Hydration and Properties of Magnesium Potassium Phosphate Cement Modified by Granulated Blast-Furnace Slag: Influence of Fineness

Abstract

:1. Introduction

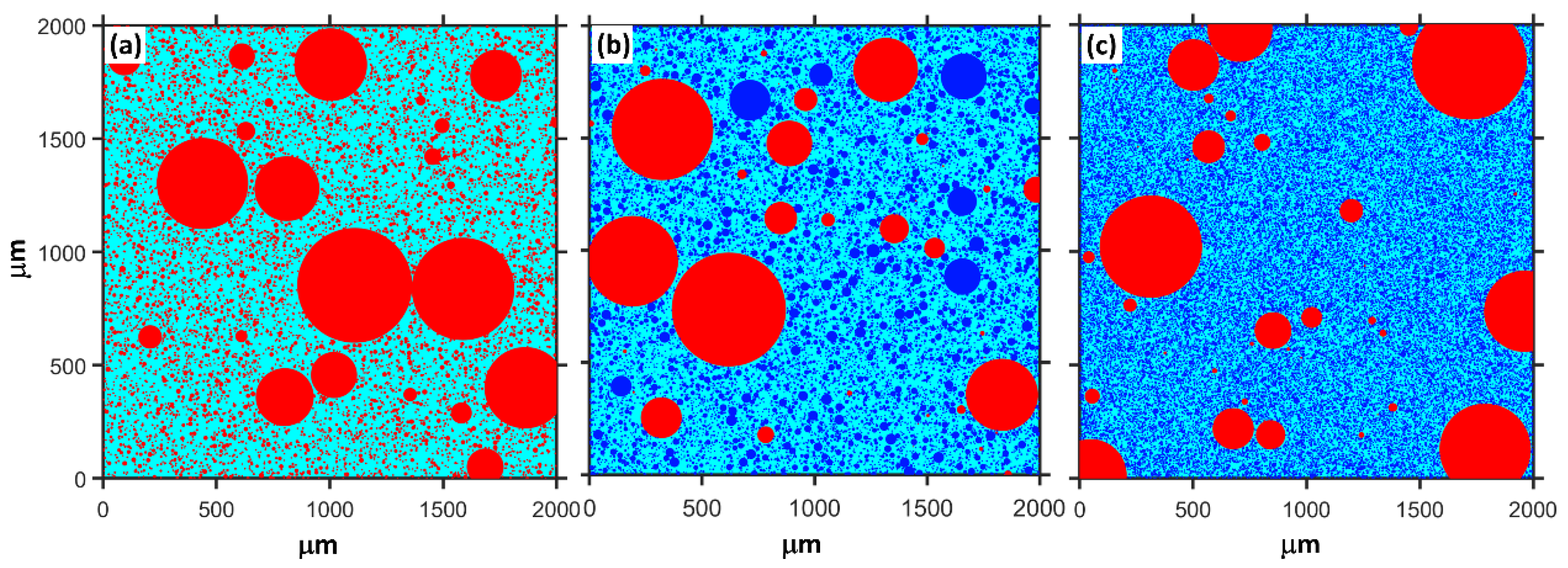

2. Materials and Methods

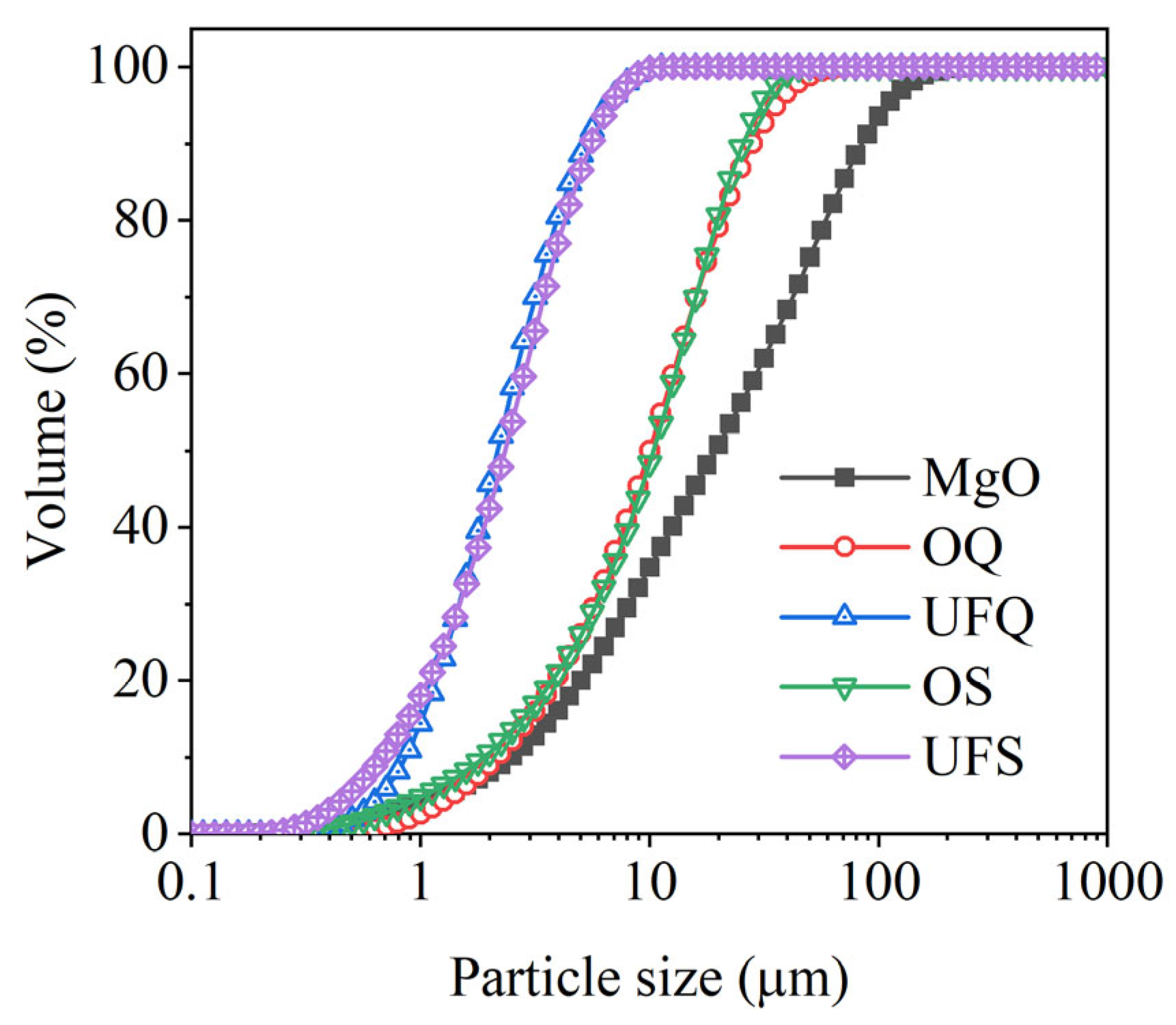

2.1. Raw Materials

2.2. Methods

2.2.1. Mixture Proportions

2.2.2. Test Methods

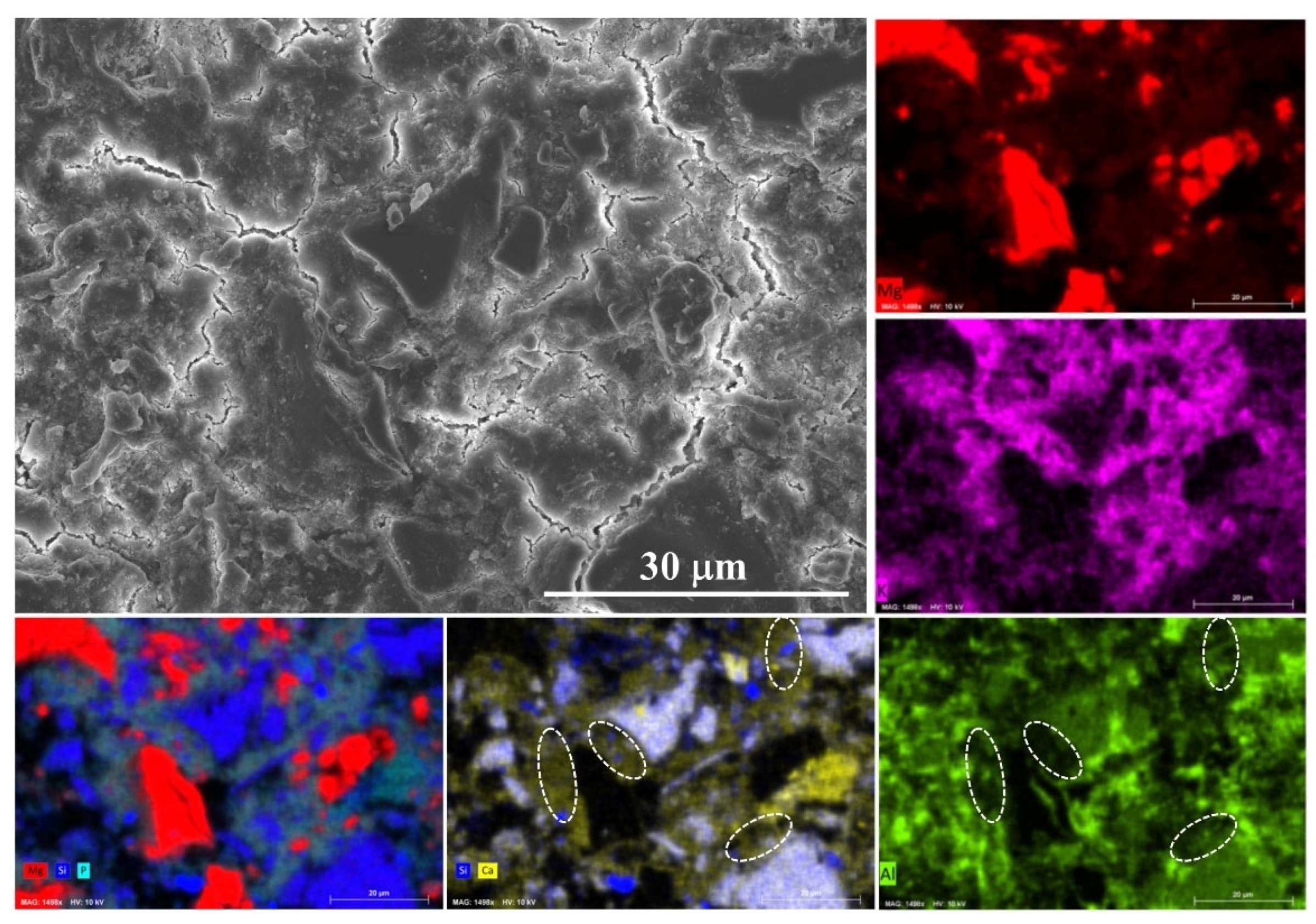

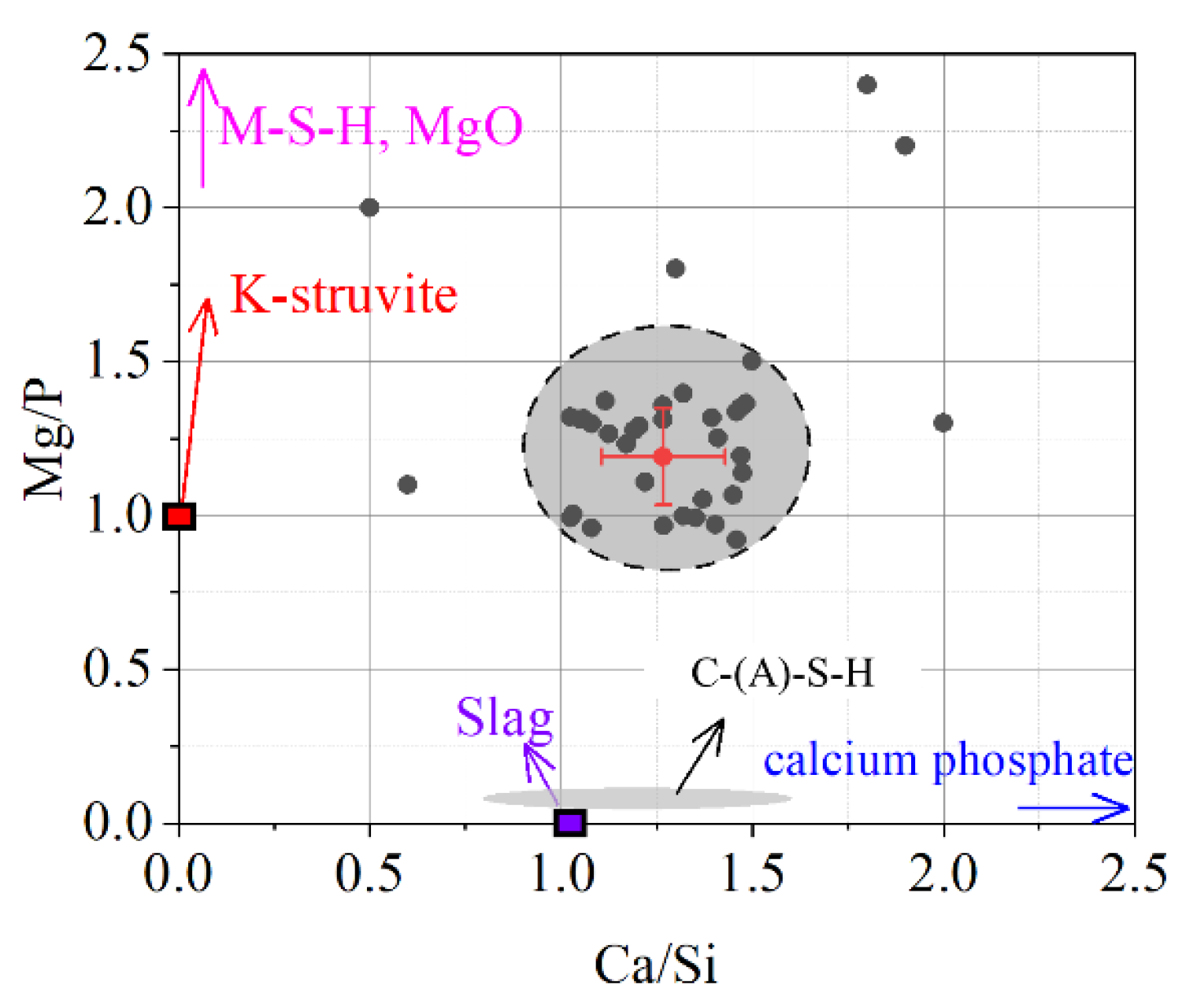

3. Results and Discussion

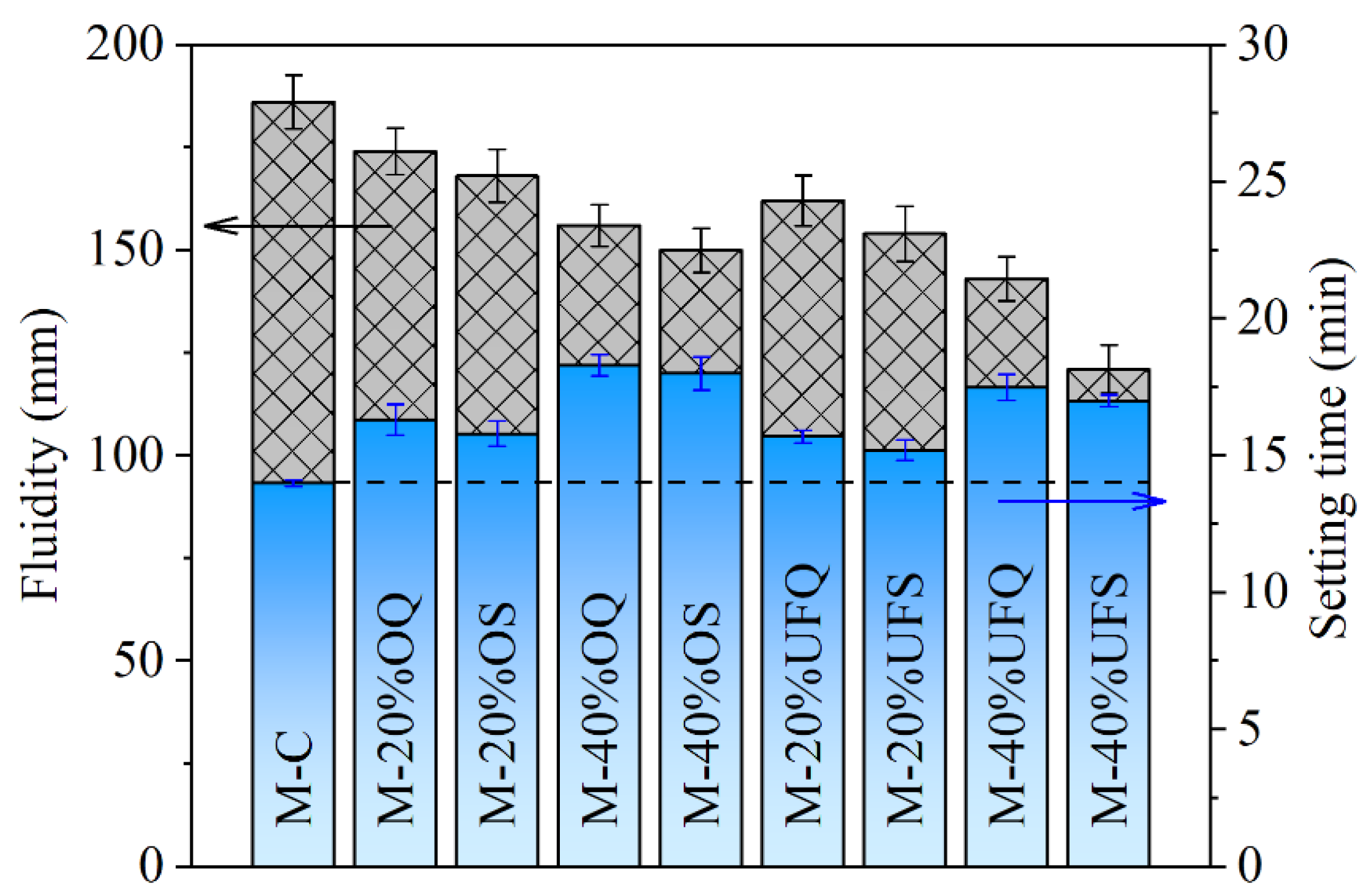

3.1. Properties of the Fresh MKPC Paste

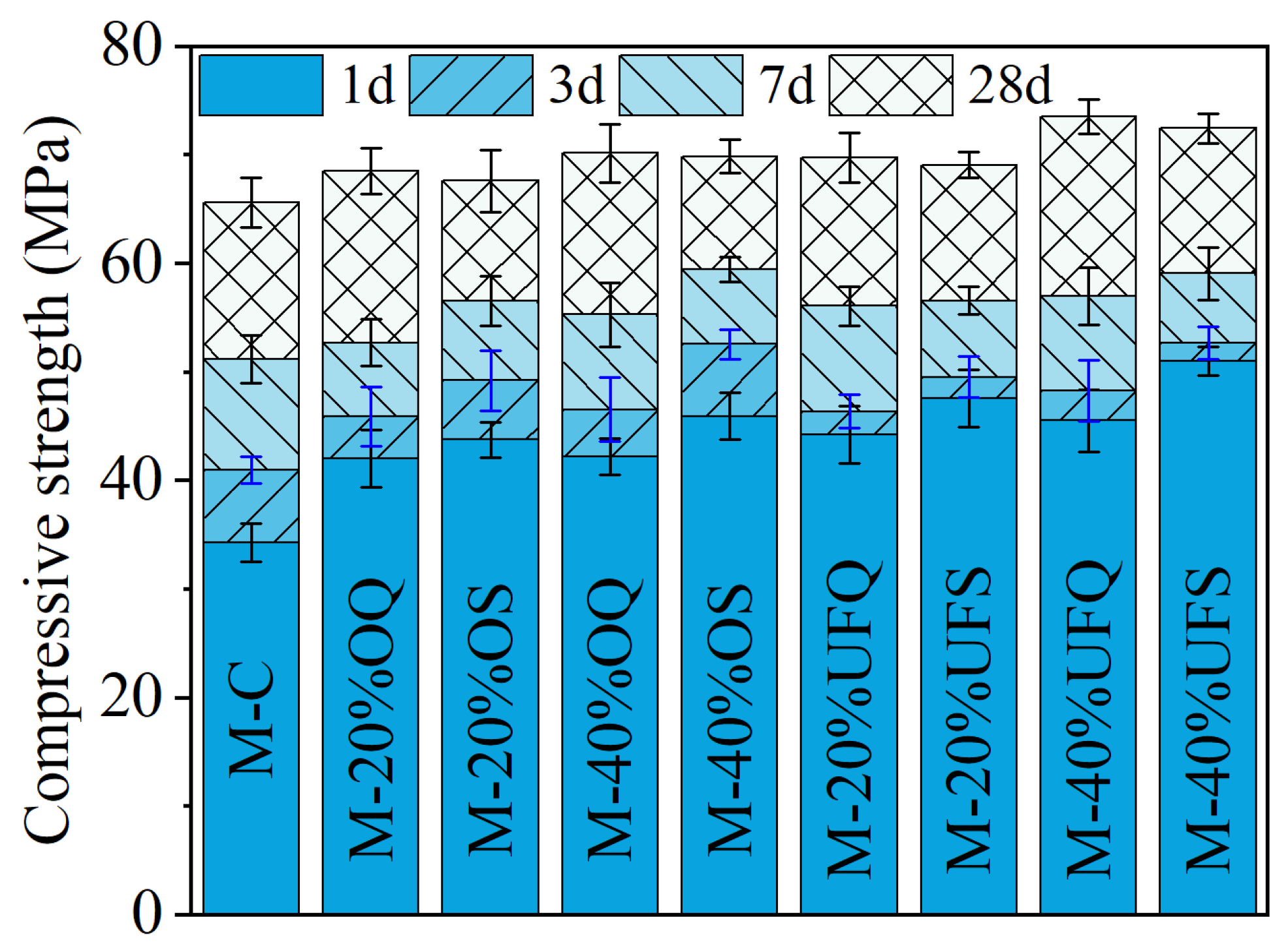

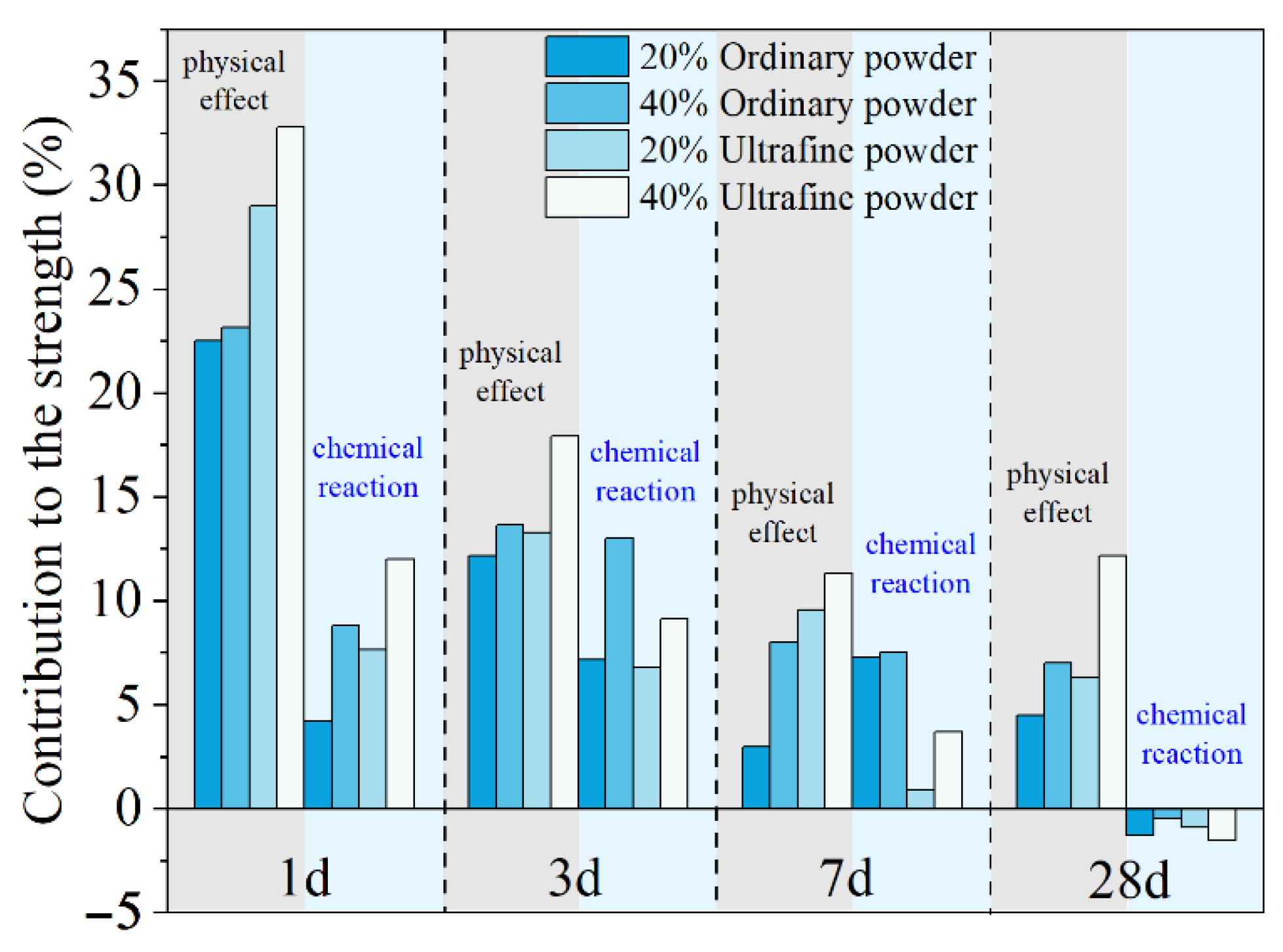

3.2. Compressive Strength of MKPC Mortar

3.3. Properties of the MKPC Paste

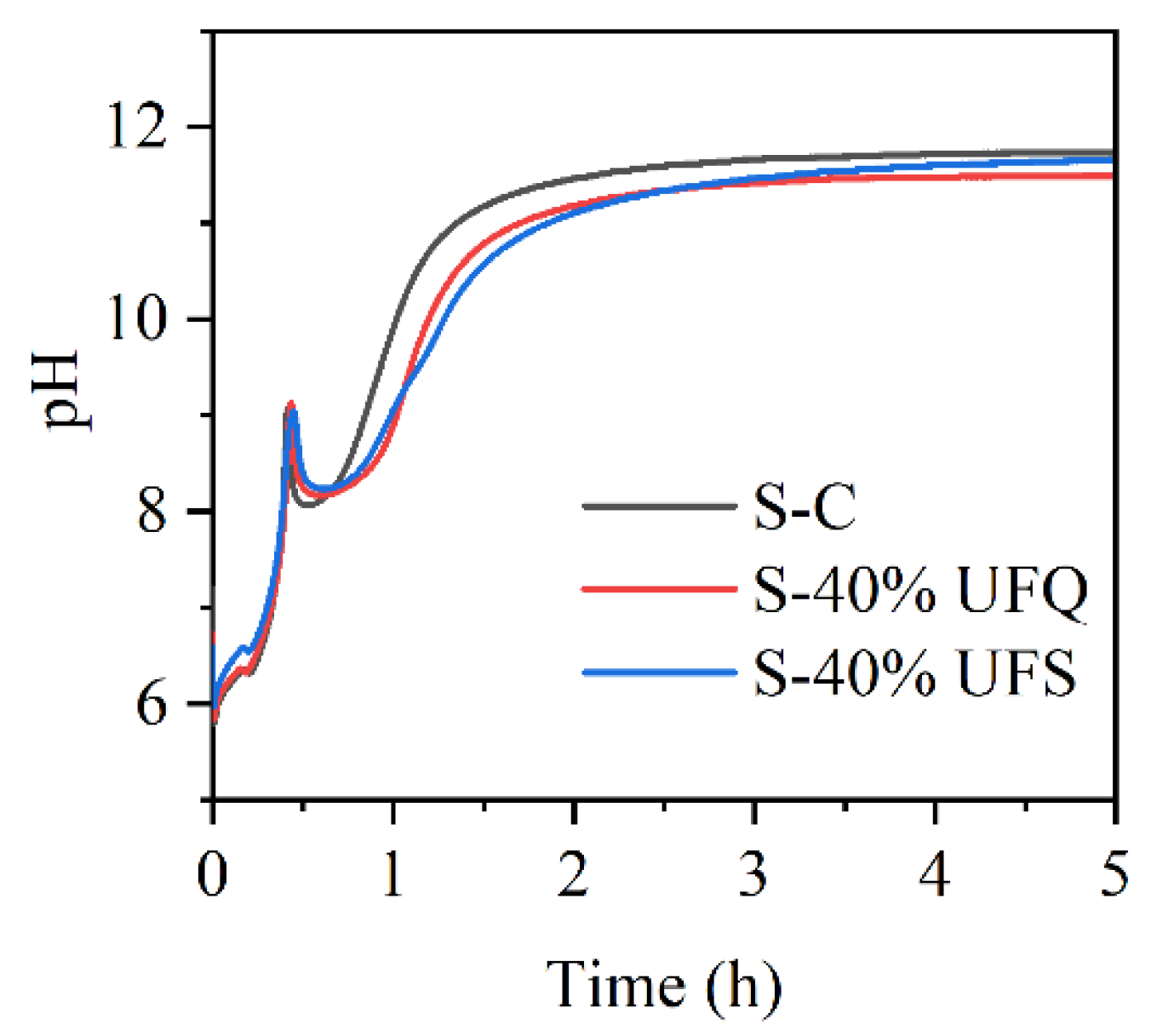

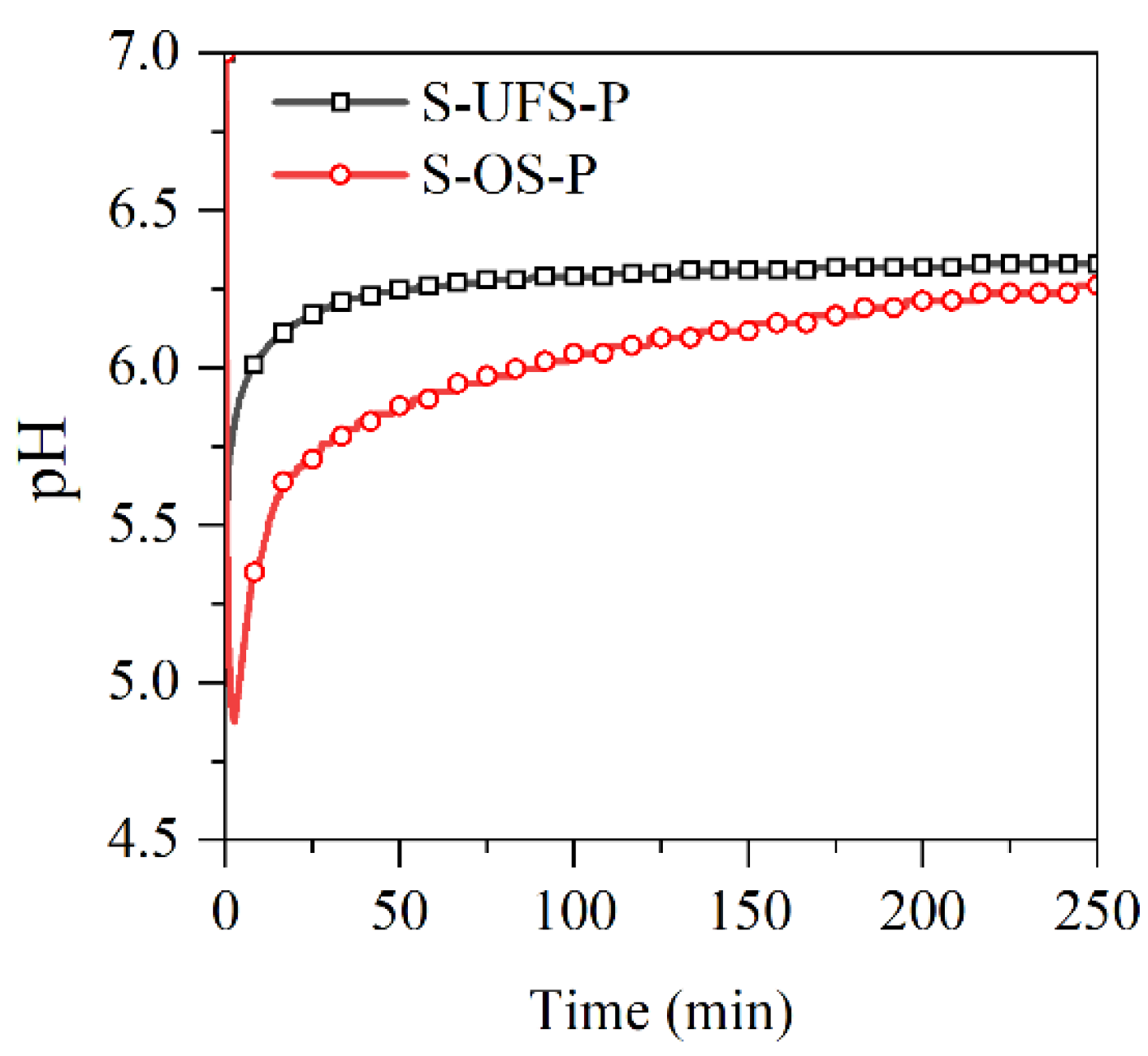

3.4. Properties of the MKPC Suspensions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, X.; Chen, B. Experimental study of magnesium phosphate cements modified by metakaolin. Constr. Build. Mater. 2016, 123, 719–726. [Google Scholar] [CrossRef]

- Liu, N.; Chen, B. Experimental research on magnesium phosphate cements containing alumina. Constr. Build. Mater. 2016, 121, 354–360. [Google Scholar] [CrossRef]

- Ding, Z.; Dong, B.; Xing, F.; Han, N.; Li, Z. Cementing mechanism of potassium phosphate based magnesium phosphate cement. Ceram. Int. 2012, 38, 6281–6288. [Google Scholar] [CrossRef]

- Xu, B.; Lothenbach, B.; Ma, H. Properties of fly ash blended magnesium potassium phosphate mortars: Effect of the ratio between fly ash and magnesia. Cem. Concr. Compos. 2018, 90, 169–177. [Google Scholar] [CrossRef]

- Qiao, F.; Chau, C.K.; Li, Z. Property evaluation of magnesium phosphate cement mortar as patch repair material. Constr. Build. Mater. 2010, 24, 695–700. [Google Scholar] [CrossRef]

- Ma, H.; Xu, B.; Li, Z. Magnesium potassium phosphate cement paste: Degree of reaction, porosity and pore structure. Cem. Concr. Res. 2014, 65, 96–104. [Google Scholar] [CrossRef]

- Qiao, F.; Chau, C.K.; Li, Z. Setting and strength development of magnesium phosphate cement paste. Adv. Cem. Res. 2009, 21, 175–180. [Google Scholar] [CrossRef]

- Buj, I.; Torras, J.; Casellas, D.; Rovira, M.; de Pablo, J. Effect of heavy metals and water content on the strength of magnesium phosphate cements. J. Hazard. Mater. 2009, 170, 345–350. [Google Scholar] [CrossRef]

- Buj, I.; Torras, J.; Rovira, M.; de Pablo, J. Leaching behaviour of magnesium phosphate cements containing high quantities of heavy metals. J. Hazard. Mater. 2010, 175, 789–794. [Google Scholar] [CrossRef]

- Ma, H.; Xu, B.; Liu, J.; Pei, H.; Li, Z. Effects of water content, magnesia-to-phosphate molar ratio and age on pore structure, strength and permeability of magnesium potassium phosphate cement paste. Mater. Des. 2014, 64, 497–502. [Google Scholar] [CrossRef]

- Xu, B.; Ma, H.; Li, Z. Influence of magnesia-to-phosphate molar ratio on microstructures, mechanical properties and thermal conductivity of magnesium potassium phosphate cement paste with large water-to-solid ratio. Cem. Concr. Res. 2015, 68, 1–9. [Google Scholar] [CrossRef]

- Li, Y.; Sun, J.; Chen, B. Experimental study of magnesia and M/P ratio influencing properties of magnesium phosphate cement. Constr. Build. Mater. 2014, 65, 177–183. [Google Scholar] [CrossRef]

- Le Rouzic, M.; Chaussadent, T.; Stefan, L.; Saillio, M. On the influence of Mg/P ratio on the properties and durability of magnesium potassium phosphate cement pastes. Cem. Concr. Res. 2017, 96, 27–41. [Google Scholar] [CrossRef]

- Ma, H.; Xu, B. Potential to design magnesium potassium phosphate cement paste based on an optimal magnesia-to-phosphate ratio. Mater. Des. 2017, 118, 81–88. [Google Scholar] [CrossRef]

- Wagh, A.S. Chemically Bonded Phosphate Ceramics, 2nd ed.; Matthew Deans: Naperville, IL, USA, 2016. [Google Scholar]

- Xu, B.; Lothenbach, B.; Winnefeld, F. Influence of wollastonite on hydration and properties of magnesium potassium phosphate cements. Cem. Concr. Res. 2020, 131, 106012. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, A.; Li, S.; Sun, B.; Zhang, L. The resistance to high temperature of magnesia phosphate cement paste containing wollastonite. Mater. Struct. Constr. 2016, 49, 3423–3434. [Google Scholar] [CrossRef]

- Xu, B.; Ma, H.; Shao, H.; Li, Z.; Lothenbach, B. Influence of fly ash on compressive strength and micro-characteristics of magnesium potassium phosphate cement mortars. Cem. Concr. Res. 2017, 99, 86–94. [Google Scholar] [CrossRef]

- Liao, W.; Ma, H.; Sun, H.; Huang, Y.; Wang, Y. Potential large-volume beneficial use of low-grade fly ash in magnesia-phosphate cement based materials. Fuel 2017, 209, 490–497. [Google Scholar] [CrossRef]

- Gardner, L.J.; Bernal, S.A.; Walling, S.A.; Corkhill, C.L.; Provis, J.L.; Hyatt, N.C. Characterisation of magnesium potassium phosphate cements blended with fly ash and ground granulated blast furnace slag. Cem. Concr. Res. 2015, 74, 78–87. [Google Scholar] [CrossRef] [Green Version]

- Ma, H.; Li, Y. Discussion of the paper “Characterisation of magnesium potassium phosphate cement blended with fly ash and ground granulated blast furnace slag” by L.J. Gardner et al. Cem. Concr. Res. 2018, 103, 245–248. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, B. Research on the preparation and properties of a novel grouting material based on magnesium phosphate cement. Constr. Build. Mater. 2019, 214, 516–526. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B. Effect of silica fume and basalt fiber on the mechanical properties and microstructure of magnesium phosphate cement (MPC) mortar. Constr. Build. Mater. 2018, 190, 466–478. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B. Microstructural characterization of basalt fiber reinforced magnesium phosphate cement supplemented by silica fume. Constr. Build. Mater. 2020, 237, 117795. [Google Scholar] [CrossRef]

- Mo, L.; Lv, L.; Deng, M.; Qian, J. Influence of fly ash and metakaolin on the microstructure and compressive strength of magnesium potassium phosphate cement paste. Cem. Concr. Res. 2018, 111, 116–129. [Google Scholar] [CrossRef]

- Zheng, D.D.; Ji, T.; Wang, C.Q.; Sun, C.J.; Lin, X.J.; Hossain, K.M.A. Effect of the combination of fly ash and silica fume on water resistance of Magnesium-Potassium Phosphate Cement. Constr. Build. Mater. 2016, 106, 415–421. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Skibsted, J.; Snellings, R. Reactivity of supplementary cementitious materials (SCMs) in cement blends. Cem. Concr. Res. 2019, 124, 105799. [Google Scholar] [CrossRef]

- Liu, J.; Qin, Q.; Yu, Q. The effect of size distribution of slag particles obtained in dry granulation on blast furnace slag cement strength. Powder Technol. 2020, 362, 32–36. [Google Scholar] [CrossRef]

- Bouaziz, A.; Hamzaoui, R.; Lakhal, R.; Achoura, D.; Leklou, N. Efficiency of high energy over conventional milling of granulated blast furnace slag powder to improve mechanical performance of slag cement paste. Powder Technol. 2017, 308, 37–46. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Peng, B.; Chai, L.; Zhang, Q.; Liu, Q. Preparation of electrolytic manganese residue—Ground granulated blastfurnace slag cement. Powder Technol. 2013, 241, 12–18. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Q.; Huang, Z. New insights into the early reaction of NaOH-activated slag in the presence of CaSO4. Compos. Part B Eng. 2020, 198, 108207. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Q.; Xue, J. Reuse of hazardous electrolytic manganese residue: Detailed leaching characterization and novel application as a cementitious material. Resour. Conserv. Recycl. 2020, 154, 104645. [Google Scholar] [CrossRef]

- Binici, H. The effect of fineness on the properties of the blended cements incorporating ground granulated blast furnace slag and ground basaltic pumice. Constr. Build. Mater. J. 2007, 21, 1122–1128. [Google Scholar] [CrossRef]

- Teng, S.; Lim, T.Y.D.; Sabet Divsholi, B. Durability and mechanical properties of high strength concrete incorporating ultra fine ground granulated blast-furnace slag. Constr. Build. Mater. 2013, 40, 875–881. [Google Scholar] [CrossRef]

- Ting, L.; Qiang, W.; Shiyu, Z. Effects of ultra-fine ground granulated blast-furnace slag on initial setting time, fluidity and rheological properties of cement pastes. Powder Technol. 2019, 345, 54–63. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Z. Effect of fineness on the pozzolanic reaction kinetics of slag in composite binders: Experiment and modelling. Constr. Build. Mater. 2021, 273, 121695. [Google Scholar] [CrossRef]

- Engr. Margaret Aina Oguntala Studies on mechanism and physico-chemical parameters at the origin of the cement setting II. Physico-chemical parameters determining the coagulation process. Cem. Concr. Res. 1996, 52, 13837–13866. [Google Scholar] [CrossRef]

- Oey, T.; Kumar, A.; Bullard, J.W.; Neithalath, N.; Sant, G. The filler effect: The influence of filler content and surface area on cementitious reaction rates. J. Am. Ceram. Soc. 2013, 96, 1978–1990. [Google Scholar] [CrossRef]

- Berodier, E.; Scrivener, K. Understanding the filler effect on the nucleation and growth of C-S-H. J. Am. Ceram. Soc. 2014, 97, 3764–3773. [Google Scholar] [CrossRef]

- Kadri, E.H.; Aggoun, S.; De Schutter, G.; Ezziane, K. Combined effect of chemical nature and fineness of mineral powders on Portland cement hydration. Mater. Struct. Constr. 2010, 43, 665–673. [Google Scholar] [CrossRef]

- Han, F.; He, X.; Zhang, Z.; Liu, J. Hydration heat of slag or fly ash in the composite binder at different temperatures. Thermochim. Acta 2017, 655, 202–210. [Google Scholar] [CrossRef]

- Cyr, M.; Lawrence, P.; Ringot, E. Efficiency of mineral admixtures in mortars: Quantification of the physical and chemical effects of fine admixtures in relation with compressive strength. Cem. Concr. Res. 2006, 36, 264–277. [Google Scholar] [CrossRef]

- Lawrence, P.; Cyr, M.; Ringot, E. Mineral admixtures in mortars effect of type, amount and fineness of fine constituents on compressive strength. Cem. Concr. Res. 2005, 35, 1092–1105. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Hou, G.; Yan, P. Preparation of sustainable and green cement-based composite binders with high-volume steel slag powder and ultrafine blast furnace slag powder. J. Clean. Prod. 2021, 289, 125133. [Google Scholar] [CrossRef]

- Das, S.K.; Mishra, J.; Mustakim, S.M.; Adesina, A.; Kaze, C.R.; Das, D. Sustainable utilization of ultrafine rice husk ash in alkali activated concrete: Characterization and performance evaluation. J. Sustain. Cem. Mater. 2021, 1–19. [Google Scholar] [CrossRef]

- Feng, J.; Liu, S.; Wang, Z. Effects of ultrafine fly ash on the properties of high-strength concrete. J. Therm. Anal. Calorim. 2015, 121, 1213–1223. [Google Scholar] [CrossRef]

- Peng, L.; Chen, B. Mechanical behavior, durability, thermal performances and microstructure of GGBFS—Modified MPC solidified dredged sludge. Constr. Build. Mater. 2021, 303, 124557. [Google Scholar] [CrossRef]

- Tan, Y.; Yu, H.; Li, Y.; Bi, W.; Yao, X. The effect of slag on the properties of magnesium potassium phosphate cement. Constr. Build. Mater. 2016, 126, 313–320. [Google Scholar] [CrossRef]

| Compound | Fe2O3 | SiO2 | Al2O3 | SO3 | CaO | MgO | P2O5 | K2O | Na2O | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| Magnesia | 1.00 | 2.41 | 0.41 | - | 3.58 | 91.67 | 0.53 | 0.02 | - | 0.38 |

| KH2PO4 | 0.01 | 0.08 | 0.03 | - | 0.13 | 0.39 | 52.58 | 45.11 | 1.38 | 0.29 |

| slag | 0.92 | 35.75 | 14.26 | 1.95 | 35.14 | 9.66 | - | - | 0.86 | 1.46 |

| Quartz | 0.01 | 99.90 | 0.04 | - | 0.01 | 0.01 | - | - | 0.01 | 0.02 |

| Sample | M/P Ratio a | w/b Ratio b | w/c Ratio b | MgO | KH2PO4 | OS/UFS | OQ/UFQ | b/s Ratio c |

|---|---|---|---|---|---|---|---|---|

| MKPC mortars | ||||||||

| M-C | 6 | 0.16 | 0.16 | 1.78 | 1 | - | - | 1:1 |

| M-20%OQ/UFQ | 6 | 0.16 | 0.186 | 1.78 | 1 | - | 0.445 | 1:1 |

| M-20%OS/UFS | 6 | 0.16 | 0.186 | 1.78 | 1 | 0.445 | - | 1:1 |

| M-40%OQ/UFQ | 6 | 0.16 | 0.195 | 1.78 | 1 | - | 0.89 | 1:1 |

| M-40%OS/UFS | 6 | 0.16 | 0.195 | 1.78 | 1 | 0.89 | - | 1:1 |

| MKPC pastes | ||||||||

| P-C | 6 | 0.5 | 0.5 | 1.78 | 1 | - | - | - |

| P-20%OQ/OQ | 6 | 0.5 | 0.58 | 1.78 | 1 | - | 0.445 | |

| P-20%OS/OS | 6 | 0.5 | 0.58 | 1.78 | 1 | 0.445 | - | |

| P-40%OQ/UFQ | 6 | 0.5 | 0.66 | 1.78 | 1 | - | 0.89 | - |

| P-40%OS/UFS | 6 | 0.5 | 0.66 | 1.78 | 1 | 0.89 | - | - |

| Suspensions | ||||||||

| S-C | 6 | 5 | - | 1.78 | 1 | - | - | - |

| S-40%UFQ/UFS | 6 | 5 | - | 1.78 | 1 | 0.89 | - | - |

| S-OS/UFS-P | 6 | 5 | - | - | 1 | 1 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, K.; Ma, S.; Zhang, Z.; Han, F. Hydration and Properties of Magnesium Potassium Phosphate Cement Modified by Granulated Blast-Furnace Slag: Influence of Fineness. Materials 2022, 15, 918. https://doi.org/10.3390/ma15030918

Liu K, Ma S, Zhang Z, Han F. Hydration and Properties of Magnesium Potassium Phosphate Cement Modified by Granulated Blast-Furnace Slag: Influence of Fineness. Materials. 2022; 15(3):918. https://doi.org/10.3390/ma15030918

Chicago/Turabian StyleLiu, Kuisheng, Shanliang Ma, Zengqi Zhang, and Fanghui Han. 2022. "Hydration and Properties of Magnesium Potassium Phosphate Cement Modified by Granulated Blast-Furnace Slag: Influence of Fineness" Materials 15, no. 3: 918. https://doi.org/10.3390/ma15030918

APA StyleLiu, K., Ma, S., Zhang, Z., & Han, F. (2022). Hydration and Properties of Magnesium Potassium Phosphate Cement Modified by Granulated Blast-Furnace Slag: Influence of Fineness. Materials, 15(3), 918. https://doi.org/10.3390/ma15030918