Two Types of Wear Mechanisms Governing Transition between Mild and Severe Wear in Ti-6Al-4V Alloy during Dry Sliding at Temperatures of 20–250 °C

Abstract

:1. Introduction

2. Experimental Details

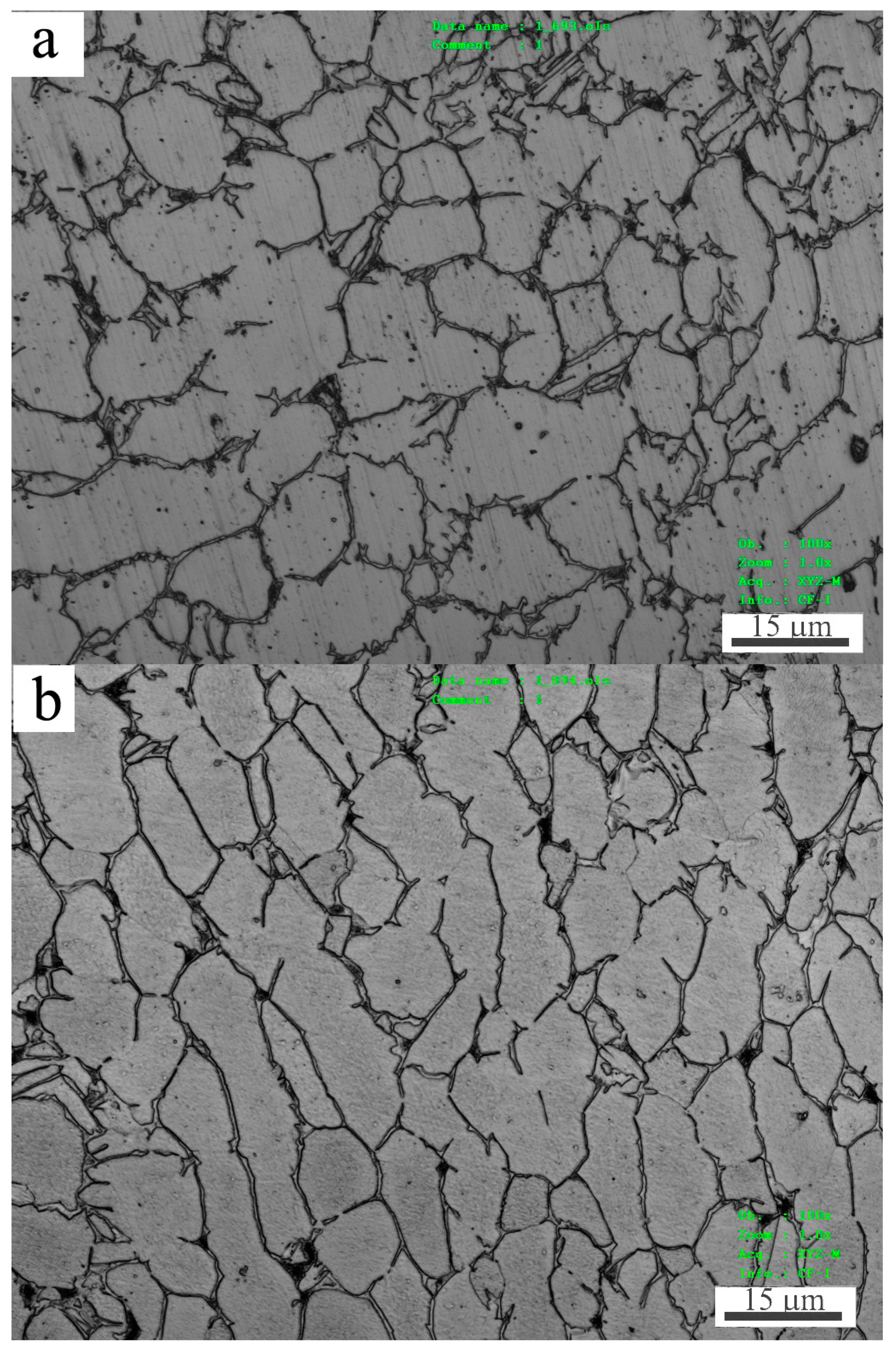

2.1. Material

2.2. Wear Tests

2.3. Microstructure Observation and Hardness Measurements in Subsurfaces

3. Results and Discussion

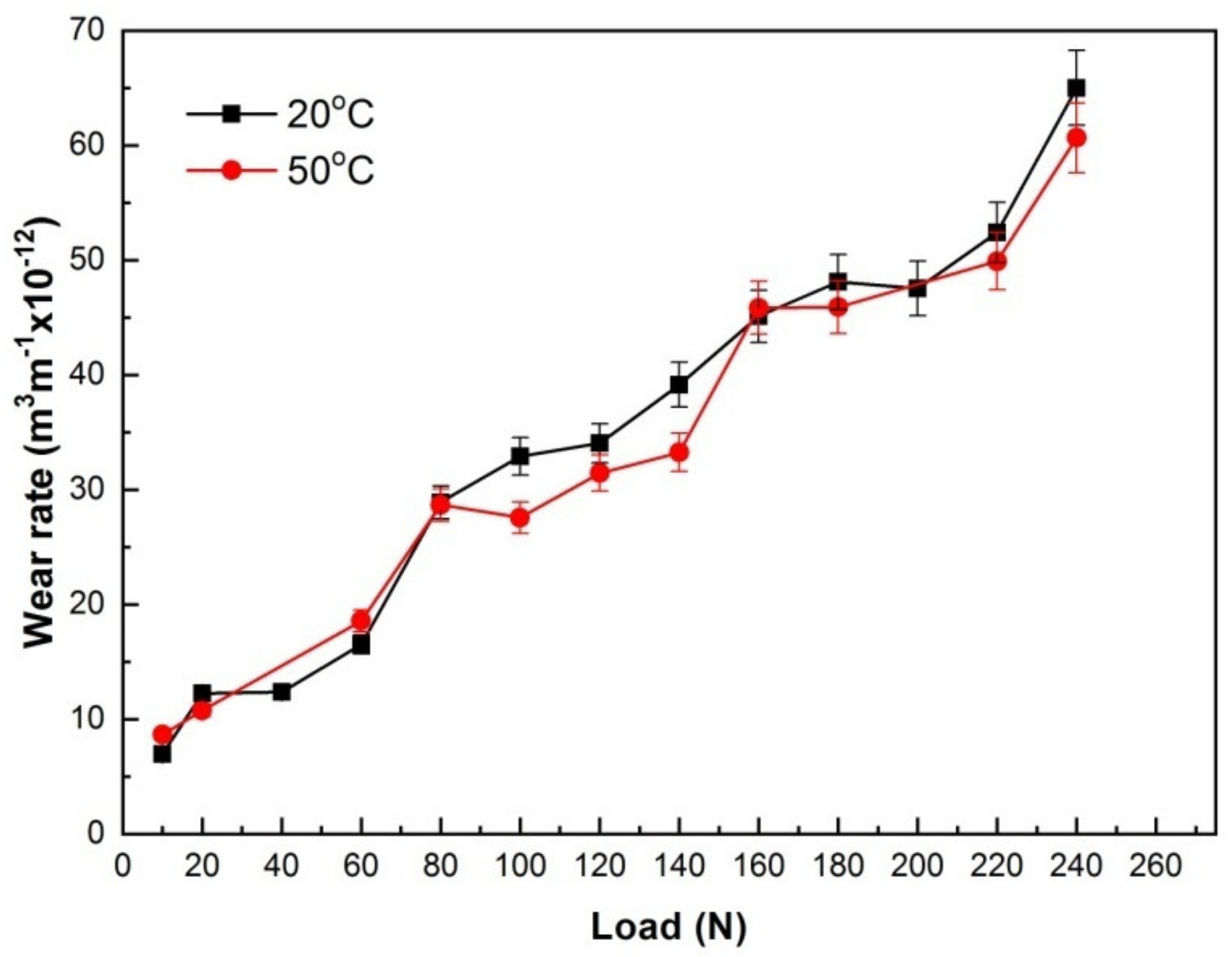

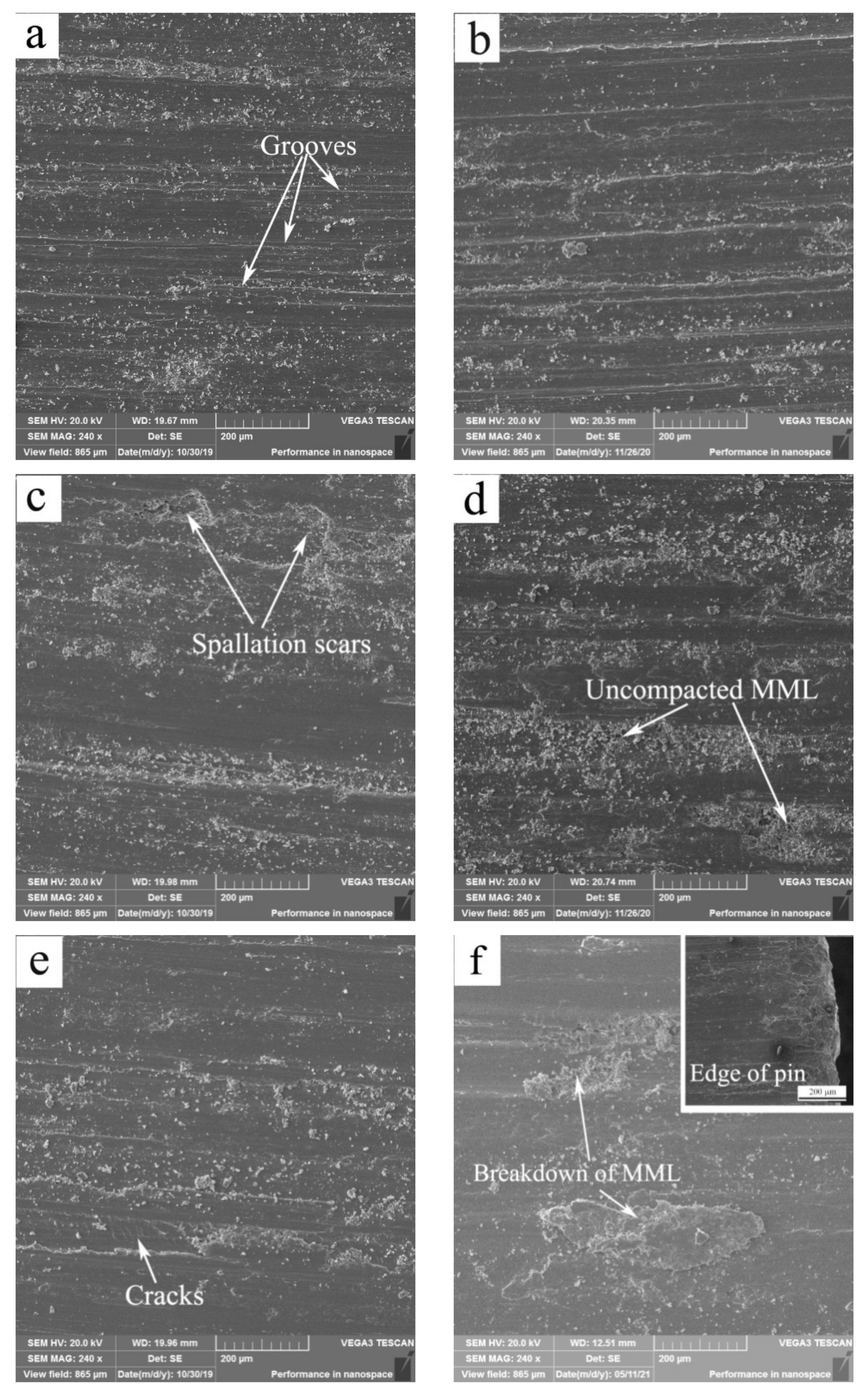

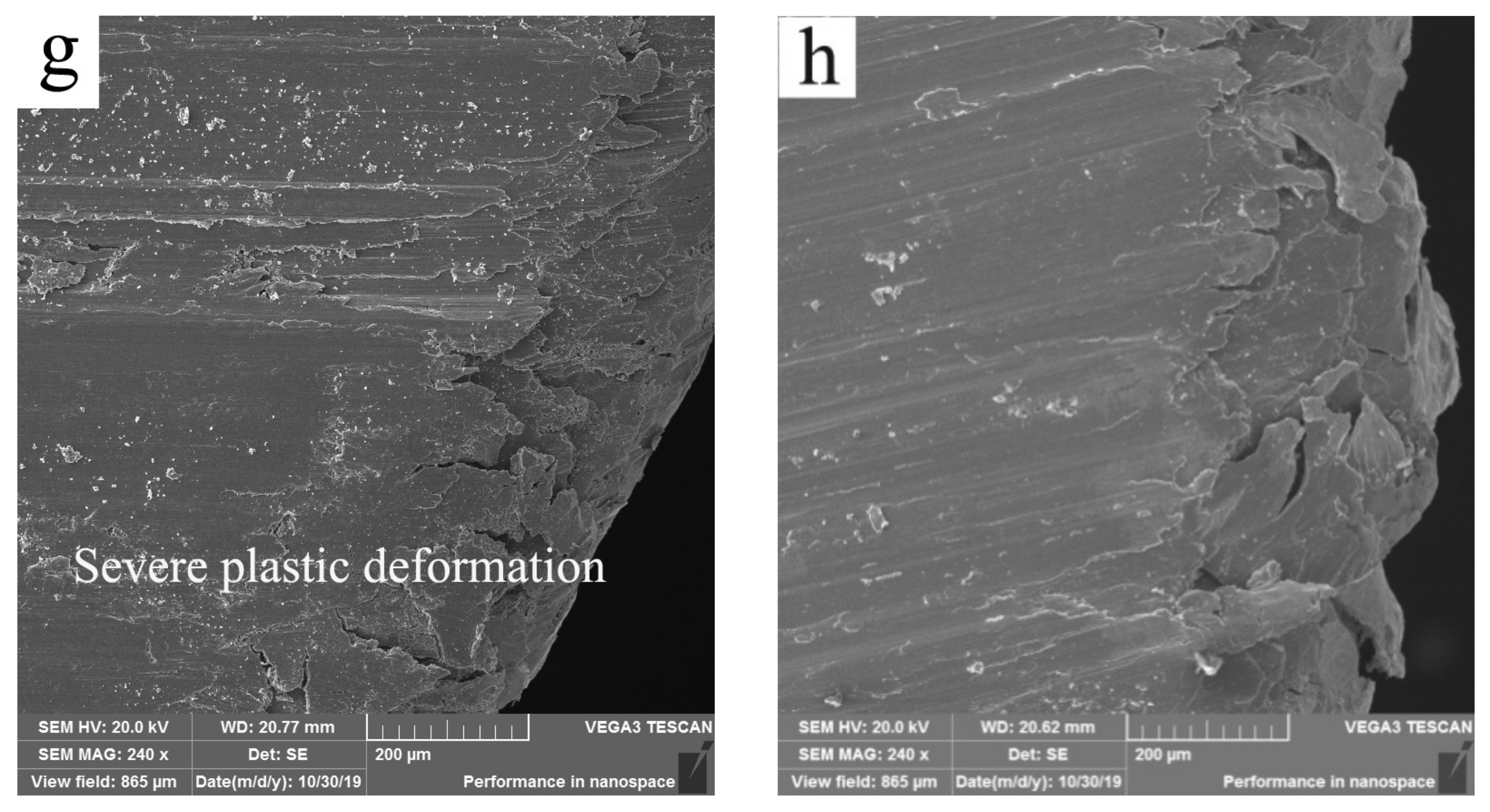

3.1. Wear at 20 and 50 °C

3.2. Wear at Temperatures of 100–250 °C

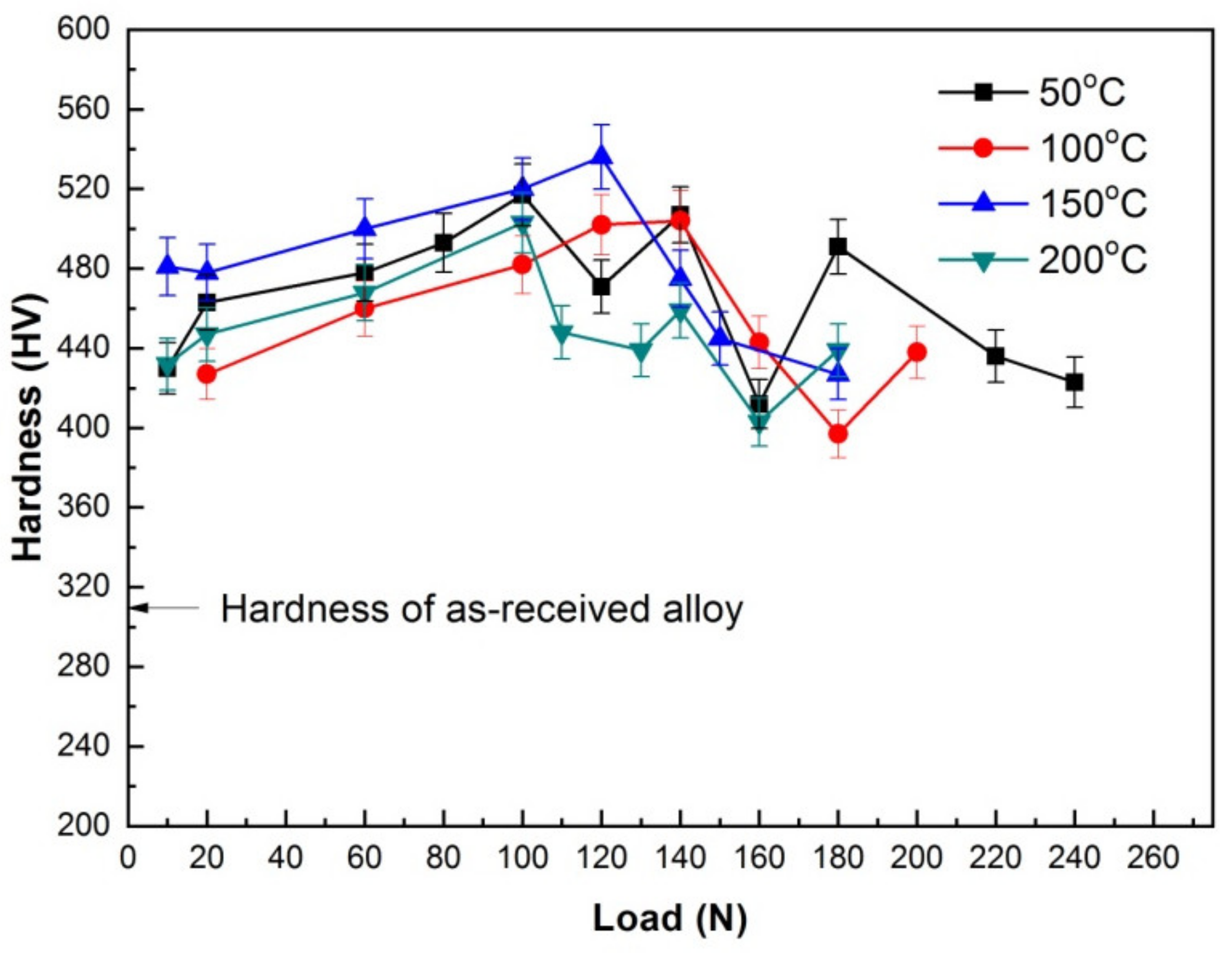

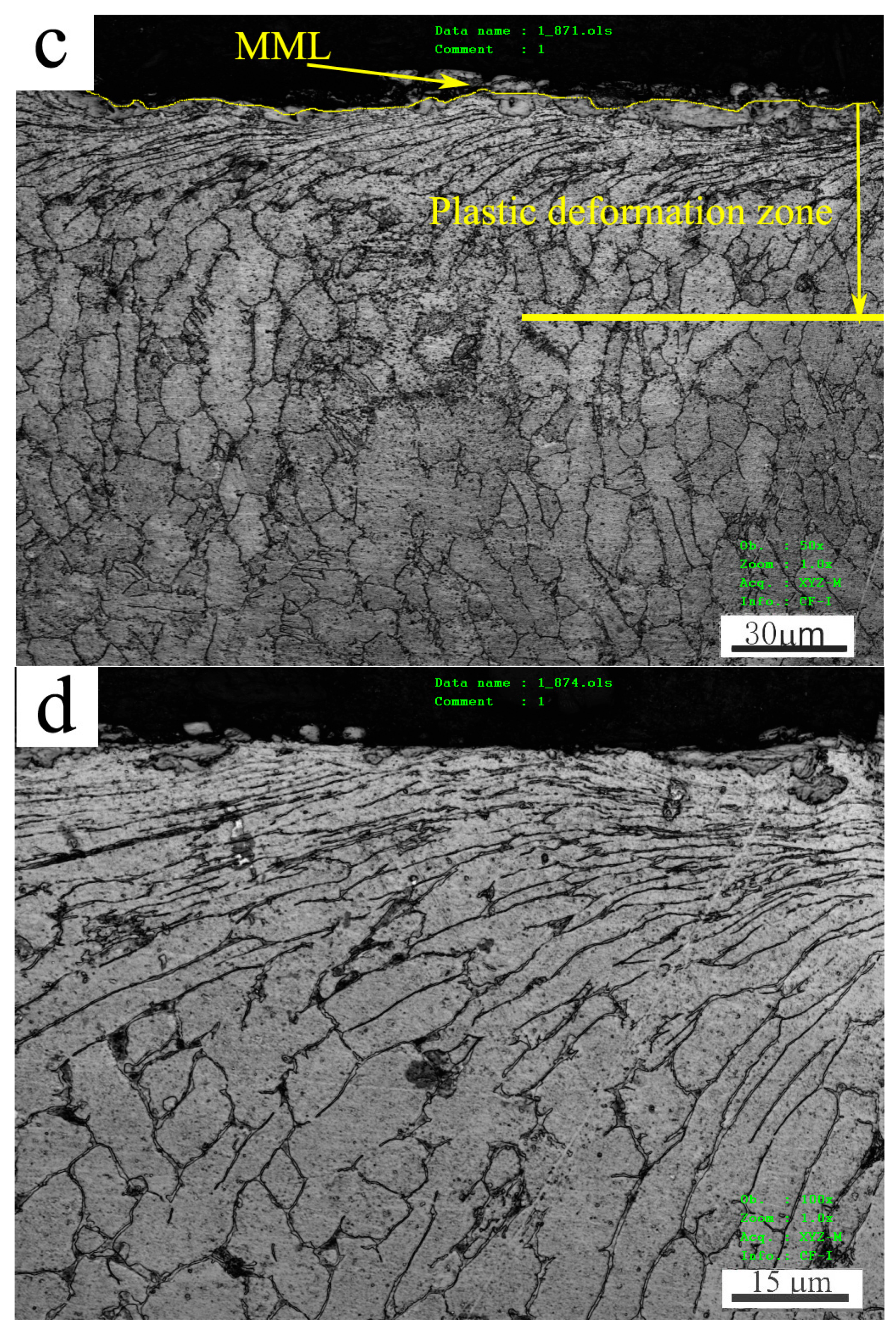

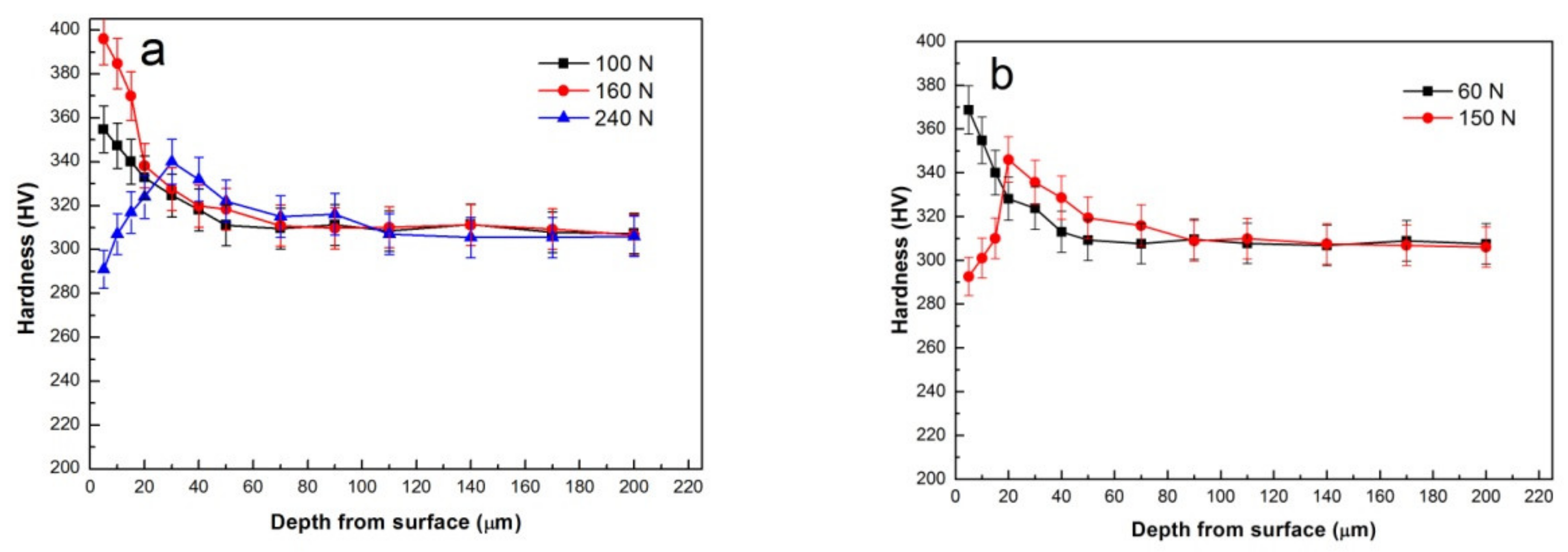

3.3. Surface Hardness

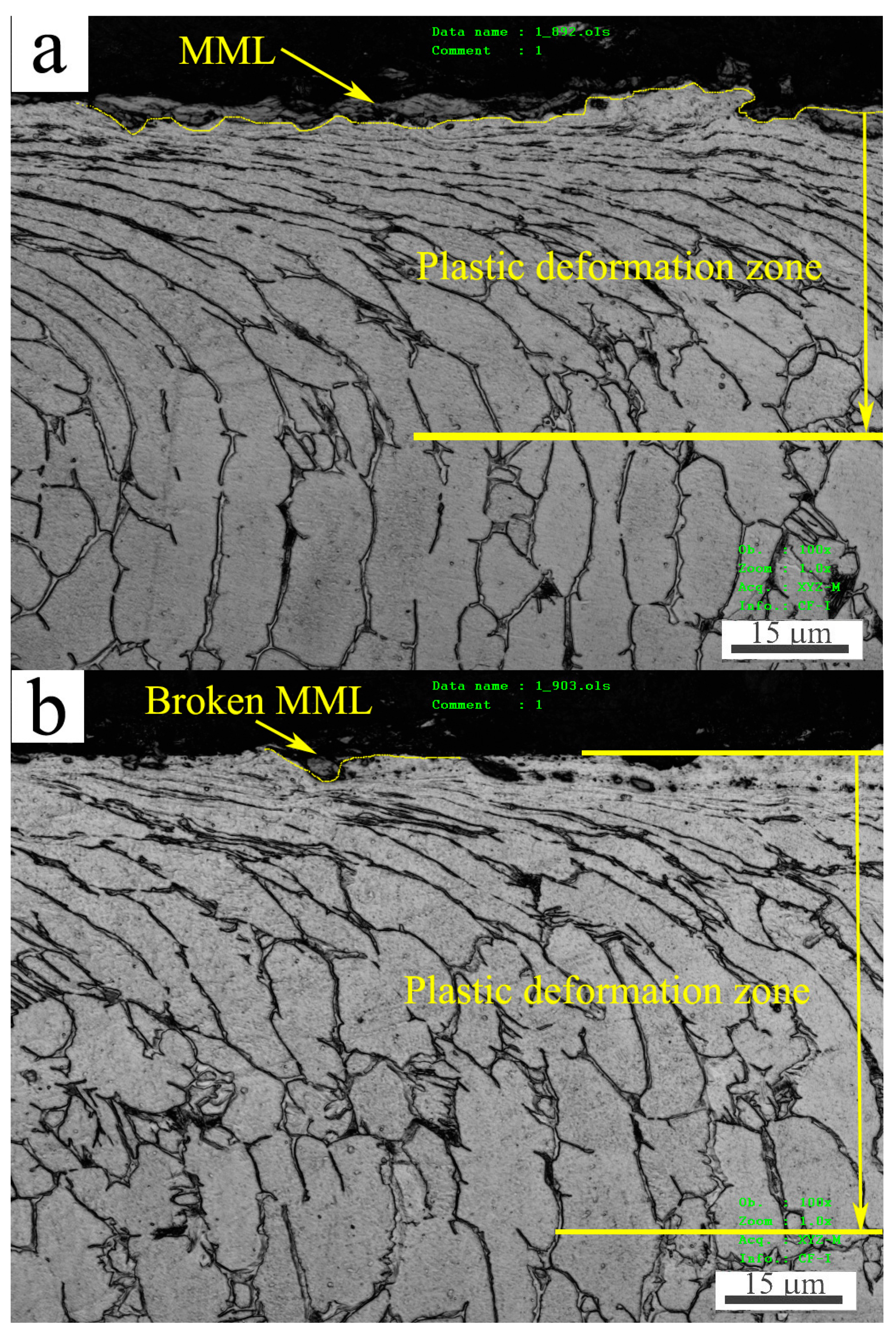

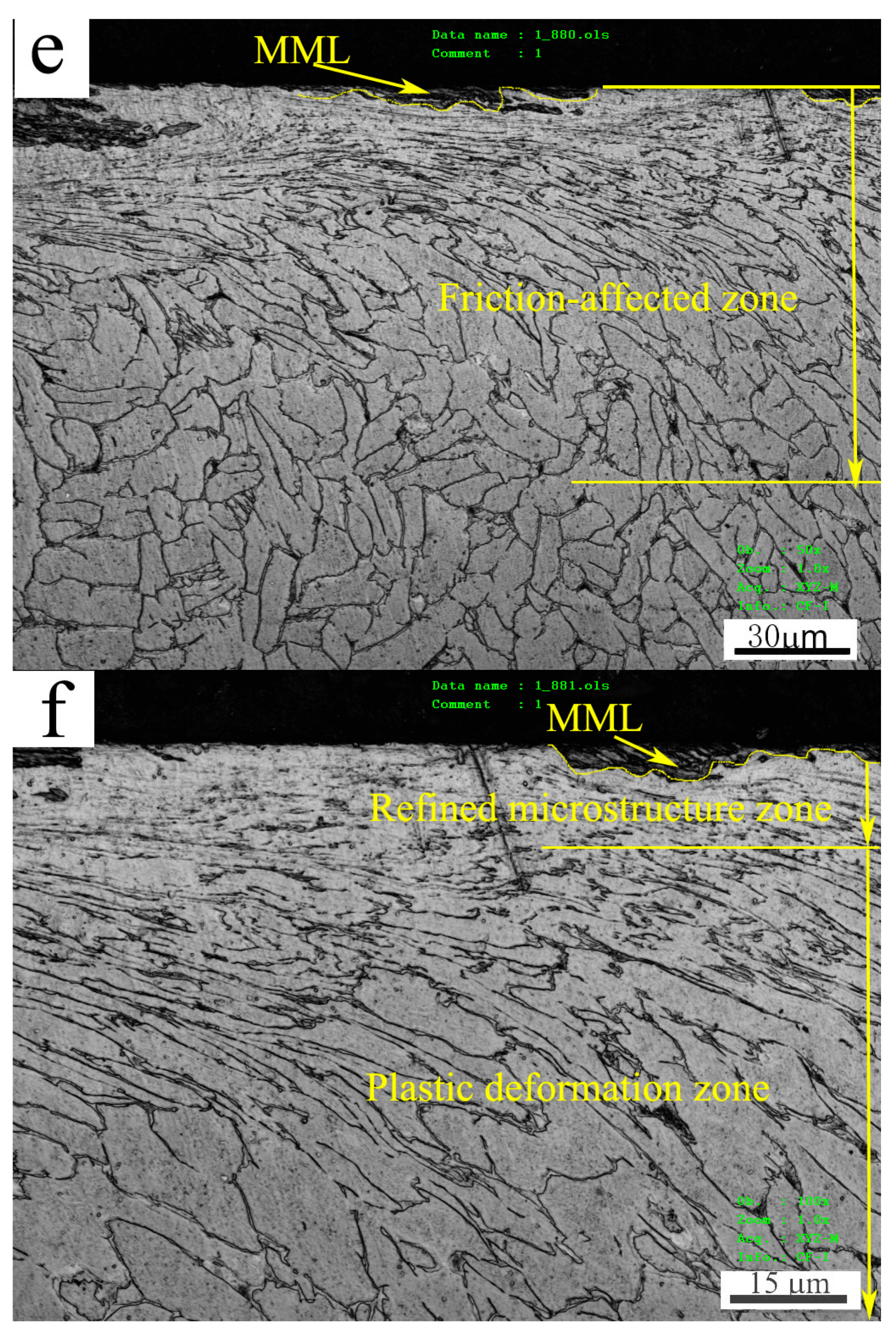

3.4. Microstructures and Hardness in Subsurfaces

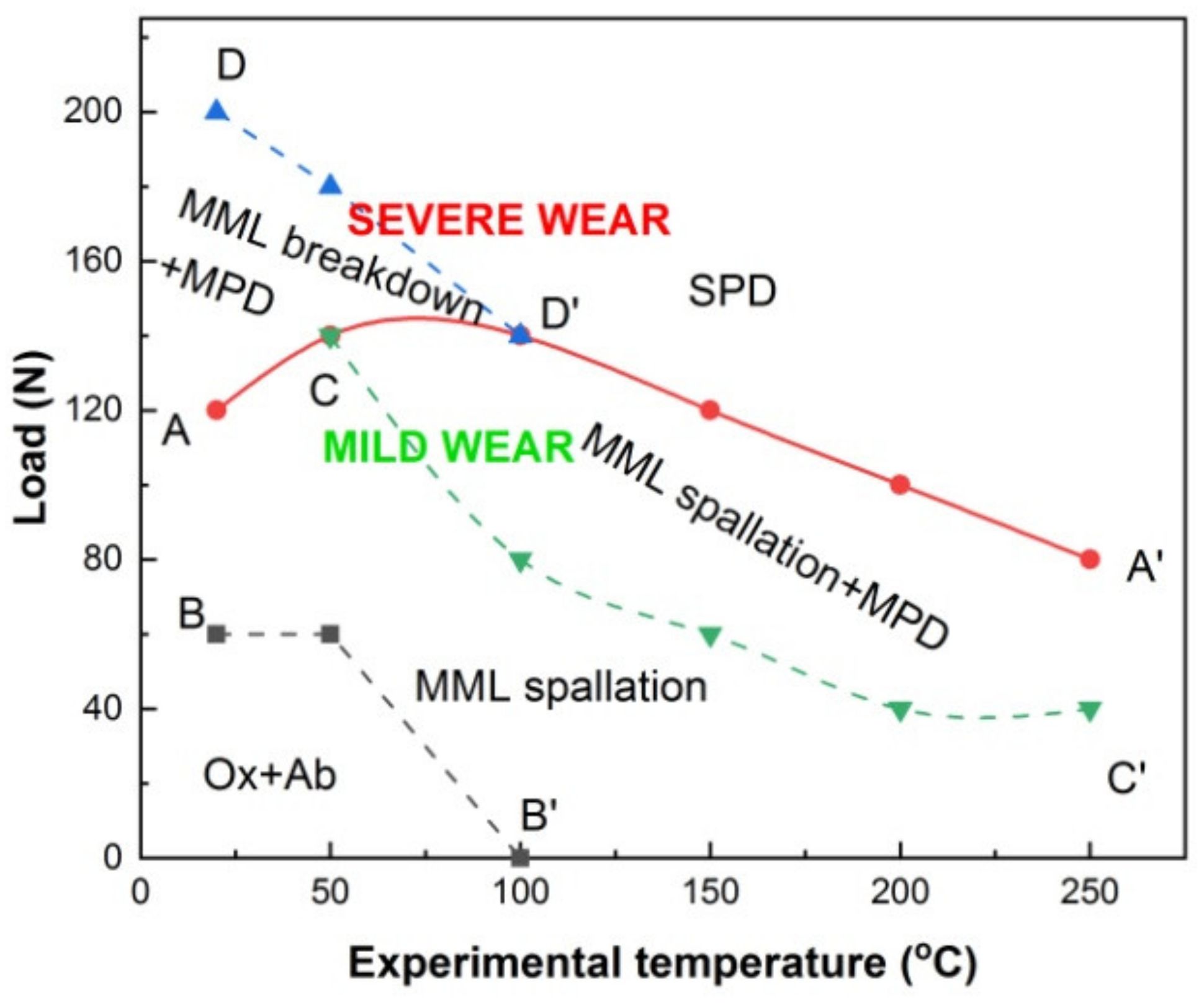

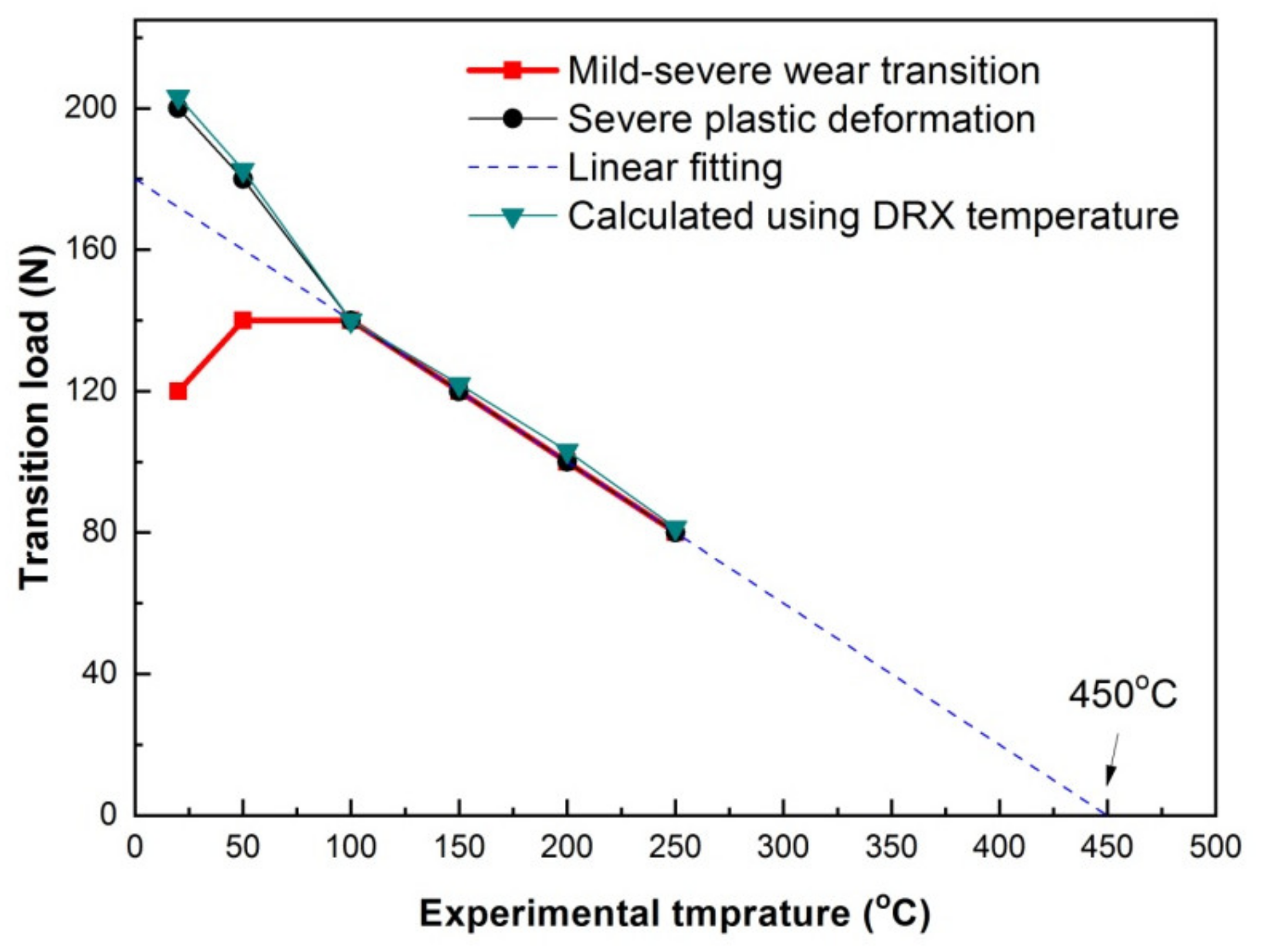

3.5. Relation between SW Transition Load and Experimental Temperature

4. Conclusions

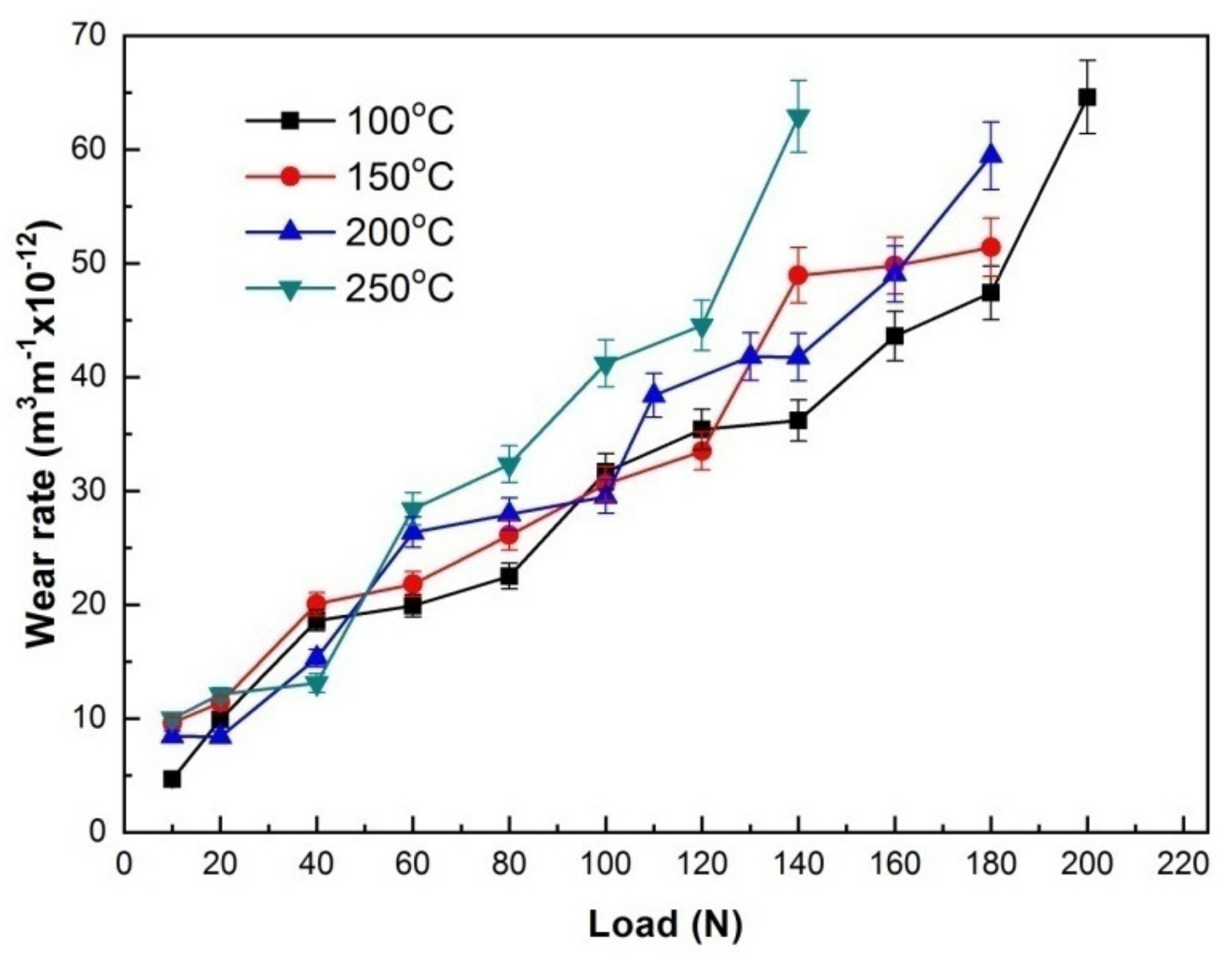

- At each experimental temperature, wear rate essentially kept an increasing trend with applied load, and wear rate-applied load curve can be divided into two stages: a gradually increasing and maintaining plateau stage and a fast increasing and/or maintaining high-level plateau stage. At temperatures of 20–100 °C, experimental temperature showed a little effect on wear rate variation, but its influence became significant at higher temperatures of 150–250 °C.

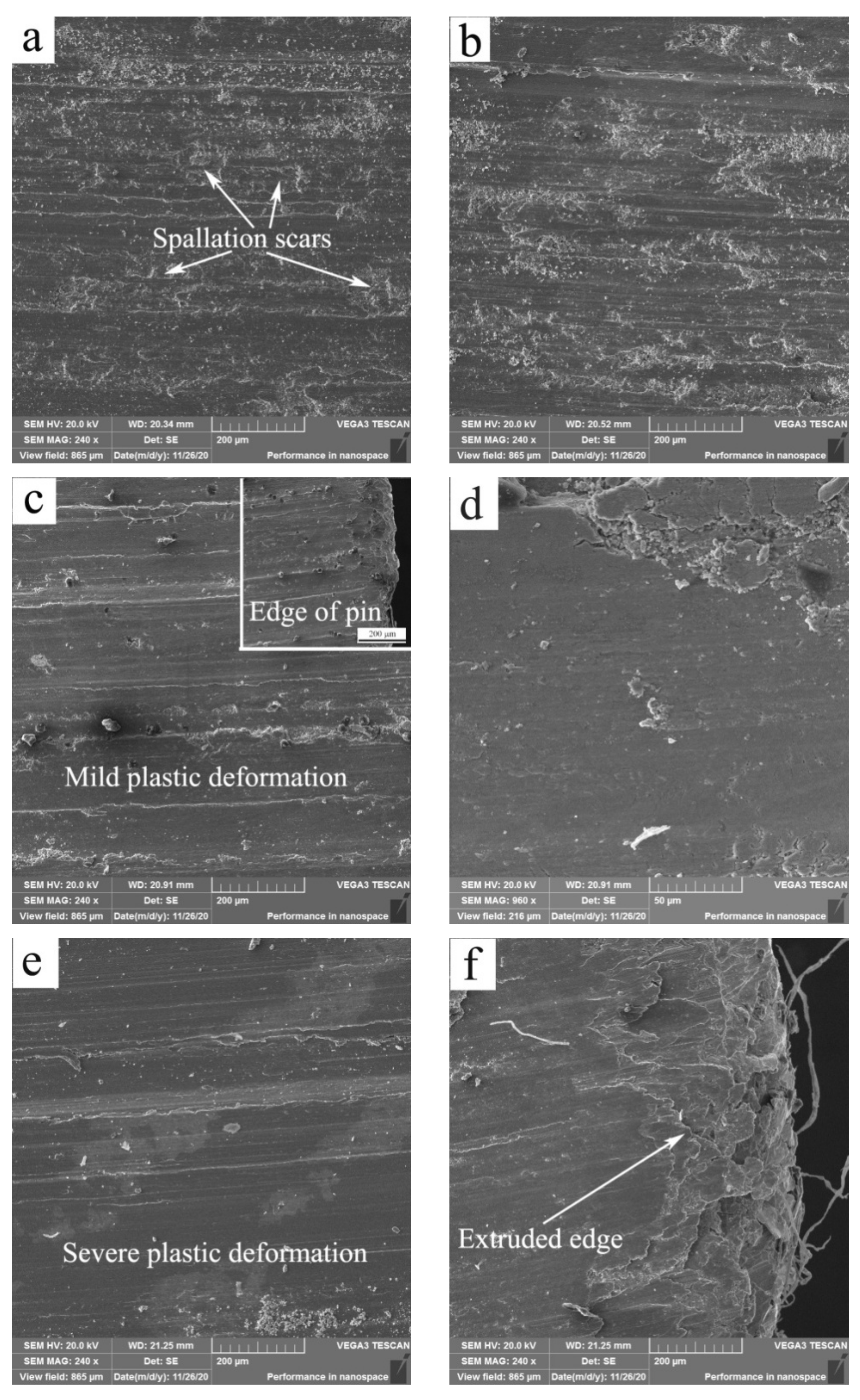

- The wear mechanisms such as oxidation + abrasion, spallation of mechanically mixed layer and mild plastic deformation operated in mild wear, while breakdown of mechanically mixed layer and severe plastic deformation worked in severe wear. The breakdown of mechanically mixed layer governed mild-severe wear transition at 20 and 50 °C, while severe plastic deformation dominated mild-severe wear transition at temperatures of 100–250 °C.

- Severe plastic deformation was activated by the softening arising from dynamic recrystallization microstructure transformation.

- Mild-severe wear transition load decreased with experimental temperature in the range of 100–250 °C, and a linear relationship was found between them. A critical surface dynamic recrystallization temperature 450 °C was obtained by linearly fitting the relation between transition load and experimental temperature at 100–250 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, P.; Pungotra, H.; Kalsi, N.S. On the characteristics of titanium alloys for the aircraft applications. Mater. Today Proc. 2017, 4, 8971–8982. [Google Scholar] [CrossRef]

- Jackson, M.; Dring, K. Materials perspective-a review of advances in processing and metallurgy of titanium alloys. Mater. Sci. Technol. 2006, 22, 881–887. [Google Scholar] [CrossRef]

- Cui, C.; Hu, B.M.; Zhao, L.; Liu, S. Titanium alloy production technology, market prospects and industry development. Mater. Des. 2011, 1687–1691. [Google Scholar] [CrossRef]

- Straffelini, G.; Molinari, A. Mild sliding wear of Fe-0.2%C, Ti-6%Al-4%V and Al-7072: A comparative study. Tribol. Lett. 2011, 14, 227–238. [Google Scholar] [CrossRef]

- Budinsky, K.G. Tribological properties of titanium alloys. Wear 1991, 151, 203–217. [Google Scholar] [CrossRef]

- Straffelini, G.; Molinari, A. Dry sliding wear of Ti-6Al-4V alloy as influenced by the counterface and sliding conditions. Wear 1999, 239, 328–338. [Google Scholar] [CrossRef]

- Qu, J.; Blau, P.J.; Wetkins, T.R.; Cavin, O.B.; Kulkarni, N.S. Friction and wear of titanium alloys sliding against metal, polymer, and ceramic counterfaces. Wear 2005, 258, 1348–1356. [Google Scholar] [CrossRef]

- Chelliah, N.; Kailas, S.V. Synergy between tribo-oxidation and strain rate response on governing the dry sliding wear behavior of titanium. Wear 2009, 266, 704–712. [Google Scholar] [CrossRef]

- Dong, H.; Bell, T. Enhanced wear resistance of titanium surface by a new thermal oxidation treatment. Wear 2000, 238, 131–137. [Google Scholar] [CrossRef]

- Dong, H.; Bell, T. Tribological behaviour of alumina sliding against Ti6Al4V in unlubricated contact. Wear 1999, 225–229, 878–884. [Google Scholar] [CrossRef]

- Zhang, J.; Alpas, A.T. Transition between mild and severe wear in aluminum alloys. Acta Mater. 1997, 45, 513–518. [Google Scholar] [CrossRef]

- Chen, H.; Alpas, A.T. Sliding wear map for the magnesium alloy Mg-9Al-0.9Zn (AZ91). Wear 2000, 246, 106–116. [Google Scholar] [CrossRef]

- Liang, C.; Lv, X.X.; An, J. Correlation between friction-induced microstructural evolution, strain hardening in subsurface and tribological properties of AZ31 magnesium alloy. Wear 2014, 312, 29–39. [Google Scholar] [CrossRef]

- Zhang, Q.; Ding, H.; Zhou, G.; Guo, X.; Zhang, M.; Li, N.; Wu, H.; Xia, M. Dry sliding wear behavior of a selected titanium alloy against counterface steel of different hardness levels. Metall. Mater. Trans. A 2019, 50, 220–233. [Google Scholar] [CrossRef]

- Mao, Y.S.; Wang, L.; Chen, K.M.; Wang, S.Q.; Cui, X.H. Tribo-layer and its role in dry sliding wear of Ti-6Al-4V alloy. Wear 2013, 297, 1032–1039. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Q.Y.; Li, X.X.; Cui, X.H.; Wang, S.Q. Severe-to-mild wear transition of titanium alloys as a function of temperature. Triobol. Lett. 2014, 53, 511–520. [Google Scholar] [CrossRef]

- Farokhzadeh, K.; Edrisy, A. Transition between mild and severe wear in titanium alloys. Tribol. Int. 2016, 94, 96–111. [Google Scholar] [CrossRef]

- Raj, A.J.; Pottirayil, A.; Kailas, S.V. Dry sliding wear behavior of Ti-6Al-4V pin against SS316L disk at constant contact pressure. J. Tribol. 2017, 139, 021603. [Google Scholar]

- Rasool, G.; Stack, M.M. Tribo-oxidation maps for Ti against steel. Tribol. Int. 2015, 91, 258–266. [Google Scholar] [CrossRef] [Green Version]

- An, J.; Tian, Y.X.; Feng, C.Q. Correlation between test temperature, applied load and wear transition of Mg97Zn1Y2 alloy. J. Mag. Alloys 2021, 9, 592–603. [Google Scholar] [CrossRef]

- Wang, Y.B.; Li, L.; An, J. Dry wear behavior and mild-to-severe wera transition in an Mg-Gd-Y-Zr alloy. Surf. Topogr. Metrol. Prop. 2021, 9, 025032. [Google Scholar] [CrossRef]

- Grainj, A.K.; Zhang, L.; Lim, S. Tribological behavior of Ti6Al4V alloy: Subsurface structure, damage mechanism and mechanical properties. Wear 2021, 464–465, 203551. [Google Scholar]

- An, J.; Zhang, Y.X.; Lv, X.X. Tribological characteristics of Mg-3Al-0.4Si-0.1Zn alloy at elevated temperatures of 50–200 °C. Tribol. Lett. 2018, 66, 14. [Google Scholar] [CrossRef]

- An, J.; Zhao, W.; Feng, C.Q. Elevated-temperature wear characteristics and mild-severe wear transition in Mg-10.1Gd-1.4Y-0.4Zr alloy. J. Tribol. 2019, 141, 121601. [Google Scholar] [CrossRef]

- Qiu, M.; Zhang, Y.; Shangguan, B.; Du, S.; Yan, Z. The relationships between tribological behavior and heat-transfer capability of Ti6Al4V alloys. Wear 2007, 263, 653–657. [Google Scholar] [CrossRef]

- Lim, S.C.; Ashby, M.F. Wear-mechanism maps. Acta Mater. 1987, 35, 1–24. [Google Scholar] [CrossRef]

- Le, V.T.; Goo, N.S.; Lim, J.Y. Experimental investigation on thermal contact resistance of alumina fibrous insulation materials with Ti-6Al-4V alloy at high temperature and its effective thermal conductivity. Heat Mass Transf. 2019, 55, 1075–1722. [Google Scholar] [CrossRef]

| Temperature (°C) | Load (N) | O | Al | Ti | Fe |

|---|---|---|---|---|---|

| 20 | 20 | 8.89 | 5.91 | 79.36 | 4.16 |

| 80 | 9.08 | 5.91 | 79.29 | 4.22 | |

| 160 | 8.31 | 5.84 | 79.83 | 4.39 | |

| 240 | 8.57 | 6.01 | 80.07 | 3.82 | |

| 50 | 20 | 8.61 | 5.80 | 79.25 | 4.87 |

| 60 | 9.31 | 5.88 | 77.71 | 5.74 | |

| 100 | 12.62 | 5.01 | 70.63 | 10.34 | |

| 120 | 10.49 | 4.90 | 74.28 | 8.97 | |

| 140 | 9.17 | 5.75 | 78.33 | 5.10 | |

| 160 | 8.10 | 5.41 | 78.36 | 6.64 | |

| 180 | 7.36 | 6.07 | 82.78 | 2.22 | |

| 240 | 3.38 | 6.22 | 87.66 | 1.11 |

| Temperature (°C) | Stage | Load Range (N) | Wear Mechanism |

|---|---|---|---|

| 20 | First | 10–60 | Oxidation + abrasion |

| 80–120 | Spallation of MML | ||

| Second | 140–200 | MPD + Breakdown of MML | |

| 220–240 | SPD | ||

| 50 | First | 10–60 | Oxidation + abrasion |

| 80–140 | Spallation of MML | ||

| Second | 160–180 | MPD + Breakdown of MML | |

| 200–240 | SPD |

| Temperature (°C) | Load (N) | O | Al | Ti | Fe |

|---|---|---|---|---|---|

| 150 | 20 | 12.39 | 5.41 | 74.31 | 6.60 |

| 60 | 11.01 | 5.68 | 75.21 | 6.71 | |

| 100 | 11.94 | 5.84 | 76.96 | 3.84 | |

| 120 | 11.81 | 5.41 | 76.81 | 4.51 | |

| 140 | 5.84 | 6.38 | 85.77 | 0.63 | |

| 150 | 4.97 | 5.53 | 78.99 | 8.80 | |

| 200 | 20 | 13.43 | 4.63 | 67.08 | 13.74 |

| 60 | 6.13 | 5.85 | 83.18 | 3.52 | |

| 100 | 9.07 | 5.29 | 80.25 | 3.99 | |

| 130 | 2.04 | 6.41 | 88.87 | 0.96 | |

| 140 | 7.33 | 5.79 | 84.20 | 1.33 | |

| 180 | 7.48 | 5.90 | 84.96 | 0.44 |

| Temperature (°C) | 20 | 50 | 100 | 150 | 200 | 250 |

|---|---|---|---|---|---|---|

| Transition load (N) | 200 (SPD) | 180 (SPD) | 140 | 120 | 100 | 80 |

| Coefficient of friction | 0.55 | 0.57 | 0.65 | 0.64 | 0.63 | 0.64 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, D.; Zhang, W.; An, J. Two Types of Wear Mechanisms Governing Transition between Mild and Severe Wear in Ti-6Al-4V Alloy during Dry Sliding at Temperatures of 20–250 °C. Materials 2022, 15, 1416. https://doi.org/10.3390/ma15041416

Du D, Zhang W, An J. Two Types of Wear Mechanisms Governing Transition between Mild and Severe Wear in Ti-6Al-4V Alloy during Dry Sliding at Temperatures of 20–250 °C. Materials. 2022; 15(4):1416. https://doi.org/10.3390/ma15041416

Chicago/Turabian StyleDu, Danhu, Wenbin Zhang, and Jian An. 2022. "Two Types of Wear Mechanisms Governing Transition between Mild and Severe Wear in Ti-6Al-4V Alloy during Dry Sliding at Temperatures of 20–250 °C" Materials 15, no. 4: 1416. https://doi.org/10.3390/ma15041416

APA StyleDu, D., Zhang, W., & An, J. (2022). Two Types of Wear Mechanisms Governing Transition between Mild and Severe Wear in Ti-6Al-4V Alloy during Dry Sliding at Temperatures of 20–250 °C. Materials, 15(4), 1416. https://doi.org/10.3390/ma15041416