Microstructural Evolution and Tensile Properties of Al0.3CoCrFeNi High-Entropy Alloy Associated with B2 Precipitates

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials and Sample Preparation

2.2. Microstructural Characterization and Mechanical Testing

3. Results

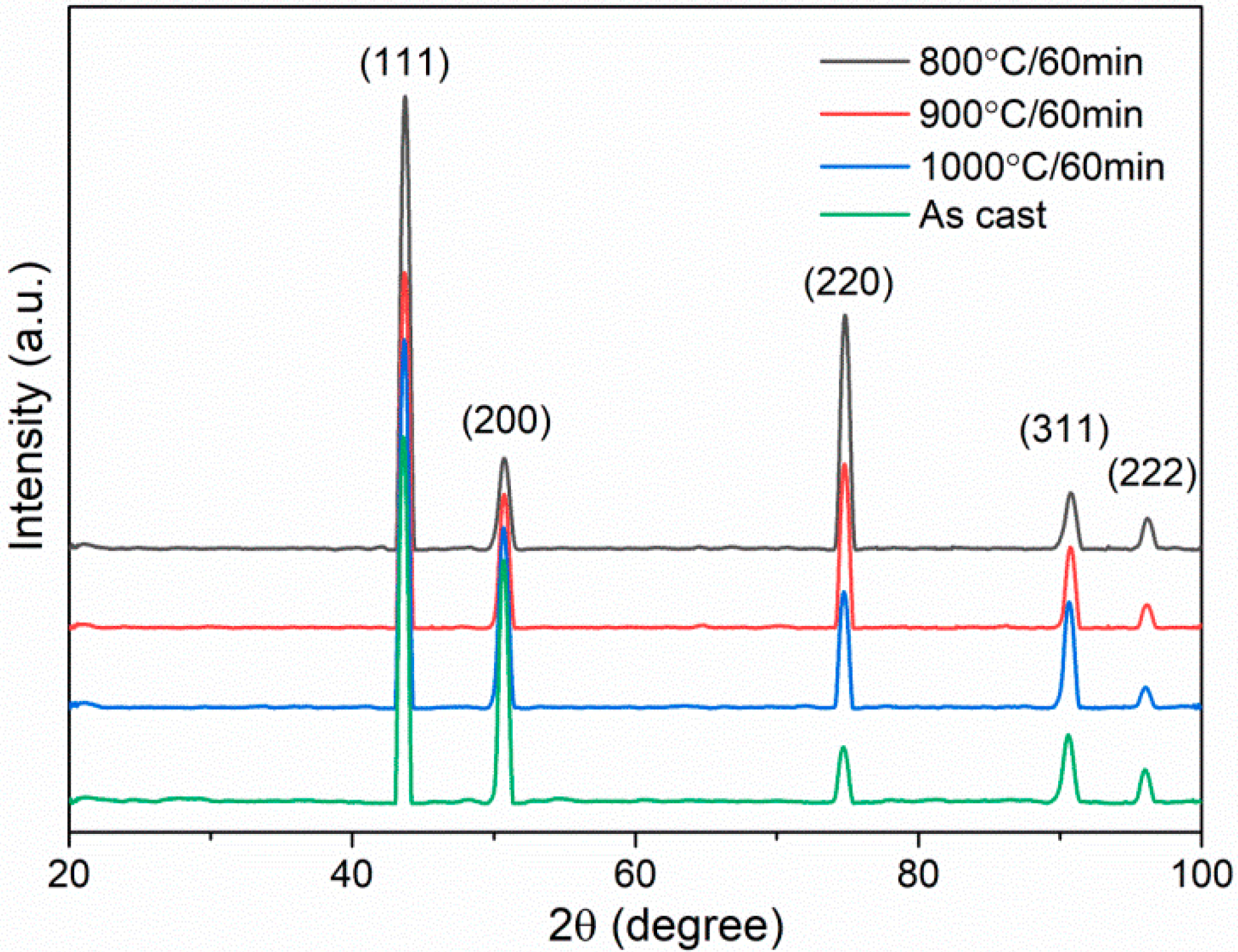

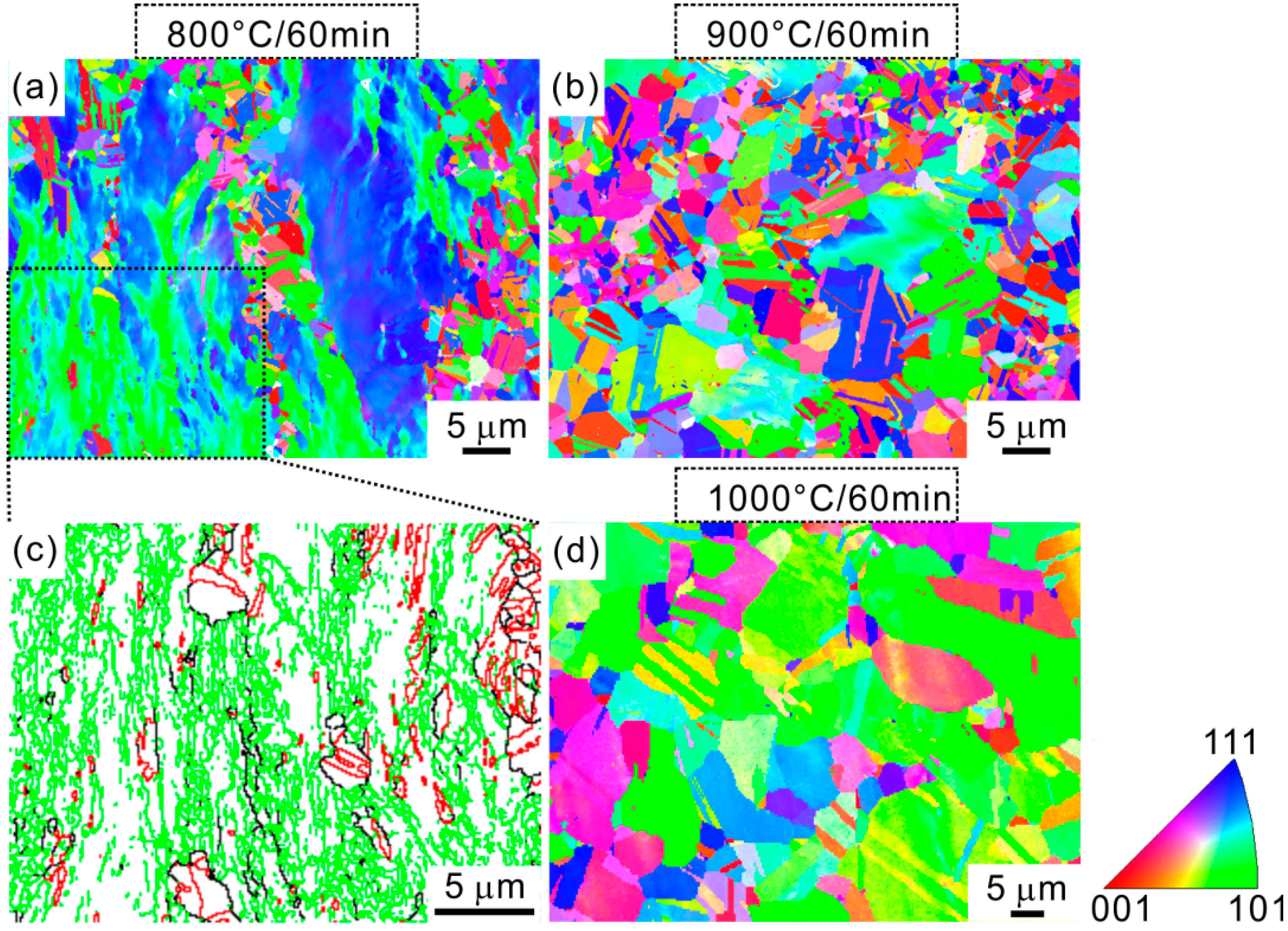

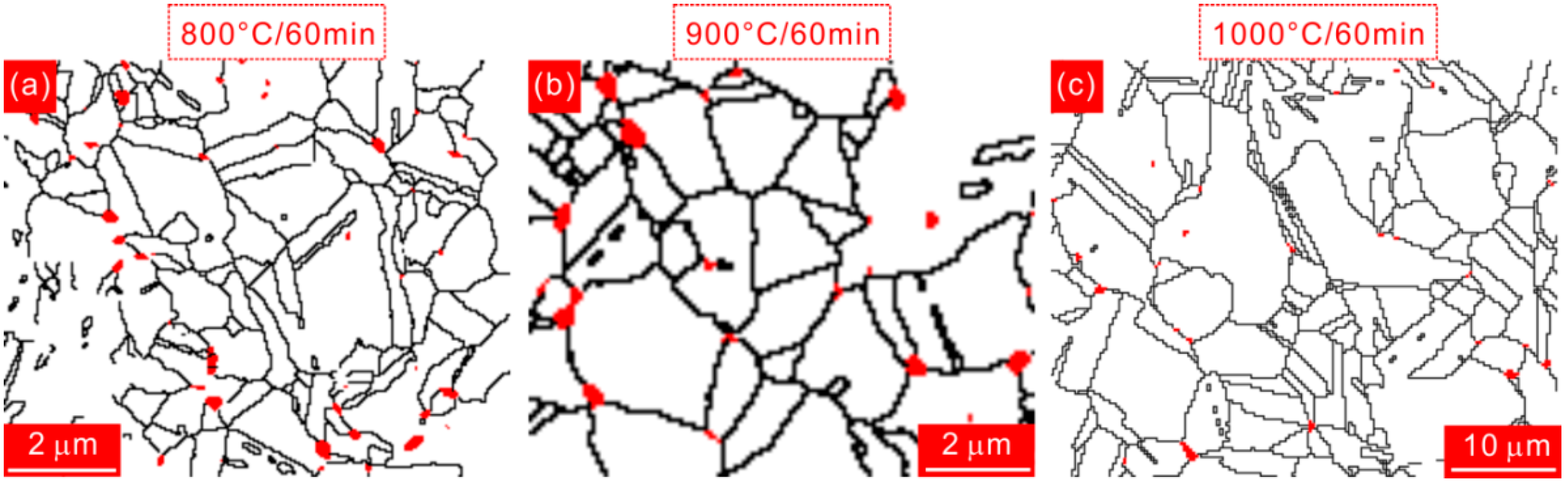

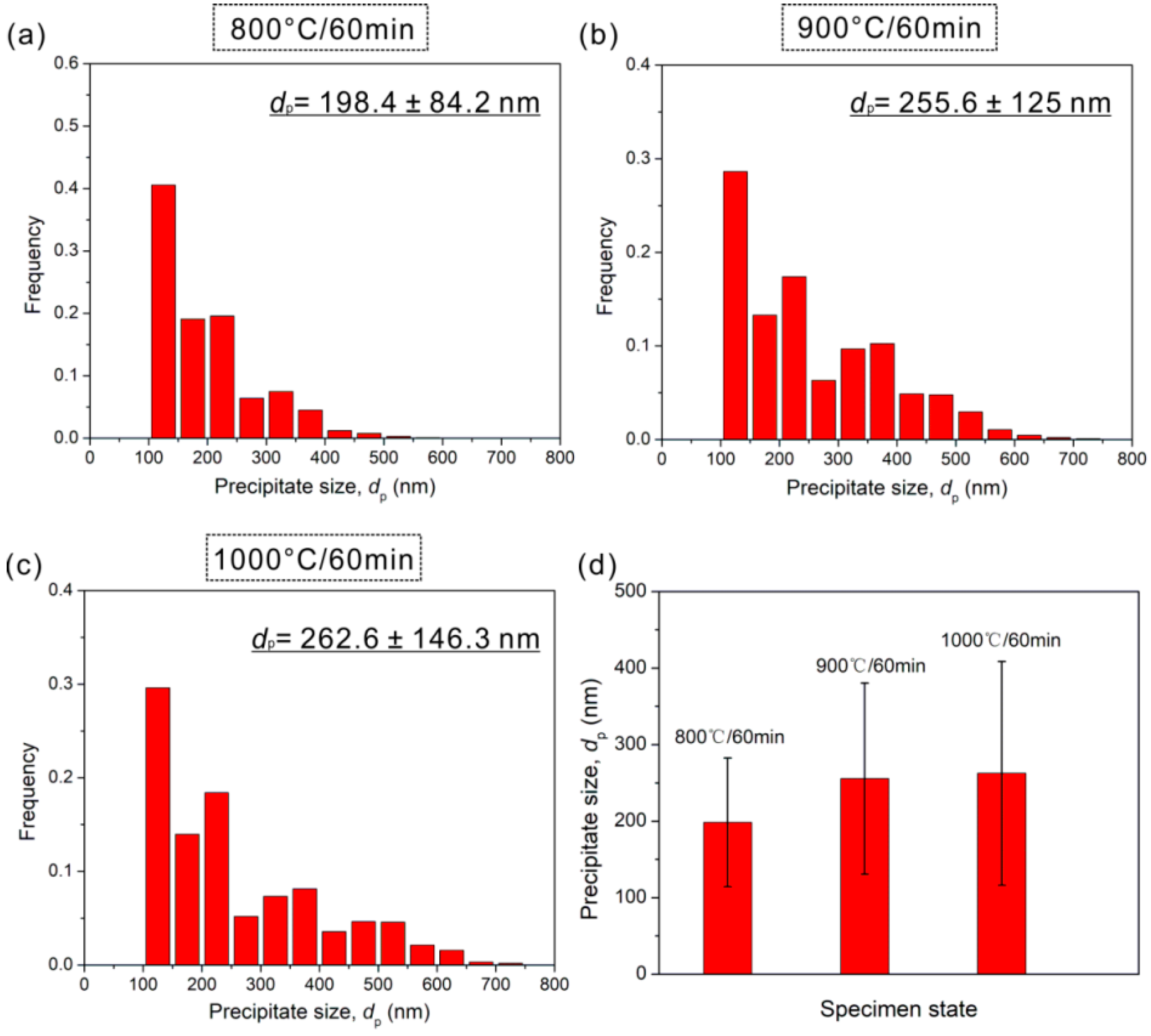

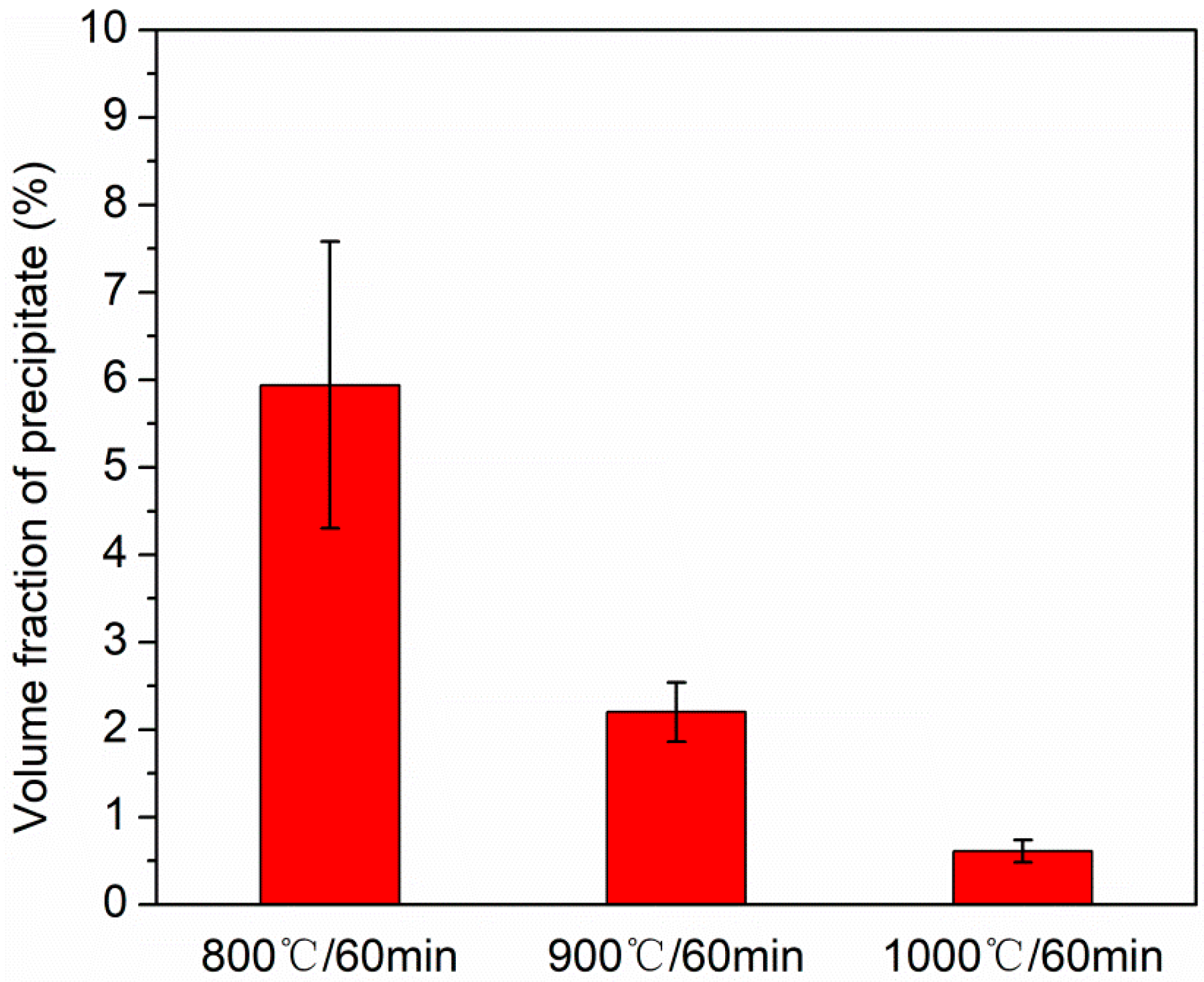

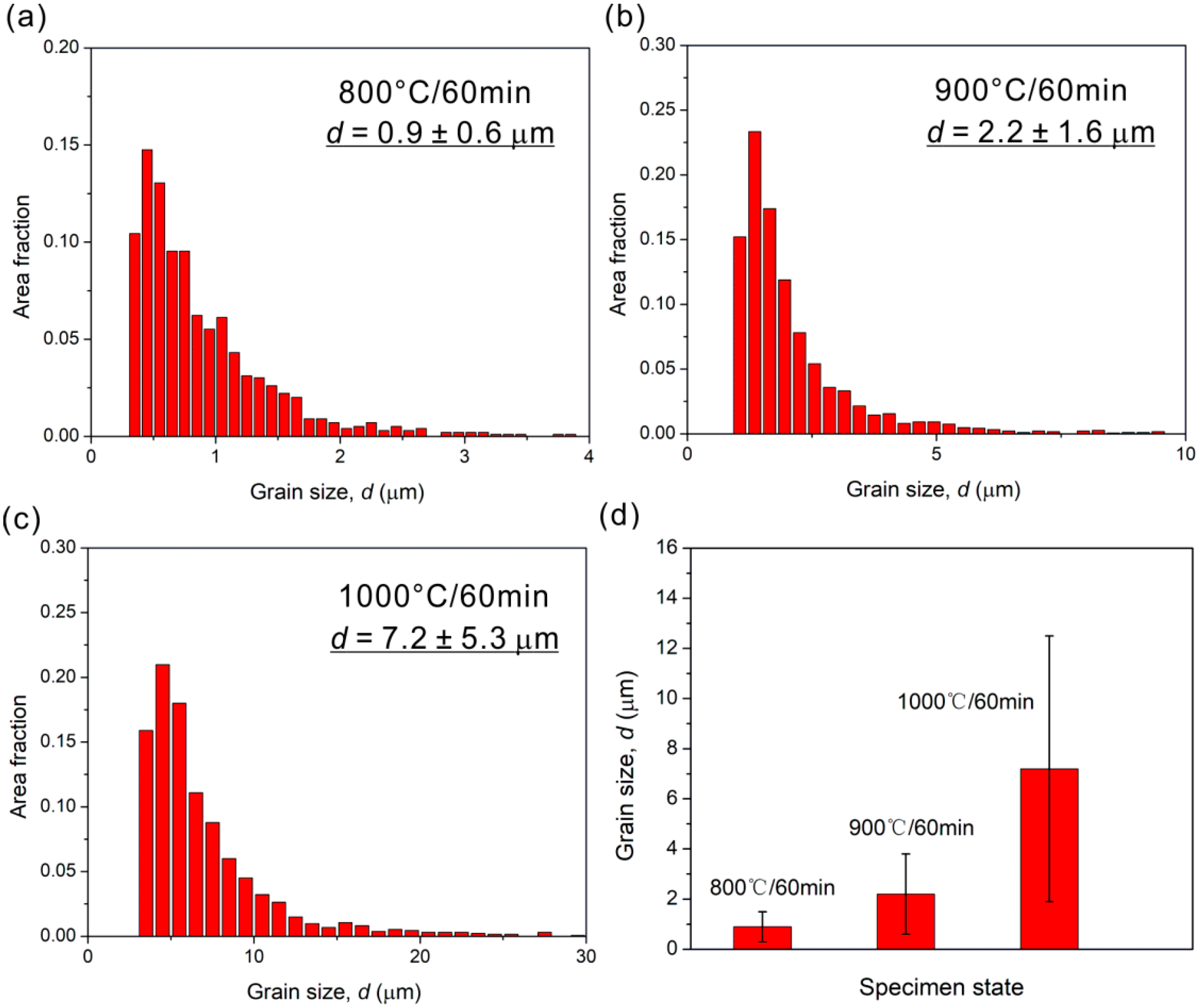

3.1. Microstructures

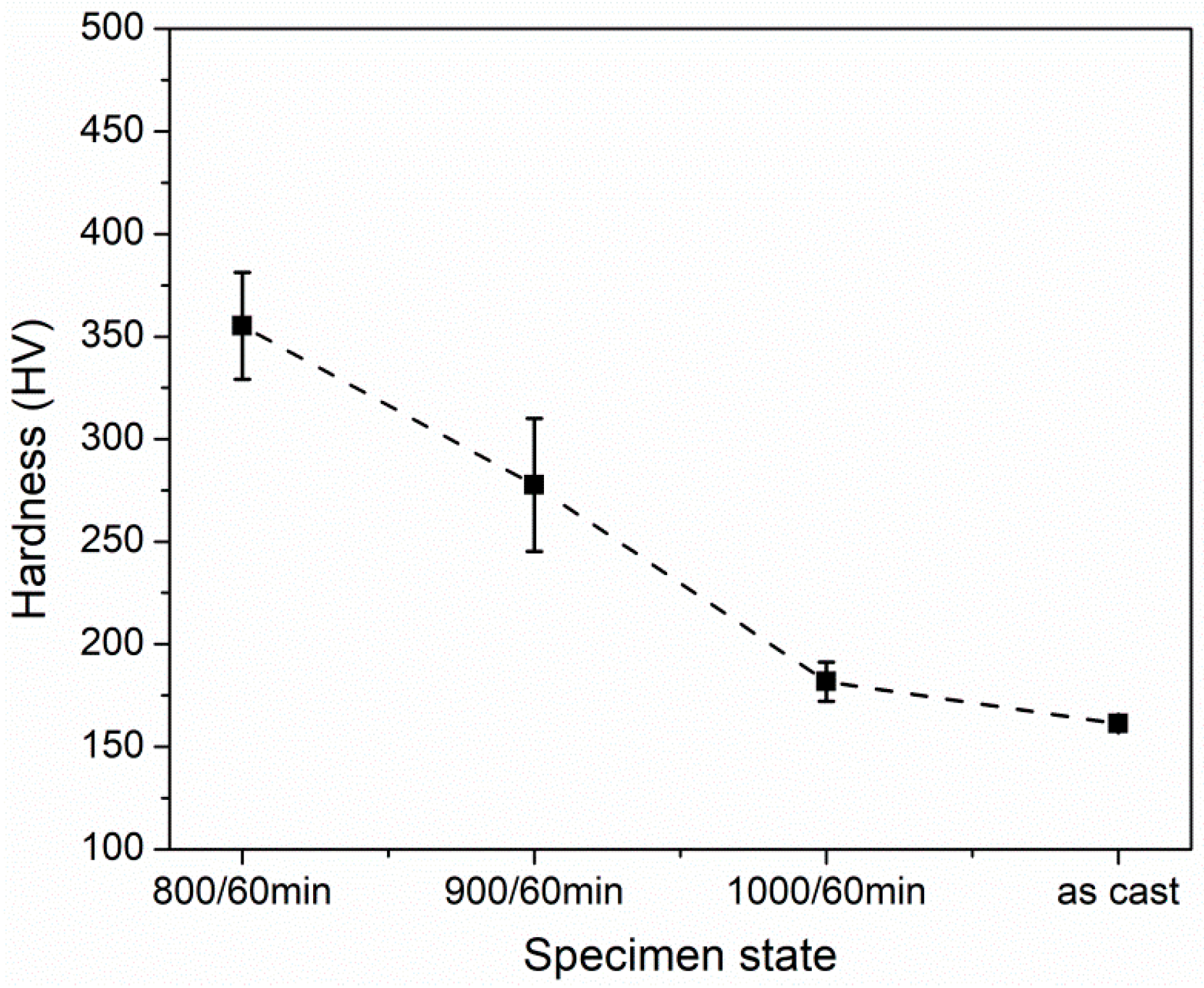

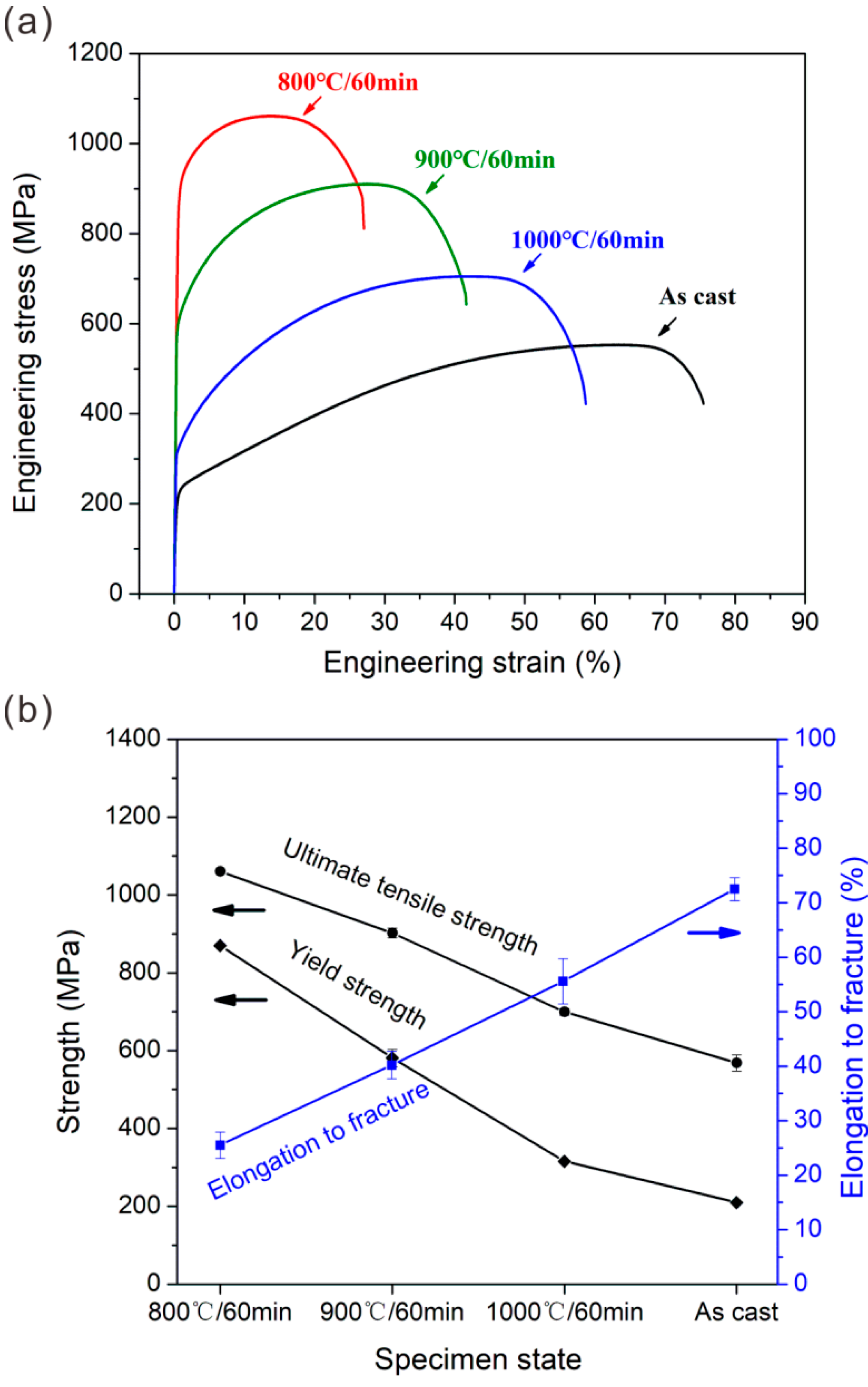

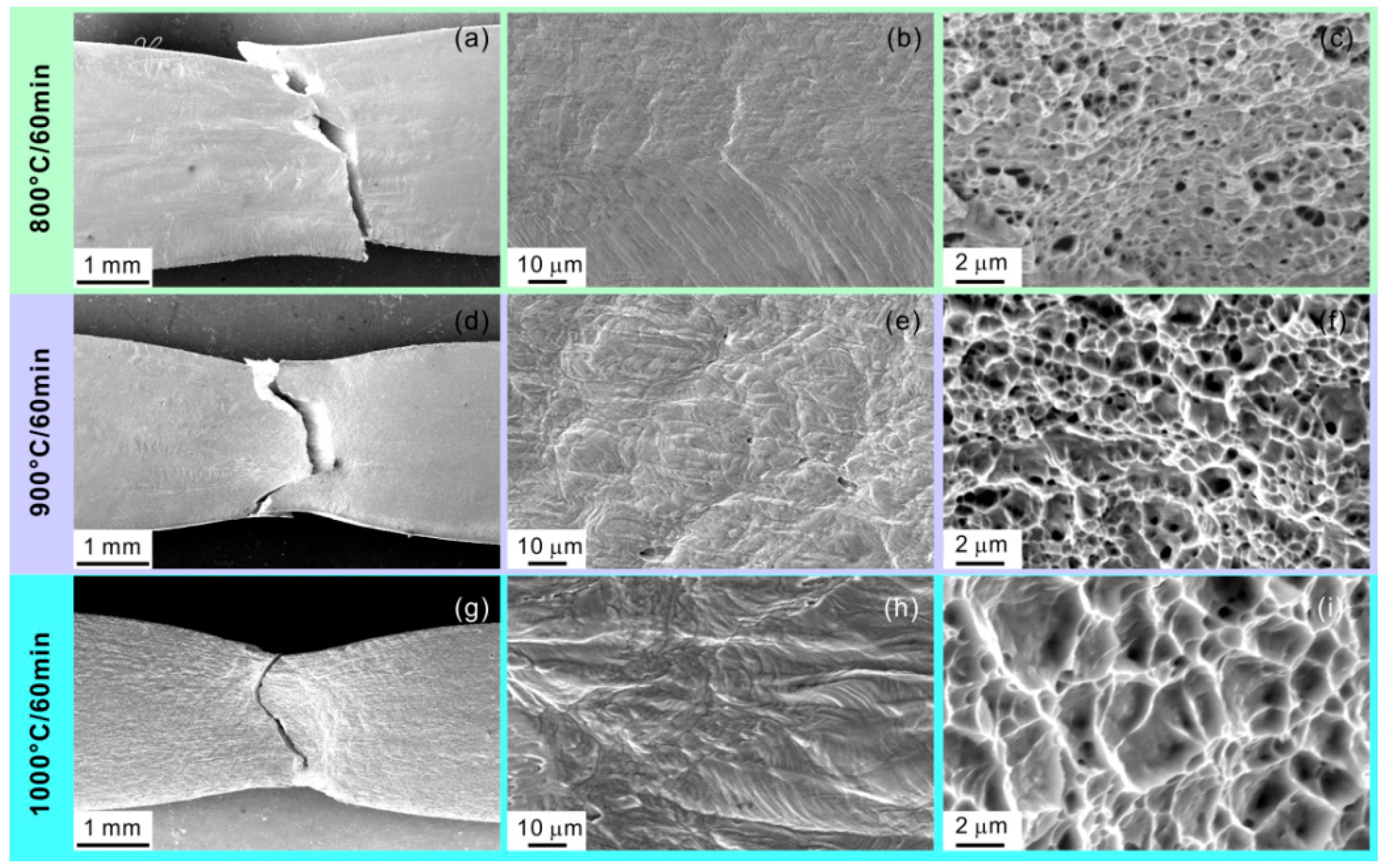

3.2. Mechanical Properties

4. Discussion

4.1. Microstructure Analysis with Increasing Annealing Temperature

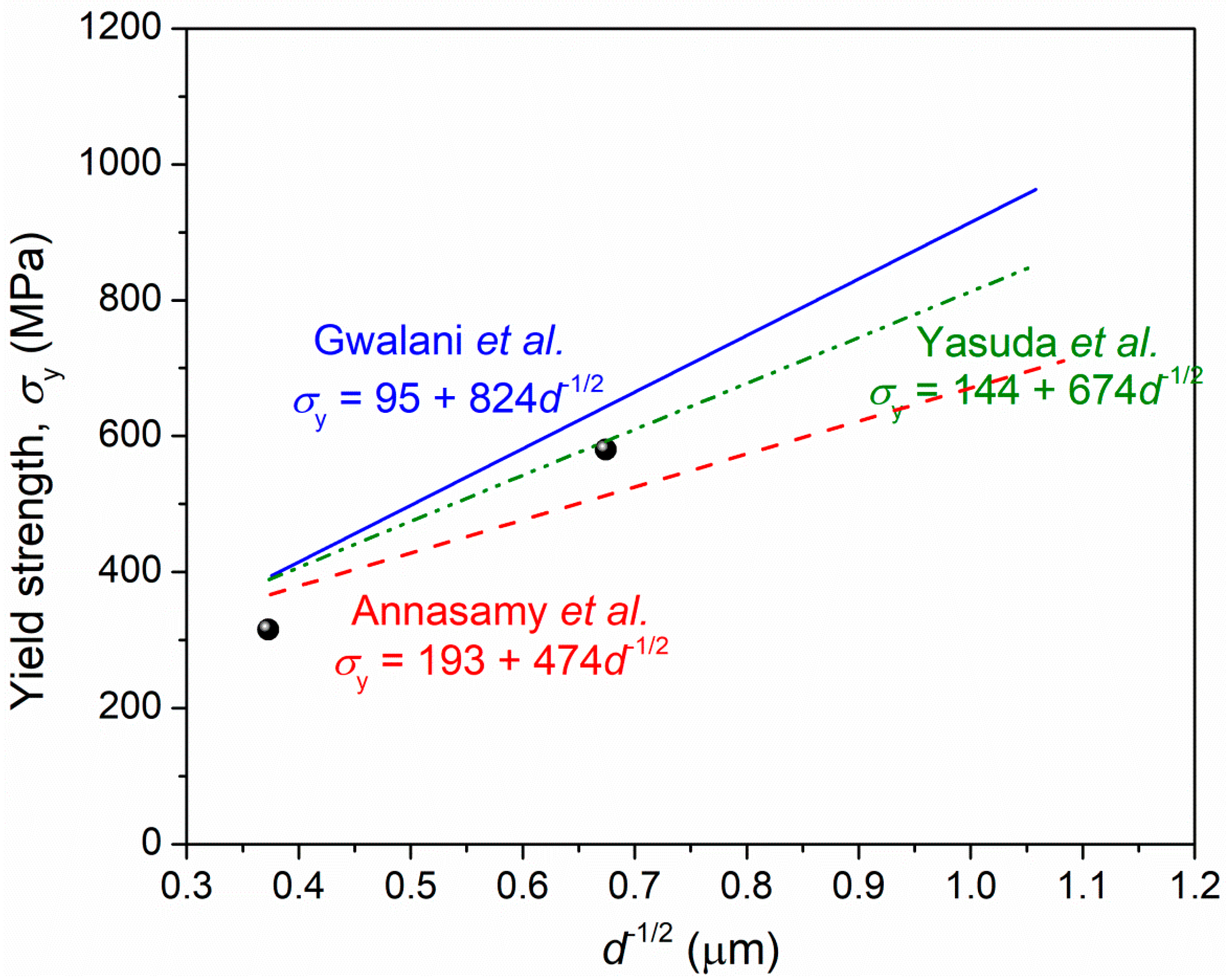

4.2. Strengthening Mechanism in 900 °C- and 1000 °C-Annealed Specimens

4.3. Strengthening Mechanism in 800 °C-Annealed Specimen

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Biswas, K.; Yeh, J.W.; Bhattacharjee, P.P.; De Hosson, J. High entropy alloys: Key issues under passionate debate. Scr. Mater. 2020, 188, 54–58. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ye, Y.F.; Wang, Q.; Lu, J.; Liu, C.T.; Yang, Y. High-entropy alloy: Challenges and prospects. Mater. Today 2016, 19, 349–362. [Google Scholar] [CrossRef]

- Zou, Y.; Li, S.L.; Liu, S.H.; Li, J.K.; Li, Y. Improved mechanical and corrosion properties of CrMnFeCoNi high entropy alloy with cold rolling and post deformation annealing process. J. Alloys Compd. 2021, 887, 161416. [Google Scholar] [CrossRef]

- Kao, Y.F.; Chen, T.J.; Chen, S.K.; Yeh, J.W. Microstructure and mechanical property of as-cast, homogenized, and deformed AlxCoCrFeNi high-entropy alloys. J. Alloys Compd. 2009, 488, 57–64. [Google Scholar] [CrossRef]

- Yang, T.F.; Xia, S.Q.; Liu, S.; Wang, C.X.; Liu, S.S.; Zhang, Y.; Xue, J.M.; Yan, S.; Wang, Y.G. Effects of Al addition on microstructure and mechanical properties of AlxCoCrFeNi High-entropy alloy. Mater. Sci. Eng. A 2015, 648, 15–22. [Google Scholar] [CrossRef]

- Li, D.Y.; Zhang, Y. The ultrahigh charpy impact toughness of forged AlxCoCrFeNi high entropy alloys at room and cryogenic temperatures. Intermetallics 2016, 70, 24–28. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, T.W.; Qiao, J.W.; Ma, S.G.; Zhao, D.; Lu, P.; Xu, B.; Wang, Z.H. Superior tensile properties of Al0.3CoCrFeNi high entropy alloys with B2 precipitated phases at room and cryogenic temperatures. Mater. Sci. Eng. A 2019, 767, 138424. [Google Scholar] [CrossRef]

- Shun, T.T.; Du, Y.C. Microstructure and tensile behaviors of FCC Al0.3CoCrFeNi high entropy alloy. J. Alloys Compd. 2009, 479, 157–160. [Google Scholar] [CrossRef]

- Annasamy, M.; Haghdadi, N.; Taylor, A.; Hodgson, P.; Fabijanic, D. Static recrystallization and grain growth behaviour of Al0.3CoCrFeNi high entropy alloy. Mater. Sci. Eng. A 2019, 754, 282–294. [Google Scholar] [CrossRef]

- Yasuda, H.Y.; Miyamoto, H.; Cho, K.; Nagase, T. Formation of ultrafine-grained microstructure in Al0.3CoCrFeNi high entropy alloys with grain boundary precipitates. Mater. Lett. 2017, 199, 120–123. [Google Scholar] [CrossRef]

- Gwalani, B.; Gorsse, S.; Choudhuri, D.; Zheng, Y.F.; Mishra, R.S.; Banerjee, R. Tensile yield strength of a single bulk Al0.3CoCrFeNi high entropy alloy can be tuned from 160 MPa to 1800 MPa. Scr. Mater. 2019, 162, 18–23. [Google Scholar] [CrossRef]

- Gwalani, B.; Soni, V.; Lee, M.; Mantri, S.; Ren, Y.; Banerjee, R. Optimizing the coupled effects of Hall-Petch and precipitation strengthening in a Al0.3CoCrFeNi high entropy alloy. Mater. Des. 2017, 121, 254–260. [Google Scholar] [CrossRef]

- He, Y.X.; Yang, H.X.; Zhao, C.D.; Zhang, Y.; Pan, X.Y.; Li, J.S.; Wang, J. Enhancing mechanical properties of Al0.25CoCrFeNi high-entropy alloy via cold rolling and subsequent annealing. J. Alloys Compd. 2020, 830, 154645. [Google Scholar] [CrossRef]

- Sathiyamoorthi, P.; Asghari-Rad, P.; Bae, J.W.; Kim, H.S. Fine tuning of tensile properties in CrCoNi medium entropy alloy through cold rolling and annealing. Intermetallics 2019, 113, 106578. [Google Scholar] [CrossRef]

- Wu, S.W.; Xu, L.; Ma, X.D.; Jia, Y.F.; Mu, Y.K.; Jia, Y.D.; Wang, G.; Liu, C.T. Effect of annealing temperatures on microstructure and deformation behavior of Al0.1CrFeCoNi high-entropy alloy. Mater. Sci. Eng. A 2021, 805, 140523. [Google Scholar] [CrossRef]

- Gu, J.; Ni, S.; Liu, Y.; Song, M. Regulating the strength and ductility of a cold rolled FeCrCoMnNi high entropy alloy via annealing treatment. Mater. Sci. Eng. A 2019, 755, 289–294. [Google Scholar] [CrossRef]

- Sun, S.J.; Tian, Y.Z.; Lin, H.R.; Yang, H.J.; Dong, X.G.; Wang, Y.H.; Zhang, Z.F. Achieving high ductility in the 1.7 GPa grade CoCrFeMnNi high-entropy alloy at 77 K. Mater. Sci. Eng. A 2019, 740, 336–341. [Google Scholar] [CrossRef]

- Li, D.Y.; Li, C.X.; Feng, T.; Zhang, Y.D.; Sha, G.; Lewandowski, J.J.; Liaw, P.K.; Zhang, Y. High-entropy Al0.3CoCrFeNi alloy fibers with high tensile strength and ductility at ambient and cryogenic temperatures. Acta Mater. 2017, 123, 285–294. [Google Scholar] [CrossRef] [Green Version]

- Tang, Q.H.; Huang, Y.; Cheng, H.; Liao, X.Z.; Langdon, T.G.; Dai, P.Q. The effect of grain size on the annealing-induced phase transformation in an Al0.3CoCrFeNi high entropy alloy. Mater. Des. 2016, 105, 381–385. [Google Scholar] [CrossRef] [Green Version]

- Dasari, S.; Sarkar, A.; Sharma, A.; Gwalani, B.; Choudhuri, D.; Soni, V.; Manda, S.; Samajdar, I.; Banerjee, R. Recovery of cold-worked Al0.3CoCrFeNi complex concentrated alloy through twinning assisted B2 precipitation. Acta Mater. 2021, 202, 448–462. [Google Scholar] [CrossRef]

- Choudhuri, D.; Shukla, S.; Green, W.B.; Gwalani, B.; Ageh, V.; Banerjee, R.; Mishra, R.S. Crystallographically degenerate B2 precipitation in a plastically deformed fcc-based complex concentrated alloy. Mater. Res. Lett. 2018, 6, 171–177. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Z.C.; Yang, T.T.; Shi, R.L.; Quan, X.T.; Zhang, J.L.; Qiu, R.S.; Song, B.; Liu, Q. The effects of annealing at different temperatures on microstructure and mechanical properties of cold-rolled Al0.3CoCrFeNi high-entropy alloy. Metals 2021, 11, 940. [Google Scholar] [CrossRef]

- Lee, D.H.; Agustianingrum, M.P.; Park, N.; Tsuji, N. Synergistic effect by Al addition in improving mechanical performance of CoCrNi medium-entropy alloy. J. Alloys Compd. 2019, 800, 372–378. [Google Scholar] [CrossRef]

- Hou, J.X.; Shi, X.H.; Qiao, J.W.; Zhang, Y.; Liaw, P.K.; Wu, Y.C. Ultrafine-grained dual phase Al0.45CoCrFeNi high-entropy alloys. Mater. Des. 2019, 180, 107910. [Google Scholar] [CrossRef]

- Wang, X.D.; Zhang, Z.; Wang, Z.B.; Ren, X.C. Excellent tensile property and its mechanism in Al0.3CoCrFeNi high-entropy alloy via thermo-mechanical treatment. J. Alloys Compd. 2021, 897, 163218. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, S.D.; Li, F.J.; Luo, Y.; Yao, Y.L.; Zhang, H.C.; Wang, Z.M.; Wang, L.B.; Wang, Z.Y. Tailoring the strength and ductility of Al0.25CoCrFeNi high entropy alloy through cryo-rolling and annealing. Mater. Sci. Eng. A 2021, 826, 141964. [Google Scholar] [CrossRef]

- Qi, Y.L.; Zhao, L.; Sun, X.; Zong, H.X.; Ding, X.D.; Jiang, F.; Zhang, H.L.; Wu, Y.K.; He, L.; Liu, F.; et al. Enhanced mechanical performance of grain boundary precipitation-hardened high-entropy alloys via a phase transformation at grain boundaries. J. Mater. Sci. Technol. 2021, 86, 271–284. [Google Scholar] [CrossRef]

- Kireeva, I.V.; Chumlyakov, Y.I.; Pobedennaya, Z.V.; Vyrodova, A.V.; Kuksgauzen, I.V.; Kuksgauzen, D.A. Orientation and temperature dependence of a planar slip and twinning in single crystals of Al0.3CoCrFeNi high-entropy alloy. Mater. Sci. Eng. A 2018, 737, 47–60. [Google Scholar] [CrossRef]

- Zhang, L.J.; Yu, P.F.; Zhang, C.Z.; Fan, J.T.; Li, G. Stress-dependent incipient plasticity of a face centered cubic based Al0.3CoCrFeNi multi-principal element alloy with nano-scaled phase separation. Scr. Mater. 2021, 203, 114053. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Wang, X.G.; Li, J.G.; Huang, Y.Q.; Lu, Y.P.; Sun, X.F. Deformation mechanism during high-temperature tensile test in an eutectic high-entropy alloy AlCoCrFeNi2.1. Mater. Sci. Eng. A 2018, 724, 148–155. [Google Scholar] [CrossRef]

- Cheng, P.; Zhao, Y.H.; Xu, X.T.; Wang, S.; Sun, Y.Y.; Hou, H. Microstructural evolution and mechanical properties of Al0.3CoCrFeNiSix high-entropy alloys containing coherent nanometer-scaled precipitates. Mater. Sci. Eng. A 2020, 772, 138681. [Google Scholar] [CrossRef]

- Gwalani, B.; Gorsse, S.; Choudhuri, D.; Styles, M.; Zheng, Y.F.; Mishra, R.S.; Banerjee, R. Modifying transformation pathways in high entropy alloys or complex concentrated alloys via thermo-mechanical processing. Acta Mater. 2018, 153, 169–185. [Google Scholar] [CrossRef]

- Yang, H.X.; Li, J.S.; Pan, X.Y.; Wang, W.Y.; Kou, H.C.; Wang, J. Nanophase precipitation and strengthening in a dual-phase Al0.5CoCrFeNi high-entropy alloy. J. Mater. Sci. Technol. 2021, 72, 1–7. [Google Scholar] [CrossRef]

- Kamikawa, N.; Sato, K.; Miyamoto, G.; Murayama, M.; Sekido, N.; Tsuzaki, K.; Furuhara, T. Stress–strain behavior of ferrite and bainite with nano-precipitation in low carbon steels. Acta Mater. 2015, 83, 383–396. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.; Liao, H.C.; Chen, H.; Huang, A.J. Effects of hot-forging and subsequent annealing on microstructure and mechanical behaviors of Fe35Ni35Cr20Mn10 high-entropy alloy. Mater. Charact. 2021, 178, 111251. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Zhang, Z.; Wang, Z.; Ren, X. Microstructural Evolution and Tensile Properties of Al0.3CoCrFeNi High-Entropy Alloy Associated with B2 Precipitates. Materials 2022, 15, 1215. https://doi.org/10.3390/ma15031215

Wang X, Zhang Z, Wang Z, Ren X. Microstructural Evolution and Tensile Properties of Al0.3CoCrFeNi High-Entropy Alloy Associated with B2 Precipitates. Materials. 2022; 15(3):1215. https://doi.org/10.3390/ma15031215

Chicago/Turabian StyleWang, Xiaodi, Zhe Zhang, Zhengbin Wang, and Xuechong Ren. 2022. "Microstructural Evolution and Tensile Properties of Al0.3CoCrFeNi High-Entropy Alloy Associated with B2 Precipitates" Materials 15, no. 3: 1215. https://doi.org/10.3390/ma15031215

APA StyleWang, X., Zhang, Z., Wang, Z., & Ren, X. (2022). Microstructural Evolution and Tensile Properties of Al0.3CoCrFeNi High-Entropy Alloy Associated with B2 Precipitates. Materials, 15(3), 1215. https://doi.org/10.3390/ma15031215