Fast-Acquiring High-Quality Prony Series Parameters of Asphalt Concrete through Viscoelastic Continuous Spectral Models

Abstract

:1. Introduction

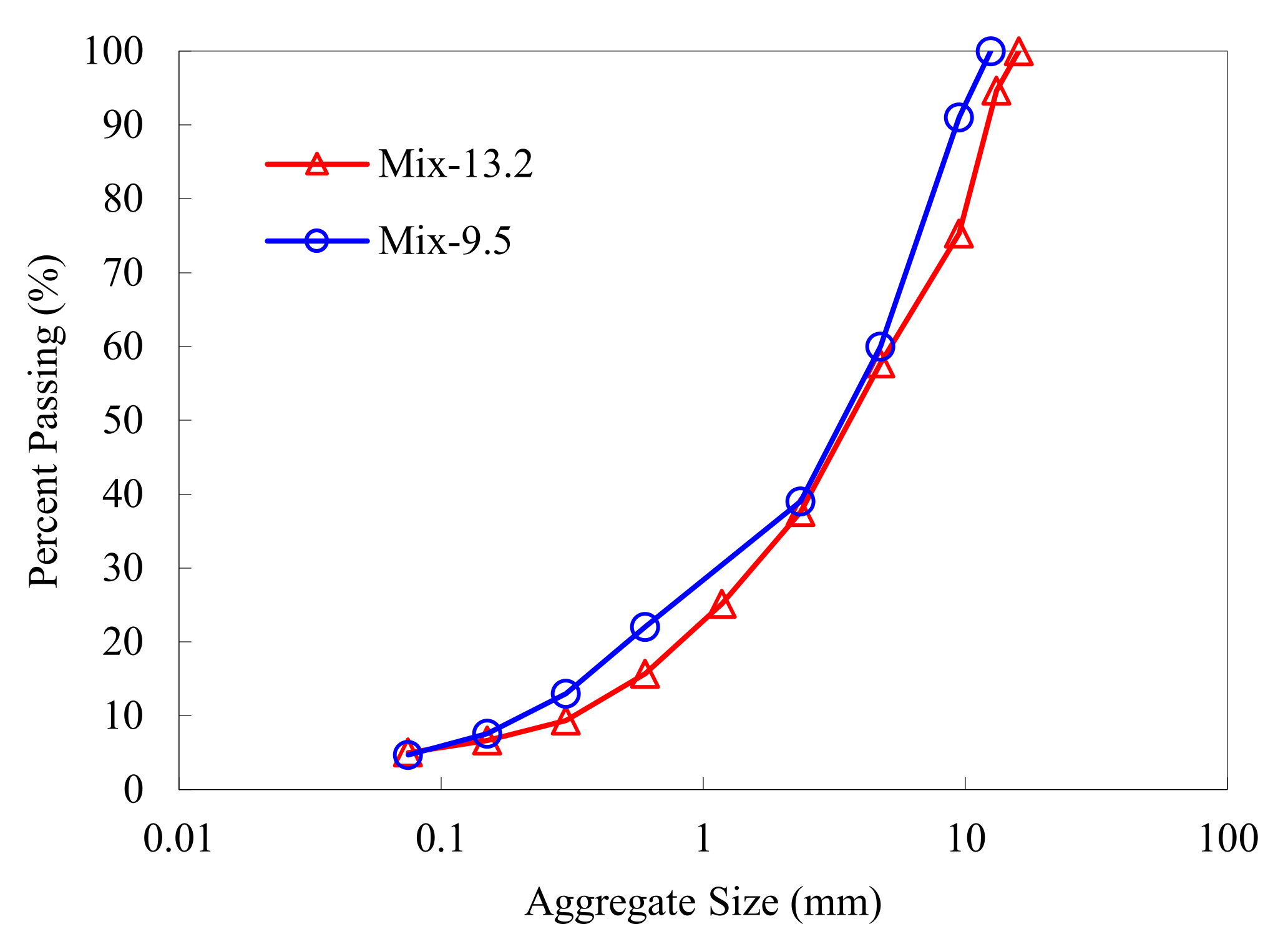

2. Materials and Complex Modulus Test

3. Methodology

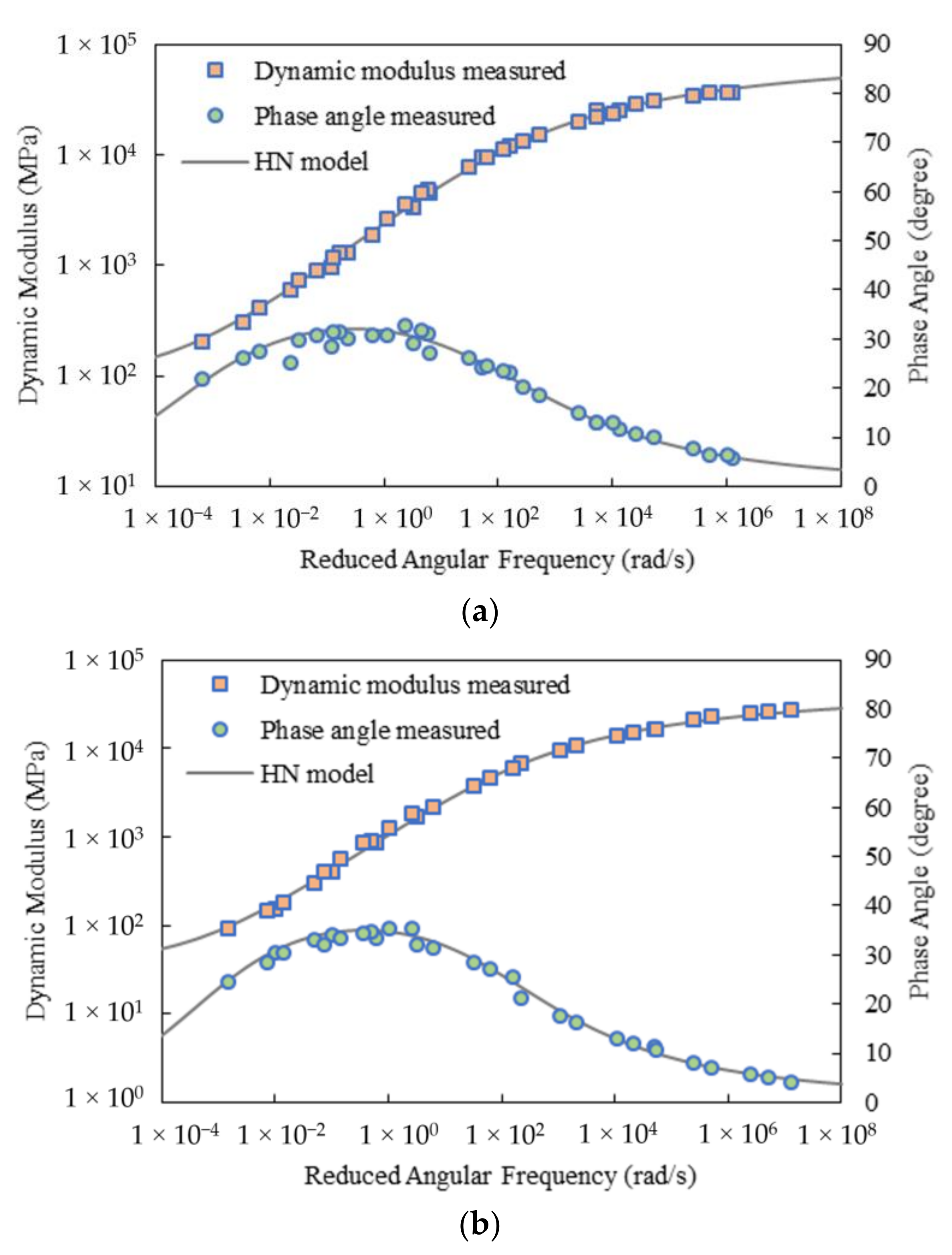

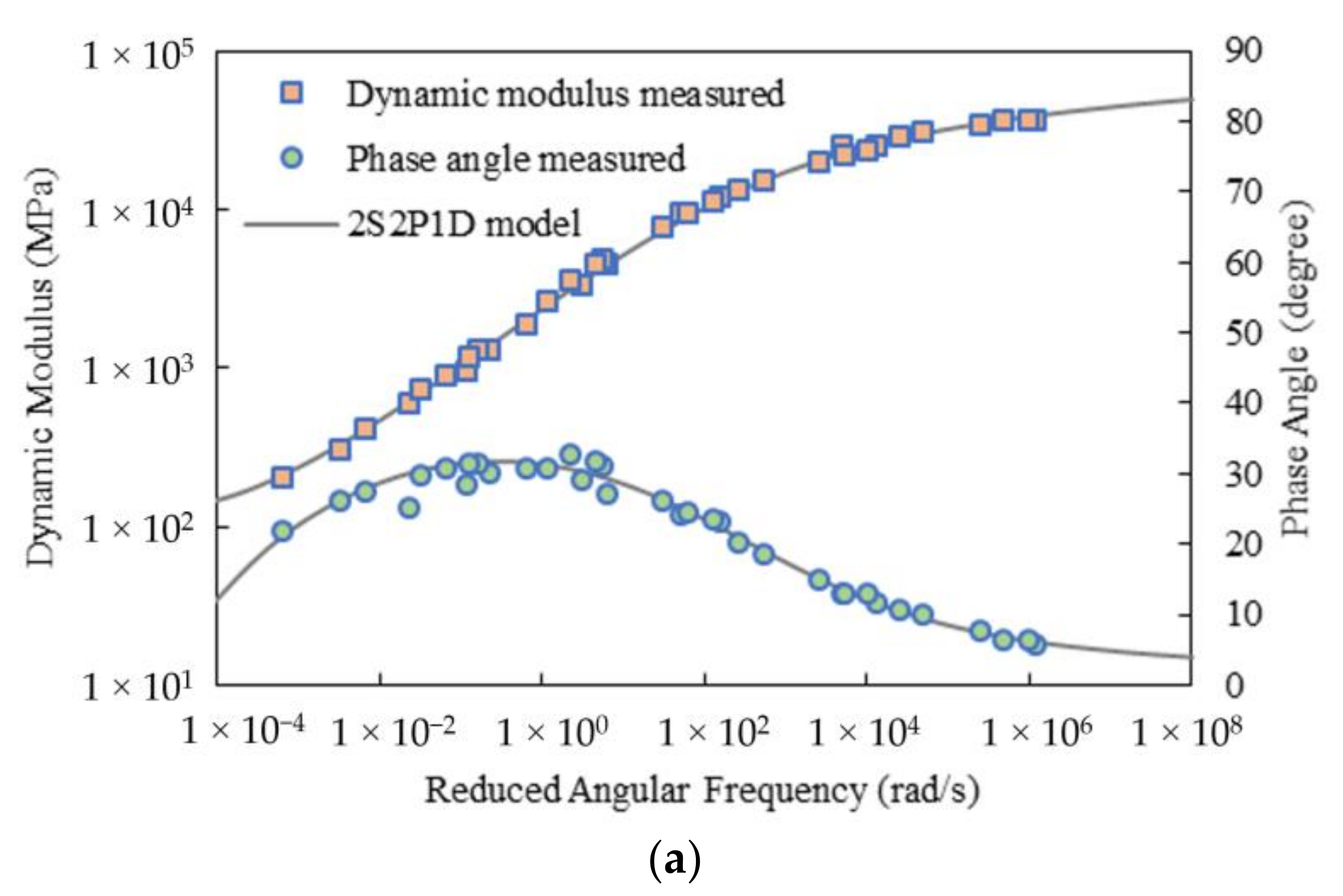

3.1. Viscoelastic Master Curve Models

3.2. Continuous Relaxation and Retardation Spectra

3.3. Construction of Master Curves

3.4. Determination of Prony Series Parameters

4. Results and Discussion

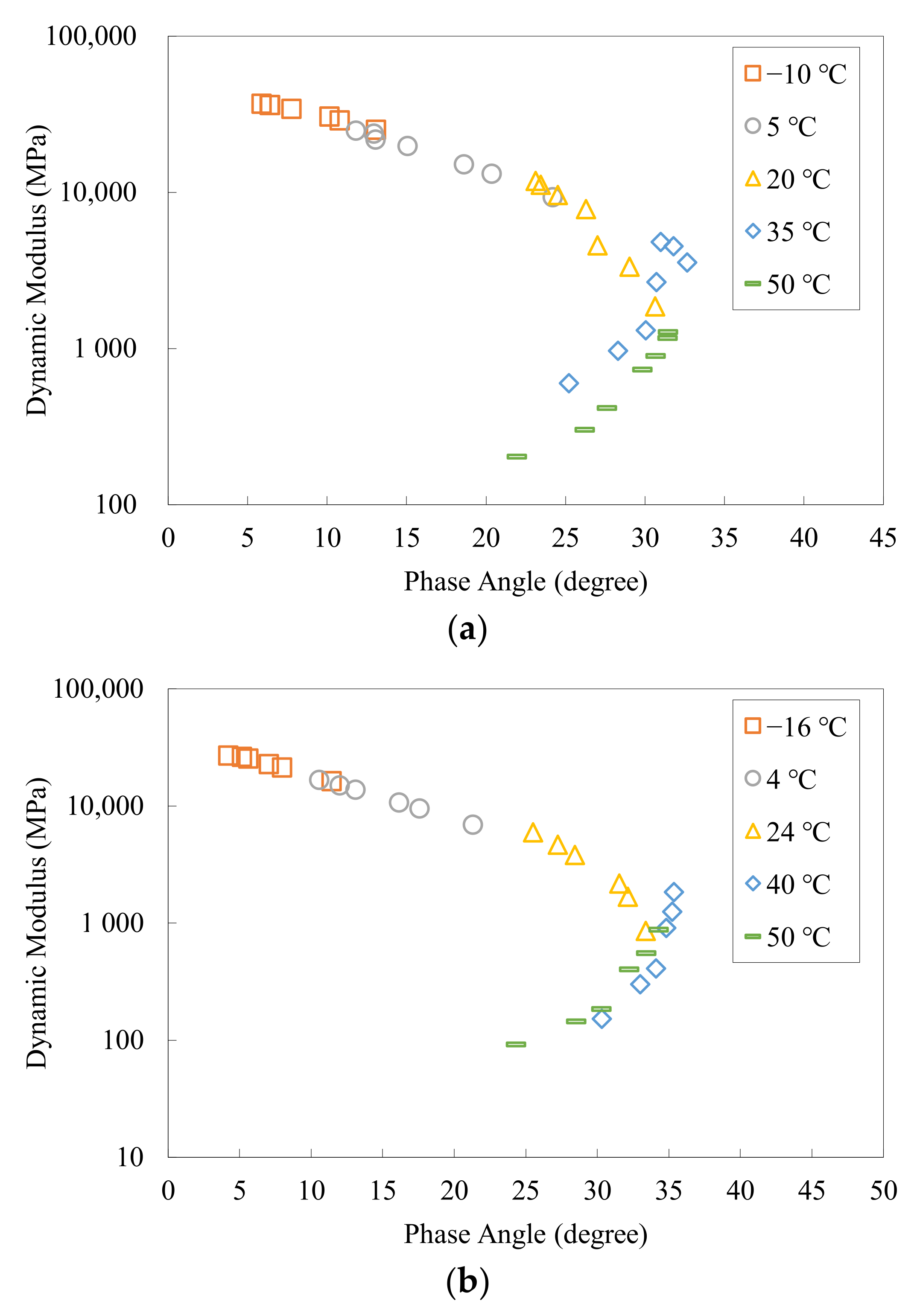

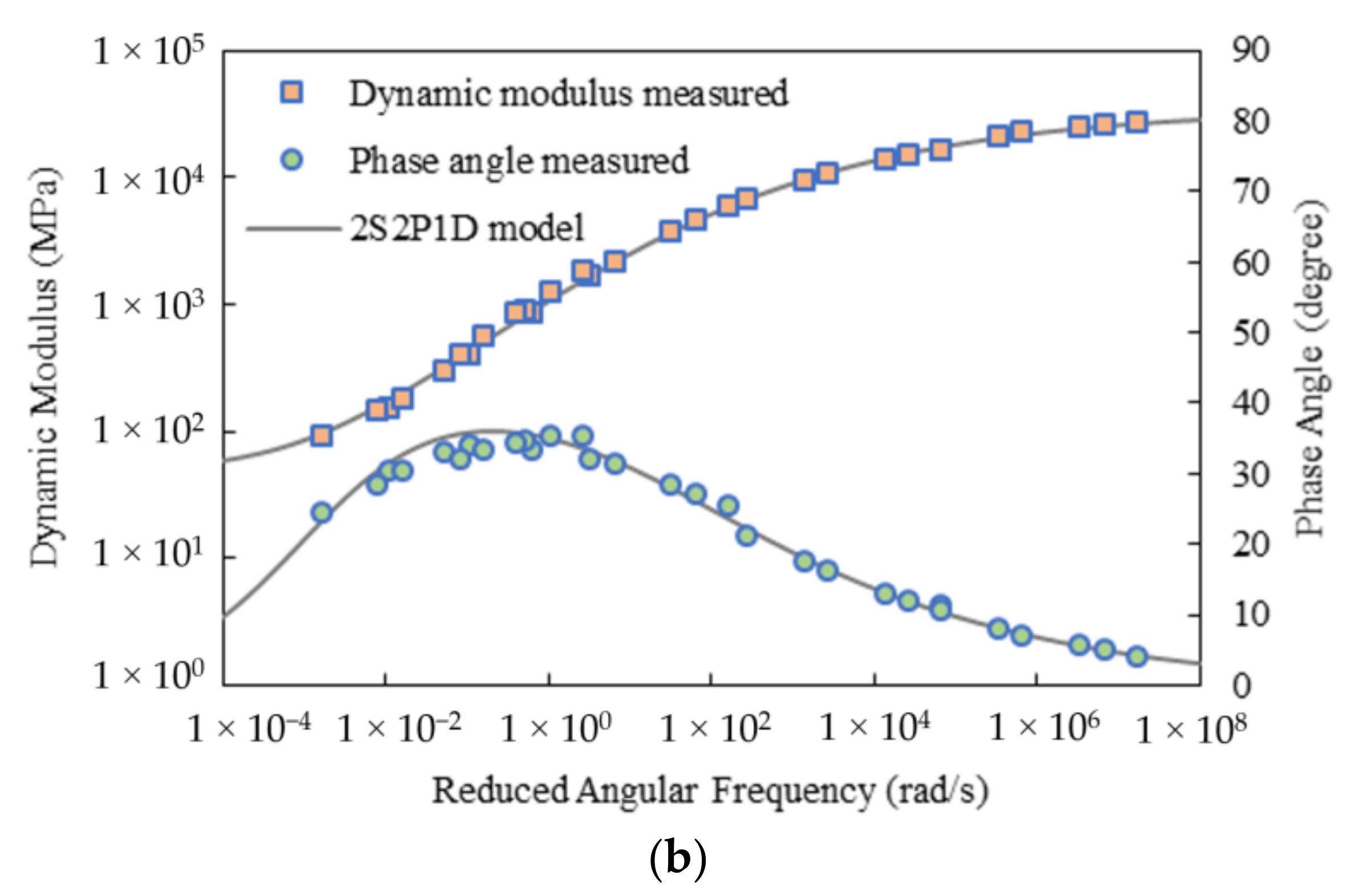

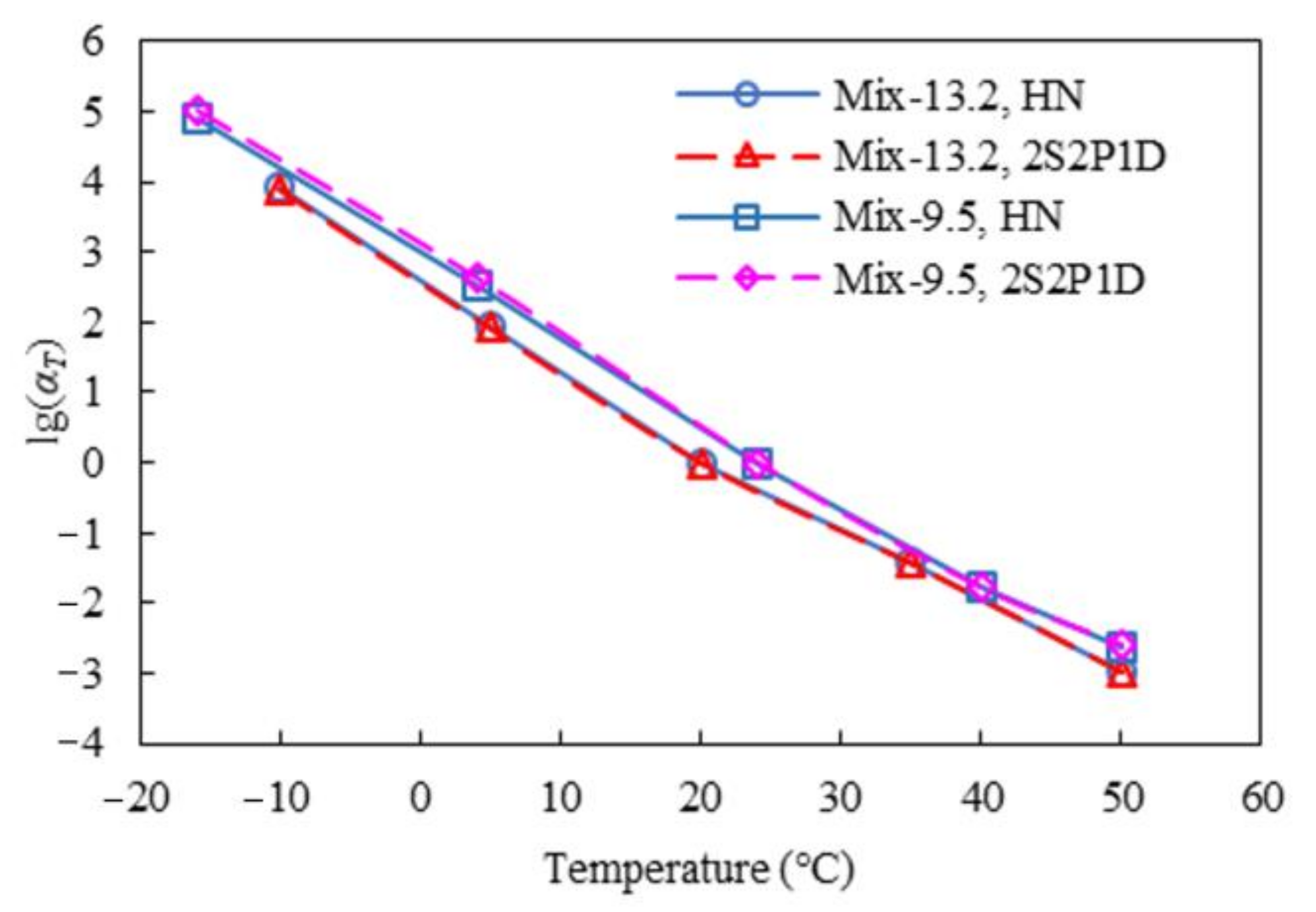

4.1. Examination of Test Data Quality of Asphalt Concrete

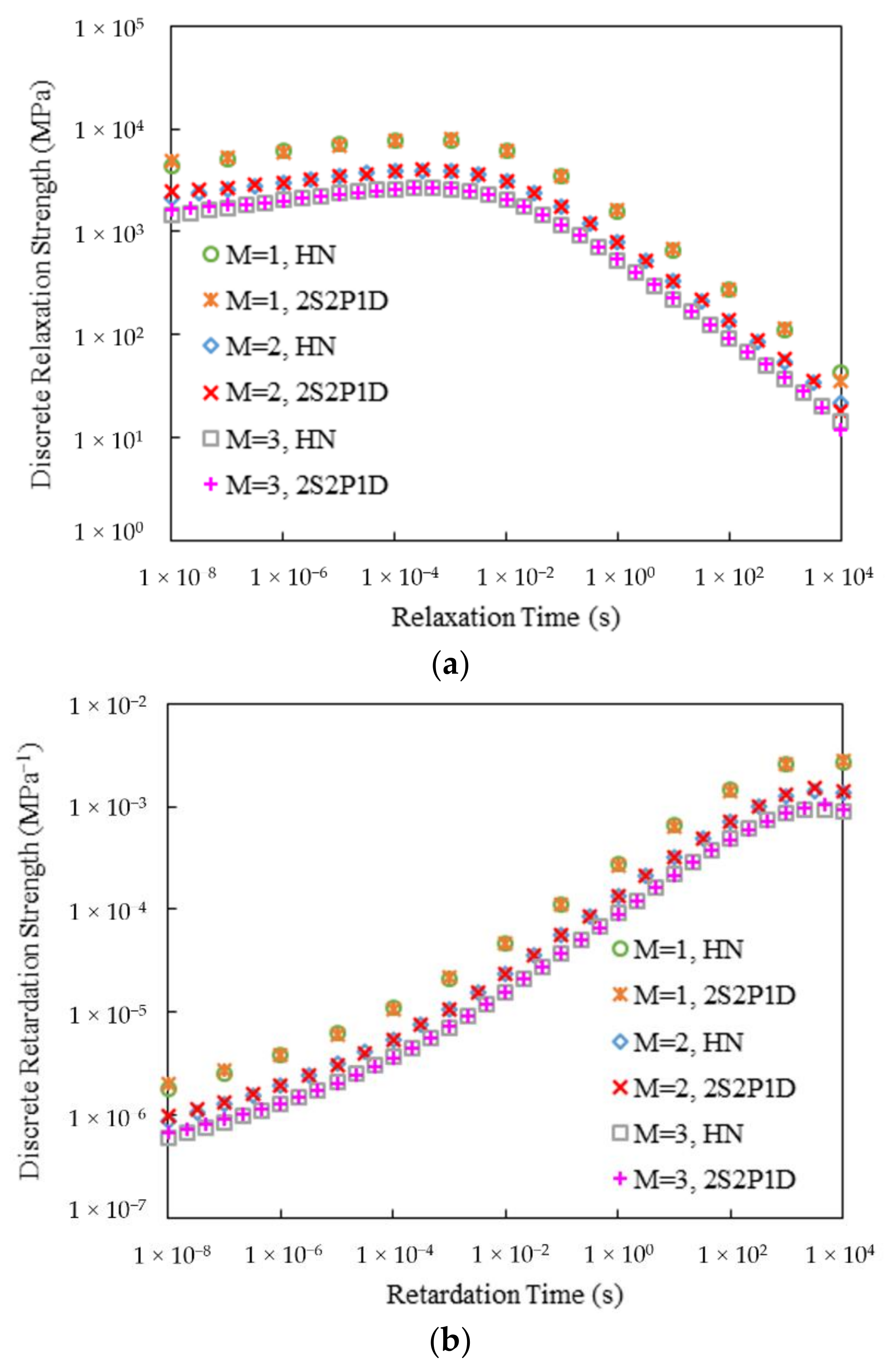

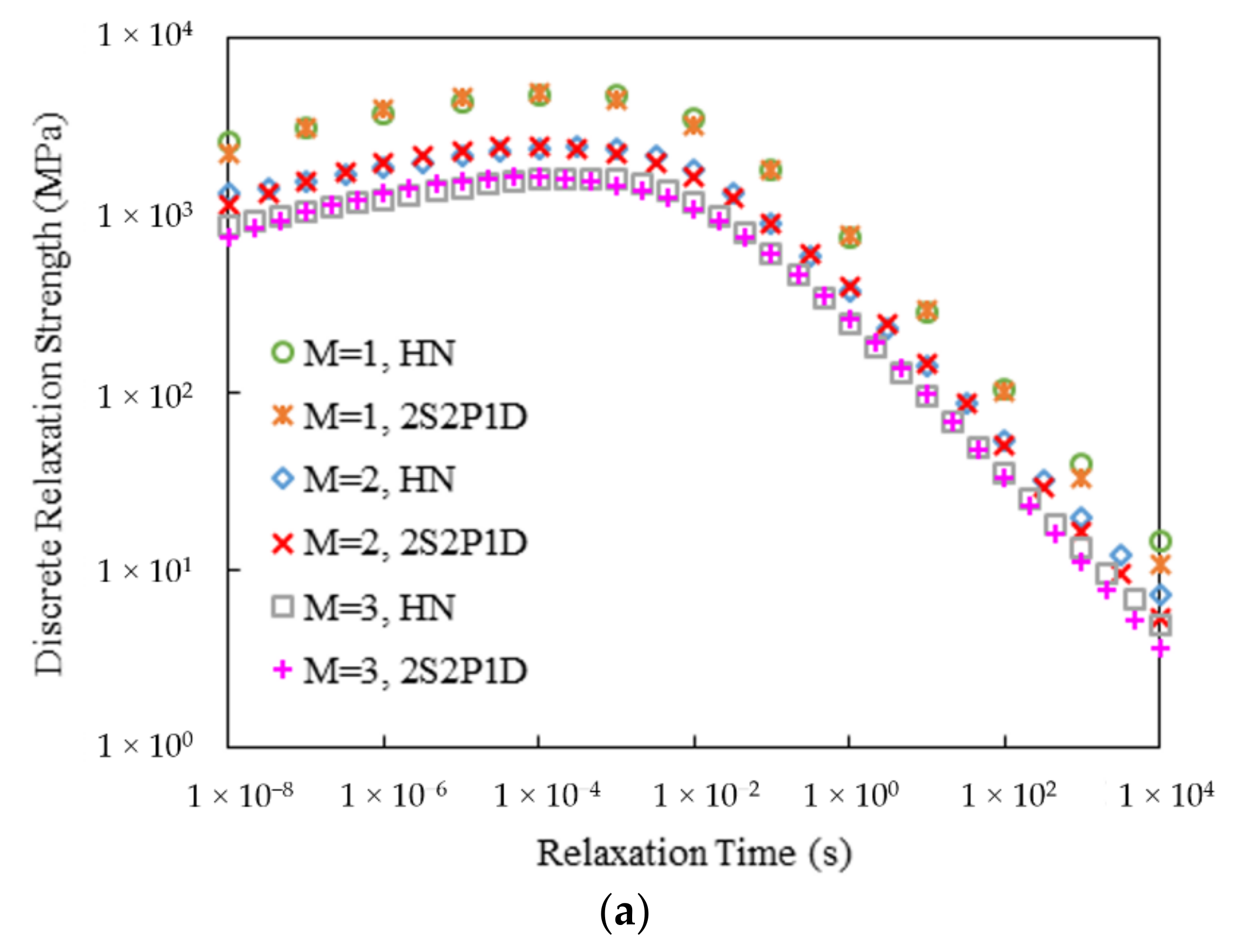

4.2. Analysis of Results from the Developed Method

4.3. Comparison to the Conventional Sigmoidal Model Method

5. Summary and Conclusions

- (1)

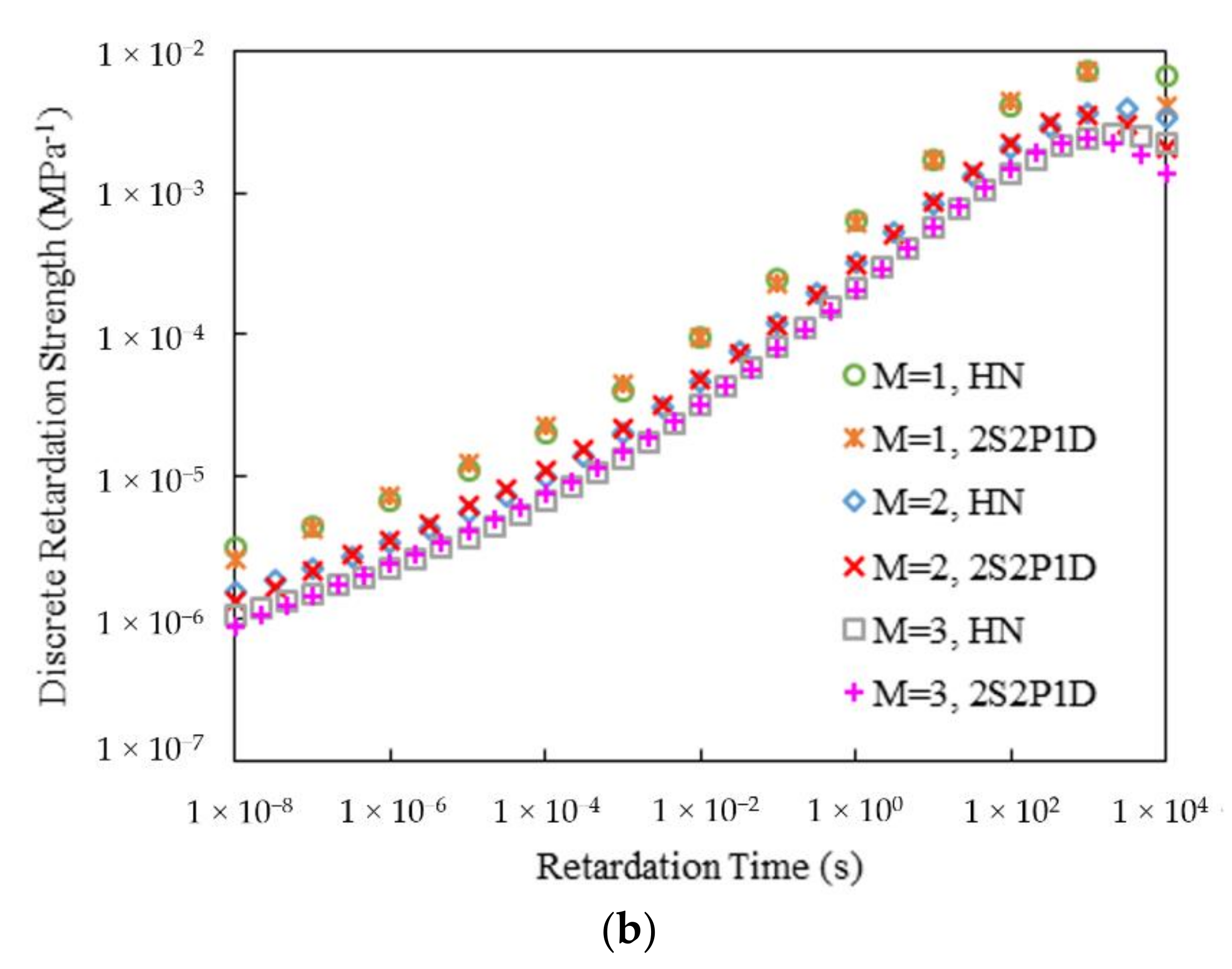

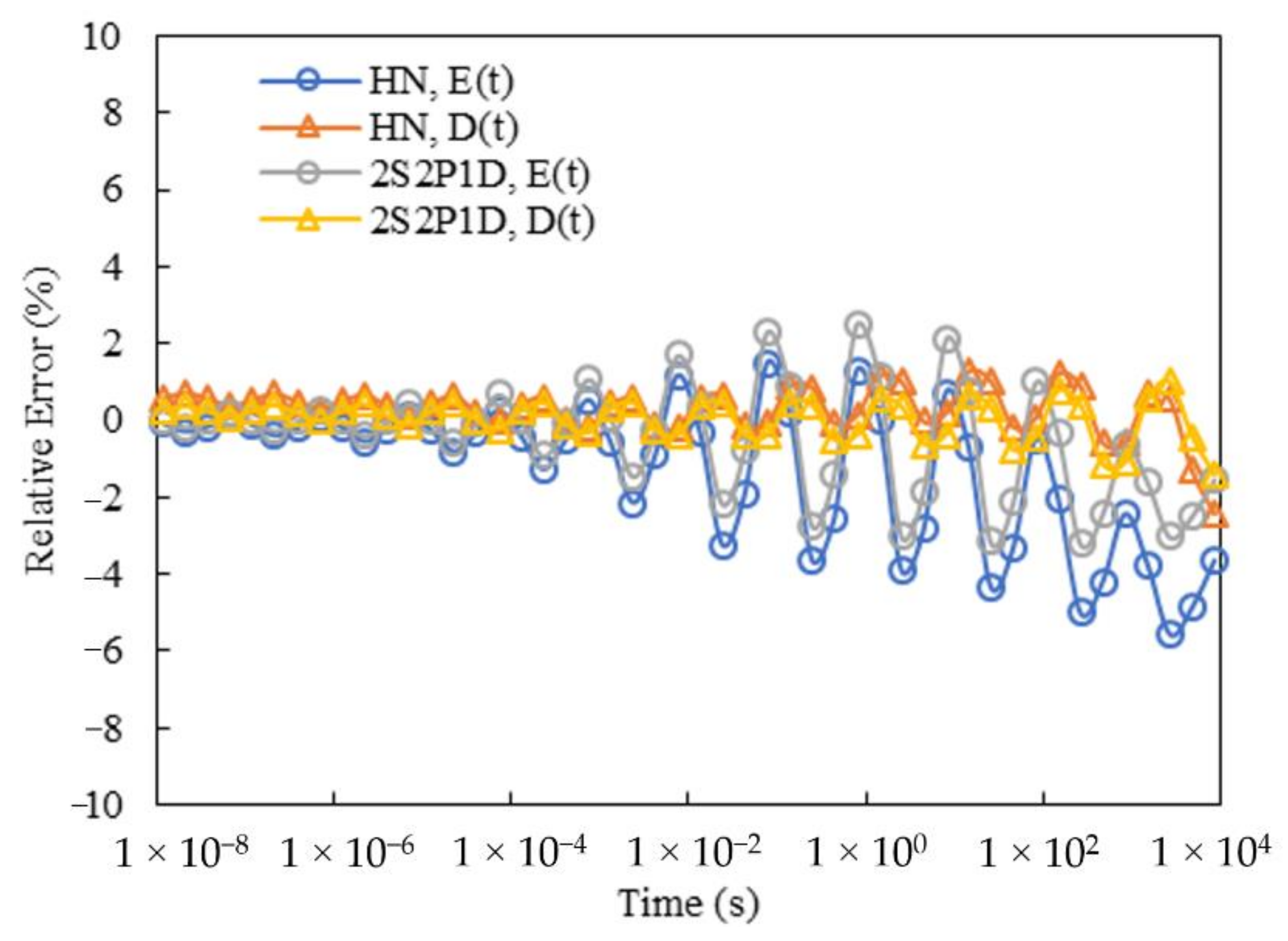

- The HN and 2S2P1D models yielded slightly different continuous spectral patterns at shorter relaxation times and longer retardation times. However, at the region covered by the test data, the continuous spectra of the two complex modulus models were very close to each other. Thus, the two models can generate comparable Prony series parameters within the time or frequency range covered by test data.

- (2)

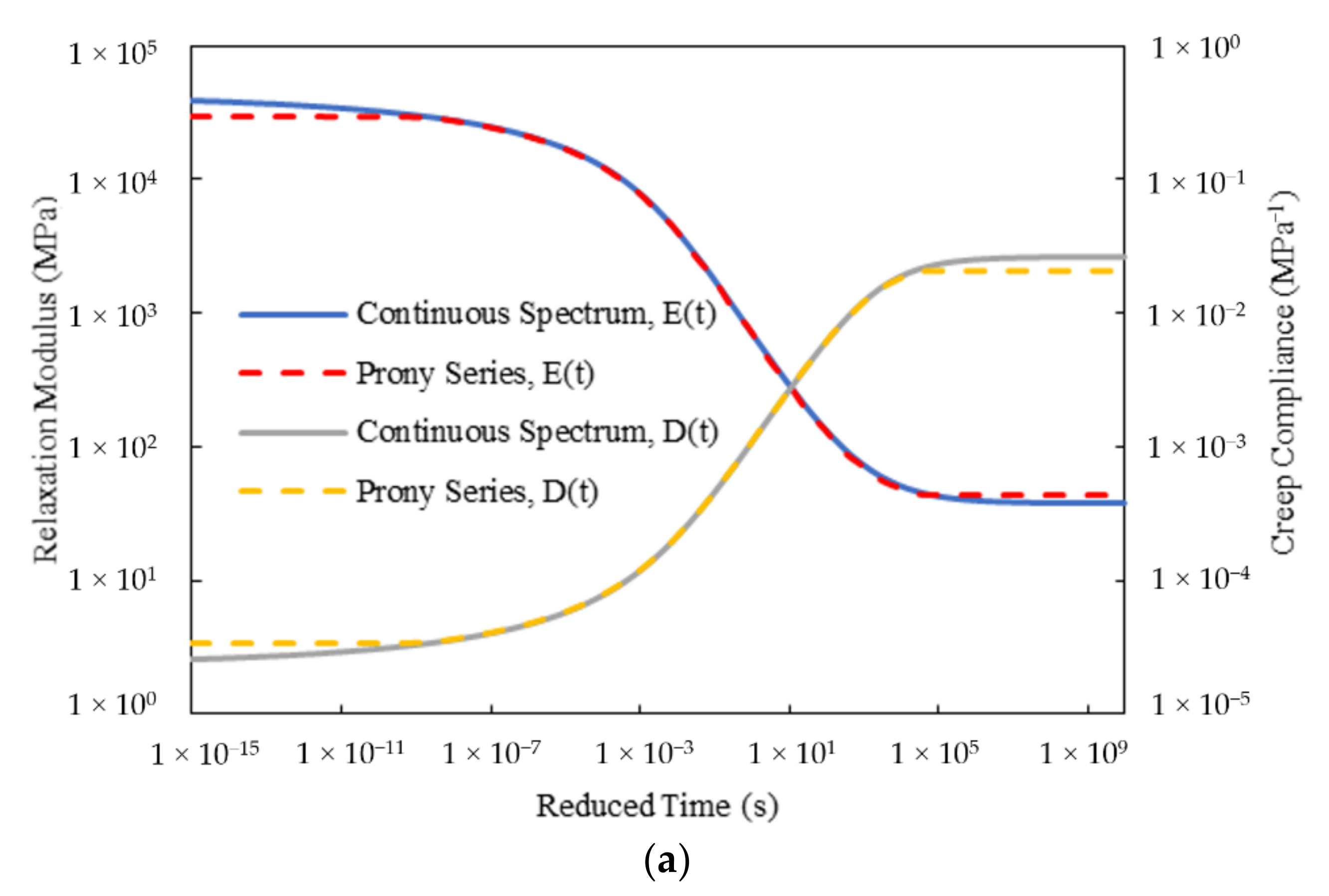

- By means of the positive analytical expressions of the continuous spectra, local spectrum oscillations and undesirable negative spectrum strengths were successfully eliminated, thus generating high-quality Prony series parameters.

- (3)

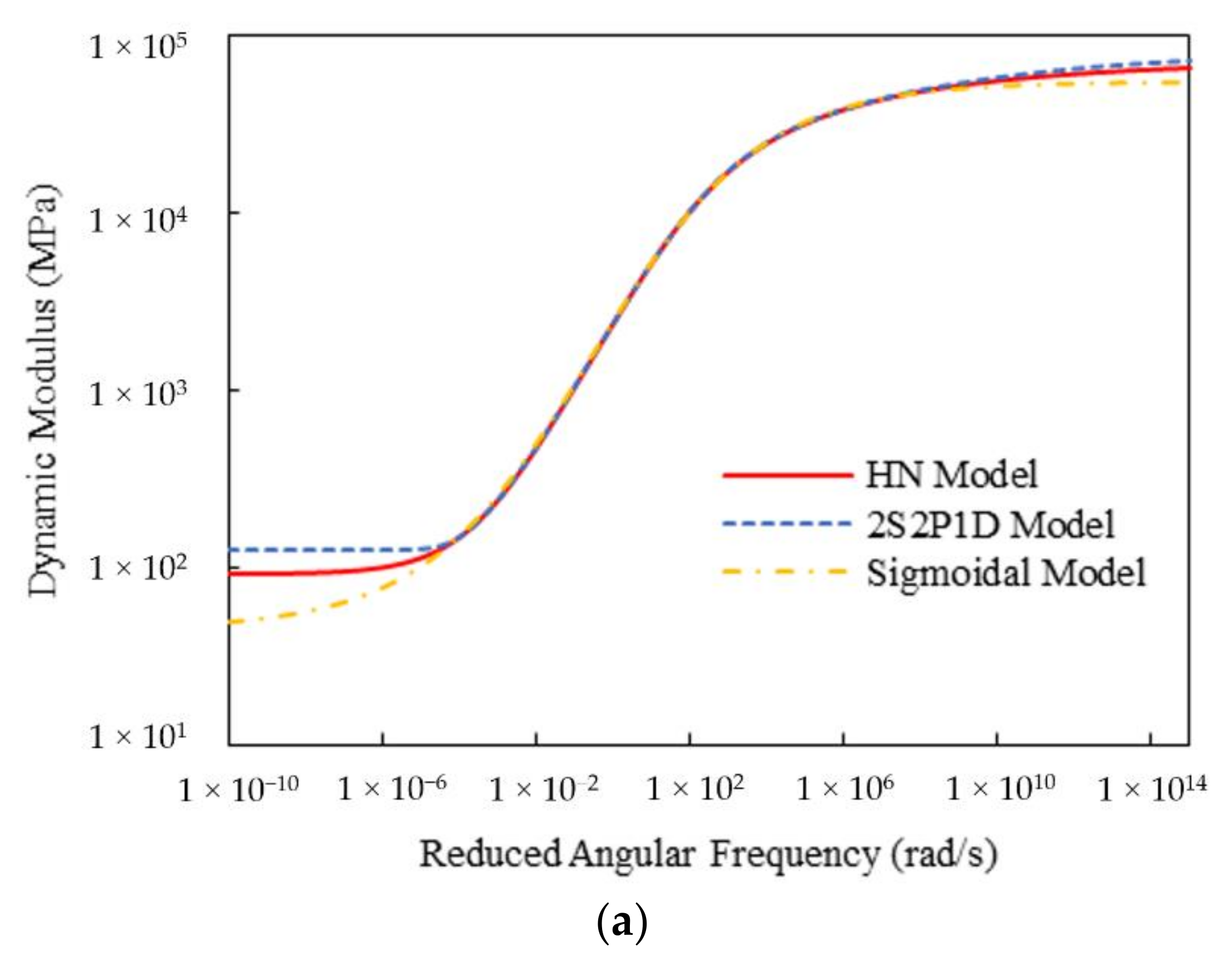

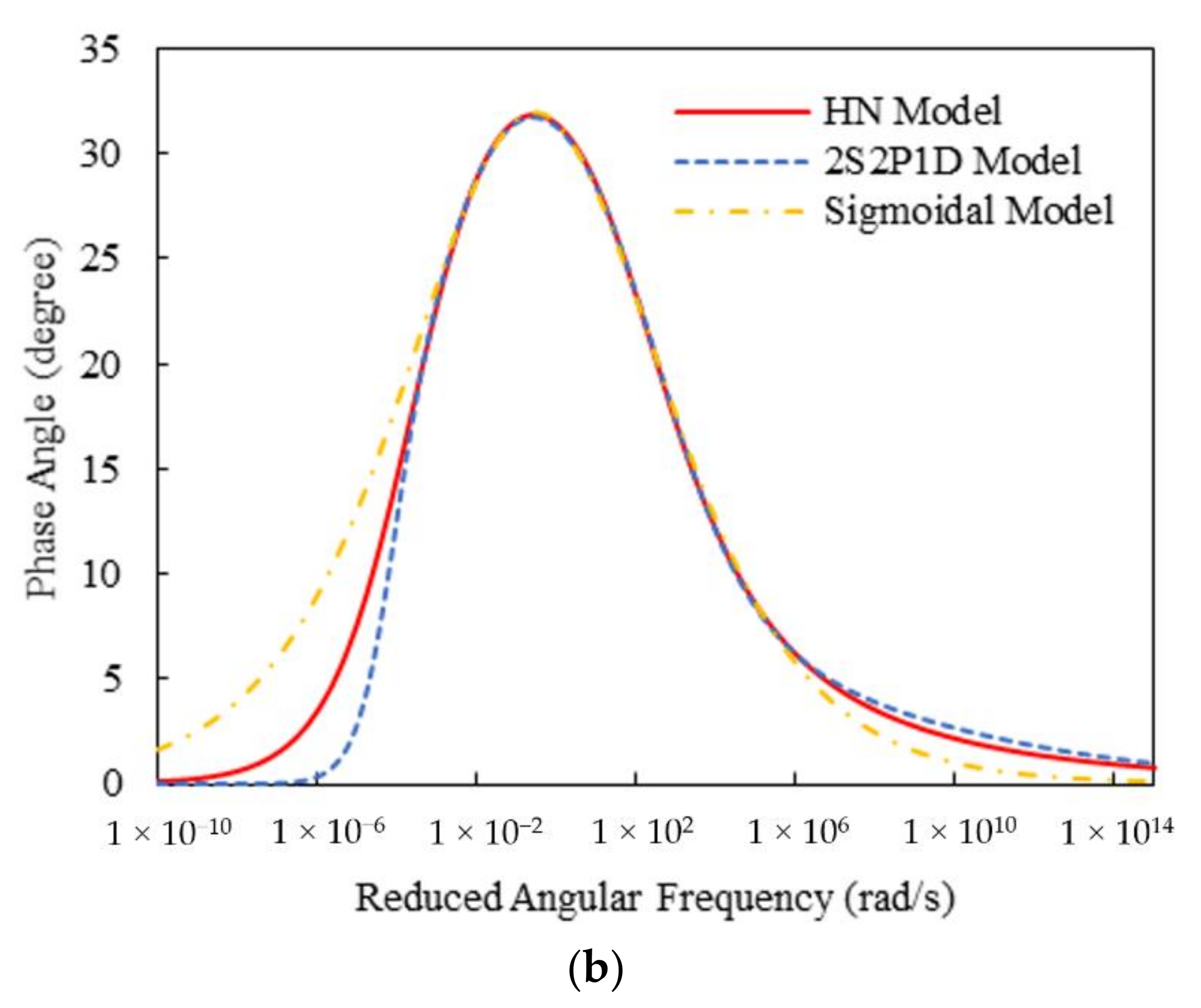

- The HN and 2S2P1D models provide non-centrosymmetric curve patterns for the dynamic modulus master curves on the log-log scale and non-axisymmetric curve patterns for the phase angle master curves on the logarithmic angular frequency scale. Therefore, they performed better than the traditional Sigmoidal model in fitting to the complex modulus test data.

- (4)

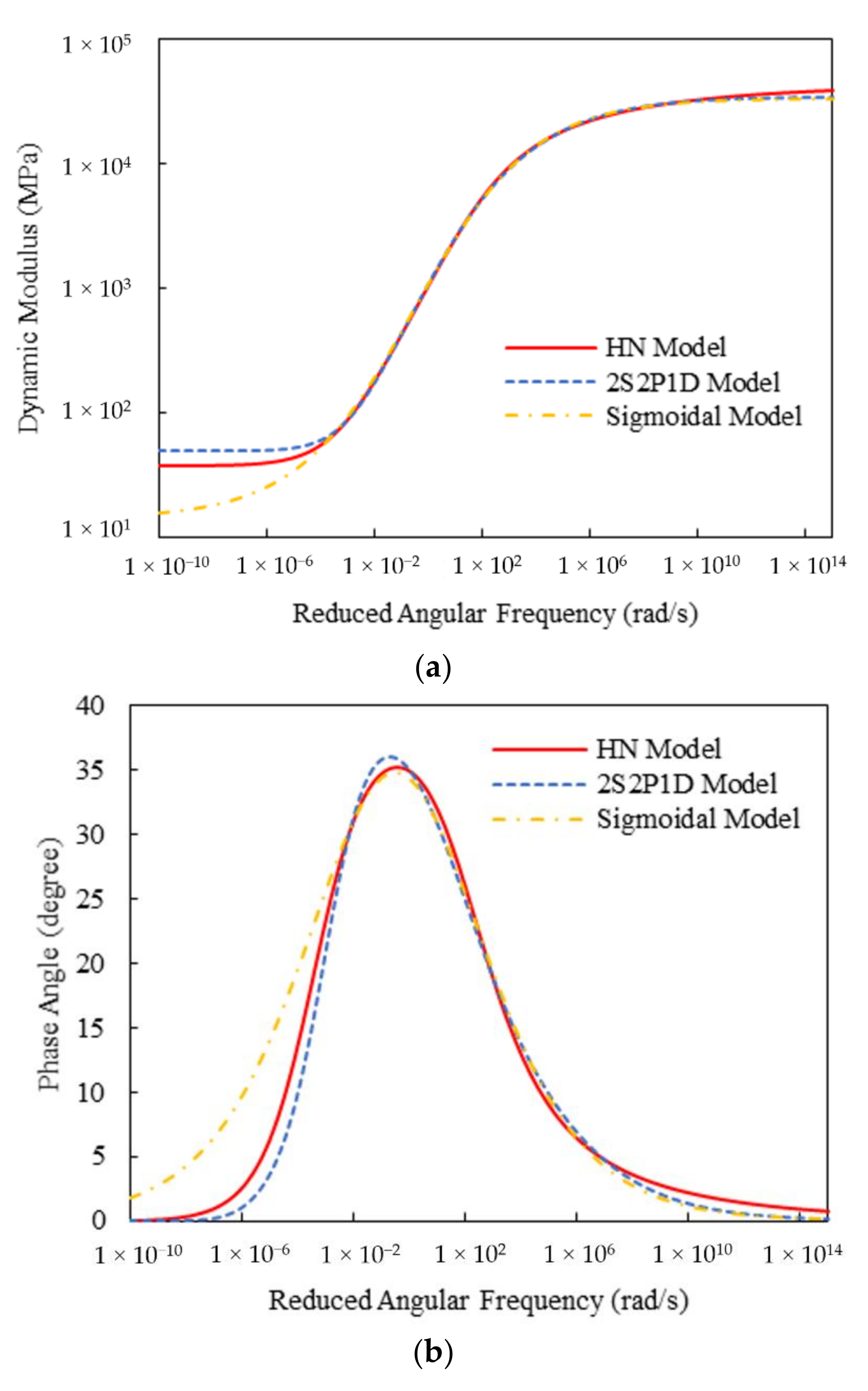

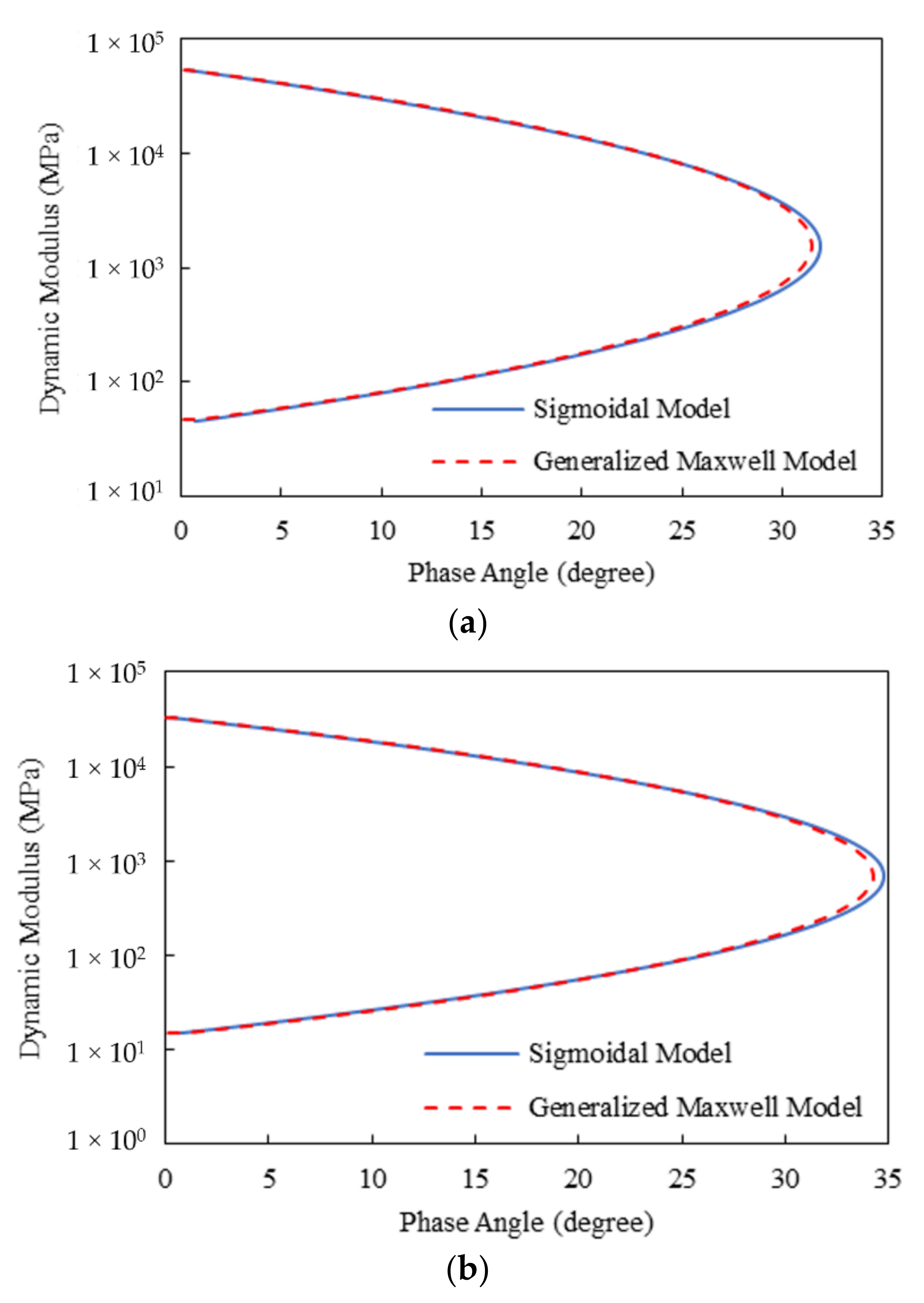

- The Black diagram is recommended for examining the quality of the complex modulus test data before constructing the master curves, because it can effectively avoid the effect of testing temperatures.

- (5)

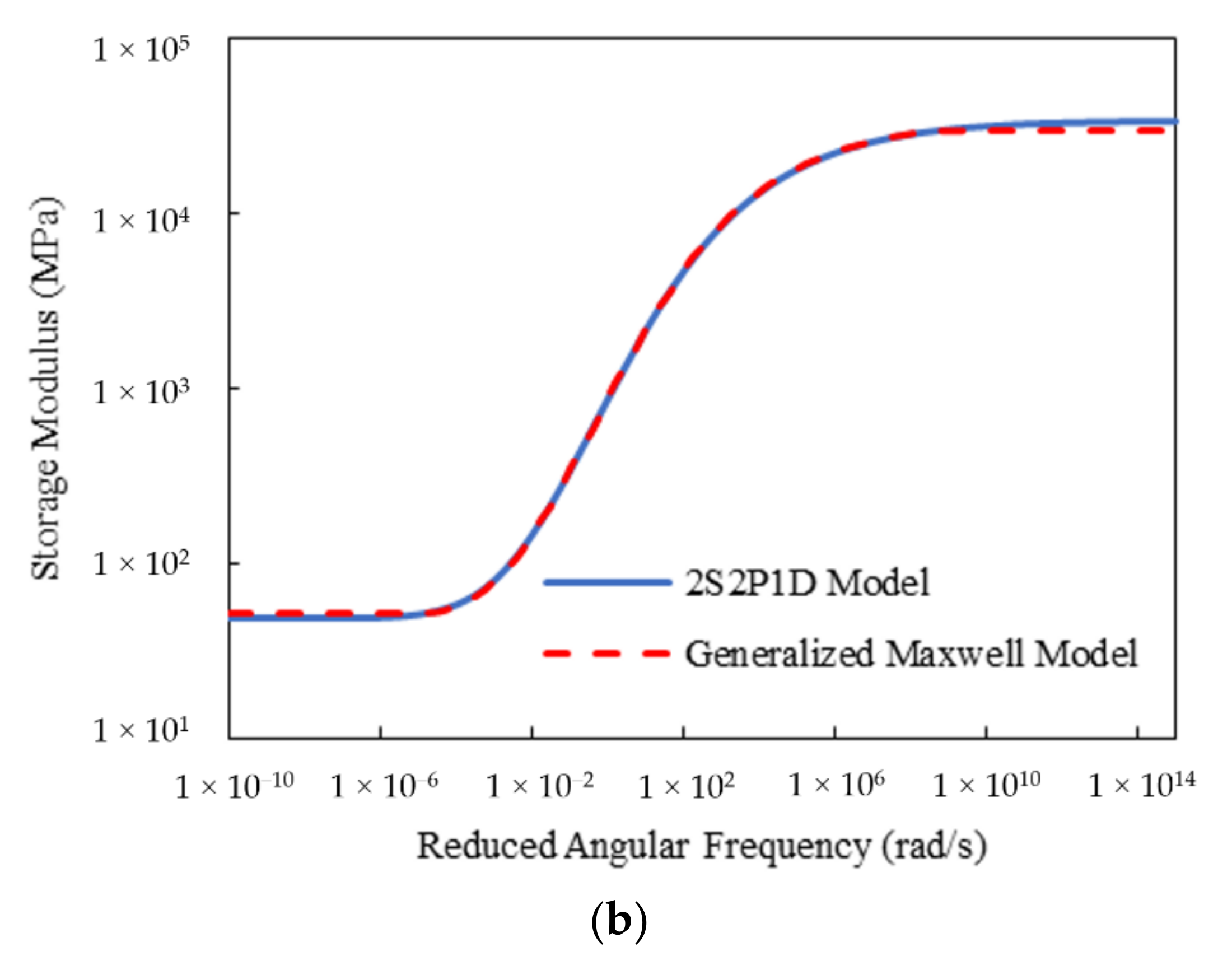

- The analytical expressions of the storage and loss moduli for both HN and 2S2P1D models accurately meet the Kronig–Kramers relation, and therefore the master curves constructed are consistent with the LVE theory.

- (6)

- All the procedures in the proposed method can be easily achieved even only by Microsoft Excel, successfully avoiding sophisticated expertise for programming in implementation process. Thus, the proposed method furnishes a practical way to fast acquiring high-quality Prony series parameters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hernandez-Fernandez, N.; Ossa-Lopez, A.; Harvey, J.T. Viscoelastic characterisation of asphalt concrete under different loading conditions. Int. J. Pavement Eng. 2021, 1–14. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, H.; Liu, W. Characterization of linear viscoelastic properties of asphalt concrete subjected to confining pressure. Mech. Time-Depend. Mater. 2012, 17, 449–463. [Google Scholar] [CrossRef]

- Park, S.W.; Kim, Y.R. Fitting Prony-series viscoelastic models with power-law presmoothing. J. Mater. Civ. Eng. 2001, 13, 26–32. [Google Scholar] [CrossRef]

- Nguyen, H.T.T.; Do, T.-T.; Tran, V.-T.; Phan, T.-N.; Pham, T.-A.; Nguyen, M.L. Determination of creep compliance of asphalt mixtures at intermediate and high temperature using creep-recovery test. Road Mater. Pavement Des. 2021, 22 (Suppl. 1), S514–S535. [Google Scholar] [CrossRef]

- Nguyen, H.T.T.; Nguyen, D.-L.; Tran, V.-T.; Nguyen, M.-L. Finite element implementation of Huet-Sayegh and 2S2P1D models for analysis of asphalt pavement structures in time domain. Road Mater. Pavement Des. 2020, 23, 22–46. [Google Scholar] [CrossRef]

- Li, L.; Wu, C.; Cheng, Y.; Ai, Y.; Li, H.; Tan, X. Comparative analysis of viscoelastic properties of open graded friction course under dynamic and static loads. Polymers 2021, 13, 1250. [Google Scholar] [CrossRef]

- Hristov, J.Y. Linear viscoelastic responses: The Prony decomposition naturally leads into the Caputo-Fabrizio fractional operator. Front. Phys. 2018, 6, 135. [Google Scholar] [CrossRef]

- Xu, Q.; Engquist, B.; Solaimanian, M.; Yan, K. A new nonlinear viscoelastic model and mathematical solution of solids for improving prediction accuracy. Sci. Rep. 2020, 10, 2202. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gu, L.; Zhang, W.; Ma, T.; Qiu, X.; Xu, J. Numerical simulation of viscoelastic behavior of asphalt mixture using fractional constitutive model. J. Eng. Mech. 2021, 147, 04021027. [Google Scholar] [CrossRef]

- Londono, J.G.; Shen, R.; Waisman, H. Temperature-dependent viscoelastic model for asphalt–concrete implemented within a novel nonlocal damage framework. J. Eng. Mech. 2020, 146, 04019119. [Google Scholar] [CrossRef]

- Yu, D.; Yu, X.; Gu, Y. Establishment of linkages between empirical and mechanical models for asphalt mixtures through relaxation spectra determination. Constr. Build. Mater. 2020, 242, 118095. [Google Scholar] [CrossRef]

- Zhao, Y.; Ni, Y.; Zeng, W. A consistent approach for characterising asphalt concrete based on generalised Maxwell or Kelvin model. Road Mater. Pavement Des. 2014, 15, 674–690. [Google Scholar] [CrossRef]

- Park, S.W.; Schapery, R.A. Methods of interconversion between linear viscoelastic material functions. Part I—A numerical method based on Prony series. Int. J. Solids Struct. 1999, 36, 1653–1675. [Google Scholar] [CrossRef]

- Sun, Y.; Huang, B.; Chen, J. A unified procedure for rapidly determining asphalt concrete discrete relaxation and retardation spectra. Constr. Build. Mater. 2015, 93, 35–48. [Google Scholar] [CrossRef]

- Schapery, R.A. A Simple Collocation Method for Fitting Viscoelastic Models to Experimental Data. GALCIT SM 61-32A; California Institute of Technology: Pasadena, CA, USA, 1961. [Google Scholar]

- Cost, T.L.; Becker, E.B. A multidata method of approximate Laplace transform inversion. Int. J. Numer. Meth. Eng. 1970, 2, 207–219. [Google Scholar] [CrossRef]

- Tschoegl, N.W.; Emri, I. Generating line spectra from experimental responses. Part II: Storage and loss functions. Rheol. Acta 1993, 32, 322–327. [Google Scholar] [CrossRef]

- Xu, Q.; Solaimanian, M. Modelling linear viscoelastic properties of asphalt concrete by the Huet–Sayegh model. Int. J. Pavement Eng. 2009, 10, 401–422. [Google Scholar] [CrossRef]

- Olard, F.; di Benedetto, H. General “2S2P1D” model and relation between the linear viscoelastic behaviours of bituminous binders and mixes. Road Mater. Pavement Des. 2003, 4, 185–224. [Google Scholar]

- Tiouajni, S.; di Benedetto, H.; Sauzéat, C.; Pouget, S. Approximation of Linear Viscoelastic Model in the 3 Dimensional Case with Mechanical Analogues of Finite Size. Road Mater. Pavement Des. 2011, 12, 897–930. [Google Scholar]

- Tschoegl, N.W.; Emri, I. Generating line spectra from experimental responses. III. Interconversion between relaxation and retardation behavior. Int. J. Polym. Mater. 1992, 18, 117–127. [Google Scholar] [CrossRef]

- Schapery, R.A.; Park, S.W. Methods of interconversion between linear viscoelastic material functions. Part II—An approximate analytical method. Int. J. Solids Struct. 1999, 36, 1677–1699. [Google Scholar] [CrossRef]

- Levenberg, E. Smoothing asphalt concrete complex modulus test data. J. Mater. Civ. Eng. 2011, 23, 606–611. [Google Scholar] [CrossRef]

- Luo, R.; Lv, H.; Liu, H. Development of Prony series models based on continuous relaxation spectrums for relaxation moduli determined using creep tests. Constr. Build. Mater. 2018, 168, 758–770. [Google Scholar] [CrossRef]

- Lv, H.; Liu, H.; Tan, Y.; Sun, Z. Improved methodology for identifying Prony series coefficients based on continuous relaxation spectrum method. Mater. Struct. 2019, 52, 86. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, J.; Huang, B. Characterization of asphalt concrete linear viscoelastic behavior utilizing Havriliak–Negami complex modulus model. Constr. Build. Mater. 2015, 99, 226–234. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Swamy, A.K.; Daniel, J.S. Continuous relaxation and retardation spectrum method for viscoelastic characterization of asphalt concrete. Mech. Time-Depend. Mater. 2011, 16, 287–305. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, L.; Li, C.; Xing, Y. The discrete and continuous retardation and relaxation spectrum method for viscoelastic characterization of warm mix crumb rubber-modified asphalt mixtures. Materials 2020, 13, 3723. [Google Scholar] [CrossRef] [PubMed]

- AASHTO. Standard Method of Test for Determining Dynamic Modulus of Hot Mix Asphalt (HMA), AASHTO T 342-11; AASHTO: Washington, DC, USA, 2011. [Google Scholar]

- Havriliak, S.; Negami, S. A complex plane representation of dielectric and mechanical relaxation processes in some polymers. Polymer 1967, 8, 161–210. [Google Scholar] [CrossRef]

- Tschoegl, N.W. The Phenomenological Theory of Linear Viscoelastic Behavior: An Introduction; Springer: New York, NY, USA, 1989. [Google Scholar]

- Alavi, M.Z.; Hajj, E.Y.; Morian, N.E. Approach for quantifying the effect of binder oxidative aging on the viscoelastic properties of asphalt mixtures. Transp. Res. Rec. 2013, 2373, 109–120. [Google Scholar] [CrossRef]

- Sun, Y.; Huang, B.; Chen, J.; Jia, X.; Ding, Y. Characterizing rheological behavior of asphalt binder over a complete range of pavement service loading frequency and temperature. Constr. Build. Mater. 2016, 123, 661–672. [Google Scholar] [CrossRef]

- Airey, G.D. Use of black diagrams to identify inconsistencies in rheological data. Road Mater. Pavement Des. 2011, 3, 403–424. [Google Scholar] [CrossRef]

- Mun, S.; Geem, Z.W. Determination of viscoelastic and damage properties of hot mix asphalt concrete using a harmony search algorithm. Mech. Mater. 2009, 41, 339–353. [Google Scholar] [CrossRef]

- ARA (Applied Research Associates), ERES Consultants Division. Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures, NCHRP 1-37A Final Report; ERES Consultants Division, Transportation Research Board: Washington, DC, USA, 2004. [Google Scholar]

- Rowe, G. Phase angle determination and interrelationships within bituminous materials. In Proceedings of the 7th International RILEM Symposium on Advanced Testing and Characterization of Bituminous Materials, Rhodes, Greece, 27–29 May 2009; pp. 43–52. [Google Scholar]

- Booij, H.C.; Thoone, G.P.J.M. Generalization of Kramers-Kronig transforms and some approximations of relations between viscoelastic quantities. Rheol. Acta 1982, 21, 15–24. [Google Scholar] [CrossRef]

| Mix Type | Tr/°C; | Eg/MPa | Ee/MPa | α | β | τ0/s | F/% |

|---|---|---|---|---|---|---|---|

| Mix-13.2 | 20 | 73,132 | 92.0 | 0.398 | 0.193 | 0.013 | 1.943 |

| Mix-9.5 | 24 | 43,707 | 37.5 | 0.431 | 0.175 | 0.011 | 2.461 |

| Mix Type | Tr/°C; | Eg/MPa | Ee/MPa | α | k | h | β | τ0/s | F/% |

|---|---|---|---|---|---|---|---|---|---|

| Mix-13.2 | 20 | 80,329 | 126.2 | 1.805 | 0.104 | 0.412 | 38,400 | 2.485 × 10−4 | 1.961 |

| Mix-9.5 | 24 | 34,132 | 49.1 | 2.329 | 0.205 | 0.493 | 41,666 | 1.558 × 10−3 | 2.204 |

| Mix Type | Tr/°C; | a1 | a2 | a3 | a4 | F/% |

|---|---|---|---|---|---|---|

| Mix-13.2 | 20 | 1.647 | 3.089 | −0.246 | −0.460 | 2.089 |

| Mix-9.5 | 24 | 1.152 | 3.370 | −0.233 | −0.459 | 2.471 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Sun, Y. Fast-Acquiring High-Quality Prony Series Parameters of Asphalt Concrete through Viscoelastic Continuous Spectral Models. Materials 2022, 15, 716. https://doi.org/10.3390/ma15030716

Zhang Y, Sun Y. Fast-Acquiring High-Quality Prony Series Parameters of Asphalt Concrete through Viscoelastic Continuous Spectral Models. Materials. 2022; 15(3):716. https://doi.org/10.3390/ma15030716

Chicago/Turabian StyleZhang, Yan, and Yiren Sun. 2022. "Fast-Acquiring High-Quality Prony Series Parameters of Asphalt Concrete through Viscoelastic Continuous Spectral Models" Materials 15, no. 3: 716. https://doi.org/10.3390/ma15030716

APA StyleZhang, Y., & Sun, Y. (2022). Fast-Acquiring High-Quality Prony Series Parameters of Asphalt Concrete through Viscoelastic Continuous Spectral Models. Materials, 15(3), 716. https://doi.org/10.3390/ma15030716