Recent Advances on Thermoelectric Silicon for Low-Temperature Applications

Abstract

:1. Introduction

2. Silicon: From to Its Practical Usability

3. Decreasing Thermal Conductivity in Single-Crystalline Silicon

4. Increasing PF in Polycrystalline Silicon

4.1. Silicon Thin Films

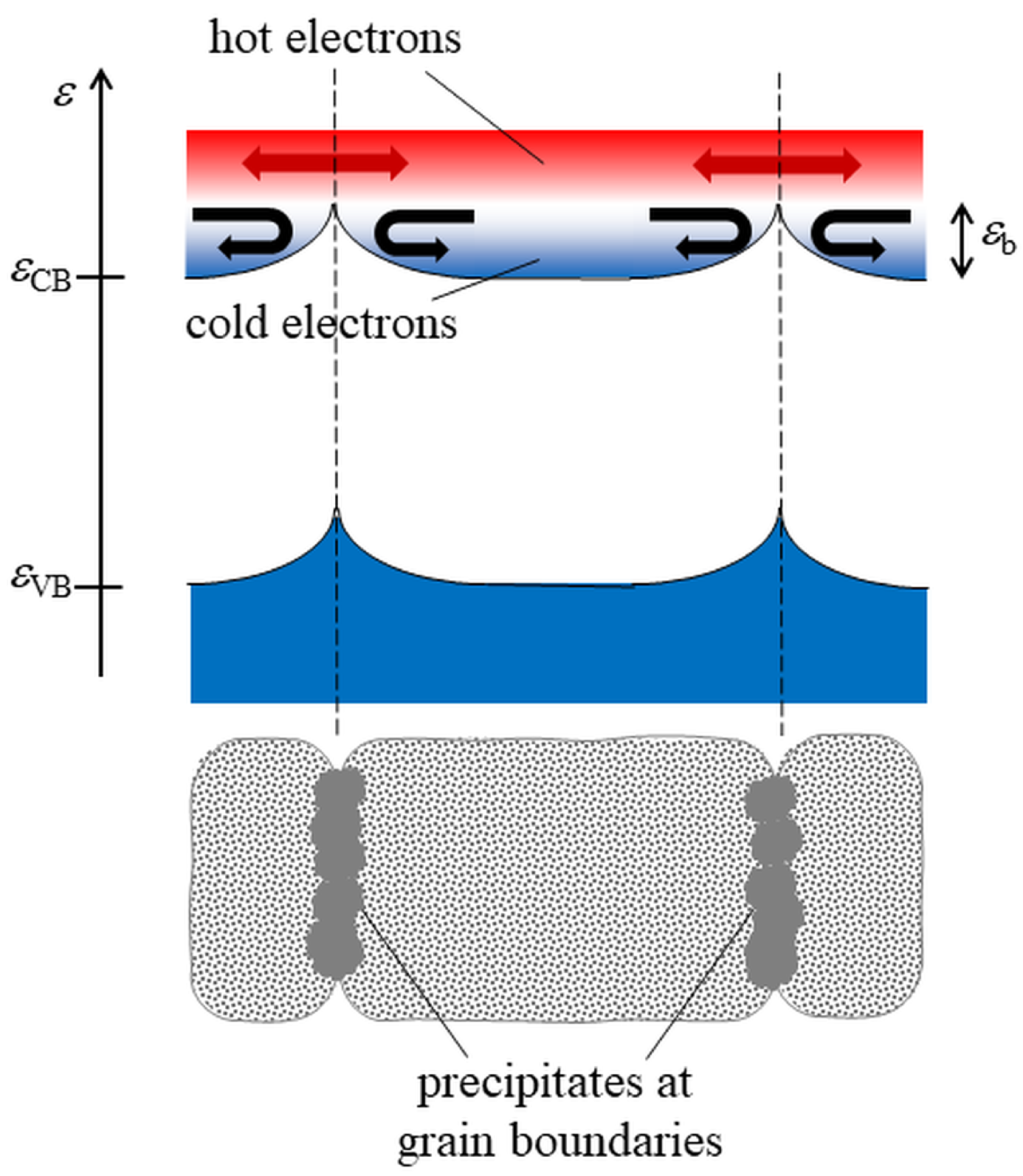

4.2. Silicon Nanocomposites

5. Low-Temperature Applications

6. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| GB | Grain boundary |

| IoT | Internet of Things |

| ncSi | Nanocrystalline silicon |

| RTG | Radio-isotope Thermoelectric Generator |

| TE | Thermoelectric |

| TEC | Thermoelectric cooler |

| TEG | Thermoelectric generator |

| PF | Power factor |

| scSi | Single-crystalline silicon |

| SiNW | Silicon nanowire |

References

- Beretta, D.; Neophytou, N.; Hodges, J.M.; Kanatzidis, M.G.; Narducci, D.; Martin-Gonzalez, M.; Beekman, M.; Balke, B.; Cerretti, G.; Tremel, W.; et al. Thermoelectrics: From history, a window to the future. Mater. Sci. Eng. R 2018, 138, 210–255. [Google Scholar] [CrossRef]

- Bennett, G.L.; Skrabek, E. Power performance of US space radioisotope thermoelectric generators. In Proceedings of the Fifteenth International Conference on Thermoelectrics, Proceedings ICT’96, Pasadena, CA, USA, 26–29 March 1996; IEEE: New York, NY, USA, 1996; pp. 357–372. [Google Scholar]

- Bubnova, O.; Khan, Z.U.; Wang, H.; Braun, S.; Evans, D.R.; Fabretto, M.; Hojati-Talemi, P.; Dagnelund, D.; Arlin, J.B.; Geerts, Y.H.; et al. Semi-metallic polymers. Nat. Mater. 2014, 13, 190–194. [Google Scholar] [CrossRef]

- Yusupov, K.; Vomiero, A. Polymer-Based Low-Temperature Thermoelectric Composites. Adv. Funct. Mater. 2020, 30, 2002015. [Google Scholar] [CrossRef]

- Choi, K.; Kim, S.L.; Yi, S.i.; Hsu, J.H.; Yu, C. Promoting dual electronic and ionic transport in PEDOT by embedding carbon nanotubes for large thermoelectric responses. ACS Appl. Mater. Interfaces 2018, 10, 23891–23899. [Google Scholar] [CrossRef] [PubMed]

- Fan, Z.; Du, D.; Guan, X.; Ouyang, J. Polymer films with ultrahigh thermoelectric properties arising from significant seebeck coefficient enhancement by ion accumulation on surface. Nano Energy 2018, 51, 481–488. [Google Scholar] [CrossRef]

- Nozariasbmarz, A.; Agarwal, A.; Coutant, Z.A.; Hall, M.J.; Liu, J.; Liu, R.; Malhotra, A.; Norouzzadeh, P.; Oeztuerk, M.C.; Ramesh, V.P.; et al. Thermoelectric silicides: A review. Jpn. J. Appl. Phys. 2017, 56, 05DA04. [Google Scholar] [CrossRef]

- Narducci, D.; Frabboni, S.; Zianni, X. Silicon de novo: Energy filtering and enhanced thermoelectric performances of nanocrystalline silicon and silicon alloys. J. Mater. Chem. C 2015, 3, 12176–12185. [Google Scholar] [CrossRef]

- Schierning, G. Silicon nanostructures for thermoelectric devices: A review of the current state of the art. Phys. Status Solidi A 2014, 211, 1235–1249. [Google Scholar] [CrossRef]

- Pérez-Taborda, J.A.; Caballero-Calero, O.; Martín-González, M. Silicon germanium (SiGe) nanostructures for thermoelectric devices: Recent advances and new approaches to high thermoelectric efficiency. In New Research on Silicon—Structure, Properties, Technology; IntechOpen: London, UK, 2017; Chapter 2. [Google Scholar]

- Gadea, G.; Pacios, M.; Morata, Á.; Tarancón, A. Silicon-based nanostructures for integrated thermoelectric generators. J. Phys. D Appl. Phys. 2018, 51, 423001. [Google Scholar] [CrossRef]

- Chen, R.; Lee, J.; Lee, W.; Li, D. Thermoelectrics of Nanowires. Chem. Rev. 2019, 119, 9260–9302. [Google Scholar] [CrossRef]

- Pennelli, G.; Dimaggio, E.; Masci, A. Silicon nanowires: A breakthrough for thermoelectric applications. Materials 2021, 14, 5305. [Google Scholar] [CrossRef] [PubMed]

- Geballe, T.H.; Hull, G.W. Seebeck Effect in Silicon. Phys. Rev. 1955, 98, 940. [Google Scholar] [CrossRef]

- Fulkerson, W.; Moore, J.P.; Williams, R.K.; Graves, R.S.; McElroy, D.L. Thermal Conductivity, Electrical Resistivity, and Seebeck Coefficient of Silicon from 100 to 1300 ∘K. Phys. Rev. 1968, 167, 765. [Google Scholar] [CrossRef]

- Stranz, A.; Kaehler, J.; Waag, A.; Peiner, E. Thermoelectric Properties of High-Doped Silicon from Room Temperature to 900 K. J. Electron. Mater. 2013, 42, 2381–2387. [Google Scholar] [CrossRef]

- Dismukes, J.; Ekstrom, L.; Steigmeier, E.; Kudman, I.; Beers, D. Thermal and electrical properties of heavily doped Ge-Si alloys up to 1300 K. J. Appl. Phys. 1964, 35, 2899–2907. [Google Scholar] [CrossRef]

- Rowe, D.; Shukla, V.; Savvides, N. Phonon scattering at grain boundaries in heavily doped fine-grained silicon–germanium alloys. Nature 1981, 290, 765–766. [Google Scholar] [CrossRef]

- Vining, C.B.; Laskow, W.; Hanson, J.O.; Van der Beck, R.R.; Gorsuch, P.D. Thermoelectric properties of pressure–sintered Si0.8Ge0.2 thermoelectric alloys. J. Appl. Phys. 1991, 69, 4333–4340. [Google Scholar] [CrossRef]

- El-Genk, M.S.; Saber, H.H. High efficiency segmented thermoelectric unicouple for operation between 973 and 300 K. Energy Convers. Manag. 2003, 44, 1069–1088. [Google Scholar] [CrossRef]

- Hochbaum, A.I.; Chen, R.K.; Delgado, R.D.; Liang, W.J.; Garnett, E.C.; Najarian, M.; Majumdar, A.; Yang, P.D. Enhanced thermoelectric performance of rough silicon nanowires. Nature 2008, 451, 163–167. [Google Scholar] [CrossRef] [PubMed]

- Boukai, A.I.; Bunimovich, Y.; Tahir-Kheli, J.; Yu, J.K.; Goddard, W.A.; Heath, J.R. Silicon nanowires as efficient thermoelectric materials. Nature 2008, 451, 168–171. [Google Scholar] [CrossRef]

- Ju, Y.S.; Goodson, K.E. Phonon scattering in silicon films with thickness of order 100 nm. Appl. Phys. Lett. 1999, 74, 3005–3007. [Google Scholar] [CrossRef]

- Wang, X.W.; Lee, H.; Lan, Y.C.; Zhu, G.H.; Joshi, G.; Wang, D.Z.; Yang, J.; Muto, A.J.; Tang, M.Y.; Klatsky, J.; et al. Enhanced thermoelectric figure of merit in nanostructured n-type silicon germanium bulk alloy. Appl. Phys. Lett. 2008, 93, 193121. [Google Scholar] [CrossRef]

- Narducci, D.; Bermel, P.; Lorenzi, B.; Wang, N.; Yazawa, K. A Primer on Thermoelectric Generators. In Hybrid and Fully Thermoelectric Solar Harvesting; Springer International Publishing: Cham, Switzerland, 2018; Volume 268, Chapter 2; pp. 11–43. [Google Scholar]

- Narducci, D. Do we really need high thermoelectric figures of merit? A critical appraisal to the power conversion efficiency of thermoelectric materials. Appl. Phys. Lett. 2011, 99, 102104. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Kim, H.S.; Jie, Q.; Ren, Z. Importance of high power factor in thermoelectric materials for power generation application: A perspective. Scr. Mater. 2016, 111, 3–9. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Caillat, T. Thermoelectric Materials for Space and Automotive Power Generation. MRS Bull. 2006, 31, 224–229. [Google Scholar] [CrossRef]

- Lee, Y.; Hwang, G.S. Mechanism of thermal conductivity suppression in doped silicon studied with nonequilibrium molecular dynamics. Phys. Rev. B 2012, 86, 075202. [Google Scholar] [CrossRef] [Green Version]

- Bennett, N.S.; Wight, N.M.; Popuri, S.R.; Bos, J.W.G. Efficient thermoelectric performance in silicon nano-films by vacancy-engineering. Nano Energy 2015, 16, 350–356. [Google Scholar] [CrossRef] [Green Version]

- Bennett, N.S.; Byrne, D.; Cowley, A.; Neophytou, N. Dislocation loops as a mechanism for thermoelectric power factor enhancement in silicon nano-layers. Appl. Phys. Lett. 2016, 109, 10–15. [Google Scholar] [CrossRef] [Green Version]

- Valalaki, K.; Vouroutzis, N.; Nassiopoulou, A. Significant enhancement of the thermoelectric figure of merit of polycrystalline Si films by reducing grain size. J. Phys. D Appl. Phys. 2016, 49, 315104. [Google Scholar] [CrossRef]

- Xie, J.; Lee, C.; Wang, M.F.; Liu, Y.; Feng, H. Characterization of heavily doped polysilicon films for CMOS-MEMS thermoelectric power generators. J. Micromech. Microeng. 2009, 19, 125029. [Google Scholar] [CrossRef] [Green Version]

- Yu, B.; Zebarjadi, M.; Wang, H.; Lukas, K.; Wang, H.; Wang, D.; Opeil, C.; Dresselhaus, M.; Chen, G.; Ren, Z. Enhancement of Thermoelectric Properties by Modulation-Doping in Silicon Germanium Alloy Nanocomposites. Nano Lett. 2012, 12, 2077–2082. [Google Scholar] [CrossRef] [PubMed]

- Rowe, D.M.; Min, G. Multiple potential barriers as a possible mechanism to increase the Seebeck coefficient and electrical power factor. AIP Conf. Proc. 1994, 316, 339–342. [Google Scholar]

- Mahan, G.D.; Woods, L.M. Multilayer Thermionic Refrigeration. Phys. Rev. Lett. 1998, 80, 4016–4019. [Google Scholar] [CrossRef] [Green Version]

- Mahan, G.D.; Sofo, J.O.; Bartkowiak, M. Multilayer thermionic refrigerator and generator. J. Appl. Phys. 1998, 83, 4683–4689. [Google Scholar] [CrossRef] [Green Version]

- Nishio, Y.; Hirano, T. Improvement of the efficiency of thermoelectric energy conversion by utilizing potential barriers. Jpn. J. Appl. Phys. 1997, 36, 170. [Google Scholar] [CrossRef]

- Faleev, S.V.; Léonard, F. Theory of enhancement of thermoelectric properties of materials with nanoinclusions. Phys. Rev. B 2008, 77, 214304. [Google Scholar] [CrossRef] [Green Version]

- Kajikawa, Y. Conduction model covering non-degenerate through degenerate polycrystalline semiconductors with non-uniform grain-boundary potential heights based on an energy filtering model. J. Appl. Phys. 2012, 112, 123713. [Google Scholar] [CrossRef]

- Kim, R.; Lundstrom, M.S. Computational study of energy filtering effects in one-dimensional composite nano-structures. J. Appl. Phys. 2012, 111, 024508. [Google Scholar] [CrossRef] [Green Version]

- Kajikawa, Y. Effects of potential barrier height and its fluctuations at grain boundaries on thermoelectric properties of polycrystalline semiconductors. J. Appl. Phys. 2013, 114, 053707. [Google Scholar] [CrossRef]

- Kajikawa, Y. Effects of grain-boundary potential barrier height and its fluctuation on conductivity of polycrystalline semiconductors in the ionized-impurity-scattering dominated case. J. Appl. Phys. 2013, 114, 043719. [Google Scholar] [CrossRef] [Green Version]

- Neophytou, N.; Kosina, H. Optimizing thermoelectric power factor by means of a potential barrier. J. Appl. Phys. 2013, 114, 044315. [Google Scholar] [CrossRef]

- Shakouri, A.; LaBounty, C.; Abraham, P.; Piprek, J.; Bowers, J.E. Enhanced Thermionic Emission Cooling in High Barrier Superlattice Heterostructures. MRS Proc. 1998, 545, 449. [Google Scholar] [CrossRef] [Green Version]

- Vashaee, D.; Shakouri, A. Improved thermoelectric power factor in metal-based superlattices. Phys. Rev. Lett. 2004, 92, 106103. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zide, J.M.O.; Vashaee, D.; Bian, Z.X.; Zeng, G.; Bowers, J.E.; Shakouri, A.; Gossard, A.C. Demonstration of electron filtering to increase the Seebeck coefficient in In0.53Ga0.47As/In0.53Ga0.28Al0.19As superlattices. Phys. Rev. B 2006, 74, 205335. [Google Scholar] [CrossRef] [Green Version]

- Xia, Y.; Park, J.; Zhou, F.; Ozoliņš, V. High Thermoelectric Power Factor in Intermetallic CoSi Arising from Energy Filtering of Electrons by Phonon Scattering. Phys. Rev. Appl. 2019, 11, 024017. [Google Scholar] [CrossRef] [Green Version]

- Paul, B.; Kumar V., A.; Banerji, P. Embedded Ag-rich nanodots in PbTe: Enhancement of thermoelectric properties through energy filtering of the carriers. J. Appl. Phys. 2010, 108, 064322. [Google Scholar] [CrossRef]

- Soni, A.; Shen, Y.; Yin, M.; Zhao, Y.; Yu, L.; Hu, X.; Dong, Z.; Khor, K.A.; Dresselhaus, M.S.; Xiong, Q. Interface Driven Energy Filtering of Thermoelectric Power in Spark Plasma Sintered Bi2Te2.7Se0.3 Nanoplatelet Composites. Nano Lett. 2012, 12, 4305–4310. [Google Scholar] [CrossRef] [PubMed]

- Dou, Y.C.; Qin, X.Y.; Li, D.; Li, L.L.; Zou, T.H.; Wang, Q.Q. Enhanced thermopower and thermoelectric performance through energy filtering of carriers in (Bi2Te3)0.2 (Sb2 Te3)0.8 bulk alloy embedded with amorphous SiO2 nanoparticles. J. Appl. Phys. 2013, 114, 044906. [Google Scholar] [CrossRef]

- Xu, H.; Chen, G.; Jin, R.; Chen, D.; Wang, Y.; Pei, J.; Yan, C.; Zhang, Y.; Qiu, Z. Enhancement of the Seebeck coefficient in stacked Bi2Se3 nanoplates by energy filtering. Eur. J. Inorg. Chem. 2015, 2014, 2625–2630. [Google Scholar] [CrossRef]

- Sabarinathan, M.; Omprakash, M.; Harish, S.; Navaneethan, M.; Archana, J.; Ponnusamy, S.; Ikeda, H.; Takeuchi, T.; Muthamizhchelvan, C.; Hayakawa, Y. Enhancement of power factor by energy filtering effect in hierarchical BiSbTe3 nanostructures for thermoelectric applications. Appl. Surf. Sci. 2017, 418, 246–251. [Google Scholar] [CrossRef]

- Ko, D.K.; Kang, Y.; Murray, C.B. Enhanced Thermopower via Carrier Energy Filtering in Solution-Processable Pt-Sb2Te3 Nanocomposites. Nano Lett. 2011, 11, 2841–2844. [Google Scholar] [CrossRef] [PubMed]

- He, M.; Ge, J.; Lin, Z.; Feng, X.; Wang, X.; Lu, H.; Yang, Y.; Qiu, F. Thermopower enhancement in conducting polymer nanocomposites via carrier energy scattering at the organic-inorganic semiconductor interface. Energy Environ. Sci. 2012, 5, 8351. [Google Scholar] [CrossRef]

- Zou, T.; Qin, X.; Zhang, Y.; Li, X.; Zeng, Z.; Li, D.; Zhang, J.; Xin, H.; Xie, W.; Weidenkaff, A. Enhanced thermoelectric performance of β-Zn4Sb3 based nanocomposites through combined effects of density of states resonance and carrier energy filtering. Sci. Rep. 2015, 5, 17803. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Burkov, A.T.; Novikov, S.V.; Khovaylo, V.V.; Schumann, J. Energy filtering enhancement of thermoelectric performance of nanocrystalline Cr1−xSix composites. J. Alloys Compd. 2017, 691, 89–94. [Google Scholar] [CrossRef] [Green Version]

- Kennedy, J.V.; Murmu, P.P.; Karthik, V.; Liu, Z.; Jovic, V.; Mori, T.; Yang, W.L.; Smith, K.E. Influence of carrier density and energy barrier scattering on a high Seebeck coefficient and power factor in transparent thermoelectric copper iodide. ACS Appl. Energy Mater. 2020, 3, 10037–10044. [Google Scholar]

- Gayner, C.; Amouyal, Y. Energy Filtering of Charge Carriers: Current Trends, Challenges, and Prospects for Thermoelectric Materials. Adv. Funct. Mater. 2019, 30, 1901789. [Google Scholar] [CrossRef]

- Seto, J.Y.W. The electrical properties of polycrystalline silicon films. J. Appl. Phys. 1975, 46, 5247–5254. [Google Scholar] [CrossRef]

- Jugdersuren, B.; Kearney, B.; Liu, X.; Stroud, R.; Culbertson, J.; Desario, P.; Nemeth, W.; Wang, Q. Thermoelectric Properties of Nanocrystalline Silicon Films Prepared by Hot-Wire and Plasma-Enhanced Chemical-Vapor Depositions. J. Electron. Mater. 2019, 48, 5218–5225. [Google Scholar] [CrossRef]

- Lu, J.; Guo, R.; Dai, W.; Huang, B. Enhanced in-plane thermoelectric figure of merit in p-type SiGe thin films by nanograin boundaries. Nanoscale 2015, 7, 7331–7339. [Google Scholar] [CrossRef] [Green Version]

- Peng, Y.; Miao, L.; Gao, J.; Liu, C.; Kurosawa, M.; Nakatsuka, O.; Zaima, S. Realizing High Thermoelectric Performance at Ambient Temperature by Ternary Alloying in Polycrystalline Si1−x−yGexSny Thin Films with Boron Ion Implantation. Sci. Rep. 2019, 9, 14342. [Google Scholar] [CrossRef]

- Lai, H.; Peng, Y.; Gao, J.; Song, H.; Kurosawa, M.; Nakatsuka, O.; Takeuchi, T.; Miao, L. Reinforcement of power factor in N-type multiphase thin film of Si1−x−yGexSny by mitigating the opposing behavior of Seebeck coefficient and electrical conductivity. Appl. Phys. Lett. 2021, 119, 113903. [Google Scholar] [CrossRef]

- Vining, C.B. The Thermoelectric Properties of Boron-Doped Silicon and Silicon-Germanium in the As-Hot Pressed Conditions; Technical Report; JPL/California Institute of Technology: Pasadena, CA, USA, 1988. [Google Scholar]

- Seager, C.H. Grain Boundaries in Polycrystalline Silicon. Annu. Rev. Mater. Sci. 1985, 15, 271–302. [Google Scholar] [CrossRef]

- Narducci, D.; Selezneva, E.; Cerofolini, G.; Frabboni, S.; Ottaviani, G. Impact of energy filtering and carrier localization on the thermoelectric properties of granular semiconductors. J. Solid State Chem. 2012, 193, 19–25. [Google Scholar] [CrossRef]

- Narducci, D.; Lorenzi, B.; Zianni, X.; Neophytou, N.; Frabboni, S.; Gazzadi, G.C.; Roncaglia, A.; Suriano, F. Enhancement of the power factor in two-phase silicon-boron nanocrystalline alloys. Phys. Status Solidi A 2014, 211, 1255–1258. [Google Scholar] [CrossRef]

- Suriano, F.; Ferri, M.; Moscatelli, F.; Mancarella, F.; Belsito, L.; Solmi, S.; Roncaglia, A.; Frabboni, S.; Gazzadi, G.; Narducci, D. Influence of Grain Size on the Thermoelectric Properties of Polycrystalline Silicon Nanowires. J. Electron. Mater. 2015, 44, 371–376. [Google Scholar] [CrossRef]

- Zianni, X.; Narducci, D. Synergy between defects, charge neutrality and energy filtering in hyper-doped nanocrystalline materials for high thermoelectric efficiency. Nanoscale 2019, 11, 7667–7673. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zulian, L.; Segrado, F.; Narducci, D. Annealing of heavily boron-doped silicon: Effect on electrical and thermoelectric properties. J. Nanosci. Nanotechnol. 2016, 17, 1657–1662. [Google Scholar] [CrossRef]

- Neophytou, N.; Zianni, X.; Kosina, H.; Frabboni, S.; Lorenzi, B.; Narducci, D. Simultaneous increase in electrical conductivity and Seebeck coefficient in highly boron-doped nanocrystalline Si. Nanotechnology 2013, 24, 205402. [Google Scholar] [CrossRef]

- Neophytou, N.; Zianni, X.; Kosina, H.; Frabboni, S.; Lorenzi, B.; Narducci, D. Power Factor Enhancement by Inhomogeneous Distribution of Dopants in Two-Phase Nanocrystalline Systems. J. Electron. Mater. 2014, 43, 1896–1904. [Google Scholar] [CrossRef]

- Narducci, D.; Zulian, L.; Lorenzi, B.; Giulio, F.; Villa, E. Exceptional thermoelectric power factors in hyperdoped, fully dehydrogenated nanocrystalline silicon thin films. Appl. Phys. Lett. 2021, 119, 263903. [Google Scholar] [CrossRef]

- Loureiro, J.; Mateus, T.; Filonovich, S.; Ferreira, M.; Figueira, J.; Rodrigues, A.; Donovan, B.; Hopkins, P.; Ferreira, I. Hydrogenated nanocrystalline silicon thin films with promising thermoelectric properties. Appl. Phys. A Mater. Sci. Process. 2015, 120, 1497–1502. [Google Scholar] [CrossRef]

- Loureiro, J.; Mateus, T.; Filonovich, S.; Ferreira, M.; Figueira, J.; Rodrigues, A.; Donovan, B.; Hopkins, P.; Ferreira, I. Improved thermoelectric properties of nanocrystalline hydrogenated silicon thin films by post-deposition thermal annealing. Thin Solid Film 2017, 642, 276–280. [Google Scholar] [CrossRef]

- Acosta, E.; Smirnov, V.; Szabo, P.; Buckman, J.; Bennett, N. Optimizing Thermoelectric Power Factor in p-Type Hydrogenated Nano-crystalline Silicon Thin Films by Varying Carrier Concentration. J. Electron. Mater. 2019, 48, 2085–2094. [Google Scholar] [CrossRef]

- Pham, N.; Vallin, Ö.; Panda, J.; Venkata Kamalakar, M.; Guo, J.; Luo, J.; Wen, C.; Zhang, S.L.; Zhang, Z.B. High thermoelectric power factor of p-type amorphous silicon thin films dispersed with ultrafine silicon nanocrystals. J. Appl. Phys. 2020, 127, 245304. [Google Scholar] [CrossRef]

- Petermann, N.; Stötzel, J.; Stein, N.; Kessler, V.; Wiggers, H.; Theissmann, R.; Schierning, G.; Schmechel, R. Thermoelectrics from silicon nanoparticles: The influence of native oxide. Eur. Phys. J. B 2015, 88, 163. [Google Scholar] [CrossRef]

- Shiomi, J. Research Update: Phonon engineering of nanocrystalline silicon thermoelectrics. APL Mater. 2016, 4, 104504. [Google Scholar] [CrossRef] [Green Version]

- Strasser, M.; Aigner, R.; Franosch, M.; Wachutka, G. Miniaturized thermoelectric generators based on poly-Si and poly-SiGe surface micromachining. Sens. Actuators A 2002, 97–98, 535–542. [Google Scholar] [CrossRef]

- Yan, J.; Liao, X.; Yan, D.; Chen, Y. Review of Micro Thermoelectric Generator. J. Microelectromech. Syst. 2018, 27, 1–18. [Google Scholar] [CrossRef]

- Yuan, Z.; Ziouche, K.; Bougrioua, Z.; Lejeune, P.; Lasri, T.; Leclercq, D. A planar micro thermoelectric generator with high thermal resistance. Sens. Actuators, A 2015, 221, 67–76. [Google Scholar] [CrossRef]

- Yang, S.; Wang, J.; Chen, M.; Tsai, M. Development of a Thermoelectric Energy Generator Chip of Small Layout and High Power/Voltage Factors by Foundry Service. IEEE Sensors J. 2019, 19, 9149–9155. [Google Scholar] [CrossRef]

- Petsagkourakis, I.; Tybrandt, K.; Crispin, X.; Ohkubo, I.; Satoh, N.; Mori, T. Thermoelectric materials and applications for energy harvesting power generation. Sci. Technol. Adv. Mater. 2018, 19, 836–862. [Google Scholar] [CrossRef] [PubMed]

- Haras, M.; Skotnicki, T. Thermoelectricity for IoT—A review. Nano Energy 2018, 54, 461–476. [Google Scholar] [CrossRef]

- Sevilla, G.A.T.; Inayat, S.B.; Rojas, J.P.; Hussain, A.M.; Hussain, M.M. Flexible and semi-transparent thermoelectric energy harvesters from low cost bulk silicon (100). Small 2013, 9, 3916–3921. [Google Scholar] [CrossRef]

- Morata, A.; Pacios, M.; Gadea, G.; Flox, C.; Cadavid, D.; Cabot, A.; Tarancón, A. Large-area and adaptable electrospun silicon-based thermoelectric nanomaterials with high energy conversion efficiencies. Nat. Commun. 2018, 9, 4759. [Google Scholar] [CrossRef]

- Narducci, D. Thermoelectric harvesters and the internet of things: Technological and economic drivers. J. Phys. Energy 2019, 1, 024001. [Google Scholar] [CrossRef]

- Dávila, D.; Tarancón, A.; Fernández-Regúlez, M.; Calaza, C.; Salleras, M.; San Paulo, A.; Fonseca, L. Silicon nanowire arrays as thermoelectric material for a power microgenerator. J. Micromech. Microeng. 2011, 21, 104007. [Google Scholar] [CrossRef]

- Fonseca, L.; Santos, J.D.; Roncaglia, A.; Narducci, D.; Calaza, C.; Salleras, M.; Donmez, I.; Tarancon, A.; Morata, A.; Gadea, G.; et al. Smart integration of silicon nanowire arrays in all-silicon thermoelectric micro-nanogenerators. Semicond. Sci. Technol. 2016, 31, 084001. [Google Scholar] [CrossRef] [Green Version]

- Dimaggio, E.; Pennelli, G. Reliable Fabrication of Metal Contacts on Silicon Nanowire Forests. Nano Lett. 2016, 16, 4348–4354. [Google Scholar] [CrossRef] [PubMed]

- Ziouche, K.; Yuan, Z.; Lejeune, P.; Lasri, T.; Leclercq, D.; Bougrioua, Z. Silicon-based monolithic planar micro thermoelectric generator using bonding technology. J. Microelectromech. Syst. 2016, 26, 45–47. [Google Scholar] [CrossRef]

- Jaziri, N.; Boughamoura, A.; Müller, J.; Mezghani, B.; Tounsi, F.; Ismail, M. A comprehensive review of Thermoelectric Generators: Technologies and common applications. Energy Rep. 2020, 6, 264–287. [Google Scholar] [CrossRef]

- Yang, S.; Hsu, Y. Packaging of semiconductor thermoelectric energy generators with in-plane thermocouples and isolation cavities. Sens. Actuators A Phys. 2021, 331, 112920. [Google Scholar] [CrossRef]

- Moreno, J.J.G.; Cao, J.; Fronzi, M.; Assadi, M.H.N. A review of recent progress in thermoelectric materials through computational methods. Mater. Renew. Sustain. Energy 2020, 9, 1–22. [Google Scholar]

- Neophytou, N.; Foster, S.; Vargiamidis, V.; Pennelli, G.; Narducci, D. Nanostructured potential well/barrier engineering for realizing unprecedentedly large thermoelectric power factors. Mater. Today Phys. 2019, 11, 100159. [Google Scholar] [CrossRef]

- Recatala-Gomez, J.; Suwardi, A.; Nandhakumar, I.; Abutaha, A.; Hippalgaonkar, K. Toward accelerated thermoelectric materials and process discovery. ACS Appl. Energy Mater. 2020, 3, 2240–2257. [Google Scholar] [CrossRef]

- Mbaye, M.T.; Pradhan, S.K.; Bahoura, M. Data-driven thermoelectric modeling: Current challenges and prospects. J. Appl. Phys. 2021, 130, 190902. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Narducci, D.; Giulio, F. Recent Advances on Thermoelectric Silicon for Low-Temperature Applications. Materials 2022, 15, 1214. https://doi.org/10.3390/ma15031214

Narducci D, Giulio F. Recent Advances on Thermoelectric Silicon for Low-Temperature Applications. Materials. 2022; 15(3):1214. https://doi.org/10.3390/ma15031214

Chicago/Turabian StyleNarducci, Dario, and Federico Giulio. 2022. "Recent Advances on Thermoelectric Silicon for Low-Temperature Applications" Materials 15, no. 3: 1214. https://doi.org/10.3390/ma15031214

APA StyleNarducci, D., & Giulio, F. (2022). Recent Advances on Thermoelectric Silicon for Low-Temperature Applications. Materials, 15(3), 1214. https://doi.org/10.3390/ma15031214