Strain Rate and Stress Amplitude Effects on the Mechanical Behavior of Carbon Paste Used in the Hall–Héroult Process and Subjected to Cyclic Loadings

Abstract

:1. Introduction

2. Material and Set-Up

2.1. Material

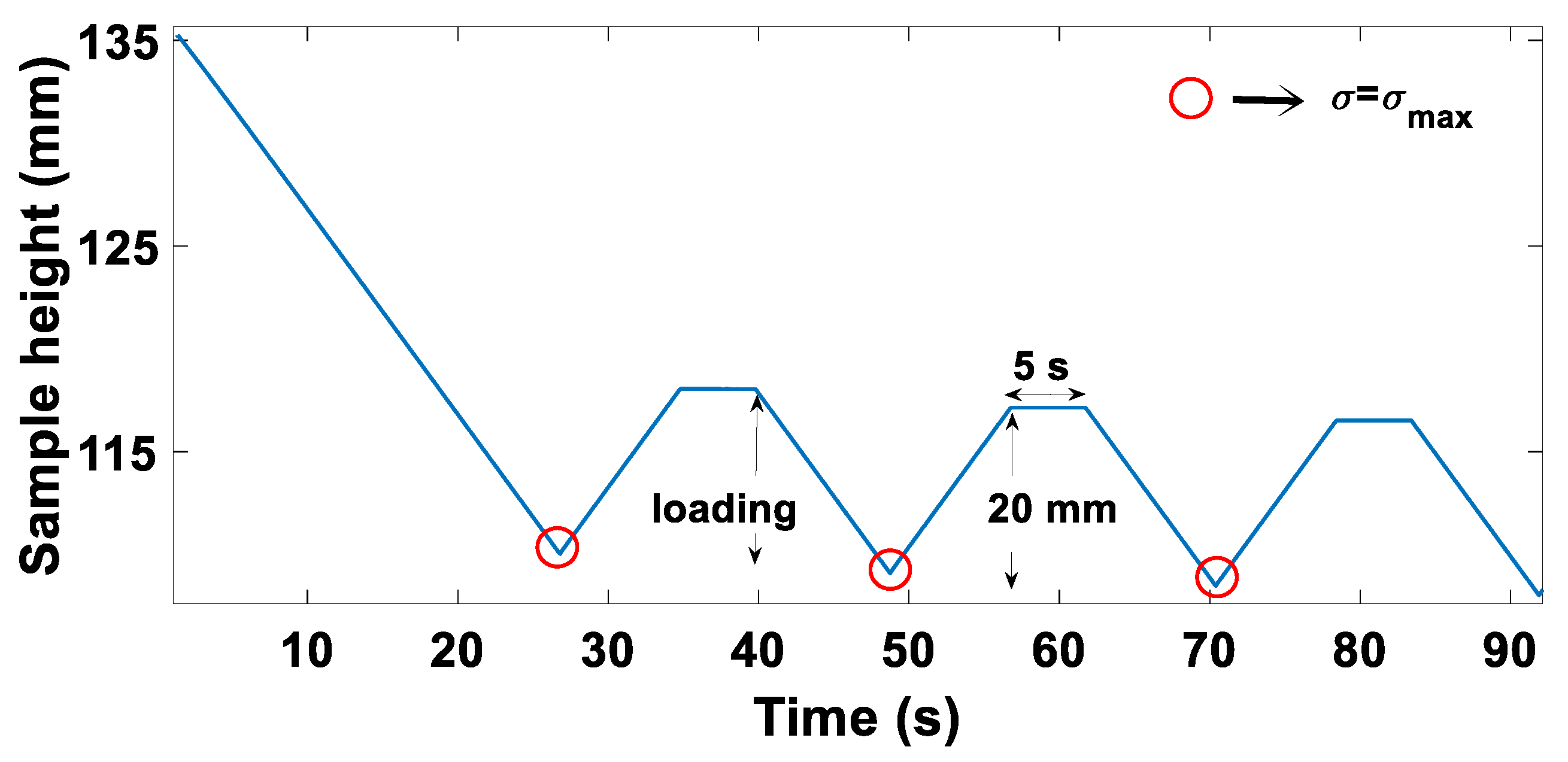

2.2. Experimental Set-Up

3. Methodology

3.1. Series I: The Effects of Strain Rate and Stress Amplitude

3.2. Series II: Effects of Unloading Level during Cyclic Tests

3.3. Measurements and Investigated Properties

4. Results and Discussion

4.1. Series I

4.1.1. Stress–Strain Behavior of the Carbon Paste Subjected to Cyclic Loading

4.1.2. Strain Rate and Stress Amplitude Effect on the Permanent Strain Evolution

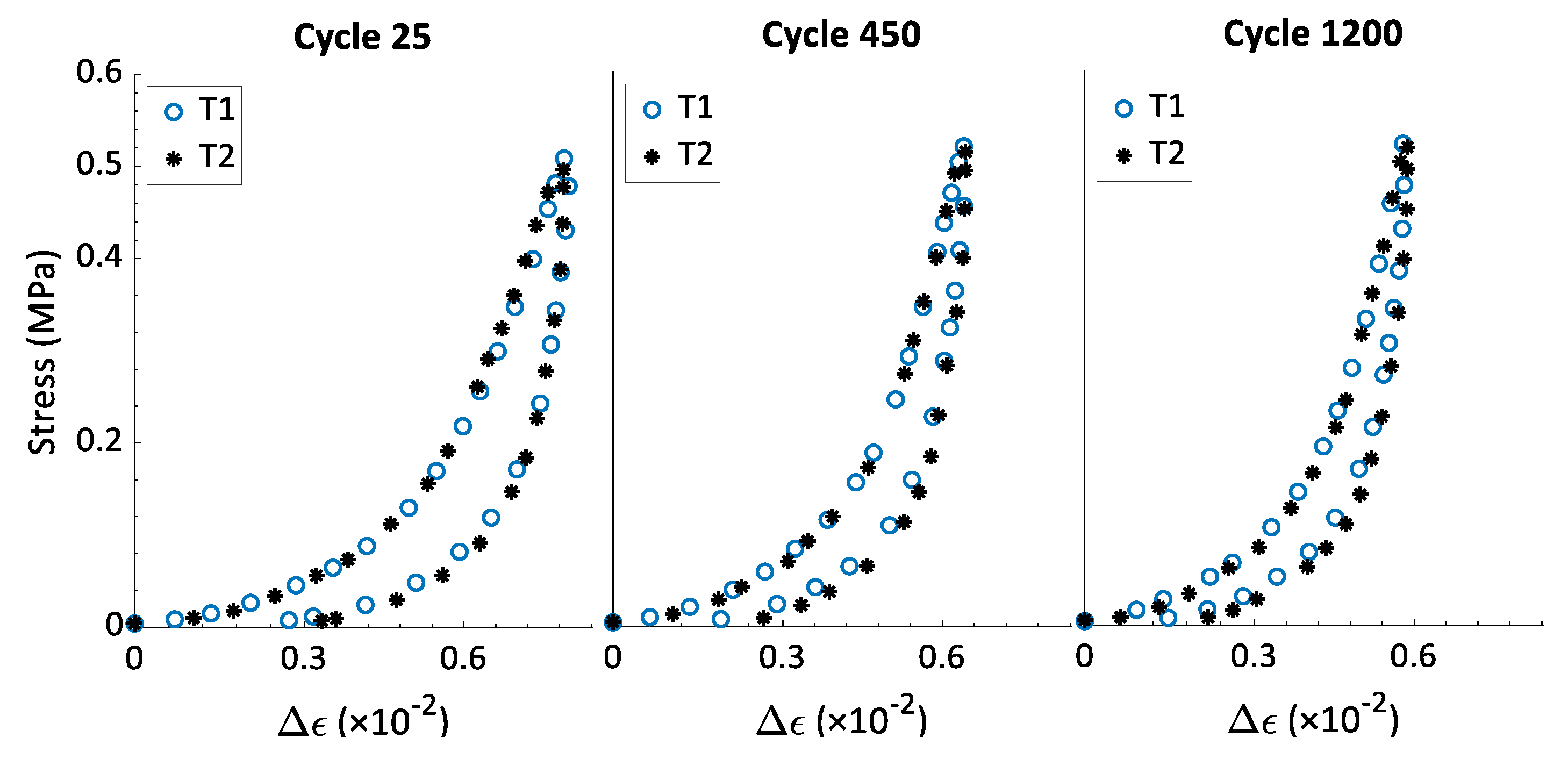

4.1.3. Strain Rate Effect on the Hysteresis Shape

4.1.4. Effect of the Stress Amplitude on the Hysteresis Shape

4.1.5. Effect of the Cycle Number on the Hysteresis Shape

4.2. Series II

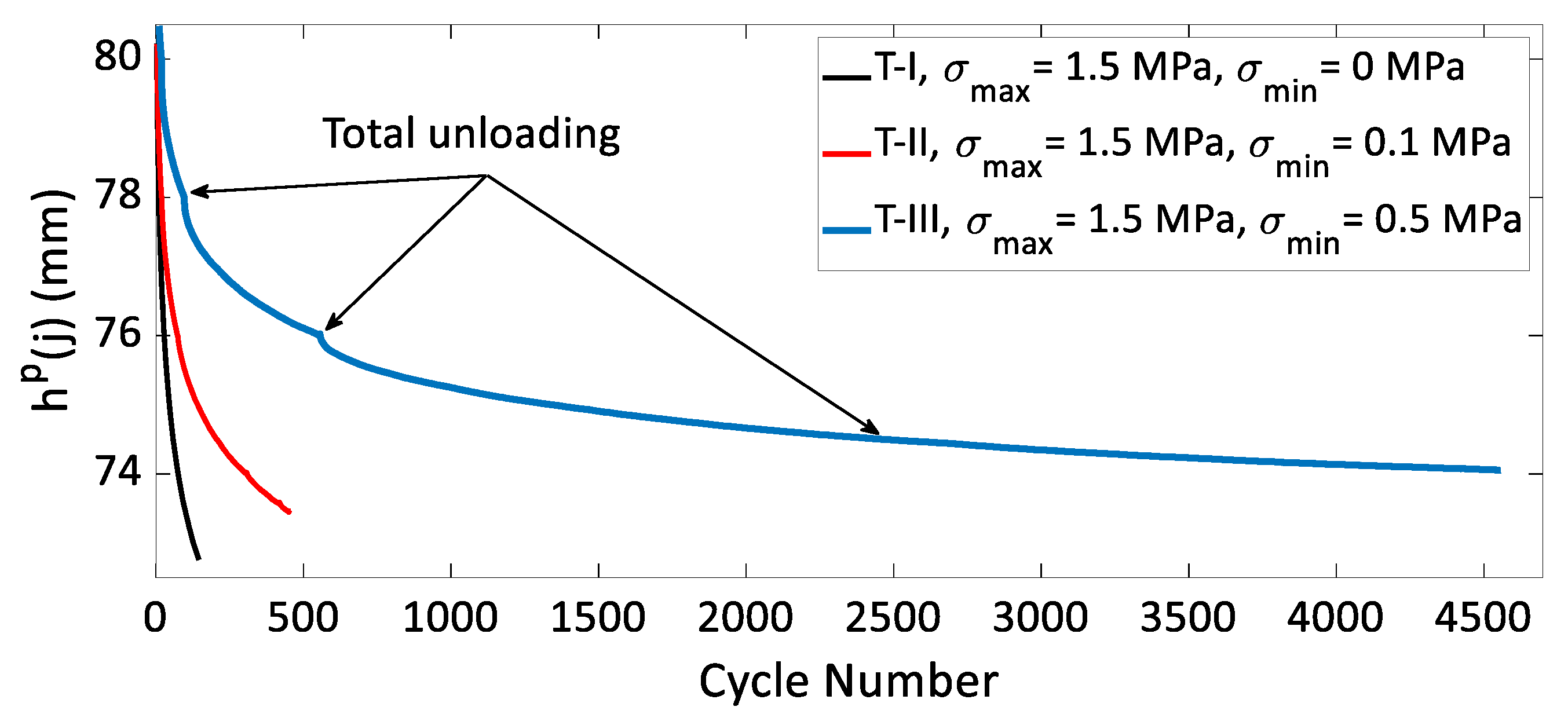

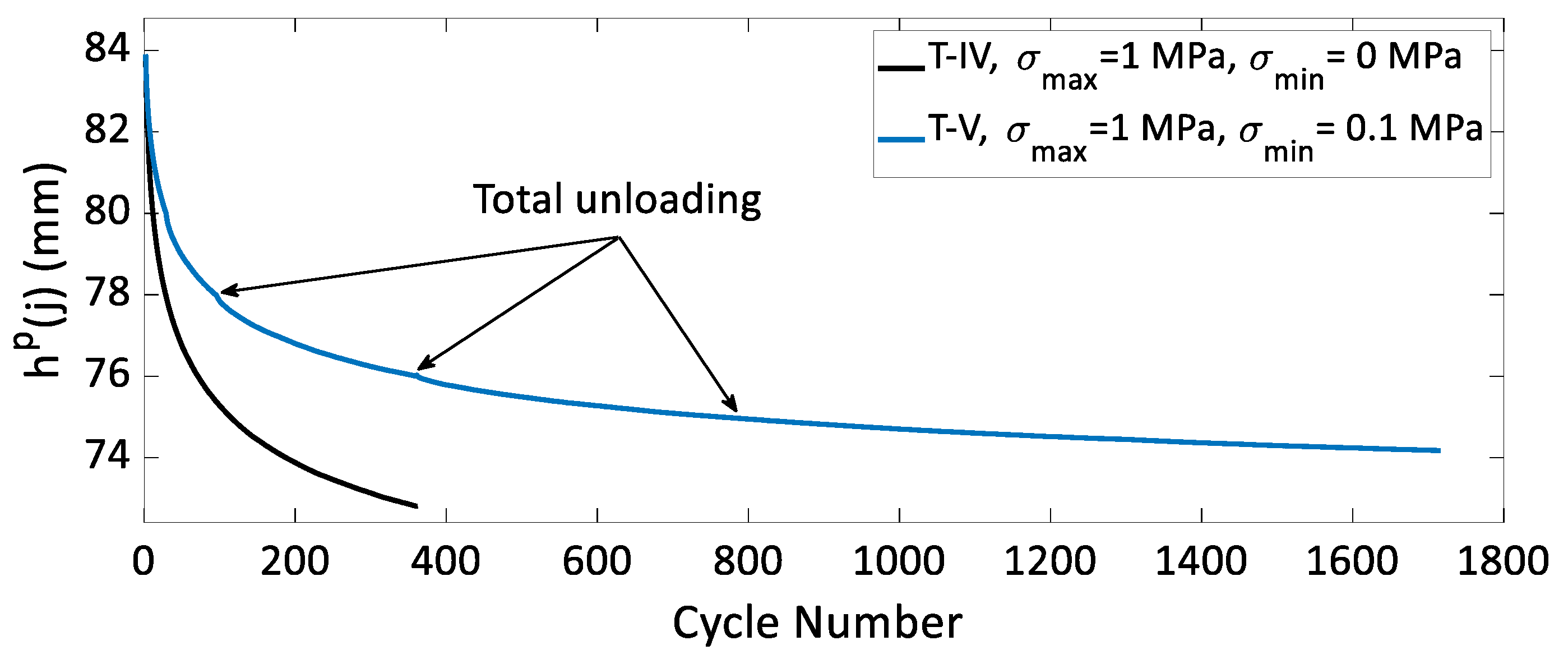

Effect of the Unloading Level on the Permanent Deformation

5. Conclusions

- The evolution of the permanent deformation as a function of the cycle number during cyclic tests with a constant maximum stress amplitude is nonlinear and is not influenced by the strain rate. Therefore, the law representing the irreversible behavior of carbon paste subjected to cyclic loading must be independent of time. In addition, the law itself or its parameters must consider the non-linearity of the permanent deformation as a function of the number of cycles.

- During cyclic tests, the stress–relative strain hysteresis curves changed shape as the number of cycles increased. They become narrower and gain a steeper slope. This reflects the evolution of the elastic properties of the paste as the number of cycles increases. On the other hand, the hysteresis shape of the stress–relative strain curves is not influenced by the strain rate. The part of behavior law describing the reversible behavior of the carbon paste subjected to cyclic loading must be independent of time and should include variable elastic parameters that evolve during compaction.

- Carbon paste samples with the same density that were subjected to different maximum stress amplitudes during compaction had different stiffness values, as highlighted by different slopes of the stress–relative strain hysteresis curves. This result implies that the elastic properties of a compacted carbon paste do not depend exclusively on its density. Therefore, the elastic parameters of any law intended to represent the cyclic behavior of carbon paste should not be exclusively as a function of the density.

- Carbon paste samples that had been subjected to the same number of cycles but different maximum stress amplitudes in their loading histories had different densities but the same elastic properties. This is reflected by the same stress–relative strain curve during loading (Figure 11). Therefore, the evolution of the elastic properties of carbon paste during cyclic compaction can be defined as a function of the cycle number.

- Complete unloading at the end of each cycle during cyclic compaction of the carbon paste enhanced the accumulation of the permanent deformation. This behavioral aspect must be taken into consideration in any work aiming at modeling the shaping process of carbon paste.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Gupta, A.; Basu, B. Sustainable Primary Aluminium Production: Technology Status and Future Opportunities. Trans. Indian Inst. Met. 2019, 72, 2135–2150. [Google Scholar] [CrossRef]

- Jentoftsen, T.E.; Linga, H.; Holden, I.; Aga, B.E.; Christensen, V.G.; Hoff, F. Correlation between anode properties and cell performance. In Light Metals; Wiley: Hoboken, NJ, USA, 2009; pp. 301–304. [Google Scholar]

- Rorvik, S.; Ratvik, A.P.; Foosnæs, T. Characterization of green anode materials by image analysis. In Light Metals; Minerals, Metals & Materials Society: Pittsburgh, PA, USA, 2006; Volume 2006, pp. 553–558. [Google Scholar]

- Gates, D. Modelling and Simulation of a Vibroformer for Carbon Anodes Used in Aluminium Production. 1992. Available online: https://miis.maths.ox.ac.uk/miis/459/1/Vibroformer-for-carbon-anodes-used-in-aluminium-production.pdf (accessed on 21 May 2021).

- Faaness, B.M.; Gran, H.; Sørlie, M.; Øye, H.A. Ramming paste related failures in cathode linings. In Essential Readings in Light Metals; Springer: Berlin, Germany, 2016; pp. 827–833. [Google Scholar]

- Thibodeau, S. Caractérisation des Propriétés Mécaniques de la Pâte de Carbone à 150 C dans le but D’optimiser la Mise en Forme des Anodes Utilisées Dans les Cuves Hall-Héroult. Ph.D. Thesis, Université Laval, Québec, QC, Canada, 2016. [Google Scholar]

- Belitskus, D.; Danka, D.J. A comprehensive determination of effects of calcined petroleum coke properties on aluminum reduction cell anode properties. In Essential Readings in Light Metals; Springer: Berlin, Germany, 2016; pp. 59–72. [Google Scholar]

- Samanos, B.; Dreyer, C. Impact of coke calcination level and anode baking temperature on anode properties. In Essential Readings in Light Metals; Springer: Berlin, Germany, 2016; pp. 101–108. [Google Scholar]

- Belitskus, D.L. An evaluation of relative effects of coke, formulation, and baking factors on aluminum reduction cell anode performance. In Light Metals; Minerals, Metals & Materials Society: Pittsburgh, PA, USA, 1993; pp. 677–681. [Google Scholar]

- Jonville, C.; Thomas, J.C.; Dreyer, C. The influence of coke source on anode performance. JOM 1995, 47, 23–24. [Google Scholar] [CrossRef]

- Hulse, K.L. Anode Manufacture: Raw Materials, Formulation And Processing Parameters; R & D Carbon Limited: Valais, Switzerland, 2000; pp. 77–158. [Google Scholar]

- Perruchoud, R.; Fischer, W.K. Granular carbon mechanical properties: Their measurement and influence on paste production. In Light Metals; Wiley: Hoboken, NJ, USA, 1992; pp. 695–700. [Google Scholar]

- Leach, C.T. Correlation of coke properties, anode properties, and carbon consumption. In Fuel and Energy Abstracts; Elsevier Science: Amsterdam, The Netherlands, 1997; Volume 6, p. 387. [Google Scholar]

- Azari, K.; Alamdari, H.; Aryanpour, G.; Ziegler, D.; Picard, D.; Fafard, M. Compaction properties of carbon materials used for prebaked anodes in aluminum production plants. Powder Technol. 2013, 246, 650–657. [Google Scholar] [CrossRef]

- Azari, K.; Ammar, H.; Alamdari, H.; Picard, D.; Fafard, M.; Ziegler, D. Effects of Physical Properties of Anode Raw Materials on the Paste Compaction Behavior. In Light Metals; Spinger: Basel, Switzerland, 2011; ISBN 978-3-319-48567-6. [Google Scholar]

- Azari, K.; Alamdari, H.; Ziegler, D.; Fafard, M. Influence of coke particle characteristics on the compaction properties of carbon paste material. Powder Technol. 2014, 257, 132–140. [Google Scholar] [CrossRef]

- Azari, K.; Alamdari, H.; Ammar, H.; Fafard, M.; Adams, A.; Ziegler, D. Influence of mixing parameters on the density and compaction behavior of carbon anodes used in aluminum production. Adv. Mater. Res. 2011, 409, 17–22. [Google Scholar] [CrossRef]

- Azari, K.; Alamdari, H.; Aryanpour, G.; Picard, D.; Fafard, M.; Adams, A. Mixing variables for prebaked anodes used in aluminum production. Powder Technol. 2013, 235, 341–348. [Google Scholar] [CrossRef]

- Kuang, Z.; Thonstad, J.; Rolseth, S.; Sørlie, M. Effect of baking temperature and anode current density on anode carbon consumption. Metall. Mater. Trans. B 1996, 27, 177–183. [Google Scholar] [CrossRef]

- Dreyer, C. Anode reactivity influence of the baking process. In Essential Readings in Light Metals; Springer: Berlin, Germany, 2016; pp. 478–485. [Google Scholar]

- Thibodeau, S.; Alamdari, H.; Ziegler, D.P.; Fafard, M. New insight on the restructuring and breakage of particles during uniaxial confined compression tests on aggregates of petroleum coke. Powder Technol. 2014, 253, 757–768. [Google Scholar] [CrossRef]

- Kansoun, Z.; Chaouki, H.; Picard, D.; Lauzon-Gauthier, J.; Alamdari, H.; Fafard, M. Compaction of Cohesive Granular Material: Application to Carbon Paste. Materials 2021, 14, 704. [Google Scholar] [CrossRef] [PubMed]

- Rebaïne, F. Étude de L’influence des Paramètres de Vibro-Compaction sur les Propriétés Mécaniques des Anodes Crues en Carbone; Université du Québec à Chicoutimi: Québec, QC, Canada, 2015. [Google Scholar]

- Sandvik, E.; Blindheim, R.; Bø, H.M. Vibration forming of carbon blocks. In Essential Readings in Light Metals; Springer: Berlin, Germany, 2016; pp. 339–350. [Google Scholar]

- Gao, S.; Bao, C.; Zhang, S.; Wang, H.; Woo, J.; Cutshall, E. Optimum vibration time for green anode production. In Light Metals; Spinger: Basel, Switzerland, 2016; pp. 1123–1126. [Google Scholar] [CrossRef]

- Jahangiri, B.; Karimi, M.M.; Tabatabaee, N. Relaxation of hardening in asphalt concrete under cyclic compression loading. J. Mater. Civ. Eng. 2017, 29, 4016288. [Google Scholar] [CrossRef]

| Test | T1 | T2 | T3 | T4 | T5 | T6 | T7 | T8 |

|---|---|---|---|---|---|---|---|---|

| (MPa) | 0.50 | 1.00 | 1.50 | |||||

| (s−1) × 10−2 | 0.7 | 7.4 | 0.7 | 3.7 | 7.4 | 0.7 | 3.7 | 7.4 |

| Test | T-I | T-II | T-III | T-IV | T-V |

|---|---|---|---|---|---|

| (MPa) | 1.5 | 1.5 | 1.5 | 1 | 1 |

| (MPa) | 0 | 0.1 | 0.5 | 0 | 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kansoun, Z.; Chaouki, H.; Picard, D.; Lauzon-Gauthier, J.; Alamdari, H.; Fafard, M. Strain Rate and Stress Amplitude Effects on the Mechanical Behavior of Carbon Paste Used in the Hall–Héroult Process and Subjected to Cyclic Loadings. Materials 2022, 15, 1263. https://doi.org/10.3390/ma15031263

Kansoun Z, Chaouki H, Picard D, Lauzon-Gauthier J, Alamdari H, Fafard M. Strain Rate and Stress Amplitude Effects on the Mechanical Behavior of Carbon Paste Used in the Hall–Héroult Process and Subjected to Cyclic Loadings. Materials. 2022; 15(3):1263. https://doi.org/10.3390/ma15031263

Chicago/Turabian StyleKansoun, Zahraa, Hicham Chaouki, Donald Picard, Julien Lauzon-Gauthier, Houshang Alamdari, and Mario Fafard. 2022. "Strain Rate and Stress Amplitude Effects on the Mechanical Behavior of Carbon Paste Used in the Hall–Héroult Process and Subjected to Cyclic Loadings" Materials 15, no. 3: 1263. https://doi.org/10.3390/ma15031263

APA StyleKansoun, Z., Chaouki, H., Picard, D., Lauzon-Gauthier, J., Alamdari, H., & Fafard, M. (2022). Strain Rate and Stress Amplitude Effects on the Mechanical Behavior of Carbon Paste Used in the Hall–Héroult Process and Subjected to Cyclic Loadings. Materials, 15(3), 1263. https://doi.org/10.3390/ma15031263