Hydration and Mechanical Properties of Calcium Sulphoaluminate Cement Containing Calcium Carbonate and Gypsum under NaCl Solutions

Abstract

:1. Introduction

2. Materials and Methods

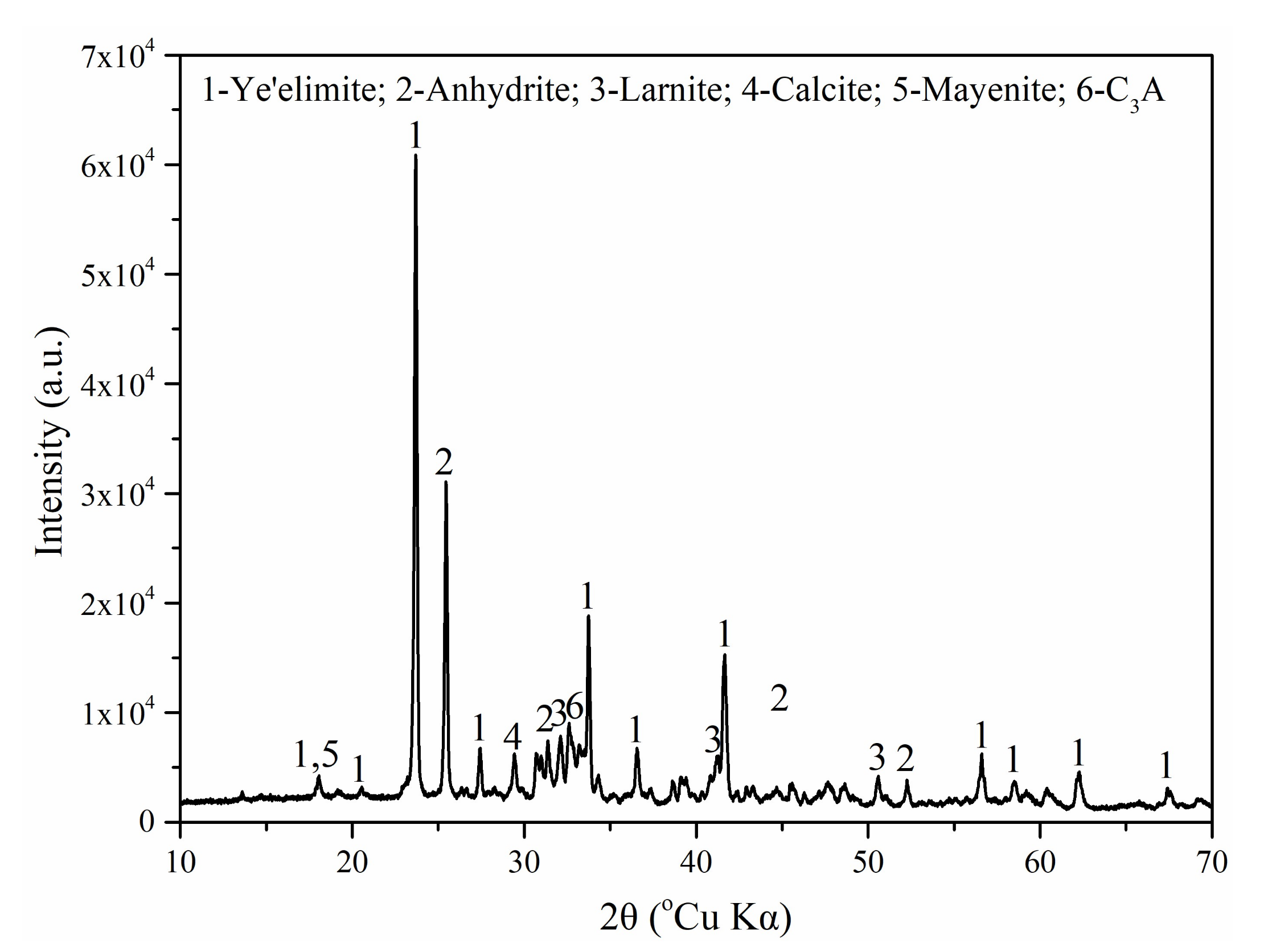

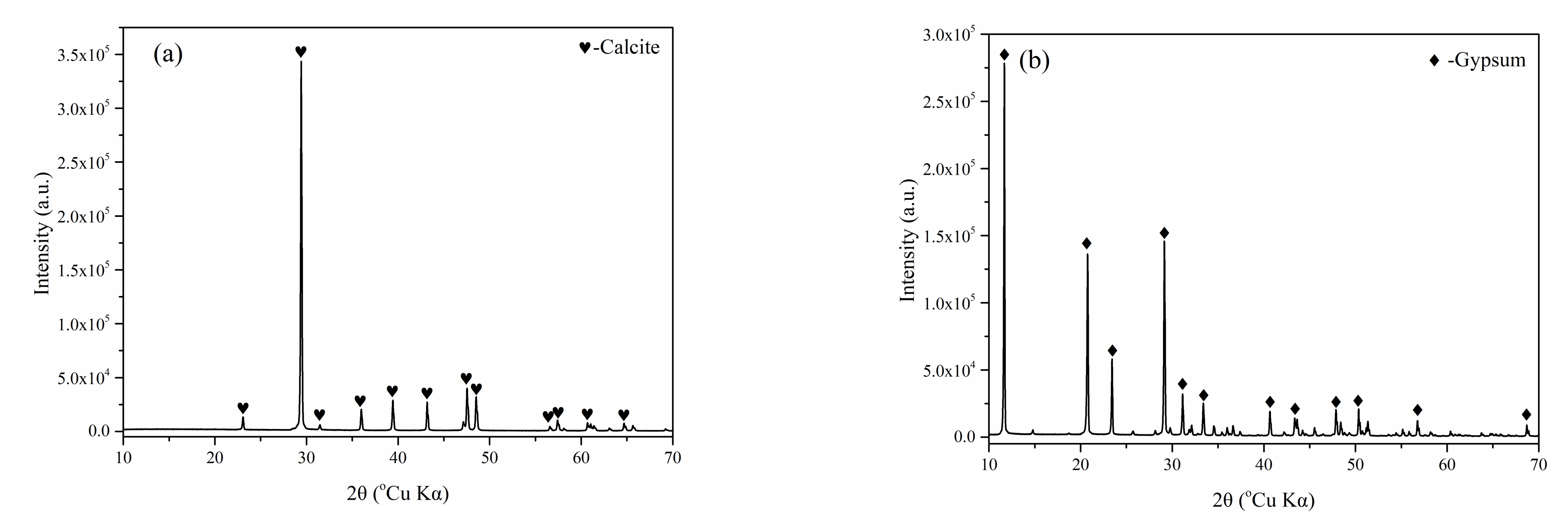

2.1. Raw Materials

2.2. Sample Preparation

2.3. Testing

2.3.1. Isothermal Calorimetry

2.3.2. X-ray Diffraction

2.3.3. Pore Structure Test

2.3.4. Linear Shrinkage Test

2.3.5. Compressive Strength Test

3. Results

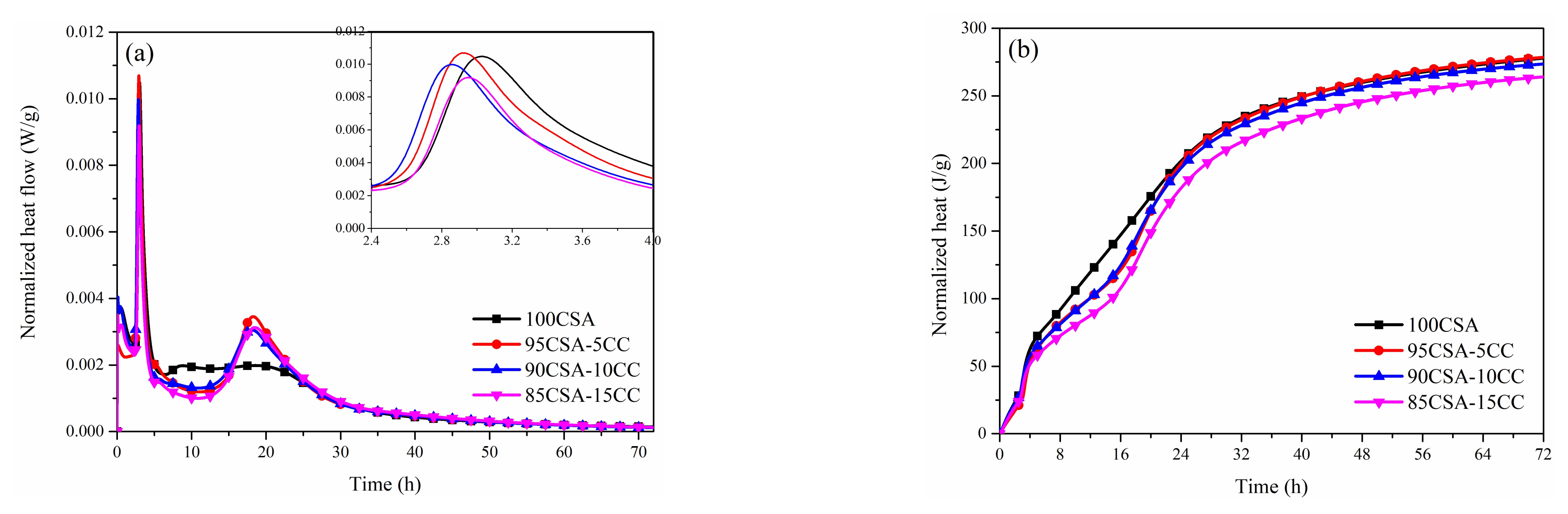

3.1. Heat Evolution

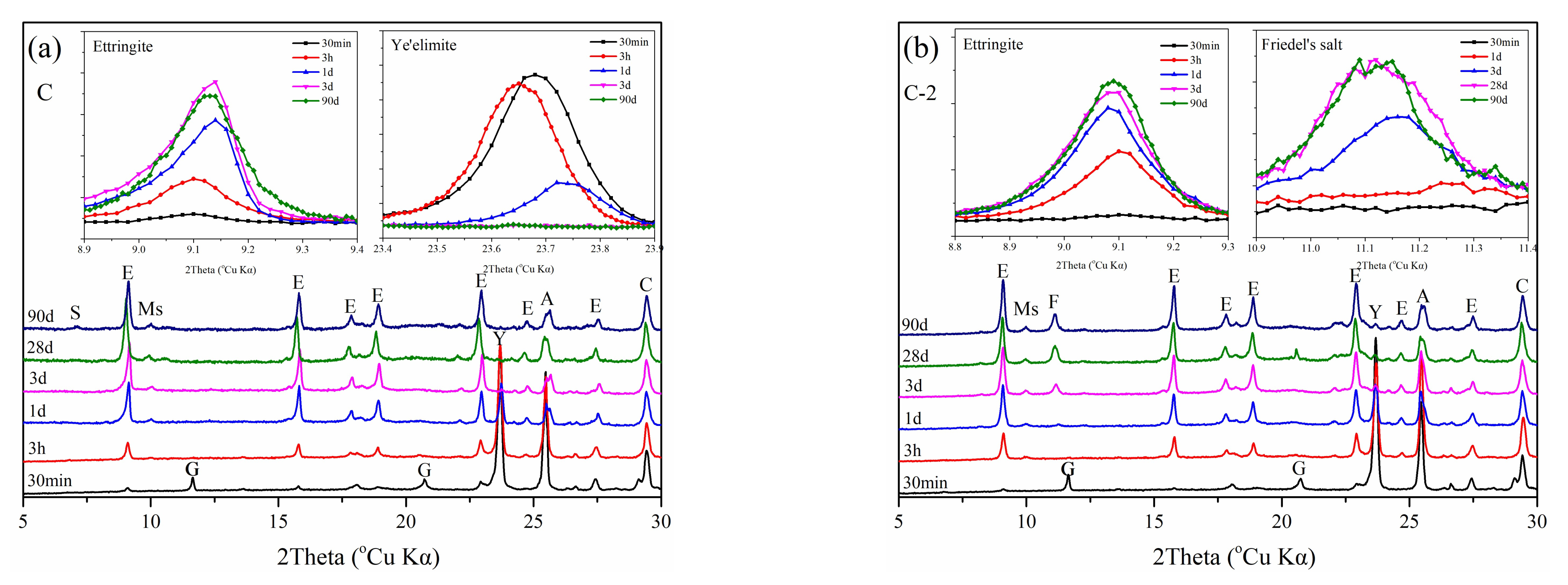

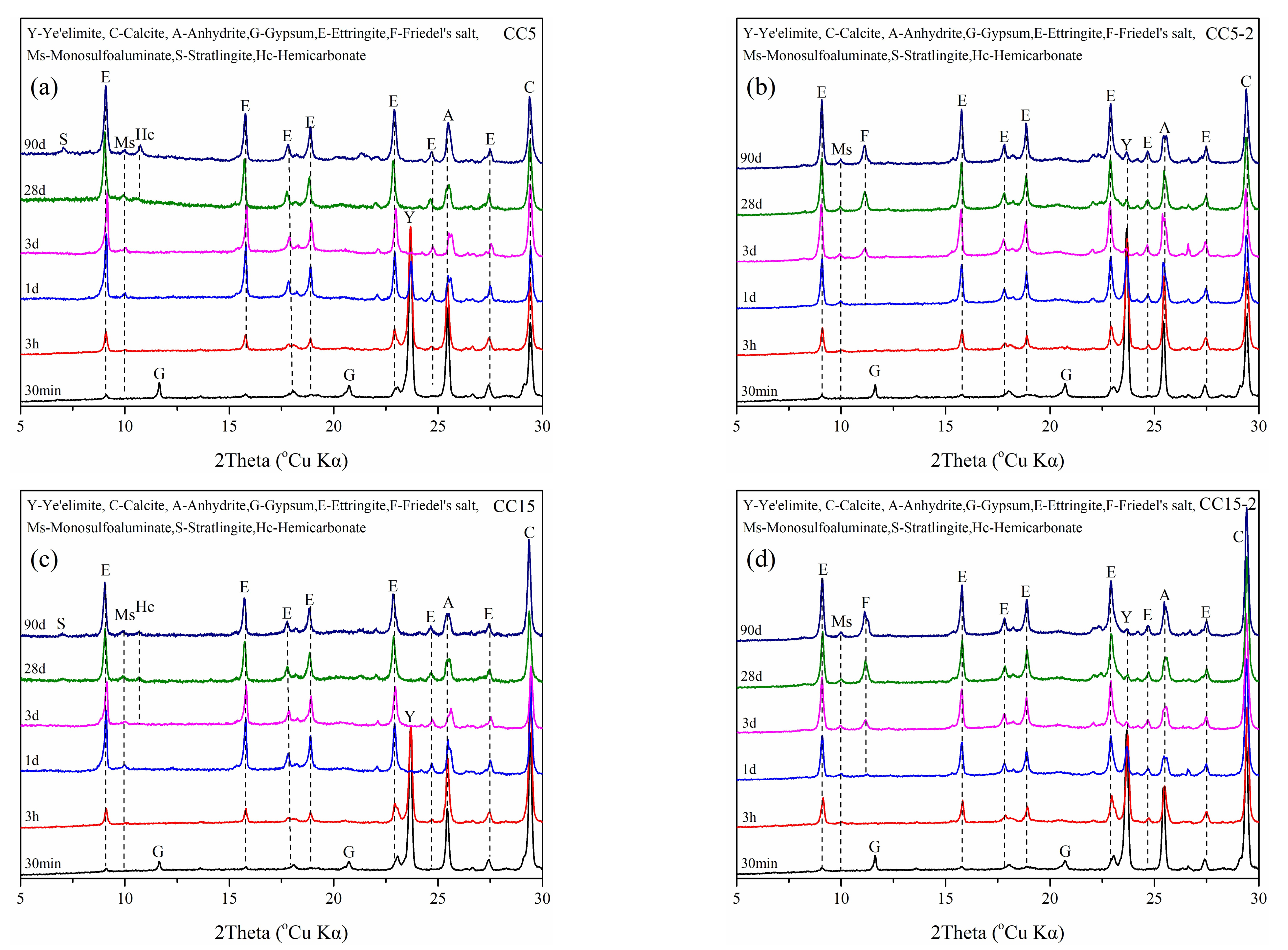

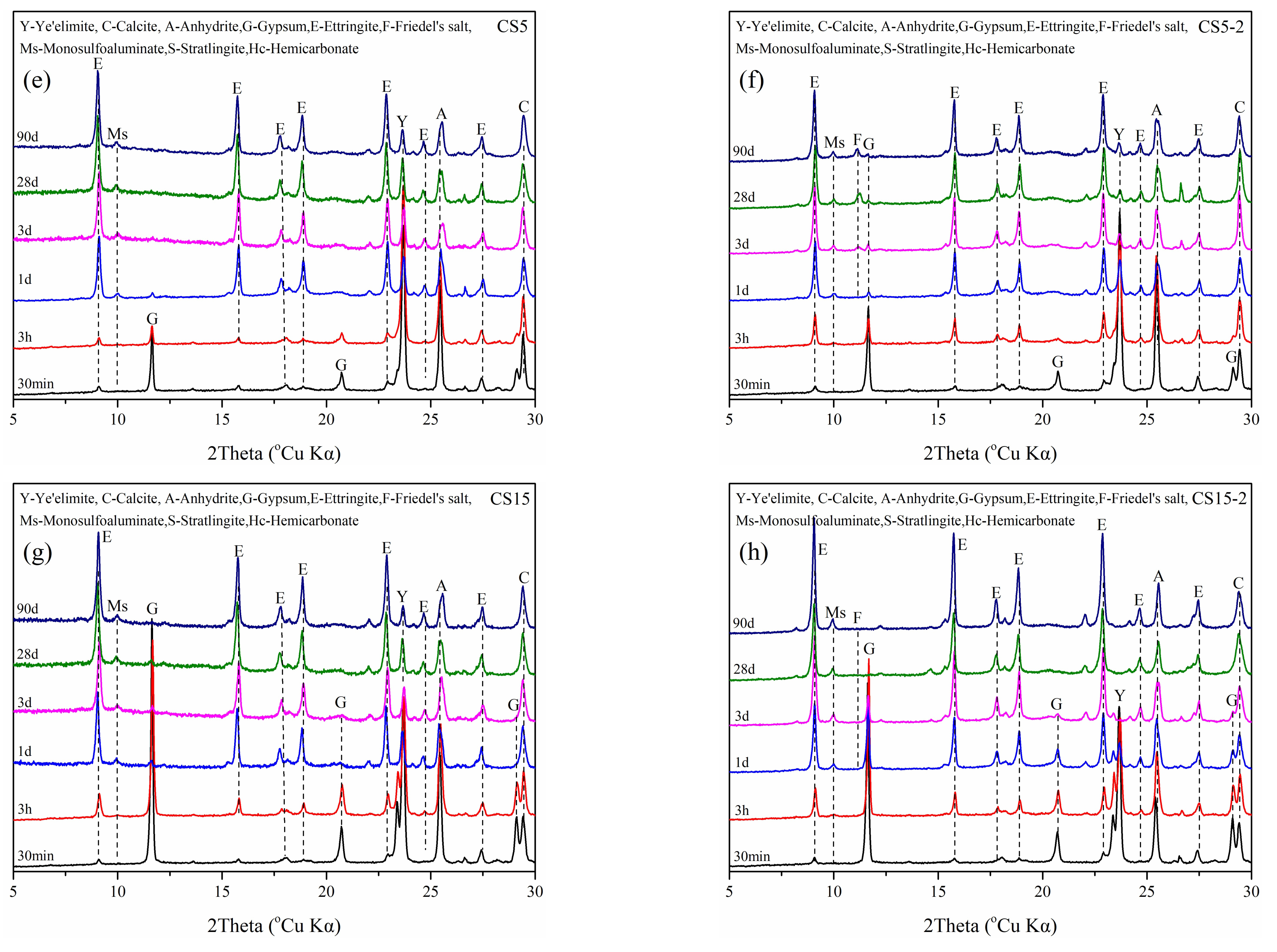

3.2. X-ray Diffraction Analyses and Phasequantitative Analyze by XRD-Rietveld Method

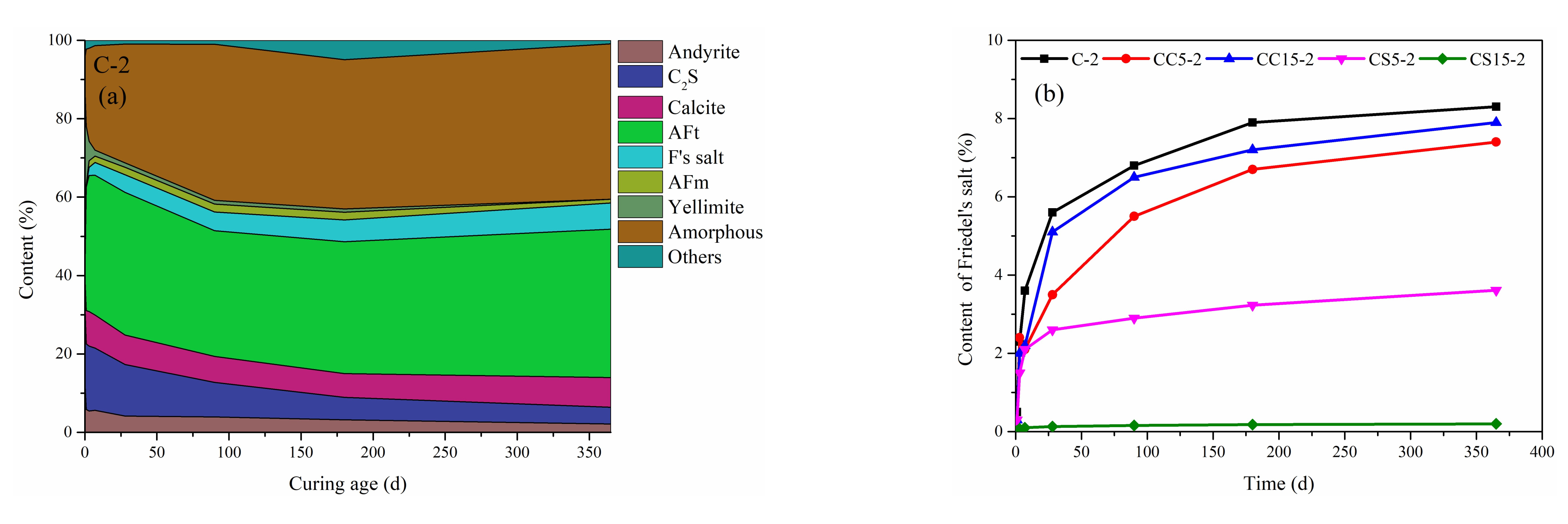

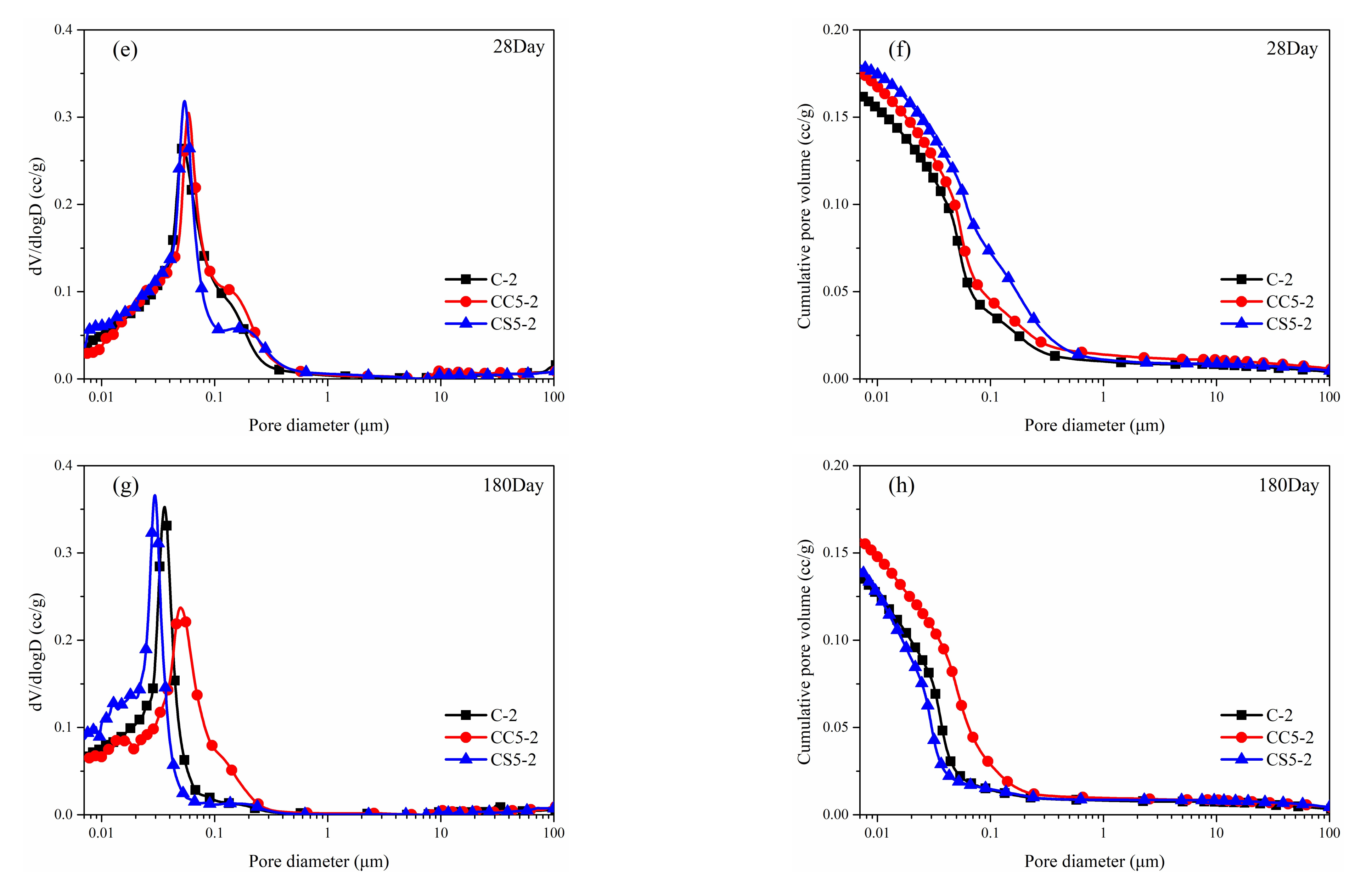

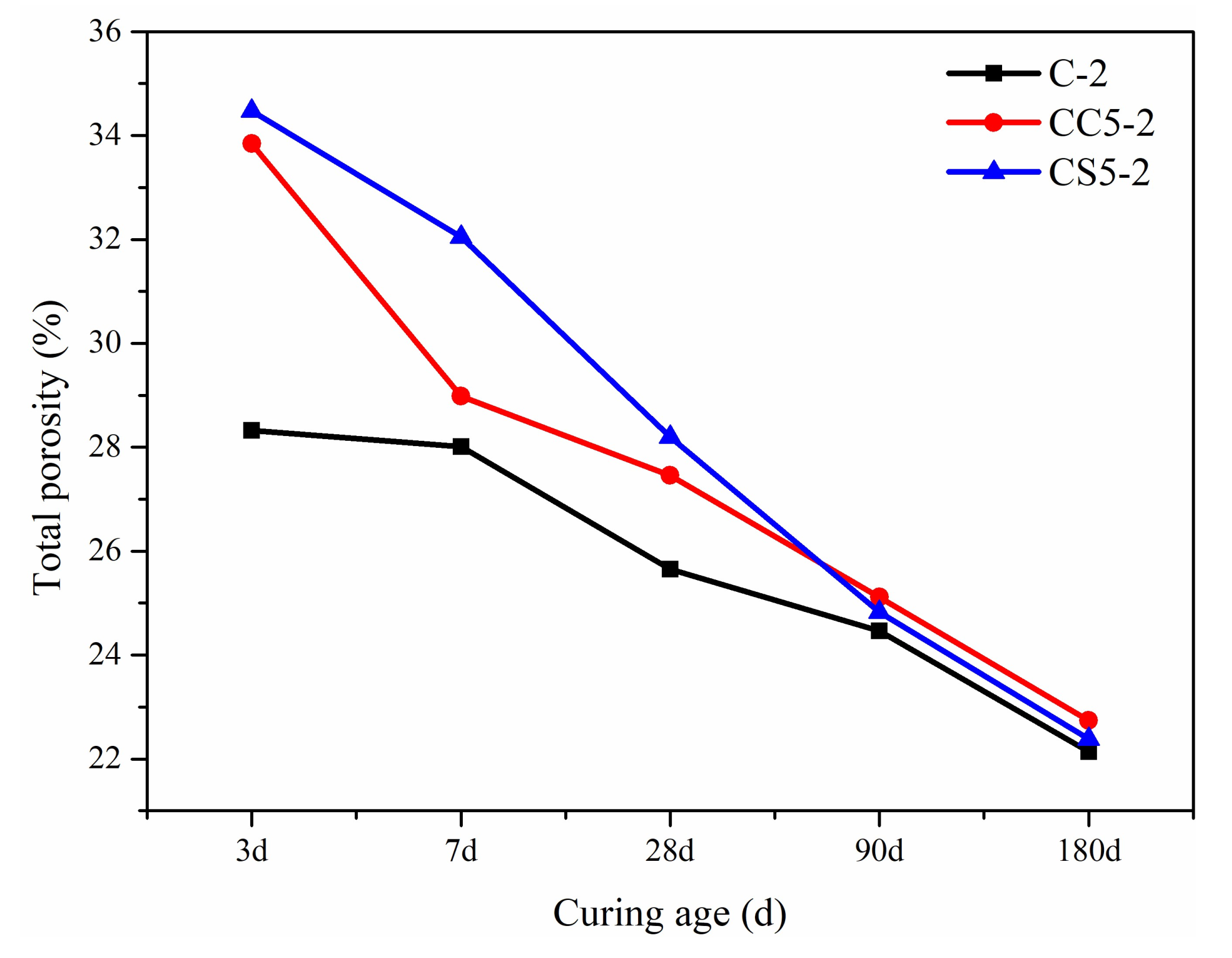

3.3. Pore Size Distribution

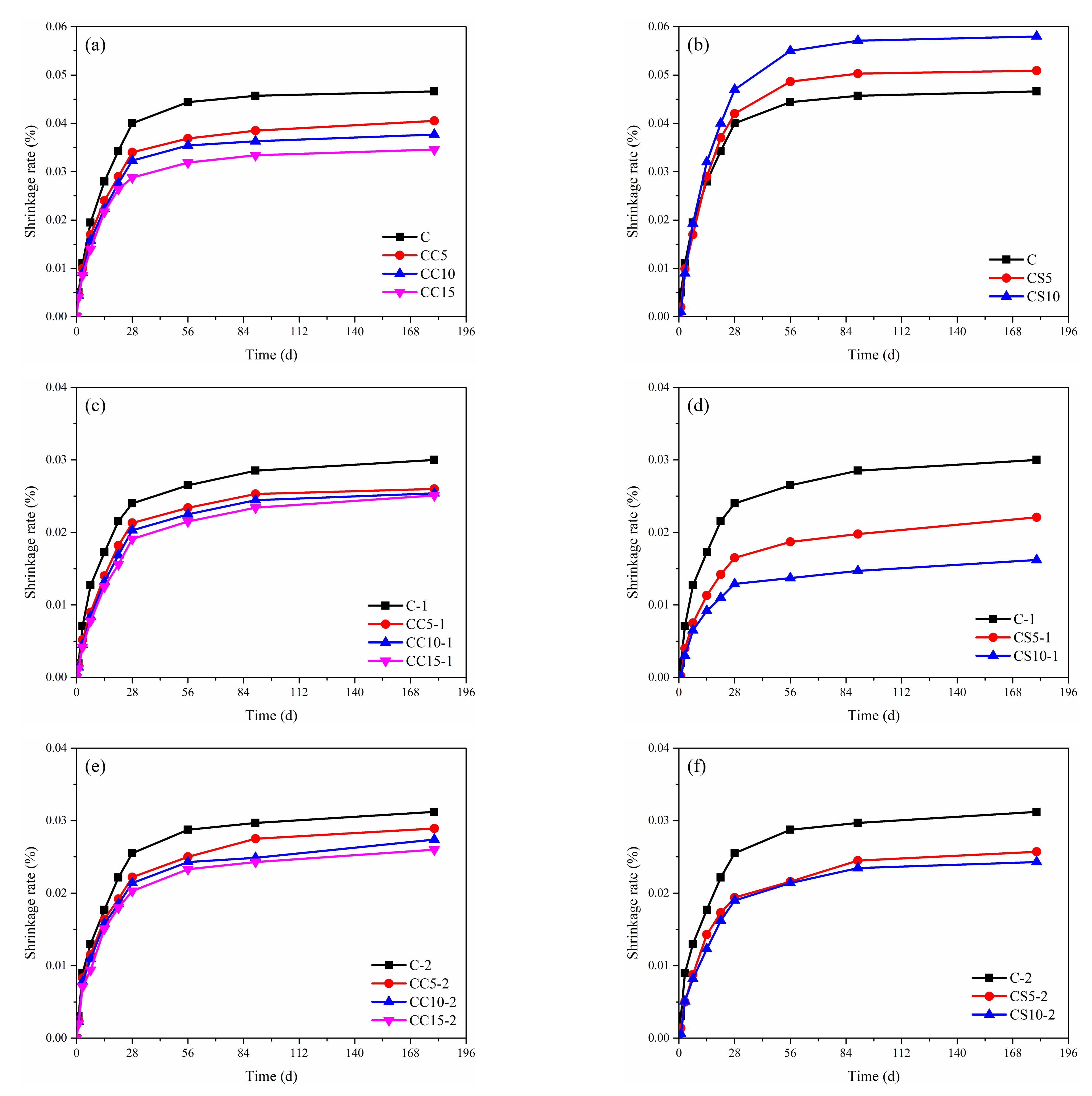

3.4. Linear Shrinkage

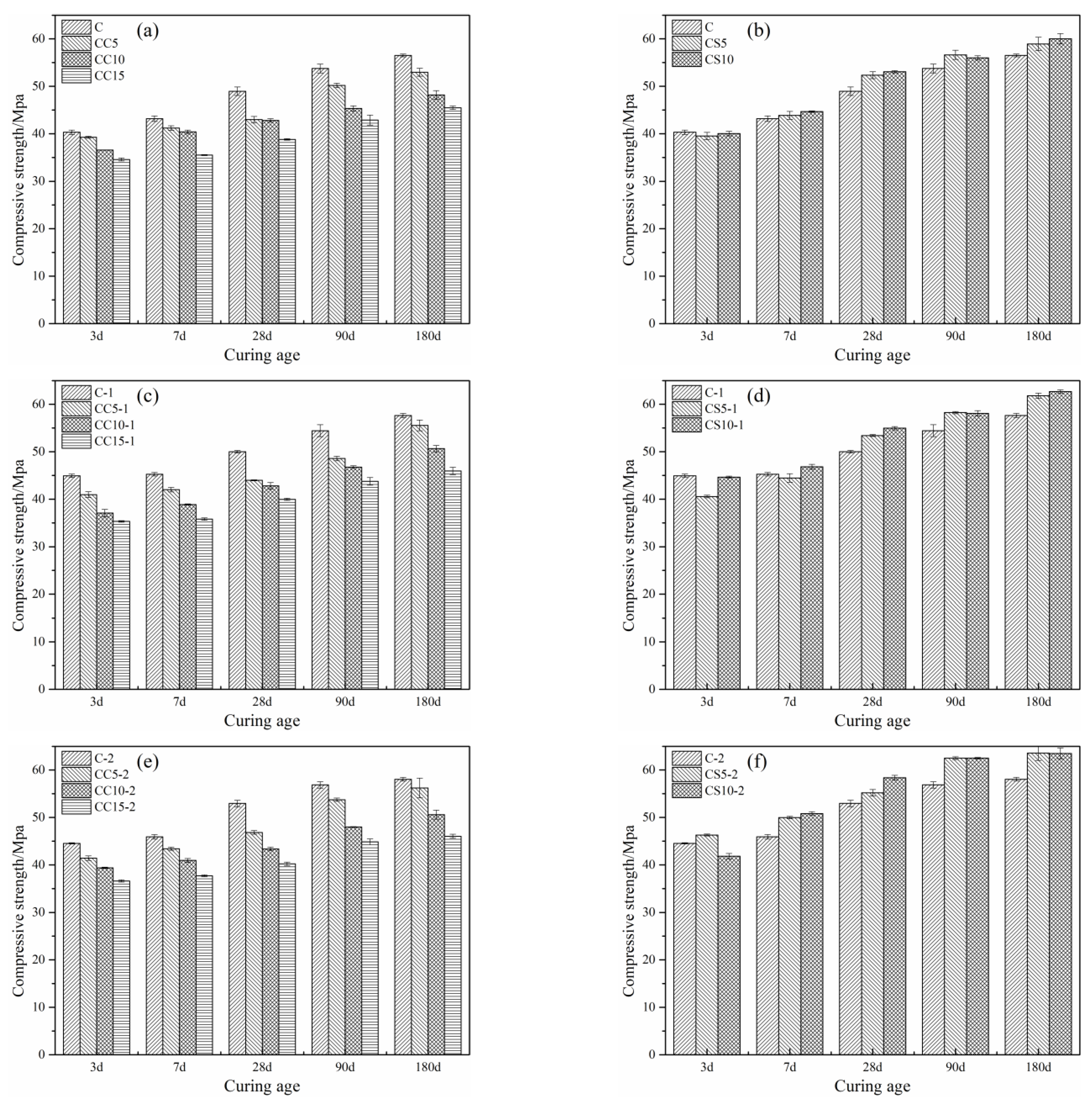

3.5. Compressive Strength of Mortar Samples

3.5.1. Compressive Strength of Fresh Water Mixing

3.5.2. Compressive Strength of NaCl Solutions Curing

4. Conclusions

- (1)

- CaCO3 and gypsum both accelerate the early hydration of CSA cement and reduce the 3-day accumulate hydration heat.

- (2)

- Under NaCl solutions, CaCO3 can react with C4A3 to form Hc, which can combine with Cl− to form Friedel’s salt, while gypsum readily reacts with C4A3 to form ettringite. Both CaCO3 and gypsum can reduce the content of bound chloride ions in CSA cement paste.

- (3)

- CaCO3 and gypsum will obviously increase the pore size of the cement paste in the early curing stages and the pore size will become finer as the curing time extends. The total porosity of CSA with CaCO3 and gypsum is higher than that of CSA cement up to 180 days.

- (4)

- The diluting effect of CaCO3 reduces the shrinkage rate of cement paste, while the shrinkage rate found by adding gypsum is higher due to the transformation of ettringite. Under NaCl solutions, the shrinkage rates of CSA obviously decreases.

- (5)

- The compressive strength of CSA mortars containing CaCO3 decreases, while gypsum can increase the compressive strength of mortar samples. Under NaCl solutions, the compressive strength develops better.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Qiao, C.; Suraneni, P.; Weiss, J. Damage in cement pastes exposed to NaCl solutions. Constr. Build. Mater. 2018, 171, 120–127. [Google Scholar] [CrossRef]

- De Weerdt, K.; Justnes, H.; Geiker, M.R. Changes in the phase assemblage of concrete exposed to sea water. Cem. Concr. Compos. 2014, 47, 53–63. [Google Scholar] [CrossRef]

- Gartner, E. Industrially interesting approaches to “low-CO2” cements. Cem. Concr. Compos. 2004, 34, 1489–1498. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, B.; Yin, J. Determinants of the increased CO2 emission and adaption strategy in Chinese energy-intensive industry. Nat. Hazards 2011, 62, 17–30. [Google Scholar] [CrossRef]

- Quillin, K. Performance of belite–sulfoaluminate cements. Cem. Concr. Res. 2001, 31, 1341–1349. [Google Scholar] [CrossRef]

- Ioannou, S.; Paine, K.; Reig, L.; Quillin, K. Performance characteristics of concrete based on a ternary calcium sulfoaluminate–anhydrite–fly ash cement. Cem. Concr. Compos. 2015, 55, 196–204. [Google Scholar] [CrossRef] [Green Version]

- Popescu, C.D.; Muntean, M.; Sharp, J.H. Industrial trial production of low energy belite cement. Cem. Concr. Compos. 2003, 25, 689–693. [Google Scholar] [CrossRef]

- Wang, X.; Wang, J. Development and production of sulphoaluminate series cement. China Enamel 1998, 4, 3–5. [Google Scholar]

- Wang, J.; Zhang, Z.; Wan, S. The development status and prospect of sulphoaluminate cement. New Century Cem. Guide 2011, 17, 51–53. [Google Scholar]

- Huang, W.; Wen, Z.; Wang, M. Research Progress of Cement for Marine Engineering. Portland Bull. 2017, 36, 3708–3713. [Google Scholar]

- Wang, C.; Gao, H. Performance test of high-durability concrete for rapid construction. Water Transp. Eng. 2019, 6, 34–38. [Google Scholar]

- Zhang, Y.; Zhuang, H.; Shi, J.; Huang, J.; Zhang, J. Time-dependent characteristic and similarity of chloride diffusivity in concrete. Mag. Concr. Res. 2018, 70, 129–137. [Google Scholar] [CrossRef]

- Wang, W.; Lu, C. Time-varying law of rebar corrosion rate in fly ash concrete. J. Hazard. Mater. 2018, 360, 520–528. [Google Scholar] [CrossRef] [PubMed]

- Martin-Perez, B.; Zibarab, H.; Hootonb, R.D.; Thomas, M.D.A. A study of the effect of chloride binding on service life predictions. Cem. Concr. Res. 2000, 30, 1215–1223. [Google Scholar] [CrossRef]

- Chang, H.; Feng, P.; Lyu, K.; Liu, J. A novel method for assessing C-S-H chloride adsorption in cement pastes. Constr. Build. Mater. 2019, 225, 324–331. [Google Scholar] [CrossRef]

- Falzone, G.; Balonis, M.; Sant, G. X-AFm stabilization as a mechanism of bypassing conversion phenomena in calcium aluminate cements. Cem. Concr. Res. 2015, 72, 54–68. [Google Scholar] [CrossRef]

- Pelletier-Chaignat, L.; Winnefeld, F.; Lothenbach, B.; Müller, C.J. Beneficial use of limestone filler with calcium sulphoaluminate cement. Constr. Build. Mater. 2012, 26, 619–627. [Google Scholar] [CrossRef]

- Kevin, D.; Ingram, K.E.D. A Review of Limestone Additions to Portland Cement and Concrete. Cem. Concr. Res. 1991, 13, 165–170. [Google Scholar]

- Dhandapani, Y.; Santhanam, M.; Kaladharan, G.; Ramanathan, S. Towards ternary binders involving limestone additions—A review. Cem. Concr. Res. 2021, 143, 106396. [Google Scholar] [CrossRef]

- Xu, J.; Chen, J.; Lu, D.; Xu, Z.; Hooton, R.D. Effect of dolomite powder on the hydration and properties of calcium sulfoaluminate cements with different gypsum contents. Constr. Build. Mater. 2019, 225, 302–310. [Google Scholar] [CrossRef]

- Shi, H.; Yu, Z.; Ma, J.; Ni, C.; Shen, X. Properties of Portland cement paste blended with coral sand powder. Constr. Build. Mater. 2019, 203, 662–669. [Google Scholar] [CrossRef]

- Shi, H.; Wu, Q.; Yu, Z.; Ma, J.; Shen, X. Properties of eco-friendly coral sand powder—Calcium sulfoaluminate cement binary system. Constr. Build. Mater. 2020, 263, 120181. [Google Scholar] [CrossRef]

- Ma, J.; Yu, Z.; Ni, C.; Shi, H.; Shen, X. Effects of limestone powder on the hydration and microstructure development of calcium sulphoaluminate cement under long-term curing. Constr. Build. Mater. 2019, 199, 688–695. [Google Scholar] [CrossRef]

- Zhao, J.; Cai, G.; Gao, D. Analysis of anti-chloride ion corrosion mechanism of sulphoaluminate cement concrete. J. Build. Mater. 2011, 14, 357–361. [Google Scholar]

- Li, P.; Ma, Z.; Zhang, Z.; Li, X.; Lu, X.; Hou, P.; Du, P. Effect of Gypsum on Hydration and Hardening Properties of Alite Modified Calcium Sulfoaluminate Cement. Materials 2019, 12, 3131. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pelletier-Chaignat, L.; Winnefeld, F.; Lothenbach, B.; Saout, G.L.; Müller, C.J.; Famy, C. Influence of the calcium sulphate source on the hydration mechanism of Portland cement–calcium sulphoaluminate clinker–calcium sulphate binders. Cem. Concr. Compos. 2011, 33, 551–561. [Google Scholar] [CrossRef]

- Allevi, S.; Marchi, M.; Scotti, F.; Bertini, S.; Cosentino, C. Hydration of calcium sulphoaluminate clinker with additions of different calcium sulphate sources. Mater. Struct. 2015, 49, 453–466. [Google Scholar] [CrossRef]

- Huang, Y.; Li, X.; Lu, Y.; Wang, H.; Wang, Q.; Sun, H.; Li, D. Effect of mix component on the mechanical properties of coral concrete under axial compression. Constr. Build. Mater. 2019, 223, 736–754. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Wang, Q.; Shah, K.W.; Wang, W. Design and properties of seawater coral aggregate alkali-activated concrete. J. Sustain. Cem.-Based Mater. 2021, 1–15. [Google Scholar] [CrossRef]

- Montanari, L.; Suraneni, P.; Tsui-Chang, M.; Khatibmasjedi, M.; Ebead, U.; Weiss, J.; Nanni, A. Hydration, Pore Solution, and Porosity of Cementitious Pastes Made with Seawater. J. Mater. Civil Eng. 2019, 31, 04019154. [Google Scholar] [CrossRef]

- Goñi, S.; Frias, M.; Vigil de la Villa, R.; García, R. Sodium chloride effect on durability of ternary blended cement. Microstructural characterization and strength. Compos. Part B Eng. 2013, 54, 163–168. [Google Scholar] [CrossRef]

- Frias, M.; Goñi, S.; García, R.; Vigil de La Villa, R. Seawater effect on durability of ternary cements. Synergy of chloride and sulphate ions. Compos. Part B Eng. 2013, 46, 173–178. [Google Scholar] [CrossRef]

- Cao, Y.; Guo, L.; Xue, X. The influence of NaCl and Na2SO4 on the mechanism of cement hydration. J. Southeast Univ. (Nat. Sci. Ed.) 2019, 49, 712–719. [Google Scholar]

- Quennoz, A.; Scrivener, K.L. Hydration of C3A–gypsum systems. Cem. Concr. Res. 2012, 42, 1032–1041. [Google Scholar] [CrossRef]

- Pang, X.; Boul, P.; Cuello Jimenez, W. Isothermal calorimetry study of the effect of chloride accelerators on the hydration kinetics of oil well cement. Constr. Build. Mater. 2015, 77, 260–269. [Google Scholar] [CrossRef]

- Sim, S.; Lee, H.; Jeon, D.; Song, H.; Yum, W.; Kim, D.; Suh, J.-I.; Oh, J. Gypsum-Dependent Effect of NaCl on Strength Enhancement of CaO-Activated Slag Binders. Appl. Sci. 2018, 8, 2515. [Google Scholar] [CrossRef] [Green Version]

- Tang, S.W.; Zhu, H.G.; Li, Z.J.; Chen, E.; Shao, H.Y. Hydration stage identification and phase transformation of calcium sulfoaluminate cement at early age. Constr. Build. Mater. 2015, 75, 11–18. [Google Scholar] [CrossRef]

- Shen, Y.; Chen, X.; Zhang, W.; Li, X. Effect of ternesite on the hydration and properties of calcium sulfoaluminate cement. J. Therm. Anal. Calorim. 2018, 136, 687–695. [Google Scholar] [CrossRef]

- Li, C.; Wu, M.; Yao, W. Eco-efficient Cementitious System Consisting of Belite-Ye’elimite-Ferrite Cement, Limestone Filler, and Silica Fume. ACS Sustain. Chem. Eng. 2019, 7, 7941–7950. [Google Scholar] [CrossRef]

- Jeong, Y.; Hargis, C.W.; Chun, S.; Moon, J. Effect of Calcium Carbonate Fineness on Calcium Sulfoaluminate-Belite Cement. Materials 2017, 10, 900. [Google Scholar] [CrossRef] [Green Version]

- Zhen, H.; Yang, H.; Liu, M. Hydration Mechanism of Sulphoaluminate Cement. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2014, 29, 70–74. [Google Scholar]

- Guo, M.; Xiao, J.; Wang, J. Impact of the coupled substitution of CaCO3 and CaSO4·2H2O on chloride binding behavior in hydrated C3A pastes. Constr. Build. Mater. 2019, 217, 638–650. [Google Scholar] [CrossRef]

- Baquerizo, L.G.; Matschei, T.; Scrivener, K.L.; Saeidpour, M.; Wadsö, L. Hydration states of AFm cement phases. Cem. Concr. Res. 2015, 73, 143–157. [Google Scholar] [CrossRef]

- Zhu, Q.; Jiang, L.; Chen, Y.; Xu, J.; Mo, L. Effect of chloride salt type on chloride binding behavior of concrete. Constr. Build. Mater. 2012, 37, 512–517. [Google Scholar] [CrossRef]

- Birnin-Yauri, U.A.; Glasser, F.P. Friedel’s salt, Ca2Al(OH)6(Cl,OH)z2H2O its solid solutions and their role in chloride binding. Cem. Concr. Res. 1998, 28, 1713–1723. [Google Scholar] [CrossRef]

- Elgalhud, A.A.; Dhir, R.K.; Ghataora, G. Limestone addition effects on concrete porosity. Cem. Concr. Compos. 2016, 72, 222–234. [Google Scholar] [CrossRef]

- Shi, X. Research on CSA High Performance Cement Concrete Shrinkage and Creep. Qinghai Transp. Technol. 2020, 32, 83–87. [Google Scholar]

- Shoude, W.; Cheng, C.; Lingchao, L.; Xin, C. Effects of slag and limestone powder on the hydration and hardening process of alite-barium calcium sulphoaluminate cement. Constr. Build. Mater. 2012, 35, 227–231. [Google Scholar] [CrossRef]

- Berger, S.; Cau Dit Coumes, C.; Le Bescop, P.; Damidot, D. Stabilization of ZnCl2-containing wastes using calcium sulfoaluminate cement: Cement hydration, strength development and volume stability. J. Hazard. Mater. 2011, 194, 256–267. [Google Scholar] [CrossRef]

- Li, X.; Ma, Y.; Shen, X.; Zhong, Y.; Li, Y. Study of Hydration and Microstructure of Mortar Containing Coral Sand Powder Blended with SCMs. Materials 2020, 13, 4248. [Google Scholar] [CrossRef]

- Subramanian, S.; Khan, Q.; Ku, T. Strength development and prediction of calcium sulfoaluminate treated sand with optimized gypsum for replacing OPC in ground improvement. Constr. Build. Mater. 2019, 202, 308–318. [Google Scholar] [CrossRef]

| Oxide | CSA Cement |

|---|---|

| Calcium oxide, CaO | 42.97 |

| Silicon dioxide, SiO2 | 13.85 |

| Aluminum oxide, Al2O3 | 22.14 |

| Sulfur trioxide, SO3 | 11.86 |

| Ferric oxide, Fe2O3 | 1.33 |

| Magnesium oxide, MgO | 2.86 |

| Potassium oxide, K2O | 0.31 |

| Sodium oxide, Na2O | 0.09 |

| Titanium oxide, TiO2 | 0.97 |

| Manganese Oxide, MnO | 0.034 |

| Phosphorus Pentoxide, P2O5 | 0.16 |

| Loss on ignition, LOI | 2.76 |

| Mineral | Content/% |

|---|---|

| 51.53 | |

| C2S | 21.25 |

| C3A | 1.71 |

| CaSO4 | 11.52 |

| CaCO3 | 9.81 |

| C12A7 | 1.28 |

| Samples | w/c | Cement | CaCO3 | Gypsum | Water for Mixing | Water for Curing |

|---|---|---|---|---|---|---|

| C | 0.5 | 100 | 0 | 0 | Deionized water | Deionized water |

| CC5 | 0.5 | 95 | 5 | 0 | Deionized water | Deionized water |

| CC10 | 0.5 | 90 | 10 | 0 | Deionized water | Deionized water |

| CC15 | 0.5 | 85 | 15 | 0 | Deionized water | Deionized water |

| CS5 | 0.5 | 95 | 0 | 5 | Deionized water | Deionized water |

| CS10 | 0.5 | 90 | 0 | 10 | Deionized water | Deionized water |

| C-1 | 0.5 | 100 | 0 | 0 | Deionized water | 3.5% NaCl solution |

| CC5-1 | 0.5 | 95 | 5 | 0 | Deionized water | 3.5% NaCl solution |

| CC10-1 | 0.5 | 90 | 10 | 0 | Deionized water | 3.5% NaCl solution |

| CC15-1 | 0.5 | 85 | 15 | 0 | Deionized water | 3.5% NaCl solution |

| CS5-1 | 0.5 | 95 | 0 | 5 | Deionized water | 3.5% NaCl solution |

| CS10-1 | 0.5 | 90 | 0 | 10 | Deionized water | 3.5% NaCl solution |

| C-2 | 0.5 | 100 | 0 | 0 | 3.5% NaCl solution | 3.5% NaCl solution |

| CC5-2 | 0.5 | 95 | 5 | 0 | 3.5% NaCl solution | 3.5% NaCl solution |

| CC10-2 | 0.5 | 90 | 10 | 0 | 3.5% NaCl solution | 3.5% NaCl solution |

| CC15-2 | 0.5 | 85 | 15 | 0 | 3.5% NaCl solution | 3.5% NaCl solution |

| CS5-2 | 0.5 | 95 | 0 | 5 | 3.5% NaCl solution | 3.5% NaCl solution |

| CS10-2 | 0.5 | 90 | 0 | 10 | 3.5% NaCl solution | 3.5% NaCl solution |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Song, S.; Zhang, Y.; Xing, T.; Ma, Y.; Qian, H. Hydration and Mechanical Properties of Calcium Sulphoaluminate Cement Containing Calcium Carbonate and Gypsum under NaCl Solutions. Materials 2022, 15, 816. https://doi.org/10.3390/ma15030816

Wang J, Song S, Zhang Y, Xing T, Ma Y, Qian H. Hydration and Mechanical Properties of Calcium Sulphoaluminate Cement Containing Calcium Carbonate and Gypsum under NaCl Solutions. Materials. 2022; 15(3):816. https://doi.org/10.3390/ma15030816

Chicago/Turabian StyleWang, Jianzheng, Shilin Song, Yu Zhang, Tao Xing, Ying Ma, and Haiyan Qian. 2022. "Hydration and Mechanical Properties of Calcium Sulphoaluminate Cement Containing Calcium Carbonate and Gypsum under NaCl Solutions" Materials 15, no. 3: 816. https://doi.org/10.3390/ma15030816

APA StyleWang, J., Song, S., Zhang, Y., Xing, T., Ma, Y., & Qian, H. (2022). Hydration and Mechanical Properties of Calcium Sulphoaluminate Cement Containing Calcium Carbonate and Gypsum under NaCl Solutions. Materials, 15(3), 816. https://doi.org/10.3390/ma15030816