A Novel GaN:C Millimeter-Wave HEMT with AlGaN Electron-Blocking Layer

Abstract

:1. Introduction

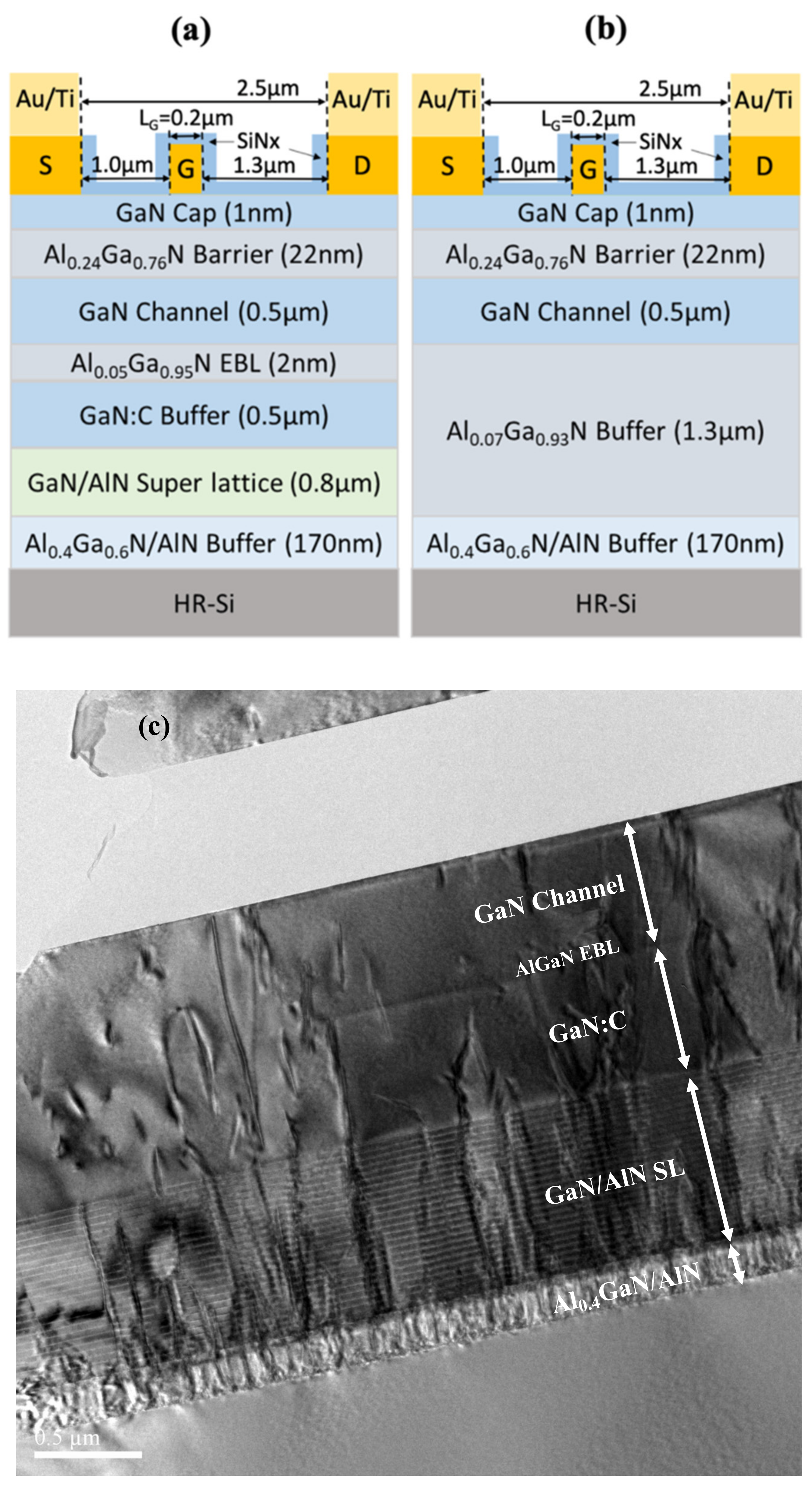

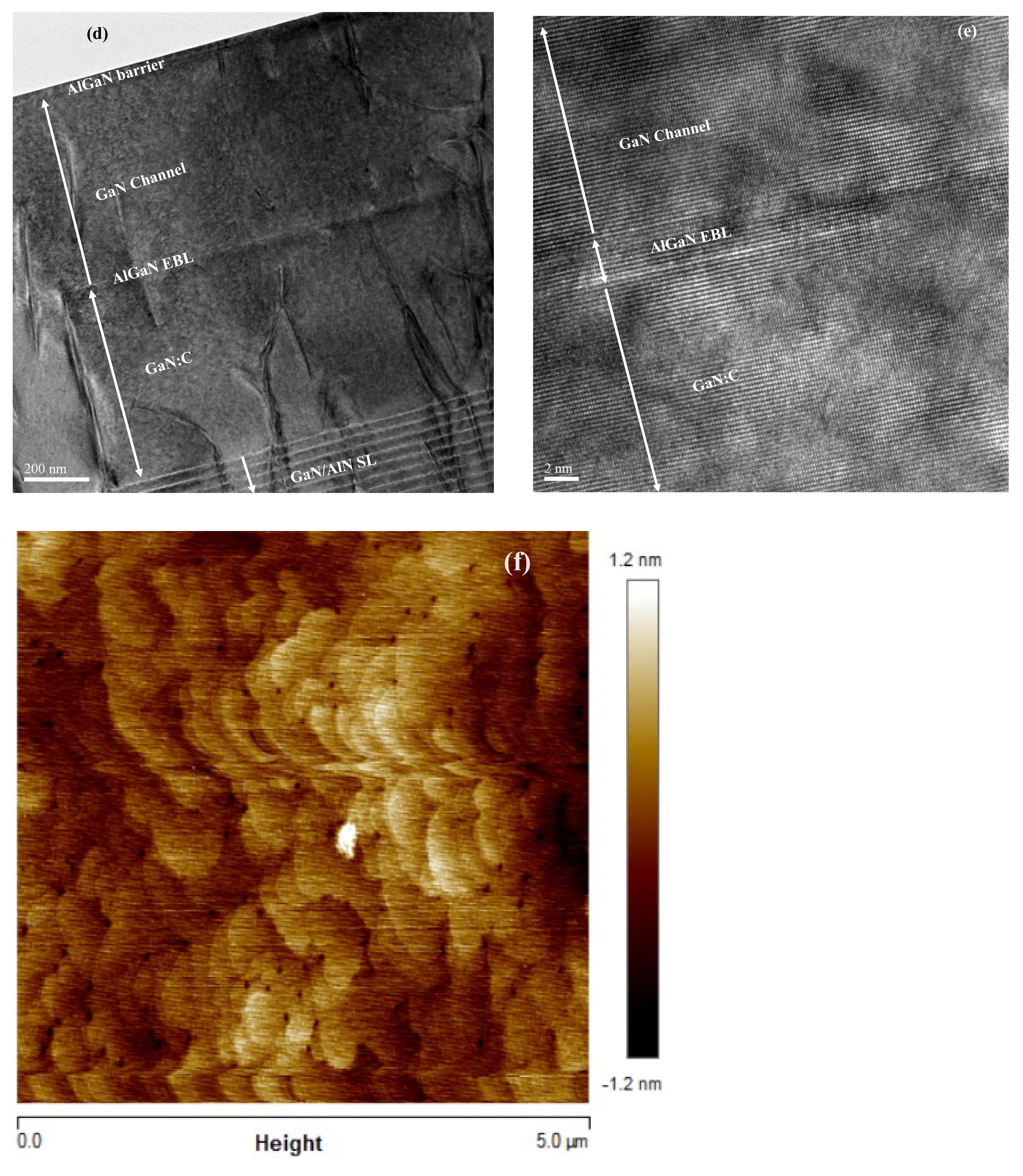

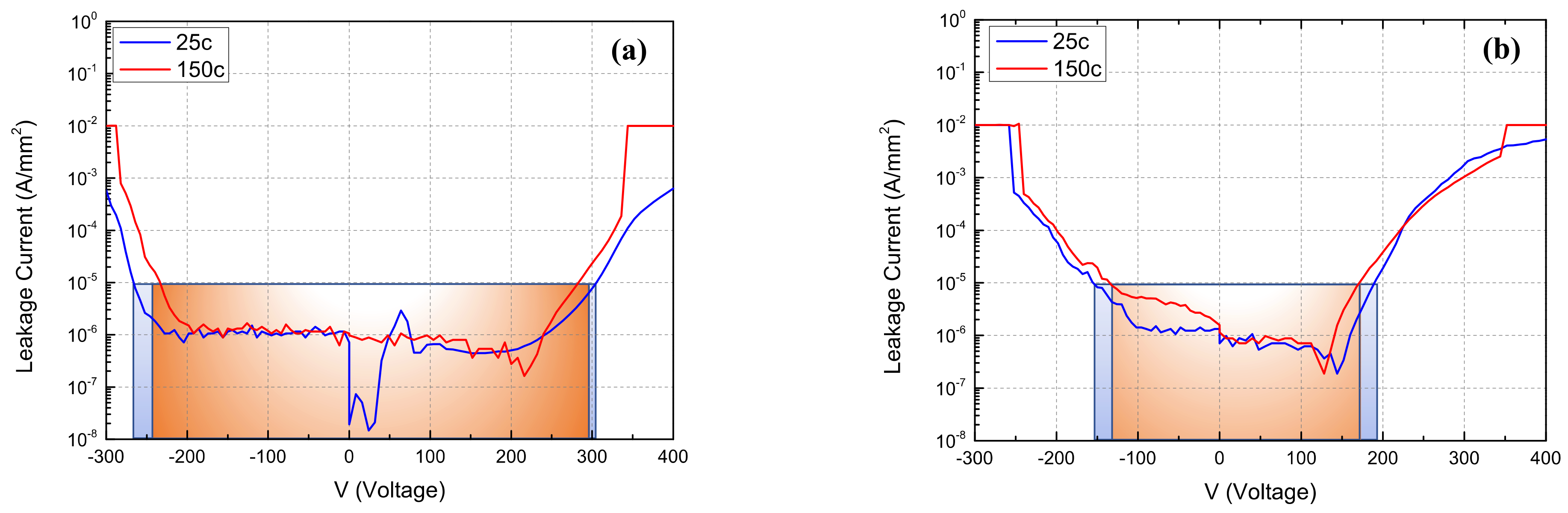

2. Materials and Methods

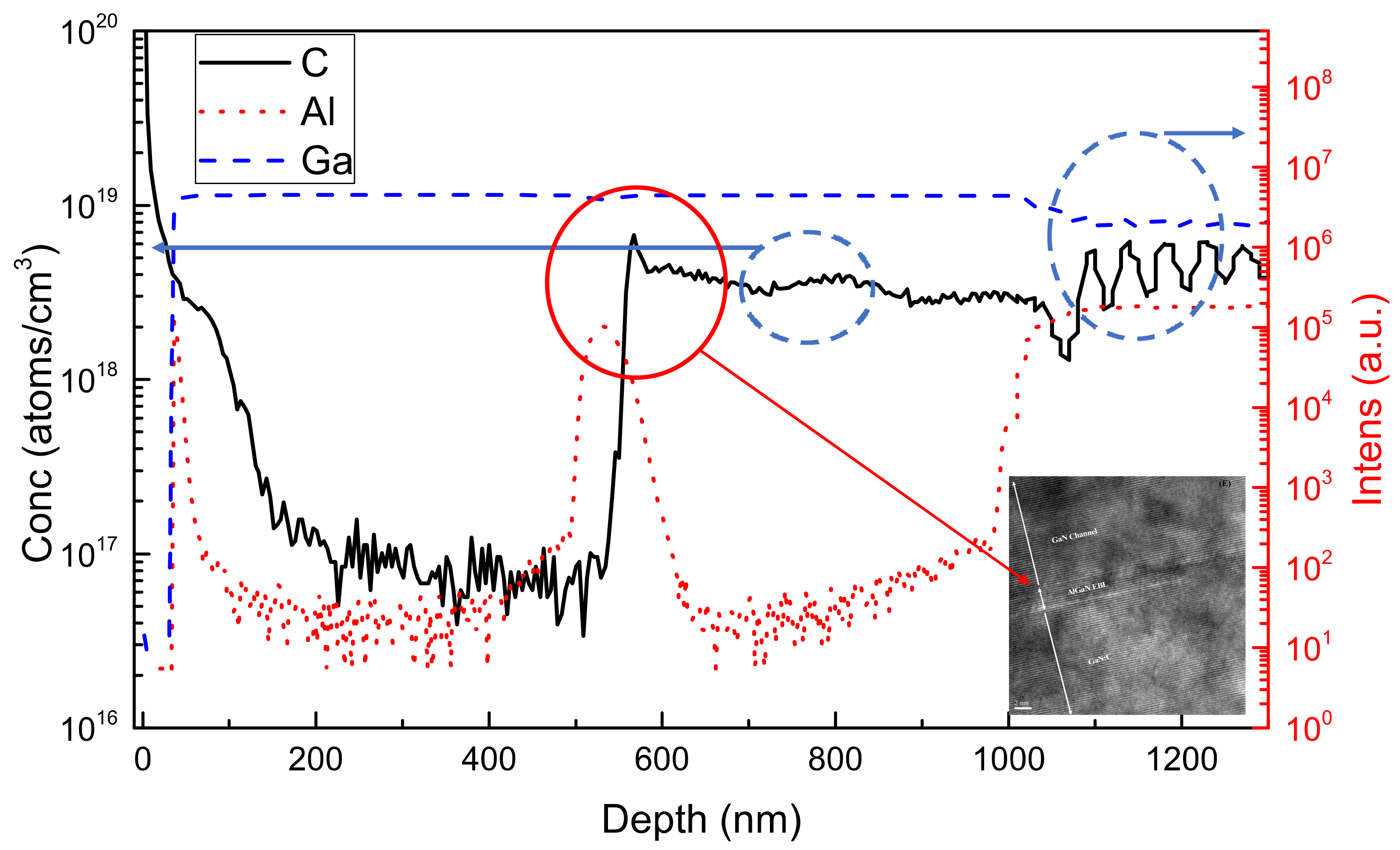

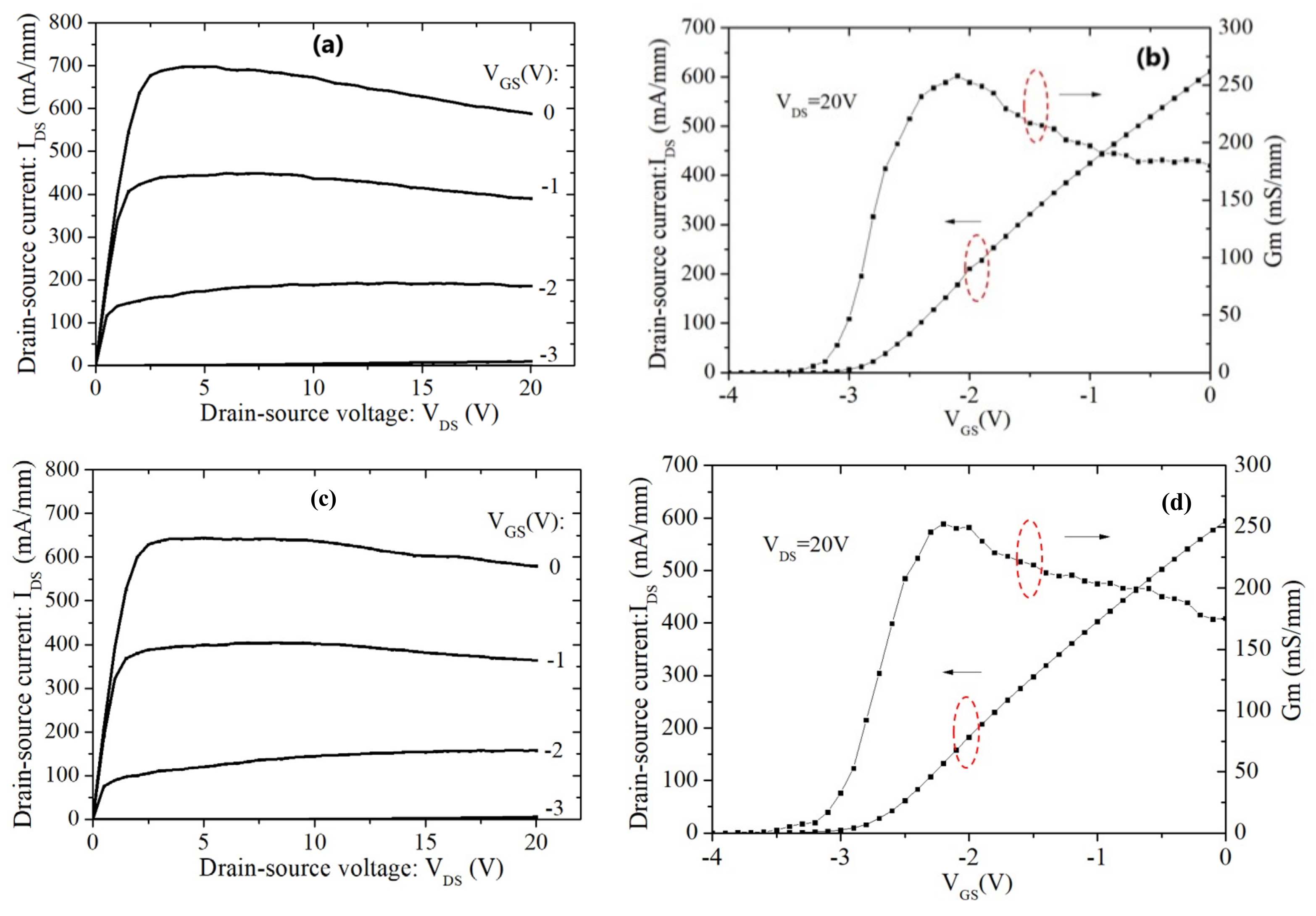

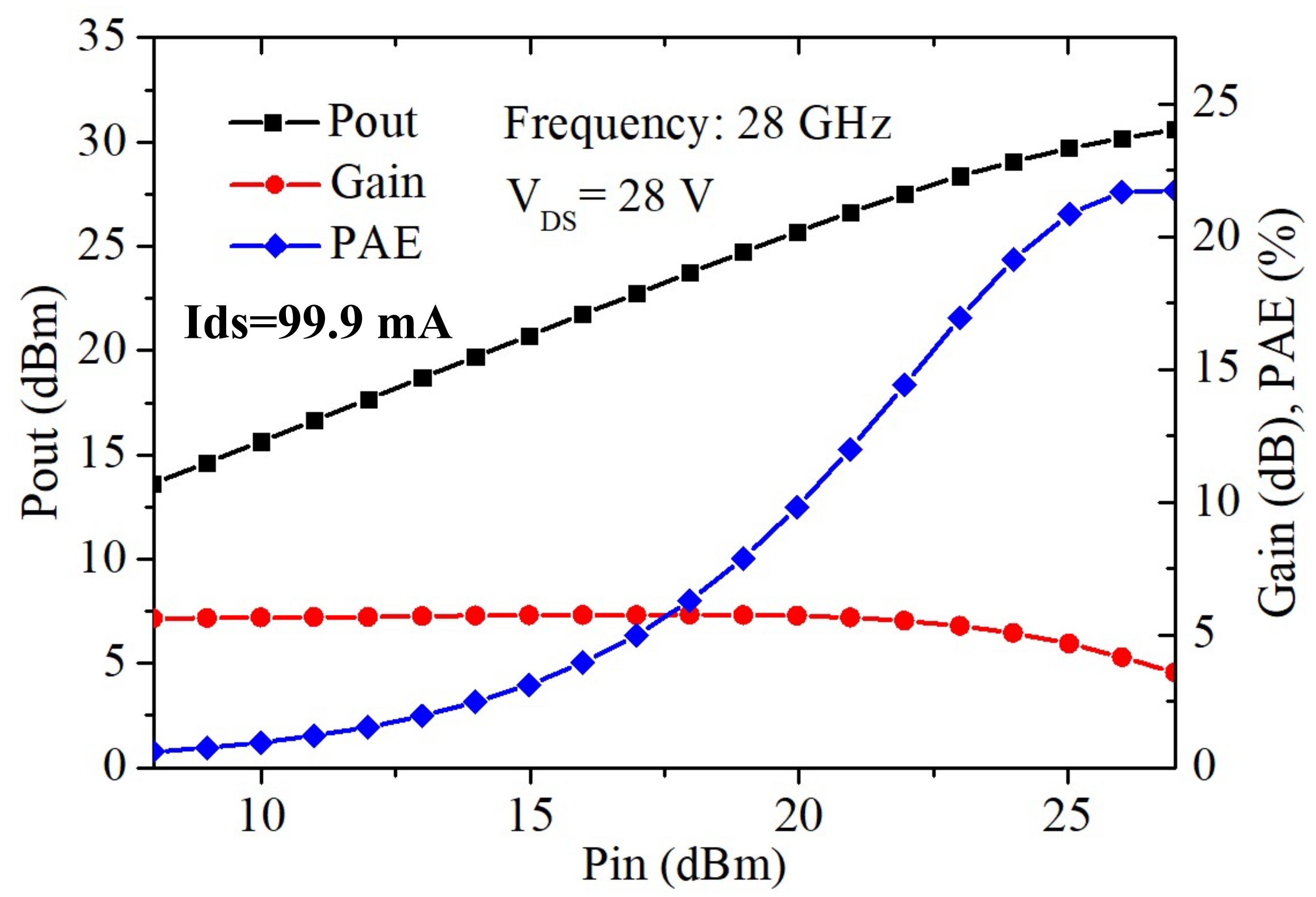

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Piotrowicz, S.; Jardell, O.; Chartier, E.; Aubry, R.; Baczkowski, L.; Casbon, M.; Dua, C.; Escotti, L.; Gamarra, P.; Jacquet, J.C.; et al. 12 W/mm with 0.15 µm InAlN/GaN HEMTs on SiC technology for K and Ka-Bands applications. In Proceedings of the 2014 IEEE MTT-S International Microwave Symposium (IMS2014), Tampa, FL, USA, 1–6 June 2014; pp. 1–3. [Google Scholar]

- Kolluri, S.; Keller, S.; DenBaars, S.P.; Mishra, U.K. Microwave Power Performance N-Polar GaN MISHEMTs Grown by MOCVD on SiC Substrates Using an Al2O3 Etch-Stop Technology. IEEE Electron Device Lett. 2012, 33, 44–46. [Google Scholar] [CrossRef]

- Higashiwaki, M.; Pei, Y.; Chu, R.; Mishra, U.K. Effects of Barrier Thinning on Small-Signal and 30-GHz Power Characteristics of AlGaN/GaN Heterostructure Field-Effect Transistors. IEEE Trans. Electron Devices 2011, 58, 1681–1686. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, S.H.; Lee, P.H.; Lai, K.H.; Huang, T.J.; Chang, E.Y.; Hsu, H.-T. Gallium Nitride (GaN) High-Electron-Mobility Transistors with Thick Copper Metallization Featuring a Power Density of 8.2 W/mm for Ka-Band Applications. Micromachines 2020, 11, 222. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Medjdoub, F.; Zegaoui, M.; Grimbert, B.; Ducatteau, D.; Rolland, N.; Rolland, P.A. First Demonstration of High-Power GaN-on-Silicon Transistors at 40 GHz. IEEE Electron Device Lett. 2012, 33, 1168–1170. [Google Scholar] [CrossRef]

- Egawa, T. Heteroepitaxial Growth and Power Devices Using AlGaN/GaN HEMT on 200 mm Si (111) Substrate. In Proceedings of the 2013 IEEE Compound Semiconductor Integrated Circuit Symposium (CSICS), Monterey, CA, USA, 13–16 October 2013; pp. 1–4. [Google Scholar]

- Ishida, M.; Ueda, T.; Tanaka, T.; Ueda, D. GaN on Si Technologies for Power Switching Devices. IEEE Trans. Electron Devices 2013, 60, 3053–3059. [Google Scholar] [CrossRef]

- Luong, T.T.; Lumbantoruan, F.; Chen, Y.Y.; Ho, Y.T.; Weng, Y.C.; Lin, Y.C.; Chang, S.; Chang, E.Y. RF loss mechanisms in GaN-based high-electron-mobility-transistor on silicon: Role of an inversion channel at the AlN/Si interface. Phys. Status Solidi A 2017, 214, 1600944. [Google Scholar] [CrossRef]

- Stoffels, S.; Zhao, M.; Venegas, R.; Kandaswamy, P.; You, S.; Novak, T.; Saripalli, Y.; Van Hove, M.; Decoutere, S. The physical mechanism of dispersion caused by AlGaN/GaN buffers on Si and optimization for low dispersion. In Proceedings of the 2015 IEEE International Electron Devices Meeting (IEDM), Washington, DC, USA, 7–9 December 2015; pp. 35.4.1–35.4.4. [Google Scholar]

- Lopatiuk, O.; Osinsky, A.; Dabiran, A.; Gartsman, K.; Feldman, I.; Chernyak, L. Electron trapping effects in C- and Fe-doped GaN and AlGaN. Solid-State Electron. 2005, 49, 1662–1668. [Google Scholar] [CrossRef]

- Klein, P.B.; Binari, S.C.; Ikossi, K.; Wickenden, A.E.; Koleske, D.D.; Henry, R.L. Current collapse and the role of carbon in AlGaN/GaN high electron mobility transistors grown by metalorganic vapor-phase epitaxy. Appl. Phys. Lett. 2001, 79, 3527–3529. [Google Scholar] [CrossRef]

- Hilt, O.; Bahat-Treidel, E.; Cho, E.; Singwald, S.; Würfl, J. Impact of buffer composition on the dynamic on-state resistance of high-voltage AlGaN/GaN HFETs. In Proceedings of the 2012 24th International Symposium on Power Semiconductor Devices and ICs, Bruges, Belgium, 3–7 June 2012; pp. 345–348. [Google Scholar]

- Meneghesso, G.; Meneghini, M.; Bisi, D.; Silvestri, R.; Zanandrea, A.; Hilt, O.; Bahat-Treidel, E.; Brunner, F.; Knauer, A.; Würfl, J.; et al. GaN-Based Power HEMTs: Parasitic, Reliability and High Field Issues. ECS Trans. 2013, 58, 187–198. [Google Scholar] [CrossRef] [Green Version]

- Kabouche, R.; Derluyn, J.; Püsche, R.; Degroote, S.; Germain, M.; Pecheux, R.; Okada, E.; Zegaoui, M.; Medjdoub, F. Comparison of C-Doped AlN/GaN HEMTs and AlN/GaN/AlGaN Double Heterostructure for mmW Applications. In Proceedings of the 2018 13th European Microwave Integrated Circuits Conference (EuMIC), Madrid, Spain, 24–25 September 2018; pp. 5–8. [Google Scholar]

- Corrion, A.L.; Shinohara, K.; Regan, D.; Milosavljevic, I.; Hashimoto, P.; Willadsen, P.J.; Schmitz, A.; Wheeler, D.C.; Butler, C.M.; Brown, D.; et al. Enhancement-Mode AlN/GaN/AlGaN DHFET with 700-mS/mm gm and 112-GHz fT. IEEE Electron Device Lett. 2010, 31, 1116–1118. [Google Scholar] [CrossRef]

- Hsiao, Y.L.; Chang, C.A.; Chang, E.Y.; Maa, J.S.; Chang, C.T.; Wang, Y.J.; Weng, Y.C. Material growth and device characterization of AlGaN/GaN single-heterostructure and AlGaN/GaN/AlGaN double-heterostructure field effect transistors on Si substrates. Appl. Phys. Express 2014, 7, 055501. [Google Scholar] [CrossRef]

- Geens, K.; Li, X.; Zhao, M.; Guo, W.; Fahle, D.; Aktas, O.; Odnoblyudov, V.; Decoutere, S. 650 V p-GaN Gate Power HEMTs on 200 mm Engineered Substrates. In Proceedings of the 2019 IEEE 7th Workshop on Wide Bandgap Power Devices and Applications (WiPDA), Raleigh, NC, USA, 29–31 October 2019; pp. 292–296. [Google Scholar]

- Besendörfer, S.; Meissner, E.; Zweipfennig, T.; Yacoub, H.; Fahle, D.; Behmenburg, H.; Kalisch, H.; Vescan, A.; Friedrich, J.; Erlbacher, T. Interplay between C-doping, threading dislocations, breakdown, and leakage in GaN on Si HEMT structures. AIP Adv. 2020, 10, 045028. [Google Scholar] [CrossRef] [Green Version]

- Uren, M.; Moereke, J.; Kuball, M. Buffer Design to Minimize Current Collapse in GaN/AlGaN HFETs. IEEE Trans. Electron Devices 2012, 59, 3327–3333. [Google Scholar] [CrossRef] [Green Version]

- Cho, E.; Brunner, F.; Zhytnytska, R.; Kotara, P.; Würfl, J.; Weyers, M. Enhancement of channel conductivity in AlGaN/GaN heterostructure field effect transistors by AlGaN:Si back barrier. Appl. Phys. Lett. 2011, 99, 103505. [Google Scholar] [CrossRef]

- Lee, J.H.; Ju, J.M.; Atmaca, G.; Kim, J.G.; Kang, S.H.; Lee, Y.S.; Lee, S.H.; Lim, J.W.; Kwon, H.S.; Lisesivdin, S.B.; et al. High Figure-of-Merit (V2BR/RON) AlGaN/GaN Power HEMT With Periodically C-Doped GaN Buffer and AlGaN Back Barrier. IEEE J. Electron Devices Soc. 2018, 6, 1179–1186. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, M.; Hou, B.; Mi, M.; Wu, M.; Zhu, Q.; Zhu, J.; Lu, Y.; Chen, L.; Zhou, X.; et al. High Channel Conductivity, Breakdown Field Strength, and Low Current Collapse in AlGaN/GaN/Si δ -Doped AlGaN/GaN:C HEMTs. IEEE Trans. Electron Devices 2019, 66, 1202–1207. [Google Scholar] [CrossRef]

- Kaun, S.; Wong, M.; Lu, J.; Mishra, U.; Speck, J. Reduction of carbon proximity effects by including AlGaN back barriers in HEMTs on free-standing GaN. Electron. Lett. 2013, 49, 893–895. [Google Scholar] [CrossRef]

- Liu, W.; Balandin, A.A. Thermal conduction in Al𝑥Ga1−𝑥N alloys and thin films. J. Appl. Phys. 2005, 97, 073710. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weng, Y.-C.; Lin, Y.-C.; Hsu, H.-T.; Kao, M.-L.; Huang, H.-Y.; Ueda, D.; Ha, M.-T.-H.; Yang, C.-Y.; Maa, J.-S.; Chang, E.-Y.; et al. A Novel GaN:C Millimeter-Wave HEMT with AlGaN Electron-Blocking Layer. Materials 2022, 15, 703. https://doi.org/10.3390/ma15030703

Weng Y-C, Lin Y-C, Hsu H-T, Kao M-L, Huang H-Y, Ueda D, Ha M-T-H, Yang C-Y, Maa J-S, Chang E-Y, et al. A Novel GaN:C Millimeter-Wave HEMT with AlGaN Electron-Blocking Layer. Materials. 2022; 15(3):703. https://doi.org/10.3390/ma15030703

Chicago/Turabian StyleWeng, You-Chen, Yueh-Chin Lin, Heng-Tung Hsu, Min-Lu Kao, Hsuan-Yao Huang, Daisuke Ueda, Minh-Thien-Huu Ha, Chih-Yi Yang, Jer-Shen Maa, Edward-Yi Chang, and et al. 2022. "A Novel GaN:C Millimeter-Wave HEMT with AlGaN Electron-Blocking Layer" Materials 15, no. 3: 703. https://doi.org/10.3390/ma15030703

APA StyleWeng, Y.-C., Lin, Y.-C., Hsu, H.-T., Kao, M.-L., Huang, H.-Y., Ueda, D., Ha, M.-T.-H., Yang, C.-Y., Maa, J.-S., Chang, E.-Y., & Dee, C.-F. (2022). A Novel GaN:C Millimeter-Wave HEMT with AlGaN Electron-Blocking Layer. Materials, 15(3), 703. https://doi.org/10.3390/ma15030703