Experimental Study on Strength Enhancement of Expansive Grout

Abstract

:1. Introduction

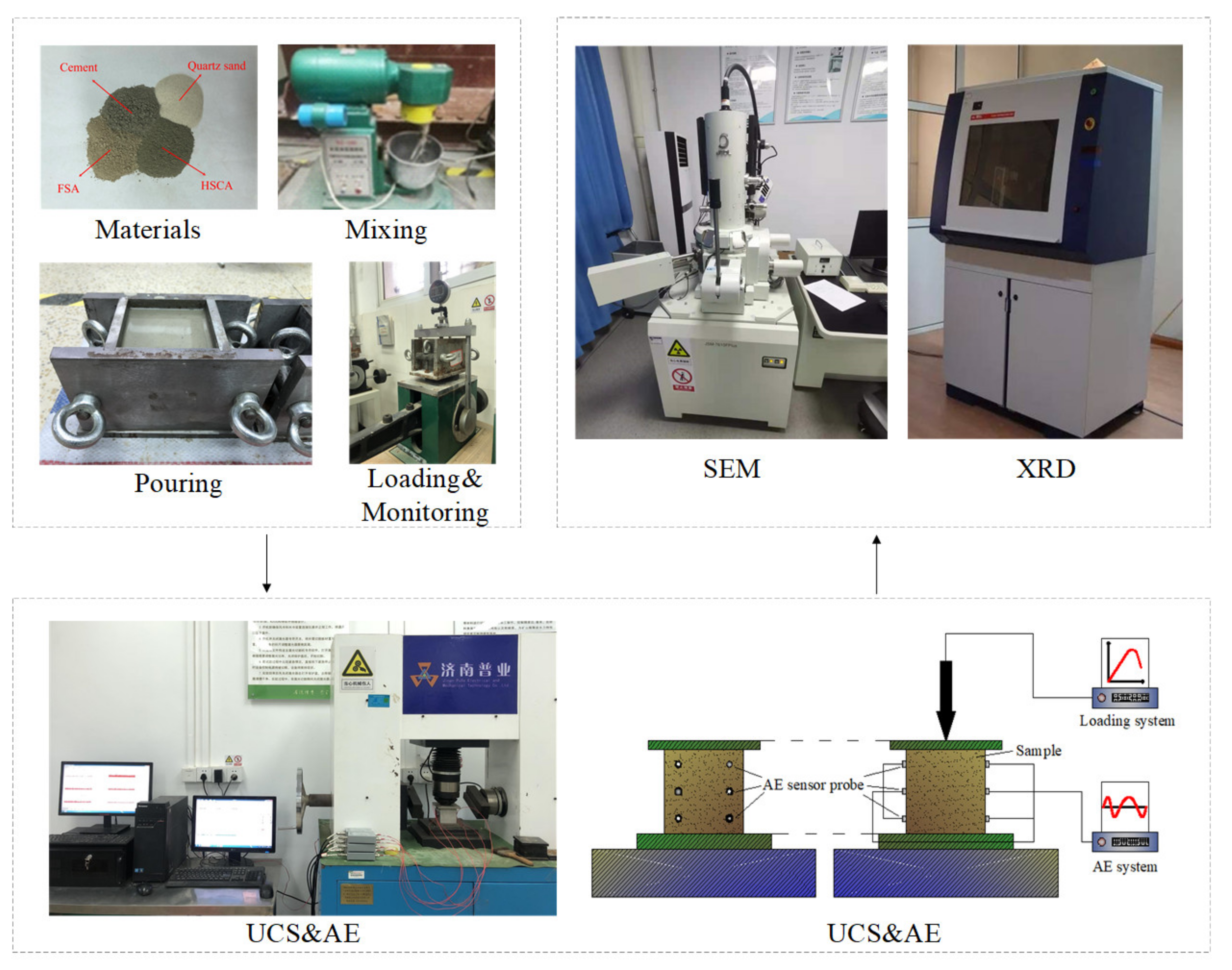

2. Experiment

2.1. Materials

2.2. Proportion Test Schemes

2.3. Experiment Methods

2.3.1. Sample Preparation

2.3.2. Volume Expansion Ratio

2.3.3. Uniaxial Compressive Strength

2.3.4. Acoustic Emission

2.3.5. Scanning Electron Microscope and Microscope X-ray Diffraction

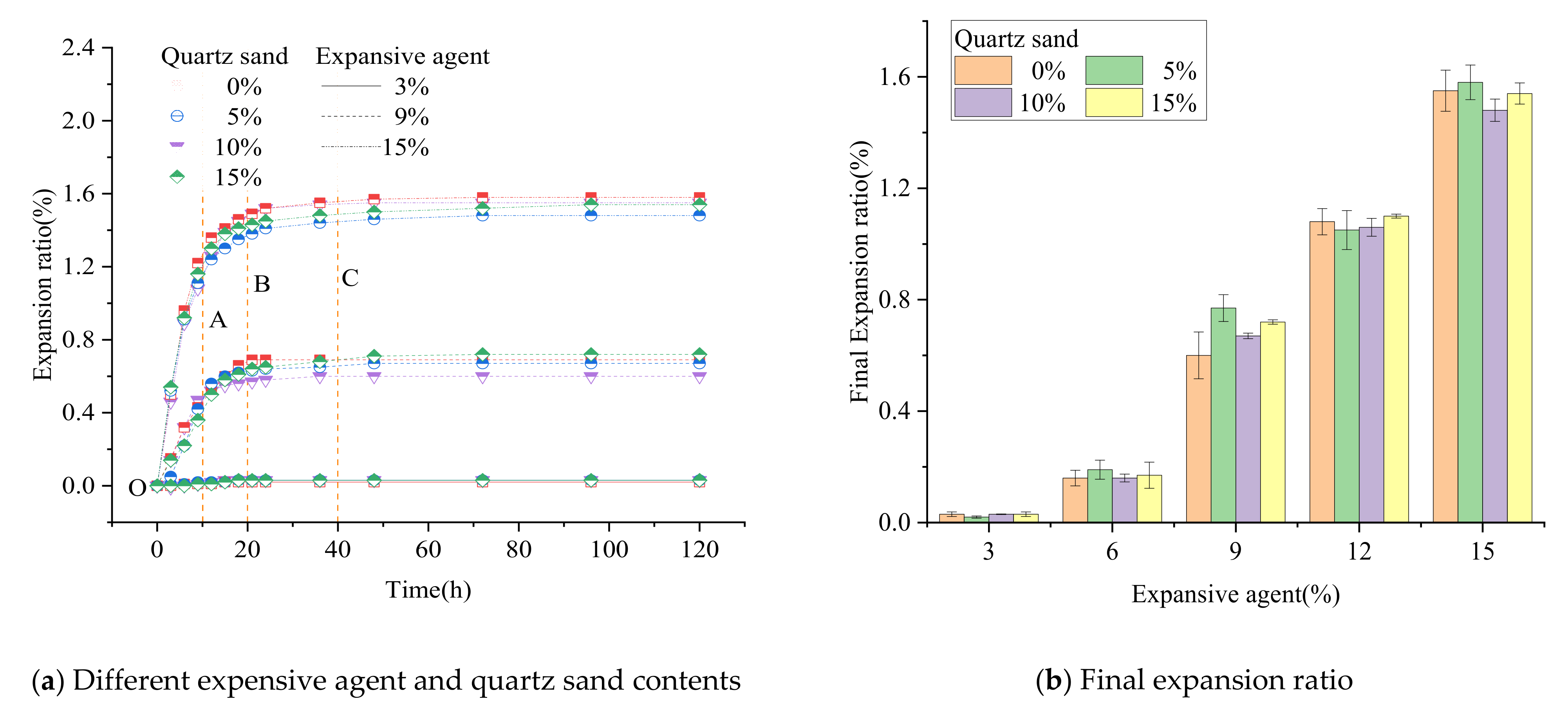

3. Expansion Characteristics

3.1. Expansion Stage

3.2. Expansion Ratio

- (1)

- Different expansive agent contents:

- (2)

- Different quartz sand contents:

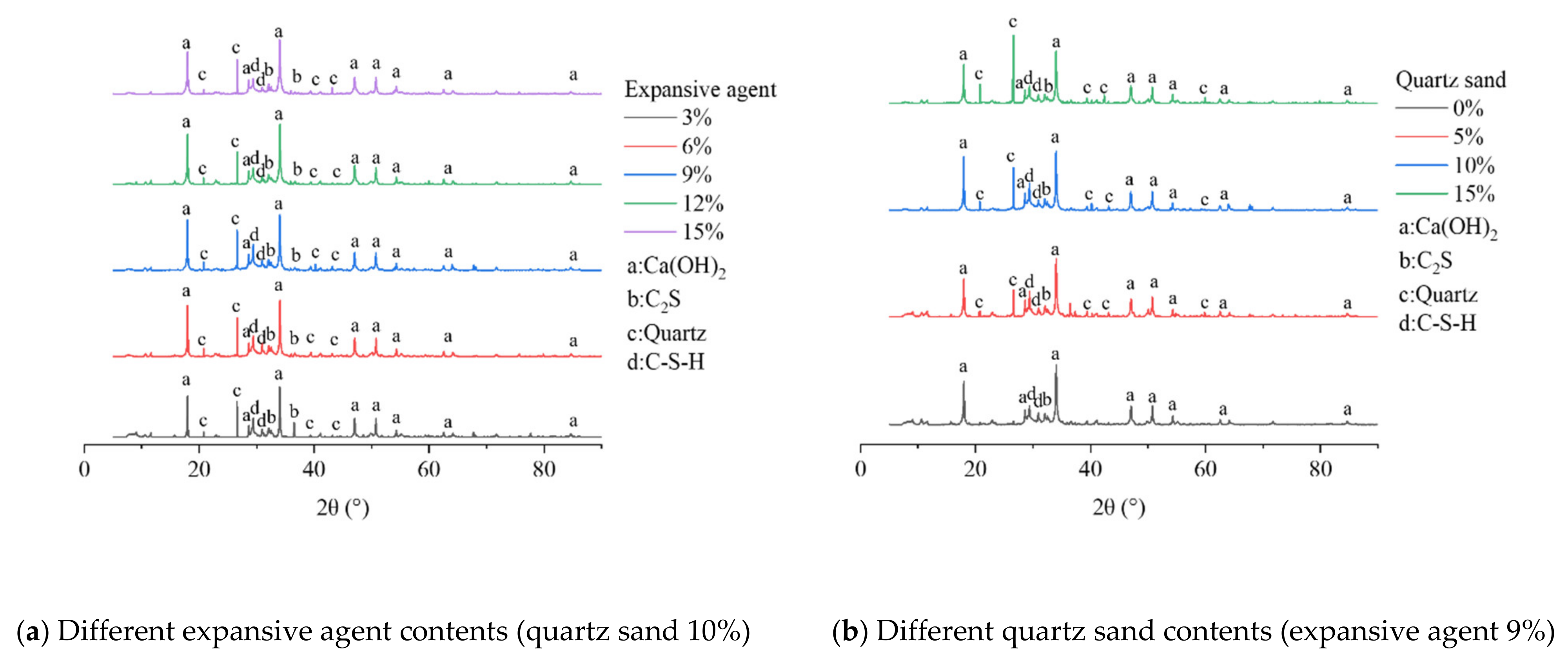

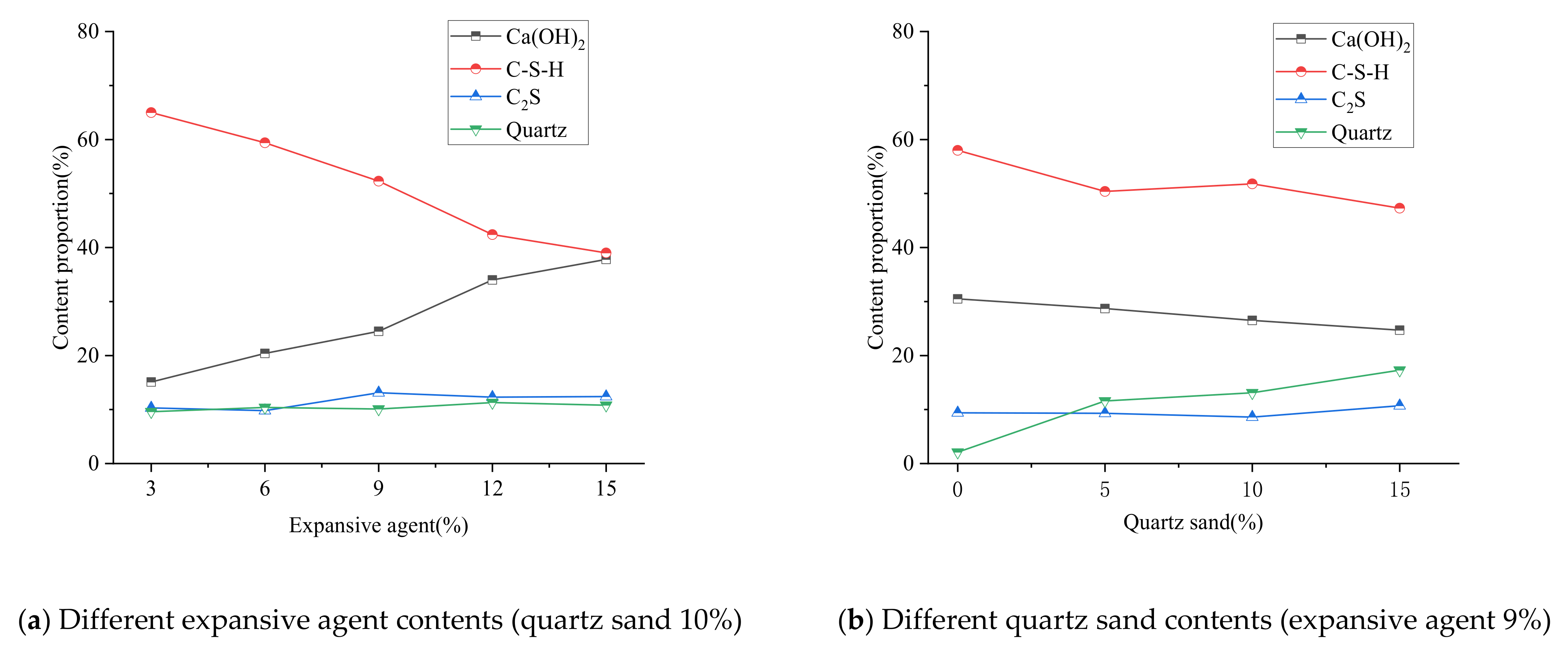

3.3. XRD

- i.

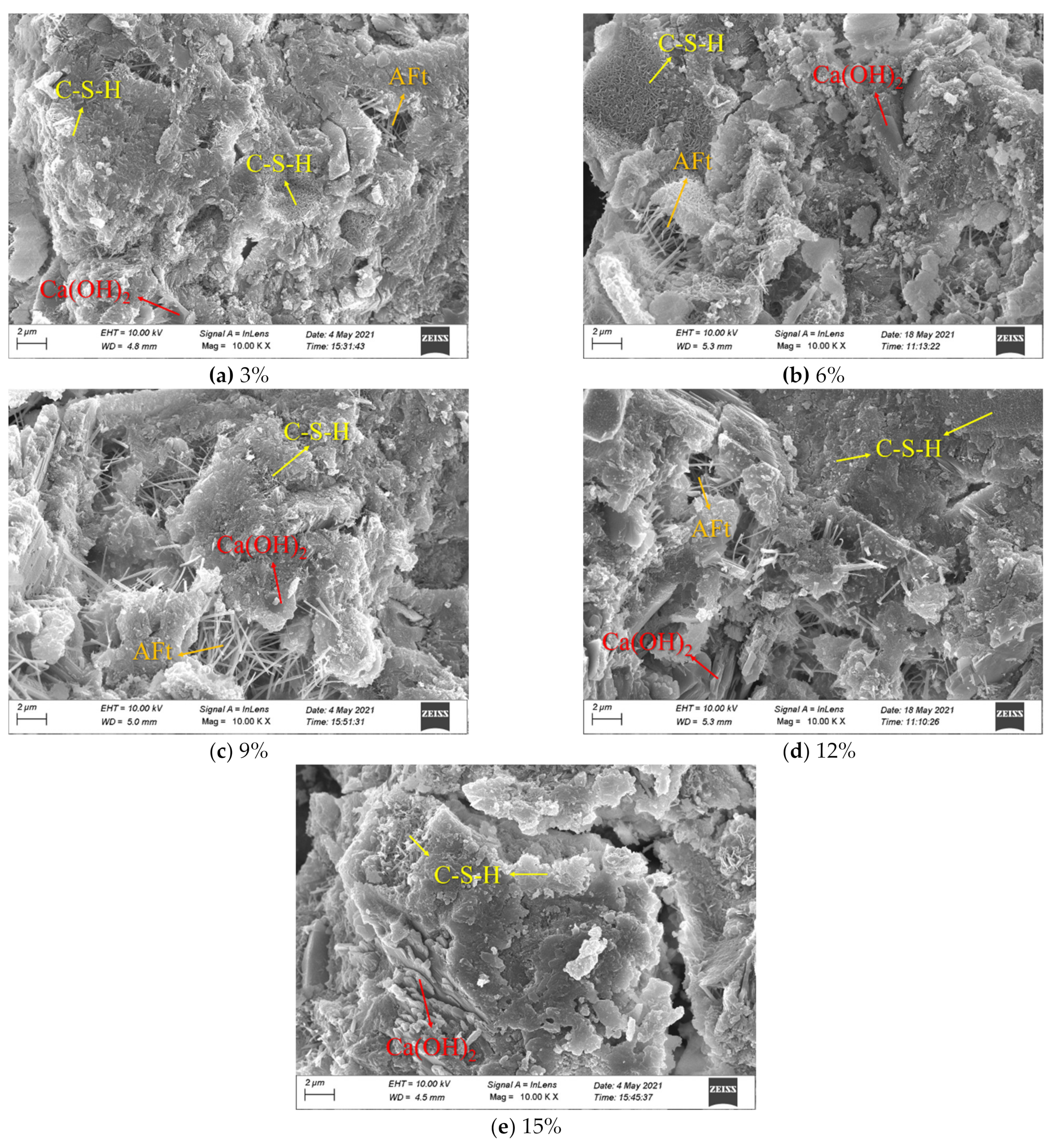

- The diffraction patterns of the samples with different expansive agent and quartz sand contents were similar, and the hydration products were basically the same. The main hydration products were C–S–H, Ca(OH)2, and C2S, which were the same as ordinary cement hydration products. Quartz can be seen in the spectrum of the samples with quartz sand, but not in the samples without it.

- ii.

- According to the peak value and peak area, C–S–H and Ca(OH)2 were the main hydration products of the grout, and their crystallinities and contents were both higher.

- iii.

- With the same quartz sand content, as the expansive agent content increased, the relative contents of C–S–H and Ca(OH)2 showed an obvious downward and upward trend, respectively, but the contents of quartz sand and C2S remained relatively stable.

- iv.

- With the same expansive agent content, as the content quartz sand increased, the contents of Ca(OH)2 and C–S–H decreased slightly, but the content of quartz shows an upward trend.

4. Mechanical Behavior

4.1. UCS

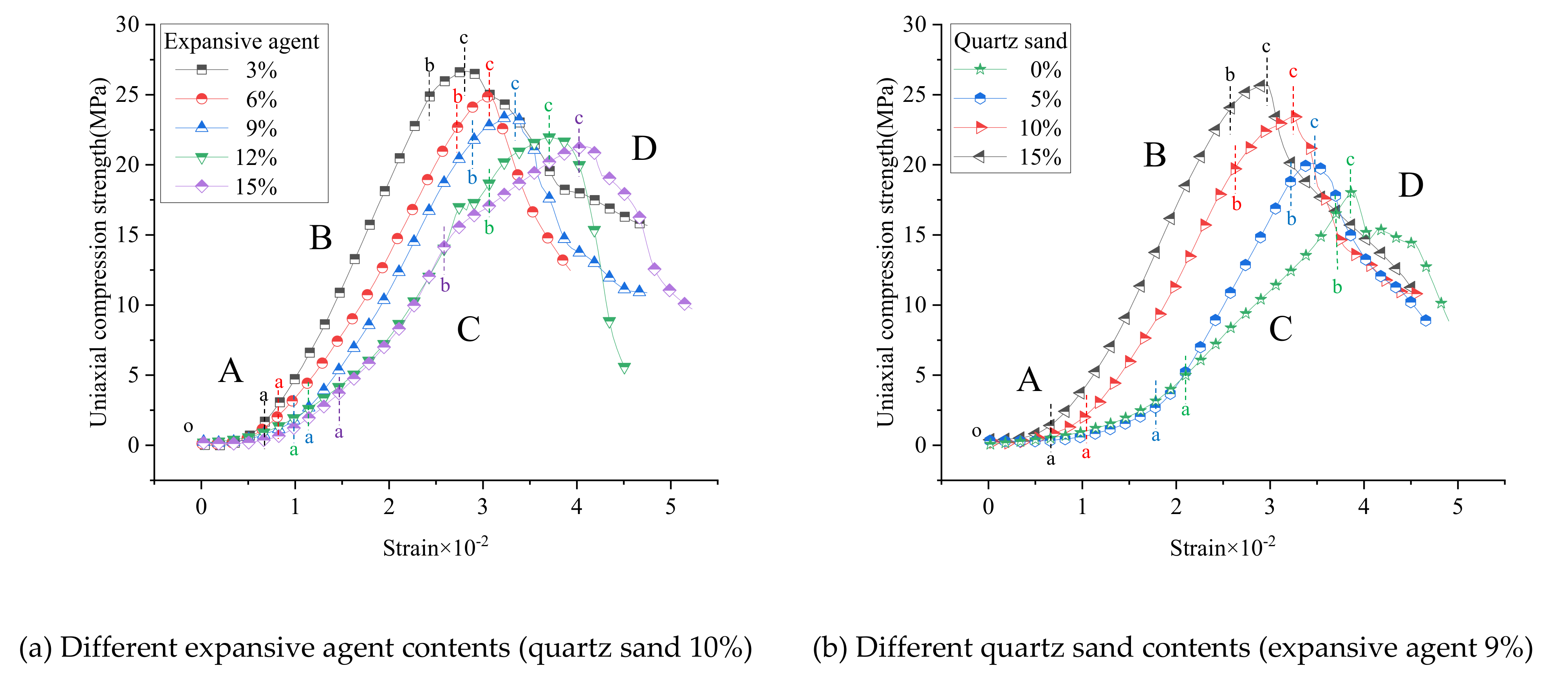

4.2. Stress–Strain Curves

- (1)

- Different expansive agent contents:

- i.

- The deformation generated during the uniaxial compression failure of the sample increased with the increase in the expansive agent content. For the lesser content of expansive agent, the deformation was lower before the sample reached its peak strength.

- ii.

- The elastic modulus of the expansive grout sample decreased with the increase in the expansive agent content. In the linear elastic stage, for the lesser content of expansive agent, the tangent slope of the straight-line segment of the curve was greater, i.e., the tangent modulus of the sample was higher.

- iii.

- The deformation of the expansive grout sample in the yield and post-peak stages increased with the increase in the expansive agent content.

- (2)

- Different quartz sand contents:

- i.

- The deformation of the expansive grout sample in the initial pore compaction stage decreased with the increase in the quartz sand content. For higher quartz sand content, the deformation of the sample was lower in this stage.

- ii.

- The deformation of the expansive grout sample before the peak point decreased with the increase in the quartz sand content. For the higher quartz sand content, the deformation was lower before the sample reached the peak strength.

- iii.

- The elastic modulus of the expansive grout sample increased with the increase in the quartz sand content. In the linear elastic stage, for higher expansive agent content, the tangent slope of the straight-line segment of the curve was greater, i.e., the tangent modulus of the sample was higher.

- iv.

- The deformation of the expansive grout sample in the yield and post-peak stages decreased with the increase in the quartz sand content.

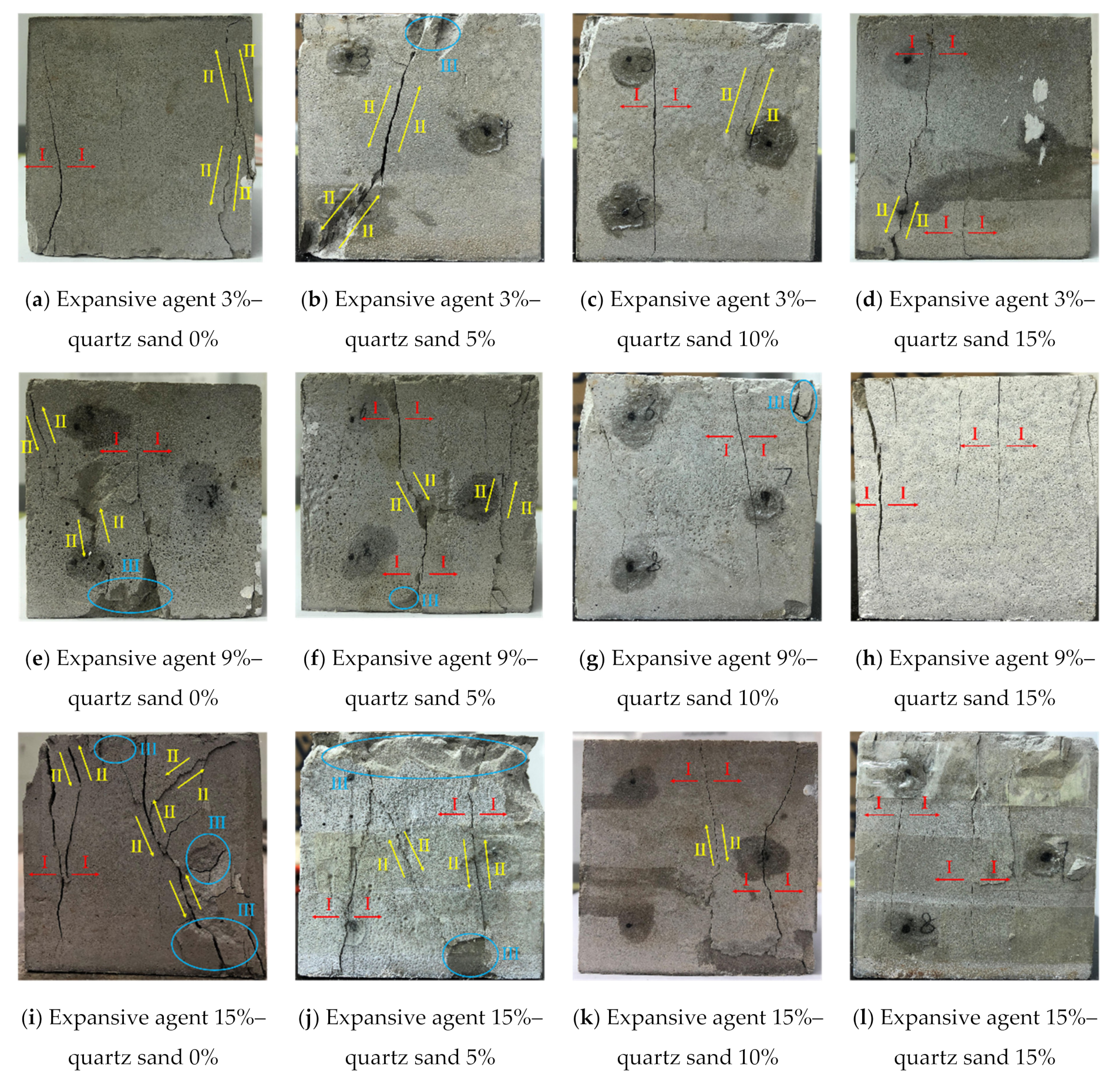

4.3. Failure Characteristics

4.4. SEM

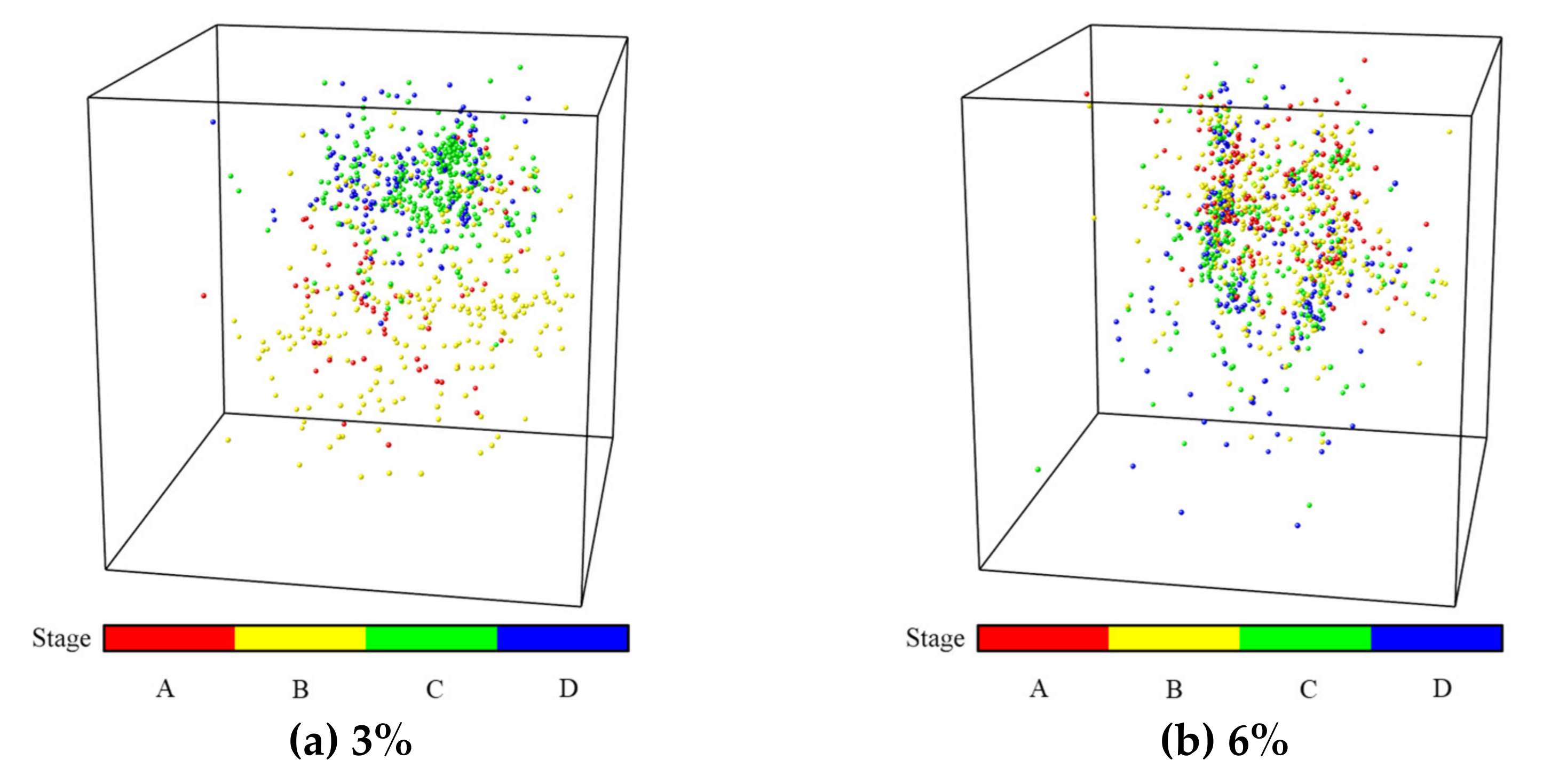

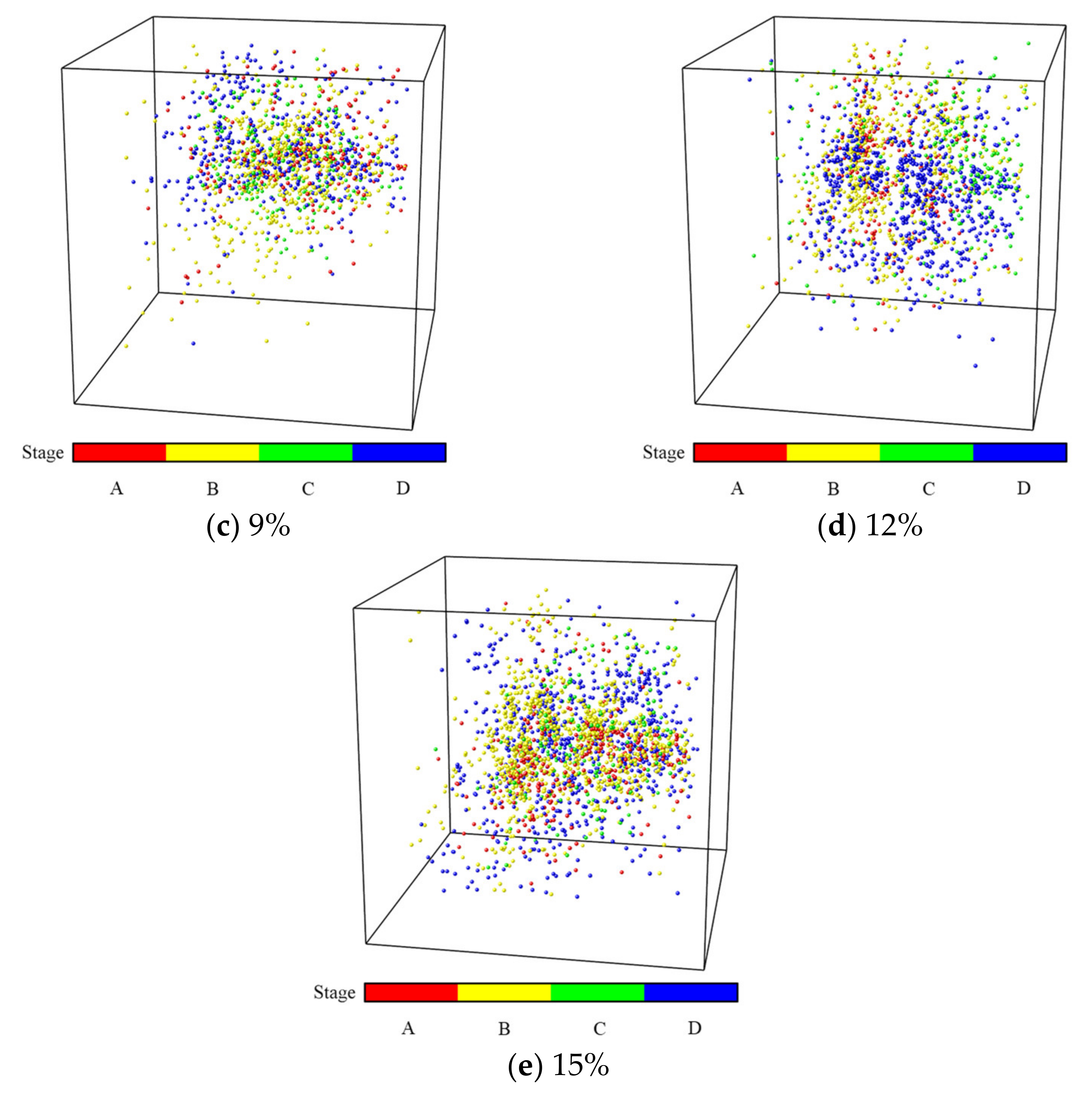

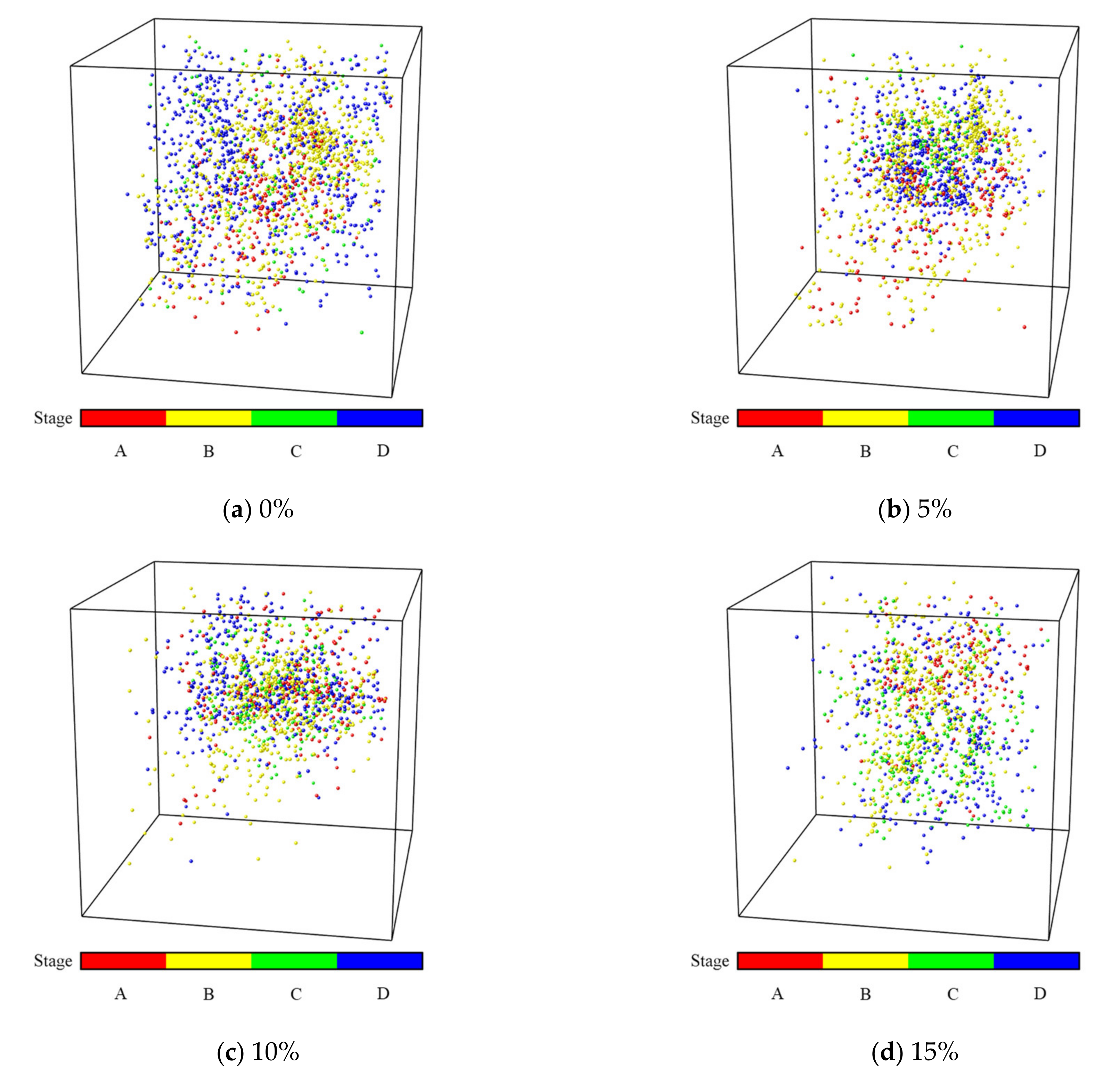

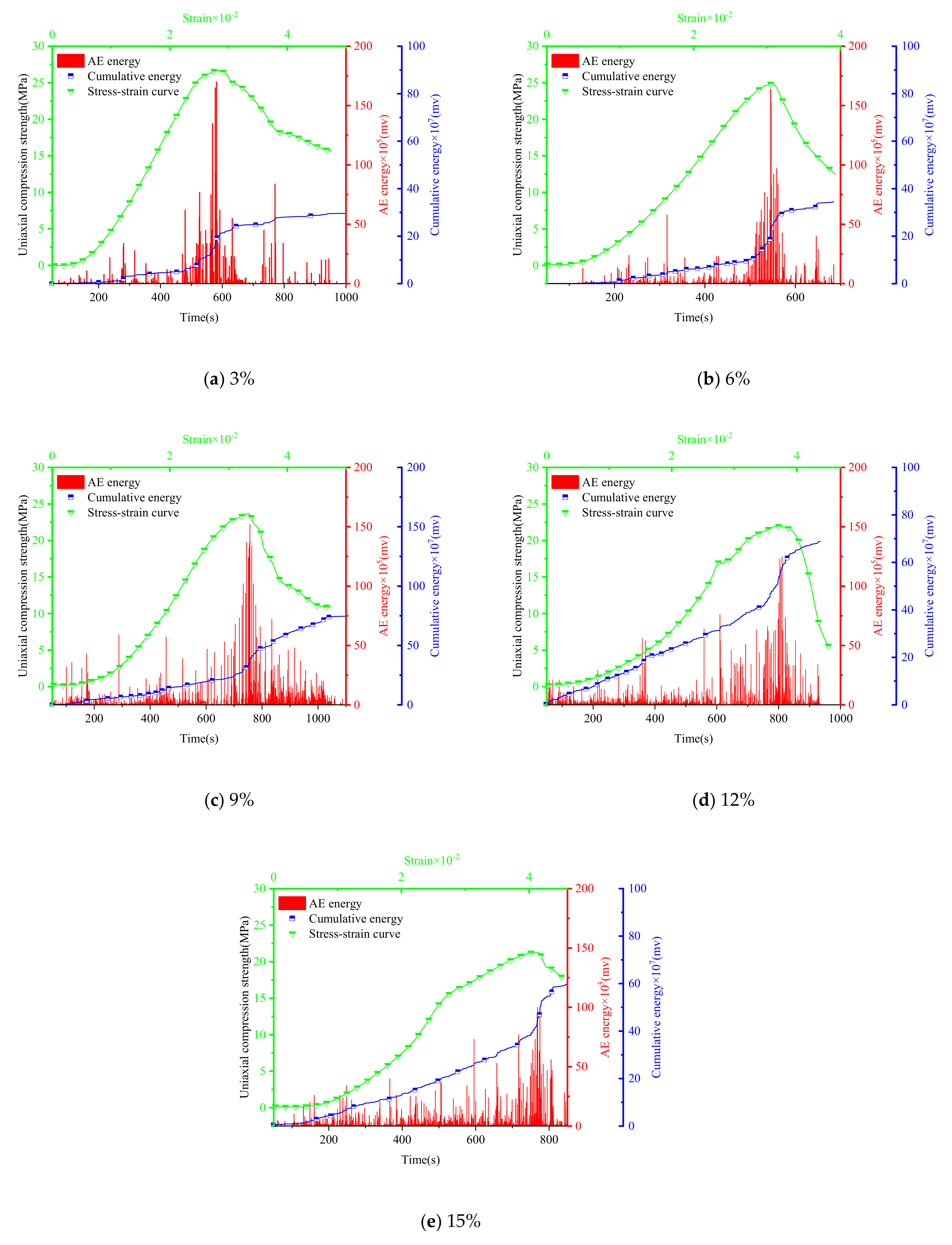

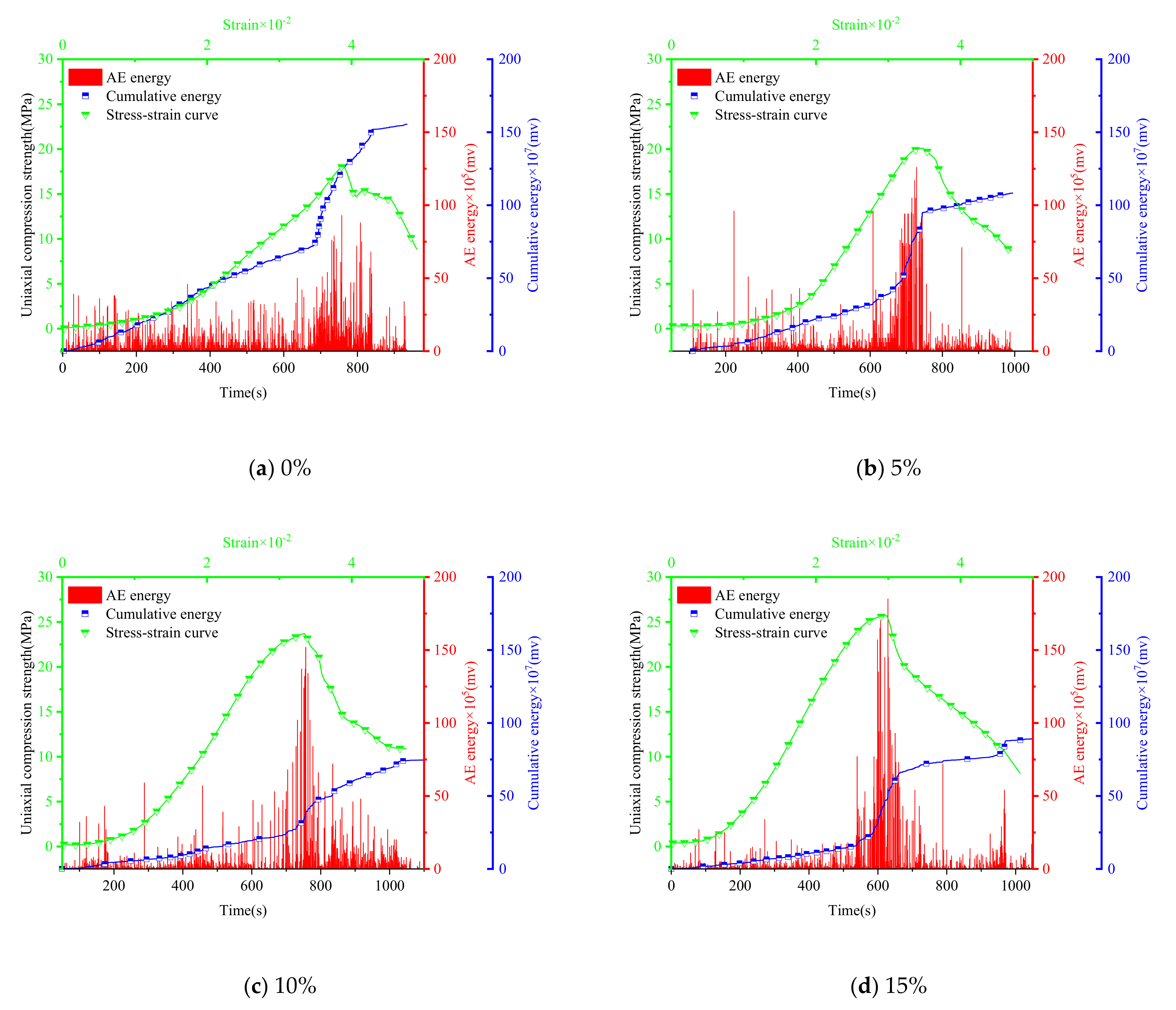

5. AE Characteristics

- i.

- The total number of AE signals and the number of them in initial pore compaction stage, linear elastic stage and post-peak failure stage increased with the increase in the expansion agent content, but the number of them in yield stages decreased. However, with the increase in the quartz sand content, the change laws of the total number of AE signals and the number of them in the four different stages were just the opposite of those with the increase in the expansion agent content.

- ii.

- With the increase in the expansion agent content, the AE energy distribution of the sample was more dispersed, mainly in the linear elastic and the post-peak failure stages. At the same time, the energy amplitude was lower during the yield stage, but the variance of energy at different times was lower during the uniaxial compression process. The accumulative energy increased overall.

- ii.

- The influence of quartz sand on AE energy was also opposite to that of the expansion agent. With the increase in the quartz sand content, the AE energy distribution of the sample was more concentrated, the energy in the linear elastic stage and the post-peak failure stage were reduced. More energy was concentrated in the yield stage, and the energy amplitude was higher. The variance of the energy at different times was higher, and the accumulative energy generally showed a downward trend.

6. Conclusions

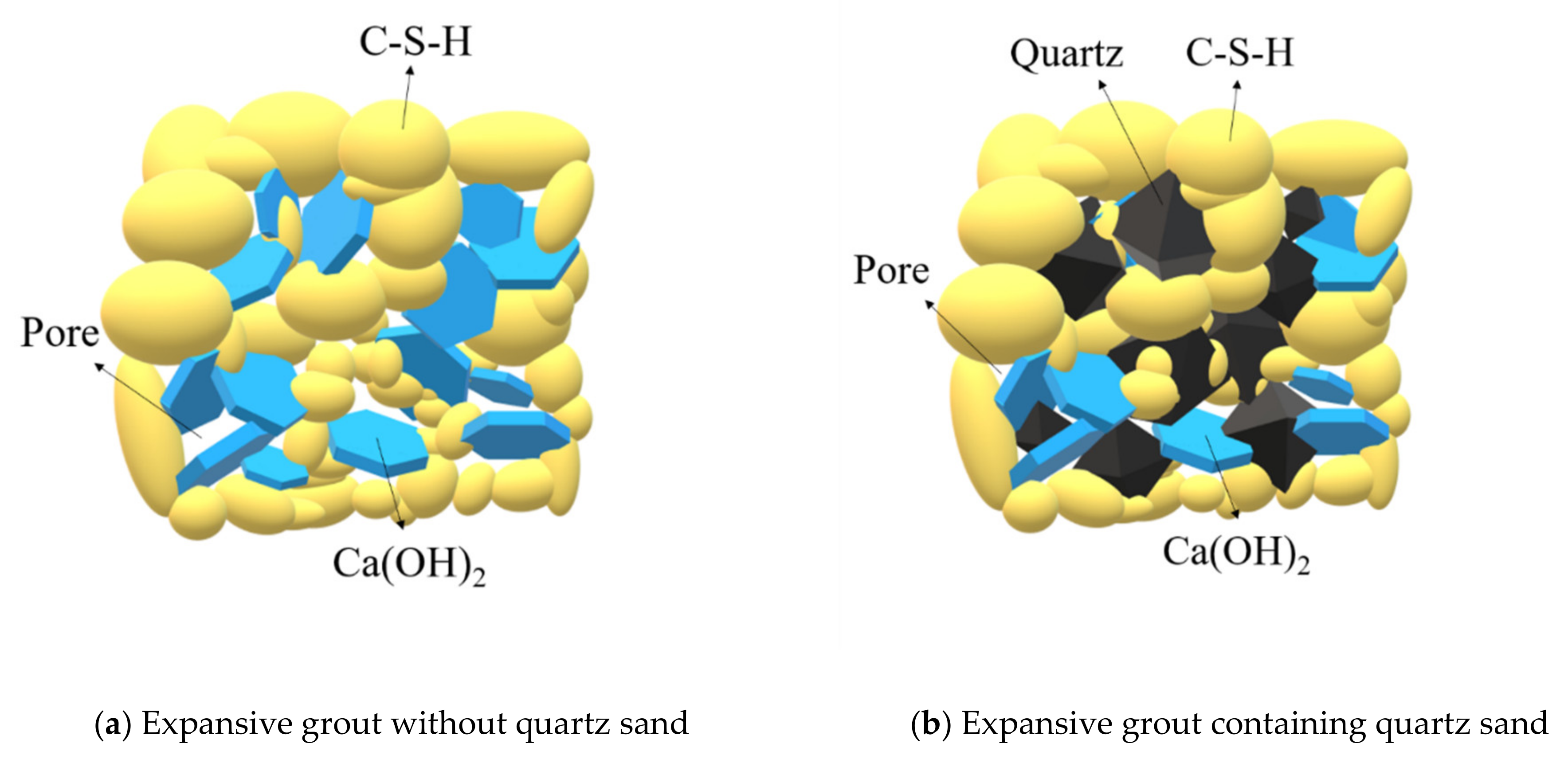

- The expansion ratio and stages of the expansive grout are not affected by quartz sand. The reason is that the main component of quartz sand is silica, which has stable chemical properties and does not effectively participate in the hydration reaction.

- Adding quartz sand to the expansive grout can effectively increase its strength. For higher quartz sand content, the UCS of the sample is greater. Compared with not adding quartz sand, when the content of quartz sand is 5%, 10%, and 15%, the UCS increases by 10.51%, 29.88%, and 37.92%, respectively. Additionally, for higher content of expansive agent, the enhancing effect of quartz sand is more significant.

- Quartz sand does not affect the growth of Ca(OH)2 crystals that determine the expansion of the grout, so it does not affect the expansion behavior of the expansive grout macroscopically. Furthermore, the micro-cracks caused by the expansion process of expansive grout are filled by the quartz, and the compactness of the grout is improved, so the UCS of the sample increases in the macroscopic view. It can be seen that quartz sand is a good strength-enhancing additive material for expansive grout.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bidgoli, M.N.; Zhao, Z.H.; Jing, L.R. Numerical evaluation of strength and deformability of fractured rocks. J. Rock Mech. Geotech. 2013, 5, 419–430. [Google Scholar] [CrossRef] [Green Version]

- Miao, S.T.; Pan, P.Z.; Li, S.J.; Chen, J.Q.; Konicek, P. Quantitative fracture analysis of hard rock containing double infilling flaws with a novel DIC-based method. Eng. Fract. Mech. 2021, 252, 107846. [Google Scholar] [CrossRef]

- Chen, X.; Liao, Z.H.; Peng, X. Deformability characteristics of jointed rock masses under uniaxial compression. Int. J. Min. Sci. Technol. 2012, 22, 213–221. [Google Scholar] [CrossRef]

- Wu, F.Q.; Deng, Y.; Wu, J.; Li, B.; Sha, P.; Guan, S.G.; Zhang, K.; He, K.Q.; Liu, H.D.; Qiu, S.H. Stress–strain relationship in elastic stage of fractured rock mass. Eng. Geol. 2020, 268, 105498. [Google Scholar] [CrossRef]

- Chen, Y.L.; Meng, Q.B.; Xu, G.; Wu, H.S.; Zhang, G.M. Bolt-grouting combined support technology in deep soft rock roadway. Int. J. Min. Sci. Technol. 2016, 26, 777–785. [Google Scholar] [CrossRef]

- El Tani, M. Grouting Rock Fractures with Cement Grout. Rock Mech. Rock Eng. 2012, 45, 547–561. [Google Scholar] [CrossRef]

- Jiang, H.B.; Qiu, X. Performance assessment of a newly developed and highly stable grouting material for a completely weathered granite dam foundation. Constr. Build. Mater. 2021, 299, 123956. [Google Scholar] [CrossRef]

- Salimian, M.H.; Baghbanan, A.; Hashemolhosseini, H.; Dehghanipoodeh, M.; Norouzi, S. Effect of grouting on shear behavior of rock joint. Int. J. Rock Mech. Min. 2017, 98, 159–166. [Google Scholar] [CrossRef]

- Chalangaran, N.; Farzampour, A.; Paslar, N.; Fatemi, H. Experimental investigation of sound transmission loss in concrete containing recycled rubber crumbs. Adv. Concr. Constr. 2021, 11, 447–454. [Google Scholar] [CrossRef]

- Farzampour, A. Compressive Behavior of Concrete Under Environmental Effects. In Compressive Strength of Concrete; IntechOpen: London, UK, 2019. [Google Scholar]

- Xiao, F.; Zhao, Z. Influence of fracture deformation on grout penetrability in fractured rock masses. Tunn. Undergr. Sp. Technol. 2020, 102, 103431. [Google Scholar] [CrossRef]

- Zhang, W.Q.; Zhu, X.X.; Xu, S.X.; Wang, Z.Y.; Li, W. Experimental study on properties of a new type of grouting material for the reinforcement of fractured seam floor. J. Mater. Res. Technol. 2019, 8, 5271–5282. [Google Scholar] [CrossRef]

- Zhao, H.T.; Xiang, Y.; Chen, X.D.; Huang, J.; Xu, W.; Li, H.; Wang, Y.J.; Wang, P.G. Mechanical properties and volumetric deformation of early-age concrete containing CaO-MgO blended expansive agent and temperature rising inhibitor. Constr. Build. Mater. 2021, 299, 123977. [Google Scholar] [CrossRef]

- Yao, N.; Chen, J.W.; Hu, N.Y.; Ye, Y.C.; Xiao, Y.H.; Huang, Y. Experimental study on expansion mechanism and characteristics of expansive grout. Constr. Build. Mater. 2021, 268, 121574. [Google Scholar] [CrossRef]

- Chen, X.; Yang, H.Q.; Li, W.W. Factors analysis on autogenous volume deformation of MgO concrete and early thermal cracking evaluation. Constr. Build. Mater. 2016, 118, 276–285. [Google Scholar] [CrossRef]

- Mo, L.; Deng, M.; Wang, A. Effects of MgO-based expansive additive on compensating the shrinkage of cement paste under non-wet curing conditions. Cem. Concr. Comp. 2012, 34, 377–383. [Google Scholar] [CrossRef]

- Yao, N.; Deng, X.M.; Wang, Q.H.; Ye, Y.C.; Zhang, W.H.; Liu, Y.D. Experimental investigation of expansion behavior and uniaxial compression mechanical properties of expansive grout under different constraint conditions. Bull. Eng. Geol. Environ. 2021, 80, 5609–5621. [Google Scholar] [CrossRef]

- Carballosa, P.; Calvo, J.L.; Revuelta, D. Influence of expansive calcium sulfoaluminate agent dosage on properties and microstructure of expansive self-compacting concretes. Cem. Concr. Comp. 2020, 107, 103464. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Nardinocchi, A.; Donnini, J. The influence of expansive agent on the performance of fibre reinforced cement-based composites. Constr. Build. Mater. 2015, 91, 171–179. [Google Scholar] [CrossRef]

- Liu, F.; Shen, S.L.; Hou, D.W.; Arulrajah, A.; Horpibulsuk, S. Enhancing behavior of large volume underground concrete structure using expansive agents. Constr. Build. Mater. 2016, 114, 49–55. [Google Scholar] [CrossRef]

- Chen, Y.; Deng, Y.F.; Li, M.Q. Influence of Nano-SiO2 on the Consistency, Setting Time, Early-Age Strength, and Shrinkage of Composite Cement Pastes. Adv. Mater. Sci. Eng. 2016, 2016, 5283706. [Google Scholar] [CrossRef] [Green Version]

- Flores, Y.C.; Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M. Performance of Portland cement pastes containing nano-silica and different types of silica. Constr. Build. Mater. 2017, 146, 524–530. [Google Scholar] [CrossRef]

- Hou, P.K.; Qian, J.S.; Cheng, X.; Shah, S.P. Effects of the pozzolanic reactivity of nanoSiO2 on cement-based materials. Cem. Concr. Comp. 2015, 55, 250–258. [Google Scholar] [CrossRef]

- Hou, P.K.; Kawashima, S.; Wang, K.J.; Corr, D.J.; Qian, J.S.; Shah, S.P. Effects of colloidal nanosilica on rheological and mechanical properties of fly ash–cement mortar. Cem. Concr. Comp. 2013, 35, 12–22. [Google Scholar] [CrossRef] [Green Version]

- Li, W.S.; Shaikh, F.U.A.; Wang, L.G.; Lu, Y.L.; Wang, B.; Jiang, C.Y.; Su, Y. Experimental study on shear property and rheological characteristic of superfine cement grouts with nano-SiO2 addition. Constr. Build. Mater. 2019, 228, 117046. [Google Scholar] [CrossRef]

- Singh, L.P.; Karade, S.R.; Bhattacharyya, S.K.; Yousuf, M.M.; Ahalawat, S. Beneficial role of nanosilica in cement based materials —A review. Constr. Build. Mater. 2013, 47, 1069–1077. [Google Scholar] [CrossRef]

- Stefanidou, M.; Papayianni, I. Influence of nano-SiO2 on the Portland cement pastes. Compos. Part B-Eng. 2012, 43, 2706–2710. [Google Scholar] [CrossRef]

- Guo, T.Y.; Wong, L.N.Y. Microcracking behavior of three granites under mode I loading: Insights from acoustic emission. Eng. Geol. 2020, 278, 105823. [Google Scholar] [CrossRef]

- Shi, X.; Wang, M.; Wang, Z.X.; Wang, Y.W.; Lu, S.F.; Tian, W.C. A brittleness index evaluation method for weak-brittle rock by acoustic emission technique. J. Nat. Gas. Sci. Eng. 2021, 95, 104160. [Google Scholar] [CrossRef]

- Shang, J.; West, L.J.; Hencher, S.R.; Zhao, Z. Tensile strength of large-scale incipient rock joints: A laboratory investigation. Acta Geotech. 2017, 13, 869–886. [Google Scholar] [CrossRef] [Green Version]

- Shang, J.; Zhao, Z.; Aliyu, M.M. Stresses induced by a demolition agent in non-explosive rock fracturing. Int. J. Rock Mech. Min. 2018, 107, 172–180. [Google Scholar] [CrossRef]

- Shen, P.L.; Lu, L.N.; He, Y.J.; Wang, F.Z.; Lu, J.X.; Zheng, H.B.; Hu, S.G. Investigation on expansion effect of the expansive agents in ultra-high performance concrete. Cem. Concr. Comp. 2020, 105, 103425. [Google Scholar] [CrossRef]

- Chen, W.; Brouwers, H.J.H. Hydration of mineral shrinkage-compensating admixture for concrete: An experimental and numerical study. Constr. Build. Mater. 2012, 26, 670–676. [Google Scholar] [CrossRef] [Green Version]

- Cao, R.H.; Cao, P.; Lin, H.; Ma, G.W.; Chen, Y. Failure characteristics of intermittent fissures under a compressive-shear test: Experimental and numerical analyses. Theor. Appl. Fract. Mech. 2018, 96, 740–757. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Liu, S.J.; Kou, M.M.; Wang, Z.Q. Mechanical and failure characteristics of fissured marble specimens under true triaxial compression: Insights from 3-D numerical simulations. Comput. Geotech. 2020, 127, 103785. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Deng, H.C.; Deng, Y.; Chen, K.P.; He, J.H. Study on crack dynamic evolution and damage-fracture mechanism of rock with pre-existing cracks based on acoustic emission location. J. Petrol. Sci. Eng. 2021, 201, 108420. [Google Scholar] [CrossRef]

- Zhang, L.; Feng, K.; He, C.; Shao, Z.M.; Guo, W.Q.; Wang, Y.C.; Xiao, M.Q. Experimental study on compression–bending damage of segmental joints based on acoustic emission. Tunn. Undergr. Sp. Technol. 2021, 115, 104078. [Google Scholar] [CrossRef]

| Material | CaO | SiO2 | SO3 | Fe2O3 | Al2O3 | MgO | K2O | TiO2 | Na2O |

|---|---|---|---|---|---|---|---|---|---|

| Portland cement | 44.00 | 30.12 | 2.05 | 2.05 | 11.66 | 4.74 | 1.07 | 0.29 | 1.73 |

| HSCA | 87.12 | 4.47 | 0.04 | 2.76 | 2.78 | 0.75 | 0.06 | 0.09 | 0.21 |

| Quartz sand | – | 99.30 | – | 0.02 | 0.3 | – | – | – | – |

| Water–Cement Ratio | Expansive Agent (%) | Quartz Sand (%) | Flash Setting Admixture (%) | Defoamer (%) |

|---|---|---|---|---|

| 0.7:1 | 3/6/9/12/15 | 0/5/10/15 | 2.5 | 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Ye, Y.; Yao, N.; Liu, Y.; Deng, X. Experimental Study on Strength Enhancement of Expansive Grout. Materials 2022, 15, 885. https://doi.org/10.3390/ma15030885

Wang D, Ye Y, Yao N, Liu Y, Deng X. Experimental Study on Strength Enhancement of Expansive Grout. Materials. 2022; 15(3):885. https://doi.org/10.3390/ma15030885

Chicago/Turabian StyleWang, Di, Yicheng Ye, Nan Yao, Yiming Liu, and Xingmin Deng. 2022. "Experimental Study on Strength Enhancement of Expansive Grout" Materials 15, no. 3: 885. https://doi.org/10.3390/ma15030885

APA StyleWang, D., Ye, Y., Yao, N., Liu, Y., & Deng, X. (2022). Experimental Study on Strength Enhancement of Expansive Grout. Materials, 15(3), 885. https://doi.org/10.3390/ma15030885