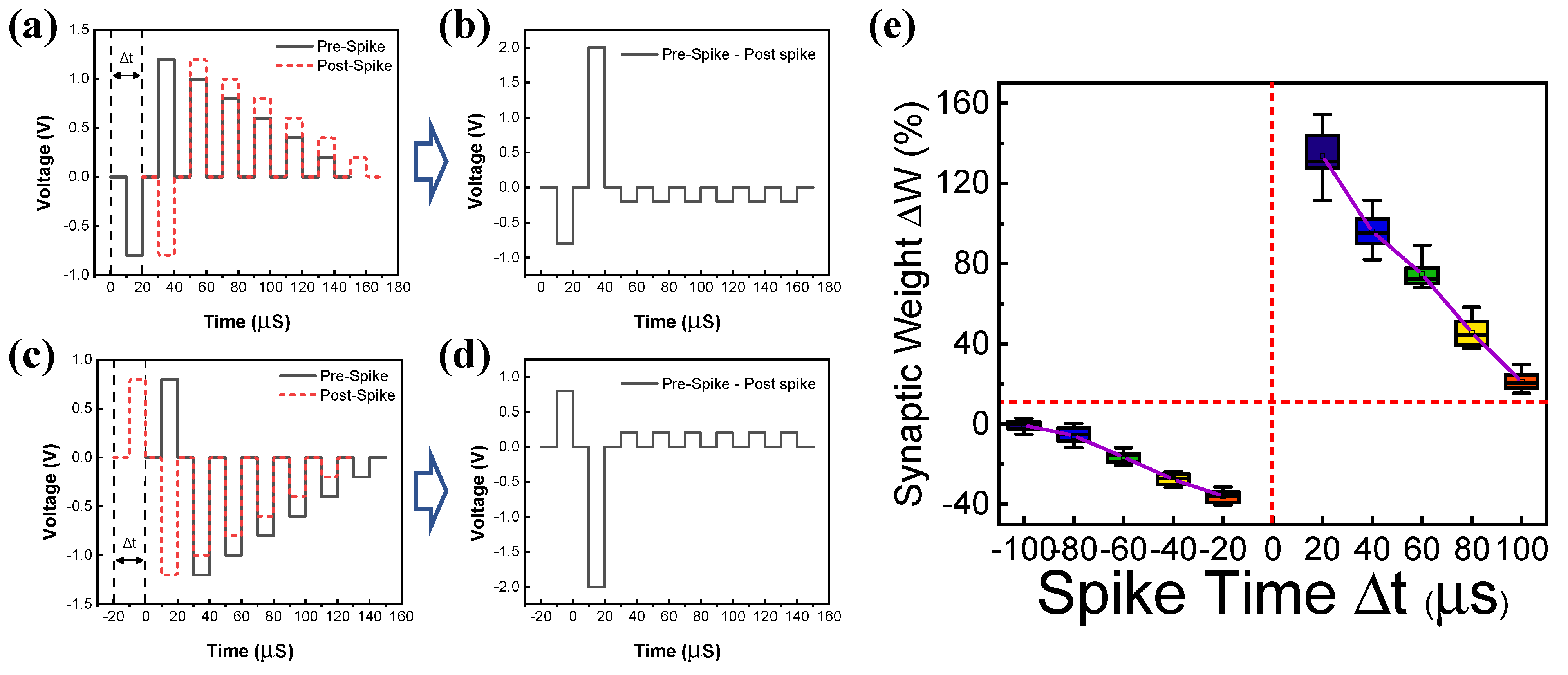

Non-Volatile Memory and Synaptic Characteristics of TiN/CeOx/Pt RRAM Devices

Abstract

1. Introduction

2. Experiments

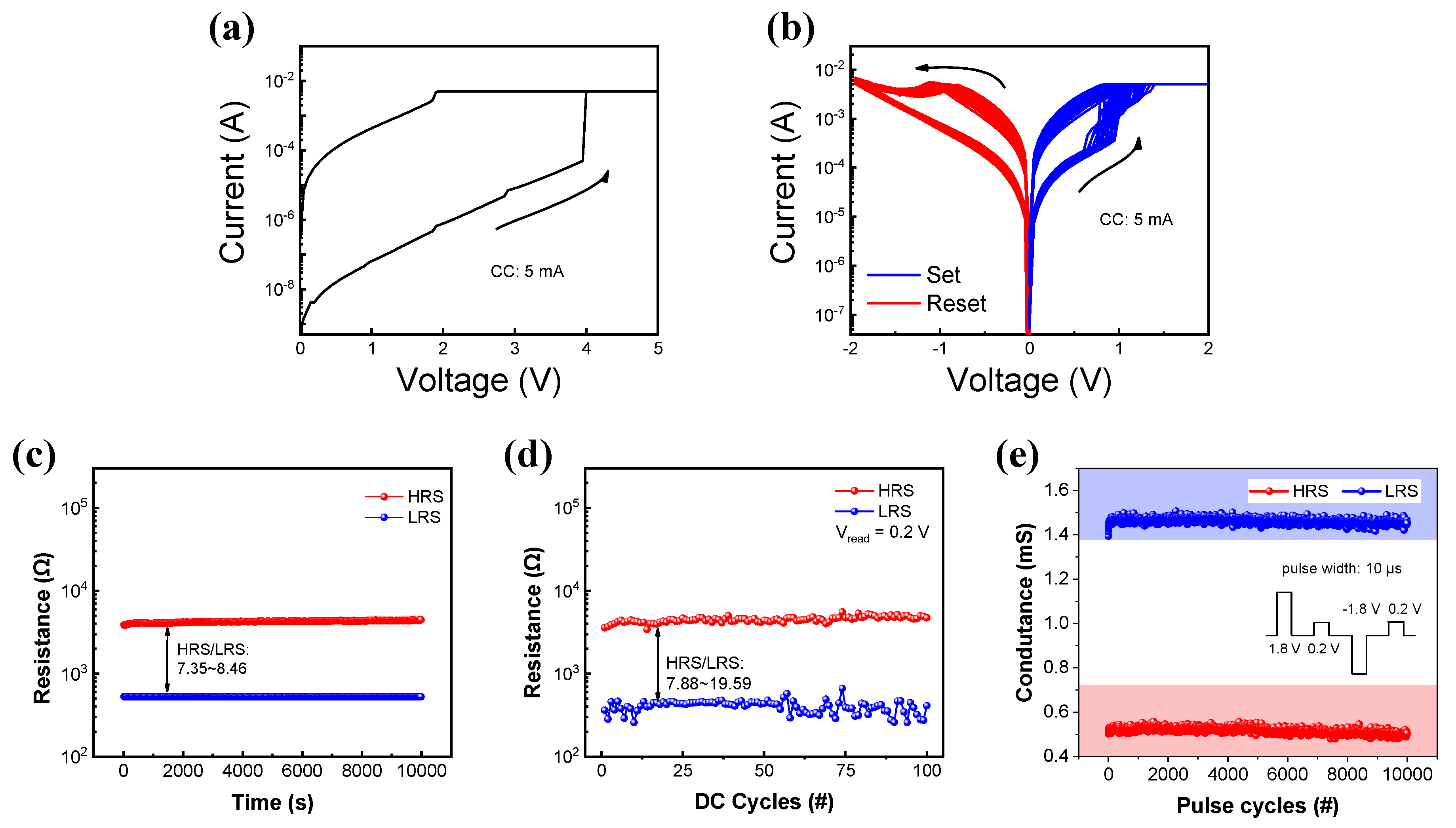

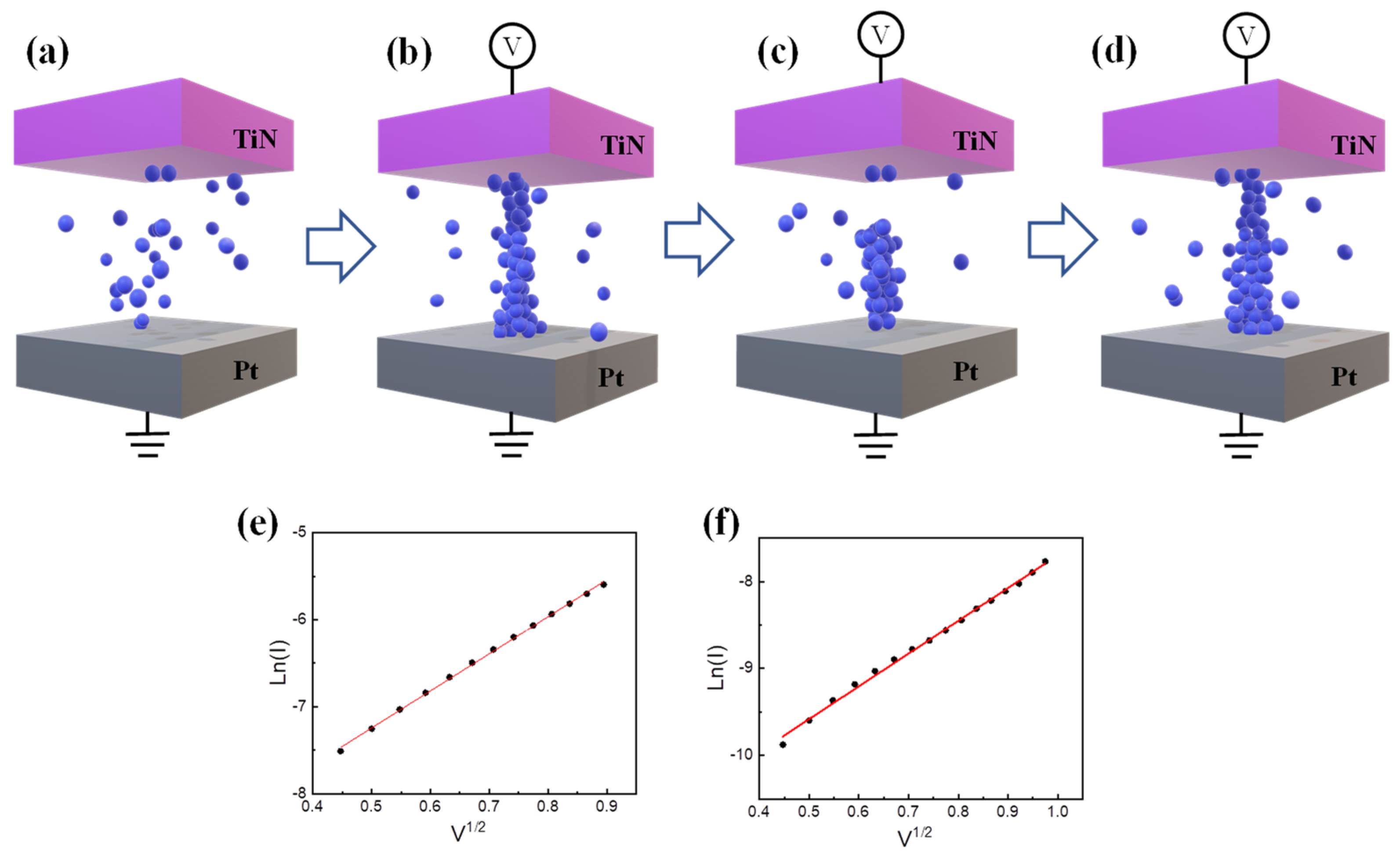

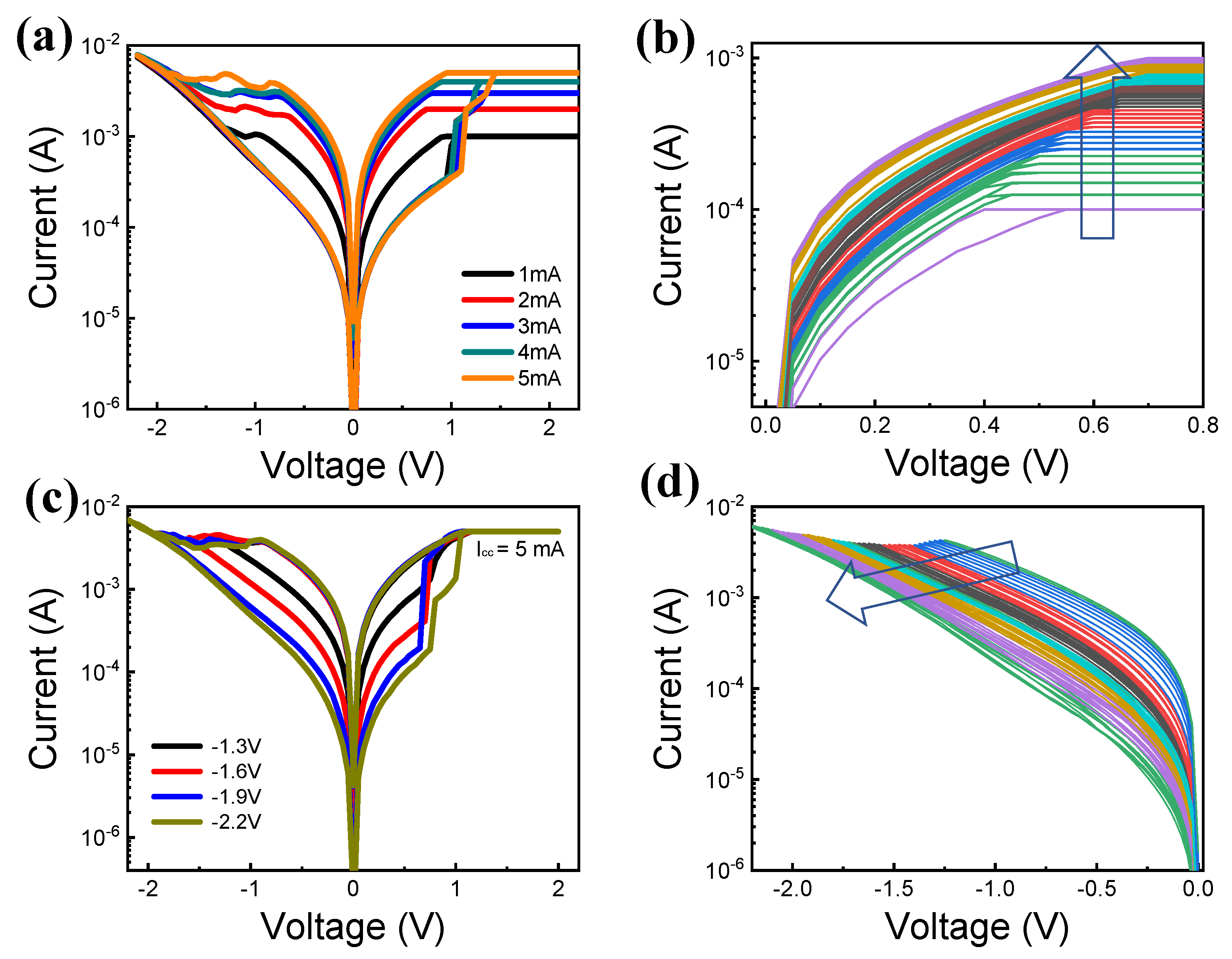

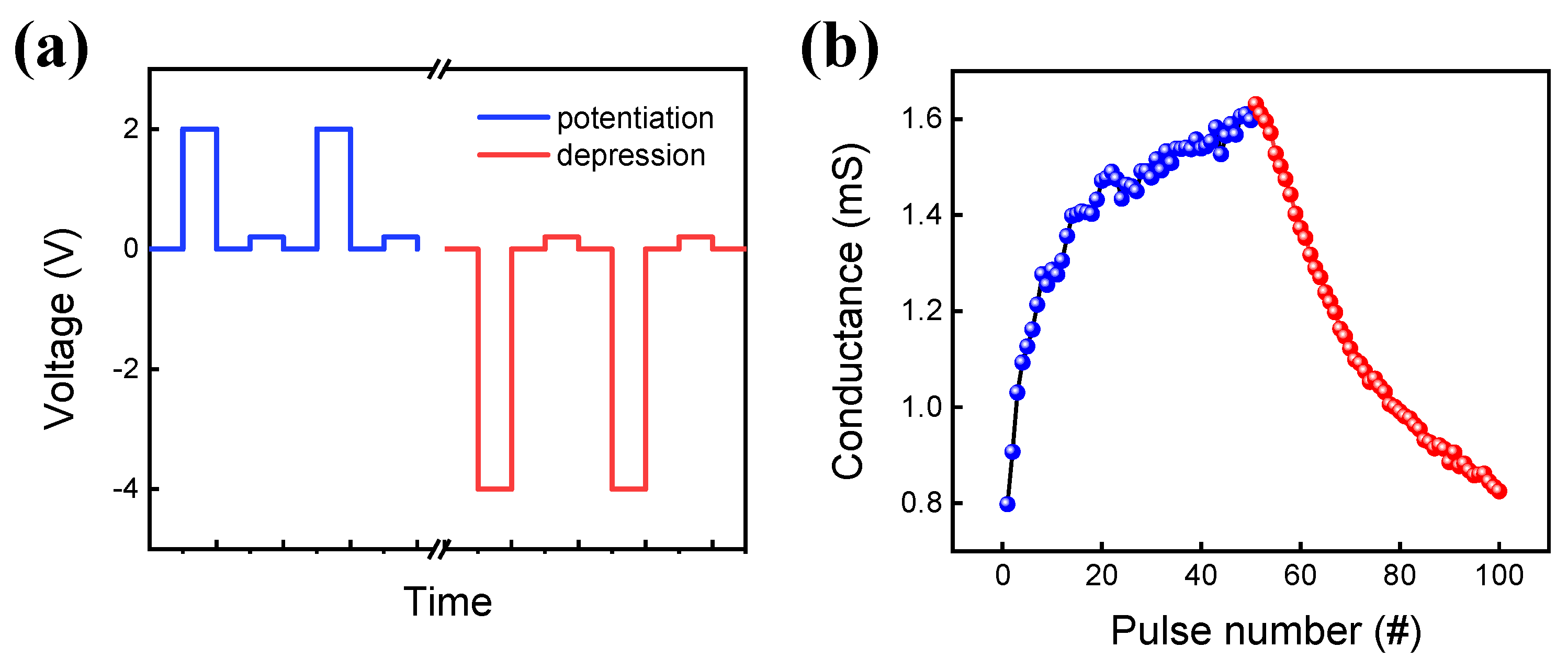

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Wang, Z.; Shi, T.; Bi, C.; Rao, F.; Cai, Y.; Liu, Q.; Wu, H.; Zhou, P. Memory Materials and Devices: From Concept to Application. InfoMat 2020, 2, 261–290. [Google Scholar] [CrossRef]

- Atzori, L.; Iera, A.; Morabito, G. The Internet of Things: A Survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Zahoor, F.; Azni Zulkifli, T.Z.; Khanday, F.A. Resistive Random Access Memory (RRAM): An Overview of Materials, Switching Mechanism, Performance, Multilevel Cell (Mlc) Storage, Modeling, and Applications. Nanoscale Res. Lett. 2020, 15, 90. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Zeng, T.; Xu, H.; Wang, Z.; Zhao, X.; Liu, W.; Ma, J.; Liu, Y. Transferable and Flexible Artificial Memristive Synapse Based on WOx Schottky Junction on Arbitrary Substrates. Adv. Electron. Mater. 2018, 4, 1800373. [Google Scholar] [CrossRef]

- Hu, D.C.; Yang, R.; Jiang, L.; Guo, X. Memristive Synapses with Photoelectric Plasticity Realized in ZnO1−x/AlOy Heterojunction. ACS Appl. Mater. Interfaces 2018, 10, 6463–6470. [Google Scholar] [CrossRef]

- Park, M.; Kang, M.; Kim, S. Pulse Frequency Dependent Synaptic Characteristics in Ta/SiN/Si Memristor Device for Neuromorphic System. J. Alloys Compd. 2021, 882, 160760. [Google Scholar] [CrossRef]

- Lu, K.; Li, Y.; He, W.F.; Chen, J.; Zhou, Y.X.; Duan, N.; Jin, M.M.; Gu, W.; Xue, K.H.; Sun, H.J.; et al. Diverse Spike-Timing-Dependent Plasticity Based on Multilevel HfOx Memristor for Neuromorphic Computing. Appl. Phys. A Mater. Sci. Process. 2018, 124, 438. [Google Scholar] [CrossRef]

- Kim, S.; Jung, S.; Kim, M.H.; Chen, Y.C.; Chang, Y.F.; Ryoo, K.C.; Cho, S.; Lee, J.H.; Park, B.G. Scaling Effect on Silicon Nitride Memristor with Highly Doped Si Substrate. Small 2018, 14, e1704062. [Google Scholar] [CrossRef]

- Sun, B.; Zhou, G.; Guo, T.; Zhou, Y.N.; Wu, Y.A. Biomemristors as the next Generation Bioelectronics. Nano Energy 2020, 75, 104938. [Google Scholar] [CrossRef]

- Guo, T.; Sun, B.; Ranjan, S.; Jiao, Y.; Wei, L.; Norman Zhou, Y.; Wu, Y.A. From Memristive Materials to Neural Networks. ACS Appl. Mater. Interfaces 2020, 12, 54243–54265. [Google Scholar] [CrossRef]

- Mikhaylov, A.; Belov, A.; Korolev, D.; Antonov, I.; Kotomina, V.; Kotina, A.; Gryaznov, E.; Sharapov, A.; Koryazhkina, M.; Kryukov, R.; et al. Multilayer Metal-Oxide Memristive Device with Stabilized Resistive Switching. Adv. Mater. Technol. 2020, 5, 1900607. [Google Scholar] [CrossRef]

- Wan, W.; Kubendran, R.; Schaefer, C.; Eryilmaz, S.B.; Zhang, W.; Wu, D.; Deiss, S.; Raina, P.; Qian, H.; Gao, B.; et al. A Compute-in-Memory Chip Based on Resistive Random-Access Memory. Nature 2022, 608, 504–512. [Google Scholar] [CrossRef] [PubMed]

- Khan, R.; Ilyas, N.; Shamim, M.Z.M.; Khan, M.I.; Sohail, M.; Rahman, N.; Khan, A.A.; Khan, S.N.; Khan, A. Oxide-Based Resistive Switching-Based Devices: Fabrication, Influence Parameters and Applications. J. Mater. Chem. C Mater. 2021, 9, 15755–15788. [Google Scholar] [CrossRef]

- Strukov, D.B.; Snider, G.S.; Stewart, D.R.; Williams, R.S. The Missing Memristor Found. Nature 2008, 453, 80–83. [Google Scholar] [CrossRef]

- Ryu, H.; Kim, S. Pseudo-Interface Switching of a Two-Terminal Taox/Hfo2 Synaptic Device for Neuromorphic Applications. Nanomaterials 2020, 10, 1550. [Google Scholar] [CrossRef]

- Shen, Z.; Zhao, C.; Qi, Y.; Xu, W.; Liu, Y.; Mitrovic, I.Z.; Yang, L.; Zhao, C. Advances of RRAM Devices: Resistive Switching Mechanisms, Materials and Bionic Synaptic Application. Nanomaterials 2020, 10, 1437. [Google Scholar] [CrossRef]

- Kim, K.H.; Gaba, S.; Wheeler, D.; Cruz-Albrecht, J.M.; Hussain, T.; Srinivasa, N.; Lu, W. A Functional Hybrid Memristor Crossbar-Array/CMOS System for Data Storage and Neuromorphic Applications. Nano Lett. 2012, 12, 389–395. [Google Scholar] [CrossRef]

- Jeon, Y.R.; Abbas, Y.; Sokolov, A.S.; Kim, S.; Ku, B.; Choi, C. Study of in Situ Silver Migration in Amorphous Boron Nitride CBRAM Device. ACS Appl. Mater. Interfaces 2019, 11, 23329–23336. [Google Scholar] [CrossRef]

- Lee, H.J.; Kim, D.; Choi, W.S.; Kim, C.; Choi, S.J.; Bae, J.H.; Kim, D.M.; Kim, S.; Kim, D.H. Effect of Oxygen Flow Rate on Long-Term and Short-Term Schottky Barrier Modulations in Pd/IGZO/SiO2/P+-Si Memristors. Mater. Sci. Semicond. Process. 2023, 153, 107183. [Google Scholar] [CrossRef]

- Kong, P.; Pu, Y.; Ma, P.; Zhu, J. Relationship between Oxygen Defects and Properties of Scandium Oxide Films Prepared by Ion-Beam Sputtering. Coatings 2019, 9, 517. [Google Scholar] [CrossRef]

- Ali, F.; Pham, N.D.; Bradford, H.J.; Khoshsirat, N.; Ostrikov, K.; Bell, J.M.; Wang, H.; Tesfamichael, T. Tuning the Amount of Oxygen Vacancies in Sputter-Deposited SnOx Films for Enhancing the Performance of Perovskite Solar Cells. ChemSusChem 2018, 11, 3096–3103. [Google Scholar] [CrossRef] [PubMed]

- Yildirim, H.; Pachter, R. Mechanistic Analysis of Oxygen Vacancy-Driven Conductive Filament Formation in Resistive Random Access Memory Metal/NiO/Metal Structures. ACS Appl. Mater. Interfaces 2018, 10, 9802–9816. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Wang, S.; Liu, H. Multi-Level Switching of al-Doped HfO2 RRAM with a Single Voltage Amplitude Set Pulse. Electronics 2021, 10, 731. [Google Scholar] [CrossRef]

- Mahata, C.; Ismail, M.; Kang, M.; Kim, S. Synaptic Plasticity and Quantized Conductance States in TiN-Nanoparticles-Based Memristor for Neuromorphic System. Nanoscale Res. Lett. 2022, 17, 58. [Google Scholar] [CrossRef] [PubMed]

- Matsukatova, A.N.; Iliasov, A.I.; Nikiruy, K.E.; Kukueva, E.V.; Vasiliev, A.L.; Goncharov, B.V.; Sitnikov, A.V.; Zanaveskin, M.L.; Bugaev, A.S.; Demin, V.A.; et al. Convolutional Neural Network Based on Crossbar Arrays of (Co-Fe-B)x(LiNbO3)100−x Nanocomposite Memristors. Nanomaterials 2022, 12, 3455. [Google Scholar] [CrossRef]

- Lee, Y.; Park, J.; Chung, D.; Lee, K.; Kim, S. Multi-Level Cells and Quantized Conductance Characteristics of Al2O3-Based RRAM Device for Neuromorphic System. Nanoscale Res. Lett. 2022, 17, 84. [Google Scholar] [CrossRef]

- Ohno, T.; Hasegawa, T.; Tsuruoka, T.; Terabe, K.; Gimzewski, J.K.; Aono, M. Short-Term Plasticity and Long-Term Potentiation Mimicked in Single Inorganic Synapses. Nat. Mater. 2011, 10, 591–595. [Google Scholar] [CrossRef]

- Prakash, A.; Jana, D.; Maikap, S. TaO X-Based Resistive Switching Memories: Prospective and Challenges. Nanoscale Res. Lett. 2013, 8, 418. [Google Scholar] [CrossRef]

- Ye, J.Y.; Li, Y.Q.; Gao, J.; Peng, H.Y.; Wu, S.X.; Wu, T. Nanoscale Resistive Switching and Filamentary Conduction in NiO Thin Films. Appl. Phys. Lett. 2010, 97, 132108. [Google Scholar] [CrossRef]

- Cheng, C.-H.; Chin, A.; Hsu, H.-H. Forming-Free SiGeOx/TiOy Resistive Random Access Memories Featuring Large Current Distribution Windows. J. Nanosci. Nanotechnol. 2019, 19, 7916–7919. [Google Scholar] [CrossRef]

- Wang, Q.; Niu, G.; Roy, S.; Wang, Y.; Zhang, Y.; Wu, H.; Zhai, S.; Bai, W.; Shi, P.; Song, S.; et al. Interface-Engineered Reliable HfO2-Based RRAM for Synaptic Simulation. J. Mater. Chem. C Mater. 2019, 7, 12682–12687. [Google Scholar] [CrossRef]

- Chen, Y.S.; Lee, H.Y.; Chen, P.S.; Wu, T.Y.; Wang, C.C.; Tzeng, P.J.; Chen, F.; Tsai, M.J.; Lien, C. An Ultrathin Forming-Free HfOx Resistance Memory with Excellent Electrical Performance. IEEE Electron. Device Lett. 2010, 31, 1473–1475. [Google Scholar] [CrossRef]

- Liu, K.C.; Tzeng, W.H.; Chang, K.M.; Chan, Y.C.; Kuo, C.C.; Cheng, C.W. The Resistive Switching Characteristics of a Ti/Gd2O3/Pt RRAM Device. Microelectron. Reliab. 2010, 50, 670–673. [Google Scholar] [CrossRef]

- Lin, C.Y.; Lee, D.Y.; Wang, S.Y.; Lin, C.C.; Tseng, T.Y. Reproducible Resistive Switching Behavior in Sputtered CeO2 Polycrystalline Films. Surf. Coat. Technol. 2008, 203, 480–483. [Google Scholar] [CrossRef]

- Huang, S.Y.; Chang, T.C.; Chen, M.C.; Chen, S.C.; Lo, H.P.; Huang, H.C.; Gan, D.S.; Sze, S.M.; Tsai, M.J. Resistive Switching Characteristics of Sm2O3 Thin Films for Nonvolatile Memory Applications. Solid State Electron. 2011, 63, 189–191. [Google Scholar] [CrossRef]

- Beie, H.-J.; Gnorich, A. Oxygen Gas Sensors Based on CeO, Thick and Thin Films. Sens. Actuators B Chem. 1991, 4, 393–399. [Google Scholar] [CrossRef]

- Ismail, M.; Talib, I.; Huang, C.Y.; Hung, C.J.; Tsai, T.L.; Jieng, J.H.; Chand, U.; Lin, C.A.; Ahmed, E.; Rana, A.M.; et al. Resistive Switching Characteristics of Pt/CeOx/TiN Memory Device. Jpn. J. Appl. Phys. 2014, 53, 060303. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhai, J. Study of the Resistive Switching Characteristics and Mechanisms of Pt/CeOx/TiN Structure for RRAM Applications. Integr. Ferroelectr. 2012, 140, 16–22. [Google Scholar] [CrossRef]

- Chen, C.F.; Schrott, A.; Lee, M.H.; Raoux, S.; Shih, Y.H.; Breitwisch, M.; Baumann, F.H.; Lai, E.K.; Shaw, T.M.; Flaitz, P.; et al. 2009 IEEE International Memory Workshop; IEEE: Piscataway, NJ, USA, 2009; ISBN 9781424437610. [Google Scholar]

- Sun, X.; Sun, B.; Liu, L.; Xu, N.; Liu, X.; Han, R.; Kang, J.; Xiong, G.; Ma, T.P. Resistive Switching in CeOχ Films for Nonvolatile Memory Application. IEEE Electron. Device Lett. 2009, 30, 334–336. [Google Scholar] [CrossRef]

- Pan, T.M.; Lu, C.H. Forming-Free Resistive Switching Behavior in Nd2O3, Dy2O3, and Er2O3 Films Fabricated in Full Room Temperature. Appl. Phys. Lett. 2011, 99, 113509. [Google Scholar] [CrossRef]

- Holgado, J.P.; Munuera, G.; Espinos, J.P.; Gonzalez-Elipe, A.R. XPS Study of Oxidation Processes of CeO Defective Layers. Appl. Surf. Sci. 2000, 158, 164–171. [Google Scholar] [CrossRef]

- Gao, P.; Wang, Z.; Fu, W.; Liao, Z.; Liu, K.; Wang, W.; Bai, X.; Wang, E. In Situ TEM Studies of Oxygen Vacancy Migration for Electrically Induced Resistance Change Effect in Cerium Oxides. Micron 2010, 41, 301–305. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.J.; Zheng, H.; Park, J.S.; Hun Kim, D.; Jung Kang, C.; Tae Jang, J.; Hwan Kim, D.; Yoon, T.S. Artificial Synaptic Characteristics with Strong Analog Memristive Switching in a Pt/CeO2/Pt Structure. Nanotechnology 2017, 28, 285203. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Huang, H.; Xia, Q.; Ye, C.; Wei, X.; Wang, J.; Zhang, L.; Zhu, L.Q. Role of Oxygen Vacancies at the TiO2/HfO2 Interface in Flexible Oxide-Based Resistive Switching Memory. Adv. Electron. Mater. 2019, 5, 1800833. [Google Scholar] [CrossRef]

- Younis, A.; Chu, D.; Li, S. Oxygen Level: The Dominant of Resistive Switching Characteristics in Cerium Oxide Thin Films. J. Phys. D Appl. Phys. 2012, 45, 355101. [Google Scholar] [CrossRef]

- Saleem, A.; Simanjuntak, F.M.; Chandrasekaran, S.; Rajasekaran, S.; Tseng, T.Y.; Prodromakis, T. Transformation of Digital to Analog Switching in TaOx-Based Memristor Device for Neuromorphic Applications. Appl. Phys. Lett. 2021, 118, 112103. [Google Scholar] [CrossRef]

- Yan, X.; Zhou, Z.; Ding, B.; Zhao, J.; Zhang, Y. Superior Resistive Switching Memory and Biological Synapse Properties Based on a Simple TiN/SiO2/p-Si Tunneling Junction Structure. J. Mater. Chem. C Mater. 2017, 5, 2259–2267. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ha, H.; Pyo, J.; Lee, Y.; Kim, S. Non-Volatile Memory and Synaptic Characteristics of TiN/CeOx/Pt RRAM Devices. Materials 2022, 15, 9087. https://doi.org/10.3390/ma15249087

Ha H, Pyo J, Lee Y, Kim S. Non-Volatile Memory and Synaptic Characteristics of TiN/CeOx/Pt RRAM Devices. Materials. 2022; 15(24):9087. https://doi.org/10.3390/ma15249087

Chicago/Turabian StyleHa, Hoesung, Juyeong Pyo, Yunseok Lee, and Sungjun Kim. 2022. "Non-Volatile Memory and Synaptic Characteristics of TiN/CeOx/Pt RRAM Devices" Materials 15, no. 24: 9087. https://doi.org/10.3390/ma15249087

APA StyleHa, H., Pyo, J., Lee, Y., & Kim, S. (2022). Non-Volatile Memory and Synaptic Characteristics of TiN/CeOx/Pt RRAM Devices. Materials, 15(24), 9087. https://doi.org/10.3390/ma15249087