Abstract

Heat-induced spalling in concrete is a problem that has been the subject of intense debate. The research community has, despite all the effort invested in this problem, few certain and definitive answers regarding the causes of and the way in which spalling happens. A major reason for this difficulty is the lack of a unified method for testing, which makes comparing data from various studies against each other a difficult task. Many studies have been performed that show the positive effects of using synthetic micro-fibres, such as polypropylene (PP). The mechanism with which PP fibres improve heat-induced spalling resistance in concrete, however, remains a subject of debate. This paper, therefore, looks at the work that has been performed in the field of spalling (particularly spalling of self-compacting concrete (SCC)). Influencing factors are identified and their links to each other (as reported) are discussed. A particular emphasis is put on discussing the role of PP fibres and how they improve the behaviour of high-performance concrete (HPC) at elevated temperatures. A brief summary of the reviewed papers are provided for each of the influencing factors to help the reader navigate with ease through the references. An introduction to heat-induced spalling and the common causes (as reported in the literature) is also included to highlight the wide range of theories trying to explain the spalling phenomenon.

1. Introduction

Concrete is the single most widely used construction material in the world [1,2] in all its variety and forms. Generally, concrete is described as a building material that offers a lot in terms of fire resistance [3]. This is a widely used claim when advantages of concrete over other construction materials are advocated.

Despite its benefits, concrete has its disadvantages too; when subjected to an incident heat flux, concrete is shown to exhibit a behaviour known as spalling. Spalling can be defined as the breaking off of concrete layers in either an explosive or a gradual manner when exposed to high temperatures [4]. Spalling is a complicated phenomenon [5] that is still the subject of intense debate amongst the research community [6].

A lot of effort has gone into understanding and mitigating spalling of concrete at elevated temperatures, with a good degree of success. However, there are still some fundamental questions that the research community has not been able to fully answer, even though some of these questions were raised a few decades ago [5,7].

A major obstacle for understanding spalling and mitigating it is the lack of a unified approach for testing [8]. This means that despite an abundance of studies and experimental and numerical results, data from various studies are difficult to compare. Furthermore, with the ever-growing thirst of the construction sector for the use of highly specialised concrete [9,10], the occurrence of spalling has been observed to be remarkably dependant on the type and grade of the concrete that is being put to use [11,12].

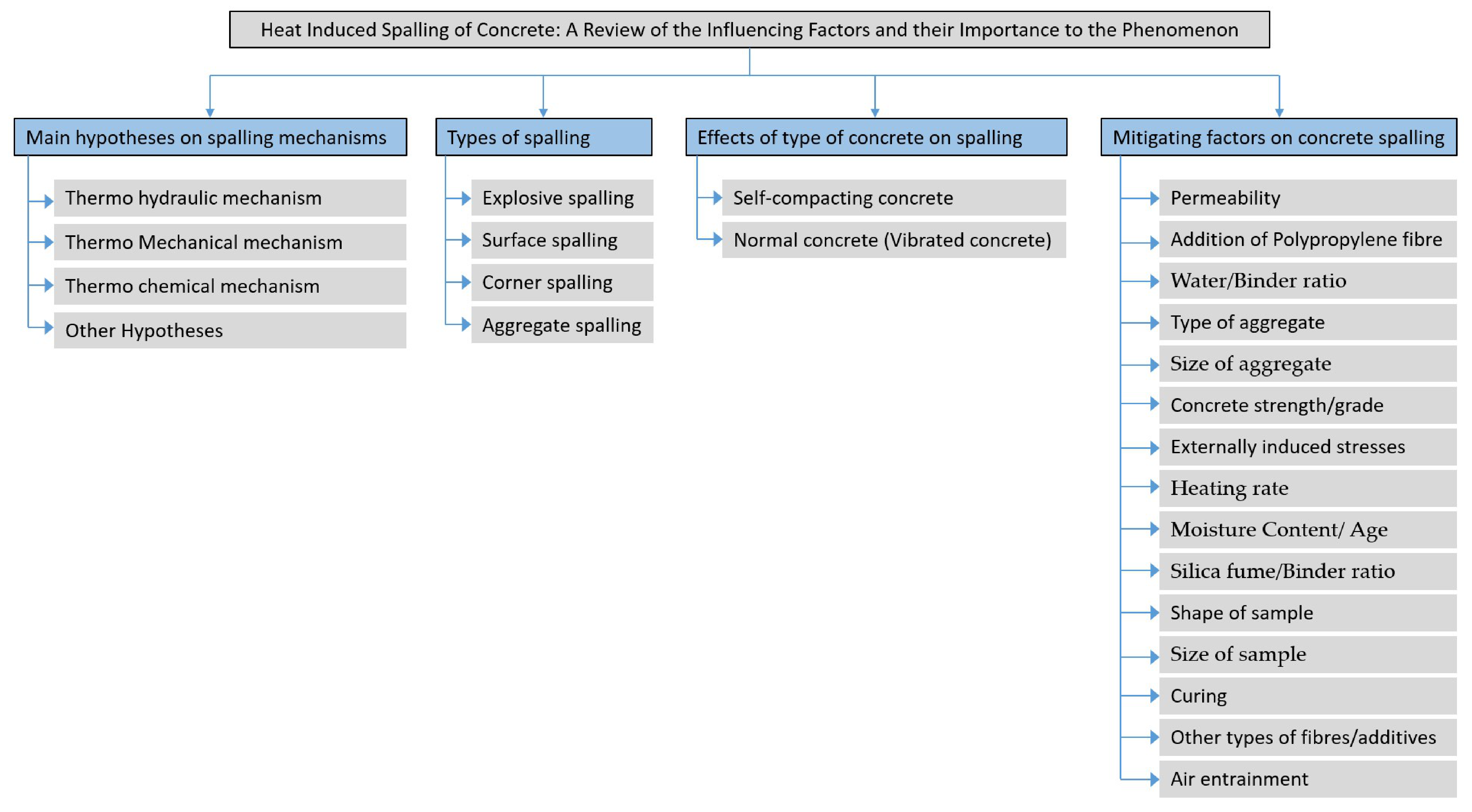

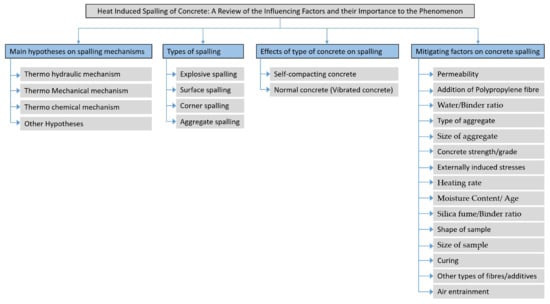

In this paper, the authors have tried to summarise the main work that has been performed in the field of spalling, with a particular focus on the factors that are deemed to be highly influential (Figure 1). It is hoped that this will help focus the research community approach to spalling and, ultimately, help understand the problem better.

Figure 1.

Structure of the paper and studied parameters.

2. Main Hypotheses on Spalling Mechanisms

There are a few hypotheses that describe the causes and mechanisms of spalling. To date, the debate is still ongoing as to which of the mechanisms, mentioned herein, correctly explain spalling and which ones do not [13]. The main hypotheses have been discussed in the next section.

2.1. Thermohydraulic Mechanism

Thermohydraulic mechanism refers to the occurrence of spalling due to water vapour pressure. In this theory, vapour forms because of the evaporation of free water and chemically bonded water at elevated temperatures [4]. Due to the gradient of both pressure and molecules that ensues, there will be a movement of moisture and air per Darcy and Fick’s law [14]. The migration of water vapour towards colder inner regions of concrete will lead to the formation of what is referred to as “moisture clog”. This moisture clog acts as a barrier that prevents further migration of vapour into the inner regions of concrete and leads to a pressure build-up [15,16]. The pressure build-up eventually overcomes the (reduced) tensile strength of the heated concrete, which leads to the occurrence of spalling [17,18,19,20,21].

Other researchers [22] have concluded that spalling occurs due to the thermal expansion of liquid water. When heated, water starts evaporating and the pressure starts building up. Since the vapour pressure cannot escape the pores and the pressure continues to rise, this results in having a higher boiling point for the water due to the thermodynamic properties of water (super-heated water). Eventually, cracks start forming in the concrete matrix (due to thermal stresses) and the pressure drops suddenly, leading to instantaneous evaporation of the water and a sudden release of energy that causes spalling.

This is certainly a plausible scenario, but some researchers [23,24,25] observed that the pore pressure was lower in samples that spalled compared to samples that did not; this led them to conclude that pore pressure was not the leading cause for spalling. Other studies show that while pore pressure measurements tend to be higher in samples that are more prone to spalling, the magnitude of the peak pore pressure is considerably less than the reduced tensile strength of the concrete at the point when spalling occurs [26]. This again casts doubt on the validity of the thermohydraulic mechanism as the main cause for spalling.

2.2. Thermo-Mechanical Mechanism

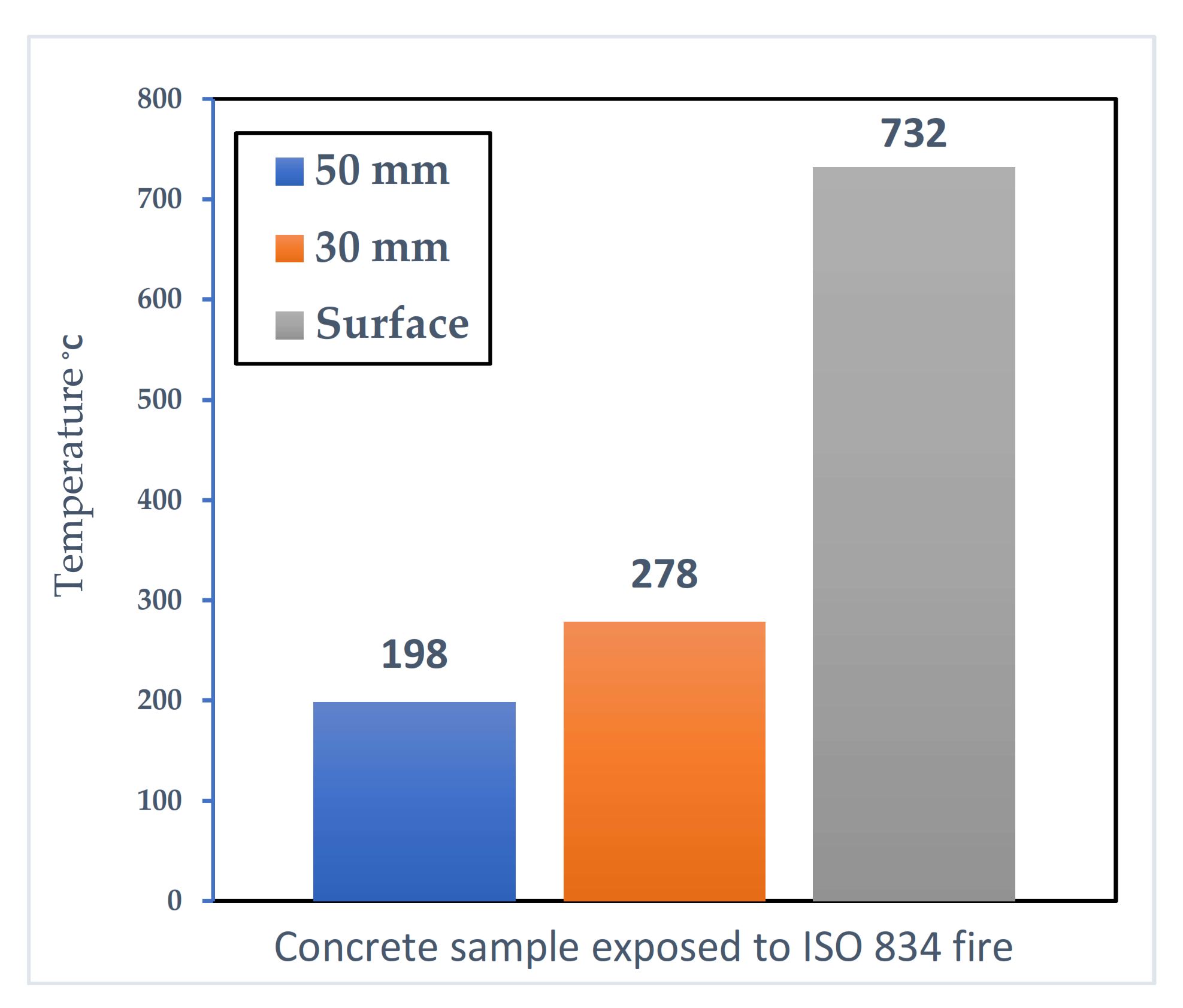

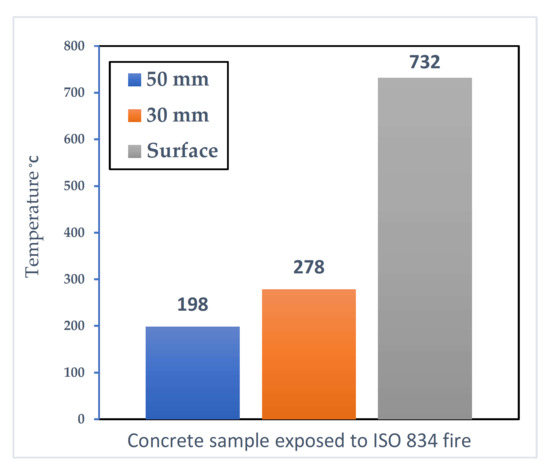

Thermo-mechanical mechanism refers to the occurrence of spalling due to mechanical stresses formed because of the temperature gradient when concrete is exposed to a sudden influx of heat. Researchers have recorded the development of a steep gradient of temperature within the concrete subjected to a rapid heating rate [22]. Figure 2 shows the extent of such a temperature gradient when a sample is subjected to a standard ISO 834 fire curve (reported by [22]).

Figure 2.

The temperature gradient after 20 min for a concrete sample exposed to ISO 834 fire. Temperatures are recorded at the exposed surface, and 30 and 50 mm from the exposed surface.

The temperature gradient results in the development of large thermal stresses [27,28]. These stresses would be in the form of compressive stresses at the heated zone (due to the thermal expansion of the concrete) and tensile stresses at the colder regions. Local strain incompatibility between the aggregate and the cement paste also plays a role in this hypothesis; due to the higher temperature, the coarse aggregate dilates while the cement paste starts to shrink due to the evaporation of the water [29]. The combined effects of these occurrences lead to the generation of enough stresses that overcome the tensile strength of the heated sample, at which point spalling occurs.

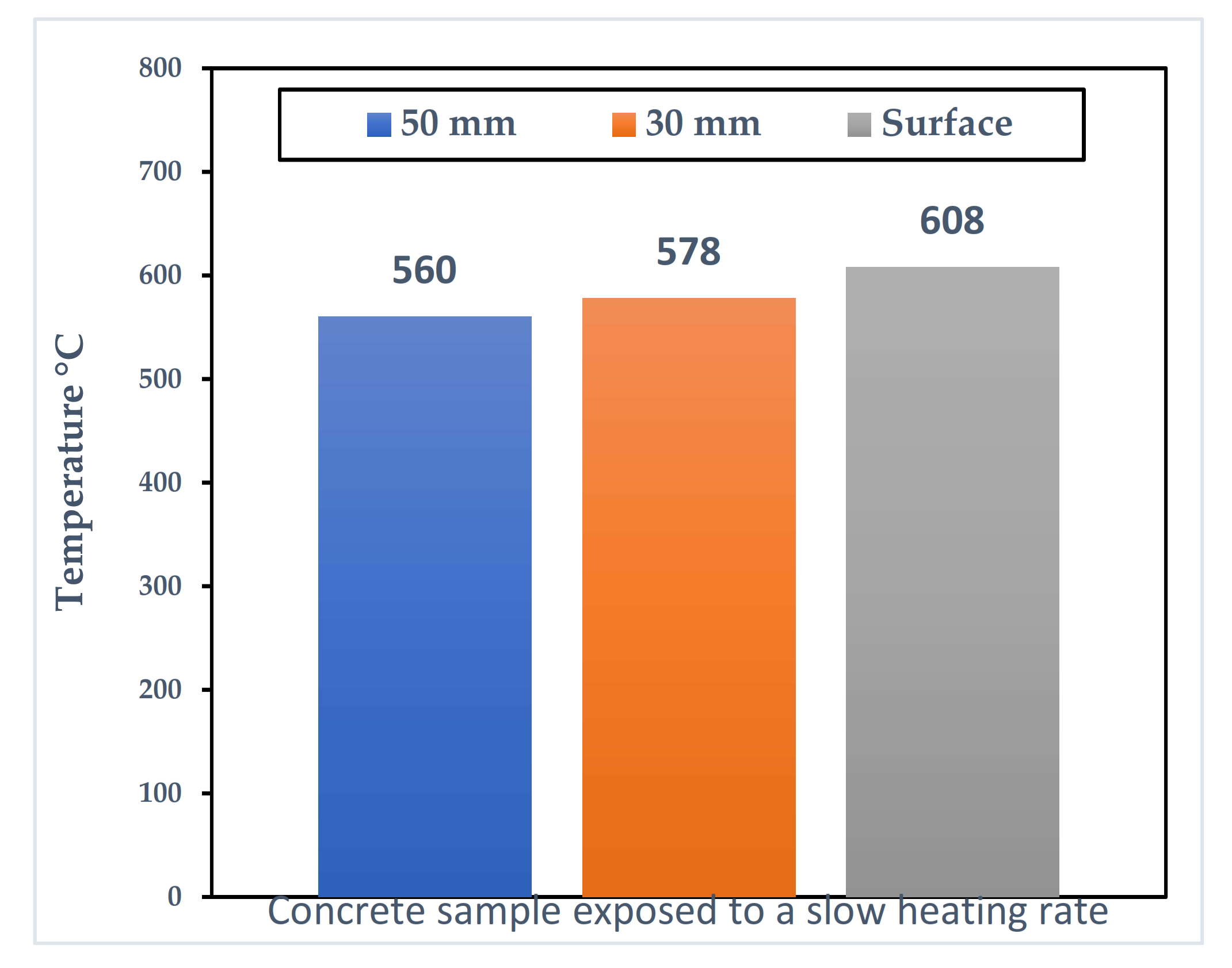

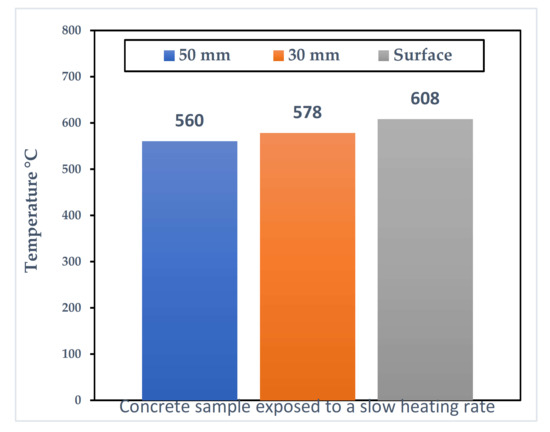

This mechanism is dependent on the temperature gradient within the concrete sample subjected to thermal loading [27]. As such, a slow heating rate will not be enough to generate the type of temperature gradient required to create enough thermal stresses to cause spalling [22]. Figure 3 (reported by [22]) shows that the in-through temperature is the same as the samples as Figure 1 when a slow heating rate of 1 °C/min is used. The figure shows that the difference between different depths and the heated surface is very small, meaning that a large enough thermal stress due to temperature gradient cannot form.

Figure 3.

The temperature gradient after 12 h for a concrete sample exposed to a slow heating rate. Temperatures are recorded at the exposed surface, and 30 and 50 mm from the exposed surface.

Researchers have also observed that the addition of small dosages of polypropylene fibres (PP) reduces (or even eliminates) spalling. Due to this observation, some researchers [30,31] have suggested that adding such small amounts of PP fibre is not enough to change the thermal incompatibility problem mentioned earlier. As such, these researchers [30,31] concluded that the thermo-mechanical mechanism alone could not fully explain the spalling phenomena.

2.3. Thermo Chemical Mechanism

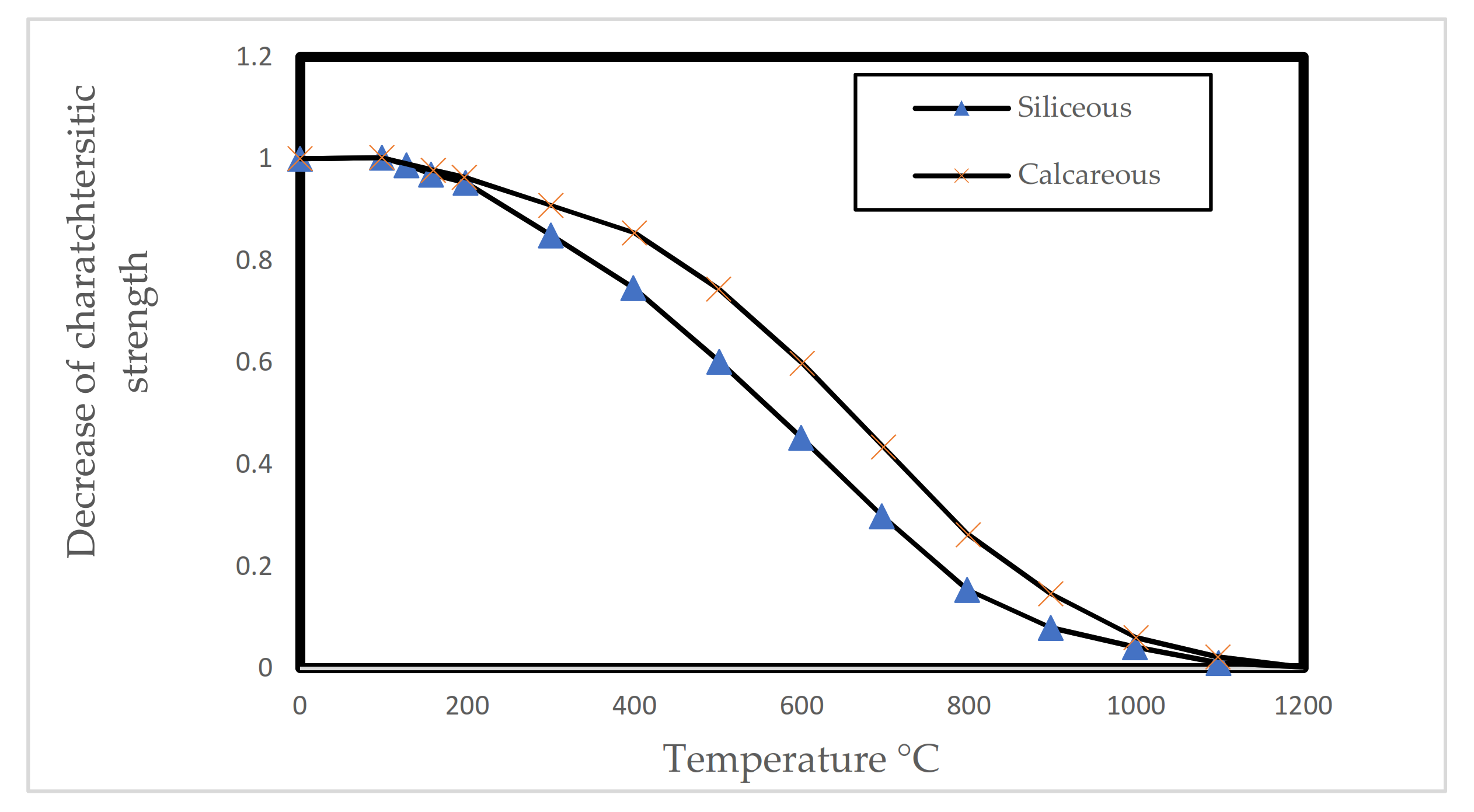

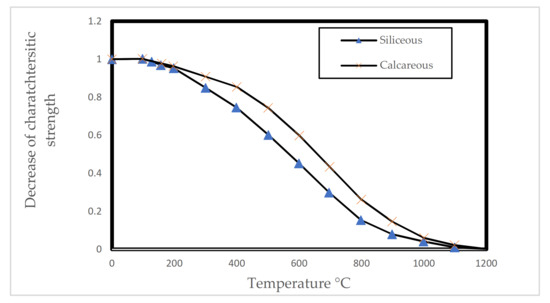

This mechanism is associated with the chemical degradation of the components of concrete at elevated temperatures. It is generally agreed upon that the strength of concrete decreases when exposed to high temperatures [32,33,34,35,36]. This process starts with hydrothermal reactions where water (free and chemically bound) starts evaporating [4]. At higher temperatures, the chemical bonds between the remaining parts of the concrete matrix start deteriorating [32]. It was observed [37] that the amount of Calcium Silicate Hydrate (C-S-H) within the concrete rapidly decrease as temperatures reach 800 °C. This is mainly due to the breakage of bonds that holds the crystals together. Figure 4 shows the reduction in the value of the characteristic compressive strength for concrete at elevated temperatures [38].

Figure 4.

Decrease in concrete strength with rising temperature according to Eurocode 2.

The reduction shown in Figure 3 is widely reported in the literature. However, the exact influence of these changes on spalling are not yet determined.

Researchers [39] found that the presence of moisture adversely affects the mechanical properties of the concrete and, thus, increases spalling propensity. They also found that a larger proportion of C-S-H phases resulted in a more pronounced thermal incompatibility and promoted spalling.

Maier et al. [40] performed a series of tests on concrete slabs (800 mm × 500 mm × 150 mm). The researchers concluded that the main factor for spalling was the increasing pore pressure and not the chemical degradation of the concrete components. The study, nonetheless, stated that deteriorating components of the concrete at elevated temperatures worsened the overall spalling level when it happened.

Whilst conceivable, there are many studies that have observed that the spalling of concrete (especially explosive spalling) happens at an early age of the heating tests when concrete temperatures would be far below the temperatures required for a significant reduction in the concrete strength. Therefore, it is unlikely that degradation of a concrete matrix due to high temperature would be the main reason behind spalling.

2.4. Other Hypotheses

Other theories have been proposed by researchers to explain the spalling of concrete at elevated temperatures. These include “the presence and movement of moisture” theory [23]. According to this theory, the presence of moisture at the critical zone (i.e., moisture clog) affects the mechanical properties of the concrete close to the exposed surface. The presence of moisture will also reduce the drying creep, which relaxes thermal stresses. Hence, when a concrete sample has low permeability (to allow for moisture migration and creation of a bigger drying creep zone when heated), the thermal stresses generated will lead to spalling.

Another theory suggests that spalling happens due to the combined effects of both thermal stresses and water vapour pressure [41,42]. Spalling is hypothesised to occur when the sum of all the stresses resulting from rising water vapour pressure and thermal stresses exceed that of the concrete tensile strength.

Researchers have also hypothesised that spalling could be occurring due to fast-moving vapour in concrete when subjected to elevated temperature [43]. According to this theory, water vapour movement creates shear stress along the pore cells. Subsequently, spalling happens when the magnitude of this shear stress exceeds the strength of the concrete. This mechanism, although plausible, has not received much attention and does not have enough evidence to prove its validity [44].

3. Types of Spalling

As outlined in the previous section, many researchers are still looking for answers regarding the causes and mechanisms of heat-induced spalling. However, there is a broad agreement that spalling can be categorised into some distinctive types [44,45,46]. A summary of these types are showcased in this section.

3.1. Explosive Spalling

Explosive spalling is the most consequential form of spalling. It is referred to as explosive due to its nature; this form of spalling is usually accompanied by a loud bang, which is the result of the explosion-like failure of concrete that is being subjected to an incident heat flux.

Explosive spalling is characterised by its sudden and explosive nature, which is the result of a big and sudden release of energy [46]. Although most spalling does not lead to structural failure [3], recent developments in concrete technology have allowed for the erection of thin, load-bearing elements [12,47]. When explosive spalling happens in such elements, it can lead to its full and sudden collapse [11].

Explosive spalling is observed at an early stage of heat exposure [3,11,43,48,49,50]. Explosive spalling is affected by many factors, such as the properties of the components of the concrete mix, shape, and geometry, presence of load, and environmental factors, such as curing temperature and curing duration [3]. A ranking order of these factors, though, is still not within reach due to the inconclusive nature of the experiments performed so far. Despite this, a lot of researchers have observed that there would be a big reduction in the likelihood of concrete to spall when permeability of the mix is increased. This has led to some researchers concluding that vapour pore pressure was responsible for concrete spalling (relevant research have been outlined in the coming sections). This concept has been disputed by others who have observed that explosive spalling could happen in samples that recorded smaller pressure peaks than samples that did not spall. However, both camps broadly agree that an increase in permeability does lead to improved spalling behaviour of concrete at elevated temperatures.

3.2. Surface Spalling

Surface spalling is similar to explosive spalling with the exception that it occurs at the surface of the specimen and is accompanied by a cracking sound [51]. This form of spalling is, depending on the continuity of the heat source, continuous and can affect the performance of a concrete element if it is allowed to continue [43,46]. Ieuan Rickard [8], in his PhD thesis, reported the observation of what he called popcorn spalling. Popcorn spalling was described to happen at very early stages of concrete heating and consisted of many small spallings that lasted for a prolonged period. The author of the study [8] was not able to provide conclusions regarding the causes and mechanism of this form of spalling. However, its properties allow for it to be potentially categorised as a form of surface spalling. Y. Li et al. [31] noticed a similar pattern in their studies where loud spalling bangs were followed by intermittent popcorn-cooking-like sounds, resulting in debris that were less than 5 mm in thickness. The main reason for the concrete to spall like this is yet to be fully determined but considering the temperature gradient between the surface of concrete samples and its inner, cooler regions, this form of spalling may be a direct result of the thermo-mechanical stresses induced by temperature variance at the surface of the sample and the layers immediately underneath the exposed surface.

3.3. Corner Spalling

This type of spalling, as its name suggests, happens at the corners of samples exposed to elevated temperatures [3]. Spalling of this type is assumed to occur mainly due to prolonged exposure to elevated temperature, which results in concrete losing its strength [46]. This theory has not been proven, experimentally or otherwise, to be accurate. Like other forms of spalling, corner spalling is very complex, and its causes are perhaps multiple factors culminating in the occurrence of the spalling. Zhao et al. [52] observed that, for cubic samples under fast heating conditions, the thermal stresses induced in the samples started evolving from the corners. These thermal stresses, coupled with the water vapour pressure, can lead to the occurrence of corner spalling, according to the study [52]. The study arrived at these conclusions based on a wide range of assumptions that were made by its authors; therefore it is difficult to say that the conclusions apply to samples without the boundaries of the samples that are considered in the study. Nonetheless, the observation that thermal stresses start from corners makes sense, given that corners have less mass than other parts of the cube and heat up quicker than the rest of the cube [53].

3.4. Aggregate Spalling

This form of spalling occurs due to the splitting of the aggregate at the face of the specimen when subjected to elevated temperatures [43]. This is said to be the result of either the mineralogical properties of the aggregate or the thermal shock that aggregate experiences when subjected to elevated temperatures [51]. This type of spalling occurs early into the sample exposed to thermal loading [3].

Aggregate spalling leaves small crates on the surface that were exposed to elevated temperatures. It is therefore considered to not affect the fire resistance properties of the element subjected to thermal load and its effects are only aesthetic [46]. Not many studies have considered this form of spalling or studied why this type of spalling takes place.

4. Effects of Type of Concrete on Spalling (Self-Compacting Concrete (SCC)/Vibrated Concrete (VC))

Generally, SCC mixes tend to have a higher propensity to spall than VC [42,54]. This is due to the lower permeability of SCC mixes (compared to VC), which leads to a slower drying rate. Some researchers [55], however, observed that the spalling propensity was influenced by the strength class of the concrete and not the mix type (i.e., SCC or VC).

Noumowe et al. [56] observed that the high strength SCC mixes had a higher propensity to spall, even at a lower heating rate of 0.5 °C/min. The authors suggested that this could be due to utilising calcareous filler in their mix design of the SCC. Having this filler leads to lower permeability of the samples and a higher propensity to spall. It was reported in the study that applying a slow heating rate of 0.5 °C/min resulted in no spalling at all for the samples made using VC, while samples made with self-compacting mix (without fibre) spalled explosively (for each mentioned study, see more details in Table 1).

Table 1.

Heating rate, measurements type, and loading of the scientific research that studied the effects of type of concrete on its spalling of concrete as reported in the literature.

Anand et al. [57] found that the reduction of strength with increasing temperatures was more severe for SCC concrete than it was for VC when other parameters were kept constant. Similar conclusions were made by Presson [58]. Other researchers [59] observed that SCC mixes were more susceptible to spalling, but that the level of strength loss was more severe in VC than SCC. The authors suggested that if spalling could be controlled (i.e., via the addition of PP fibres), then the residual mechanical properties of SCC mixes would be higher than VC when exposed to elevated temperatures.

Jansson and Boström [54] reported that the probability of high-strength SCC to spall was higher than the corresponding high strength VC. Bakhtiyari et al. [59] also reported that the likelihood of SCC to spall was higher than VC; however, the rate at which mechanical properties of concrete deteriorate at elevated temperatures was found to be steeper in SCC than it was in VC.

The contradictions that exist in the reported literature make it difficult to draw conclusions, but overall, SCC mixes seem to be more prone to explosive spalling due to lower permeability [42].

5. Influencing/Mitigating Factors

There are many factors that can, and do, influence the spalling behaviour of concrete subjected to elevated temperatures [5,16,27,60,61,62,63,64]. The influencing parameters can be generally divided into four categories [43]:

- I.

- Material: factors related to the properties of the materials used in the mix design of the concrete specimens that are subjected to thermal loading.

- II.

- Structural: factors related to the function that the concrete sample is assumed to be serving when in service (i.e., column, beams, slabs, etc.).

- III.

- Mechanical: factors associated with the presence of any externally/internally applied loads and the restraint conditions for the sample when it is exposed to elevated temperatures.

- IV.

- Temperature: the rate of heating and the max temperature that the sample is exposed to when spalling tests are performed.

These factors are all shown to influence the spalling behaviour of concrete. In the next section, the effects of the most influential factors are discussed as reported in the public literature over the past 15 years, with a particular focus on studies involving self-compacting concrete (SCC). In some locations, older references have been included due to their high relevance to the topic of heat-induced concrete spalling.

5.1. Permeability

The permeability of concrete has a major effect on its durability. Researchers have observed that a denser matrix leads to a reduction in the amount of hazardous material that could ingress into the structure of the concrete and cause damages [51].

Permeability is also a big factor in how concrete responds to elevated temperatures; several researchers have noticed that increased permeability almost always leads to a better response as far as spalling is concerned (relevant publications are highlighted in the coming paragraphs). In fact, almost every other factor affecting the spalling of concrete could be viewed from the prism of permeability, as outlined in the next few sections of this paper. Generally, measures that lead to a rise in permeability of concrete at elevated temperatures have a positive impact on the spalling propensity of concrete. One of the most effective ways of mitigating the risks of spalling is through the addition of PP fibres, which most researchers agree improve the spalling behaviour of concrete by increasing its permeability (for each mentioned study, see more details in Table 2). The next section will explain this in more detail.

Table 2.

Heating rate, measurements type, and loading of the scientific research that studied the effects of permeability on the spalling of concrete as reported in the literature.

The permeability of concrete has a major effect on its durability. Researchers have observed that a denser matrix leads to a reduction in the amount of hazardous material that could ingress into the structure of the concrete and cause damages [51].

Permeability is also a big factor in how concrete responds to elevated temperatures; several researchers have noticed that increased permeability almost always leads to a better response as far as spalling is concerned (relevant publications have been highlighted in the coming paragraphs). In fact, almost every other factor affecting the spalling of concrete could be viewed from the prism of permeability, as outlined in the next few sections of this paper. Generally, measures that lead to a rise in permeability of concrete at elevated temperatures have a positive impact on the spalling propensity of concrete. One of the most effective ways of mitigating the risks of spalling is through the addition of PP fibres, which most researchers agree improves the spalling behaviour of concrete by increasing its permeability. The next section will explain this in more detail.

At elevated temperatures, lower permeability may cause explosive spalling due to vapour pore pressure being unable to escape [51] or due to a slow drying front [25] (these concepts are further expanded on later).

Dauti et al. [65] found that the permeability of concrete samples increased with increasing temperature. They found that the rate of the increase in permeability was also affected by the heating rate; the higher the heating rate was, the higher the rate of increase in permeability. The researchers found that axial permeability was influenced by the existence of compressive stresses, even at very low values, such as 0.6 MPa (compared with concrete strength of about 50 MPa).

Peng et al. [66] looked into the effects of curing on spalling. It was observed that combined curing increased permeability of samples and this led to an improvement of their spalling behaviour. The researchers reported that there was little difference in the total amount of pores between samples that spalled and samples that did not. However, it was noted that samples that did not spall had a pore size distribution which was significantly different to samples that spalled. In specimens that were cured using normal curing, pore sizes were either large or small, but in the samples subjected to combined curing (which performed better during spalling tests), pores were refined and there was a better distribution of large, medium, and small pores. This could be the result of having a more connected structure, which enables the movement of moisture at elevated temperatures without causing localised stresses that could lead to spalling.

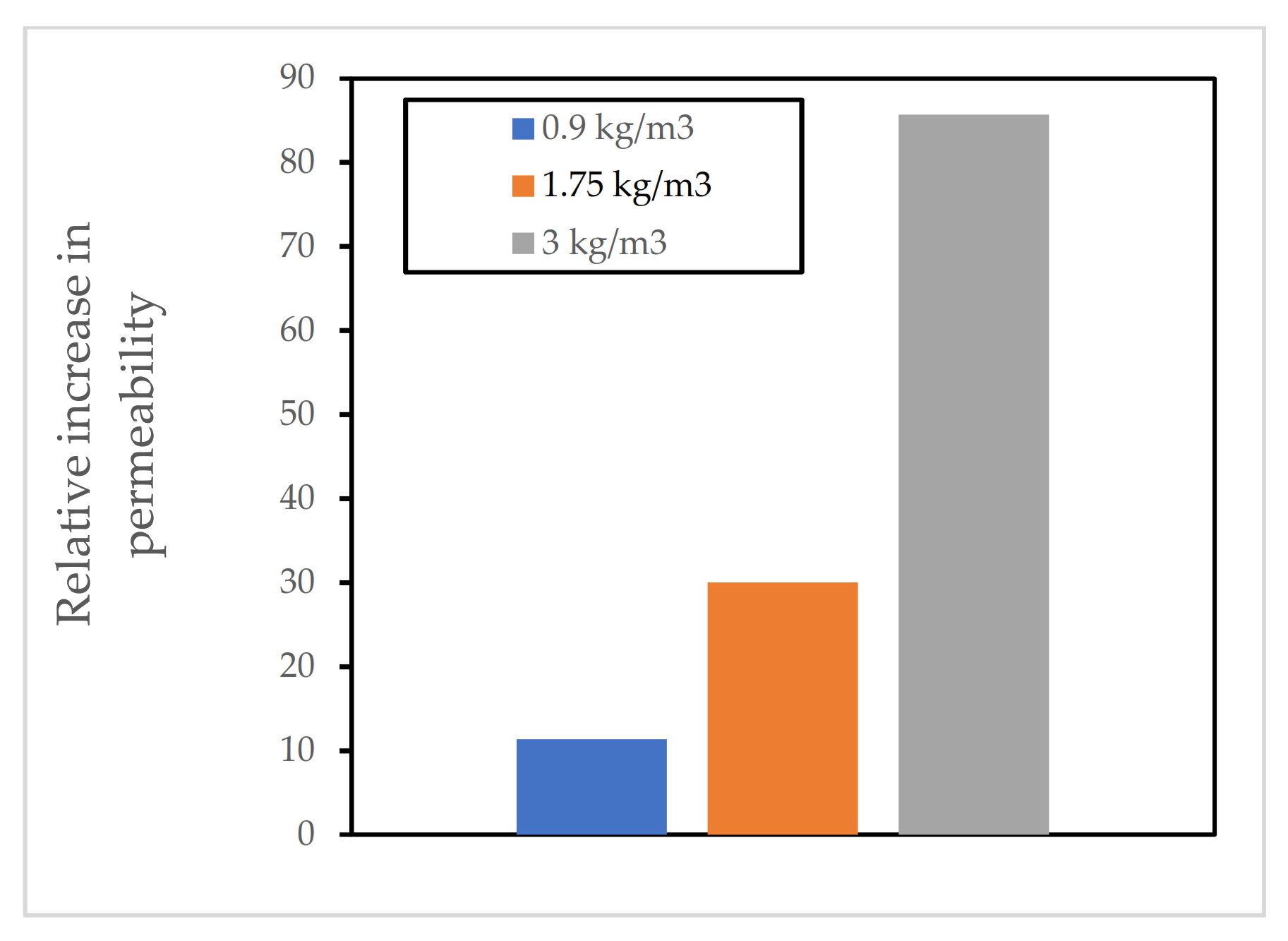

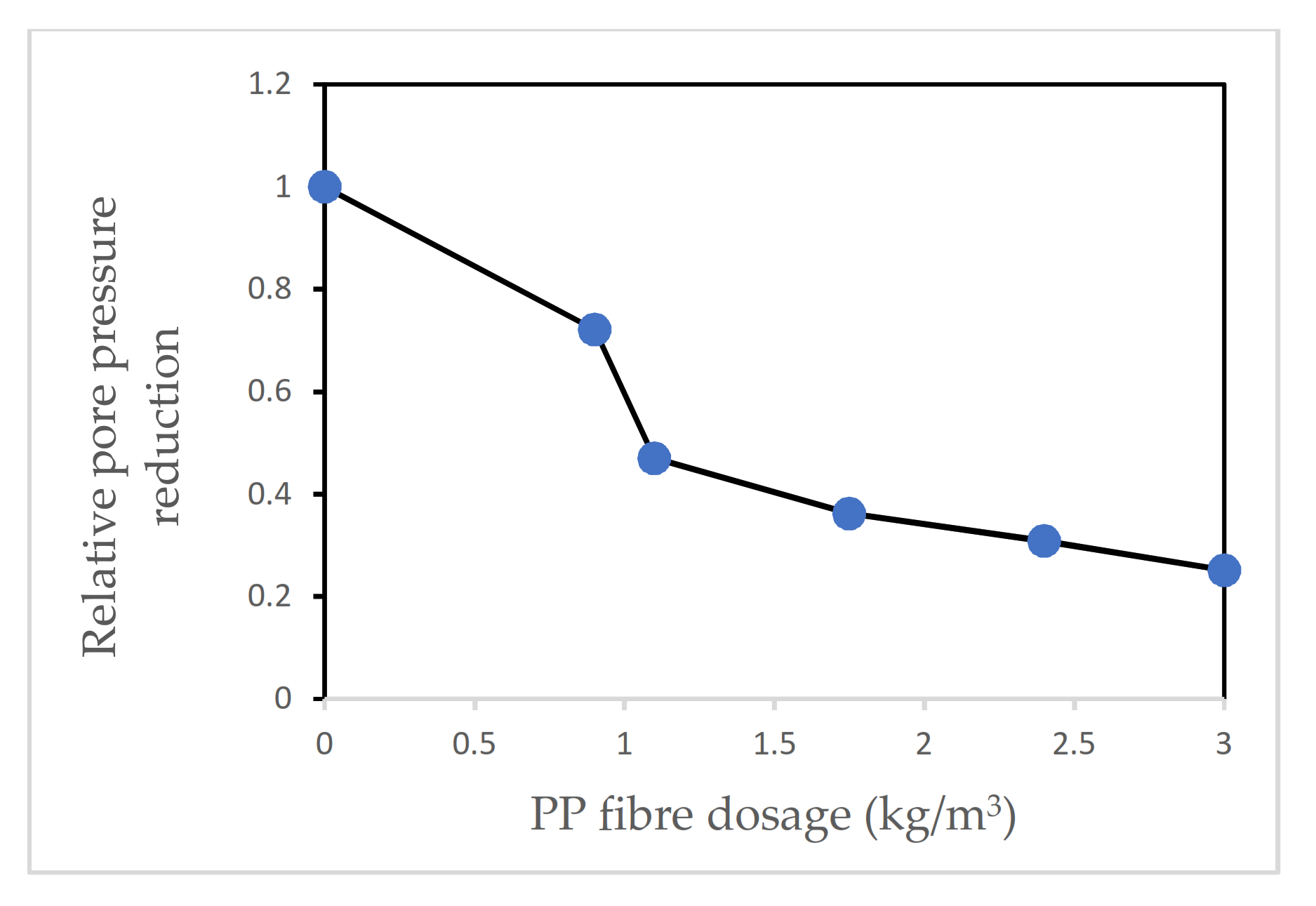

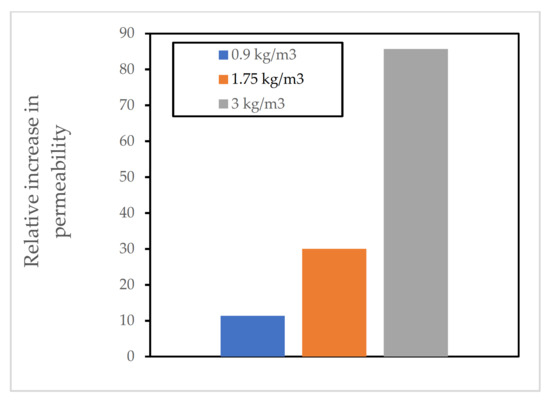

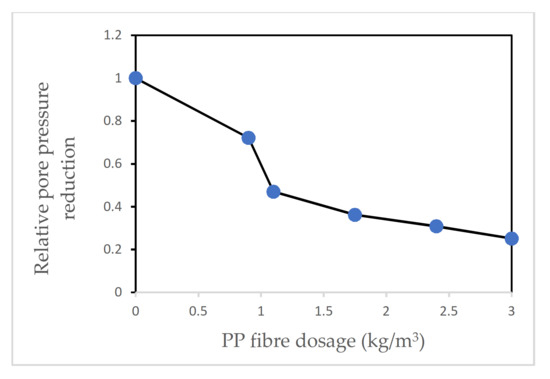

Kalifa et al. [17] investigated the effects of adding PP fibres to HPC at elevated temperatures. Based on the results, it was observed that the addition of PP fibres improved the performance of concrete at elevated temperatures. The researchers noted that this improvement was accompanied by a big rise in the permeability of the samples that had PP fibre added to them. For mixes with a dosage of 3 kg/m3 of PP fibre, it was noticed that the relative permeability (permeability of fibre samples/permeability of non-fibre samples) increased by as much as 85 times at 200 °C. It was also noted that the intrinsic permeability of all samples increased with rising temperature, but the rise in samples with PP fibres was far bigger than samples without fibres. This rise in permeability was accompanied by a big drop in pore pressure for the samples. Maximum pore pressure of 4 MPa was reported for samples without PP fibres whilst pore pressure had a peak value of just over 1 MPa when 3 kg/m3 PP fibre was added to the mix. Figure 5 and Figure 6 [17] show the relative increase in the gas permeability of the concrete mixes and the reduction in the value of the peak pore pressure compared to that of concrete mixes without PP fibres, respectively.

Figure 5.

Increase in the relative permeability of concrete samples with PP fibres compared to samples without PP fibres at 200 °C.

Figure 6.

Relative reduction in the peak pore pressure with the increased dosage of PP fibres.

Zeiml et al. [67] also looked at how PP fibres improve the spalling behaviour of concrete. The authors concluded that the inclusion of PP fibres results in the rise of permeability of the samples at elevated temperatures. However, their results indicated that this rise in permeability took place at temperatures below the melting point of the fibres. The authors reported that at temperatures below 140 °C, the permeability of concrete samples with 1.5 kg/m3 of PP fibres was 3 to 4 times larger than the permeability of samples without PP fibres. According to the authors, this extra permeability, before the melting of fibres in the concrete, is introduced due to the additional interfacial transition zones (ITZ) that are brought about by the fibres.

Miah et al. [21] found that the gas permeability of concrete samples was affected significantly by the applied loads. They reported that the permeability of concrete could either increase or decrease depending on the direction of the compressive load that is applied to the samples. According to the authors, axial permeability increased when preheated samples were loaded axially (parallel to the cracks). Radial permeability, on the other hand, reduced when the axial load was increased for preheated samples up to a certain level of load. After this, permeability stabilised and then increased with a further increase of the load. This is said to be the result of the closing of the cracks (due to the load) and then the opening of the cracks at higher loads due to lateral expansion (Poisson’s effect).

Bosnjak et al. [18] noticed that the addition of PP fibres caused a sudden rise of nearly two orders of magnitude in permeability of concrete samples between temperatures 80 °C and 130 °C. Beyond the range of 130 °C, the rate of increase in permeability was stated by the authors to be almost the same as concrete without fibres. The authors stated that, based on the results, the increase in permeability of fibre reinforced concrete was not related solely to the melting of PP fibres. It was concluded that explosive spalling was prevented in HPC via PP fibres because of the increased permeability.

Ding et al. [68] explored the effect of different fibres on pore pressure for SCC at elevated temperatures. According to the study, pore pressure was reduced significantly in samples with fibres. This is explained by the introduction of extra ITZ around the fibres, which in turn enhances permeability. The increase in permeability was reported to inversely hinder the formation of moisture clog, and this delayed/prevented the occurrence of explosive spalling.

Niknezhad et al. [69] reported that there was no significant difference in the structure between concrete with PP fibre and concrete without PP fibre at room temperature. This changed when the temperature was increased to 500 °C. The SCC with PP fibre showed a greater porous network than concrete samples without PP fibre. This is said to be due to the melting of the fibres that created supplementary porosity in the cementitious paste.

The highlighted studies above all show that measures that result in having a more permeable sample lead to an improvement in the spalling behaviour of concrete at elevated temperatures. The next section shows the impact of adding PP fibres as a way of mitigating spalling.

5.2. Addition of Polypropylene Fibre (PP)

It is almost universally agreed upon that the addition of PP fibres is one of the most effective ways to reduce/eliminate spalling in concrete subjected to elevated temperatures. Since the early 1980s, when one of the first reported studies on the effects of the addition of polymers was published [70], numerous studies have been conducted on the effects of the addition of PP fibres into concrete mixes as a way of countering spalling.

The addition of PP fibres to high-performance concrete (HPC) and ultra-high-performance concrete (UHPC) is now included in some design codes in various countries [38]. The Eurocode [38] states that for concrete grades between C80/95 and C90/105, 2 kg/m3 PP fibre by weight of cement should be added to the mix to avoid spalling. This value, though, is contested by some researchers who have observed that spalling is still likely even after the addition of 2 kg/m3 of PP fibres [71,72]. Furthermore, the code specifies neither the geometry nor the type of the PP fibres to be used, which are shown to significantly affect the spalling behaviour of HPC [48,73,74,75].

Despite its wide usage, the exact mechanism with which PP fibres reduce spalling is not yet fully known [5,6,48]. Some researchers [18,41,51] have concluded that PP fibres release the water vapour pressure (through increased permeability) generated within the concrete when it is subjected to an incident heat flux. However, other researchers [25] have disputed this theory and believe that PP fibres enhance the spalling behaviour of concrete in two ways: first, by reducing moisture in the critical zone that adversely affects the mechanical properties of the concrete, and second, by moving moisture away from the critical zone, which leads to the forming of larger drying creep that releases the thermal stresses within the critical zone.

Below, each of these mechanisms are discussed and the supporting evidence is highlighted.

5.2.1. Pressure Relief Mechanism

The pressure relief mechanism is a theory that has garnered a lot of attention amongst researchers investigating how PP fibres enhance spalling behaviour of heated concrete. According to researchers [18,20,41,51,67,76], PP fibres release the accumulated water vapour pore pressure in concrete in the following ways:

- I.

- Discontinuous reservoirs: because the coefficient of thermal expansion of PP fibres is a few orders of magnitude bigger than that of the surrounding paste, micro-cracks are formed when the sample is heated due to the expansion the PP fibre. These micro-cracks lead to increased permeability, which results in pore pressure being released outside of the sample subjected to elevated temperature.

- II.

- Continuous channels: the difference in polarity between PP fibre and water, with PP fibre on one hand and cementitious paste on the other, leads to poor adhesion between PP fibre and the surrounding concrete. Due to this poor interface adhesion, moisture transport can happen via capillary action. PP fibres show thermal instability at temperatures above 80 °C; this is key for this theory to materialise because a weakened PP fibre makes it easier for vapour pressure to escape. Studies [67] have shown that the permeability of concrete samples with PP fibres was 3 to 4 times higher than concrete without PP fibres at temperatures below 140 °C. Since PP fibres melt at about 165–175 °C [77], and the porosity of the samples with and without PP fibres was not significantly different at this temperature range, this further validates the continuous channel theory.

- III.

- Vacated channels: at higher temperatures, PP fibres start to melt and then vaporise, leaving behind a series of channels that allow for vapour pressure to escape. This theory is said [41] to be less favourable than the previous ones since the size of these channels is roughly 20–30 µm when the typical capillary pore size within the concrete is 1 µm.

5.2.2. Drying Creep

This mechanism is proposed as an alternative to the pressure release theory. According to this theory [25], PP fibres help to move moisture away from what is defined as the critical zone by the authors. This helps, according to the authors, to improve spalling behaviour of concrete in two ways; (1) the presence of moisture affects the mechanical properties of concrete adversely, and by moving moisture away, the concrete layers at the critical zone retain more of their strength which gives it better spalling resistance; (2) by moving moisture away from the critical zone, the drying creep zone becomes bigger. This helps to release more thermal stresses that were generated by the in-through temperature gradient.

5.2.3. Effects of PP as Reported in the Literature

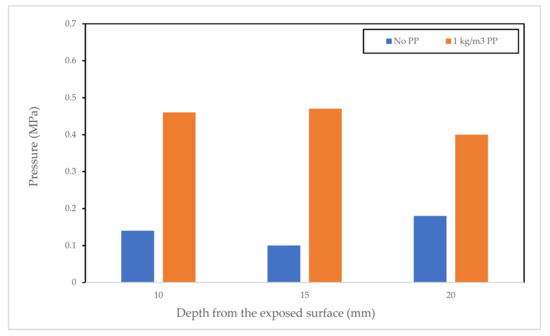

Researchers have tried to understand the influence of PP fibres on SCC and the mechanism with which PP fibres help to enhance spalling resistance of concrete. Jansson and Boström [25] investigated the influence of pore pressure on spalling. They casted a large number of specimens [78] that ranged from small slabs (600 mm × 500 mm × 200 mm), large slabs, (1800 mm × 1200 mm × 200 mm) and beam samples (3200 mm × 600 mm × 200 mm). Samples had small tubes (2 mm diameter) inserted during casting. Just before the start of the tests, these tubes were filled with silicon oil with a syringe to ensure that no air bubbles were formed at the bottom. The ends of the tubes were connected to a pressure gauge to measure pressure at different depths from the exposed surfaces (for each mentioned study, see more details in Table 3).

Table 3.

Heating rate, measurements type, and loading of the scientific research that studied the effects of PP on the spalling of concrete as reported in the literature.

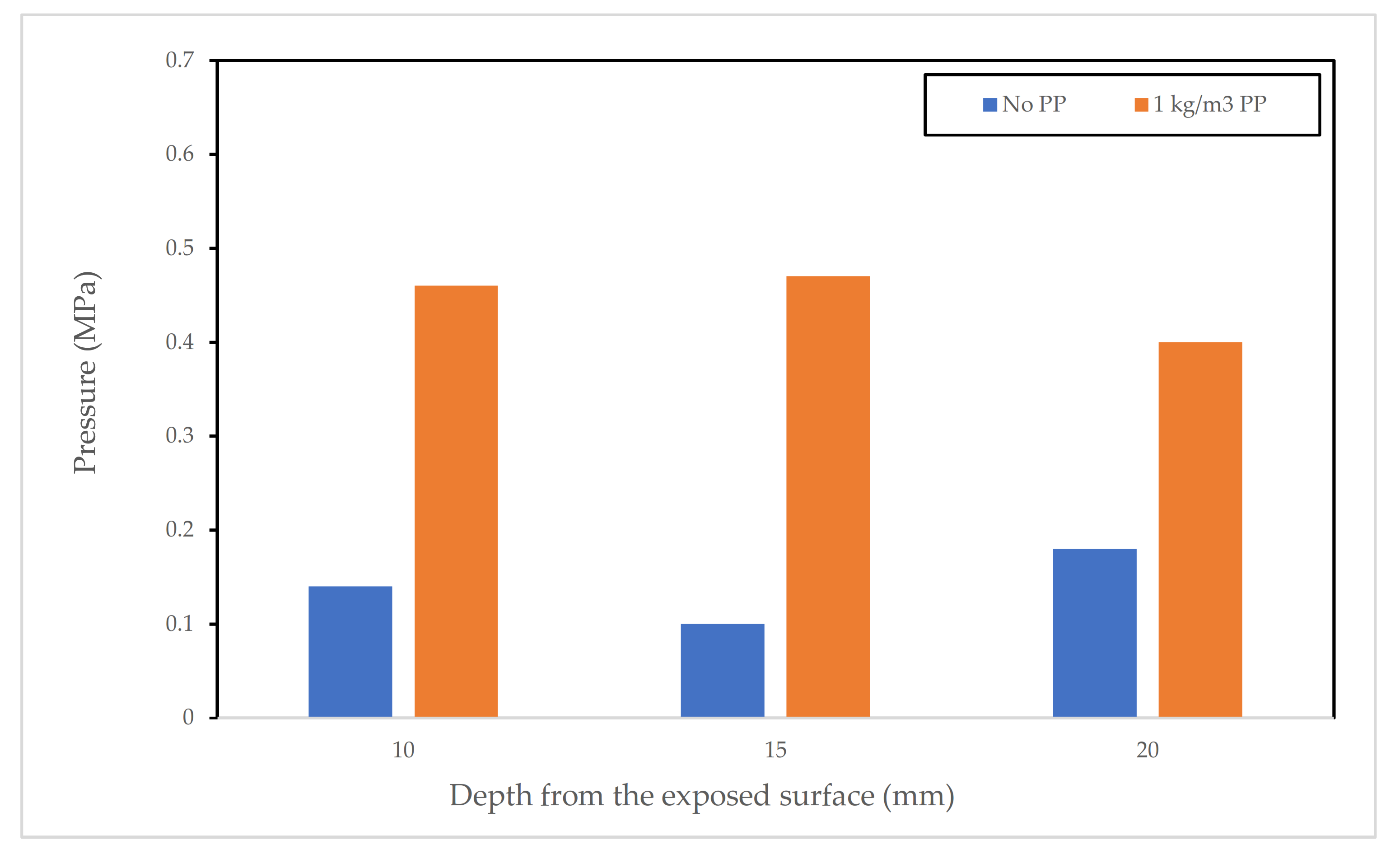

The mixes were cast with a W/C ratio of 0.4. Mix SCC B contained a dosage of 1 kg/m3 of PP fibres (18 µm diameter) while mix SCC A did not contain any PP fibres. The samples were then subjected to standard (EN 1363-1) fire, modified Hydrocarbon (HCM), and Rijiskwaterstaat fire curves. All the samples were loaded unidirectionally during testing with 10% of their compressive strength.

Results from the tests show that mix SCC B did not spall whereas the SCC A mix experienced spalling. Pressure measurements taken from this test (at different depths from the exposed face) show that the pore pressure was higher in samples that contained PP fibres (i.e., samples that did not spall) except for one case where the reverse was true. These findings can be seen in Figure 7. The authors concluded that, based on their findings, pore pressure was not the main factor behind spalling of concrete.

Figure 7.

Peak pore pressure for SCC A and SCC B during exposure to HC fire. Slabs with PP fibre recorded higher peak pressure values than slabs without PP fibres.

The researchers published further findings of their report in [60]. They reiterated the positive influence of PP fibres. It was reported that no specimen with PP fibres exhibited any signs of spalling except for one sample, which showed some flaking. The authors reported that this was due to loading. The authors reported that PP fibres accelerated the formation of the drying creep in the critical zone, and this worked to destress the concrete in the critical zone. However, regardless of the point that the researchers raise, PP fibres in this case still work by accelerating the moisture migration from the critical zone through enhanced permeability.

Terrasi et al. [79] performed a large experimental programme to investigate the fire behaviour of prestressed Carbon Fibre Reinforced Polymer (CFRP) High-Performance self-compacting concrete (HPSCC). The slabs had three different thicknesses and three different lengths. Three different mixes were used for the slabs. Mix 042 (no PP fibre), Mix 142 (2 kg/m3 PP fibre) and Mix 242 (5 kg/m3 PP fibre). The samples were tested in a large-scale fire test corresponding to the ISO 834 fire curve. The slabs were loaded in four-point bending to a level that ensured the decompression of the exposed surface of the slab (i.e., the level of the applied load was determined based on the amount of prestressing within the slabs at the time of testing). In total, 20 CFRP pre-stressed slabs and 2 slabs prestressed with steel tendons were tested.

It was observed that the samples without PP fibres (Mix 042) all spalled extensively in under 30 min. The authors noted that the addition of PP fibres enhanced the spalling resistance of identical slabs. However, only the samples with 5 kg/m3 (Mix 242) did not show any spalling at all. Accordingly, requirements in the Eurocode [38] for High-Performance Concrete (HPC) to have 2 kg/m3 of PP fibre seem to be insufficient to fully avoid spalling at elevated temperatures. The geometry of the PP fibres used in this study was not reported by the authors. This finding shows that the threshold reported by Kalifa et al. [17] and the amount of PP fibre required by the Eurocode [38] are not sufficient to mitigate spalling completely.

The findings from the above study [79] were corroborated by further research. Maluk et al. [11] tested five slabs under almost similar circumstances. In the experiments, five prestressed CFRP HPSCC slabs were cast. The slabs were 45 and 60 mm in thickness. The prestressing of the slabs took place via stressing the CFRP tendons to an initial 1000 MPa. Two different mixes were used: Mix #A (2 kg/m3 PP fibre, 3 mm long) and Mix #B (1.2 kg/m3 PP fibre, 6 mm long). The PP fibres were monofilament fibres that had a cross-section of 32 µm.

The slabs were tested in a single, large-scale fire test using the standard ISO 834 fire curve. The samples were subjected to four-point bending during the test. The level of the load was determined such that the exposed faces of the slabs were decompressed (i.e., σc Bottom = 0 MPa).

It was noted that samples from Mix #A (containing 2 kg/m3 PP fibre, 3 mm long) tended to spall explosively (3 out of 2 samples) whereas both slabs belonging to Mix #B did not spall. The researchers stated that this was clear evidence that the geometry of fibre influences spalling of concrete as well as its dosage. The method through which PP fibres enhanced the spalling properties of concrete was not investigated by the researchers.

In a detailed experimental programme, Maluk et al. [48] investigated the effects of PP fibre dosage, geometry, number of fibres, type (by supplier), and surface area of fibres on the spalling propensity of HPSCC. In total, 66 medium-sized, unreinforced samples of dimensions 500 × 200 × 45 mm were tested using the Heat-Transfer Rate Inducing System (H-TRIS), a novel technique that utilises radiant heat panels, which were developed at the University of Edinburgh [80]. Samples were subjected to a variable incident heat flux with a maximum value of 100 kW/m2. This thermal load was kept for 60 min unless spalling happened before this time. A mechanical loading rig was used to induce compressive stress into the samples during testing. The maximum applied compressive stress during these tests was 12.3 MPa, based on prior research by the authors [6].

Results obtained by the authors indicated that the inclusion of PP fibres with a smaller cross-section were more effective in reducing the propensity of concrete to spall, although the reason for this was not explored by the authors. As for the length of fibres, the authors reported that mixes with shorter fibres (3 mm) exhibited a higher propensity to spall than mixes with longer fibres (6 or 12 mm). Monofilament and multifilament fibres were reported to reduce the propensity of spalling more than fibrillated fibres, although the authors note that this could be related to the difference in surface area for each type.

The results from this study [48], again, suggest that the dosage of PP fibre is not the only influencing factor for spalling propensity. It was observed that some samples, which included a low dosage of 0.68 kg/m3 of PP fibres with a smaller cross-section (18 µm diameter), did not spall, while samples containing as much as 2 kg/m3 of fibres with a bigger cross-section (37 µm × 200 µm) did. Further, it was noticed that surface area was an important factor in determining the propensity to spall the tested samples. Specimens that included 2.34 kg/m3 and 20 mm long fibres did not spall despite having a low number of fibres and a low total length, but they did have a similar surface area compared to other mixes. This, the researchers suggest, shows the importance of the surface area of fibres in improving the spalling behaviour of concrete.

Sultangaliyeva et al. [74] also found that the geometry of PP fibres strongly influences the yield stress of cement pastes. The authors reported that the yield stress of cement pastes increased generally with the increase of the fibre dosage, but the rate of this increase was significantly influenced by the geometry of the fibres used. For the fibres (length = 6 mm, diameter = 18 µm) the increase in the yield stress is 50% more than the increase obtained when using stockier fibres (length = 18 mm, diameter = 34 µm). Further research by the same author [81] suggested that 12 mm long PP fibres were almost 50% less efficient in preventing spalling than 6 mm long PP fibres. This could be a direct result of the deformation that the fibres experience when the concrete is mixed, resulting in shorter fibres providing a higher percolation than longer PP fibres.

Al Qadi et al. [82] investigated the effects of PP fibres on the residual properties of SCC. In this study, four concrete mixes with varying dosages of PP fibres were tested. The mixes were M 0.00 (no PP fibre), M 0.05 (5% PP fibre by volume), M 0.10 (10% PP fibre by volume), and M 0.15 (15% PP fibre by volume). The authors cast 42 cubes and cylinders using the mixes described. Samples were cured for 89 days using a wet curing method. After this period, the samples were tested in an electrical oven for temperatures 200, 400, and 600 °C. The applied heating rate of the oven was 5–10 °C/min. Two testing regimes were followed: heating for two hours and heating for four hours.

The authors observed that the residual strength (both compressive and tensile) of samples containing PP fibres was greater than samples that did not. The authors concluded that 0.05% PP fibre was the optimum dosage since it led to the greatest amount of retention of concrete’s mechanical properties at elevated temperatures.

These findings, however, contradict other researchers’ works. Uysal and Taniyildiz [83] investigated the effects of PP fibres and other mineral additives on the residual compressive strength of SCC after exposure to elevated temperatures. The researchers cast concrete cubes with and without the addition of PP fibres (2 kg/m3 dosage) and evaluated the residual compressive strength after subjecting the samples to a heating rate of 1 °C/min in an electric oven. The samples were subjected to 200, 400, 600, and 800 °C. The samples were cooled down at a rate of 0.4 °C/min after 3 h of exposure to the thermal load. The researchers found that the residual compressive strength of samples containing PP fibres was significantly lower than identical samples without PP fibres. Other researchers [55,84] arrived at similar conclusions. Interestingly, the research results performed in [55] suggest that SCC mixes were less prone to spalling compared to Vibrated Concrete (VC) of the same strength class (no explanation is given with regards to this). This is contradictory to what others have reported [54].

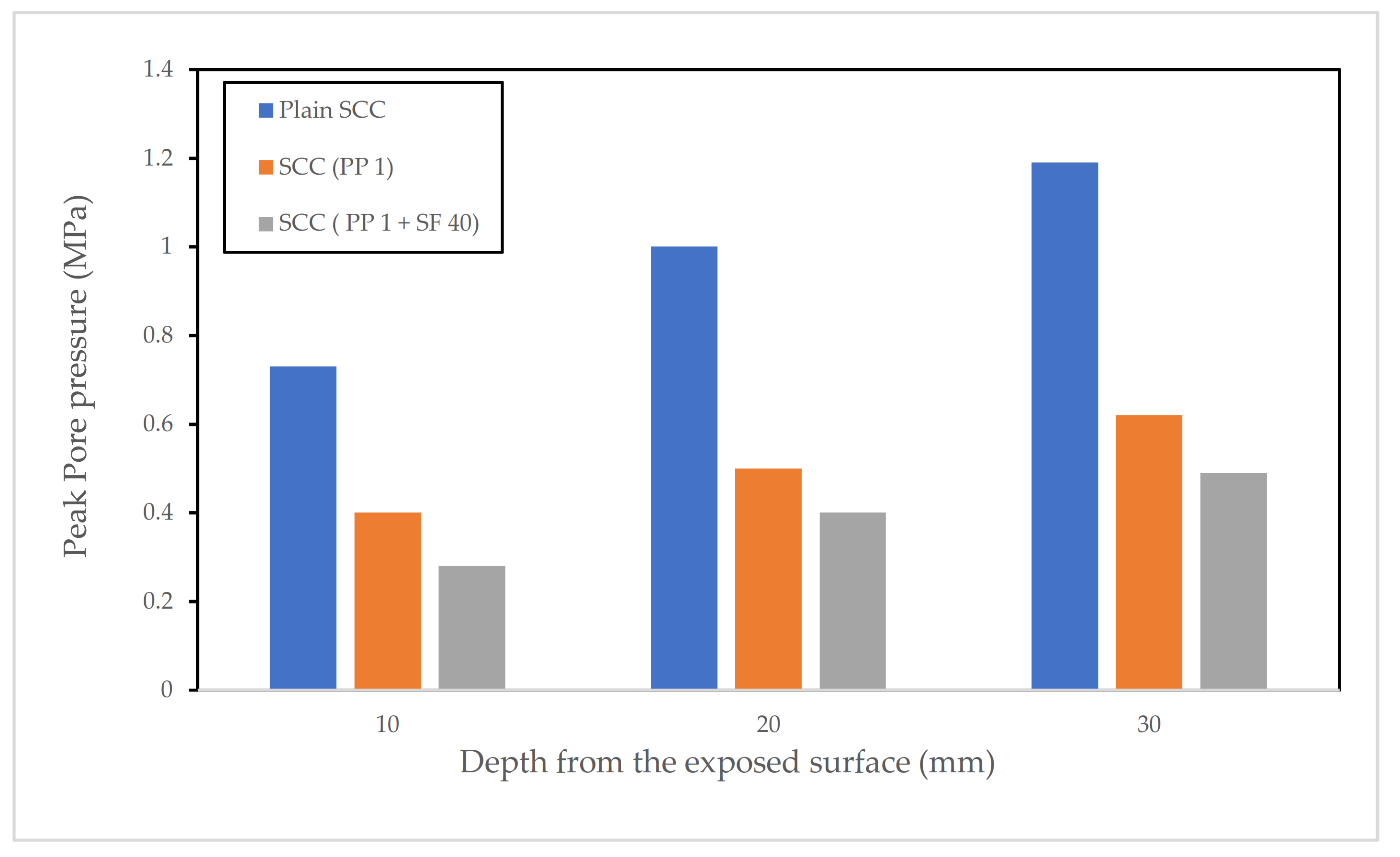

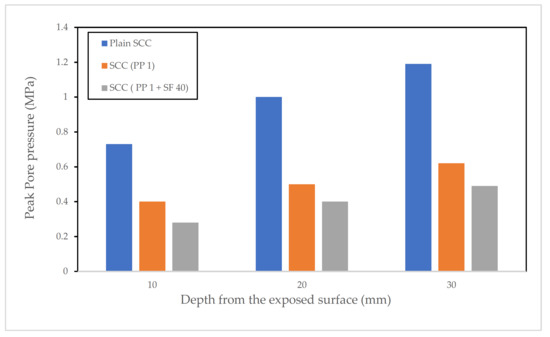

Y. Ding et al. [68] investigated the effects of micro PP fibres and macro PP fibres on the spalling behaviour of SCC. The authors prepared 7 different mixes with each mix containing different dosages of either micro-PP fibre or macro PP fibre. Steel fibres (SF) were also used in some of the mixes. The geometry of the microfibres was (length = 9 mm, diameter = 18 µm), and the macro fibre (length = 45 mm, diameter = 74 µm). The microfibre was added to the concrete mixes in doses of 0.5 and 1 kg/m3 while the macro fibre was added at a much larger dosage of 4 kg/m3. All the mixes were reported to have a compressive strength between 60 and 70 MPa. From these mixes, small beams (150 mm × 150 mm × 550 mm) were cast and wet cured for 28 days. Small tubes were inserted into the mix during the casting of concrete at depths of 10, 20, and 30 mm away from the exposed face of the specimen. These tubes were filled with silicon oil before testing and the end was attached to pressure sensors to measure the pore pressure at these points. Fire tests were then performed to the standard temperature-time curve outlined in ISO 834. Peak pore pressure values at different depths from the exposed surface are shown in Figure 8.

Figure 8.

Peak pore pressure values at various depths from the exposed surface.

The researchers [68] conclude that the micro PP fibres play a big role in reducing the pore pressure of the samples subjected to elevated temperatures. It was reported that the inclusion of fibres led to a delay in the formation of peak pressure within the concrete, and that the peak pressure in samples containing PP fibres was much smaller than samples that did not.

From the results obtained in [68], the researchers reported that the inclusion of micro PP fibre with SF leads to the best results for the prevention of spalling. It was also reported that measured pore pressure was lower in all samples containing some form of fibres (either PP or SF). This is because of the introduction of new percolation paths by the fibres, which provides a path for the vapour pressure to escape. These paths are likely due to the percolation of the ITZ of the fibres. The authors also reported that the lowest pressure in all the samples was observed closer to the exposed face. This highlights the importance of heat in the build-up of pressure, according to the authors. The researchers observed a steep decline in the mechanical properties of concrete with rising temperatures but noted that the mixes including a cocktail of fibres retained a bigger portion of their strength compared to plain SCC at similar temperatures. The conclusions of the work noted above match well with the results of the investigation into the effects of the cross section of PP fibres on enhancing spalling resistance reported in [48].

Bangi and Horiguchi [75] studied the effects of fibres on pore pressure. They arrived at conclusions that were similar to those obtained in [68]. They casted several cylinders (diameter = 175 mm, length = 100 mm) and tested them using an electric heating plate that could induce a maximum temperature of 600 °C onto the samples. Based on their findings, the authors concluded that the use of longer PP fibres with a smaller cross-section (length = 12 mm, diameter = 16 or 18 µm) performed better than shorter, stockier fibres (length = 6 mm, diameter = 28 and 40 µm) regarding pore pressure reduction. They also noted that PP fibres performed better than polyvinyl alcohol (PVA) fibres. This is said to be due to the lower melting point of PP fibres compared to PVA and its bonding properties. The authors also noted that organic fibres with a melting point close to or lower than the spalling temperature range 190–250 °C performed better, as far as spalling reduction is concerned.

Noumowé et al. [56] investigated a large number of parameters, such as the effect of PP fibre inclusion, heating rate, and type of concrete (SCC or VC). The authors prepared four mixes: High-Strength Concrete (HSC), High-Strength Concrete with fibres (HSCF), High-Strength Self-Compacting Concrete (SCHS), and High-Strength Self-Compacting Concrete with fibre (SCHSCF). The PP fibre dosage was 2 kg/m3. Cylinders (diameter = 160 mm, height = 320 mm) and prisms (100 mm × 100 mm × 400 mm) were cast and air-cured for 90 days before testing. Samples were subjected to both a rapid heating ISO 834 fire curve and a slow heating rate of 0.5 °C/min up to 600 °C.

The authors observed that no samples containing PP fibre experienced any spalling at all. This, according to the authors, is evidence of the benefits of including PP fibre in High-Strength Concrete mixes. They also stated that having PP fibres in the HSSC led to slightly lower mechanical properties at ambient temperature compared to their identical counterpart that did not include PP fibre. Having PP fibre also led to lower residual strength of HSCC samples after they were exposed to elevated temperatures. The authors stated that since PP fibres led to a more permeable mix at elevated temperatures, it is therefore common for such mixes to have lower residual strength after exposure to elevated temperatures.

Lura and Terrasi [72] explored a novel approach to reduce/eliminate spalling by adding a cocktail of super absorbent polymers (SAP) and PP fibres together. They hypothesised that the SAP particles (with a diameter ranging between 100 and 300 µm) form water-filled voids. These voids, when the sample is heated, will become void of water, and will form a pore system that allows for the percolation of the ITZ of the PP fibres at lower doses. This is similar to air entrainment agents, but the authors note that the addition of SAP (instead of air entrainment) has the advantage of pore stability and compatibility with superplasticisers and fly ash in the concrete mix.

The researchers cast 6 slab samples (1080 mm × 175 mm × 45 mm) with each slab having 4 CFRP prestressing tendons in the middle of the section. These tendons were stressed to between 1000 and 1200 MPa, creating a central compressive prestress between 7.6 and 105 MPa. Samples were cured for one week in 90% relative humidity (RH) and then for 6–8 months at 50% RH before testing. Fire tests were performed using a small furnace at EMPA laboratories in Switzerland. The time-temperature curve used for this study was the standard ISO 834 fire curve.

The results from the study show that both slabs, which included only PP fibres (2 kg/m3 dosage), experienced spalling (at 15 min and 18 min from the start of the test) while slabs containing a mix of both SAP + PP did not show any signs of spalling at all. The authors note that the addition of SAP did reduce the compressive strength of the concrete by about 12% at 90 days. This was explained by the authors to be because of the extra porosity that is generated within the concrete matrix due to the inclusion of SAP. The authors note that this reduction could be overcome by optimising the amount of SAP (1.93 kg/m3 were used in this study) and the size of the SAP particles used.

Bosnjak et al. [18] also reported a sudden rise in permeability of samples that included PP fibres when the concrete temperature was ranged from 80 to 160 °C, which is below the melting temperature of PP fibres. The authors explained this as follows: PP fibres have a melting temperature of 171 °C but exhibit thermal instability at about 120 °C. This is accompanied by a reduction in elastic modulus of the fibres, and they become soft. Further, due to the nature of PP fibres, they expand transversely to the direction of the fibre while shortening in length when exposed to heat. A combination of these actions, the authors concluded, leads to the weakening of the bond between the fibre and the surrounding cement paste. This, in turn, leads to a rapid rise in the magnitude of the gas permeability. Due to this, vapour pressure can find a path and move past the not-yet molten PP fibres. These findings further solidify the continuous channel theory that was discussed at the start of the section.

Xargay et al. [85] investigated the residual mechanical properties of high-performance SCC with and without the inclusion of fibres after they had been subjected to elevated temperatures. The authors casted cylinders (diameter = 100 mm, height = 200 mm) and beams (150 × 150 × 600 mm) from 2 different mixes: one was plain SCC and the other had a mixture of steel and PP fibres. Samples were cured at room temperature for 28 days at 90% RH before testing. Testing was performed using an electric furnace. Mechanical properties of samples were tested at 20 °C and after being exposed to 300 °C and 600 °C. The authors reported that the addition of fibres led to samples retaining a bigger portion of their mechanical properties after exposure to higher temperatures compared to samples that did not have fibres in them. Further, the authors noticed that the addition of fibres also led to better integrity of the samples post-exposure to 600 °C and post cracking.

Zhang et al. [86] also investigated the effects of PP fibres on permeability and spalling. They used disc-shaped concrete samples (diameter = 150 mm, height = 45 mm) made using UHPC for gas permeability measurements. They also casted cylinders (diameter = 50 mm, height = 100 mm) to investigate the spalling behaviour of the mixes. The concrete mixes had a compressive strength between 148 MPa and 159 MPa. A 3 kg/m3 dosage of PP fibres (length = 12 mm, diameter = 33 µm) was used for the mixes with fibre in them. Discs were heated at a rate of 1 °C/min to 100, 150, 200, and 300 °C. For the spalling tests, the standard time-temperature curve per ISO 834 was used.

The authors reported that permeability increased in all samples with increasing temperature. However, there was a sudden rise of two orders of magnitude in permeability for samples including PP fibre when the concrete temperature was between 105 °C and 150 °C. The authors state that this sudden rise in permeability is because of a network of micro-cracks forming at the fibre-matrix interface due to thermal expansion incompatibilities between the fibres and the surrounding cement paste. Other researchers [21], however, found a similar increase in permeability in concrete samples with no fibres in them. They associated this with the possibility of pores becoming accessible due to the removal of free and physically bound water in these pores.

Y. Li et al. [73] investigated the effect of the geometry of PP fibres on spalling through permeability. The authors found that increasing the length of the PP fibres had a much stronger effect on permeability than increasing the cross-section of the fibre. This was explained by the greater percolation that longer fibres would help to form compared to shorter and thicker fibres.

PP fibres, based on the studies highlighted above, improve the spalling behaviour of concrete at elevated temperatures. Most of this improvement comes from the extra permeability that can be measured when PP fibres are added to the mix of concrete samples at elevated temperatures. No conclusive answer has been found yet regarding how this extra permeability comes about (i.e., is it due to the melting of the fibres, ITZ of the fibres and the surrounding matrix, or the micro-cracks that are formed in the surrounding cement paste because of the thermal expansion of the fibres?). Furthermore, the questions of the dosage of the fibre and the effects of the geometry of the fibre are other parameters that need to be addressed. The dosage of fibres, particularly, is very important given the adverse effects of PP fibres on the flow properties of SCC, as discussed in the next section.

5.2.4. Effect of PP Fibres on Workability

It is generally accepted that the addition of PP fibres to concrete mixes reduces workability. Many researchers [11,17,69,79,82,83,85] have observed this phenomenon. Further, researchers [48] state that the geometry of the fibre used also affects the workability of concrete mixes. According to the results of tests performed on fresh concrete, it was observed that mixes with 0.68 kg/m3 of 18 µm diameter PP fibres had a slump flow of 740 mm while mixes that included 1.2 kg/m3 of 32 µm diameter PP fibres had a slump flow of 745 mm. This shows that the geometry, as well as the dosage, of fibres has a strong influence on the workability of concrete mixes made using such fibres.

The reason why PP fibres adversely affect the workability of concrete mixes could stem from the fact that flexible fibres (such as PP fibres) tend to bend when they are mixed with concrete [87]. This leads to the fibre occupying any remaining voids within the matrix, which makes the mix denser and less flowable.

5.3. Water/Binder Ratio

The amount of water used in the mixing of the components of concrete has a significant effect on the spalling propensity of the concrete produced (for each mentioned study, see more details in Table 4). Many studies have been conducted and there is a broad agreement that a higher W/B ratio leads to a lower propensity of spalling. This is mainly because a higher W/C ratio leads to a more permeable and porous mix, which is generally associated with better spalling behaviour in concrete.

Table 4.

Heating rate, measurements type, and loading of the scientific research that studied the effects of water/binder ratio on the spalling of concrete as reported in the literature.

One of the earliest studies on this issue, highlighted in [46], looks into the effects of various parameters on the spalling behaviour of concrete. These parameters include W/C, strength, and moisture content. The study provided a monogram, based on the results, which correlated spalling with moisture content and applied stresses.

Morita et al. [76] performed a series of experimental studies using 30 beam samples (500 mm × 400 mm × 3600 mm) made of high-strength concrete. Samples had varying moisture content (4.2–6.1%), and varying strength (21–118 MPa). The testing took place under the time-temperature curve prescribed in ISO 834. A central load of 44 kN was applied during testing.

The researchers concluded that the W/C ratio had a big effect on the spalling behaviour of concrete. The lower the W/C ratio, the higher the degree of spalling. It was reported that spalling would not occur if the W/C ratio could be kept above 0.5 for two-month-old concrete, and 0.45 for one-year-old concrete. This threshold was defined by the researchers without giving the exact circumstances where this threshold would be applicable.

Hager et al. [88] performed a series of experimental tests using 7 different mixes. The parameters studied were W/C ratio, type of aggregate, and type of cement used. The W/C ratio that was considered in these tests were 0.3, 0.45, and 0.6. Slabs (1200 mm × 1000 mm × 300 mm) were cast, and they were cured in dry air for 90 days. ISO 834 fire curve was used for these experiments.

The authors stated that the W/C ratio had a significant effect on spalling. They found that no spalling occurred in samples with a W/C ratio of 0.6. Spalling was observed to take place in both other samples, but the level of spalling was bigger for samples with a W/C ratio of 0.3 compared to a W/C ratio of 0.45. According to the authors, this is the result of having denser concrete mixes when a higher W/C ratio is used during mixing.

Boström [89] found that there was a linear relationship between the water to powder ratio and the amount of spalling. Results were varying in severity depending on how the samples were cured, though. Further research by the same author [61] showed similar results. However, the author noted that the effect of water/powder ratio did not seem to be as pronounced as reported in the literature.

5.4. Type of Aggregate

In an experimental campaign performed by Hager et al. [88], it was found that the amount of spalling was reduced by nearly half when basalt and granite aggregates were used instead of riverbed aggregate.

Khoury [3] suggests that the propensity of thermal explosive spalling is reduced if low thermal expansion aggregate is used. A hierarchy is then provided by the author for aggregates in order of their effect on spalling. Lightweight, basalt, and limestone aggregate is said to be less prone to spalling if used in concrete rather than siliceous and River Thames gravel aggregate. The author emphasises the fact that the hierarchy applies to relatively dry aggregate only. Saturated lightweight aggregate is said to be prone to explosive spalling. Other researchers, however, reported [90] that the type of aggregate had no clear influence on the spalling behaviour of concrete samples. This could be because the authors for [90] considered only two types of aggregate, namely basalt and granite aggregate.

Wu et al. [91] observed that SCC mixes made using lightweight aggregates retained more of their mechanical properties after exposure to elevated temperatures compared to normal weight mixes. However, the use of PP fibres with the mixes makes it difficult to draw any firm conclusion regarding the effects of lightweight aggregates (for each mentioned study, see more details in Table 5).

Table 5.

Heating rate, measurement type, and loading of the scientific research that studied the effects of aggregate type on the spalling of concrete as reported in the literature.

5.5. Size of Aggregate

The results showed that samples containing small- and medium-sized aggregates all spalled at 380 °C while samples containing larger aggregates did not experience any spalling at all. The authors explained the improvement in spalling behaviour of concrete with the increase in aggregate size because larger aggregates have a longer fracture process than smaller ones. This leads to improved spalling behaviour of heated concrete samples, according to the authors (for each mentioned study, see more details in Table 6).

Table 6.

Heating rate, measurement type, and loading of the scientific research that studied the effects of aggregate size on the spalling of concrete as reported in the literature.

Pan et al. [92] studied the effects of aggregate size on the spalling propensity of concrete. Three different sizes of aggregate were used, namely 2.36–4.75 mm, 4.75–10 mm, and 10–14 mm. Cylinders were cast, and they were cured under different curing regimes. Samples were tested at the ages of 28 and 210 days. Samples were subjected to 800 °C for a duration of 5 h.

Y. Li et al. [31] studied the effects of aggregate size and PP fibres on permeability and pore pressure. They found that utilising PP fibres with larger aggregates increased permeability, mainly due to the thermal mismatch between PP fibres and the aggregate. This mismatch led to the formation of micro-cracks, which increased permeability.

Mohd Ali et al. [90] sought to determine the effects of sample size and aggregate size on concrete at elevated temperatures. Three different aggregate sizes were used; 7, 10 and 14 mm. The results showed that samples with smaller aggregates experienced a greater level of spalling than samples with larger aggregates. Although, the authors noted that the results for the medium-sized aggregates were sporadic and inconsistent.

5.6. Concrete Strength/Grade

According to Sideris and Manita [55], spalling likelihood is increased with the increase in the strength of the samples subjected to elevated temperatures. The results of the study show that the tendency to spall is even lower in some of the SCC samples than it is for the VC samples when exposed to the same target temperature (for each mentioned study, see more details in Table 7).

Table 7.

Heating rate, measurement type, and loading of the scientific research that studied the effects of concrete strength on its spalling as reported in the literature.

Bakhtiyari et al. [59] conducted tests on samples with compressive strengths between 40 and 50 MPa. They reported that the samples that had higher strength did not spall at 500 °C, which they identified as the critical temperature for spalling. The authors stated that this could be because SF was used for these mixes, which would have increased their residual tensile strength.

Mindeguia et al. [63] experimented with different mixes of concrete to determine the influencing parameters on concrete spalling. The authors found that by increasing the compressive strength of the concrete, the depth of spalling increased. Aslani et al. [93] conducted an experiment using lightweight SCC. During the tests, high-strength and normal strength mixes were used. It was observed that the higher the strength of the concrete, the more prone to spalling it became.

Zheng et al. [49] found that concrete strength was indirectly contributing to an increase in the level of spalling; concrete strength is directly linked to permeability and it is permeability that affects spalling.

Generally, High Strength Concrete seems to be more prone to spalling due to the lower permeability of such mixes [51]. However, it may not be appropriate to categorise spalling using concrete strength since the strength of concrete is dependent on other factors, such as the cement quantity, inclusion of silica fume, and other ingredients.

5.7. Externally Induced Stresses

Terrasi et al. [79] observed that spalling happened in the region where there was a minimum bending moment (i.e., near the supports where compressive stress from prestressing would be greatest). This is reported by the authors to showcase the adverse effects of compressive stress on spalling. Such behaviour was also highlighted by other researchers experimenting with simply supported, prestressed concrete elements [94] (for each mentioned study, see more details in Table 8).

Table 8.

Heating rate, measurement type, and loading of the scientific research that studied the effects of externally induced stresses on the spalling of concrete as reported in the literature.

Maluk et al. [48] observed that inducing compressive stress resulted in having a higher propensity of spalling for medium-sized, unreinforced samples. No further comment was provided by the author to explain why this was happening. Bosnjak et al. [18] reported that compressive stress led to a slight decrease in the gas permeability of concrete, which led to a rise in the propensity of HPC to spall.

Miah et al. [21] investigated the effects of compressive loading on the permeability of ordinary concrete samples at elevated temperatures. Permeability studies were performed at room temperature on samples subjected to various preloading conditions and preheated to 80, 120, 250, 400, 600, and 800 °C. The authors reported that the presence of a compressive load could lead to an increase or decrease of concrete permeability depending on the direction of the applied load; when the load was in the direction of gas flow (i.e., parallel to the cracks formed at the interface of aggregate and cement paste), permeability increased, but when the load was applied perpendicular to the direction of the gas flow (and the cracks), permeability of the sample decreased. The permeability of concrete also increases in the presence of shrinkage and/or creep due to the occurrence of cracking as, e.g., in PC members, as was reported by Gan et al. [95].

Jansson and Boström [60] found a strong correlation between applied loads and the spalling of concrete slabs. They observed that the effect of the load was more severe in smaller samples than they were in larger ones. The authors noticed that the starting of spalling did not seem to be influenced by the load though; spalling started at similar times for loaded and unloaded samples under identical heating regimes. It was noted that the presence of load, nonetheless, led to a longer period of spalling (in the form of flaking). This was explained by the authors to happen because of compressive stresses closing cracks within the sample that would otherwise help release stresses.

Miah [96] performed a series of tests to determine the effects of load and cement type on spalling of concrete. The conclusion from this study was that the specimens loaded were more prone to spalling than unloaded samples, although there were a few samples that did not experience any spalling even when they were loaded. The author reports that the spalling depth increased with the increase in uniaxial loading. The study found that under low stress, maximum pore pressure tended to increase with the applied stress. For the set-up that was used in this study, it was observed that the depth of spalling was much higher for samples subjected to biaxial loading than samples subjected to uniaxial loading.

Zheng et al. [49] concluded that concrete samples spalled easier in the presence of compressive stress or when the tensile stress was lower on the exposed surface to elevated temperatures. Rickard [8] found that applying a uniaxial load that generated compressive stress equal to 5 MPa led to the occurrence of severe explosive spalling. When the compressive stress was increased beyond this limit, it was noticed that severity of spalling decreased. This observation looks similar to the findings reported in [21] where it was reported that compressive stress beyond a certain point leads to the formation of micro-cracks due to Poisson’s effect.

5.8. Heating Rate

Noumawe et al. [56] observed that heating rate influenced the propensity of samples to spall. When a heating rate of 0.5 °C/min was applied, only SCC mixes spalled, and no samples made with VC experienced any spalling. However, when a rapid heating rate (ISO 834) was used, both SCC and VC samples (no fibres included) spalled explosively (for each mentioned study, see more details in Table 9).

Table 9.

Heating rate, measurement type, and loading of the scientific research that studied the effects of heating rate on the spalling of concrete as reported in the literature.

Mindeguia et al. [63] noticed that an increase in the severity of thermal loading (i.e., heating rate) caused a decrease in the gas pore pressure in the tested specimens. This was explained by the author to be the result of a damaged concrete surface (as a result of the thermal stresses) which would provide a path for the pressure to escape [97].

Felicetti et al. [98] looked at the influence of pore pressure on spalling using a novel testing method. A concrete cube was placed in the middle of two radiant panels and the pore pressure within the cube was measured using a pressure sensor that was placed within the cube. Four different heating rates were used during these tests (1 °C/min, 2 °C/min, 10 °C/min, and 120 °C/min). According to the results of this study, the heating rate influenced the pore pressure as the following: a quicker heating rate led to faster vaporisation and higher-pressure peaks, but at the same time, thermally induced cracks resulted in higher permeability and pressure release. The authors report that the thermal gradient significantly affected the splitting tensile strength of the samples.

According to Phan [16], higher heating rates lead to the formation of micro-cracks and increased permeability. These cracks allow the pore pressure to escape, thus reducing the maximum measured pore pressure in the sample subjected to such heating regimes. Choe et al. [22] subjected cylindrical specimens to two heating rates: fast and slow heating rates. The authors concluded that fast heating rates resulted in moisture movement due to the thermal gradient because of a fast heating regime. This movement of moisture, according to the authors, led to the formation of a moisture clog that caused spalling. Slow heating, on the other hand, did not lead to the formation of steep temperature gradients. Spalling, in this case, happened due to the boiling liquid pressure within the microstructure of the concrete (BLEVE), according to the study [22].

According to Zhao et al. [52], who numerically analysed cubes (100 mm × 100 mm × 100 mm) subjected to the ISO 834 fire curve and a slow heating rate of 5 °C/min, it was found that the heating rate greatly influenced the way HPC samples spalled. For samples subjected to a rapid heating rate, the temperature gradient induced by rapid heating played a dominant role in the occurrence of explosive spalling, while in samples subjected to a slow heating rate, pore pressure was the dominant factor. It was reported that if the samples subjected to rapid heating could withstand the thermal stresses at early ages, then pore pressure would become the dominant factor in spalling.

5.9. Moisture Content/Age of Sample

In Eurocode 2 [38], a limit (k) was prescribed for moisture content. If this limit is smaller than 3%, then spalling is unlikely to occur, according to Eurocode 2. For normal strength concrete, the Eurocode does not mandate any further checks, should this criterion be fulfilled. For concrete grades C55/67 to C80/95, the same rules are applicable if the amount of silica fume is kept below 6% of the weight of the cement. For higher grades of concrete, other measures are prescribed (for each mentioned study, see more details in Table 10).

Table 10.

Heating rate, measurement type, and loading of the scientific research that studied the effects of moisture content/sample age on the spalling of concrete as reported in the literature.

The above 3% moisture content limit in the Eurocode is somewhat arbitrary. Looking through the literature, there are several instances where concrete samples spalled explosively when the measured moisture content was less than 3% [46,60]. This 3% limit is not likely to be very accurate since the moisture content of concrete varies with thickness. This means that there is more water deep within the concrete layers than there would be near the surface [99].

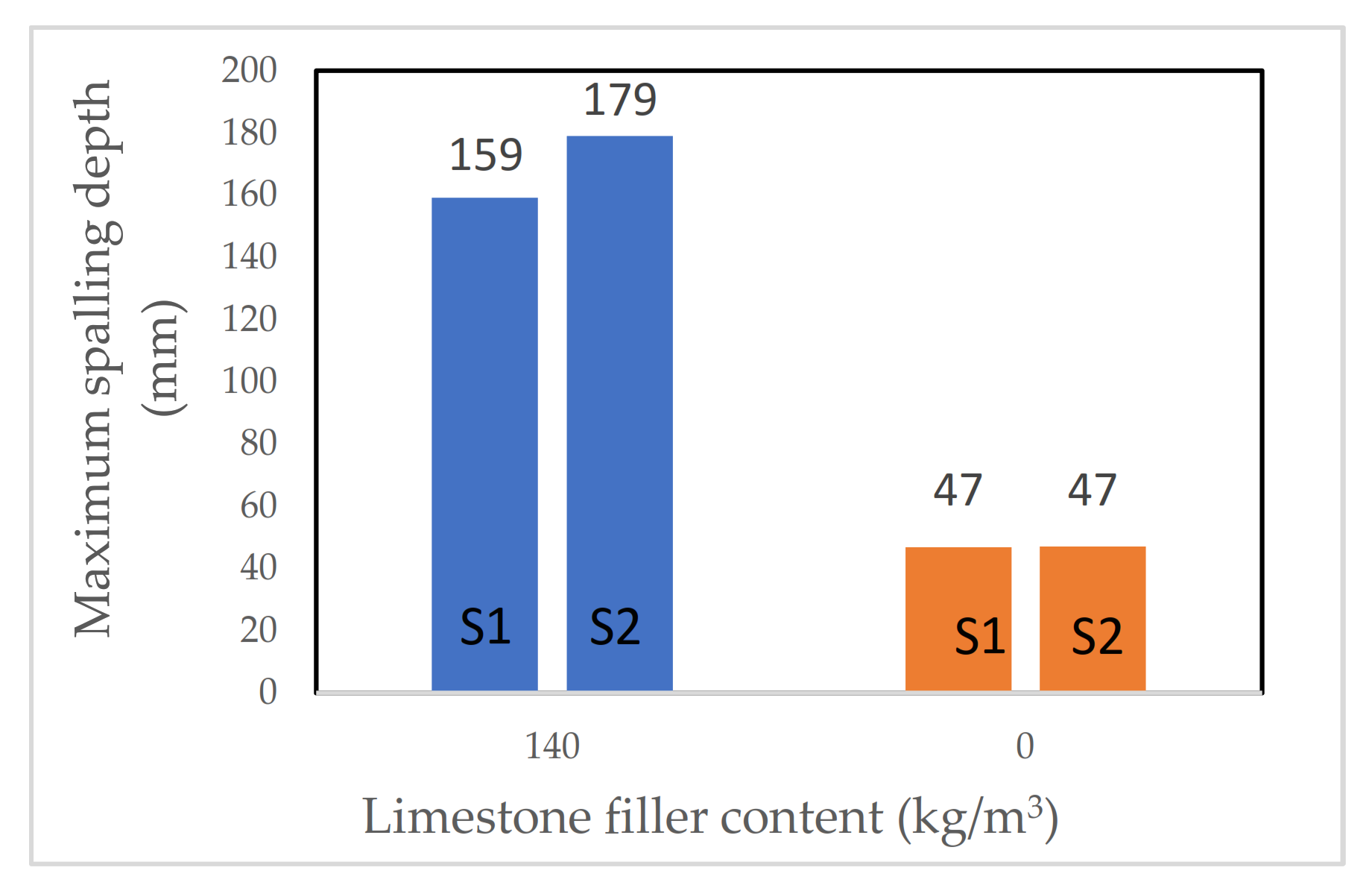

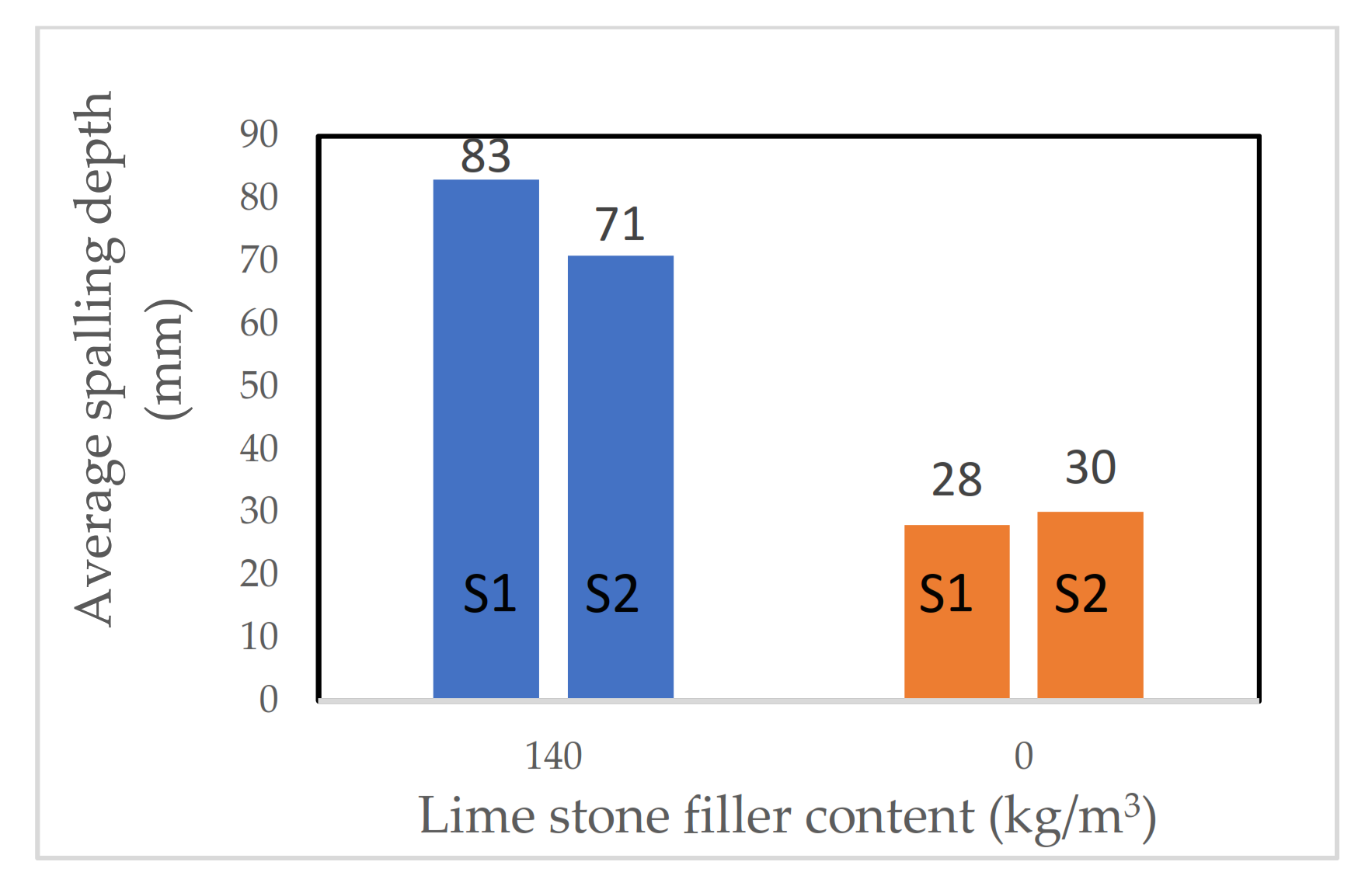

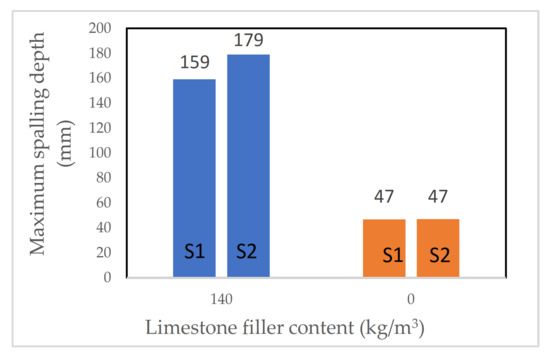

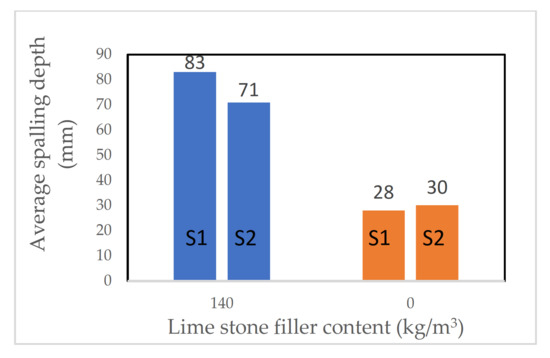

Jansson and Boström [60] performed a large number of tests on the spalling of SCC. The authors tried to, among other things, assess the influence of ageing and moisture content on the spalling behaviour of SCC mixes. The study showed that the effect of added limestone filler was more dominant than the influence of the W/C ratio for large samples stored for more than two years. The researchers stated that the amount of spalling decreased for samples stored for a longer period. However, spalling was eliminated for only three out of four mixes. Figure 9 and Figure 10 show the maximum and average spalling depths of concrete made with 140 kg/m3 and without limestone filler, respectively. It is worth noting that the magnitude of the compressive stress on the samples with no filler was 6.8 MPa while 7.7 MPa was applied for samples with limestone filler in them.

Figure 9.

Maximum spalling depth as a function of the amount of limestone filler. For each concrete mix two samples (S1 and S2) were considered.

Figure 10.

Average spalling depth as a function of the amount of limestone filler. For each mix two samples (S1 and S2) were considered.

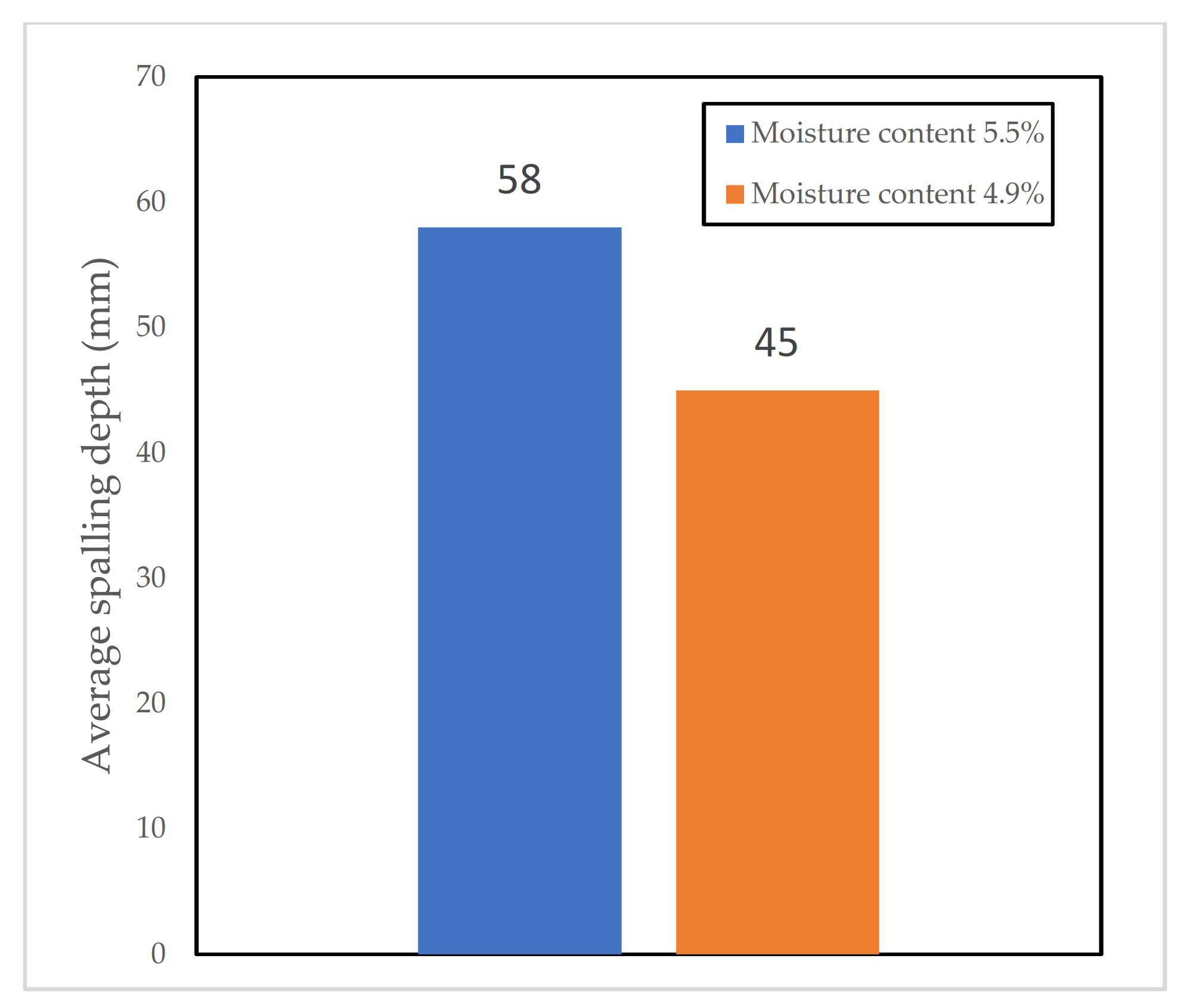

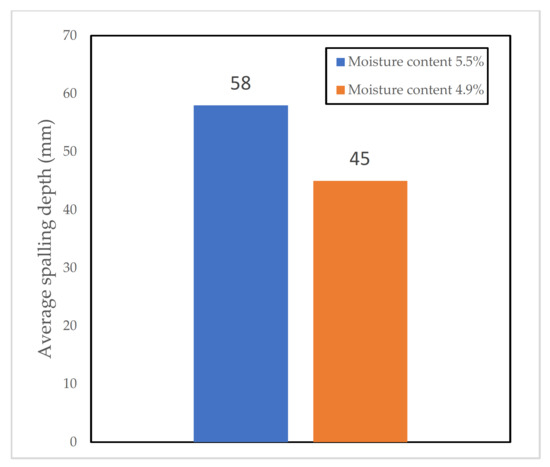

The study [60] showed a strong correlation between moisture content and spalling depth. However, series 39, with the highest amount of limestone filler (140 kg/m3), spalled explosively even though the moisture content for this sample was similar to others tested. Figure 11 shows the effect of moisture on the average spalling depths.

Figure 11.

Average spalling depth as a function of the moisture content at the time of testing.

Mindeguia et al. [97] looked into the effects of air drying on the spalling behaviour of concrete. Small slabs (700 mm × 600 mm × 150 mm) were cast and subjected to three types of heating rates: Slow heating, medium heating, and rapid heating. It was noted that when concrete samples were pre-dried at 80 °C, no spalling was observed. The study found that pre-drying the samples at 80 °C played a significant role in the reduction of the pore pressure generated when the samples were exposed to elevated temperatures. According to the authors, this showed that free water in the specimens (i.e., moisture content) was responsible for the formation of pore pressure. It was also highlighted that chemically bound water could be released from C-S-H or Portlandlite dehydration since the pressure peak occurred at a temperature where C-S-H dehydration had not started yet.