Strain Rate-Dependent Compressive Properties of Bulk Cylindrical 3D-Printed Samples from 316L Stainless Steel

Abstract

:1. Introduction

2. Materials and Methods

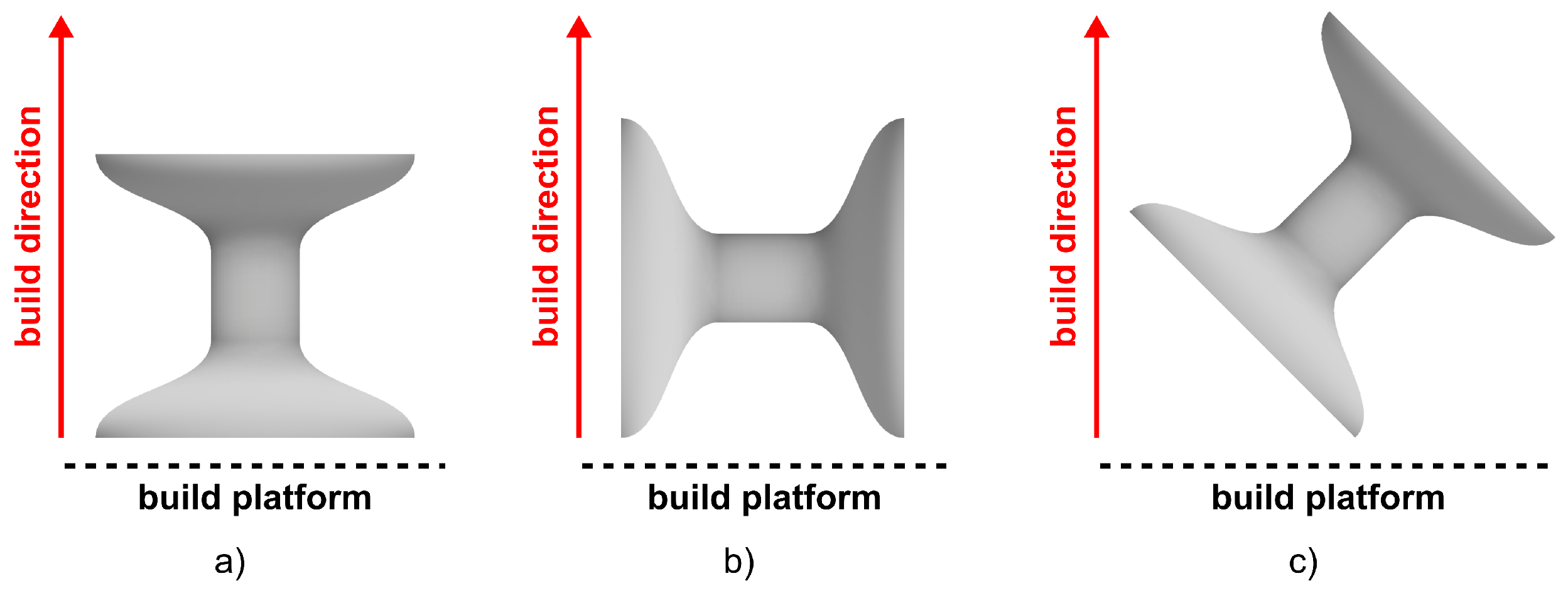

2.1. Specimens

2.2. Quasi-Static Experiments

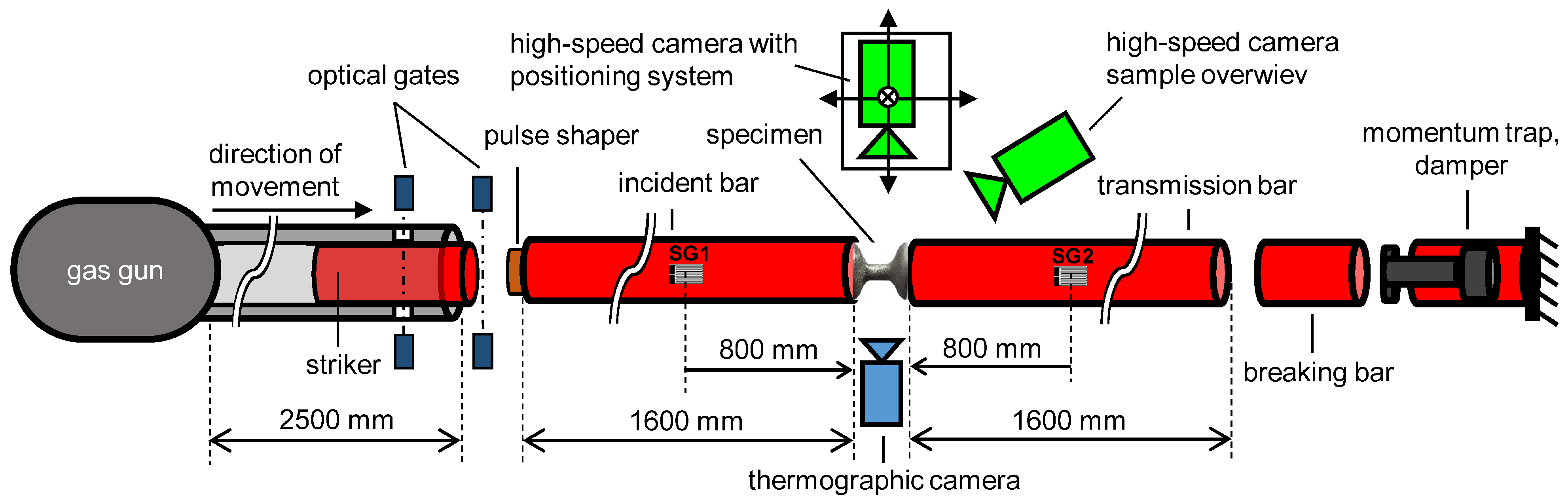

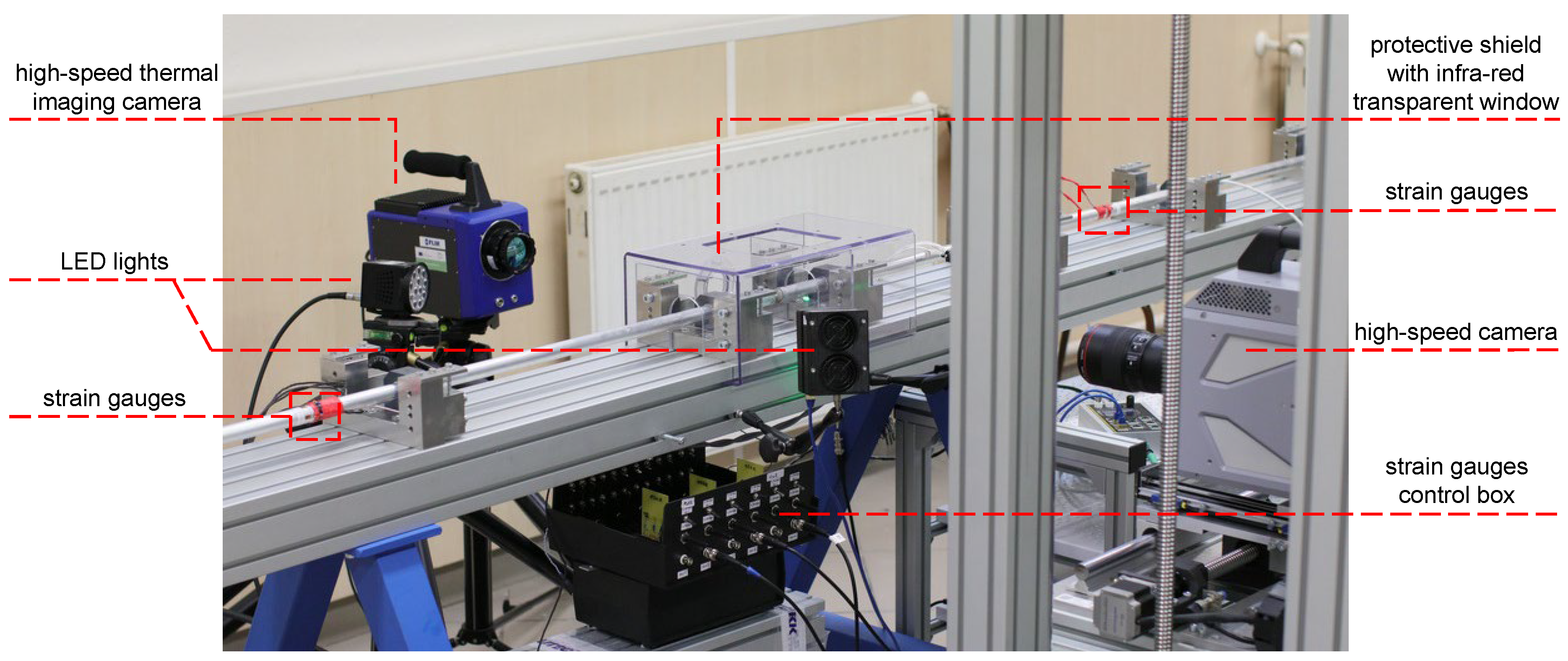

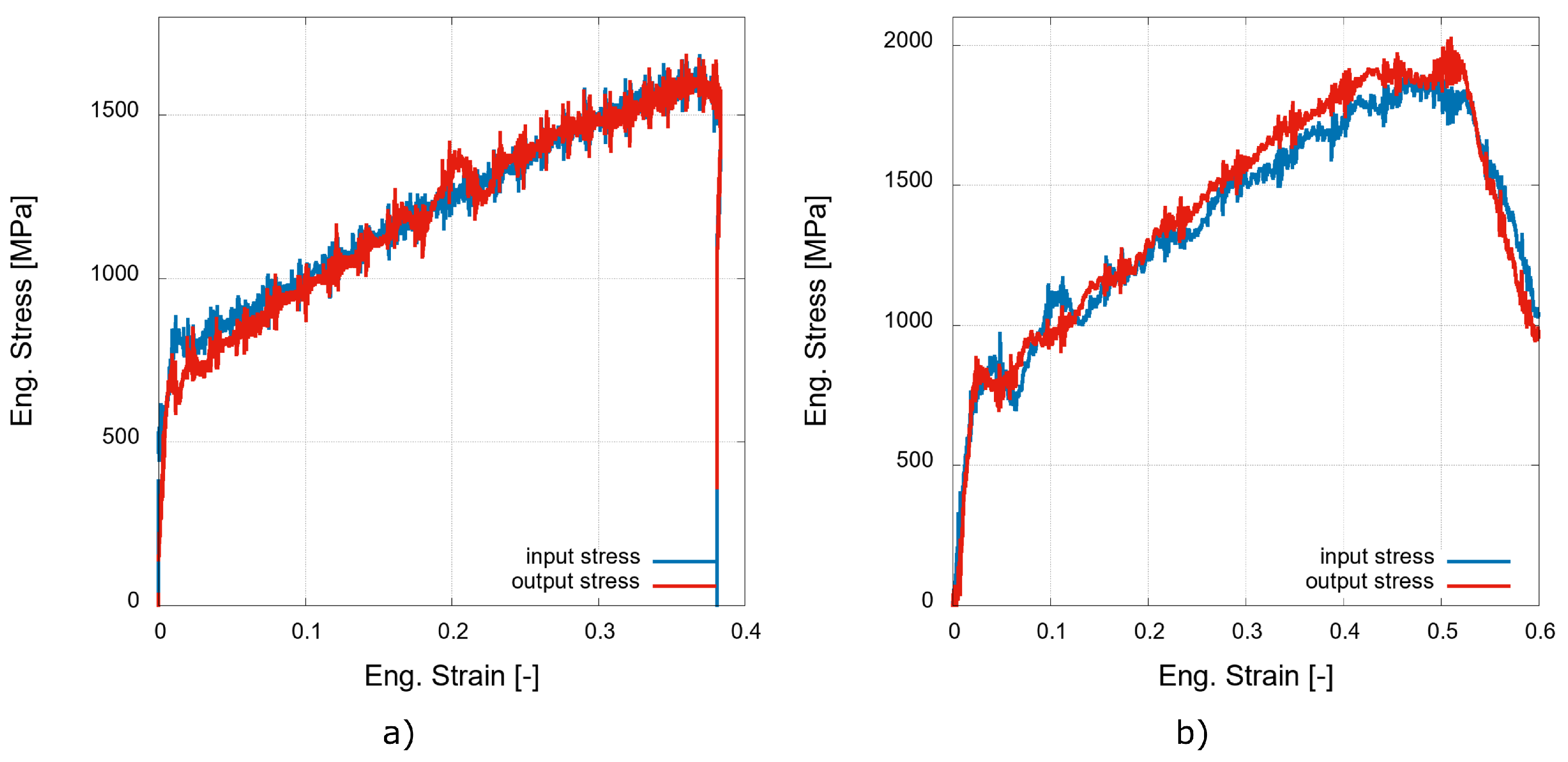

2.3. Dynamic Experiments

2.4. Digital Image Correlation

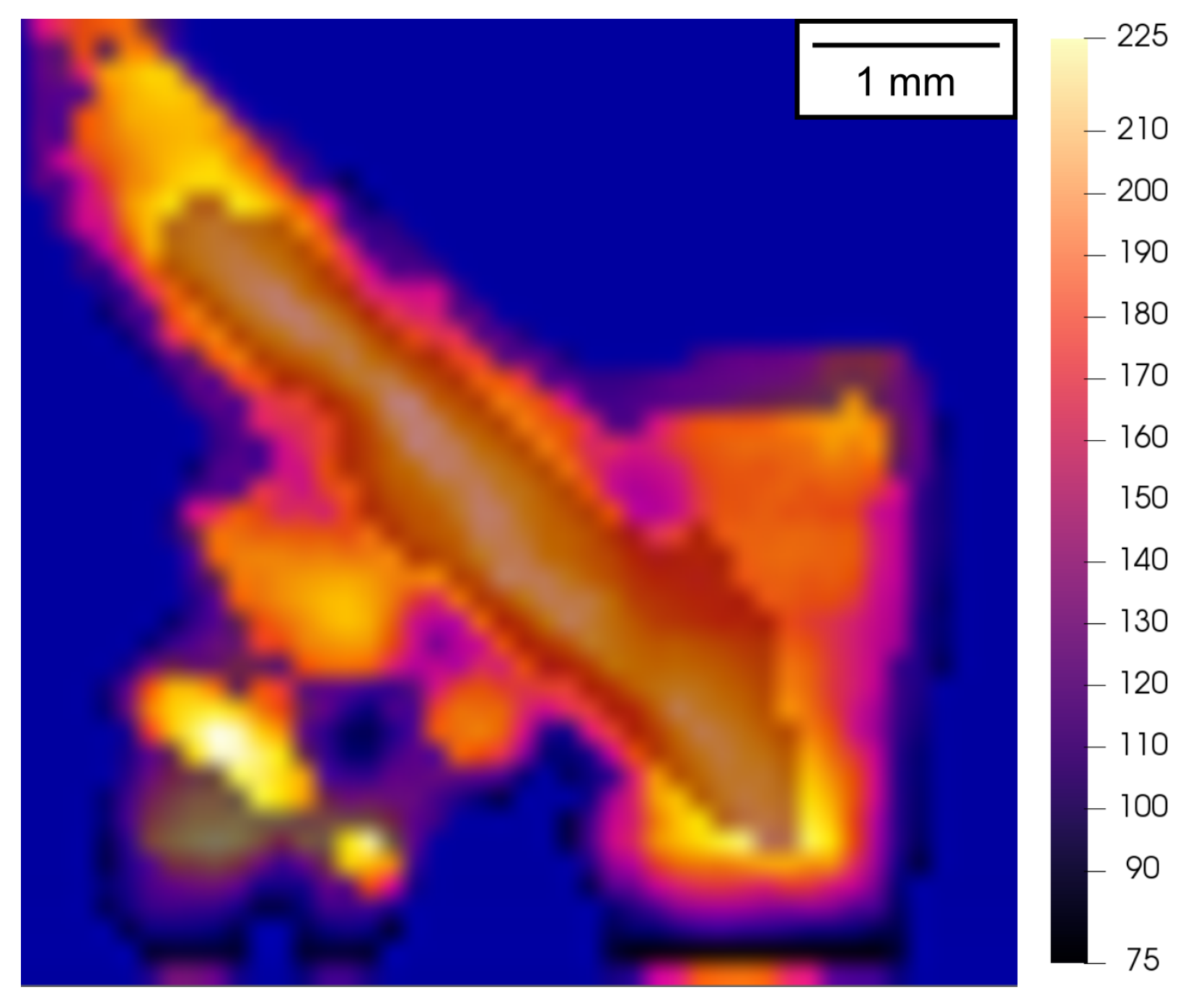

2.5. High-Speed Thermography

3. Results

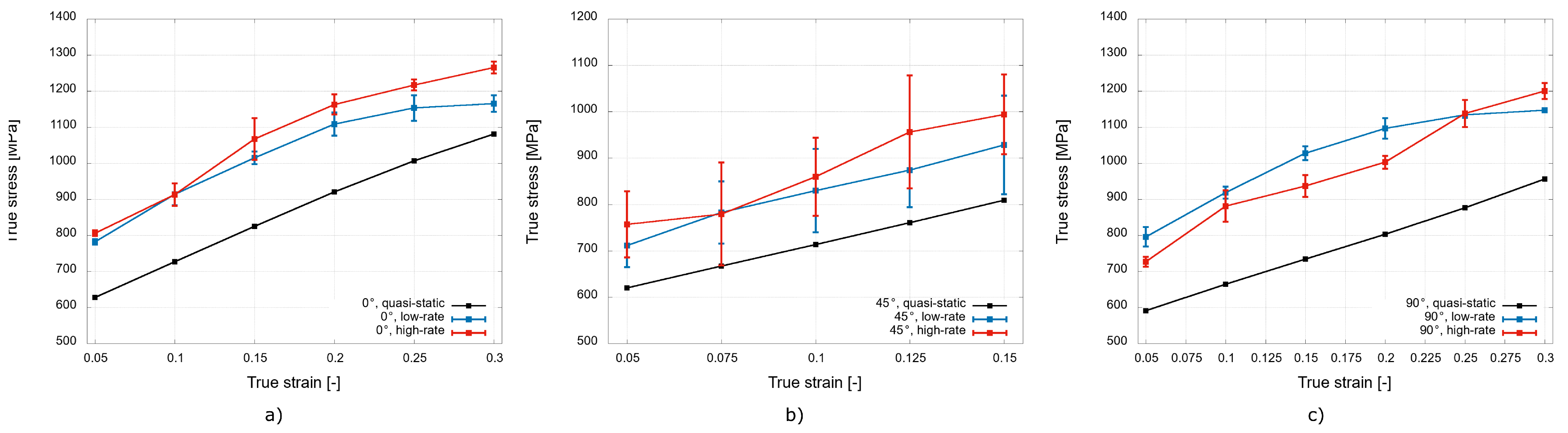

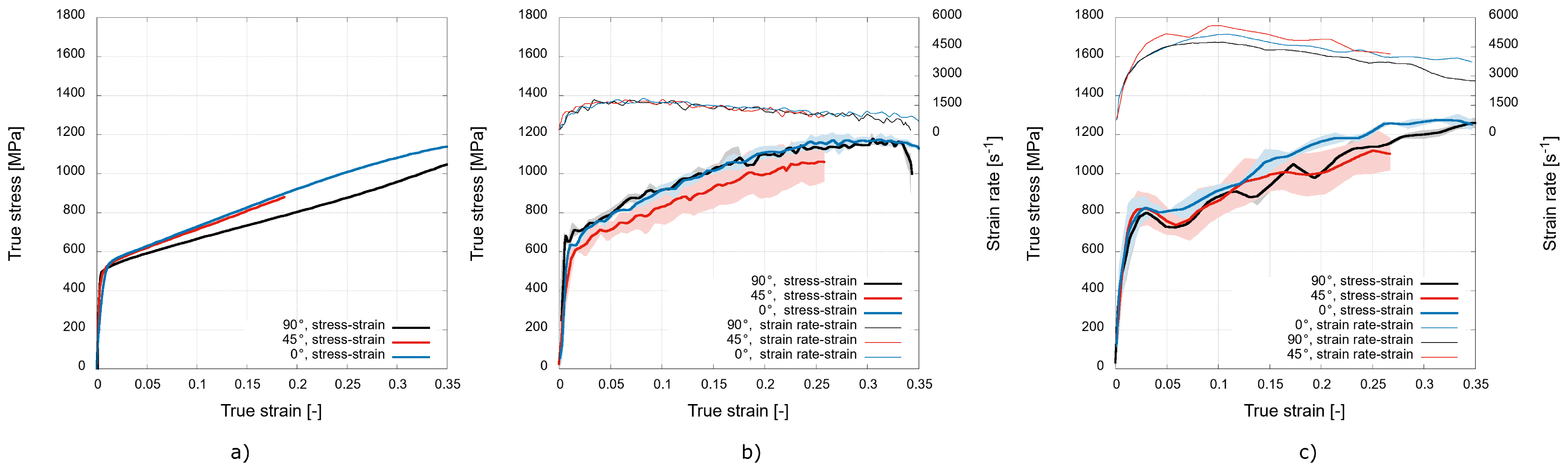

3.1. True Stress–True Strain Analysis

3.2. High-Speed Thermography

4. Discussion

5. Conclusions

- Based on comparison of the stress values evaluated from the quasi-static and low-rate dynamic experiments, the most prominent strain rate sensitivity was identified for specimens produced with the printing direction of 90.

- Based on the mechanical response to the dynamic loading, the 0 orientation can be considered as the strongest amongst the investigated printing directions.

- Based on the mechanical response to the dynamic loading, the 45 orientation can be considered as the weakest amongst the investigated printing directions.

- The experimental data from the dynamic experiments for the specimens printed with the 45 orientation were burdened with the largest deviations since such a printing orientation generates the most errors in the geometry of the 3D-printed parts, which significantly affects the evaluated mechanical behaviour for the specimens printed in this manner.

- A tendency of the material to have brittle behaviour was revealed during the dynamic experiments. The 0 and 45 orientations exhibited such behaviour even during the low-rate experiments. The 90 orientation was prone to brittle cracking only during the high-rate experiments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tofail, S.A.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.; Zuback, J.; Mukherjee, T.; Elmer, J.; Milewski, J.; Beese, A.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufacturing: A Review of Common Processes, Industrial Applications, and Current Challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Farshidianfar, M.; Gerlich, A.; Nosko, M.; Trembošová, V.; Khajepour, A. Microstructure, strain-rate sensitivity, work hardening, and fracture behavior of laser additive manufactured austenitic and martensitic stainless steel structures. Mater. Sci. Eng. A 2019, 756, 545–561. [Google Scholar] [CrossRef]

- DebRoy, T.; Mukherjee, T.; Wei, H.L.; Elmer, J.W.; Milewski, J.O. Metallurgy, mechanistic models and machine learning in metal printing. Nat. Rev. Mater. 2021, 6, 48–68. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.M.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Gray, G.; Livescu, V.; Rigg, P.; Trujillo, C.; Cady, C.; Chen, S.; Carpenter, J.; Lienert, T.; Fensin, S. Structure/property (constitutive and dynamic strength/damage) characterization of additively manufactured 316L SS. EPJ Web Conf. 2015, 94, 02006. [Google Scholar] [CrossRef] [Green Version]

- Bevan, M.; Ameri, A.; East, D.; Austin, D.; Brown, A.; Hazell, P.; Escobedo, J. Mechanical Properties and Behavior of Additive Manufactured Stainless Steel 316L. In Characterization of Minerals, Metals, and Materials; Springer: Cham, Switzerland, 2017; pp. 577–583. [Google Scholar] [CrossRef]

- Song, B.; Nishida, E.; Sanborn, B.; Maguire, M.; Adams, D.; Carroll, J.; Wise, J.; Reedlunn, B.; Bishop, J.; Palmer, T. Compressive and Tensile Stress–Strain Responses of Additively Manufactured (AM) 304L Stainless Steel at High Strain Rates. J. Dyn. Behav. Mater. 2017, 3, 412–425. [Google Scholar] [CrossRef]

- Ghayoor, M.; Lee, K.; He, Y.; Chang, C.H.; Paul, B.; Pasebani, S. Selective laser melting of 304L stainless steel: Role of volumetric energy density on the microstructure, texture and mechanical properties. Addit. Manuf. 2020, 32, 101011. [Google Scholar] [CrossRef]

- Nisi, J.D.; Pozzi, F.; Folgarait, P.; Ceselin, G.; Ronci, M. Precipitation hardening stainless steel produced by powder bed fusion: Influence of positioning and heat treatment. Procedia Struct. Integr. 2019, 24, 541–558. [Google Scholar] [CrossRef]

- Tucho, W.M.; Lysne, V.H.; Austbø, H.; Sjolyst-Kverneland, A.; Hansen, V. Investigation of effects of process parameters on microstructure and hardness of SLM manufactured SS316L. J. Alloys Compd. 2018, 740, 910–925. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Biswas, N.; Ding, J. Numerical study of the deformation and fracture behavior of porous Ti6Al4V alloy under static and dynamic loading. Int. J. Impact Eng. 2015, 82, 89–102. [Google Scholar] [CrossRef]

- Fíla, T.; Koudelka, P.; Zlámal, P.; Falta, J.; Adorna, M.; Neuhäuserová, M.; Luksch, J.; Jiroušek, O. Strain Dependency of Poisson’s Ratio of SLS Printed Auxetic Lattices Subjected to Quasi-Static and Dynamic Compressive Loading. Adv. Eng. Mater. 2019, 21, 1900204. [Google Scholar] [CrossRef]

- Mauko, A.; Fíla, T.; Falta, J.; Koudelka, P.; Rada, V.; Neuhäuserová, M.; Zlámal, P.; Vesenjak, M.; Jiroušek, O.; Ren, Z. Dynamic deformation behaviour of chiral auxetic lattices at low and high strain-rates. Metals 2021, 11, 52. [Google Scholar] [CrossRef]

- Neuhäuserová, M.; Fíla, T.; Koudelka, P.; Falta, J.; Rada, V.; Šleichrt, J.; Zlámal, P.; Jiroušek, O. Compressive behaviour of additively manufactured periodical re-entrant tetrakaidecahedral lattices at low and high strain-rates. Metals 2021, 11, 1196. [Google Scholar] [CrossRef]

- Fíla, T.; Koudelka, P.; Falta, J.; Šleichrt, J.; Adorna, M.; Zlámal, P.; Neuhäuserová, M.; Mauko, A.; Valach, J.; Jiroušek, O. Impact Behavior of Additively Manufactured Stainless Steel Auxetic Structures at Elevated and Reduced Temperatures. Adv. Eng. Mater. 2021, 23, 2000669. [Google Scholar] [CrossRef]

- Fíla, T.; Koudelka, P.; Falta, J.; Zlámal, P.; Rada, V.; Adorna, M.; Bronder, S.; Jiroušek, O. Dynamic impact testing of cellular solids and lattice structures: Application of two-sided direct impact Hopkinson bar. Int. J. Impact Eng. 2021, 148, 103767. [Google Scholar] [CrossRef]

- Šleichrt, J.; Fíla, T.; Koudelka, P.; Adorna, M.; Falta, J.; Zlámal, P.; Glinz, J.; Neuhäuserová, M.; Doktor, T.; Mauko, A.; et al. Dynamic penetration of cellular solids: Experimental investigation using Hopkinson bar and computed tomography. Mater. Sci. Eng. A 2021, 800, 140096. [Google Scholar] [CrossRef]

- Leicht, A.; Rashidi, M.; Klement, U.; Hryha, E. Effect of process parameters on the microstructure, tensile strength and productivity of 316L parts produced by laser powder bed fusion. Mater. Charact. 2020, 159, 110016. [Google Scholar] [CrossRef]

- Larimian, T.; Kannan, M.; Grzesiak, D.; AlMangour, B.; Borkar, T. Effect of energy density and scanning strategy on densification, microstructure and mechanical properties of 316L stainless steel processed via selective laser melting. Mater. Sci. Eng. A 2020, 770, 138455. [Google Scholar] [CrossRef]

- Marattukalam, J.J.; Karlsson, D.; Pacheco, V.; Beran, P.; Wiklund, U.; Jansson, U.; Hjörvarsson, B.; Sahlberg, M. The effect of laser scanning strategies on texture, mechanical properties, and site-specific grain orientation in selective laser melted 316L SS. Mater. Des. 2020, 193, 108852. [Google Scholar] [CrossRef]

- Yu, J.; Kim, D.; Ha, K.; Jeon, J.B.; Lee, W. Strong feature size dependence of tensile properties and its microstructural origin in selectively laser melted 316L stainless steel. Mater. Lett. 2020, 275, 128161. [Google Scholar] [CrossRef]

- Leicht, A.; Pauzon, C.; Rashidi, M.; Klement, U.; Nyborg, L.; Hryha, E. Effect of part thickness on the microstructure and tensile properties of 316L parts produced by laser powder bed fusion. Adv. Ind. Manuf. Eng. 2021, 2, 100037. [Google Scholar] [CrossRef]

- Luo, C.; Zhang, Y. Effect of printing orientation on anisotropic properties in resistance spot welded 316L stainless steels via selective laser melting. Mater. Lett. 2019, 254, 237–241. [Google Scholar] [CrossRef]

- Sing, S.L.; Kuo, C.N.; Shih, C.T.; Ho, C.C.; Chua, C.K. Perspectives of using machine learning in laser powder bed fusion for metal additive manufacturing. Virtual Phys. Prototyp. 2021, 16, 372–386. [Google Scholar] [CrossRef]

- Smith, C.; Grima, J.; Evans, K. A novel mechanism for generating auxetic behaviour in reticulated foams: Missing rib foam model. Acta Mater. 2000, 48, 4349–4356. [Google Scholar] [CrossRef]

- Evans, K.; Alderson, A.; Christian, F. Auxetic two-dimensional polymer networks. An example of tailoring geometry for specific mechanical properties. J. Chem. Soc. Faraday Trans. 1995, 91, 2671–2680. [Google Scholar] [CrossRef]

- Choi, J.B.; Lakes, R.S. Nonlinear Analysis of the Poisson’s Ratio of Negative Poisson’s Ratio Foams. J. Compos. Mater. 1995, 29, 113–128. [Google Scholar] [CrossRef]

- Pan, B.; Qian, K.; Xie, H.; Asundi, A. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review. Meas. Sci. Technol. 2009, 20, 062001. [Google Scholar] [CrossRef]

- Liu, D.; Nocedal, J. On the limited memory BFGS method for large scale optimization. Math. Program. 1989, 45, 503–528. [Google Scholar] [CrossRef] [Green Version]

- Ganzenmüller, G.; Plappert, D.; Trippel, A.; Hiermaier, S. A Split-Hopkinson Tension Bar study on the dynamic strength of basalt-fibre composites. Compos. Part Eng. 2019, 171, 310–319. [Google Scholar] [CrossRef]

| Printing Orientation | Yield Stress R |

|---|---|

| 0 | |

| 45 | |

| 90 |

| Printing Orientation | Quasi-Static | Low Rate | High Rate |

|---|---|---|---|

| 0 | |||

| 45 | |||

| 90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neuhäuserová, M.; Koudelka, P.; Fíla, T.; Falta, J.; Rada, V.; Šleichrt, J.; Zlámal, P.; Mauko, A.; Jiroušek, O. Strain Rate-Dependent Compressive Properties of Bulk Cylindrical 3D-Printed Samples from 316L Stainless Steel. Materials 2022, 15, 941. https://doi.org/10.3390/ma15030941

Neuhäuserová M, Koudelka P, Fíla T, Falta J, Rada V, Šleichrt J, Zlámal P, Mauko A, Jiroušek O. Strain Rate-Dependent Compressive Properties of Bulk Cylindrical 3D-Printed Samples from 316L Stainless Steel. Materials. 2022; 15(3):941. https://doi.org/10.3390/ma15030941

Chicago/Turabian StyleNeuhäuserová, Michaela, Petr Koudelka, Tomáš Fíla, Jan Falta, Václav Rada, Jan Šleichrt, Petr Zlámal, Anja Mauko, and Ondřej Jiroušek. 2022. "Strain Rate-Dependent Compressive Properties of Bulk Cylindrical 3D-Printed Samples from 316L Stainless Steel" Materials 15, no. 3: 941. https://doi.org/10.3390/ma15030941

APA StyleNeuhäuserová, M., Koudelka, P., Fíla, T., Falta, J., Rada, V., Šleichrt, J., Zlámal, P., Mauko, A., & Jiroušek, O. (2022). Strain Rate-Dependent Compressive Properties of Bulk Cylindrical 3D-Printed Samples from 316L Stainless Steel. Materials, 15(3), 941. https://doi.org/10.3390/ma15030941