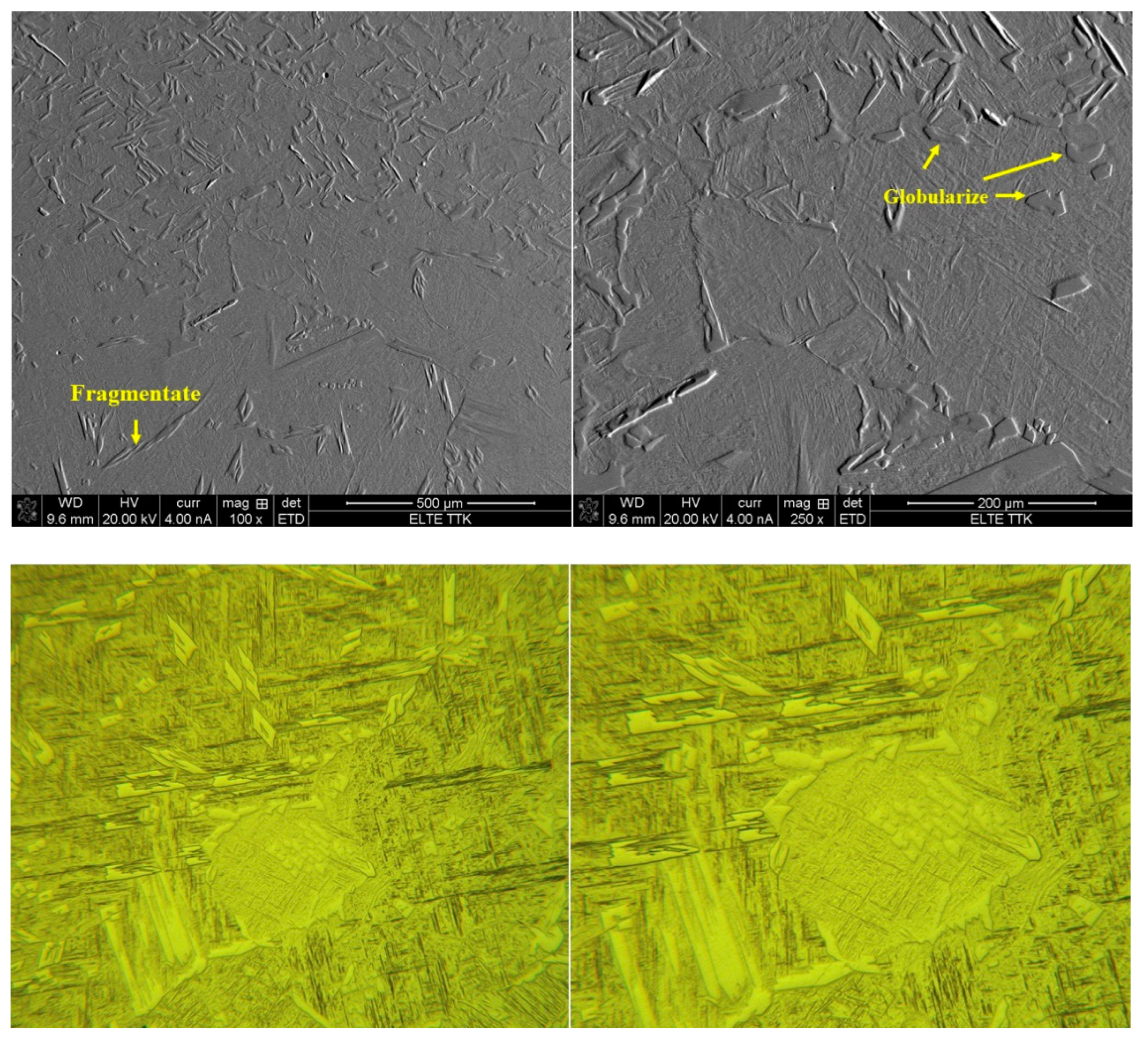

3.1.2. Microstructure of Subtransus Heat Treatments

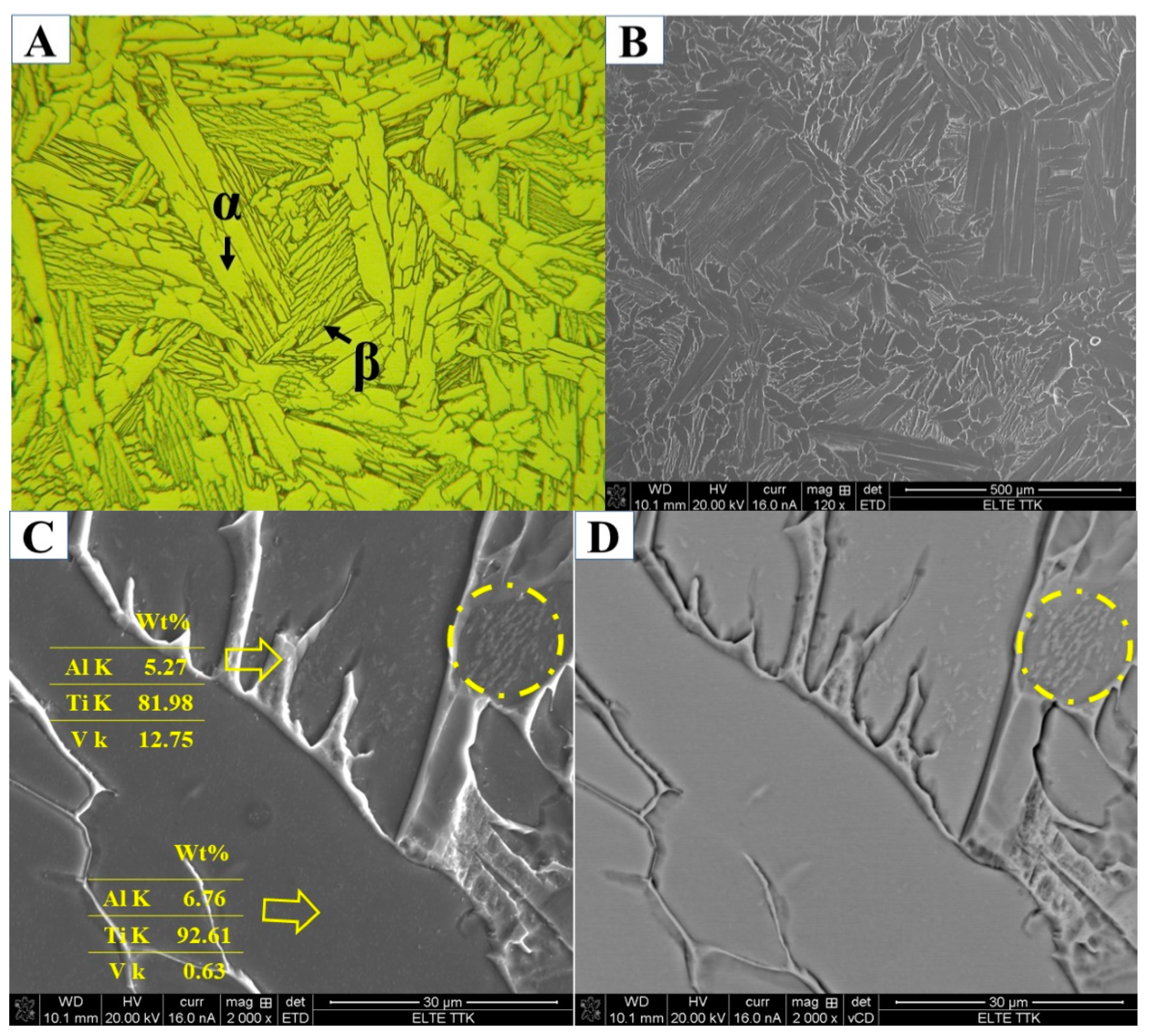

3.1.3. Microstructure of Supertransus Heat Treatments

3.2. Tensile Properties

4. Conclusions

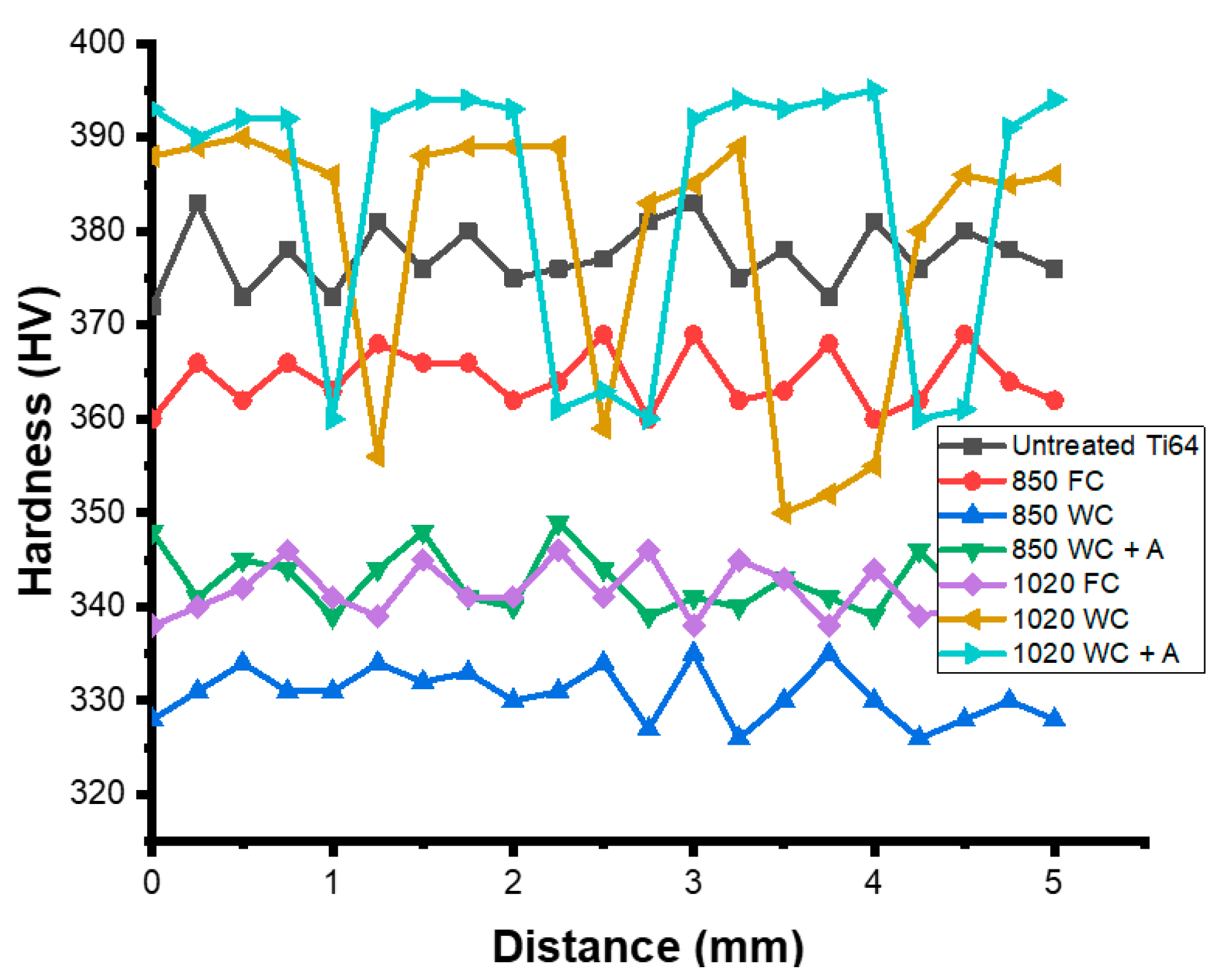

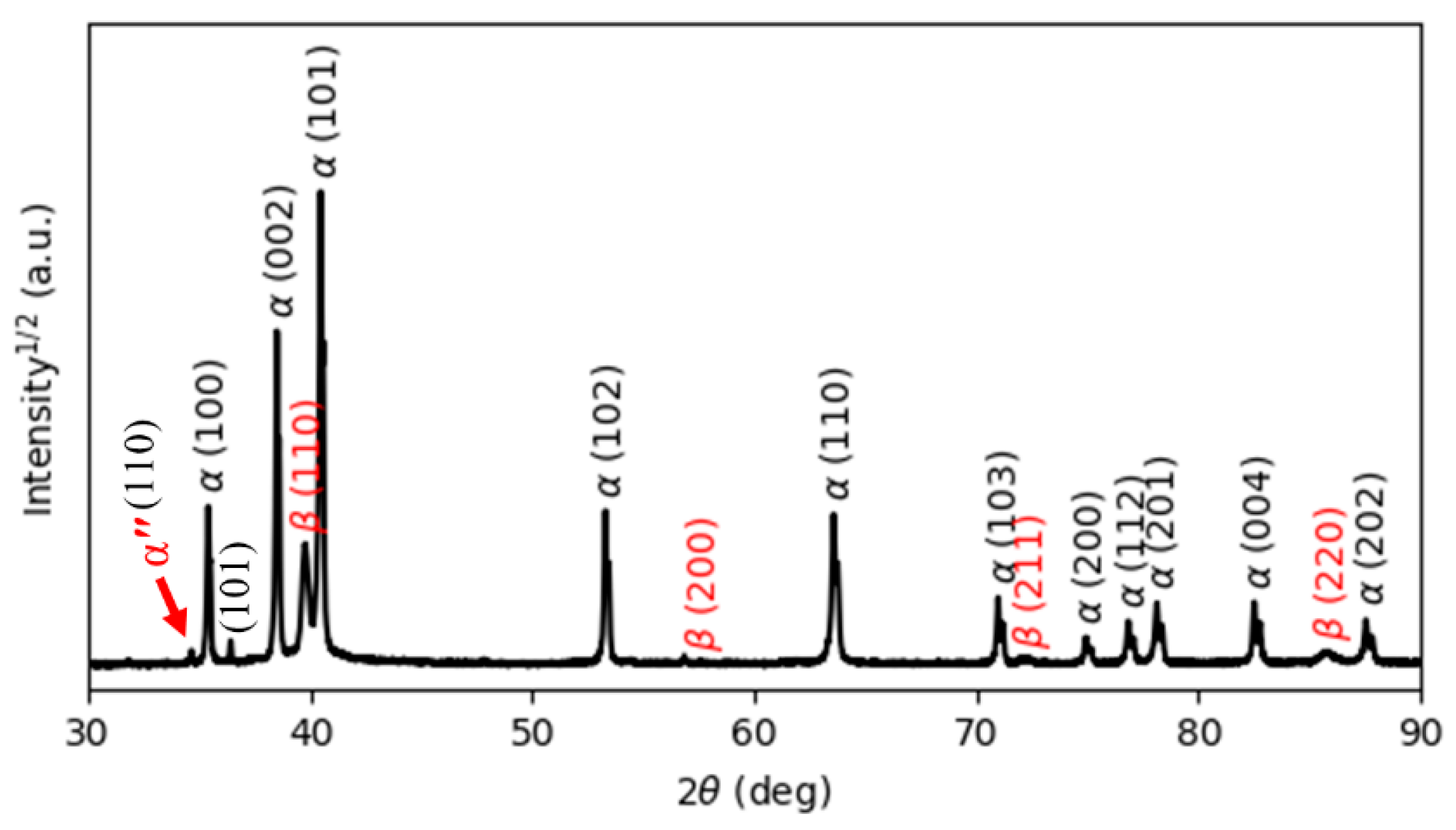

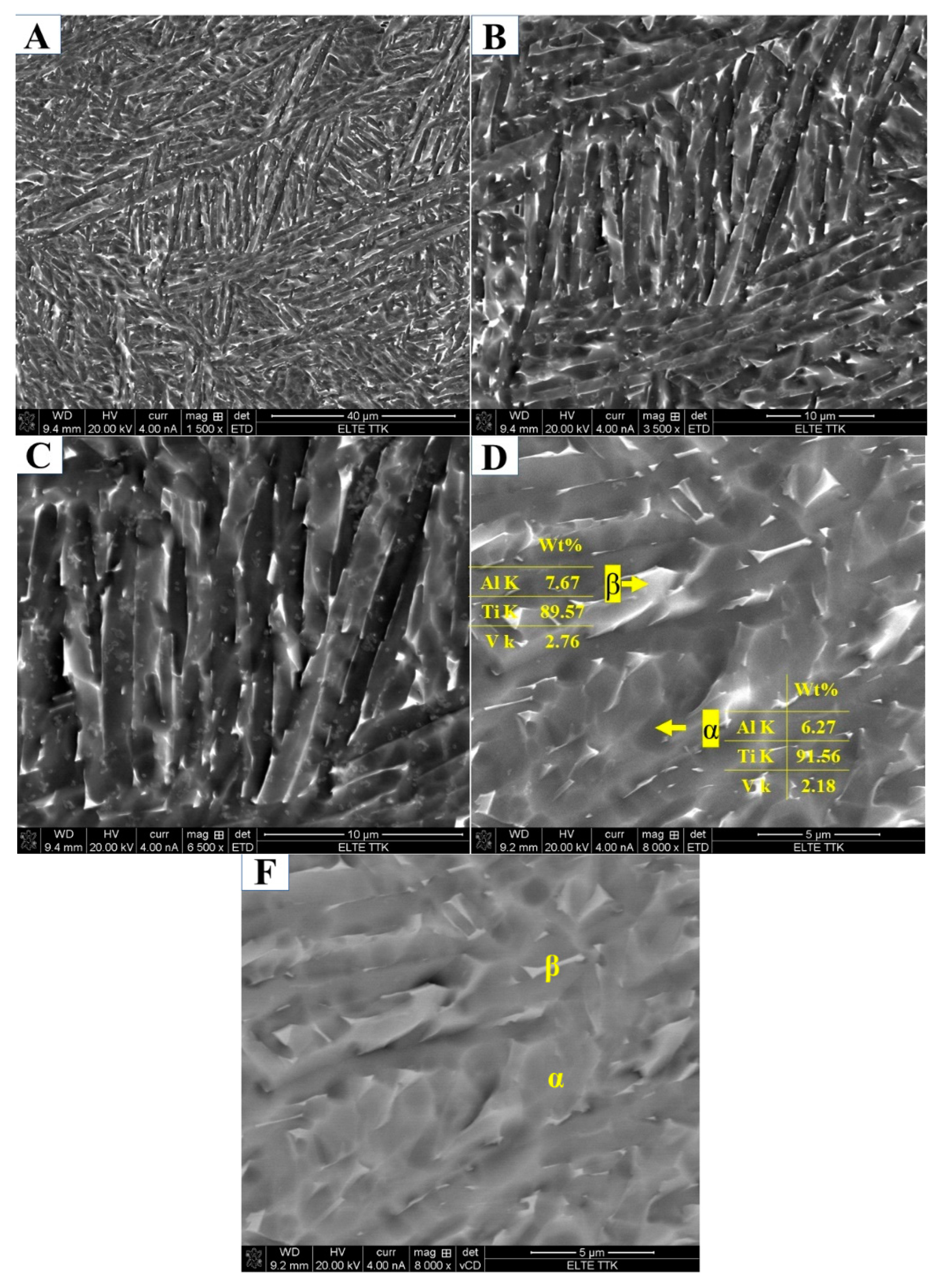

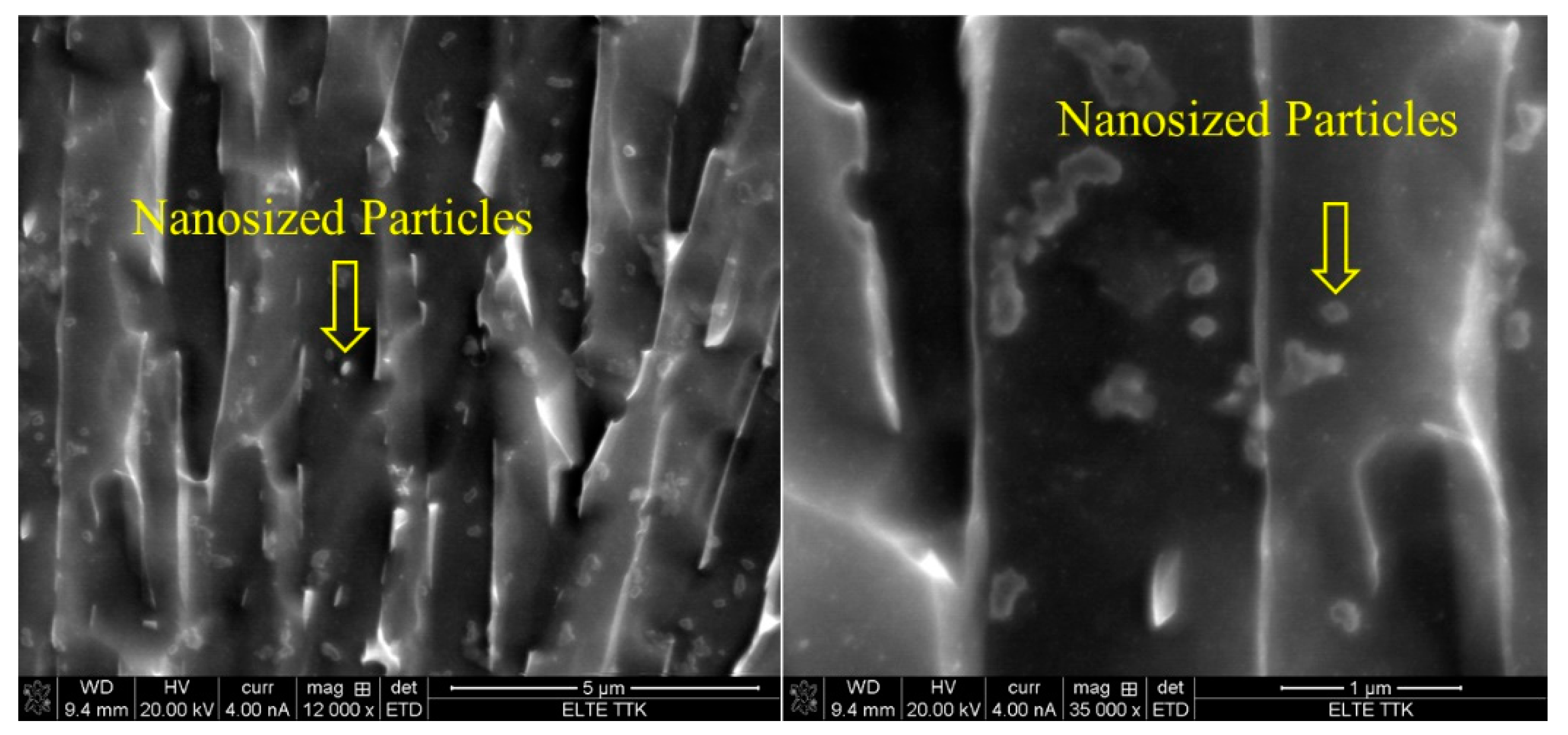

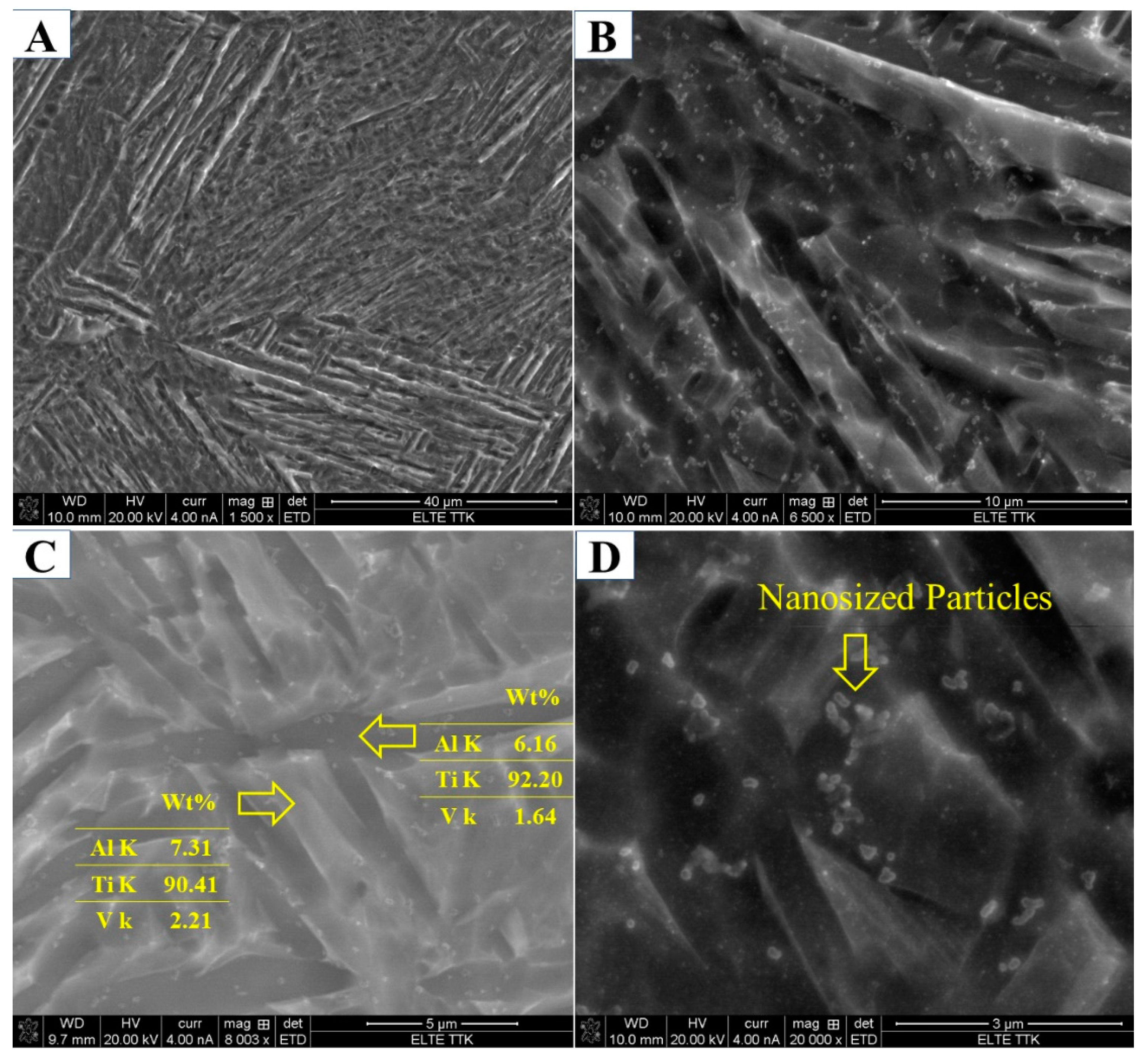

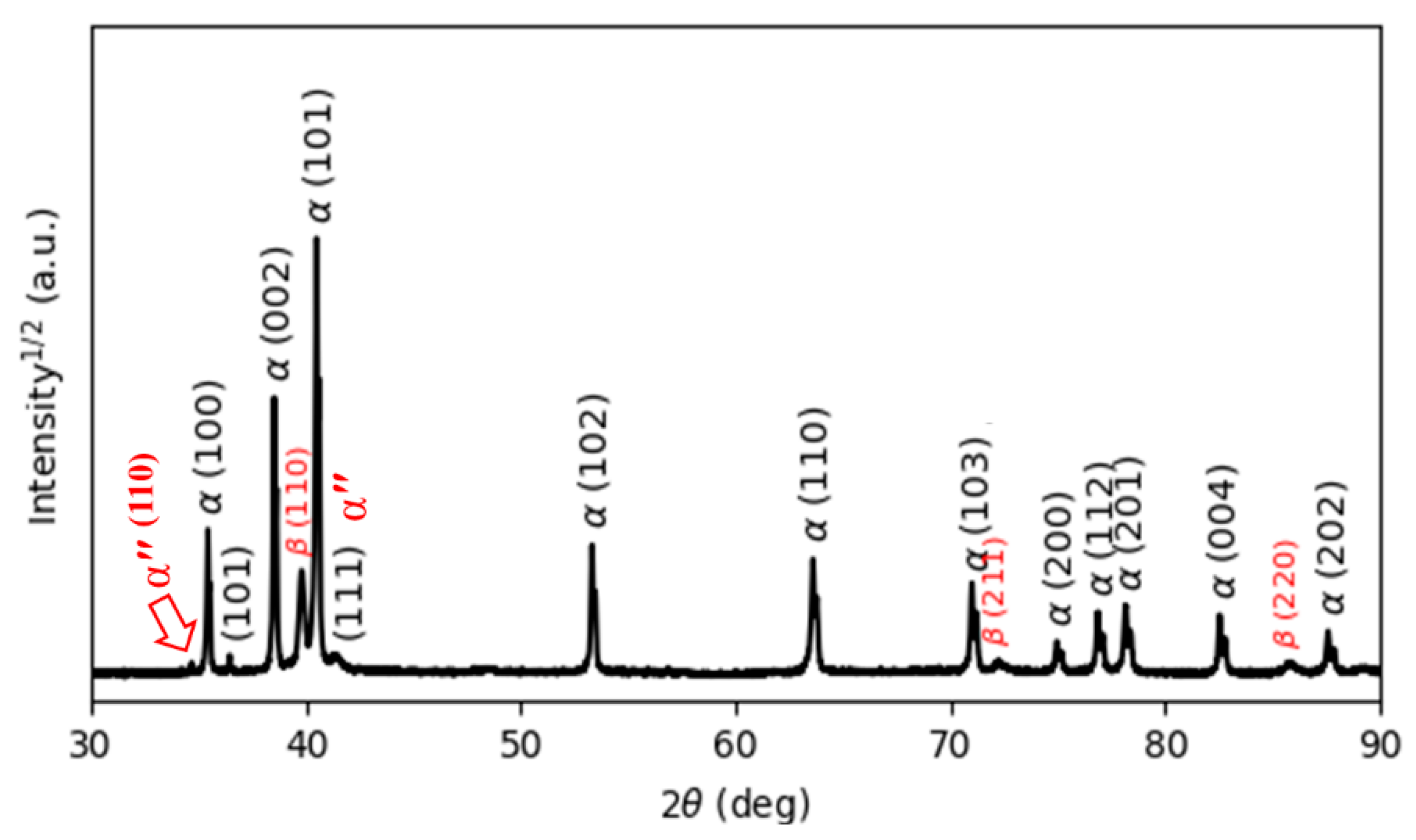

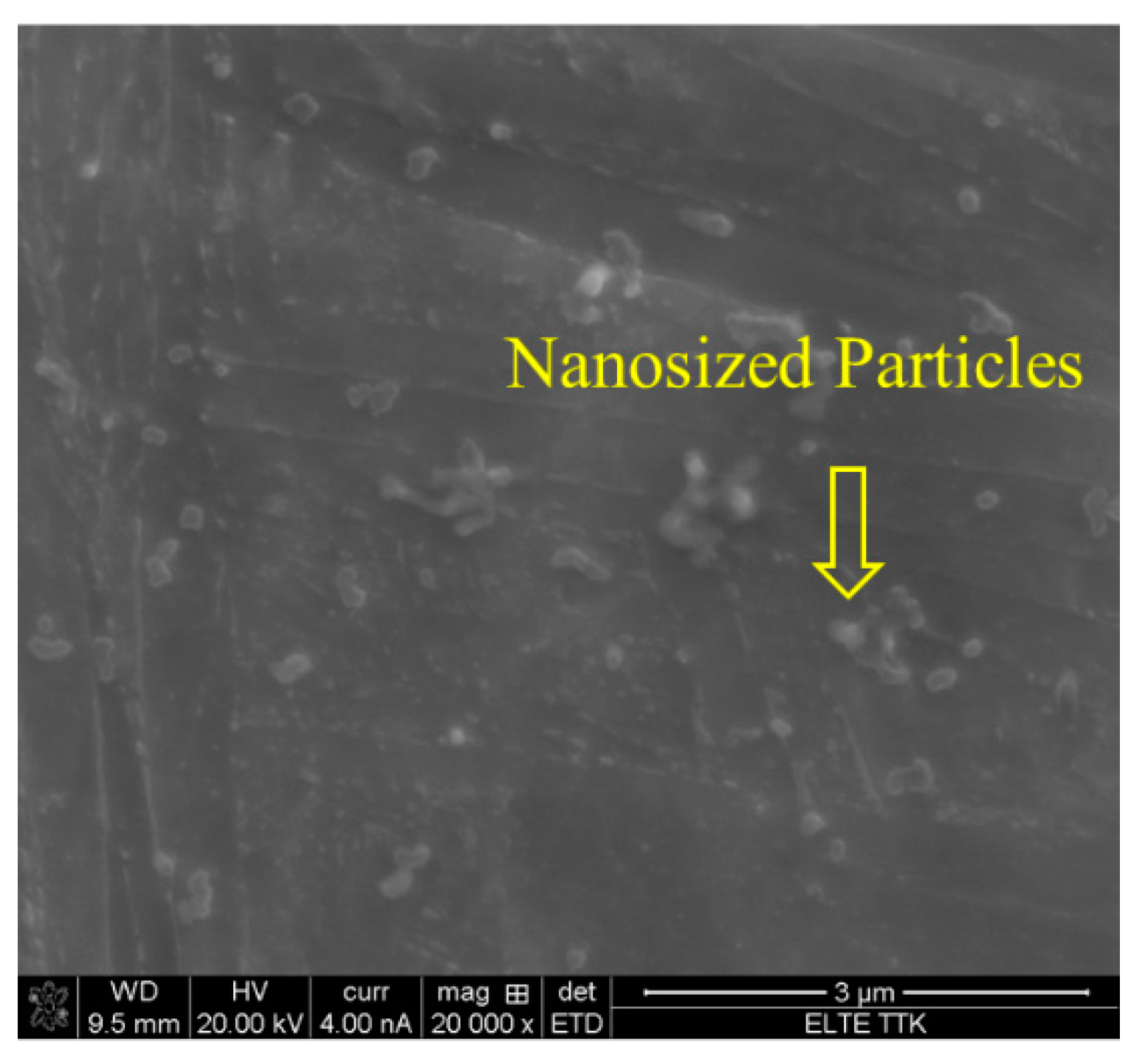

- In the microstructure of Ti64, a very fine acicular martensite α′ with a small amount of β and α″ structure developed due to the extremely high cooling rate associated with the SLM. Microstructural observations confirmed the complete decomposition of the fine acicular martensite α′ during the post-heat treatment cycle, the transformation of α′ to α, β, and α″ phases, and the formation of some nanoscale β particles during the cooling stage, confirming the need for post-treatments after SLM of Ti64.

- The best mechanical properties were obtained by heat treatment at 850 °C followed by cooling in the furnace. This heat treatment enhanced the ductility to 13%, compared to 8% for as-manufactured specimens. The improved ductility of HT850FC can be attributed to the complete decomposition of α′ into mainly α plus β and a small amount of α″ phases as well as the coarsening of the microstructure of HT850FC compared to the original fine α′ martensite.

- No improvement in mechanical properties was observed for HT850WC due to the formation of soft orthorhombic α″, α, and β. The presence of α″ is responsible for a significant decrease in hardness.

- The microstructure of HT1020FC is characterized by the formation of an α + β lamellar structure. In contrast, the microstructure of HT1020WC is characterized by the formation of semi-equiaxial β grains with a diameter of about 170 µm with longer elongated α grains and basket-weave α′. Moreover, XRD analysis confirmed the presence of α″.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alcisto, J.; Enriquez, A.; Garcia, H.; Hinkson, S.; Steelman, T.; Silverman, E.; Valdovino, P.; Gigerenzer, H.; Foyos, J.; Ogren, J.; et al. Tensile properties and microstructures of laser-formed Ti-6Al-4V. J. Mater. Eng. Perform. 2011, 20, 203–212. [Google Scholar] [CrossRef]

- Niinomi, M.; Narushima, T.; Nakai, M. Advances in Metallic Biomaterials Processing and Applications; Springer Series in Biomaterials Science and Engineering; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 9783662468418. [Google Scholar]

- Shipley, H.; Mcdonnell, D.; Culleton, M.; Coull, R.; Lupoi, R.; Donnell, G.O.; Trimble, D. Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: A review. Int. J. Mach. Tools Manuf. 2018, 128, 1–20. [Google Scholar] [CrossRef]

- Hassanen, J.; Tunde, K. Selective laser melting of Ti alloys and hydroxyapatite for tissue engineering: Progress and challenges. Mater. Res. Express 2019, 6, 082003. [Google Scholar] [CrossRef]

- Zhao, Z.Y.; Li, L.; Bai, P.K.; Jin, Y.; Wu, L.Y.; Li, J.; Guan, R.G.; Qu, H.Q. The heat treatment influence on the microstructure and hardness of TC4 titanium alloy manufactured via selective laser melting. Materials 2018, 11, 1318. [Google Scholar] [CrossRef] [Green Version]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Jaber, H.; Kónya, J.; Kovács, T.A. Selective laser melting of ti6al4v-2%hydroxyapatite composites: Manufacturing behavior and microstructure evolution. Metals 2021, 11, 1295. [Google Scholar] [CrossRef]

- Jaber, H.; Kovacs, T.; János, K. Investigating the impact of a selective laser melting process on Ti6Al4V alloy hybrid powders with spherical and irregular shapes. Adv. Mater. Process. Technol. 2020. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Debroy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Cottam, R.; Palanisamy, S.; Avdeev, M.; Jarvis, T.; Henry, C.; Cuiuri, D.; Balogh, L.; Rashid, R.A.R. Diffraction line profile analysis of 3D wedge samples of Ti-6Al-4V fabricated using four different additive manufacturing processes. Metals 2019, 9, 60. [Google Scholar] [CrossRef] [Green Version]

- Motyka, M.; Kubiak, K.; Sieniawski, J.; Ziaja, W. Phase Transformations and Characterization of α + β Titanium Alloys. In Comprehensive Materials Processing; Elsevier: Amsterdam, The Netherlands, 2014; Volume 2, pp. 7–36. ISBN 9780080965338. [Google Scholar]

- Xu, W.; Brandt, M.; Sun, S.; Elambasseril, J.; Liu, Q.; Latham, K.; Xia, K.; Qian, M. Additive manufacturing of strong and ductile Ti–6Al–4V by selective laser melting via in situ martensite decomposition. Acta Mater. 2015, 85, 74–84. [Google Scholar] [CrossRef]

- Vandenbroucke, B.; Kruth, J.P. Selective laser melting of biocompatible metals for rapid manufacturing of medical parts. Rapid Prototyp. J. 2007, 13, 196–203. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-Fabricated and Heat-Treated Microstructures of the Ti-6Al-4V Alloy Processed by Selective Laser Melting. Metall. Mater. Trans. A 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

- Murr, L.E.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Rodela, A.; Martinez, E.Y.; Hernandez, D.H.; Martinez, E.; Medina, F.; Wicker, R.B. Microstructure and mechanical behavior of Ti-6Al-4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. Mater. 2009, 2, 20–32. [Google Scholar] [CrossRef]

- Facchini, L.; Magalini, E.; Robotti, P.; Molinari, A.; Höges, S.; Wissenbach, K.; Facchini, L.; Magalini, E.; Robotti, P.; Molinari, A.; et al. Ductility of a Ti-6Al-4V alloy produced by selective laser melting of prealloyed powders. Rapid Prototyp. J. 2011, 16, 450–459. [Google Scholar] [CrossRef]

- Vrancken, B. Study of Residual Stresses in Selective Laser Melting Supervisor; KU Leuven: Leuven, Belgium, 2016. [Google Scholar]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.A.; Maier, H.J. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- ASTM International F136-13; Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications (UNS R56401). ASTM International: West Conshohocken, PA, USA, 2013. [CrossRef]

- ASTM International F2924-14; Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium with Powder Bed Fusion 1. ASTM International: West Conshohocken, PA, USA, 2014; Volume i, pp. 1–9. [CrossRef]

- Xu, W.; Lui, E.W.; Pateras, A.; Qian, M.; Brandt, M. In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater. 2017, 125, 390–400. [Google Scholar] [CrossRef]

- Ali, H.; Ma, L.; Ghadbeigi, H.; Mumtaz, K. In-situ residual stress reduction, martensitic decomposition and mechanical properties enhancement through high temperature powder bed pre-heating of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A 2017, 695, 211–220. [Google Scholar] [CrossRef]

- Qiu, C.; Adkins, N.J.E.; Attallah, M.M. Microstructure and tensile properties of selectively laser-melted and of HIPed laser-melted Ti-6Al-4V. Mater. Sci. Eng. A 2013, 578, 230–239. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.; Humbeeck, J. Van ScienceDirect Microstructure and mechanical properties of a novel b titanium metallic composite by selective laser melting. Acta Mater. 2014, 68, 150–158. [Google Scholar] [CrossRef] [Green Version]

- Muhammad, M.; Pegues, J.W.; Shamsaei, N.; Haghshenas, M. Effect of heat treatments on microstructure / small-scale properties of additive manufactured Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 103, 4161–4172. [Google Scholar] [CrossRef]

- Guo, Z.; Malinov, S.; Sha, W. Modelling beta transus temperature of titanium alloys using artificial neural network. Comput. Mater. Sci. 2005, 32, 1–12. [Google Scholar] [CrossRef]

- Lütjering, G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys. Mater. Sci. Eng. A 1998, 243, 32–45. [Google Scholar] [CrossRef]

- Ahmed, T.; Rack, H.J. Phase transformations during cooling in α+β titanium alloys. Mater. Sci. Eng. A 1998, 243, 206–211. [Google Scholar] [CrossRef]

- ASTM: E407; Standard Practice for Microetching Metals and Alloys 1. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- Malinov, S.; Sha, W.; Guo, Z.; Tang, C.C.; Long, A.E. Synchrotron X-ray diffraction study of the phase transformations in titanium alloys. Mater. Charact. 2002, 48, 279–295. [Google Scholar] [CrossRef] [Green Version]

- Kazantseva, N.; Krakhmalev, P.; Thuvander, M.; Yadroitsev, I.; Vinogradova, N.; Ezhov, I. Martensitic transformations in Ti-6Al-4V (ELI) alloy manufactured by 3D Printing. Mater. Charact. 2018, 146, 101–112. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting. Mater. Des. 2016, 108, 308–318. [Google Scholar] [CrossRef]

- Haar, G.M.T.; Becker, T.H. Selective Laser Melting Produced Ti-6Al-4V: Post-Process Heat Treatments to Achieve Superior Tensile Properties. Materials 2018, 11, 146. [Google Scholar] [CrossRef] [Green Version]

- Premkumar, M.; Singh, A.K. Deformation behavior of an ordered B2 phase in Ti-25Al-25Zr alloy. Intermetallics 2010, 18, 199–201. [Google Scholar] [CrossRef]

- Brandl, E.; Schoberth, A.; Leyens, C. Morphology, microstructure, and hardness of titanium (Ti-6Al-4V) blocks deposited by wire-feed additive layer manufacturing (ALM). Mater. Sci. Eng. A 2012, 532, 295–307. [Google Scholar] [CrossRef]

- Katzarov, I.; Malinov, S.; Sha, W. Finite element modeling of the morphology of β to α phase transformation in Ti-6Al-4V alloy. Metall. Mater. Trans. A 2002, 33, 1027–1040. [Google Scholar] [CrossRef]

- Etesami, S.A.; Fotovvati, B.; Asadi, E. Heat treatment of Ti-6Al-4V alloy manufactured by laser-based powder-bed fusion: Process, microstructures, and mechanical properties correlations. J. Alloys Compd. 2022, 895, 162618. [Google Scholar] [CrossRef]

- Wu, S.Q.; Lu, Y.J.; Gan, Y.L.; Huang, T.T.; Zhao, C.Q.; Lin, J.J.; Guo, S.; Lin, J.X. Microstructural evolution and microhardness of a selective-laser-melted Ti-6Al-4V alloy after post heat treatments. J. Alloys Compd. 2016, 672, 643–652. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin, Germany, 2006; ISBN 9783642057274. [Google Scholar]

| (Mass%) | Al | V | Fe | O | N | C | H | Ti | |

|---|---|---|---|---|---|---|---|---|---|

| Ti6Al4V powder | 6.11 | 4.02 | 0.17 | 0.090 | 0.023 | 0.01 | 0.003 | Bal | |

| ASTM B348 Gr.23 | Max | 6.50 | 4.50 | 0.25 | 0.13 | 0.03 | 0.08 | 0.0125 | Bal |

| Min | 5.50 | 3.50 | - | - | - | - | - | - | |

| Process | α/α′ Phase | β Phase | ||||||

|---|---|---|---|---|---|---|---|---|

| Lattice Parameters (Å) | (101) | Lattice Parameters (Å) | (110) | |||||

| Sample Name | a | c | c/a | 2θ° | FWHM | a | 2θ° | FWHM |

| As-printed | 2.9324 | 4.6716 | 1.5930 | 40.56 | 0.1466 | - | - | - |

| HT850FC | 2.9218 | 4.6667 | 1.5972 | 40.54 | 0.0876 | 3.1989 | 39.80 | 0.253 |

| HT850WC | 2.9236 | 4.6701 | 1.5973 | 40.51 | 0.094 | 3.2419 | 39.25 | 0.27 |

| HT850WC + AG | 2.9228 | 4.6692 | 1.5975 | 40.52 | 0.0792 | 3.2001 | 39.80 | 0.211 |

| HT1020FC | 2.9264 | 4.6819 | 1.5956 | 40.46 | 0.1008 | 3.2316 | 39.41 | 0.366 |

| HT1020WC | 2.9295 | 4.6699 | 1.5968 | 40.43 | 0.114 | - | - | - |

| HT1020WC + AG | 2.9238 | 4.6714 | 1.5977 | 40.47 | 0.1373 | 3.1973 | 39.80 | 0.243 |

| No. | T/°C | t/h | Cooling Rate | Aging | YS/MPa | UTS/MPa | T.E% | ||

|---|---|---|---|---|---|---|---|---|---|

| T/°C | t/h | Cooling | |||||||

| 1 | 1060 | 1180 | 8 | ||||||

| 2 | 850 | 2 | FC | - | - | - | 932 | 986 | 13 |

| 3 | 850 | 2 | WC | - | - | - | 870 | 930 | 10.4 |

| 4 | 850 | 2 | WC | 550 | 3 | FC | 892 | 970 | 9.3 |

| 5 | 1020 | 1 | FC | - | - | - | 748 | 833 | 14.5 |

| 6 | 1020 | 1 | WC | - | - | - | 878 | 990 | 8.6 |

| 7 | 1020 | 1 | WC | 550 | 3 | FC | 944 | 1035 | 7.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaber, H.; Kónya, J.; Kulcsár, K.; Kovács, T. Effects of Annealing and Solution Treatments on the Microstructure and Mechanical Properties of Ti6Al4V Manufactured by Selective Laser Melting. Materials 2022, 15, 1978. https://doi.org/10.3390/ma15051978

Jaber H, Kónya J, Kulcsár K, Kovács T. Effects of Annealing and Solution Treatments on the Microstructure and Mechanical Properties of Ti6Al4V Manufactured by Selective Laser Melting. Materials. 2022; 15(5):1978. https://doi.org/10.3390/ma15051978

Chicago/Turabian StyleJaber, Hassanen, János Kónya, Klaudia Kulcsár, and Tünde Kovács. 2022. "Effects of Annealing and Solution Treatments on the Microstructure and Mechanical Properties of Ti6Al4V Manufactured by Selective Laser Melting" Materials 15, no. 5: 1978. https://doi.org/10.3390/ma15051978

APA StyleJaber, H., Kónya, J., Kulcsár, K., & Kovács, T. (2022). Effects of Annealing and Solution Treatments on the Microstructure and Mechanical Properties of Ti6Al4V Manufactured by Selective Laser Melting. Materials, 15(5), 1978. https://doi.org/10.3390/ma15051978