Evolution and Regulation of Radial Structure of PAN Pre-Oxidized Fiber Based on the Fine Denier Model

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Sample Preparation

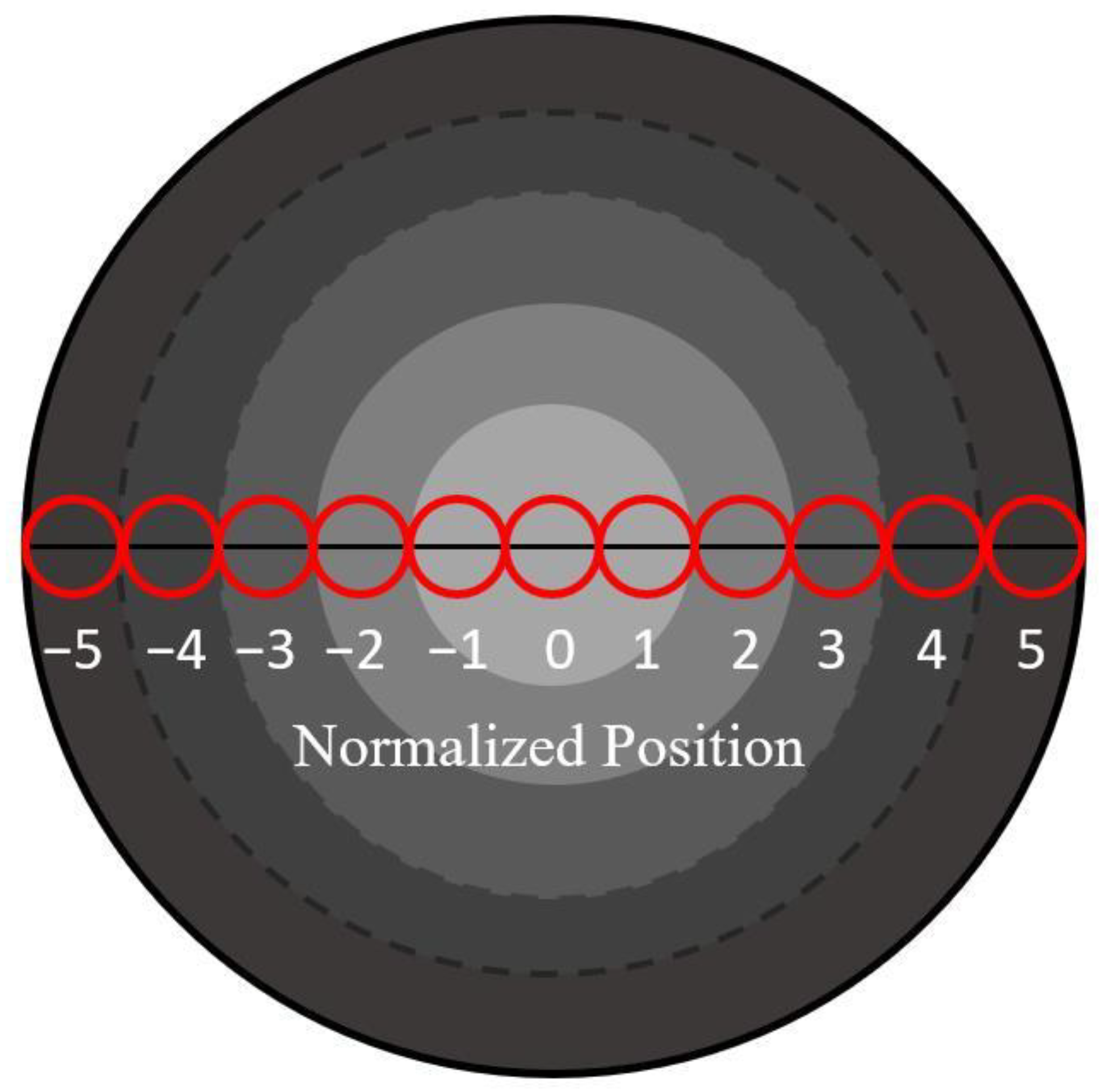

2.2. Optical Microscope Measurements

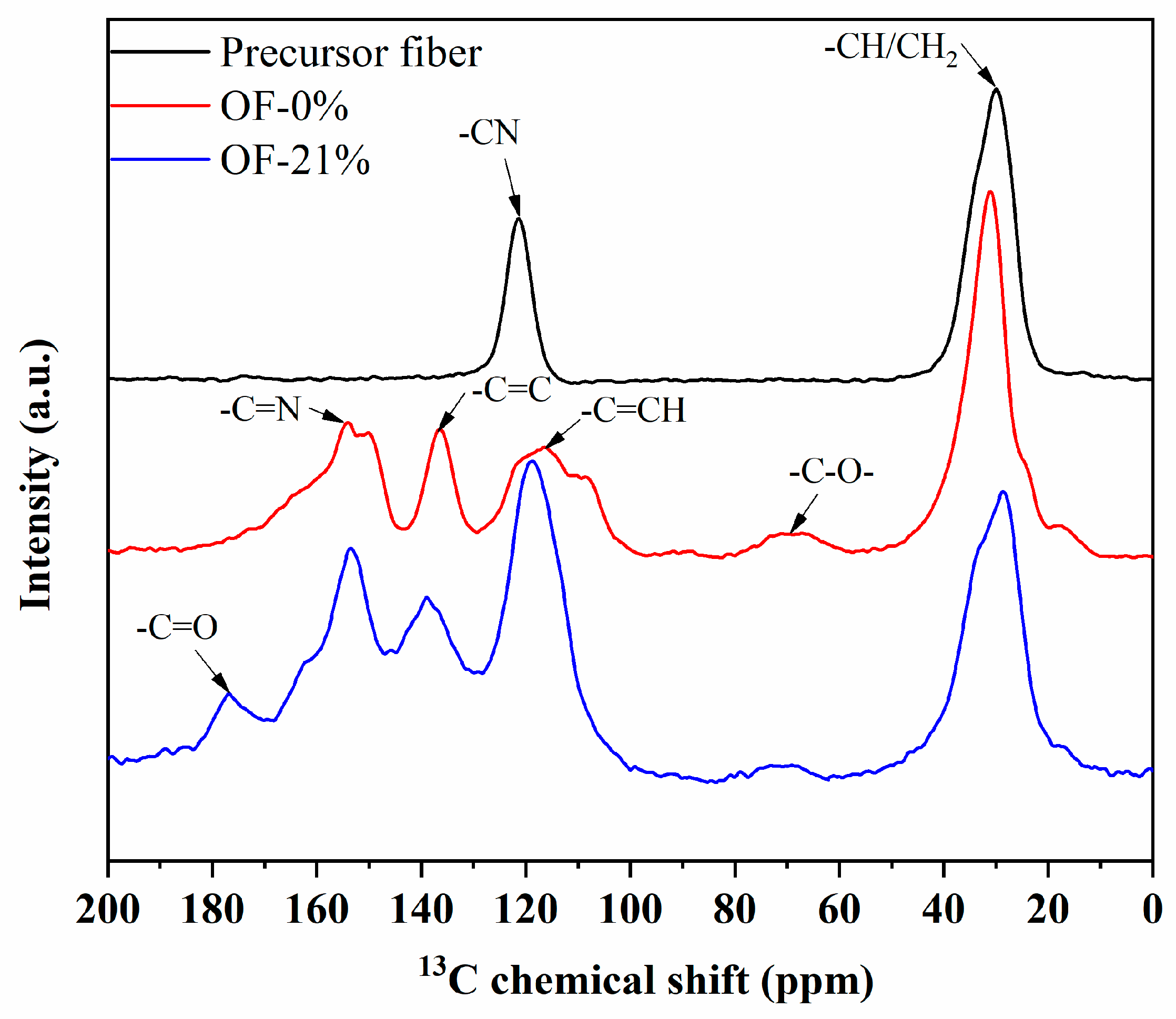

2.3. C-NMR Measurements

2.4. TGA Measurements

3. Results and Discussion

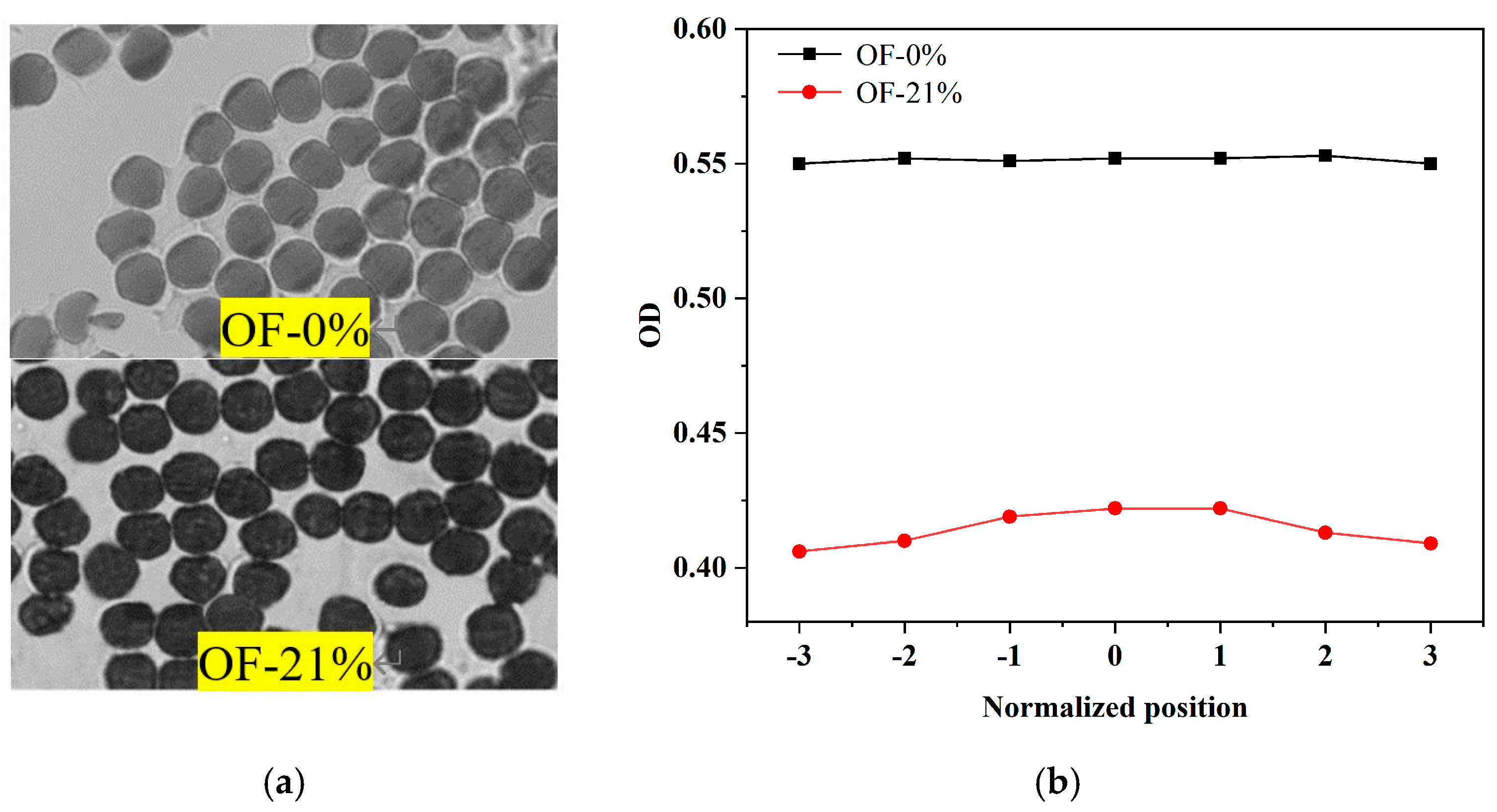

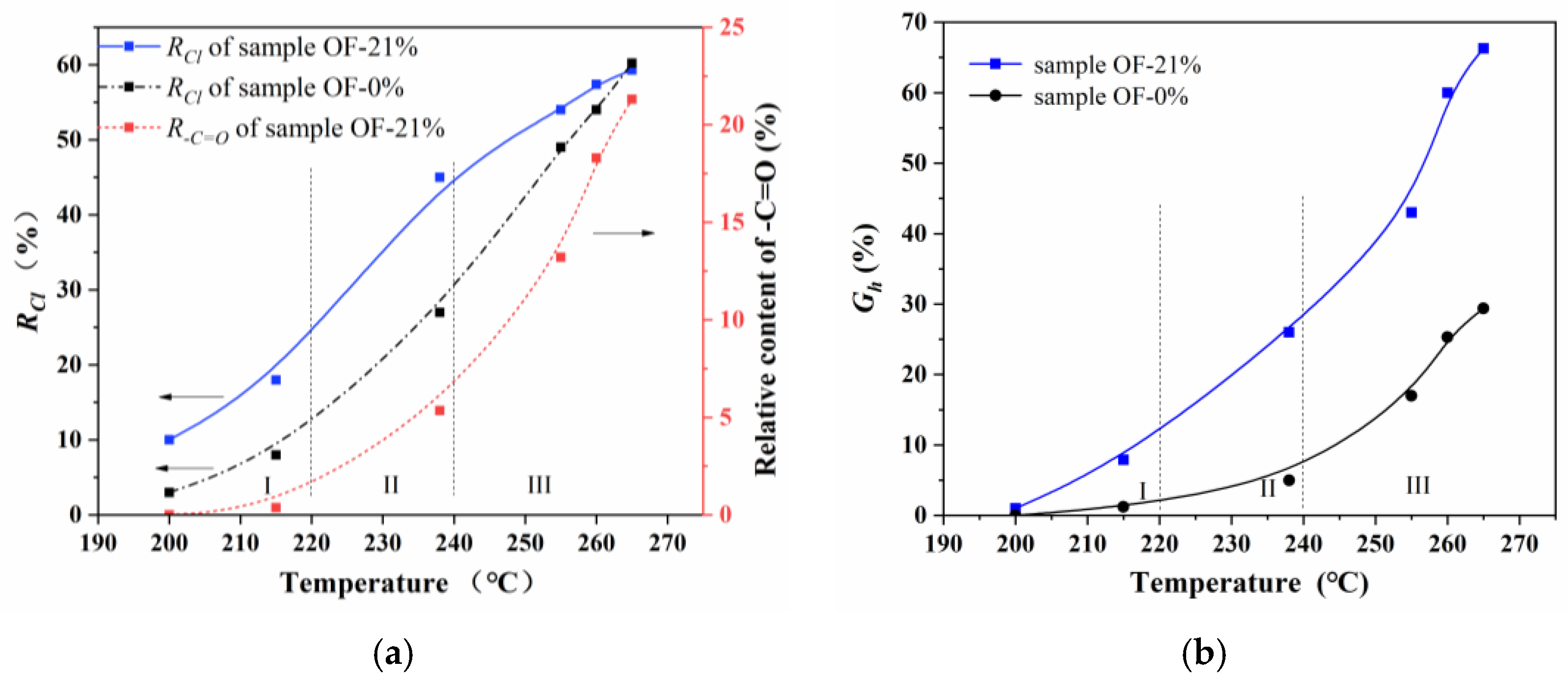

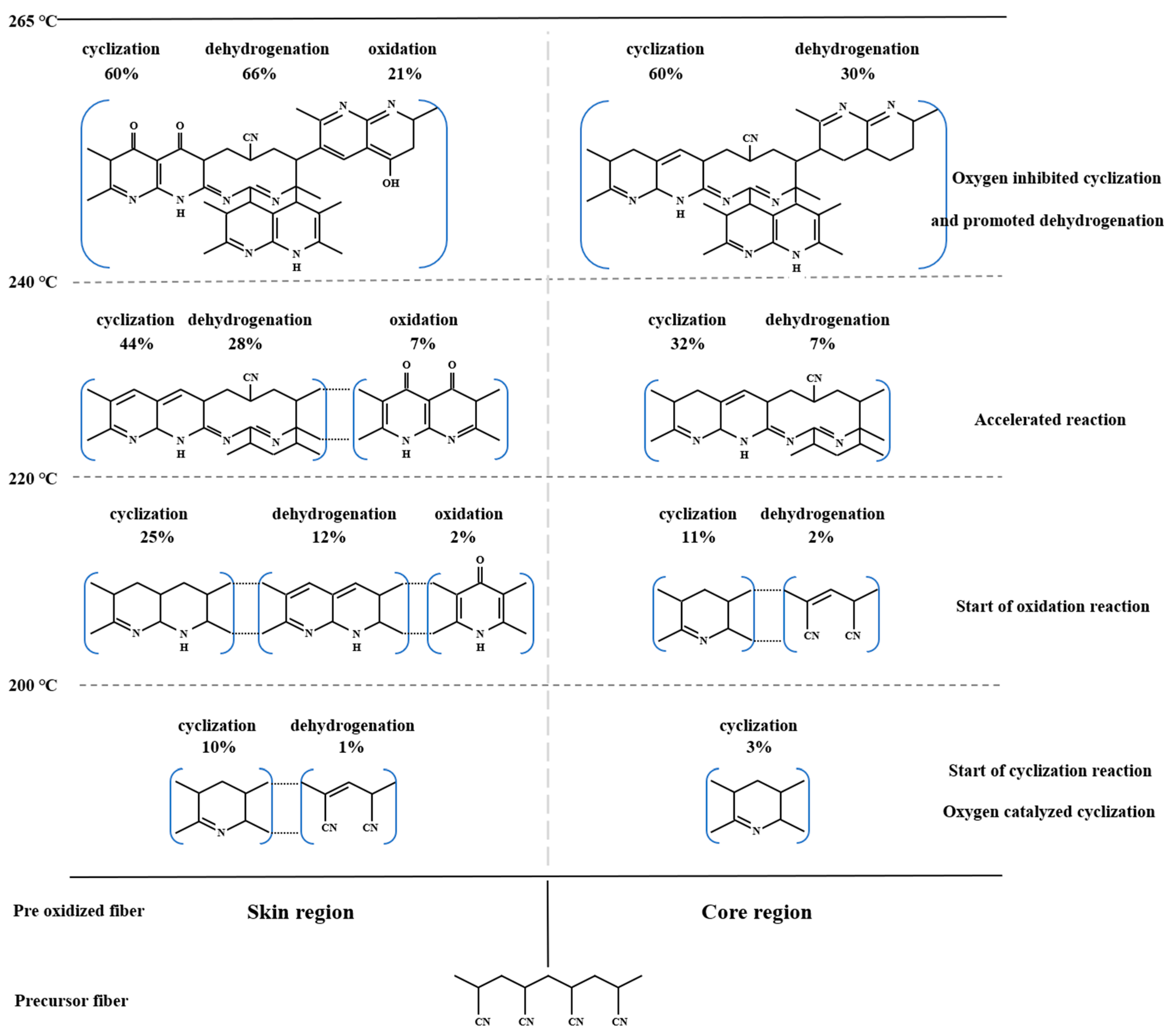

3.1. Characteristics of Skin-Core Structure and its Chemical Evolution of PAN Based Pre-Oxidized Fiber Based on Fine Denier Model

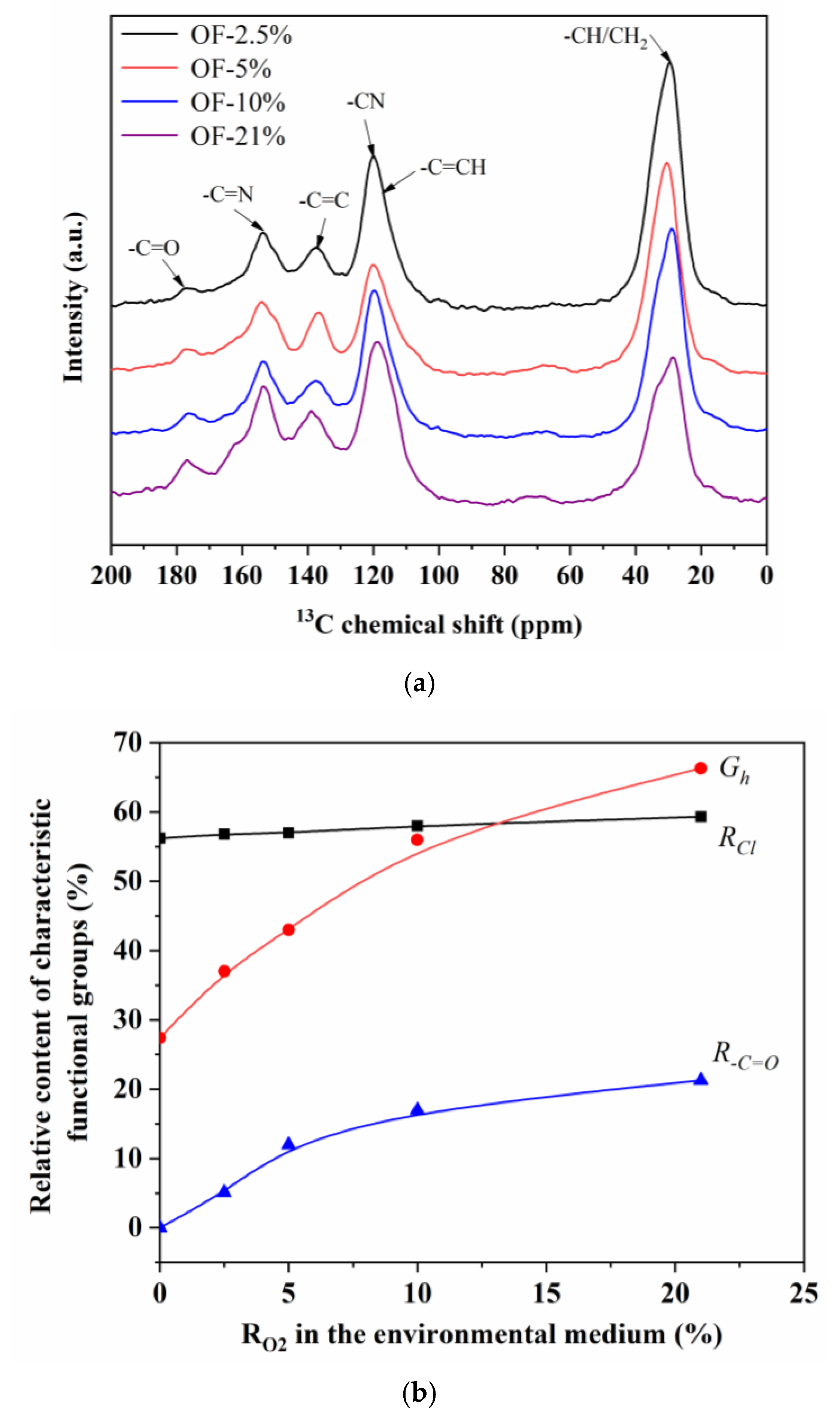

3.2. Radial Structure Characteristics of PAN-Based Pre-Oxidized Fiber Affected by Ambient Oxygen Concentration

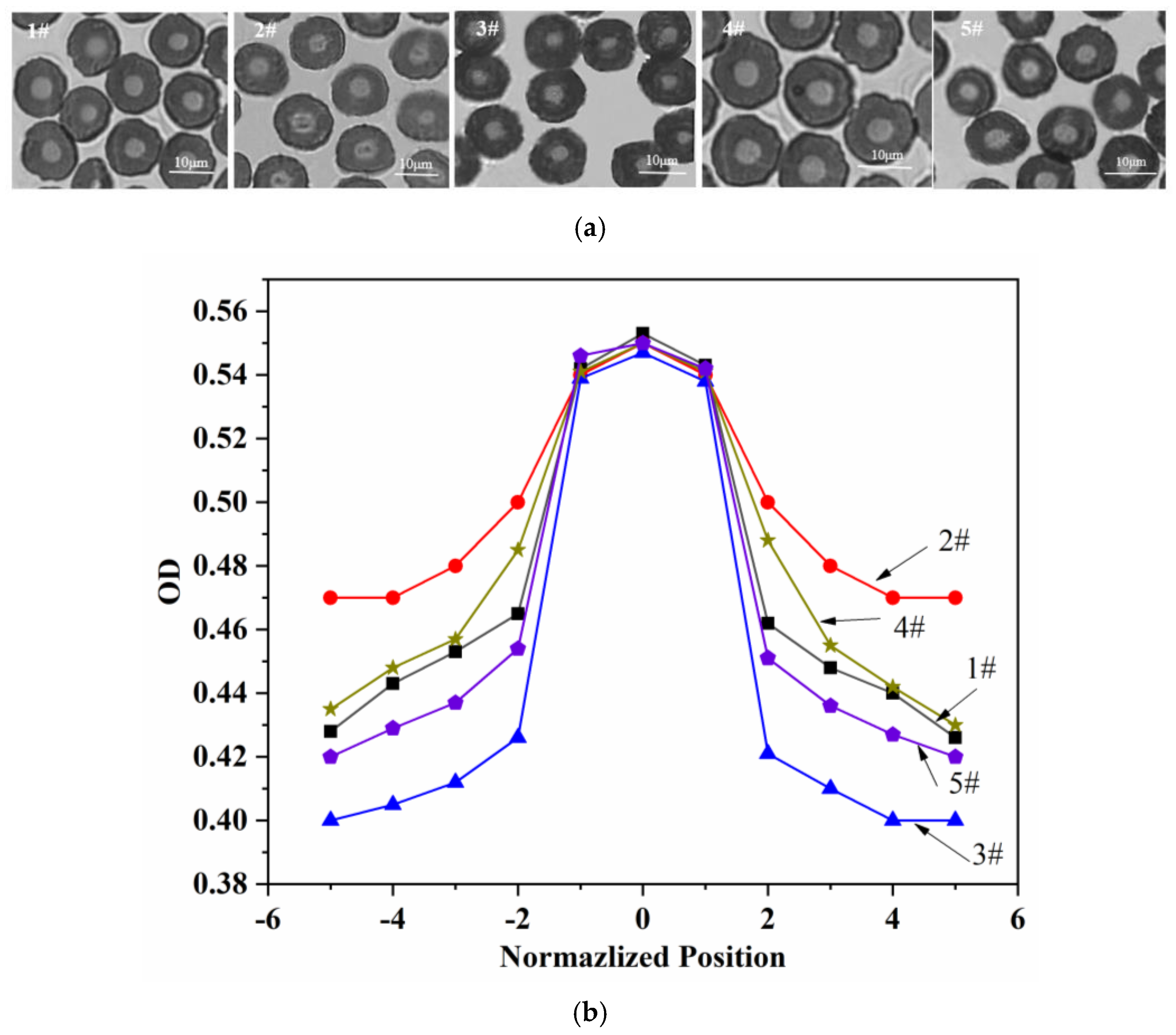

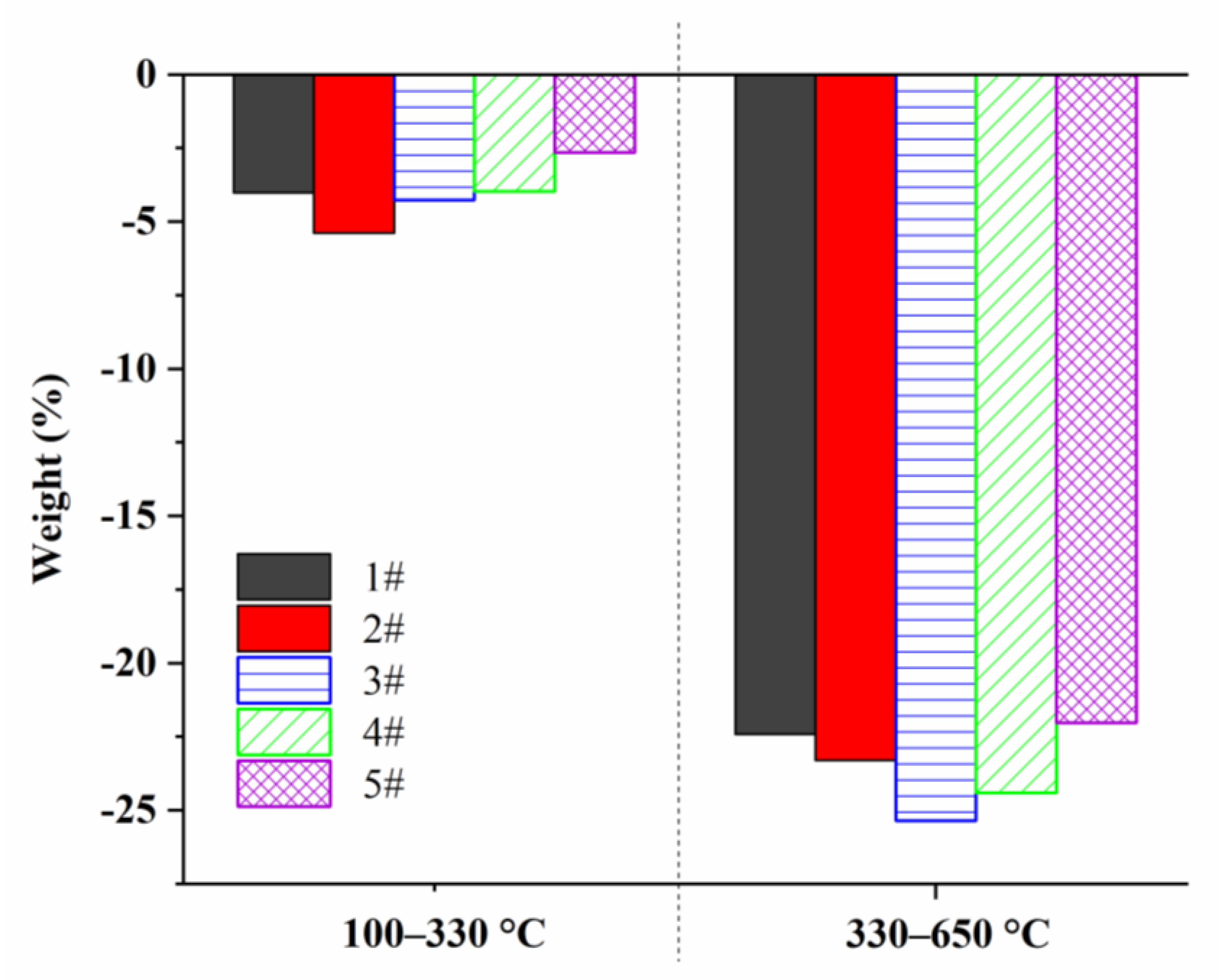

3.3. Radial Structure of PAN Pre-Oxidized Fiber

4. Conclusions

- The pre-oxidation reaction of PAN fiber resulted in the existence of a skin-core structure. Along the fiber radial direction from skin to core, the degree of cyclization changed little, and the dehydrogenation and oxygen-containing structure gradually decreased. Specifically, the oxygen-containing functional groups in the core decreased to the lowest level or even disappeared.

- With the increase of a heat treatment temperature, a three-stage variation of the skin-core structure of the PAN fiber was observed. For stage I, there were mainly cyclization and dehydrogenation structures in the skin region. For stage II, the oxygen-containing structure in the skin increased slowly. Lastly for stage III, the cyclization structure in the skin and core was similar.

- Upon increasing the heat treatment temperature in stage III, the cyclization reaction in the skin was inhibited, and there were relatively more dehydrogenation and oxidation reaction structures. Moderate increasing the heat treatment temperature in stages I and II could promote the formation of a more cyclized structure and a more stable cross-linked ladder structure in the skin of fiber.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qian, X.; Wang, X.; Ma, H.; Zhang, Y. Technology status and research progress of PAN-based high-modulus carbon fibers in China and abroad. China Synth. Fiber Ind. 2021, 44, 58–64. (In Chinese) [Google Scholar]

- Frank, E.; Steudle, L.M.; Ingildeev, D.; Spoerl, J.M.; Buchmeiser, M.R. ChemInform Abstract: Carbon Fibers: Precursor Systems, Processing, Structure, and Properties. ChemInform 2014, 45. [Google Scholar] [CrossRef]

- Chae, H.G.; Newcomb, B.A.; Gulgunje, P.V.; Liu, Y.; Gupta, K.K.; Kamath, M.G.; Lyons, K.M.; Ghoshal, S.; Pramanik, C.; Giannuzzi, L.; et al. High strength and high modulus carbon fibers. Carbon 2015, 93, 81–87. [Google Scholar] [CrossRef] [Green Version]

- Guo, R.; Xian, G.; Li, F.; Li, C.; Hong, B. Hygrothermal resistance of pultruded carbon, glass and carbon/glass hybrid fiber reinforced epoxy composites. Constr. Build. Mater. 2022, 315, 125710. [Google Scholar] [CrossRef]

- Nunna, S.; Creighton, C.; Hameed, N.; Naebe, M.; Henderson, L.C.; Setty, M.; Fox, B.L. Radial structure and property relationship in the thermal stabilization of PAN precursor fibres. Polym. Test. 2017, 59, 203–211. [Google Scholar] [CrossRef]

- Nunna, S.; Maghe, M.; Rana, R.; Varley, R.J.; Knorr, D.B., Jr.; Sands, J.M.; Creighton, C.; Henderson, L.C.; Naebe, M. Time Dependent Structure and Property Evolution in Fibres during Continuous Carbon Fibre Manufacturin. Materials 2019, 12, 1069. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Li, C.; Cao, W. Effect of stretching on the orientation structure and reaction behavior of PAN fiber during the thermal stabilization. Mater. Res. Express 2021, 8, 085603. [Google Scholar] [CrossRef]

- Chai, X.; Mi, H.; Zhu, C.; He, C.; Xu, J.; Zhou, X.; Liu, J. Low-temperature thermal stabilization of polyacrylontrile-based precursor fibers towards efficient preparation of carbon fibers with improved mechanical properties. Polymer 2015, 76, 131–139. [Google Scholar] [CrossRef]

- Wu, S.; Liu, Y.; Ge, Y.; Ran, L.; Peng, K.; Yi, M. Microstructure difference on skin and core of domestic PAN-based carbon fibers characterized by Raman spectroscopy. Chin. J. Nonferrous Met. 2015, 8, 2131–2138. (In Chinese) [Google Scholar]

- Johnson, D.J. Structure property relationships in carbon. J. Phys. D-Appl. Phys. 1987, 20, 285–291. [Google Scholar] [CrossRef]

- Bennett, S.E.; Johnson, D.J. Electron-microscope studies of structural heterogeneity in pan-based carbon fibres. Carbon 1979, 17, 25. [Google Scholar] [CrossRef]

- Kong, L.Q.; Liu, H.; Cao, W.Y. PAN Fiber diameter effect on the structure of PAN-based carbon fibers. Fibers Polym. 2014, 15, 2480–2488. [Google Scholar] [CrossRef]

- Wang, J.; Hu, L.; Yang, C.; Zhao, W.; Lu, Y. Effects of oxygen content in the atmosphere on thermal oxidative stabilization of polyacrylonitrile fibers. R. Soc. Chem. 2016, 6, 73404–73411. [Google Scholar] [CrossRef]

- Liu, R.; Wang, X.; Zhang, Y.; Qian, X.; Li, D.; Ding, P. Structure evolution of stabilized polyacrylonitrile fiber during carbonization. China Synth. Fiber Ind. 2016, 39, 9–13. (In Chinese) [Google Scholar]

- Xue, Y.; Liu, J.; Lian, F.; Liang, J. Effect of the oxygen-induced modification of polyacrylonitrile fibers during thermal-oxidative stabilization on the radial microcrystalline structure of the resulting carbon fibers. Polym. Degrad. Stab. 2013, 98, 2259–2267. [Google Scholar] [CrossRef]

- Hu, X.; Wang, C.; Wang, Q.; Lu, W.; Wang, Y. Formation and evolution of skin-core structure of PAN-based carbon fibers. Mater. Rep. 2010, 9, 71–74. [Google Scholar]

- Sun, L.; Shang, L.; Xiao, L.; Zhang, M.; Ao, Y.; Li, M. The influence of stabilization of efficiency on Skin-core structure and properties of polyacrylonitrile fibers. J. Mater. Sci. 2020, 55, 3408–3418. [Google Scholar] [CrossRef]

- Wang, B.; Wu, S.; Li, C.; Cao, W. Evolution mechanism of cyclized structure of PAN-based pre-oxidized fiber during low temperature carbonization process. Mater. Res. Express 2021, 8, 115602. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.; Wang, L.; Liang, J.Y. Effect of preoxidation temperature on core/shell structure during the preoxidation procession of PAN fibers. J. Beijing Univ. Chem. Technol. Nat. Sci. Ed. 2006, 1, 41–45. (In Chinese) [Google Scholar]

- Liu, Y. Effect of PAN Fiber Diameter and Gradient Temperature Stabilization on Carbon Fiber Structure and Properties; Beijing University of Chemical Technology: Beijing, China, 2017. [Google Scholar]

- Zhong, S.; Xu, F.; Lei, S. Optical density method of radial structure of PAN-based pre-oxidized fibers. J. Mater. Eng. 2017, 45, 65–71. (In Chinese) [Google Scholar]

- Wang, X.; Zhang, Y.; Qi, M.; Ouyang, Q.; Chen, Y.; Yan, Q. Optical density study on the influence of pre-oxidation process on skin-core structure of polyacrylonitrile fiber. Synth. Fiber China 2011, 40, 1–4. (In Chinese) [Google Scholar]

- Wang, Y.F.; Wang, Y.W.; Xu, L.H.; Wang, Y. Regulating the radial structure of polyacrylonitrile fibers during pre-oxidation and its effect on the mechanical properties of the resulting carbon fibers. N. Carbon Mater. 2021, 36, 827–834. [Google Scholar] [CrossRef]

- Wang, B.; Li, C.; Cao, W. Effect of Polyacrylonitrile Precursor Orientation on the Structures and Properties of Thermally Stabilized Carbon Fiber. Materials 2021, 14, 3237. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C. Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/glass fiber reinforced polymer composite. Compos. Struct. 2022, 281, 115060. [Google Scholar] [CrossRef]

- Li, C.; Yin, X.; Liu, Y.; Guo, R.; Xian, G. Long-term service evaluation of a pultruded carbon/glass hybrid rod exposed to elevated temperature, hydraulic pressure and fatigue load coupling. Int. J. Fatigue 2020, 134, 105480. [Google Scholar] [CrossRef]

- Frank, E.; Steudle, L.M.; Ingildeev, D.; Spörl, J.M.; Buchmeiser, M.R. Carbon fibers: Precursor systems, processing, structure, and properties. Angew. Chem. Int. Ed. 2014, 53, 5262–5298. [Google Scholar] [CrossRef]

- Peebles, L.H.; Brandrup, J. A chemical means of distinguishing between conjugated, and conjugated, bonds. Die Makromol. Chem. 2003, 98, 189–203. [Google Scholar] [CrossRef]

- Xiao, S.; Cao, W.; Wang, B.; Xu, L.; Chen, B. Mechanism and kinetics of oxidation during the thermal stabilization of polyacrylonitrile fibers. J. Appl. Polym. Sci. 2013, 127, 3198–3203. [Google Scholar] [CrossRef]

- Xiao, S.; Wang, B.; Zhao, C.; Xu, L.; Chen, B. Influence of oxygen on the stabilization reaction of polycarylonitrile fibers. J. Appl. Polym. Sci. 2013, 127, 2332–2338. [Google Scholar] [CrossRef]

- Jing, M.; Wang, C.G.; Wang, Q.; Bai, Y.J.; Zhu, B. Chemical structure evolution and mechanism during pre-carbonization of PAN-based stabilized fiber in the temperature range of 350–600 °C. Polym. Degration Stab. 2007, 92, 1737–1742. [Google Scholar] [CrossRef]

| Sample No. | Relative Content of Oxygen |

|---|---|

| OF-0% | 0% |

| OF-2.5% | 2.5% |

| OF-5% | 5% |

| OF-10% | 10% |

| OF-21% | 21% |

| Sample No. | Furnace Temperature of Each Section (°C) | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| 1# | 200 | 215 | 238 | 255 | 260 | 265 |

| 2# | 200 | 213 | 235 | 250 | 255 | 260 |

| 3# | 200 | 220 | 243 | 255 | 265 | 270 |

| 4# | 200 | 215 | 243 | 258 | 260 | 265 |

| 5# | 210 | 225 | 238 | 255 | 260 | 265 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Wang, Y.; Li, C.; Gao, A. Evolution and Regulation of Radial Structure of PAN Pre-Oxidized Fiber Based on the Fine Denier Model. Materials 2022, 15, 1409. https://doi.org/10.3390/ma15041409

Wang B, Wang Y, Li C, Gao A. Evolution and Regulation of Radial Structure of PAN Pre-Oxidized Fiber Based on the Fine Denier Model. Materials. 2022; 15(4):1409. https://doi.org/10.3390/ma15041409

Chicago/Turabian StyleWang, Bin, Yunfeng Wang, Chenggao Li, and Aijun Gao. 2022. "Evolution and Regulation of Radial Structure of PAN Pre-Oxidized Fiber Based on the Fine Denier Model" Materials 15, no. 4: 1409. https://doi.org/10.3390/ma15041409

APA StyleWang, B., Wang, Y., Li, C., & Gao, A. (2022). Evolution and Regulation of Radial Structure of PAN Pre-Oxidized Fiber Based on the Fine Denier Model. Materials, 15(4), 1409. https://doi.org/10.3390/ma15041409