Influence of Phosphorus Sources on the Compressive Strength and Microstructure of Ferronickel Slag-Based Magnesium Phosphate Cement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Sample Preparation

2.3. Test Methods and Characterization

3. Results and Discussion

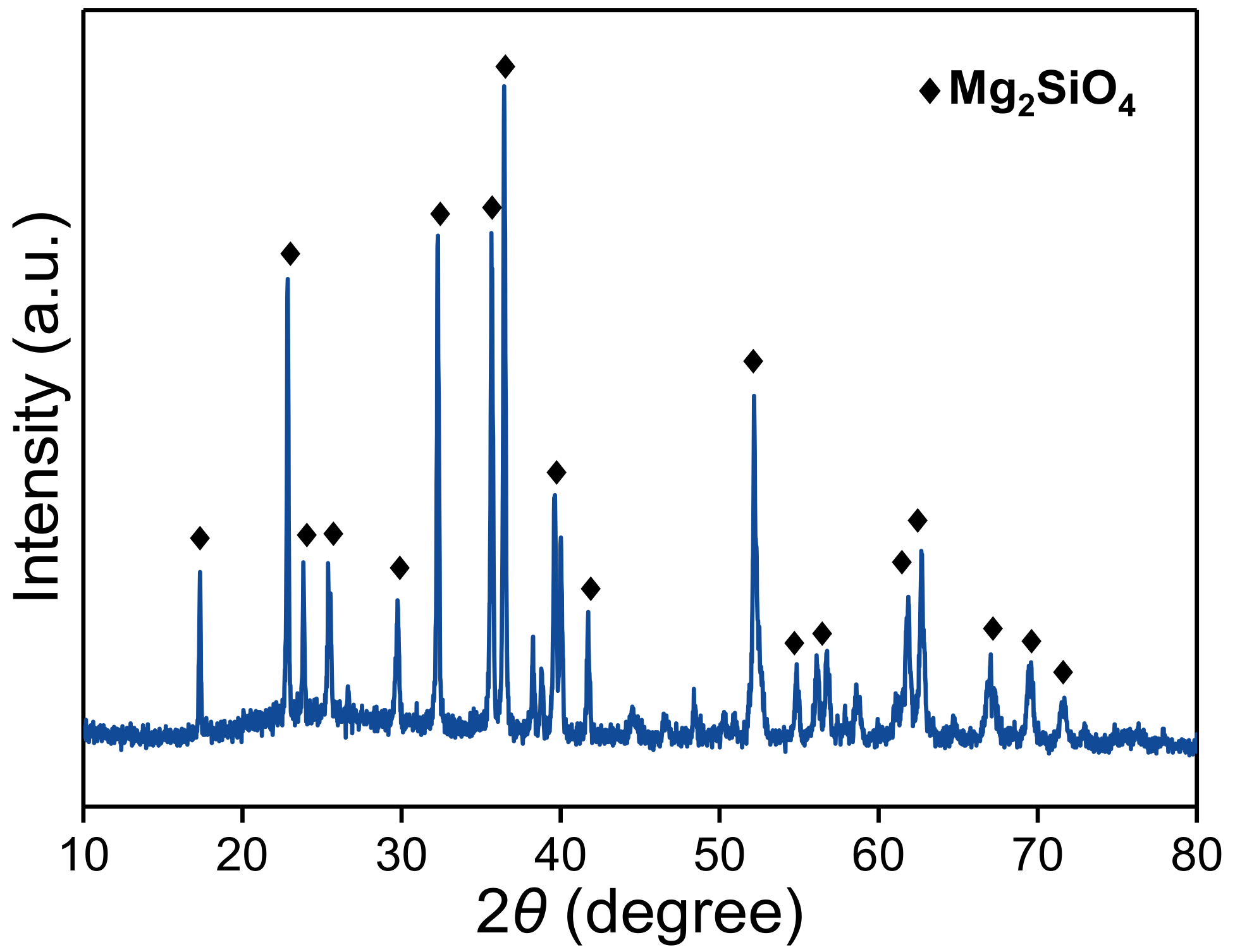

3.1. Physical and Chemical Properties of EFS

3.2. Mechanical Property and the Evolution of the Hydration Temperature of EMPC Paste

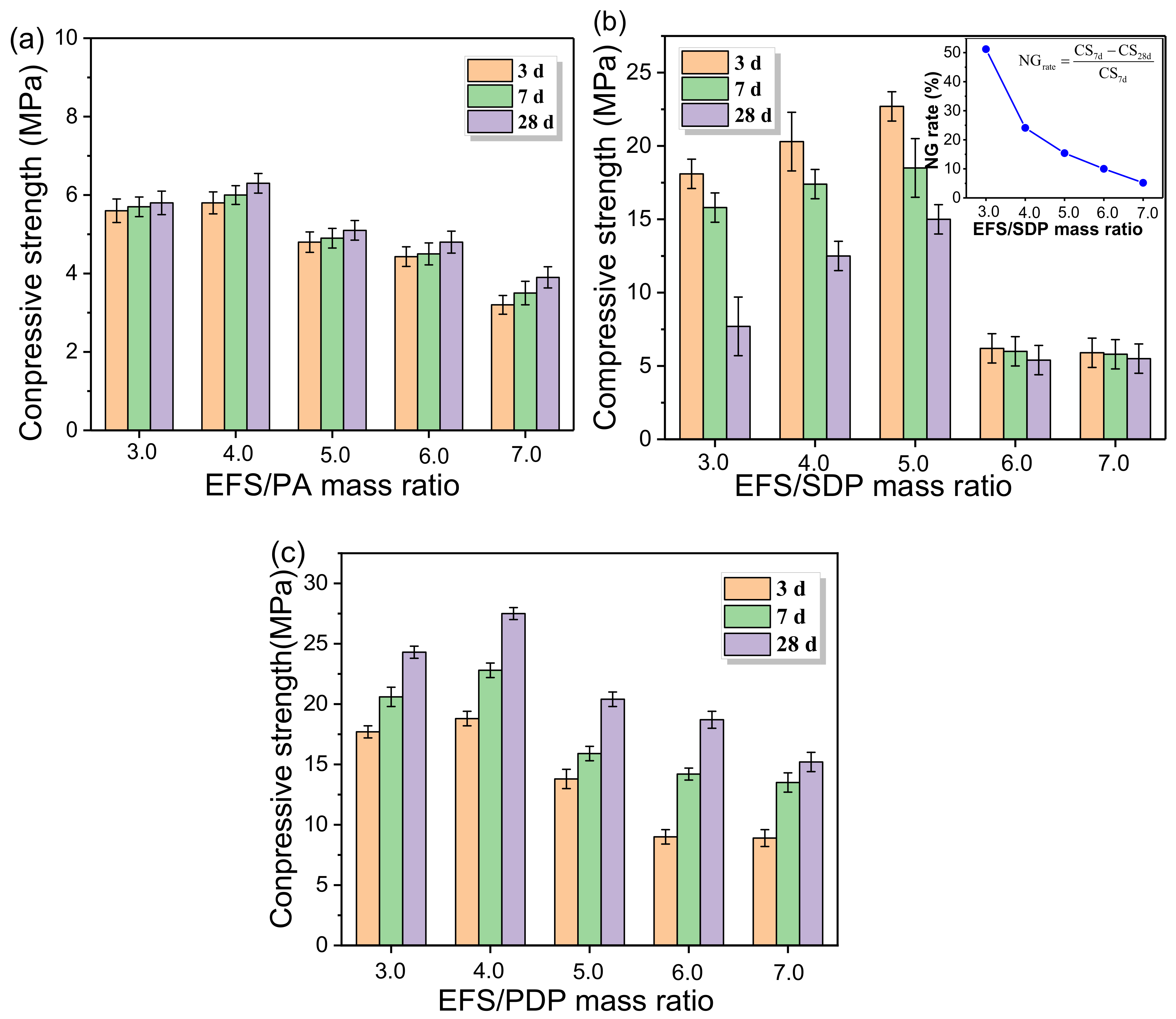

3.2.1. Effect of the Raw Materials Ratio on the Compressive Strength of EMPC Paste

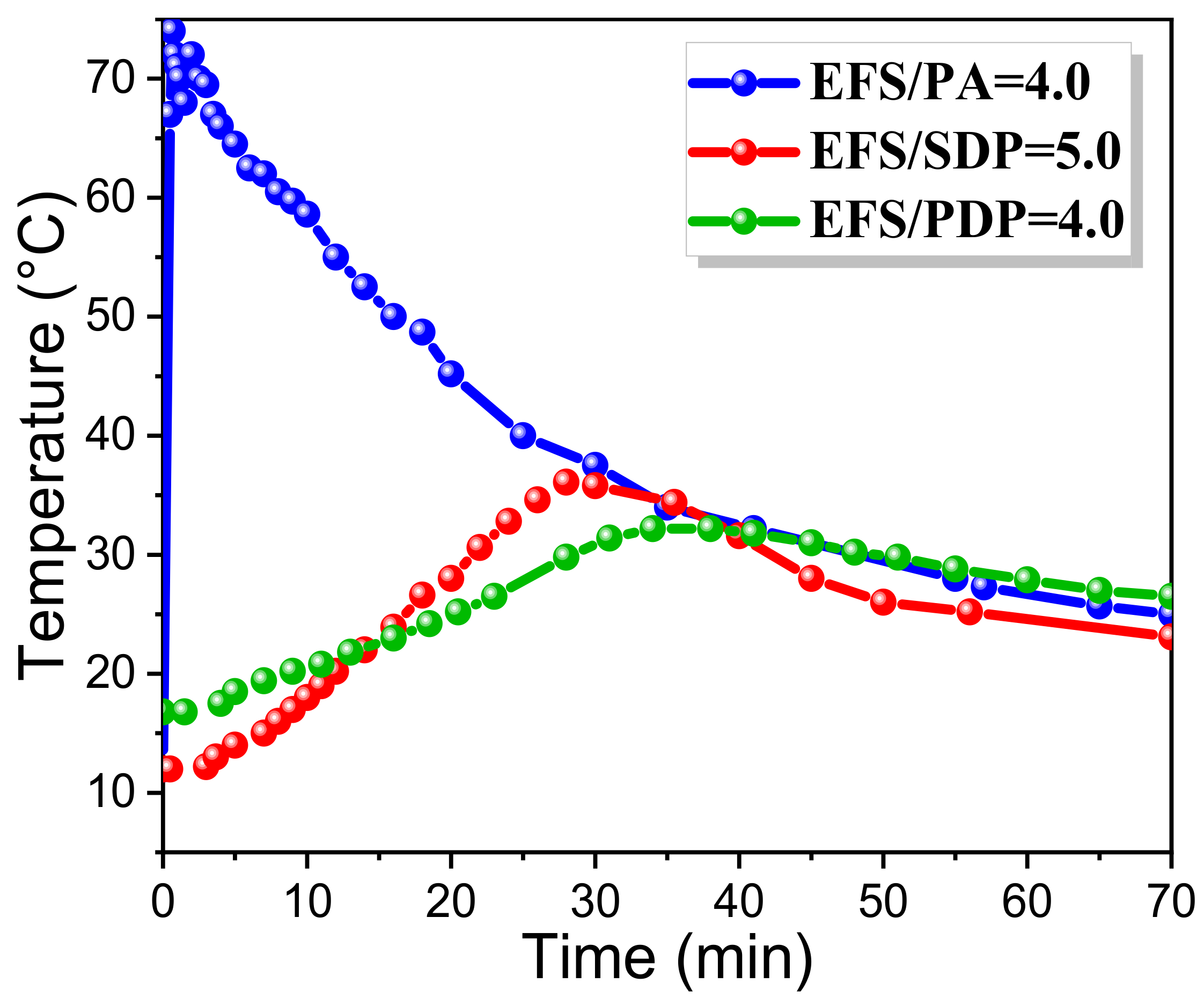

3.2.2. Early Hydration Temperature Analysis of EMPC Paste

3.3. Characterization of EMPC Pastes

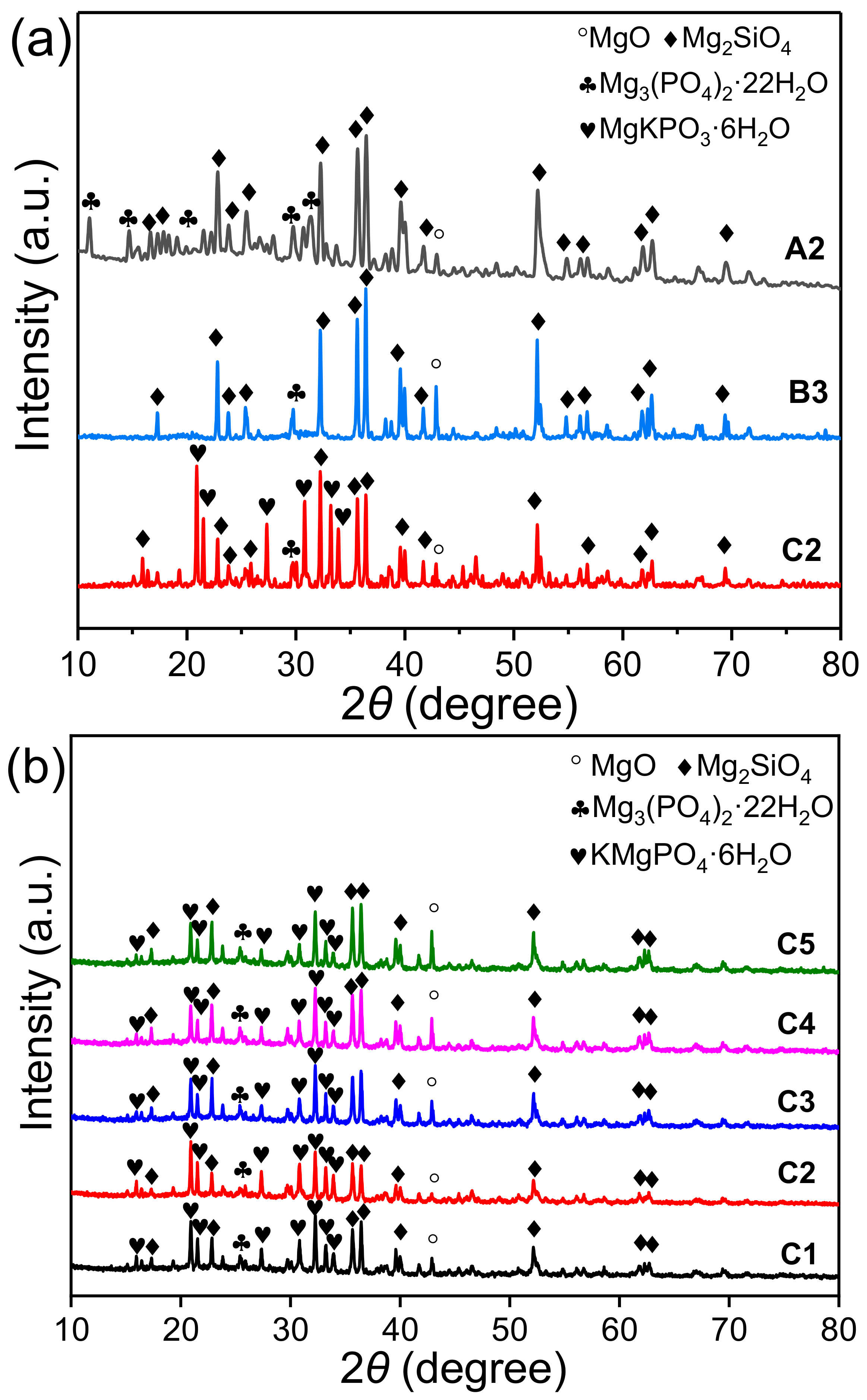

3.3.1. Mineralogical Composition Analysis

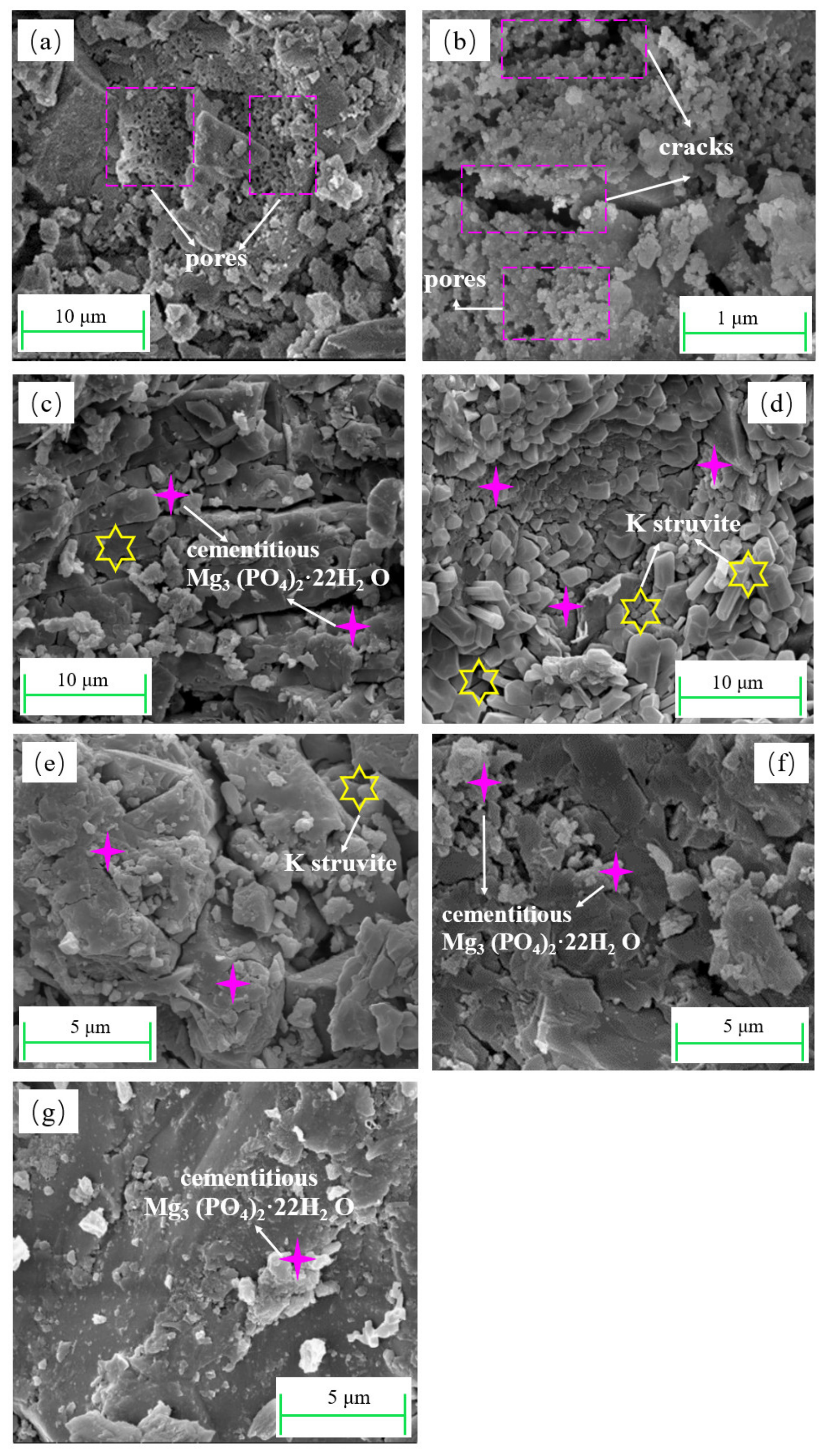

3.3.2. SEM Analysis of EMPC Paste

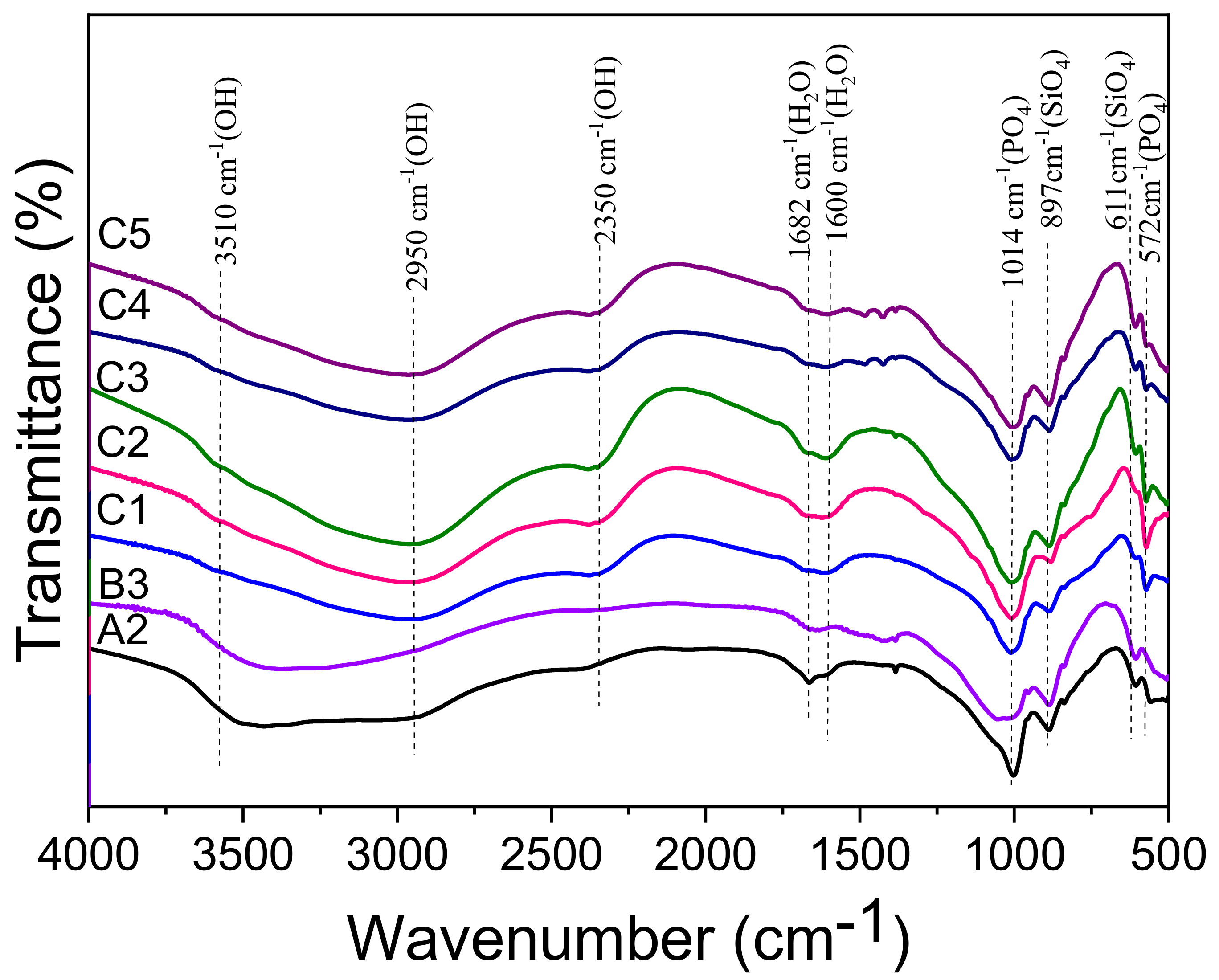

3.3.3. FTIR Analysis

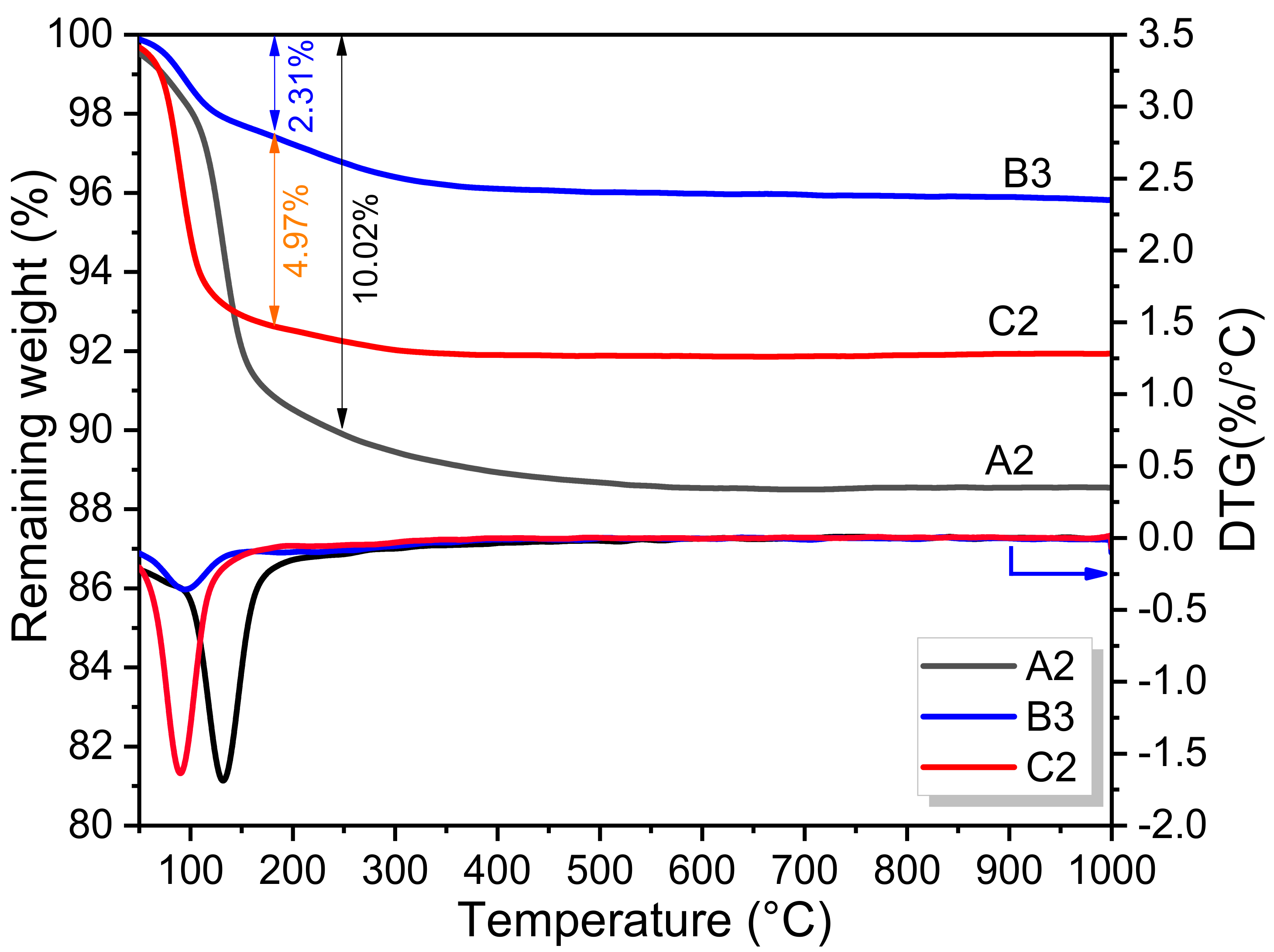

3.3.4. TG/DTG Analysis

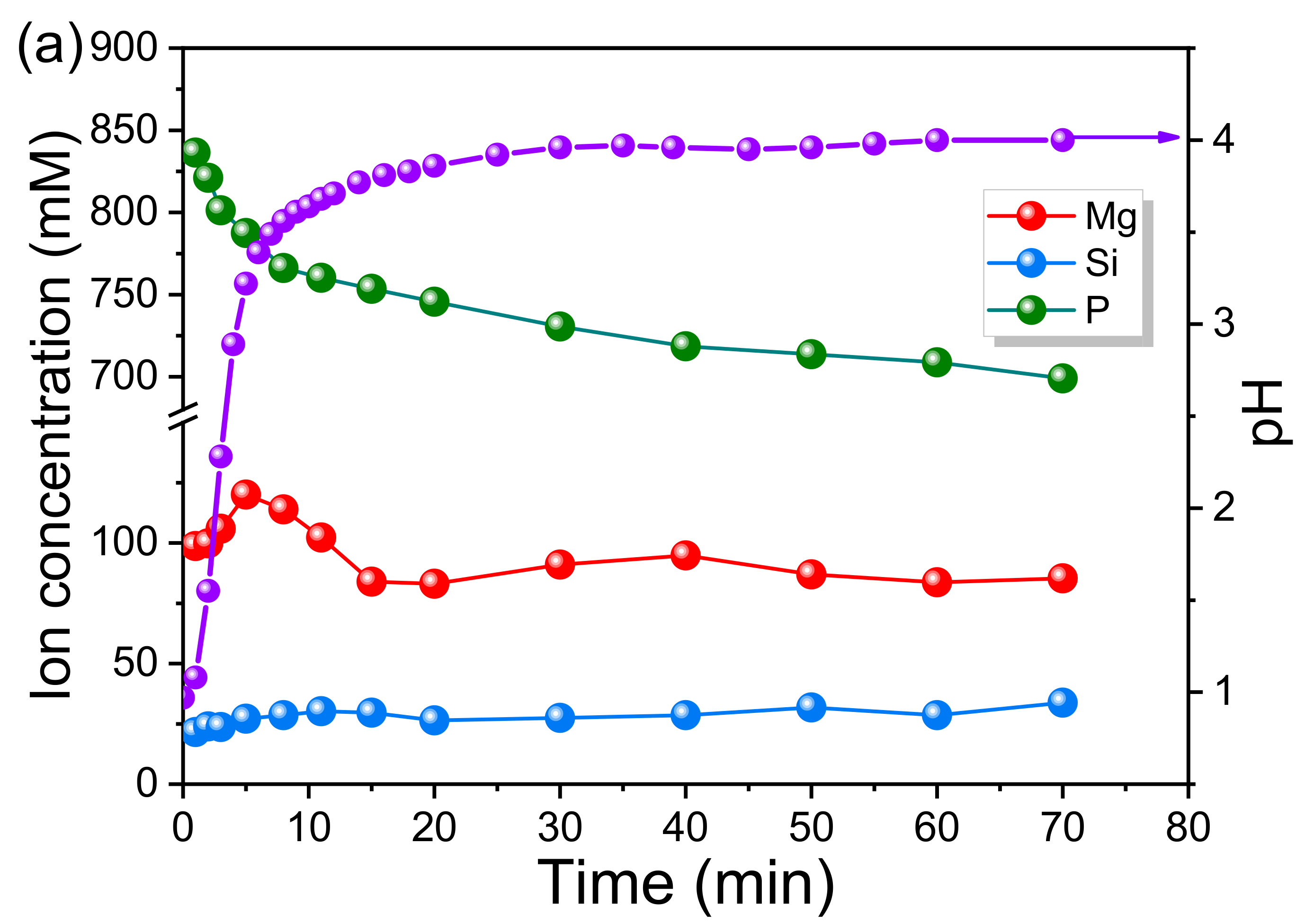

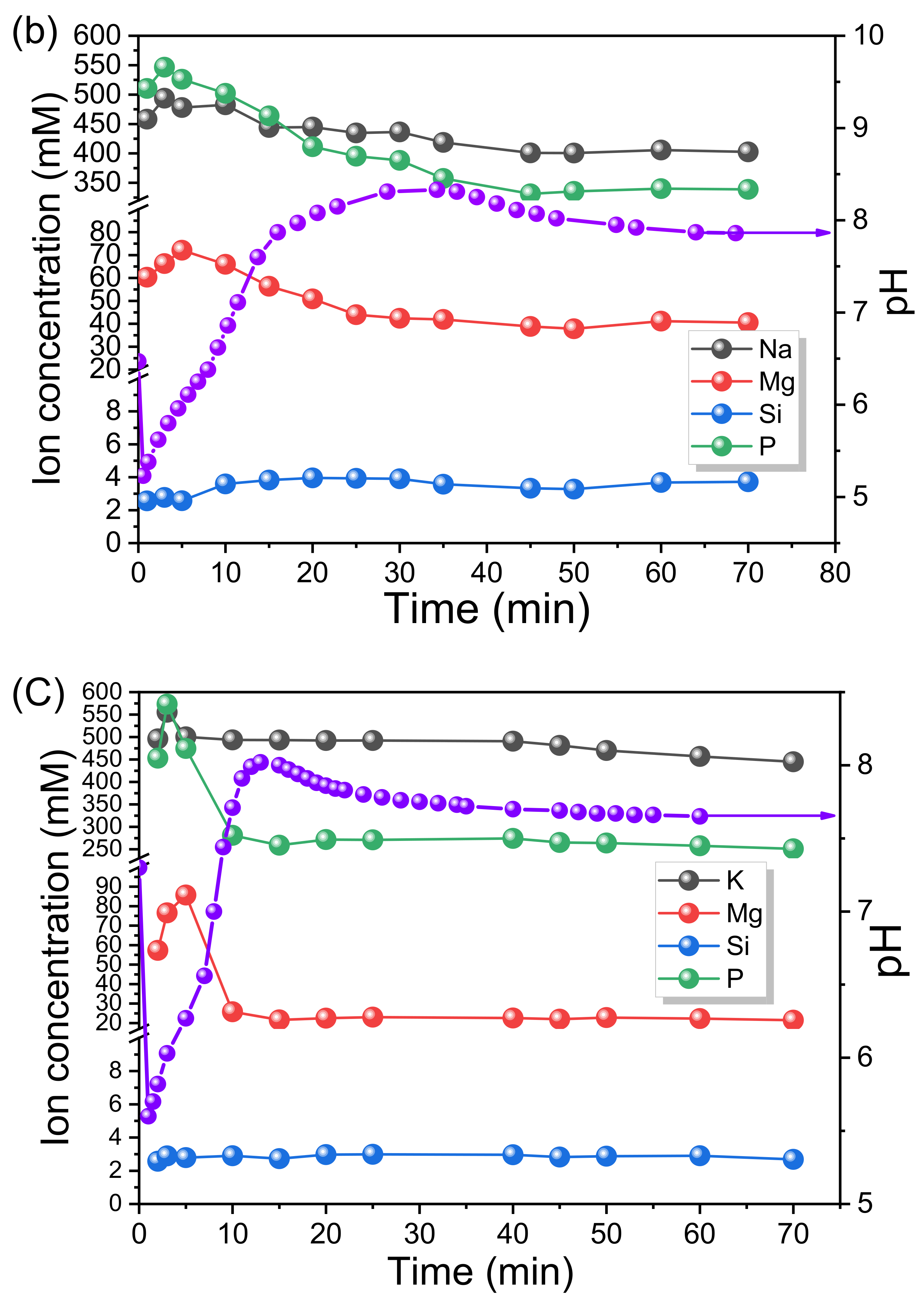

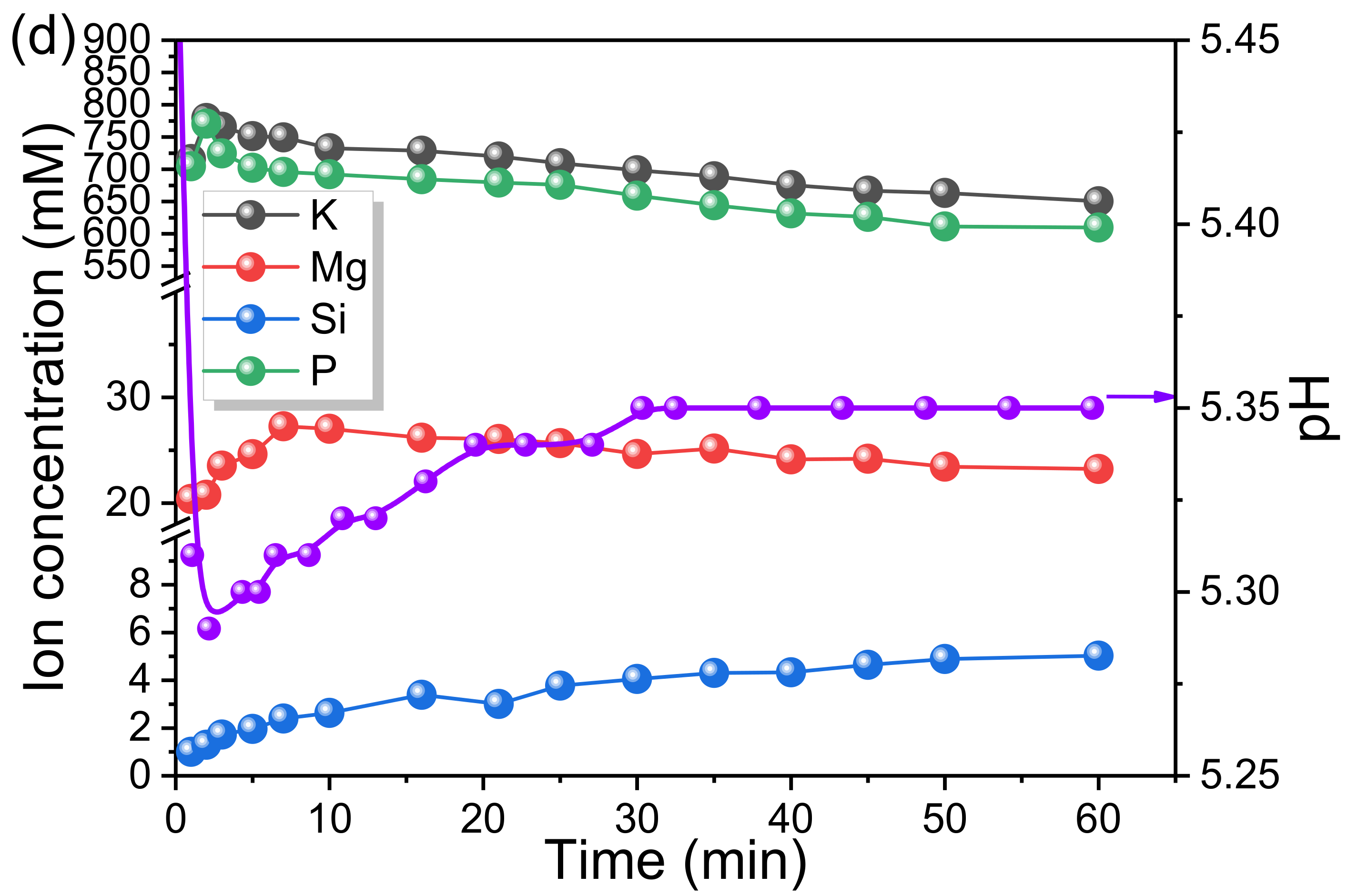

3.4. Evolutions of pH and Ions Concentrations in EMPC Suspension

3.5. Discussion of the Hydration Mechanism of EMPC

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xi, B.; Li, R.; Zhao, X.; Dang, Q.; Zhang, D.; Tan, W. Constraints and opportunities for the recycling of growing ferronickel slag in China. Resour. Conserv. Recycl. 2018, 139, 15–16. [Google Scholar] [CrossRef]

- Peng, Z.; Gu, F.; Zhang, Y.; Tang, H.; Ye, L.; Tian, W.; Liang, G.; Rao, M.; Li, G.; Jiang, T. Chromium: A Double-Edged Sword in Preparation of Refractory Materials from Ferronickel Slag. ACS Sustain. Chem. Eng. 2018, 8, 10536–10544. [Google Scholar] [CrossRef]

- Bian, Z.; Jin, G.; Ji, T. Effect of combined activator of Ca(OH)2 and Na2CO3 on workability and compressive strength of alkali-activated ferronickel slag system. Cem. Concr. Compos. 2021, 123, 104179. [Google Scholar] [CrossRef]

- Gu, F.; Peng, Z.; Zhang, Y.; Tang, H.; Ye, L.; Tian, W.; Liang, G.; Lee, J.; Rao, M.; Li, G. Thermodynamic Characteristics of Ferronickel Slag Sintered in the Presence of Magnesia. In Characterization of Minerals, Metals, and Materials; Springer: Berlin/Heidelberg, Germany, 2019; pp. 379–388. [Google Scholar]

- Kuri, J.C.; Majhi, S.; Sarker, P.K.; Mukherjee, A. Microstructural and non-destructive investigation of the effect of high temperature exposure on ground ferronickel slag blended fly ash geopolymer mortars. J. Build. Eng. 2021, 43, 103099. [Google Scholar] [CrossRef]

- Kuri, J.C.; Sarker, P.K.; Shaikh, F.U.A. Sulphuric acid resistance of ground ferronickel slag blended fly ash geopolymer mortar. Constr. Build. Mater. 2021, 313, 125505. [Google Scholar] [CrossRef]

- Komnitsas, K.; Zaharaki, D.; Bartzas, G. Effect of sulphate and nitrate anions on heavy metal immobilisation in ferronickel slag geopolymers. Appl. Clay Sci. 2013, 73, 103–109. [Google Scholar] [CrossRef]

- Bouasria, M.; Babouri, L.; Khadraoui, F.; Chateigner, D.; Gascoin, S.; Pralong, V.; Benzaama, M.-H.; Orberger, B.; El Mendili, Y. Insight into the partial replacement of cement by ferronickel slags from New Caledonia. Eur. J. Environ. Civ. Eng. 2020, 1–19. [Google Scholar] [CrossRef]

- Choi, S.-J.; Kim, J.-H.; Bae, S.-H.; Oh, T.-G. Effect of Fly Ash on Compressive Strength, Drying Shrinkage, and Carbonation Depth of Mortar with Ferronickel-Slag Powder. Appl. Sci. 2021, 3, 1037. [Google Scholar] [CrossRef]

- Cosme, J.; Fernandes, G.; Fernandes, D.P. Utilization of ferronickel slag in hot mix asphalt. REM-Int. Eng. J. 2021, 1, 19–26. [Google Scholar] [CrossRef]

- Nguyen, Q.D.; Castel, A.; Kim, T.; Khan, M.S.H. Performance of fly ash concrete with ferronickel slag fine aggregate against alkali-silica reaction and chloride diffusion. Cem. Concr. Res. 2021, 139, 106265. [Google Scholar] [CrossRef]

- Saha, A.K.; Khan, M.N.N.; Sarker, P.K. Value added utilization of by-product electric furnace ferronickel slag as construction materials: A review. Resour. Conserv. Recycl. 2018, 134, 10–24. [Google Scholar] [CrossRef] [Green Version]

- Yang, L.; Peng, Z.; Huang, Y.; Wang, L.; Zheng, L.; Rao, M.; Li, G.; Jiang, T. Co-utilization of ferronickel slag and fly ash cenosphere for production of superior thermal insulation materials. Ceram. Int. 2021, 7, 10019–10026. [Google Scholar] [CrossRef]

- Wang, W.; Chen, J.; Yu, J.; Zhou, L.; Dai, S.; Tian, W. Adjusting the melting and crystallization behaviors of ferronickel slag via partially replacing of SiO2 by B2O3 for mineral wool production. Waste Manag. 2020, 111, 34–40. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, M.; Sohn, J.; Park, H. Applicability of gold tailings, waste limestone, red mud, and ferronickel slag for producing glass fibers. J. Clean. Prod. 2018, 203, 957–965. [Google Scholar] [CrossRef]

- Wang, W.; Dai, S.; Zhou, L.; Zhang, T.; Tian, W.; Xu, J. Effect of B2O3 on the properties of ferronickel melt and mineral wool. Ceram. Int. 2020, 9, 13460–13465. [Google Scholar] [CrossRef]

- Yun, J.-J.; Kang, B.-H.; Kang, S.-W.; Kim, S.-Y.; Seo, D.-C.; Cho, J.-S. Effect of fertilizers using Ferro-nickel slag on Chinese cabbage growth and soil chemical properties. Korean Soc. Soil Sci. Fertil. 2018, 51, 204–210. [Google Scholar]

- Peng, Z.; Wang, L.; Gu, F.; Tang, H.; Rao, M.; Zhang, Y.; Li, G.; Jiang, T. Recovery of chromium from ferronickel slag: A comparison of microwave roasting and conventional roasting strategies. Powder Technol. 2020, 372, 578–584. [Google Scholar] [CrossRef]

- Zulhan, Z.; Agustina, N. A novel utilization of ferronickel slag as a source of magnesium metal and ferroalloy production. J. Clean. Prod. 2021, 292, 125307. [Google Scholar] [CrossRef]

- Liu, Y.; Qin, Z.; Chen, B. Experimental research on magnesium phosphate cements modified by red mud. Constr. Build. Mater. 2020, 231, 117131. [Google Scholar] [CrossRef]

- Liao, J.; Lu, S.; Duan, X.; Xie, Y.; Zhang, Y.; Li, Y.; Zhou, A. Affecting mechanism of chitosan on water resistance of magnesium phosphate cement. Int. J. Appl. Ceram. Technol. 2018, 2, 514–521. [Google Scholar] [CrossRef]

- Haque, M.A.; Chen, B. Research progresses on magnesium phosphate cement: A review. Constr. Build. Mater. 2019, 211, 885–898. [Google Scholar] [CrossRef]

- Eliaz, N.; Metoki, N. Calcium Phosphate Bioceramics: A Review of Their History, Structure, Properties, Coating Technologies and Biomedical Applications. Materials 2017, 4, 334. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Liu, W.; Schnitzler, V.; Tancret, F.; Bouler, J.-M. Calcium phosphate cements for bone substitution: Chemistry, handling and mechanical properties. Acta Biomater. 2014, 3, 1035–1049. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, B.; Qin, Z.; Pen, D.; Aminul Haque, M. Experimental research on properties and microstructures of magnesium-iron phosphate cement. Constr. Build. Mater. 2020, 257, 119570. [Google Scholar] [CrossRef]

- Sagadin, C.; Luidold, S.; Wagner, C.; Pichler, C.; Kreuzer, D.; Spanring, A.; Antrekowitsch, H.; Clarke, A.; Clarke, K. Thermodynamic Refractory Corrosion Model for Ferronickel Manufacturing. Metall. Mater. Trans. B 2021, 2, 1052–1060. [Google Scholar] [CrossRef]

- Thompson, A.; Saha, A.K.; Sarker, P.K. Comparison of the alkali-silica reactions of ferronickel slag aggregate in fly ash geopolymer and cement mortars. Eur. J. Environ. Civ. Eng. 2019, 26, 891–904. [Google Scholar] [CrossRef]

- Yang, N.; Shi, C.; Yang, J.; Chang, Y. Research Progresses in Magnesium Phosphate Cement–Based Materials. J. Mater. Civ. Eng. 2014, 10, 04014071. [Google Scholar] [CrossRef]

- Fan, S.; Chen, B. Experimental study of phosphate salts influencing properties of magnesium phosphate cement. Constr. Build. Mater. 2014, 65, 480–486. [Google Scholar] [CrossRef]

- Kuri, J.C.; Khan, M.N.N.; Sarker, P.K. Workability, strength and microstructural properties of ground ferronickel slag blended fly ash geopolymer mortar. J. Sustain. Cem. Based Mater. 2020, 2, 1–18. [Google Scholar] [CrossRef]

- Sakkas, K.; Panias, D.; Nomikos, P.P.; Sofianos, A.I. Potassium based geopolymer for passive fire protection of concrete tunnels linings. Tunn. Undergr. Sp. Tech. 2014, 43, 148–156. [Google Scholar] [CrossRef]

- Gu, F.; Peng, Z.; Tang, H.; Ye, L.; Tian, W.; Liang, G.; Rao, M.; Zhang, Y.; Li, G.; Jiang, T. Preparation of Refractory Materials from Ferronickel Slag. In Characterization of Minerals, Metals, and Materials; Springer: Berlin/Heidelberg, Germany, 2018; pp. 633–642. [Google Scholar]

- Ostrowski, N.; Roy, A.; Kumta, P.N. Magnesium Phosphate Cement Systems for Hard Tissue Applications: A Review. ACS Biomater. Sci. Eng. 2016, 7, 1067–1083. [Google Scholar] [CrossRef] [PubMed]

- Xiao, H.; Xing, S.; Wu, C. Preparation of Magnesium Phosphate Cement and Application in Concrete Repair. In Proceedings of the 2nd International Conference on Materials Engineering and Industrial Applications, Phuket, Thailand, 6–7 August 2017; EDP Science: Ulys, France, 2018. [Google Scholar]

- Zhang, Q.; Cao, X.; Ma, R.; Sun, S.; Fang, L.; Lin, J.; Luo, J. Solid waste-based magnesium phosphate cements: Preparation, performance and solidification/stabilization mechanism. Constr. Build. Mater. 2021, 297, 123761. [Google Scholar] [CrossRef]

- Sun, D.; Wu, K.; Kang, W.; Shi, H.; Li, S. Characterisation of water stability of magnesium phosphate cement blended with steel slag and fly ash. Adv. Cem. Res. 2020, 6, 251–261. [Google Scholar] [CrossRef]

- Ruan, W.; Liao, J.; Li, F.; Gu, X.; Zhou, A.; Xie, Y. Effects of water purifying material waste and red mud on performance of magnesium phosphate cement. Constr. Build. Mater. 2021, 303, 124563. [Google Scholar] [CrossRef]

- Jiang, Y.; Ahmad, M.R.; Chen, B. Properties of magnesium phosphate cement containing steel slag powder. Constr. Build. Mater. 2019, 195, 140–147. [Google Scholar] [CrossRef]

- Luo, Z.; Ma, Y.; Mu, W.; Liu, J.; He, J.; Zhou, X. Magnesium phosphate cement prepared with electric furnace ferronickel slag: Properties and its hydration mechanism. Constr. Build. Mater. 2021, 300, 123991. [Google Scholar] [CrossRef]

- Pang, B.; Liu, J.; Wang, B.; Liu, R.; Yang, Y. Enhancement of magnesium phosphate cement solidification of Pb2+ by K-struvite whisker in lead-contaminated solution. J. Clean. Prod. 2021, 320, 128848. [Google Scholar] [CrossRef]

- Mestres, G.; Ginebra, M.P. Novel magnesium phosphate cements with high early strength and antibacterial properties. Acta Biomater. 2011, 4, 1853–1861. [Google Scholar] [CrossRef]

- Li, H.; Yao, Q.Z.; Wang, Y.Y.; Li, Y.L.; Zhou, G.T. Biomimetic synthesis of struvite with biogenic morphology and implication for pathological biomineralization. Sci. Rep. 2015, 5, 7718. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; Wu, X.; Li, H.; Tsang, D.C.W.; Li, G.; Ren, H. Struvite pyrolysate cycling technology assisted by thermal hydrolysis pretreatment to recover ammonium nitrogen from composting leachate. J. Clean. Prod. 2020, 242, 118442. [Google Scholar] [CrossRef]

- Stefov, V.; Šoptrajanov, B.; Spirovski, F.; Kuzmanovski, I.; Lutz, H.D.; Engelen, B. Infrared and Raman spectra of magnesium ammonium phosphate hexahydrate (struvite) and its isomorphous analogues. I. Spectra of protiated and partially deuterated magnesium potassium phosphate hexahydrate. J. Mol. Struct. 2004, 689, 1–10. [Google Scholar] [CrossRef]

- Zhang, T.; Ding, L.; Ren, H.; Xiong, X. Ammonium nitrogen removal from coking wastewater by chemical precipitation recycle technology. Water Res. 2009, 20, 5209–5215. [Google Scholar] [CrossRef]

- Wang, N.; Yu, H.; Bi, W.; Guan, Y.; Gong, W.; Zhang, N.; Wu, C. The Improvement Effects of NaH2PO4 and KH2PO4 on the Properties of Magnesium Oxysulfate Cement. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2021, 1, 50–57. [Google Scholar] [CrossRef]

- Colorado, H.A.; Singh, D. High-sodium waste streams stabilized with inorganic acid–base phosphate ceramics fabricated at room temperature. Ceram. Int. 2014, 7, 10621–10631. [Google Scholar] [CrossRef]

- Soudée, E.; Péra, J. Mechanism of setting reaction in magnesia-phosphate cements. Cem. Concr. Res. 2000, 2, 315–321. [Google Scholar] [CrossRef]

| Series | PS | No. | EFS/PS a | EFS (g) | PS (g) | MgO (g) | W/C b |

|---|---|---|---|---|---|---|---|

| A | H3PO4 | A1 | 3.0 | 90.0 | 30.0 | 4.5 | 0.2 |

| A2 | 4.0 | 96.0 | 24.0 | 4.8 | 0.2 | ||

| A3 | 5.0 | 100.0 | 20.0 | 4.5 | 0.2 | ||

| A4 | 6.0 | 102.9 | 17.1 | 5.1 | 0.2 | ||

| A5 | 7.0 | 105.0 | 15.0 | 5.3 | 0.2 | ||

| B | NaH2PO4 | B1 | 3.0 | 90.0 | 30.0 | 4.5 | 0.2 |

| B2 | 4.0 | 96.0 | 24.0 | 4.8 | 0.2 | ||

| B3 | 5.0 | 100.0 | 20.0 | 4.5 | 0.2 | ||

| B4 | 6.0 | 102.9 | 17.1 | 5.1 | 0.2 | ||

| B5 | 7.0 | 105.0 | 15.0 | 5.3 | 0.2 | ||

| C | KH2PO4 | C1 | 3.0 | 90.0 | 30.0 | 4.5 | 0.2 |

| C2 | 4.0 | 96.0 | 24.0 | 4.8 | 0.2 | ||

| C3 | 5.0 | 100.0 | 20.0 | 4.5 | 0.2 | ||

| C4 | 6.0 | 102.9 | 17.1 | 5.1 | 0.2 | ||

| C5 | 7.0 | 105.0 | 15.0 | 5.3 | 0.2 | ||

| S | H3PO4 | SA2 | 4.0 | 40.0 | 10.0 | 2.0 | 2.0 |

| NaH2PO4 | SB2 | 4.0 | 40.0 | 10.0 | 2.0 | 2.0 | |

| KH2PO4 | SC2 | 4.0 | 40.0 | 10.0 | 2.0 | 2.0 | |

| SC | KH2PO4 | SCC2 | 4.0 | 40.0 | 10.0 | / | 2.0 |

| Particle Size (μm) | Percentage (wt.%) |

|---|---|

| <6.30 | 24.10 |

| 6.30~12.70 | 28.52 |

| 12.7~20.69 | 16.90 |

| 20.69~48.08 | 21.56 |

| 48.08~69.68 | 5.00 |

| >69.68 | 3.92 |

| Compound | Percentage (wt.%) |

|---|---|

| SiO2 | 55.18 |

| MgO | 23.05 |

| Fe2O3 | 11.55 |

| Al2O3 | 3.37 |

| CaO | 1.85 |

| MnO | 1.79 |

| SO3 | 0.37 |

| K2O | 0.05 |

| Others | 2.79 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, C.; Ma, H.; Luo, Z.; Zhou, X.; Wang, L. Influence of Phosphorus Sources on the Compressive Strength and Microstructure of Ferronickel Slag-Based Magnesium Phosphate Cement. Materials 2022, 15, 1965. https://doi.org/10.3390/ma15051965

Yan C, Ma H, Luo Z, Zhou X, Wang L. Influence of Phosphorus Sources on the Compressive Strength and Microstructure of Ferronickel Slag-Based Magnesium Phosphate Cement. Materials. 2022; 15(5):1965. https://doi.org/10.3390/ma15051965

Chicago/Turabian StyleYan, Cuirong, Hongyan Ma, Zhongqiu Luo, Xintao Zhou, and Luxing Wang. 2022. "Influence of Phosphorus Sources on the Compressive Strength and Microstructure of Ferronickel Slag-Based Magnesium Phosphate Cement" Materials 15, no. 5: 1965. https://doi.org/10.3390/ma15051965

APA StyleYan, C., Ma, H., Luo, Z., Zhou, X., & Wang, L. (2022). Influence of Phosphorus Sources on the Compressive Strength and Microstructure of Ferronickel Slag-Based Magnesium Phosphate Cement. Materials, 15(5), 1965. https://doi.org/10.3390/ma15051965