Tribological Behavior of Aluminum Hybrid Nanocomposites Reinforced with Alumina and Graphene Oxide

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of the Hybrid Nanocomposites

2.1.1. Sonication and Ball Milling to Disperse and Mix the Powders

2.1.2. Spark Plasma Sintering Process

2.2. Densification and Hardness Measurements

2.3. Friction and Wear Tests

3. Results

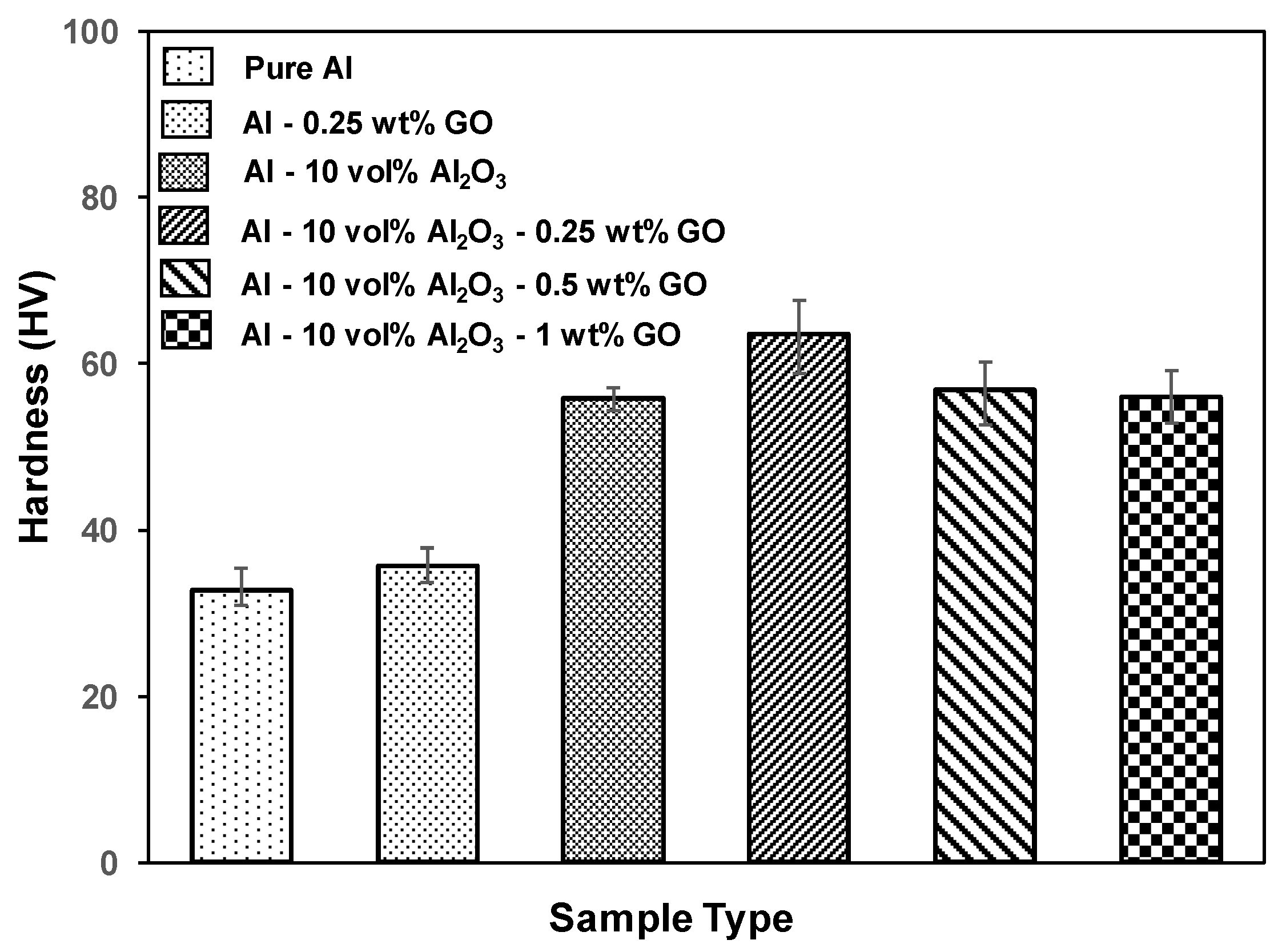

3.1. Density and Hardness of the Nanocomposites

3.2. Tribological Characterization of the Nanocomposite/Hybrid Samples

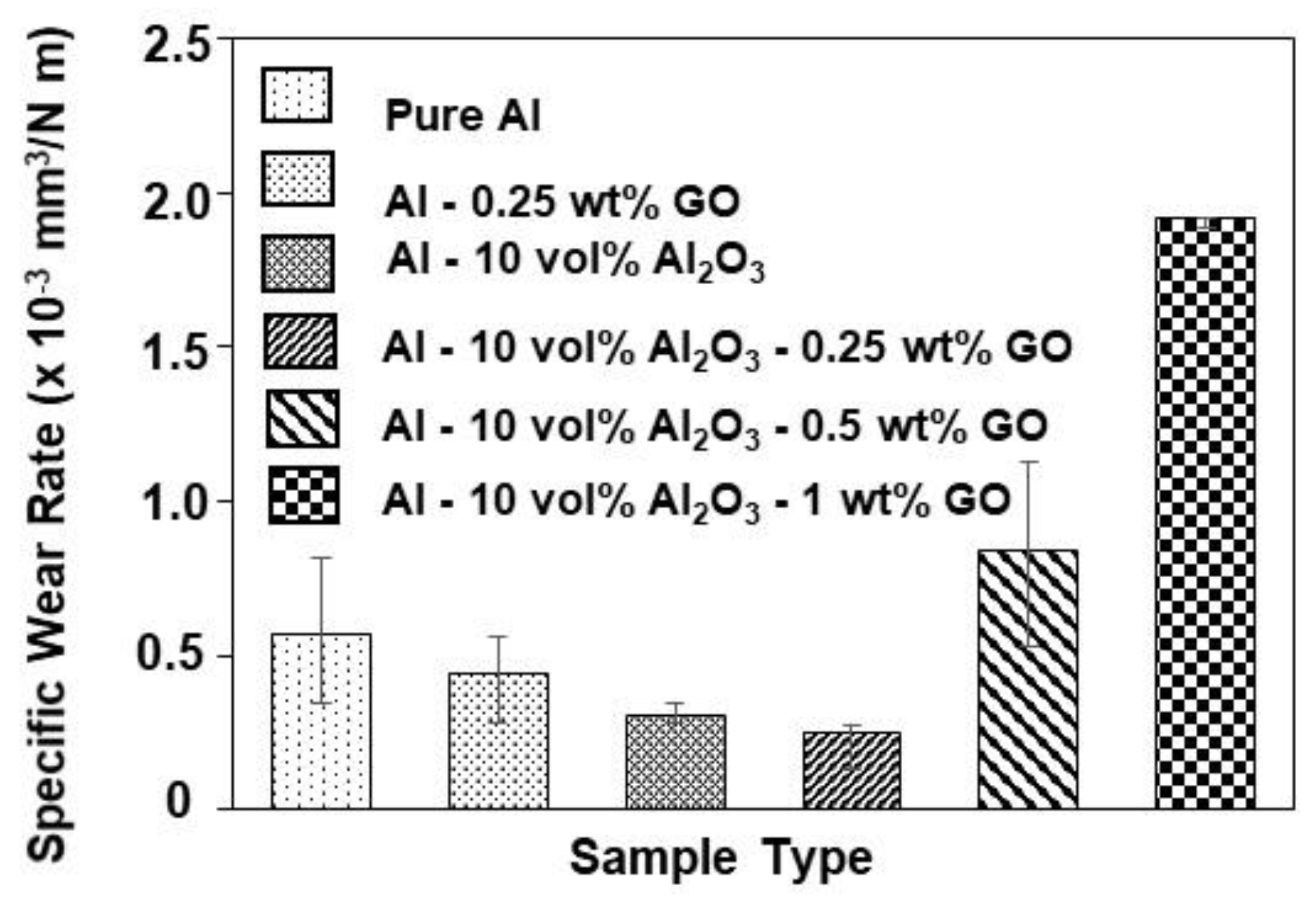

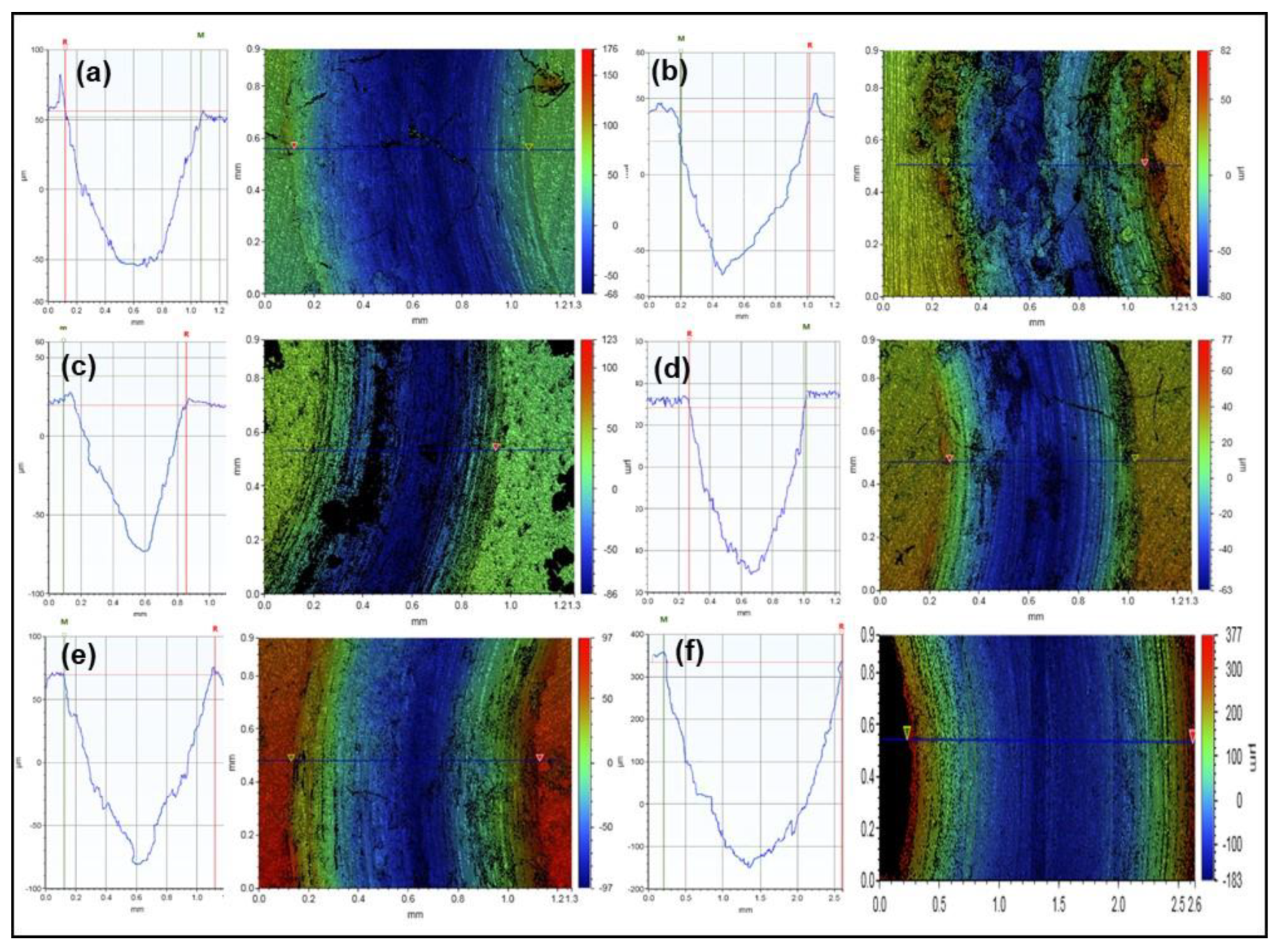

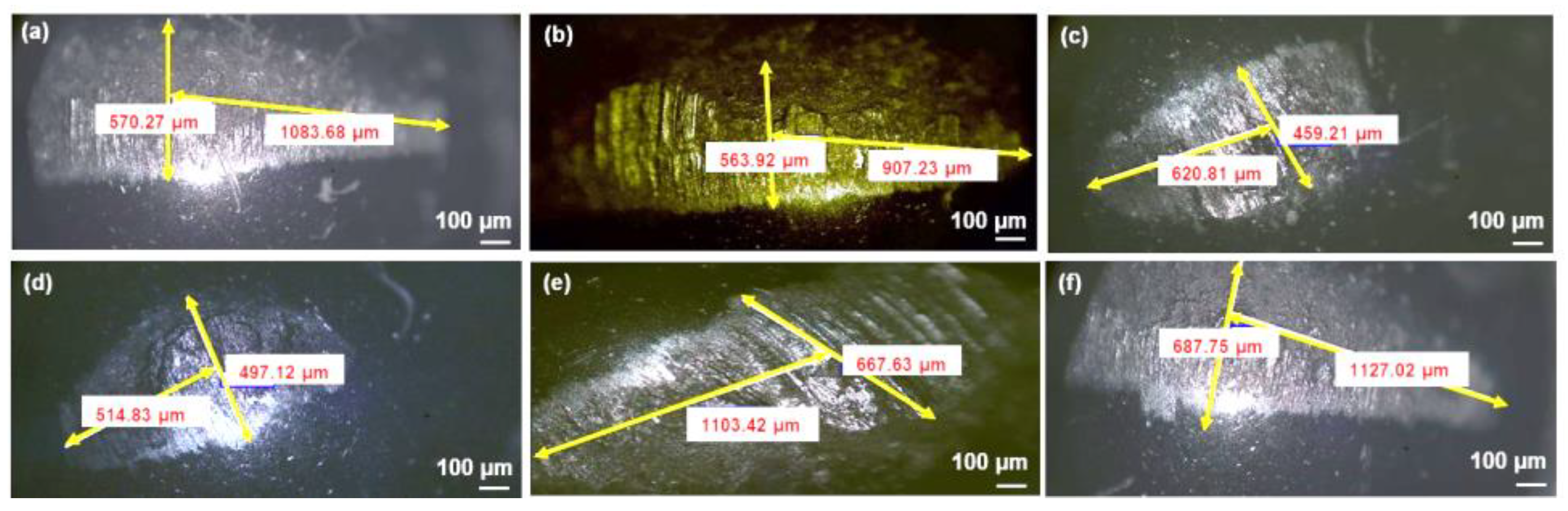

3.2.1. Specific Wear Rate of the Developed Nanocomposite/Hybrid Samples

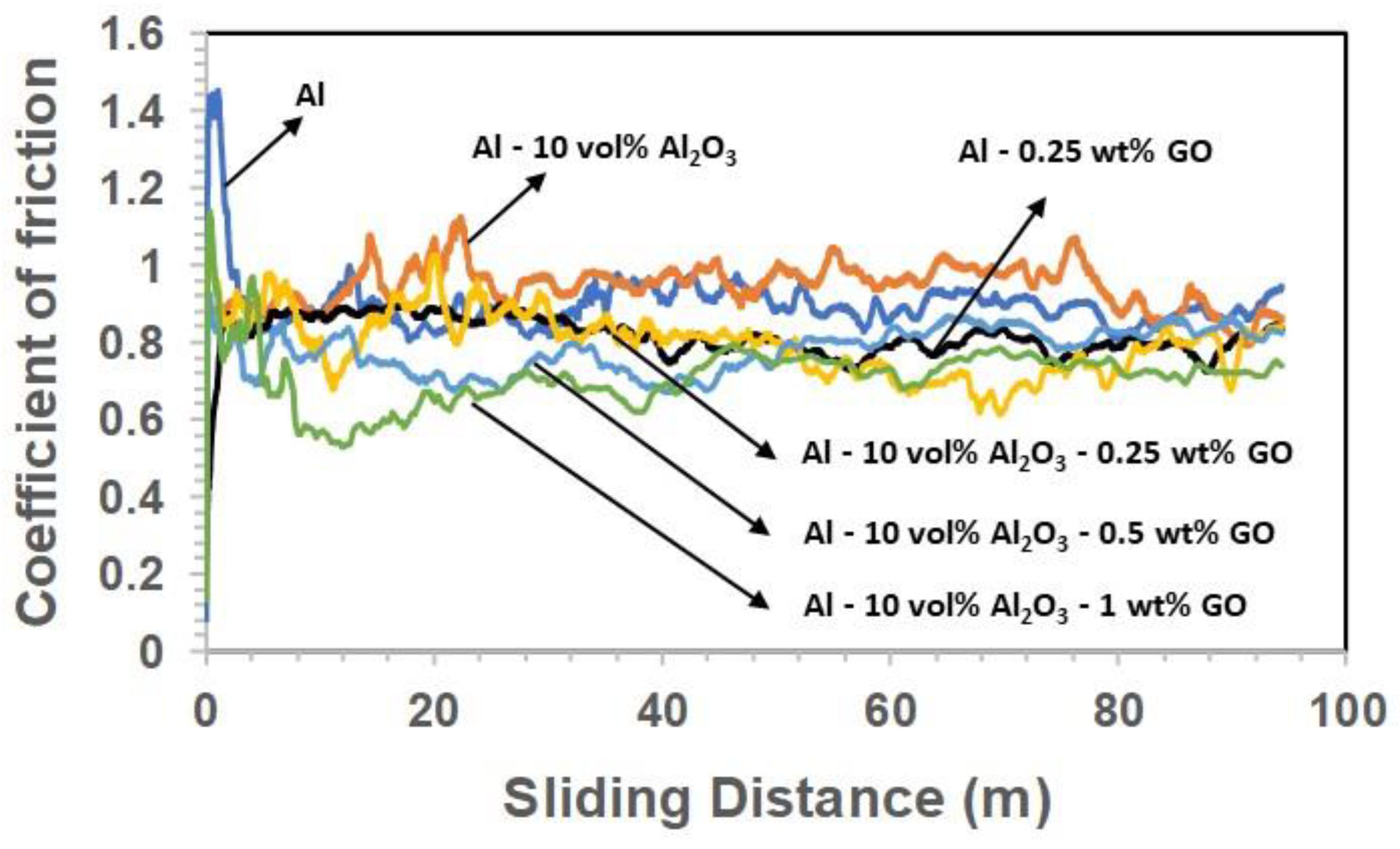

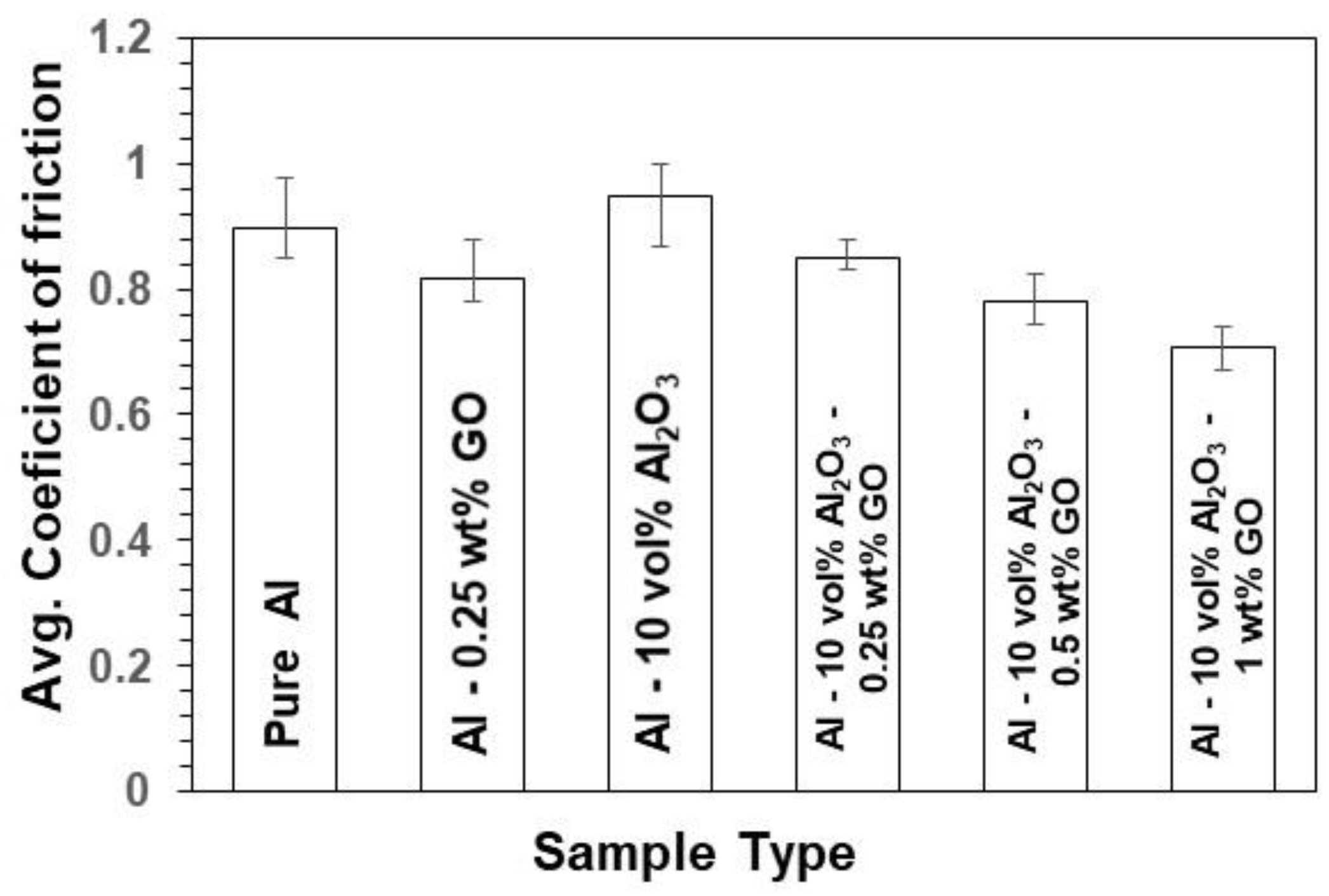

3.2.2. Friction Coefficient of the Developed Nanocomposites/Hybrid Samples

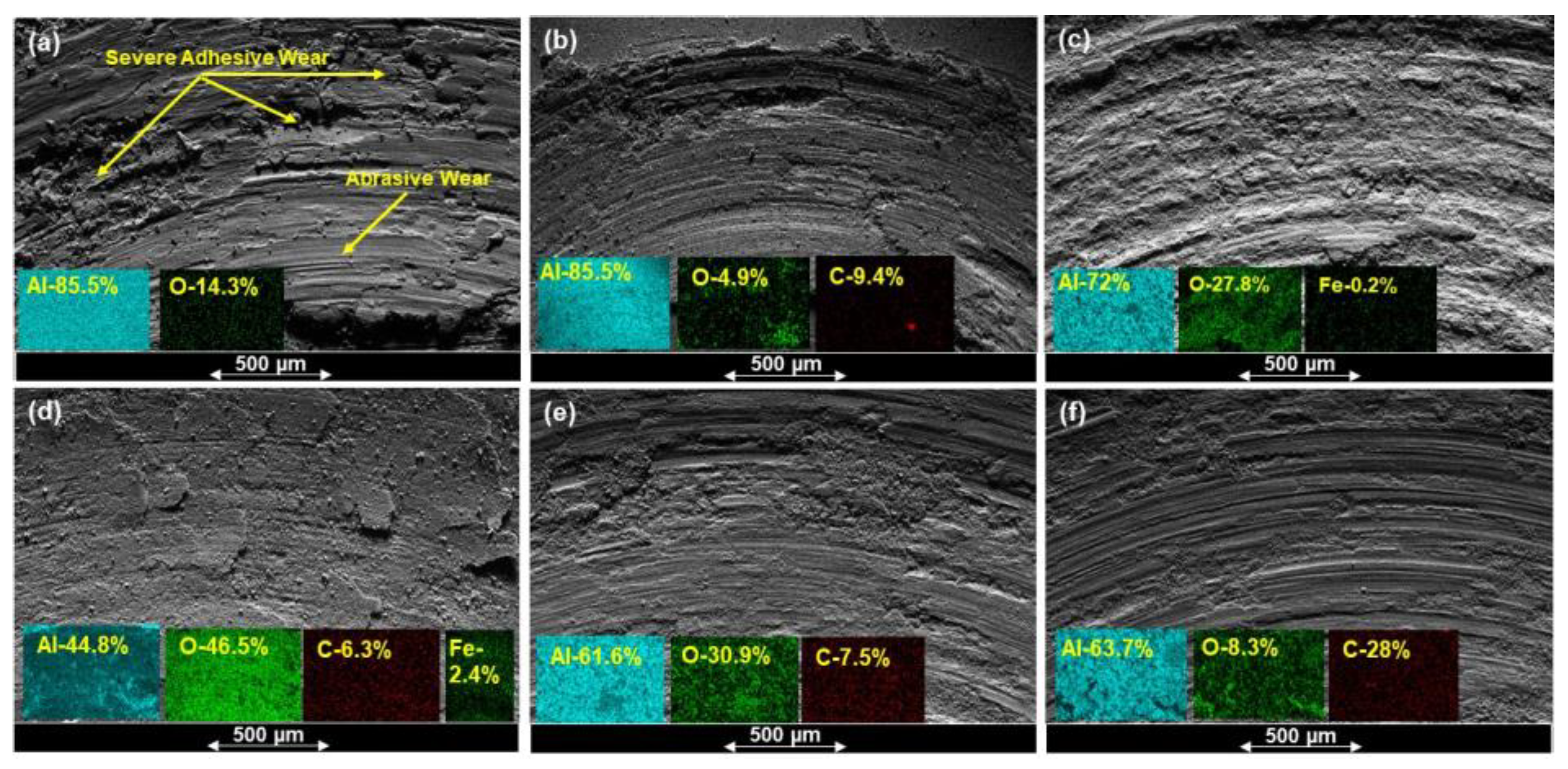

3.2.3. SEM/EDS Analysis

4. Summary and Comparative Analysis

5. Conclusions

- Al-10 Vol% Al2O3-0.25 wt% GO hybrid nanocomposite showed the maximum increase in hardness of 48.4% compared with Al. This significant increase was attributed to the inherent hard nature of Al2O3 nanoparticles and the uniform dispersion of both the reinforcements within the Al matrix.

- Al-10 Vol% Al2O3-0.25 wt% GO hybrid nanocomposite showed the lowest specific wear rate. It exhibited the highest reduction of about 55.6% in the specific wear rate as compared with Al. This was attributed to the enhancement in the mechanical properties due to the reinforcements.

- The most predominant wear mechanism was found to be abrasive wear due to plastic deformation, with smooth surface characteristics of the wear track with significantly fewer debris particles. The scar mark on the counterface ball sliding against the Al-10 Vol% Al2O3-0.25 wt% GO hybrid nanocomposite was also the smallest.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Clyne, T.W.; Withers, P.J. An Introduction to Metal Matrix Composites; Cambridge University Press: Cambridge, UK, 1993. [Google Scholar] [CrossRef]

- Kainer, K.U. Metal Matrix Composites: Custom-Made Materials for Automotive and Aerospace Engineering; John Wiley & Sons: Chichester, UK, 2006; p. 314. [Google Scholar]

- Lloyd, D.J. Particle reinforced aluminum and magnesium matrix composites. Int. Mater. Rev. 1994, 39, 1–23. [Google Scholar] [CrossRef]

- Lee, J.M.; Lee, S.K.; Hong, S.J.; Kwon, Y.N. Microstructures and thermal properties of A356/SiCp composites fabricated by liquid pressing method. Mater. Des. 2012, 37, 313–316. [Google Scholar] [CrossRef]

- Alidokht, S.A.; Zadeh, A.A.; Soleymani, S.; Assadi, H. Microstructure and tribological performance of an aluminum alloy based hybrid composite produced by friction stir processing. Mater. Des. 2011, 32, 2727–2733. [Google Scholar] [CrossRef]

- Torralba, J.; da Costa, C.; Velasco, F.J. P/M aluminum matrix composites: An overview. J. Mater. Process. Technol. 2003, 133, 203–206. [Google Scholar] [CrossRef]

- Chakrapani, P.; Suryakumari, T.S.A. Mechanical properties of aluminium metal matrix composites-A review. Mater. Today Proc. 2021, 45, 5960–5964. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2013, 56, 862–871. [Google Scholar] [CrossRef]

- Sevik, H.; Kurnaz, S.C. Properties of alumina particulate reinforced aluminum alloy produced by pressure die casting. Mater. Des. 2005, 27, 676–683. [Google Scholar] [CrossRef]

- Freitas, B.J.M.; Junior, A.M.J.; Zepon, G.; Kiminami, C.S.; Botta, W.J.; Bolfarini, C. Outstanding Tensile Ductility in High Iron-Containing Al-Si-Cu Alloys. Met. Mater. Trans. A 2020, 51, 2703–2710. [Google Scholar] [CrossRef]

- Hutchinson, C.R.; Ringer, S.P. Precipitation processes in Al-Cu-Mg alloys microalloyed with Si. Met. Mater. Trans. A 2000, 31, 2721–2733. [Google Scholar] [CrossRef]

- Dev, S.P.; Charoo, M.S. Aluminum metal matrix composites a review of reinforcement; Mechanical and tribological behavior. Int. J. Eng. Technol. 2018, 7, 117. [Google Scholar]

- Tjong, S.C. Processing and Deformation Characteristics of Metals Reinforced with Ceramic Nanoparticles, 2nd ed.; Tjong, J., Ed.; Elsevier: Oxford, UK, 2014; pp. 269–304. [Google Scholar]

- Tham, L.; Gupta, M.; Cheng, L. Effect of limited matrix–reinforcement interfacial reaction on enhancing the mechanical properties of aluminium–silicon carbide composites. Acta Mater. 2001, 49, 3243–3253. [Google Scholar] [CrossRef]

- Rana, R.; Purohit, R.; Soni, V.; Das, S. Characterization of Mechanical Properties and Microstructure of Aluminium Alloy-SiC Composites. Mater. Today Proc. 2015, 2, 1149–1156. [Google Scholar] [CrossRef]

- Song, M. Effects of volume fraction of SiC particles on mechanical properties of SiC/Al composites. Trans. Nonferrous Met. Soc. China 2009, 19, 1400–1404. [Google Scholar] [CrossRef]

- Kumar, C.A.V.; Rajadurai, J.S. Influence of rutile (TiO2) content on wear and microhardness characteristics of aluminium-based hybrid composites synthesized by powder metallurgy. Trans. Nonferrous Met. Soc. China 2016, 26, 63–73. [Google Scholar] [CrossRef]

- Ezatpour, H.; Torabi-Parizi, M.; Sajjadi, S.A. Microstructure and mechanical properties of extruded Al/Al2O3 composites fabricated by stir-casting process. Trans. Nonferrous Met. Soc. China 2013, 23, 1262–1268. [Google Scholar] [CrossRef]

- Zahid, G.; Azhar, T.; Musaddiq, M.; Rizvi, S.; Ashraf, M.; Hussain, N.; Iqbal, M. In situ processing and aging behaviour of an aluminium/Al2O3 composite. Mater. Des. 2011, 32, 1630–1635. [Google Scholar] [CrossRef]

- Razavi-Tousi, S.; Yazdani-Rad, R.; Manafi, S. Effect of volume fraction and particle size of alumina reinforcement on compaction and densification behavior of Al–Al2O3 nanocomposites. Mater. Sci. Eng. A 2010, 528, 1105–1110. [Google Scholar] [CrossRef]

- Jiang, X.-S.; Wang, N.-J.; Zhu, D.-G. Friction and wear properties of in-situ synthesized Al2O3 reinforced aluminum composites. Trans. Nonferrous Met. Soc. China 2014, 24, 2352–2358. [Google Scholar] [CrossRef]

- Rahimian, M.; Parvin, N.; Ehsani, N. The effect of production parameters on microstructure and wear resistance of powder metallurgy Al–Al2O3 composite. Mater. Des. 2010, 32, 1031–1038. [Google Scholar] [CrossRef]

- Shuvho, M.; Chowdhury, M.; Kchaou, M.; Roy, B.; Rahman, A.; Islam, M. Surface characterization and mechanical behavior of aluminum based metal matrix composite reinforced with nano Al2O3, SiC, TiO2 particles. Chem. Data Collect. 2020, 28, 100442. [Google Scholar] [CrossRef]

- Kumar, N.; Chittappa, H.C.; Ezhil Vannan, S. Development of Aluminium-Nickel Coated Short Carbon Fiber Metal Matrix Composites. Mater. Today Proc. 2018, 5, 11336–11345. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Y.; Sun, P.; Cui, Y.; Wu, G. Microstructure and Flexural Properties of Z-Pinned Carbon Fiber-Reinforced Aluminum Matrix Composites. Materials 2019, 12, 174. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharma, P.; Sharma, S.; Khanduja, D. Effect of graphite reinforcement on physical and mechanical properties of alu-minum metal matrix composites. Part. Sci. Technol. 2016, 34, 17–22. [Google Scholar] [CrossRef]

- Schrecengost, T.R.; Shaw, B.A.; Wendt, R.G.; Moshier, W.C. Nonequilibrium Alloying of Graphite-Reinforced Aluminum Metal Matrix Composites. Corrosion 1993, 49, 842–849. [Google Scholar] [CrossRef]

- Jagannatham, M.; Chandran, P.; Sankaran, S.; Haridoss, P.; Nayan, N.; Bakshi, S.R. Tensile properties of carbon nanotubes reinforced aluminum matrix composites: A review. Carbon 2020, 160, 14–44. [Google Scholar] [CrossRef]

- Sridhar, I.; Narayanan, K.R. Processing and characterization of MWCNT reinforced aluminum matrix composites. J. Mater. Sci. 2009, 44, 1750–1756. [Google Scholar] [CrossRef]

- Munir, K.; Wen, C.; Li, Y. Graphene nanoplatelets-reinforced magnesium metal matrix nanocomposites with superior mechanical and corrosion performance for biomedical applications. J. Magnes. Alloy. 2019, 8, 269–290. [Google Scholar] [CrossRef]

- Pourmand, N.S.; Asgharzadeh, H. Aluminum Matrix Composites Reinforced with Graphene: A Review on Production, Microstructure, and Properties. Crit. Rev. Solid State Mater. Sci. 2019, 45, 289–337. [Google Scholar] [CrossRef]

- Lian, W.; Mai, Y.; Wang, J.; Zhang, L.; Liu, C.; Jie, X. Fabrication of graphene oxide-Ti3AlC2 synergistically reinforced copper matrix composites with enhanced tribological performance. Ceram. Int. 2019, 45, 18592–18598. [Google Scholar] [CrossRef]

- Dasari, B.; Morshed, M.; Nouri, J.M.; Brabazon, D.; Naher, S. Mechanical properties of graphene oxide reinforced aluminium matrix composites. Compos. Part B Eng. 2018, 145, 136–144. [Google Scholar] [CrossRef]

- Şahin, Y. Tribological behavior and wear surface analysis of metal-matrix composites. J. Mater. Sci. 1999, 34, 875–880. [Google Scholar] [CrossRef]

- Prabhakar, N.S.; Radhika, N.; Raghu, R. Analysis of Tribological Behavior of Aluminium/B4C Composite Under Dry Sliding Motion. Procedia Eng. 2014, 97, 994–1003. [Google Scholar] [CrossRef] [Green Version]

- Faisal, N.; Kumar, K. Mechanical and tribological behaviour of nano scaled silicon carbide reinforced aluminium composites. J. Exp. Nanosci. 2018, 13, S1–S13. [Google Scholar] [CrossRef]

- Jiang, J.; Xiao, G.; Che, C.; Wang, Y. Microstructure, Mechanical Properties and Wear Behavior of the Rheoformed 2024 Aluminum Matrix Composite Component Reinforced by Al2O3 Nanoparticles. Metals 2018, 8, 460. [Google Scholar] [CrossRef] [Green Version]

- Al-Qutub, A.; Allam, I.; Qureshi, T. Effect of sub-micron Al2O3 concentration on dry wear properties of 6061 aluminum based composite. J. Mater. Process. Technol. 2005, 172, 327–331. [Google Scholar] [CrossRef]

- Ramachandra, M.; Abhishek, A.; Siddeshwar, P.; Bharathi, V. Hardness and Wear Resistance of ZrO2 Nano Particle Reinforced Al Nanocomposites Produced by Powder Metallurgy. Procedia Mater. Sci. 2015, 10, 212–219. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.; Arafath, Y.; Gupta, P.; Kumar, D.; Hussain, C.M.; Jamwal, A. Microstructural and mechano-tribological behavior of Al reinforced SiC-TiC hybrid metal matrix composite. Mater. Today Proc. 2020, 21, 1417–1420. [Google Scholar] [CrossRef]

- Rengifo, S.; Zhang, C.; Harimkar, S.; Boesl, B.; Agarwal, A. Tribological Behavior of Spark Plasma Sintered Aluminum-Graphene Composites at Room and Elevated Temperatures. Technologies 2017, 5, 4. [Google Scholar] [CrossRef]

- Singh, J. Fabrication characteristics and tribological behavior of Al/SiC/Gr hybrid aluminum matrix composites: A review. Friction 2016, 4, 191–207. [Google Scholar] [CrossRef] [Green Version]

- Mosleh-Shirazi, S.; Akhlaghi, F.; Li, D.-Y. Effect of SiC content on dry sliding wear, corrosion and corrosive wear of Al/SiC nanocomposites. Trans. Nonferrous Met. Soc. China 2016, 26, 1801–1808. [Google Scholar] [CrossRef]

- Mohammed, A.; Alahmari, T.; Laoui, T.; Hakeem, A.; Patel, F. Mechanical and Thermal Evaluation of Aluminum Hybrid Nanocomposite Reinforced with Alumina and Graphene Oxide. Nanomaterials 2021, 11, 1225. [Google Scholar] [CrossRef] [PubMed]

- Ajit, S.D.; Jayakumar, J. Evaluation of mechanical and wear properties of aluminium-Al2O3 composite material. Int. Res. J. Eng. Technol. (IRJET) 2012, 5, 5–18. [Google Scholar]

- Bharath, V.; Madev, N.; Auradi, V.; Kori, S.A. Preparation of 6061Al-Al2O3 MMC’s by Stir Casting and Evaluation of Mechanical and Wear Properties. Procedia Mater. Sci. 2014, 6, 1658–1667. [Google Scholar] [CrossRef] [Green Version]

- Al-Salihi, H.A.; Judran, H.K. Effect of Al2O3 reinforcement nanoparticles on the tribological behaviour and mechanical properties of Al6061 alloy. AIMS Mater. Sci. 2020, 7, 486–498. [Google Scholar] [CrossRef]

- Tabandeh, K.; Meysam, O.; Emad, M.; Pradeep, R. and Pradeep, K.H. Tribological performance of self-lubricating aluminum matrix nanocomposites: Role of graphene nanoplatelets. Eng. Sci. Technol. Int. J. 2016, 19, 463–469. [Google Scholar]

- Xia, H.-M.; Zhang, L.; Zhu, Y.-C.; Li, N.; Sun, Y.-Q.; Zhang, J.-D.; Ma, H.-Z. Mechanical properties of graphene nanoplatelets reinforced 7075 aluminum alloy composite fabricated by spark plasma sintering. Int. J. Miner. Met. Mater. 2020, 27, 1295–1300. [Google Scholar] [CrossRef]

- Sekar, K.; Allesu, K.; Joseph, M.A. Mechanical and Wear Properties of Al–Al2O3 Metal Matrix Composites Fabricated by the Combined Effect of Stir and Squeeze Casting Method. Trans. Indian Inst. Met. 2015, 68, 115–121. [Google Scholar] [CrossRef]

- Aswin, S.; Soney, V. Tribology study of graphene-aluminium nanocomposites. Int. J. Mech. Prod. Eng. (IJMPE) 2014, 2, 29–33. [Google Scholar]

- Prashantha, K.H.G.; Anthony, X.M. Tribological Aspects of Graphene-Aluminum Nanocomposites; IntechOpen: London, UK, 2017; Available online: https://www.intechopen.com/chapters/54209 (accessed on 1 December 2021). [CrossRef] [Green Version]

- Srinivasa, M.R.; Rammohan, Y.S.; Karthik, U.N.; Sadashiva, A.N.D. Analysis on wear properties of graphene hydroxyl rein-forced aluminum composites. IJAST 2020, 29, 4162. [Google Scholar]

| Die Material | Graphite |

| Die diameter | 20 mm |

| Temperature | 550 °C |

| Heating rate | 200 °C/min |

| Holding time (t) | 10 min |

| Pressure (Pr.) | 50 MPa |

| Sample | Relative Density (%) |

|---|---|

| Al | 99.8 |

| Al-10 Vol % Al2O3 | 99.5 |

| Al-10 Vol % Al2O3-0.25 wt% GO | 98.9 |

| Al-10 Vol % Al2O3-0.5 wt% GO | 98.6 |

| Al-10 Vol % Al2O3-1 wt% GO | 97.4 |

| Property | Sample | |||||

|---|---|---|---|---|---|---|

| Al | Al + 0.25 wt% GO | Al + 10 Vol% Al2O3 | Al + 10 Vol% Al2O3+ 0.25 wt% GO | Al + 10 Vol% Al2O3+ 0.5 wt% GO | Al + 10 Vol% Al2O3+1 wt% GO | |

| Hardness (HV) | 32.8 | 35.76 | 55.8 | 63.56 | 56.9 | 56 |

| Relative density (%) | 99.8 | 99.2 | 99.5 | 98.9 | 98.6 | 97.4 |

| Specific Wear Rate (10−6 mm3/Nm) | 566 | 439 | 303 | 251 | 837 | 1920 |

| Reduction in Wear Rate (%) | 0 | 22.63 | 46.37 | 55.65 | −47.87 | −238.8 |

| Composite | Fabrication Method | Relative Density (%) | Hardness | Wear | Reduction in Wear Rate % | Ref |

|---|---|---|---|---|---|---|

| Al-6082 | Stir Casting | 98.3 | 74 BHN | 62 µg | 0 | [45] |

| Al-6082 + 10% Al2O3 | 97.5 | 78 BHN | 45 µg | 27.41% | ||

| Al-6082 + 15% Al2O3 | 97.3 | 81 BHN | 35 µg | 43.35% | ||

| Al-6082 + 20% Al2O3 | 96.9 | 87 BHN | 30 µg | 51.61% | ||

| Al 6061 | Stir Casting | −− | 95 HV | 0.035 gm | 0 | [46] |

| Al 6061 + 6% Al2O3 | −− | 105 HV | 0.028 gm | 20% | ||

| Al 6061 + 9% Al2O3 | −− | 150 HV | 0.023 gm | 34.28% | ||

| Al-6061 + 12% Al2O3 | −− | 188 HV | 0.020 gm | 42.85% | ||

| Al-6061 | Stir Casting | −− | 28 BHN | 1.4 × 10−3 (mm3/m) | 0 | [47] |

| Al-6061-5% Al2O3 | −− | 33 BHN | 0.9 × 10−3 (mm3/m) | 35.71% | ||

| Al-6061-10% Al2O3 | −− | 38 BHN | 0.64 × 10−3 (mm3/m) | 54.42% | ||

| Al-6061-15% Al2O3 | −− | 39 BHN | 0.66 × 10−3 (mm3/m) | 52.85% | ||

| Al | Powder Metallurgy | 98 | 111 HV | 0.006 (g) | 0 | [48] |

| Al + 0.1 wt% GNP | 98.8 | 98 HV | 0.005 (g) | 16.66% | ||

| Al + 1 wt% GNP | 98.8 | 97 HV | 0.007 (g) | −16.66% | ||

| Al 7075 | Spark Plasma Sintering | 99 | 96.8 HV | 0.0034 (mm3/m) | 0 | [49] |

| Al-7075/GNPs | 99 | 124.9 HV | 0.00275 (mm3/m) | 19.11% | ||

| A356 | Stir and squeeze casting | −− | −− | 44 Vol loss (mm3) | 0 | [50] |

| A356-0.5% Al2O3 | −− | −− | 27 Vol loss (mm3) | 38.63% | ||

| A356-1% Al2O3 | −− | −− | 25 Vol loss (mm3) | 43.18% | ||

| A356-1.5% Al2O3 | −− | −− | 32 Vol loss (mm3) | 27.27% | ||

| Al | Sintering Process | −− | 53 HRB | 0.039 (g) | 0 | [51] |

| Al + 0.01 wt%Greaphene | −− | 54 HRB | 0.037 (g) | 5.12% | ||

| Al + 0.5 wt%Greaphene | −− | 62 HRB | 0.021 (g) | 46.15 | ||

| Al + 1 wt%Greaphene | −− | 58 HRB | 0.055 (g) | −41.02% | ||

| Al + 2 wt%Greaphene | −− | 49 HRB | 0.105 (g) | −169.23% | ||

| Al + 5 wt%Greaphene | −− | 45 HRB | 0.170 (g) | −335.89% | ||

| AA 6061 | Microwave sintering | −− | 65 HV | 0.075 (gms) | 0 | [52] |

| AA 6061 + 0.3%Graphene | −− | 77 HV | 0.062 (gms) | 17.33% | ||

| AA 6061 + 0.6%Graphene | −− | 75 HV | 0.062 (gms) | 17.33% | ||

| AA 6061 + 0.9%Graphene | −− | 73 HV | 0.066 (gms) | 12% | ||

| AA 6061 + 1.2%Graphene | −− | 71 HV | 0.070 (gms) | 6.66% | ||

| Al-2024 | Stir Casting | −− | −− | 0.109 (g) | 0 | [53] |

| Al-2024 + 0.25 wt% Graphene | −− | −− | 0.104 (g) | 4.58% | ||

| Al-2024 + 0.50 wt% Graphene | −− | −− | 0.0998 (g) | 8.44% | ||

| Al-2024 + 0.75 wt% Graphene | −− | −− | 0.0942 (g) | 13.57% | ||

| Al-2024 + 1 wt% Graphene | −− | −− | 0.0892 (g) | 18.16% | ||

| Al-0.25wt% GO-10Vol% Al2O3 | Spark Plasma Sintering | 98.9 | 63.56 HV | 251 × 10−6 mm3/Nm | 55.65% | Present Study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammed, A.S.; Aljebreen, O.S.; Hakeem, A.S.; Laoui, T.; Patel, F.; Ali Baig, M.M. Tribological Behavior of Aluminum Hybrid Nanocomposites Reinforced with Alumina and Graphene Oxide. Materials 2022, 15, 865. https://doi.org/10.3390/ma15030865

Mohammed AS, Aljebreen OS, Hakeem AS, Laoui T, Patel F, Ali Baig MM. Tribological Behavior of Aluminum Hybrid Nanocomposites Reinforced with Alumina and Graphene Oxide. Materials. 2022; 15(3):865. https://doi.org/10.3390/ma15030865

Chicago/Turabian StyleMohammed, Abdul Samad, Omar Saad Aljebreen, Abbas Saeed Hakeem, Tahar Laoui, Faheemuddin Patel, and Mirza Murtuza Ali Baig. 2022. "Tribological Behavior of Aluminum Hybrid Nanocomposites Reinforced with Alumina and Graphene Oxide" Materials 15, no. 3: 865. https://doi.org/10.3390/ma15030865

APA StyleMohammed, A. S., Aljebreen, O. S., Hakeem, A. S., Laoui, T., Patel, F., & Ali Baig, M. M. (2022). Tribological Behavior of Aluminum Hybrid Nanocomposites Reinforced with Alumina and Graphene Oxide. Materials, 15(3), 865. https://doi.org/10.3390/ma15030865