Experimental Study and Verification of New Monolithic Rotary Cutting Tool for an Active Driven Rotation Machining

Abstract

1. Introduction

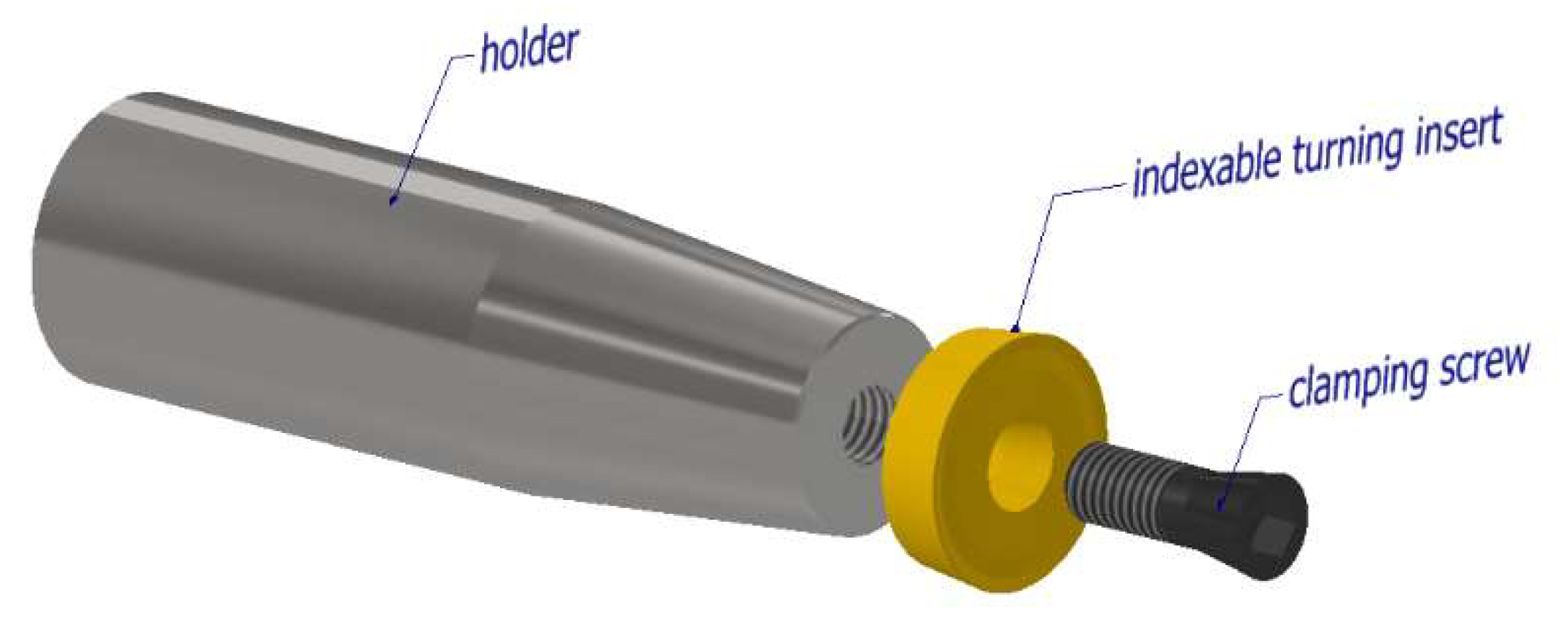

2. Cutting Tool

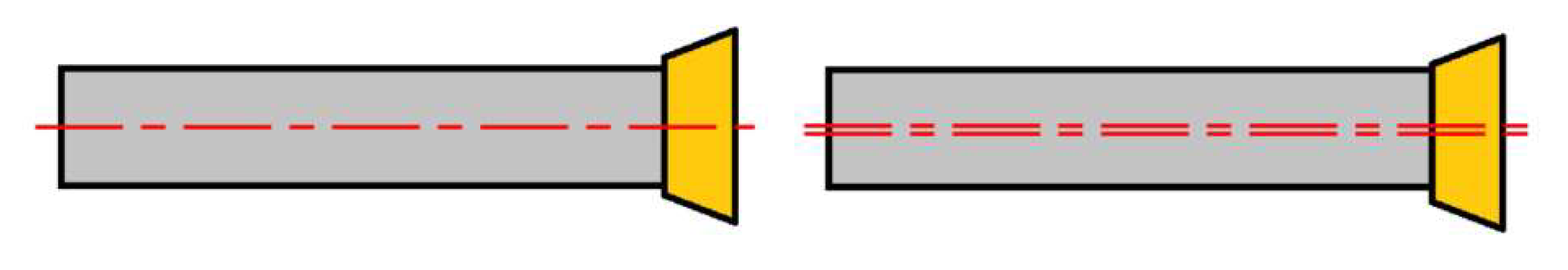

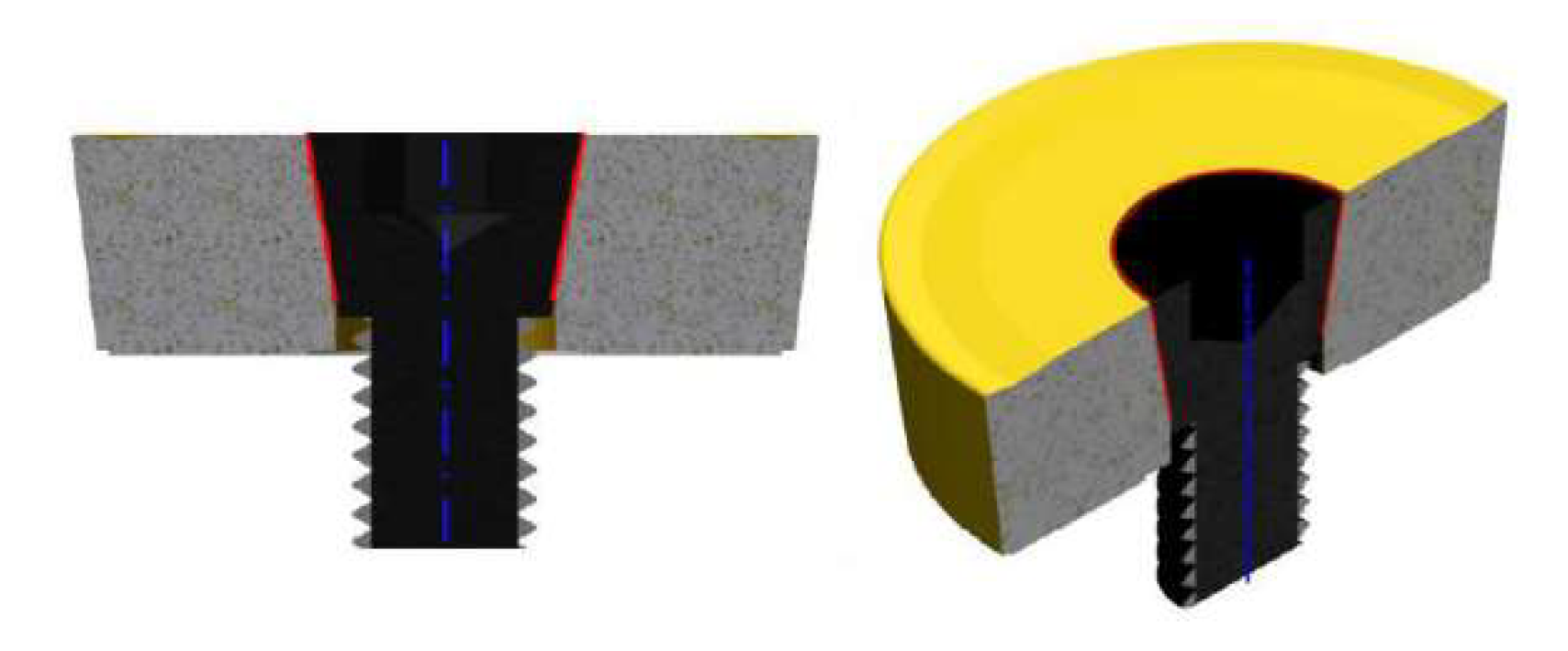

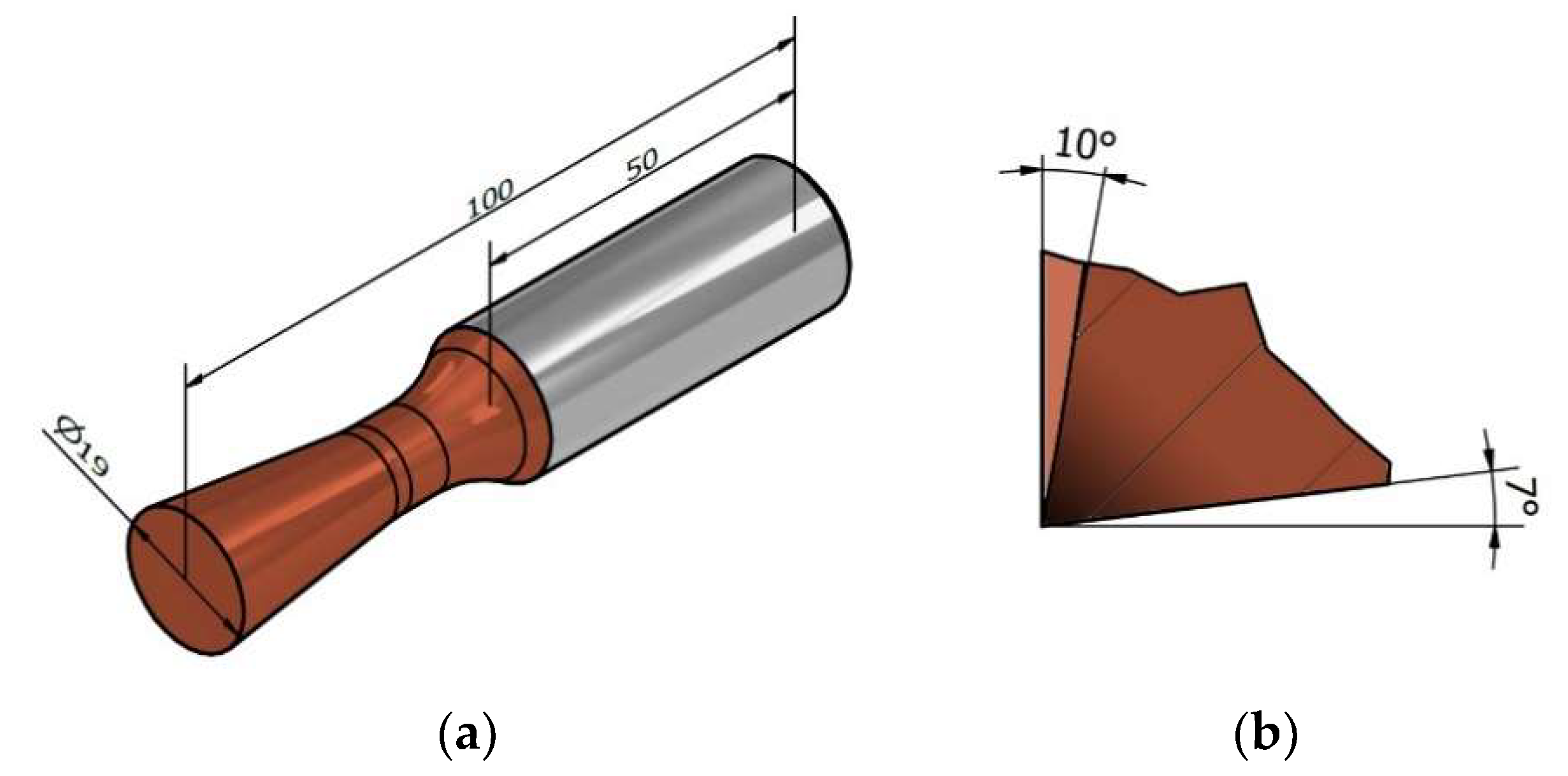

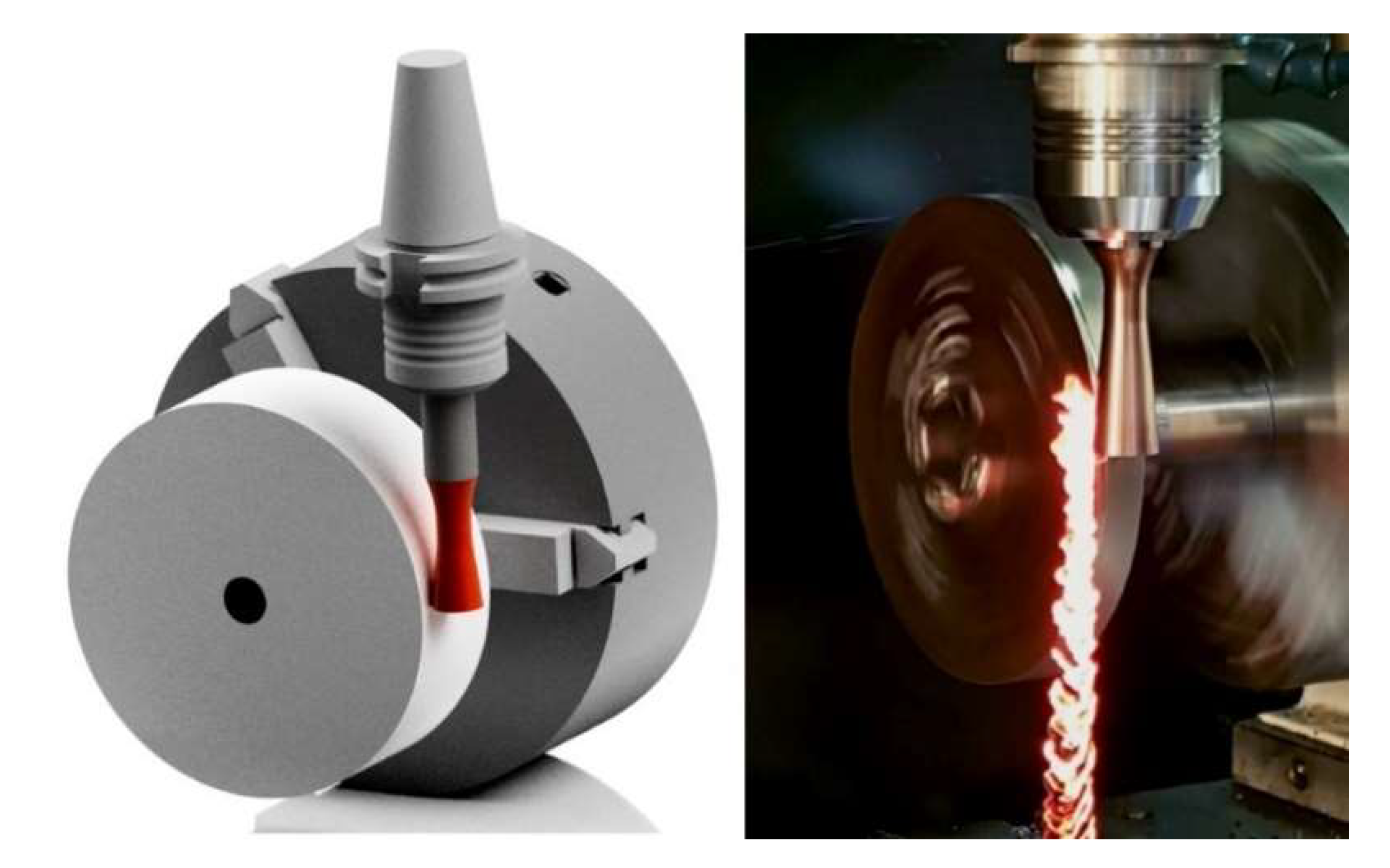

2.1. Desing of the Rotary Tool

2.2. Monolithic Rotary Tool

3. Materials

3.1. Material to Be Machined—Tool Steel

3.2. Material to Be Machined—Aluminium Alloy

3.3. Material to Be Machined—Refractory Steel Alloy

4. Experimental Part

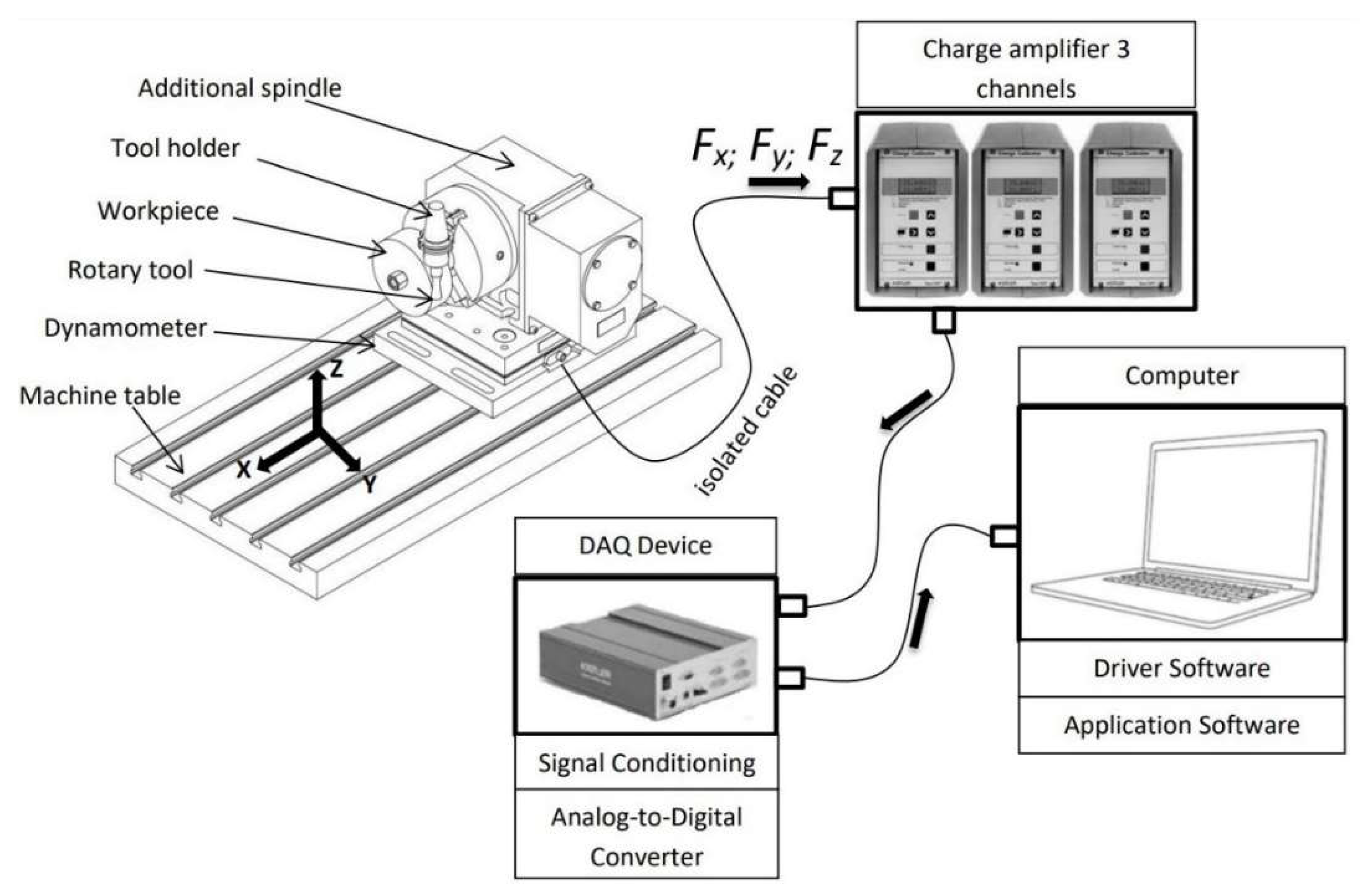

4.1. Experimental Setup

4.2. Selection of Cutting Parameters

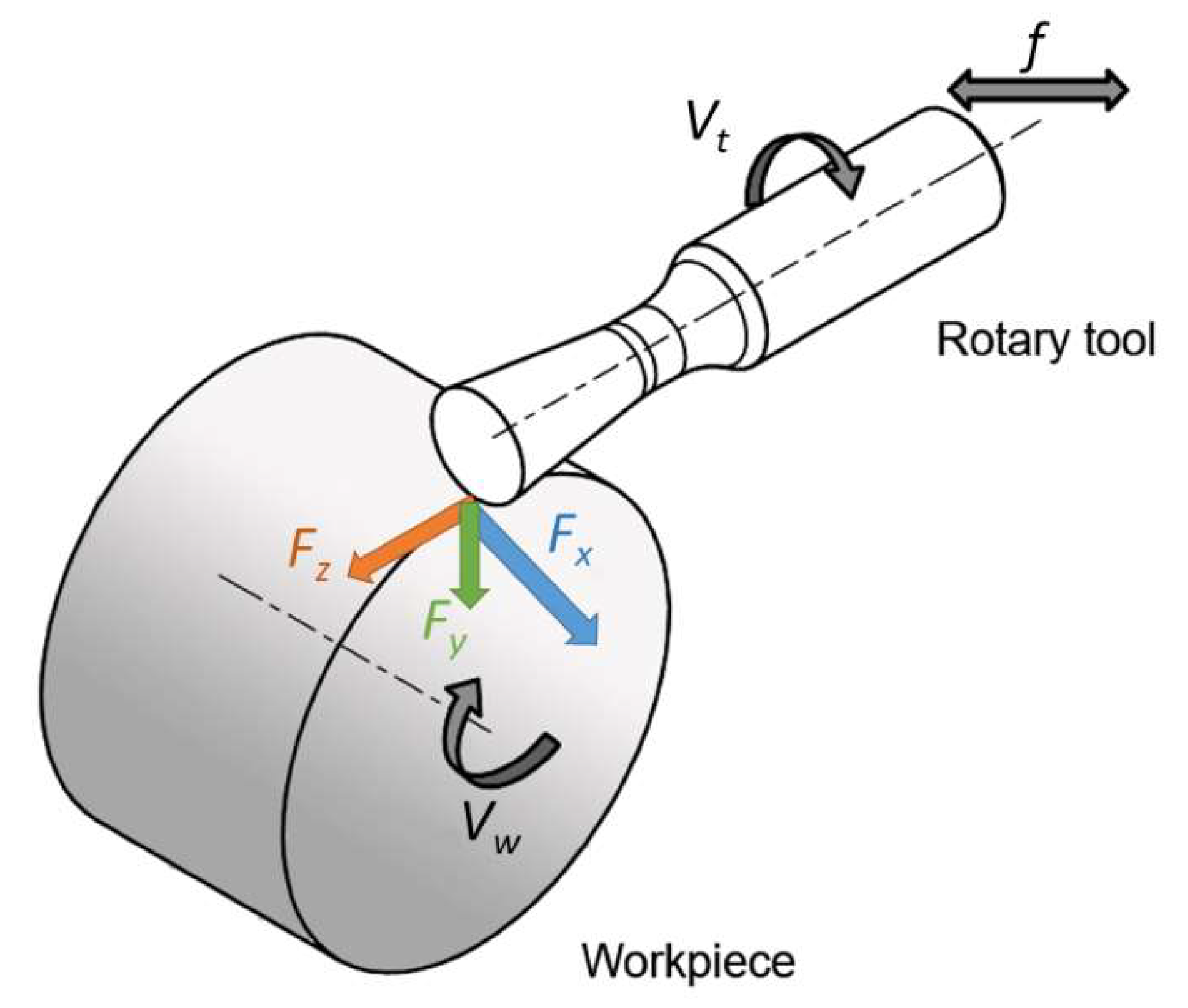

4.3. Measurement of Cutting Forces

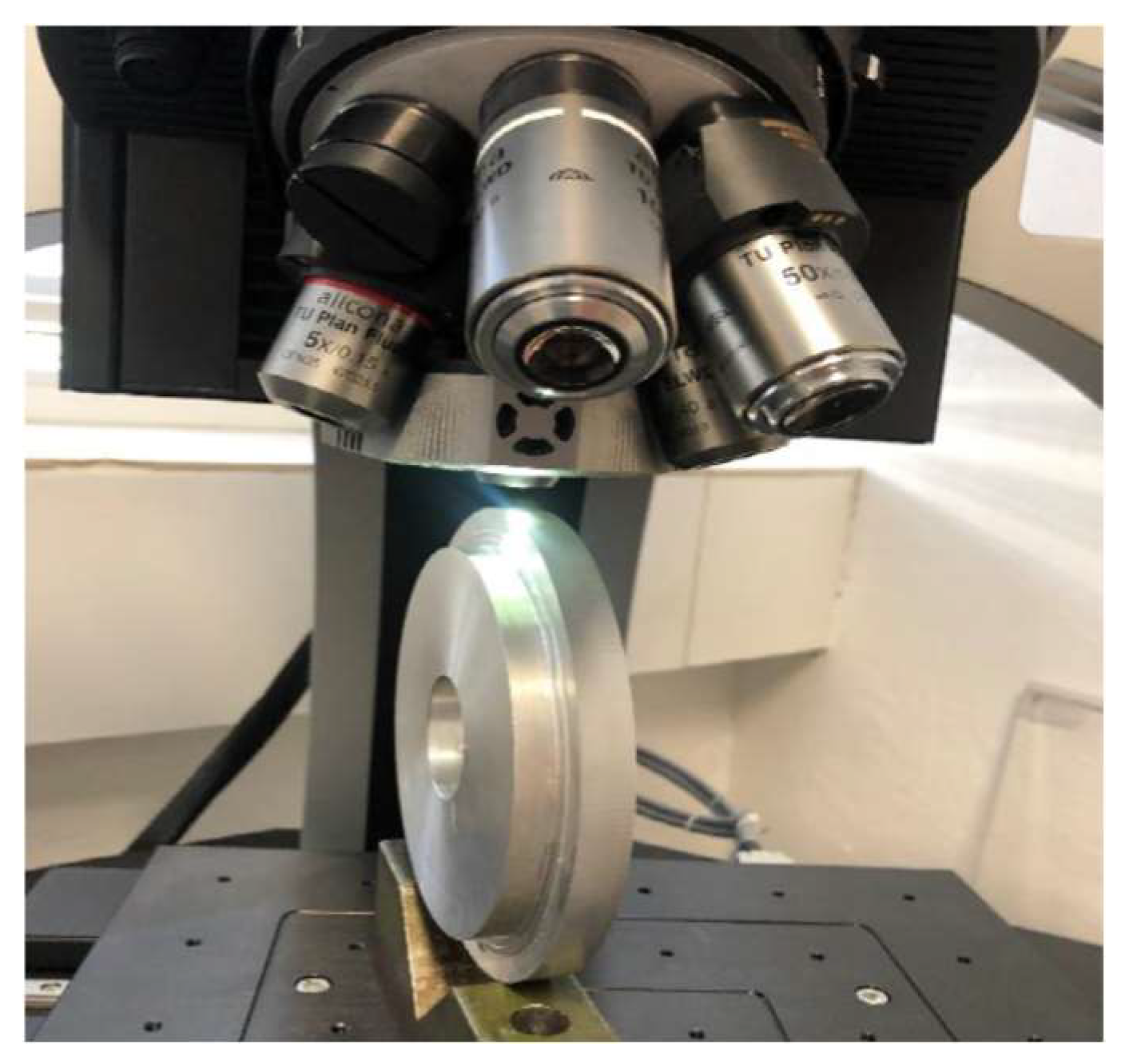

4.4. Surface Measurement

5. Results

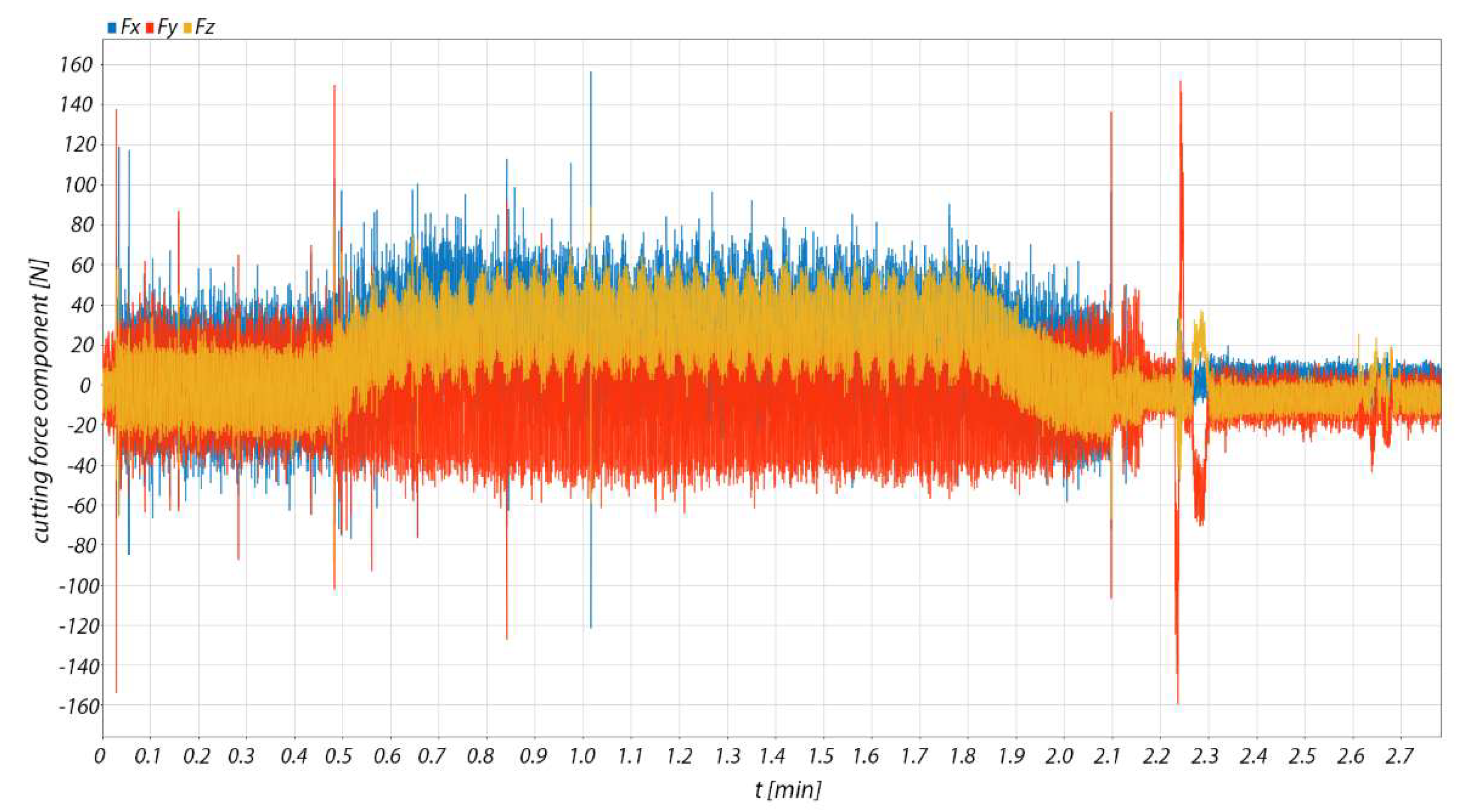

5.1. Components of Cutting Force in Machining

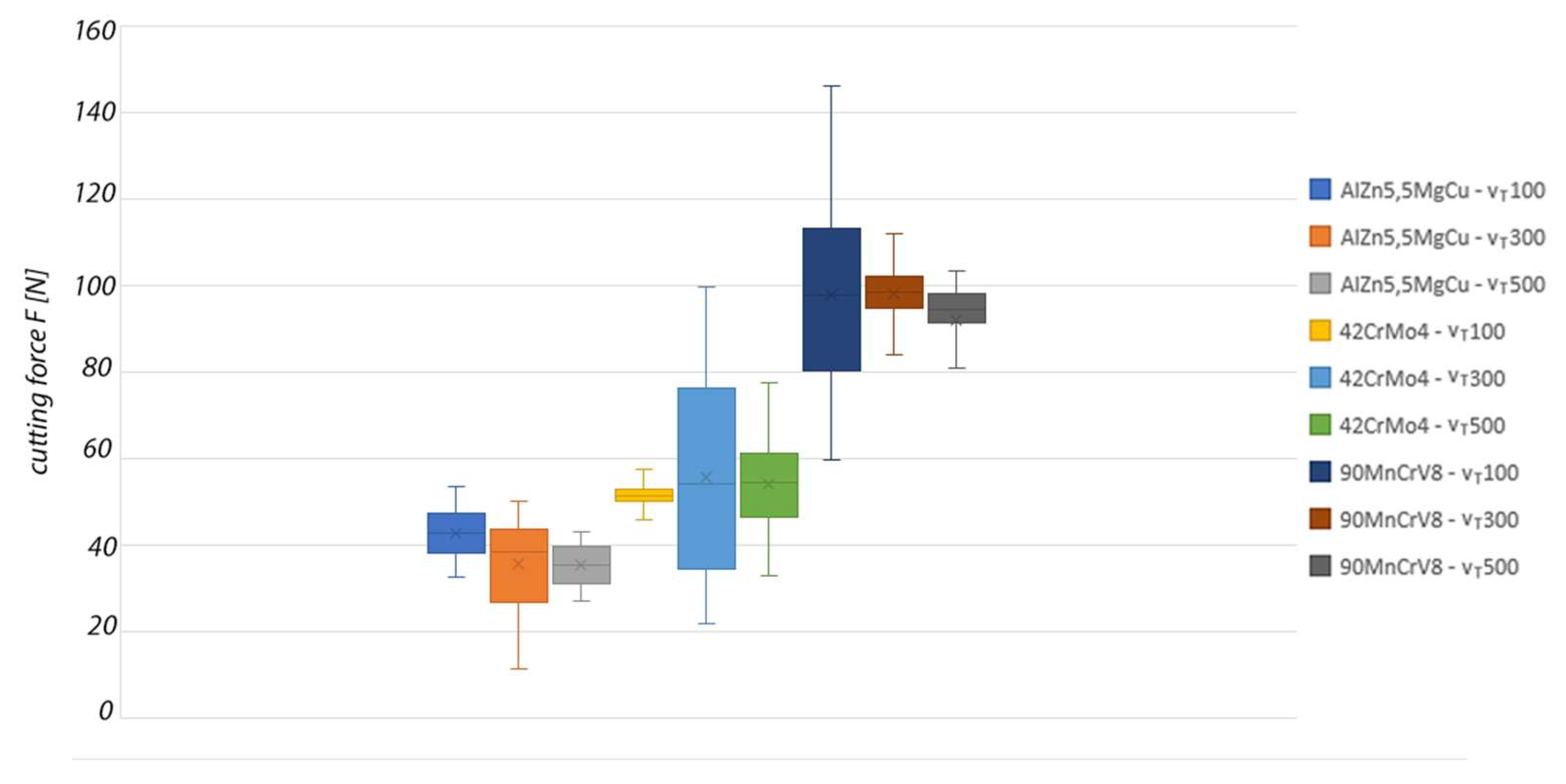

5.2. Comparison of the Resulting Cutting Forces

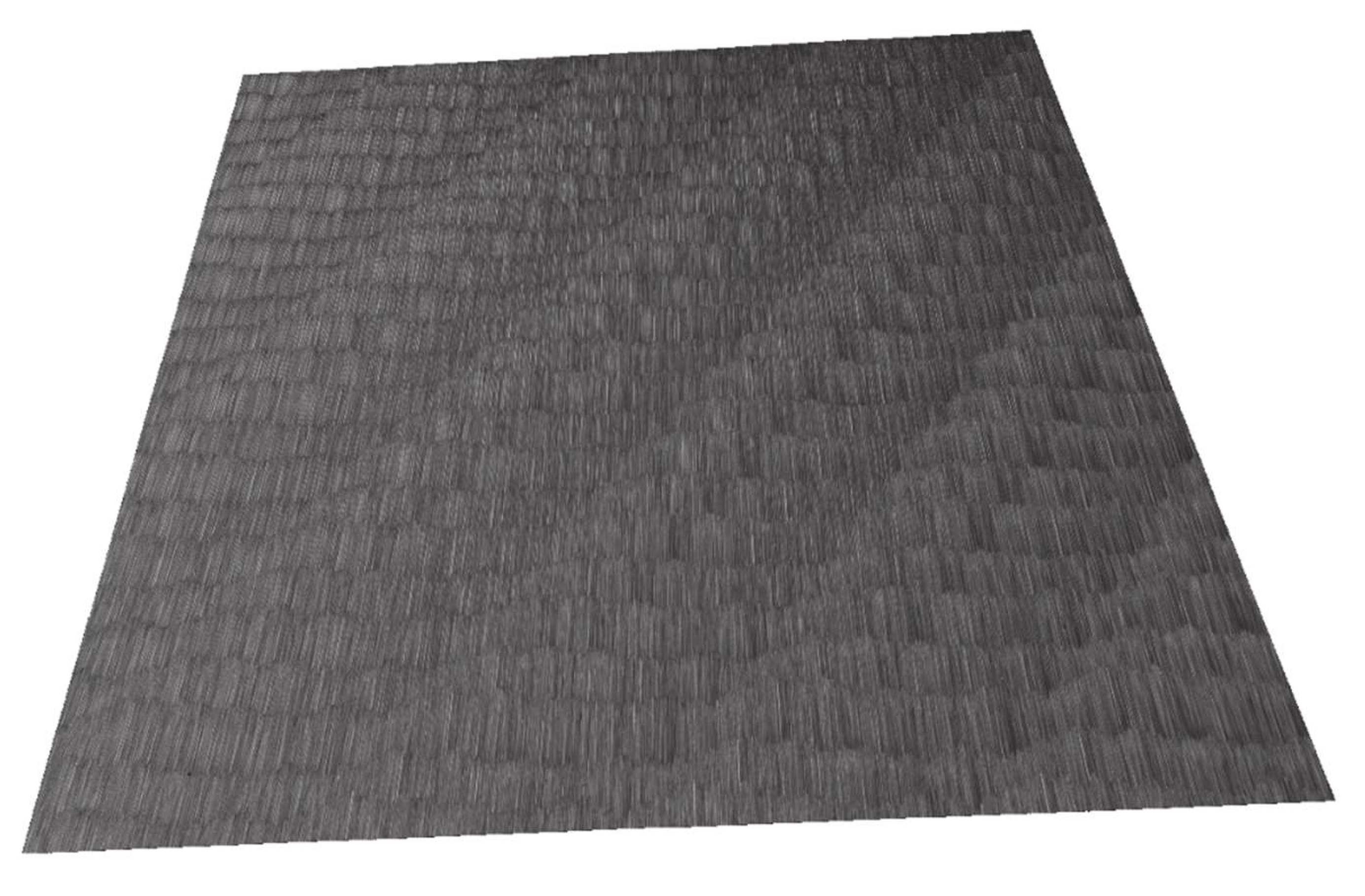

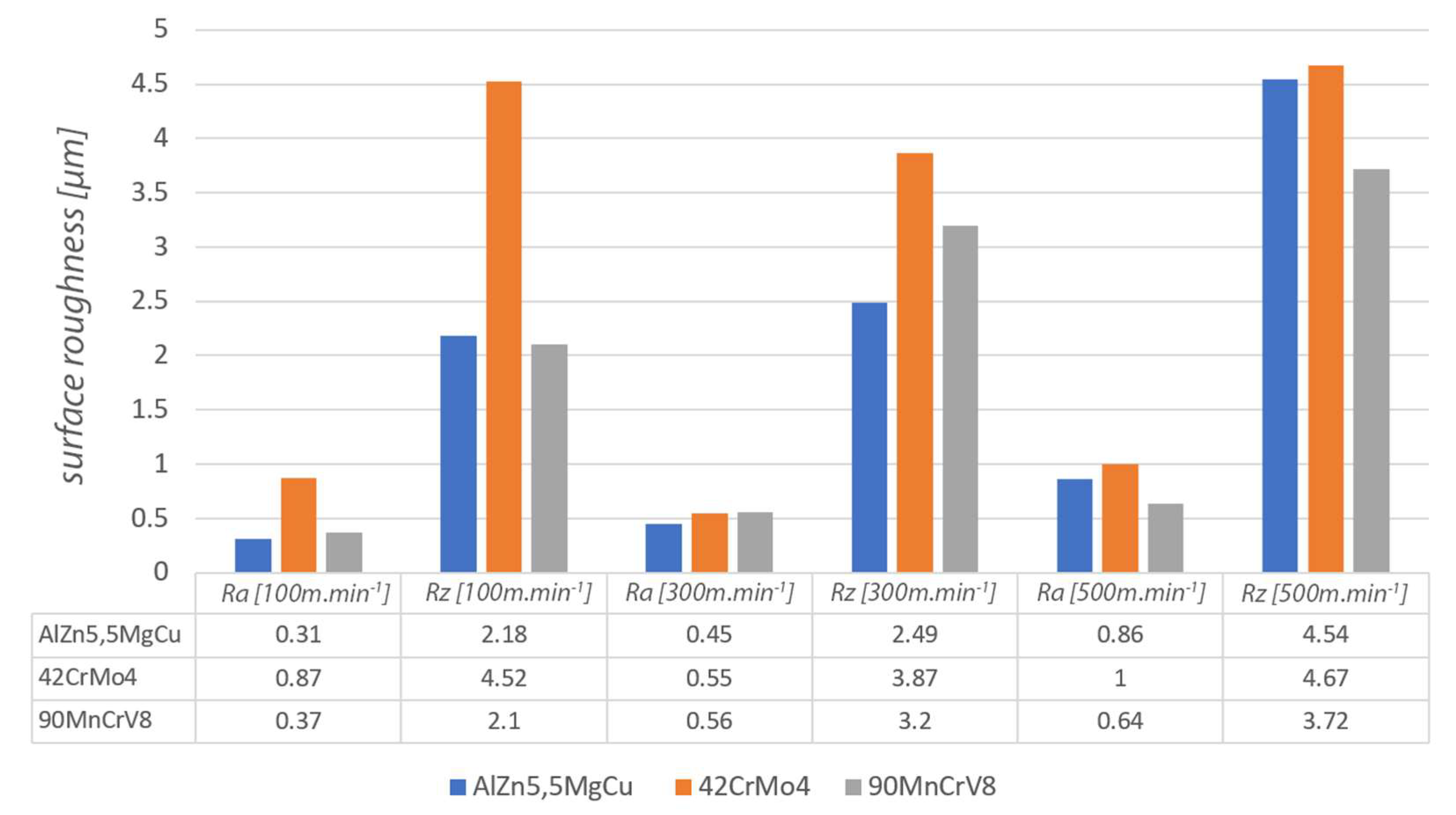

5.3. Comparison of the Machined Surface

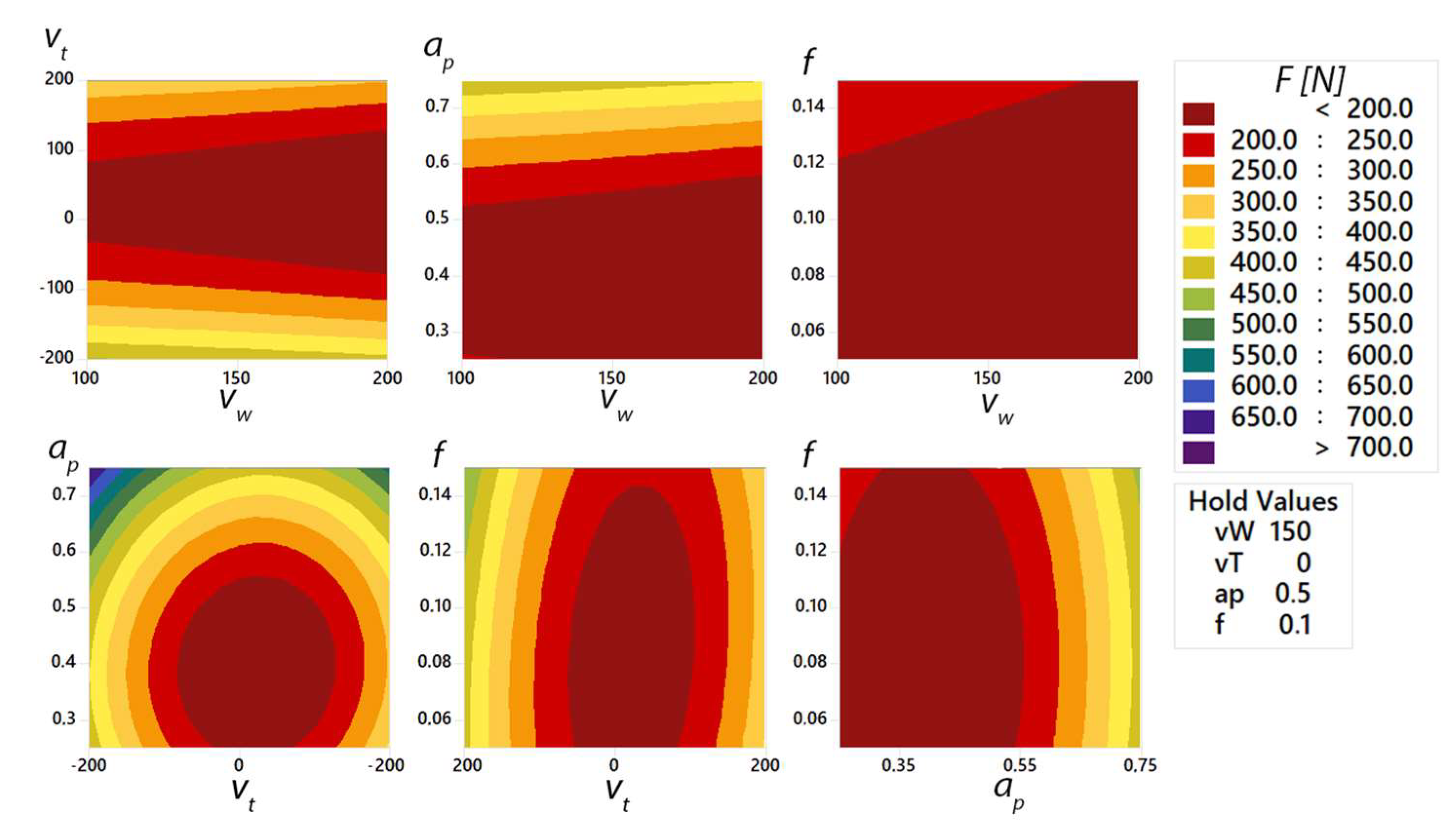

5.4. Influence of Cutting Machining Parameters

2187 ap2 + 10450 f2 + 0.00007 vw · vt − 0.297 vt· ap − 2.27 vt· f

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kaulfersch, F.; Roeder, M. Cutting of nickel-based superalloys with rotating indexable inserts. Adv. Mat. Res. 2013, 769, 116–123. [Google Scholar] [CrossRef]

- Lei, S.; Liu, W. High-speed machining of titanium alloys using the driven rotary tool. Int. J. Mach. Tools Manuf. 2002, 42, 653–661. [Google Scholar] [CrossRef]

- Uhlmann, E.; Kaulfersch, F.; Roeder, M. Turning of high-performance materials with rotating indexable inserts. Procedia CIRP 2014, 14, 610–615. [Google Scholar] [CrossRef]

- Yamamoto, H.; Satake, K.; Sasahara, H.; Narita, T.; Tsutsumi, M.; Muraki, T. Thermal behavior and tool failures on rotary cutting of difficult-to-cut materials utilizing multi tasking lathe. Key Eng. Mater. 2010, 447, 806–810. [Google Scholar] [CrossRef]

- Hosokawa, A.; Yoshimatsu, H.; Koyano, T.; Furumoto, T.; Hashimoto, Y. Turning of difficult-to-machine materials with an actively driven rotary tool (ADRT)—Proposition of reciprocating turning contingent on fundamental cutting characteristics. J. Adv. Mech. Des. Syst. Manuf. 2018, 12, JAMDSM0103. [Google Scholar] [CrossRef]

- Hosokawa, A.; Ueda, T.; Onishi, R.; Tanaka, R.; Furumoto, T. Turning of difficult-to-machine materials with actively driven rotary tool. CIRP Ann. Manuf. Technol. 2010, 59, 89–92. [Google Scholar] [CrossRef]

- Joch, R.; Pilc, J.; Stančeková, D.; Miturska, I.; Görögová, I. Evaluation of Surface Roughness after Actively Rotary Turning Method. Mater. Sci. Forum. 2020, 994, 11–18. [Google Scholar] [CrossRef]

- Ezugwu, E.O. Improvements in the machining of aero-engine alloys using self-propelled rotary tooling technique. J. Mater. Process. Technol. 2007, 185, 60–71. [Google Scholar] [CrossRef]

- Čep, R.; Janásek, A.; Martinický, B.; Sadílek, M. Cutting tool life tests of ceramic inserts for car engine sleeves. Teh. Vjesn. 2011, 18, 203–209. [Google Scholar]

- Sasahara, H.; Kato, A.; Nakajima, H.; Yamamoto, H.; Muraki, T.; Tsutsumi, M. High-speed rotary cutting of difficult-to-cut materials on multitasking lathe. Int. J. Mach. Tools Manuf. 2008, 48, 841–850. [Google Scholar] [CrossRef]

- Ahmed, W.; Hegab, H.; Kishawy, H.A.; Mohany, A. Estimation of temperature in machining with self-propelled rotary tools using finite element method. J. Manuf. Process. 2021, 61, 100–110. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Duong, Q.D.; Mia, M. Sustainability-based optimization of the rotary turning of the hardened steel. Metals 2020, 10, 939. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Ahmed, W.; Mohany, A. Analytical modeling of metal cutting process with self-propelled rotary tools. CIRP J. Manuf. Sci. Technol. 2021, 33, 115–122. [Google Scholar] [CrossRef]

- Ahmed, W.; Hegab, H.; Mohany, A.; Kishawy, H. Analysis and Optimization of Machining Hardened Steel AISI 4140 with Self-Propelled Rotary Tools. Materials 2021, 14, 6106. [Google Scholar] [CrossRef] [PubMed]

- Dessoly, V.; Melkote, S.N.; Lescalier, C. Modeling and verification of cutting tool temperatures in rotary tool turning of hardened steel. Int. J. Mach. Tools Manuf. 2004, 44, 1463–1470. [Google Scholar] [CrossRef]

- Zlámal, T.; Petrů, J.; Vortel, O.; Pagáč, M.; Krajkovič, P. Mechanisms of cutting blade wear and their influence on cutting ability of the tool during machining special alloys. Adv. Sci. Technol. Res. J. 2016, 10, 144–150. [Google Scholar] [CrossRef][Green Version]

- Ekinović, S.; Dolinšek, S.; Begović, E. Machinability of 90MnCrV8 steel during high-speed machining. J. Mater. Process. Technol. 2005, 162, 603–608. [Google Scholar] [CrossRef]

- Isik, Y. Investigating the machinability of tool steels in turning operations. Mater. Des. 2007, 28, 1417–1424. [Google Scholar] [CrossRef]

- Lacková, P.; Žabecká, D.; Milkovič, O.; Škrobian, M.; Bajcura, M. Effect of Technologies Processing on Material Properties of Selected Aluminium Alloys. Mater. Sci. Forum. 2014, 782, 394–397. [Google Scholar] [CrossRef]

- Özdemir, M.; Kaya, M.; Akyildiz, H. Analysis of surface roughness and cutting forces in hard turning of 42CrMo4 steel using Taguchi and RSM method. Mechanika 2020, 26, 231–241. [Google Scholar] [CrossRef]

- Bronis, M.; Miko, E.; Nowakowski, L. Analyzing the Effects of the Kinematic System on the Quality of Holes Drilled in 42CrMo4 + QT Steel. Materials 2021, 14, 4046. [Google Scholar] [CrossRef] [PubMed]

- Bajor, T.; Kulakowska, A.; Dyja, H. Analysis of the rolling process of alloy 6005 in a three-high skew rolling mill. Materials 2020, 13, 1114. [Google Scholar] [CrossRef] [PubMed]

- Olgun, U.; Budak, E. Machining of difficult-to-cut-alloys using rotary turning tools. Procedia CIRP 2013, 8, 81–87. [Google Scholar] [CrossRef]

- Šajgalík, M.; Kušnerová, M.; Harničárová, M.; Valíček, J.; Czán, A.; Czánová, T.; Drbúl, M.; Boržan, M.; Kmec, J. Analysis and prediction of the machining force depending on the parameters of trochoidal milling of hardened steel. Appl. Sci. 2020, 10, 1788. [Google Scholar] [CrossRef]

- Joch, R.; Pilc, J.; Daniš, I.; Drbúl, M.; Krajčoviech, S. Analysis of surface roughness in turning process using rotating tool with chip breaker for specific shapes of automotive transmission shafts. Transp. Res. Proc. 2019, 40, 295–301. [Google Scholar] [CrossRef]

- Akhyar, G.; Harun, S.; Hamni, A. Surface Roughness Values of Magnesium Alloy AZ31 When Turning by Using Rotary Cutting Tool. Insist 2016, 1, 54–59. [Google Scholar] [CrossRef][Green Version]

| C | Si | Mn | P | S | Cr | V |

|---|---|---|---|---|---|---|

| 0.85–0.95 | 0.1–0.4 | 1.9–2.1 | 0.03 max | 0.03 max | 0.2–0.5 | 0.05–0.15 |

| Cr | Cu | Fe | Mg | Mn | Si | Ti | Zn |

|---|---|---|---|---|---|---|---|

| 0.18–0.28 | 1.2–2 | 0.3 max | 2.1–2.9 | 0.3 max | 0.4 max | 0.2 max | 5.1–6.1 |

| C | Mn | Si | P | S | Cr | Mo | Cu |

|---|---|---|---|---|---|---|---|

| 0.38–0.45 | 0.6–0.9 | 0.1–0.4 | 0.025 max | 0.035 max | 0.9–1.2 | 0.15–0.3 | 0.4 max |

| Material | Tool Cutting Speed vT [m·min−1] | Workpiece Rotation Speed vw [m·min−1] | Depth of Cut ap [mm] | Feed Rate f [mm] |

|---|---|---|---|---|

| 42CrMo4 | 100 | 10 | 0.2 | 0.1 |

| 300 | ||||

| 500 | ||||

| 90MnCrV8 | 100 | |||

| 300 | ||||

| 500 | ||||

| AlZn5.5MgCu | 100 | |||

| 300 | ||||

| 500 |

| Property | Numerical Value |

|---|---|

| Measuring range in the direction of x-axis | −20 to +20 kN |

| Measuring range in the direction of y-axis | −20 to +20 kN |

| Measuring range in the direction of z-axis | 10 to 40 kN |

| Allowed operating temperature | 0 to 70 °C |

| Actual frequency | 3 kHz |

| Relative measurement uncertainty | 1% |

| Measurement sensitivity | 8 pC∙N−1 |

| vw (m·min−1) | vt (m·min−1) | ap (mm) | f (mm) |

|---|---|---|---|

| 50.00 | |||

| 100.00 | |||

| 100.00 | 150.00 | 0.25 | 0.05 |

| 160.00 | 200.00 | 0.50 | 0.10 |

| 200.00 | −50.00 | 0.75 | 0.15 |

| −100.00 | |||

| −150.00 | |||

| −200.00 |

| Source | DF | Contribution (%) | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Model | 11 | 90.6 | 823,072 | 74,825 | 32.53 | 0.000 |

| Linear | 5 | 34.21 | 310,365 | 77,591 | 39.96 | 0.000 |

| vw | 1 | 0.2 | 6320 | 6320 | 3.25 | 0.078 |

| vt | 1 | 8.83 | 75,248 | 75,248 | 38.75 | 0.000 |

| ap | 1 | 24.55 | 223,020 | 223,020 | 114.84 | 0.000 |

| f | 1 | 0.64 | 5776 | 5776 | 2.97 | 0.092 |

| Square | 4 | 55.78 | 506,762 | 126,691 | 65.24 | 0.000 |

| vw * vw | 1 | 5.59 | 32 | 32 | 0.02 | 0.898 |

| vt * vt | 1 | 34.76 | 315,782 | 315,782 | 162.61 | 0.000 |

| ap * ap | 1 | 15.03 | 99,645 | 99,645 | 51.31 | 0.000 |

| f * f | 1 | 0.4 | 3640 | 3640 | 1.87 | 0.178 |

| 2-Way Interaction | 3 | 0.61 | 5526 | 1842 | 0.95 | 0.425 |

| vw * vt | 1 | 0 | 4 | 4 | 0 | 0.964 |

| vt * ap | 1 | 0.18 | 1658 | 1658 | 0.85 | 0.361 |

| vt * f | 1 | 0.43 | 3865 | 3865 | 1.99 | 0.165 |

| Error | 44 | 9.4 | 85,445 | 1942 | ||

| Total | 55 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czán, A.; Joch, R.; Šajgalík, M.; Holubják, J.; Horák, A.; Timko, P.; Valíček, J.; Kušnerová, M.; Harničárová, M. Experimental Study and Verification of New Monolithic Rotary Cutting Tool for an Active Driven Rotation Machining. Materials 2022, 15, 1630. https://doi.org/10.3390/ma15051630

Czán A, Joch R, Šajgalík M, Holubják J, Horák A, Timko P, Valíček J, Kušnerová M, Harničárová M. Experimental Study and Verification of New Monolithic Rotary Cutting Tool for an Active Driven Rotation Machining. Materials. 2022; 15(5):1630. https://doi.org/10.3390/ma15051630

Chicago/Turabian StyleCzán, Andrej, Richard Joch, Michal Šajgalík, Jozef Holubják, Andrej Horák, Pavol Timko, Jan Valíček, Milena Kušnerová, and Marta Harničárová. 2022. "Experimental Study and Verification of New Monolithic Rotary Cutting Tool for an Active Driven Rotation Machining" Materials 15, no. 5: 1630. https://doi.org/10.3390/ma15051630

APA StyleCzán, A., Joch, R., Šajgalík, M., Holubják, J., Horák, A., Timko, P., Valíček, J., Kušnerová, M., & Harničárová, M. (2022). Experimental Study and Verification of New Monolithic Rotary Cutting Tool for an Active Driven Rotation Machining. Materials, 15(5), 1630. https://doi.org/10.3390/ma15051630