Effect of the Geometry of Thin-Walled Aluminium Alloy Elements on Their Deformations after Milling

Abstract

1. Introduction

- Elements of increased thickness, which ultimately results in the growth of the aircraft weight;

- Additional stiffening walls, which are so-called “ribs.”

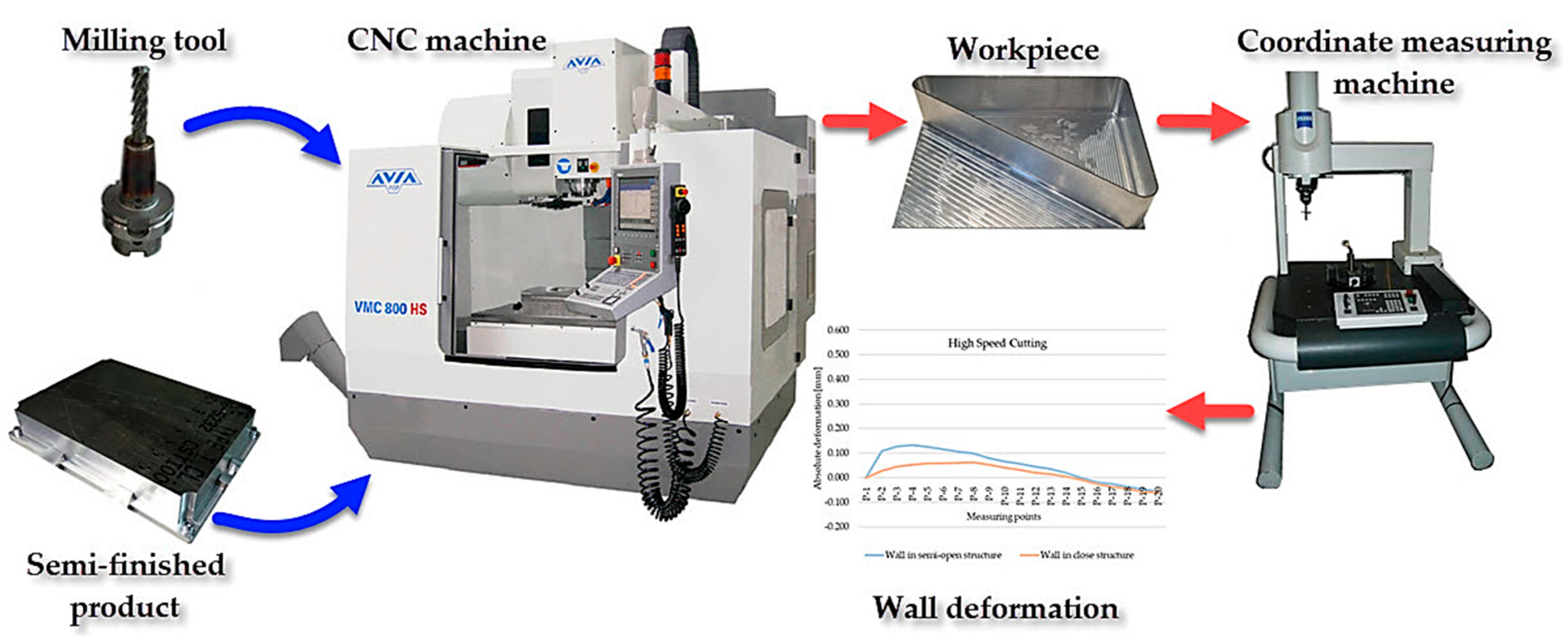

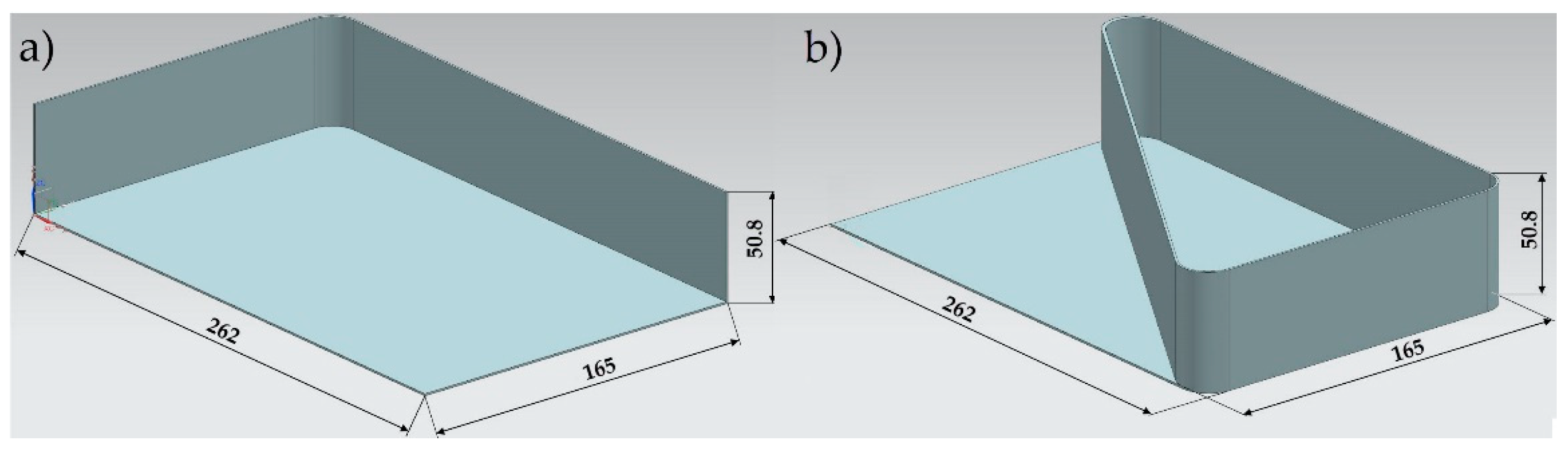

2. Materials and Methods

- Tensile strength: Rm min. = 525 MPa;

- Yield strength: Rp0,2 min. = 440 MPa;

- Elongation: min. A = 4%;

- Hardness on the Brinell scale: 155 HB.

- Tensile strength: Rm min. = 295 MPa;

- Yield strength: Rp0,2 min. = 240 MPa;

- Elongation: min. A = 8%;

- Hardness on the Brinell scale: 89 HB.

- SGS Tools 44303 (Wokingham, Berkshire, England): roughing of the bottom and the walls—high performance cutting (Figure 4a);

- SGS Tools 44631 (Wokingham, Berkshire, England): machining of the bottom and the vertical walls—conventional cutting and high speed cutting (HSC) (Figure 4b);

- SEGER F103AL-120 (Wiśniowa, Poland): used to “remove” the workpiece from the “frame” type fixture (Figure 4c).

| Tool | SGS Tools 44303 | SGS Tools 44631 | SEGER F103AL-120 |

|---|---|---|---|

| Cutting diameter (mm) | 16 | 12 | 12 |

| Overall length (mm) | 92 | 100 | 81 |

| Length of cut (mm) | 32 | 48 | 24 |

| Number of flutes (-) | 3 | 4 | 3 |

| Helix angle (°) | 38 | inconstant (38 to 41) | 45 |

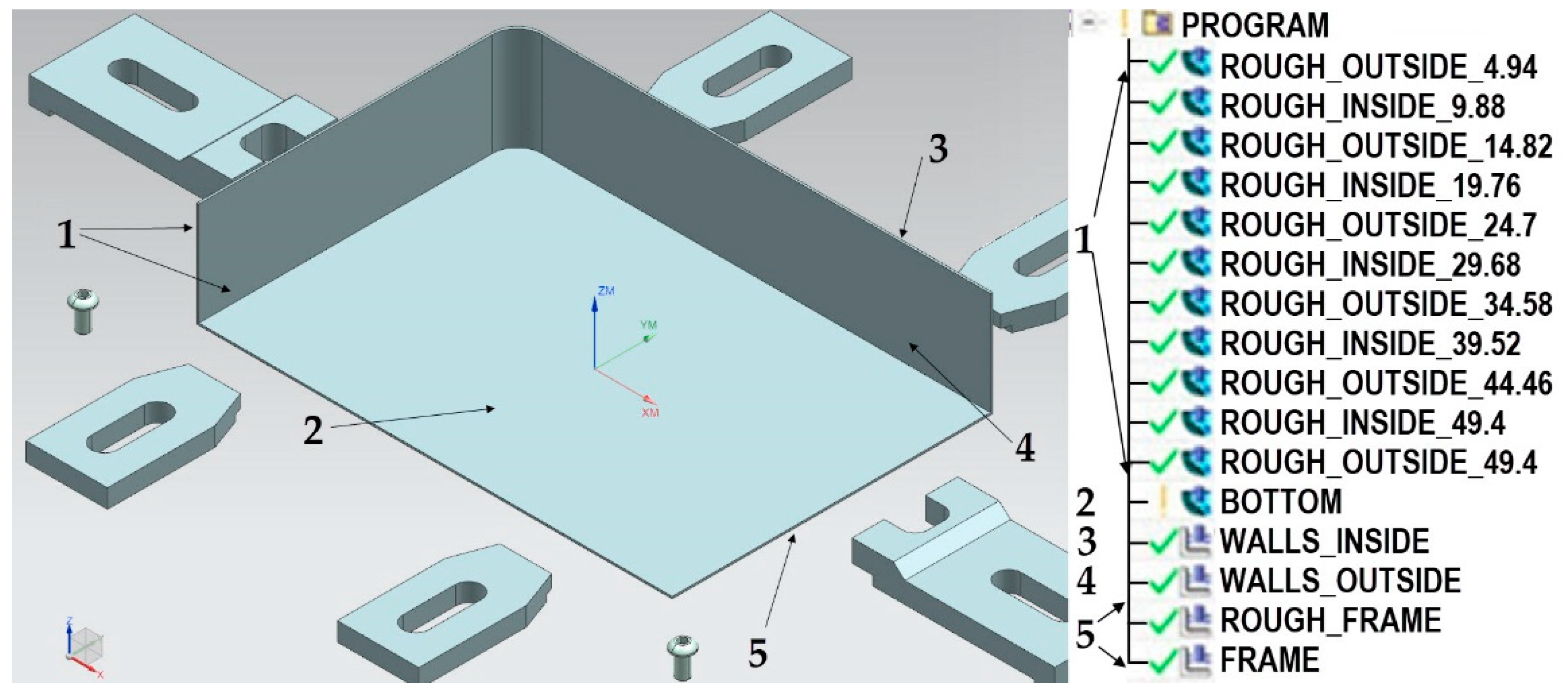

- Alternate roughing of outside and inside wall surface;

- Machining of the bottom;

- Finishing machining of the inside surface of walls;

- Finishing machining of the outside surface of walls;

- Cutting out of the structure from the frame.

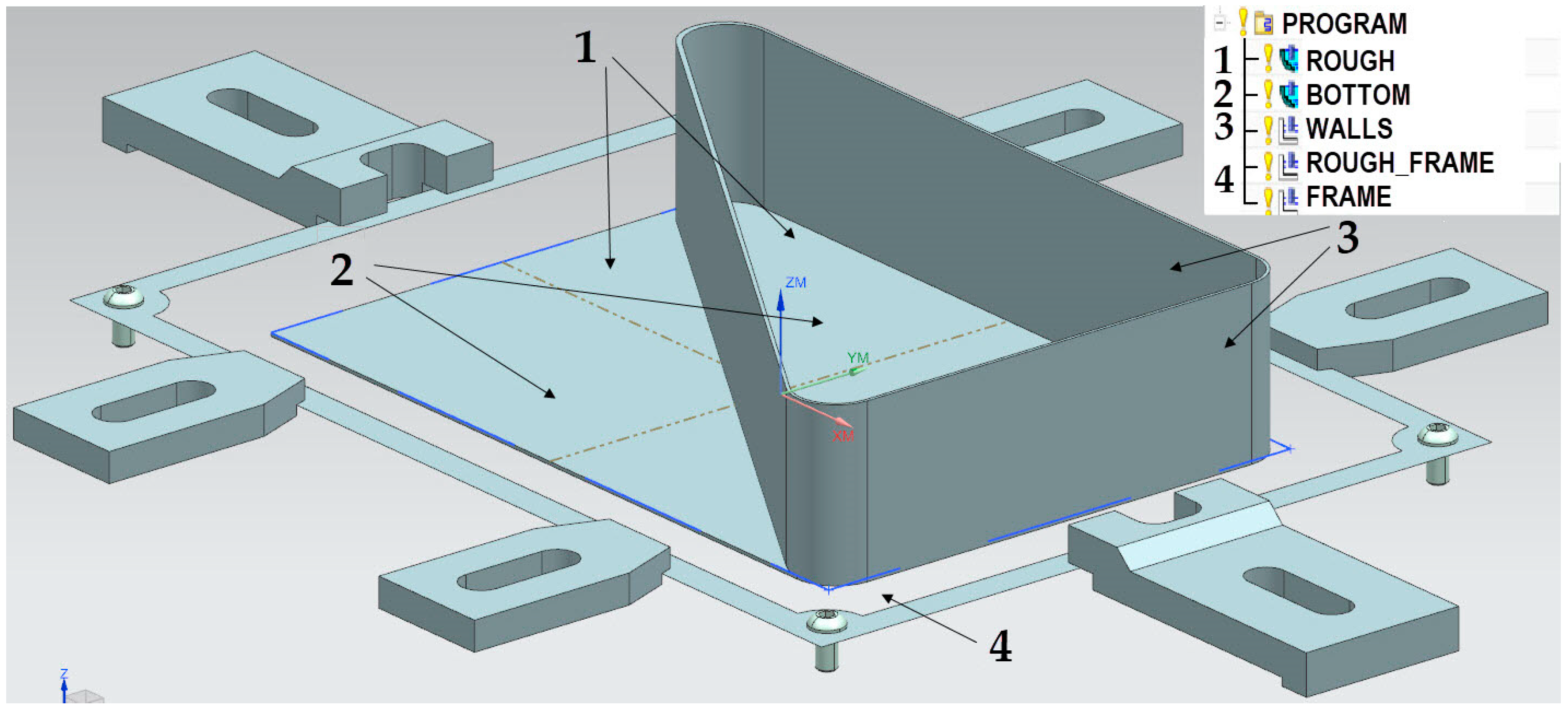

- Alternately roughing the inside and outside of the wall’s surface;

- Machining the bottom;

- Finishing machining of the inside and outside surfaces of walls;

- Cutting out of the structure from the frame.

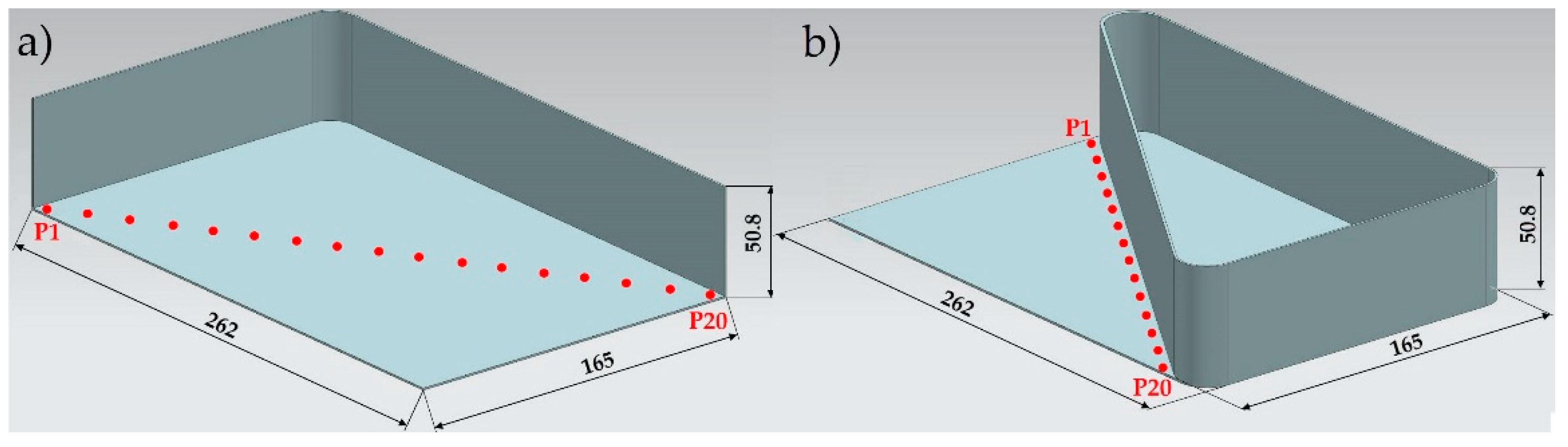

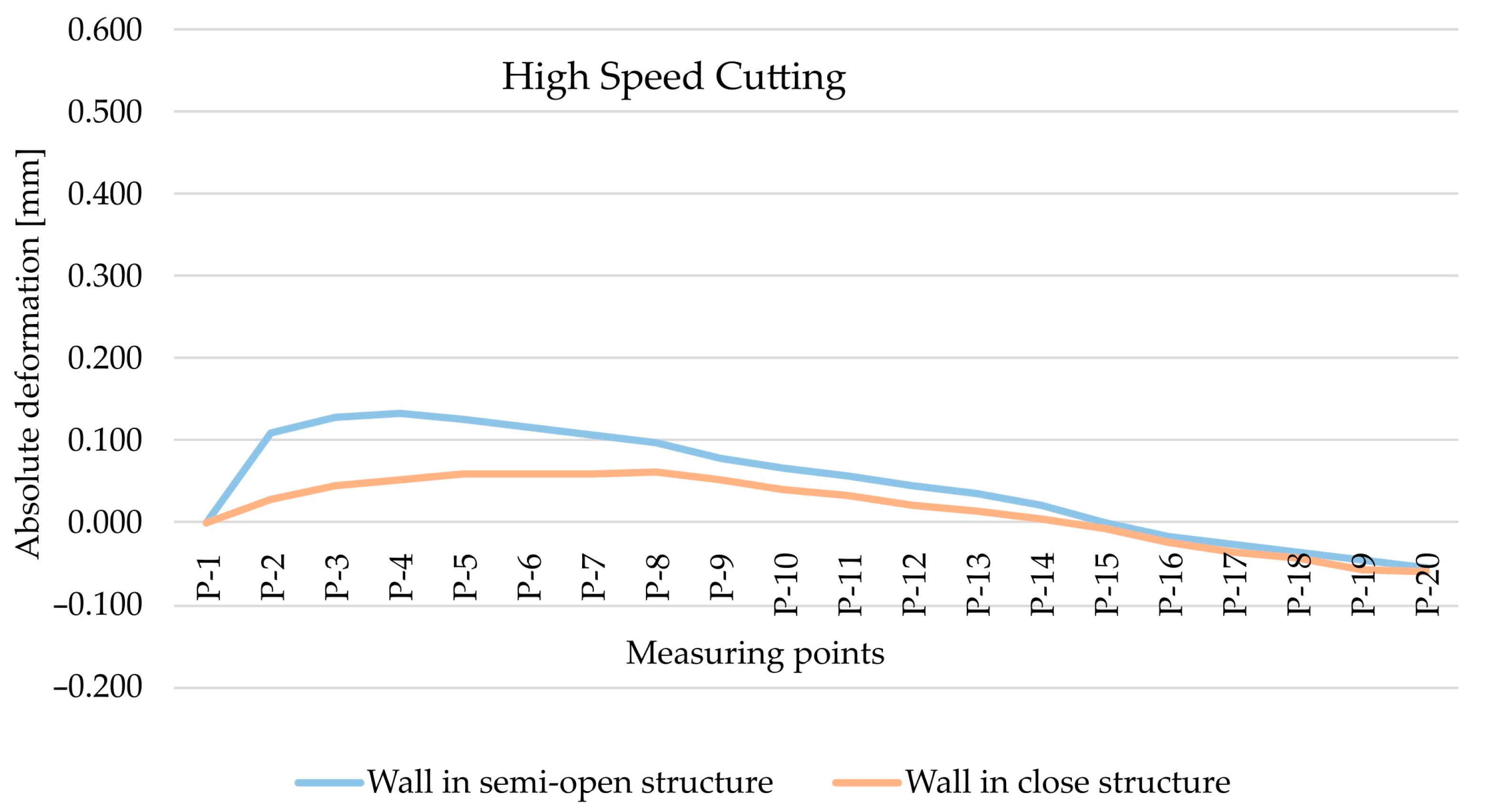

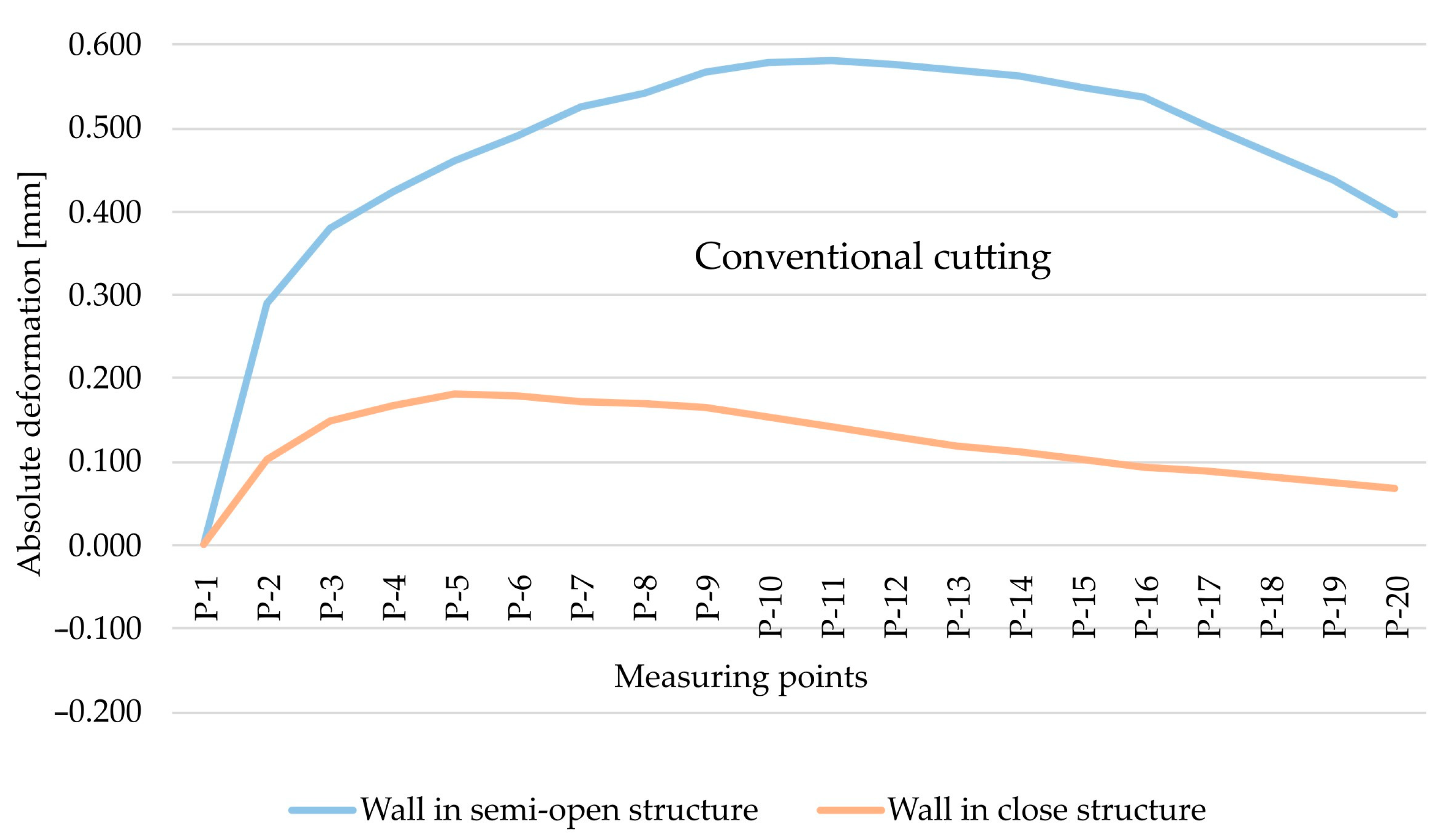

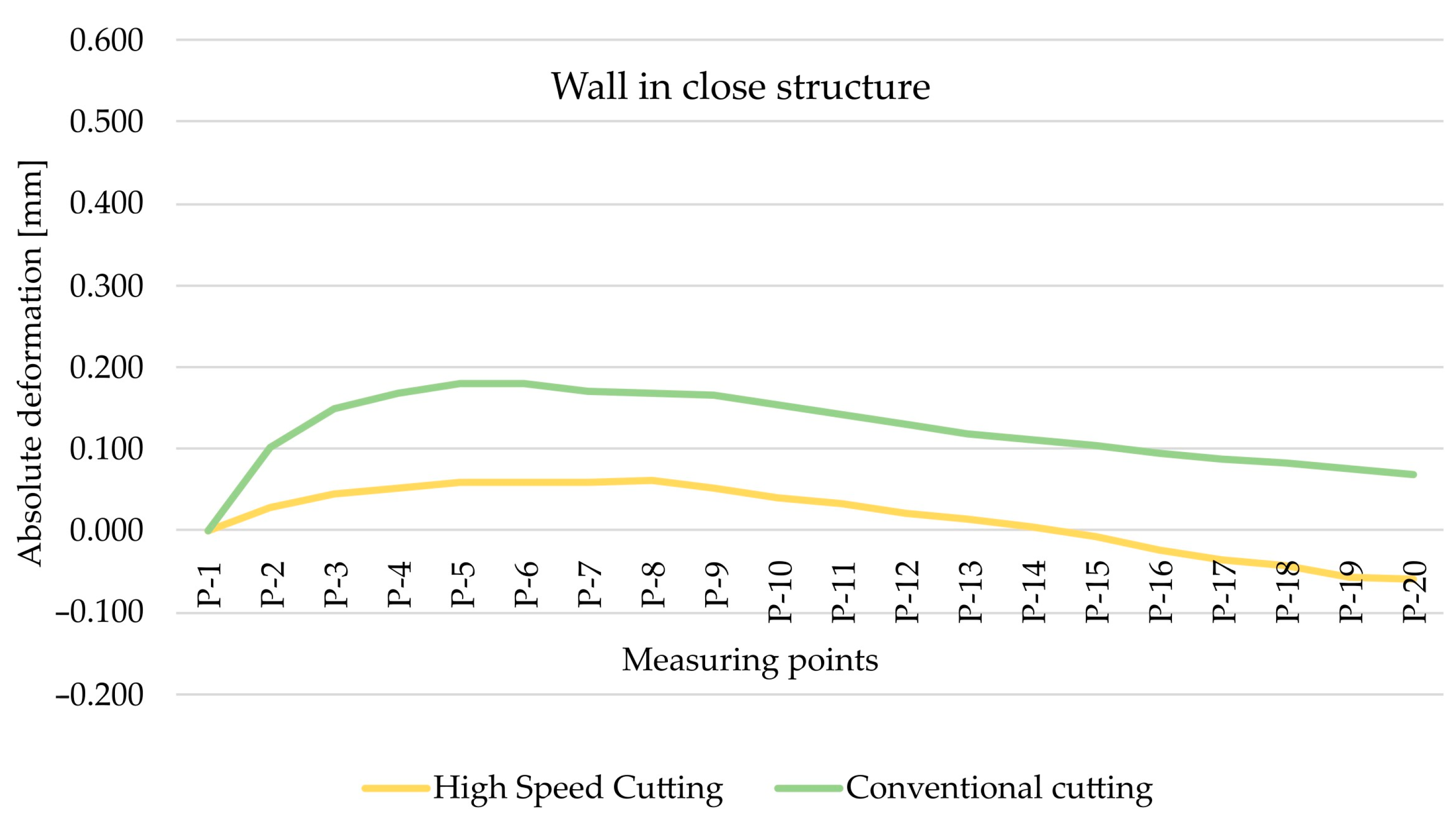

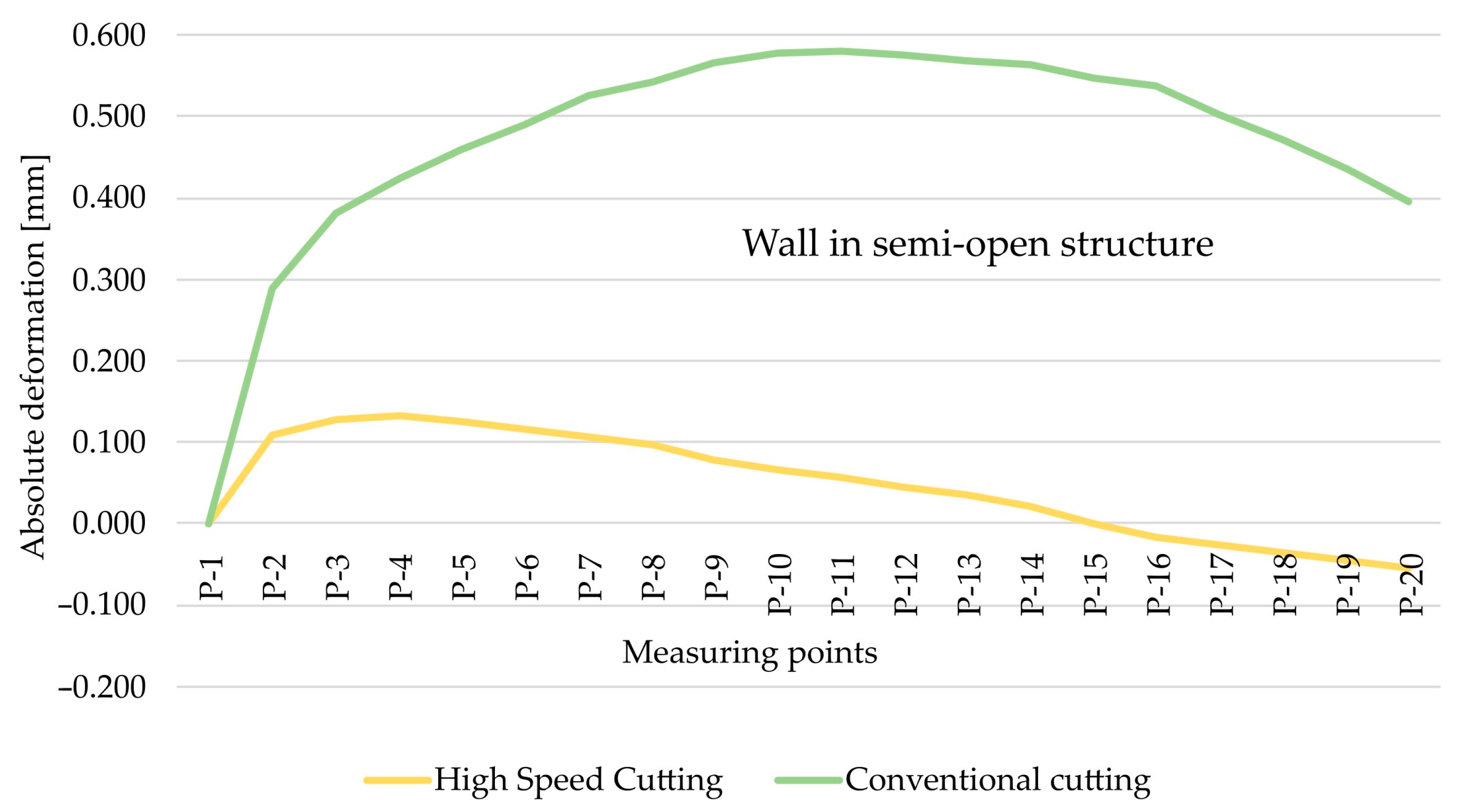

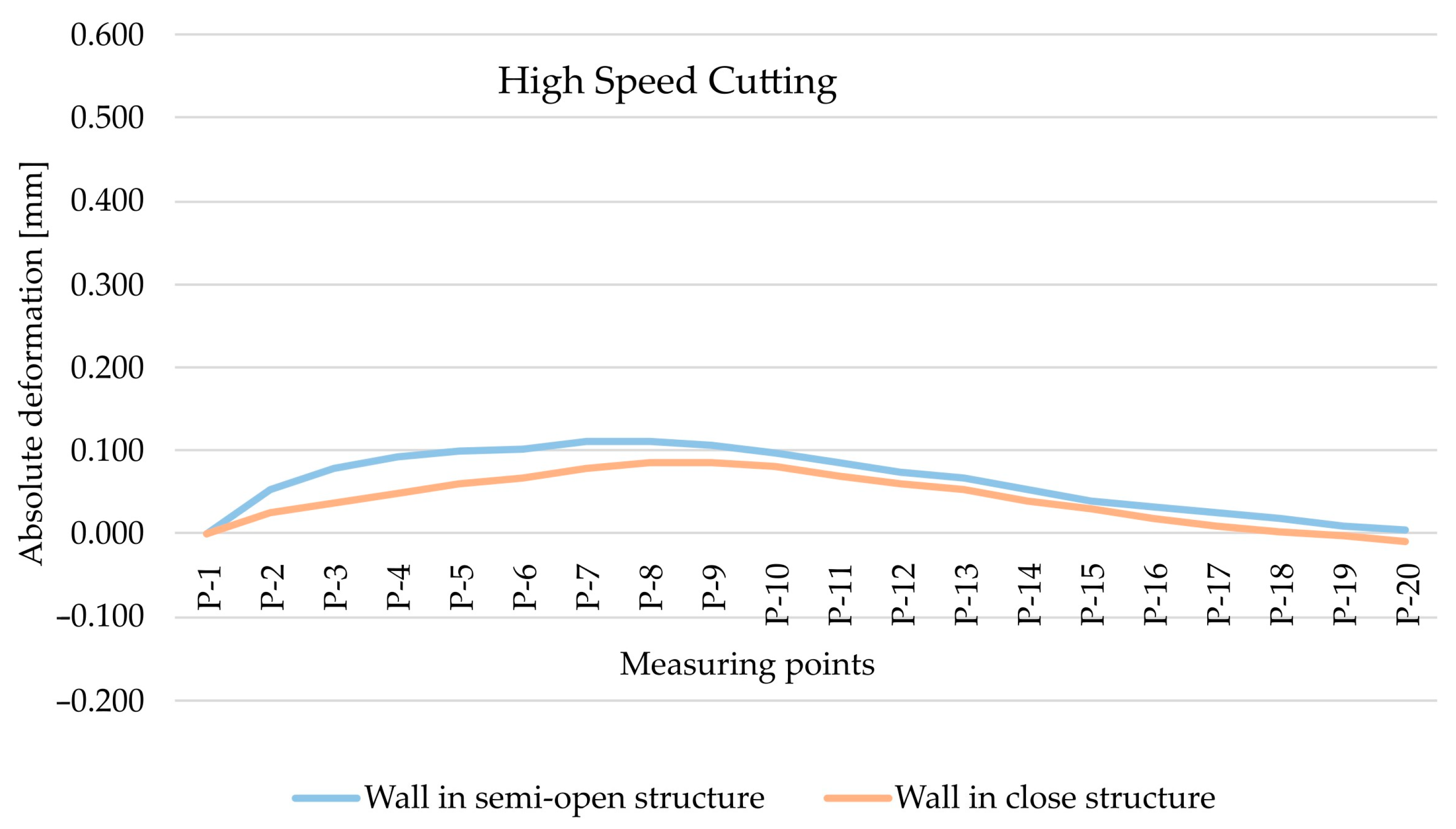

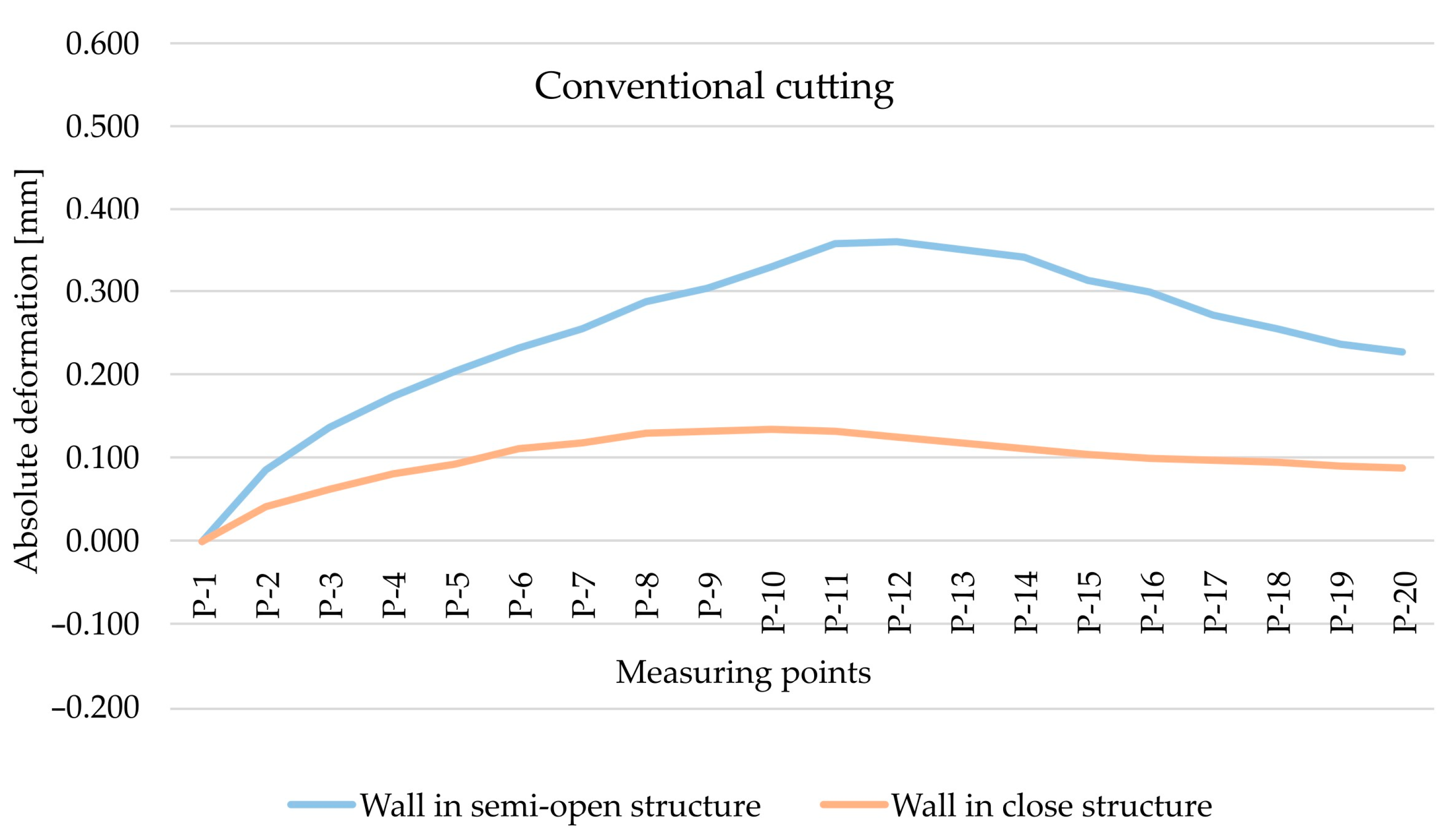

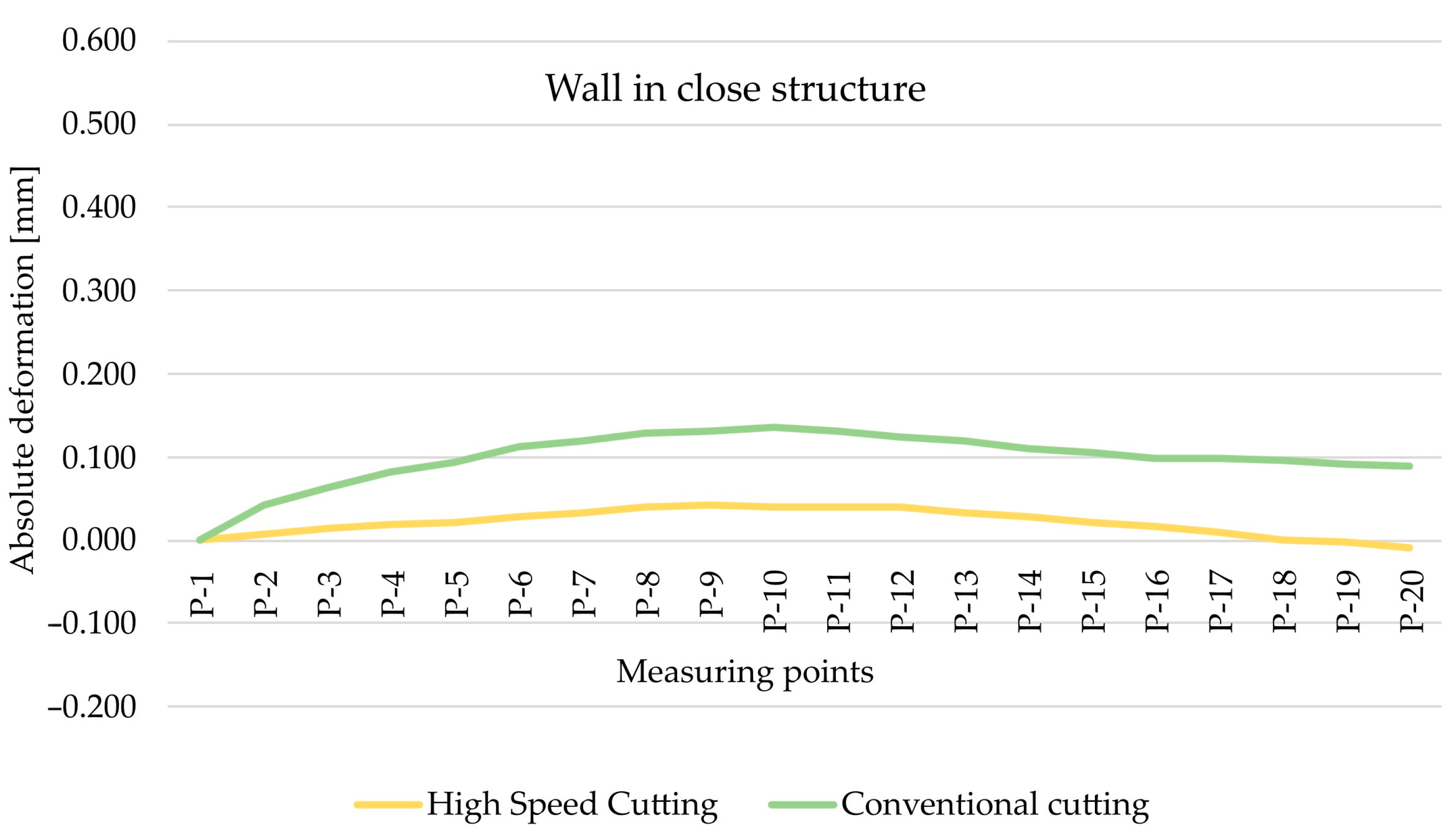

3. Results

4. Discussion

5. Conclusions

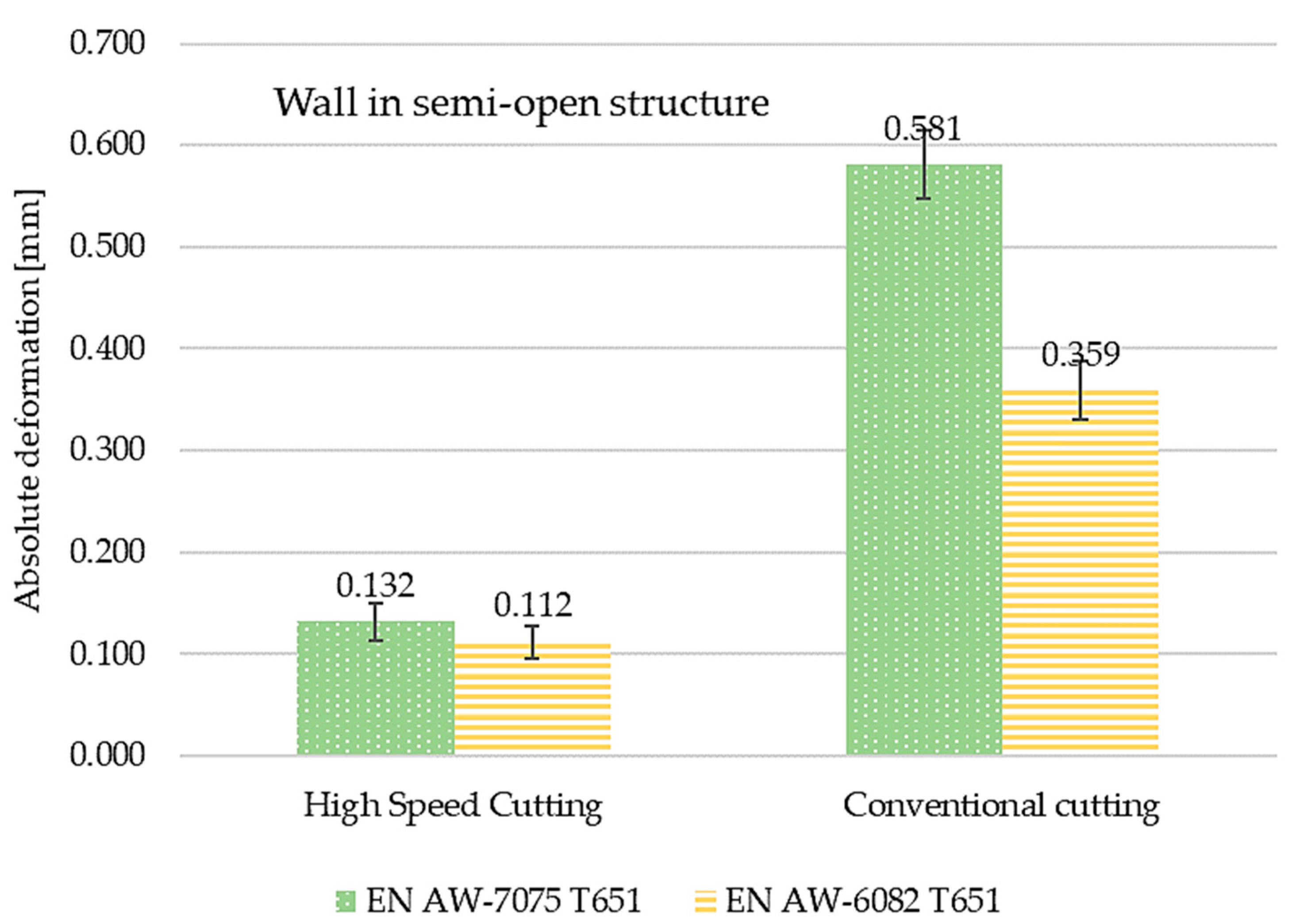

- Lower post-machining deformation values were obtained for the EN AW-6082 T651 alloy, which, compared to the EN AW-7075 T651 alloy, is characterised by greater plasticity and lower cutting resistance, and it translates into lower cutting forces and post-machining stresses.

- Regardless of the component geometry, higher absolute deformations were observed after conventional machining, which means that the use of high-speed HSC machining has positive effects in terms of minimizing the deformation of thin-walled components. This is probably due to the lower values of cutting forces in HSC machining.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Global Service Forecast of Airbus. Available online: https://aircraft.airbus.com/en/market/global-services-forecast-gsf-2022-2041 (accessed on 1 October 2022).

- Bałon, P.; Rejman, E.; Smusz, R.; Szostak, J.; Kiełbasa, B. Implementation of high speed machining in thin-walled aircraft integral elements. Open Eng. 2018, 8, 162–169. [Google Scholar] [CrossRef]

- Duan, Z.; Li, C.; Ding, W.; Zhang, Y.; Yang, M.; Gao, T.; Cao, H.; Xu, X.; Wang, D.; Mao, C.; et al. Milling Force Model for Aviation Aluminum Alloy: Academic Insight and Perspective Analysis. Chin. J. Mech. Eng. 2021, 34, 18. [Google Scholar] [CrossRef]

- Samuel, A.U.; Araoyinbo, A.O.; Elewa, R.R.; Biodun, M.B. Effect of Machining of Aluminium Alloys with Emphasis on Aluminium 6061 Alloy—A Review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1107, 012157. [Google Scholar] [CrossRef]

- Seguy, S.; Campa, F.J.; Lopez de Lacalle, L.N.; Arnaud, L.; Dessein, G.; Aramendi, G. Toolpath dependent stability lobes for the milling of thin-walled parts. Int. J. Mach. Mach. Mater. 2008, 4, 377–392. [Google Scholar] [CrossRef]

- Ning, H.; Zhigang, W.; Chengyu, J.; Bing, Z. Finite element method analysis and control stratagem for machining deformation of thin-walled components. J. Mater. Process. Technol. 2003, 139, 332–336. [Google Scholar] [CrossRef]

- Masoudi, S.; Amini, S.; Saeidi, E.; Eslami-Chalander, H. Effect of machining-induced residual stress on the distortion of thin-walled parts. Int. J. Adv. Manuf. Technol. 2015, 76, 597–608. [Google Scholar] [CrossRef]

- Del Sol, I.; Rivero, A.; López de Lacalle, L.N.; Gamez, A.J. Thin-Wall Machining of Light Alloys: A Review of Models and Industrial Approaches. Materials 2019, 12, 2012. [Google Scholar] [CrossRef]

- Zagórski, I.; Korpysa, J. Surface Quality Assessment after Milling AZ91D Magnesium Alloy Using PCD Tool. Materials 2020, 13, 617. [Google Scholar] [CrossRef]

- Zagórski, I.; Korpysa, J.; Weremczuk, A. Influence of Tool Holder Types on Vibration in Rough Milling of AZ91D Magnesium Alloy. Materials 2021, 14, 2517. [Google Scholar] [CrossRef]

- Kuczmaszewski, J.; Zaleski, K.; Matuszak, J.; Mądry, J. Testing Geometric Precision and Surface Roughness of Titanium Alloy Thin-Walled Elements Processed with Milling. In Advances in Manufacturing II. MANUFACTURING 2019. Lecture Notes in Mechanical Engineering; Diering, M., Wieczorowski, M., Brown, C., Eds.; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Burek, J.; Plodzień, M.; Zyłka, L.; Sulkowicz, P. High-performance end milling of aluminum alloy: Influence of different serrated cutting edge tool shapes on the cutting force. Adv. Prod. Eng. Manag. 2019, 14, 494–506. [Google Scholar] [CrossRef]

- Zaleski, K.; Matuszak, J.; Zyśko, A. Highly Efficient Milling on the Example of Selected Machining Strategies. Adv. Sci. Technol. Res. J. 2020, 14, 167–177. [Google Scholar] [CrossRef]

- Awan, W.S.; Mabrouki, T. Numerical and experimental investigations of post-machining distortions in thin machined structures considering material-induced residual stress. J. Braz. Soc. Mech. Sci. 2017, 39, 509–521. [Google Scholar] [CrossRef]

- Kuczmaszewski, J.; Pieśko, P.; Zawada-Michałowska, M. Influence of Milling Strategies of Thin-Walled Elements on Effectiveness of their Manufacturing. Procedia Eng. 2017, 182, 381–386. [Google Scholar] [CrossRef]

- Kuczmaszewski, J.; Pieśko, P.; Zawada-Michałowska, M. Surface Roughness of Thin-Walled Components Made of Aluminium Alloy EN AW-2024 Following Different Milling Strategies. Adv. Sci. Technol. Res. J. 2016, 10, 150–158. [Google Scholar] [CrossRef]

- Twardowski, P.; Legutko, S.; Krolczyk, G.M.; Hloch, S. Investigation of wear and tool life of coated carbide and cubic boron nitride cutting tools in high speed milling. Adv. Mech. Eng. 2015, 7, 1–9. [Google Scholar] [CrossRef]

- Feldshtein, E.; Józwik, J.; Legutko, S. The influence of the conditions of emulsion mist formation on the surface roughness of AISI 1045 steel after finish turning. Adv. Sci. Technol. Res. J. 2016, 10, 144–149. [Google Scholar] [CrossRef]

- Maruda, R.; Feldshtein, E.; Legutko, S.; Królczyk, G. Research on Emulsion Mist Generation in the Conditions of Minimum Quantity Cooling Lubrication (MQCL). Teh. Vjesn. 2015, 22, 1213–1218. [Google Scholar] [CrossRef]

- Maruda, R.W.; Wojciechowski, S.; Szczotkarz, N.; Legutko, S.; Mia, M.; Gupta, M.K.; Nieslony, P.; Krolczyk, G.M. Metrological analysis of surface quality aspects in minimum quantity cooling lubrication. Measurement 2021, 171, 108847. [Google Scholar] [CrossRef]

- Singh, A.; Agrawal, A. Comparison of deforming forces, residual stresses and geometrical accuracy of deformation machining with conventional bending and forming. J. Mater. Process. Technol. 2016, 234, 259–271. [Google Scholar] [CrossRef]

- Borojević, S.; Lukić, D.; Milošević, M.; Vukman, J.; Kramar, D. Optimization of process parameters for machining of Al 7075 thin-walled structures. Adv. Prod. Eng. Manag. 2018, 13, 125–135. [Google Scholar] [CrossRef]

- Ciecieląg, K.; Zaleski, K. Milling of Three Types of Thin-Walled Elements Made of Polymer Composite and Titanium and Aluminum Alloys Used in the Aviation Industry. Materials 2022, 15, 5949. [Google Scholar] [CrossRef]

- Czyżycki, J.; Twardowski, P.; Znojkiewicz, N. Analysis of the Displacement of Thin-Walled Workpiece Using a High-Speed Camera during Peripheral Milling of Aluminum Alloys. Materials 2021, 14, 4771. [Google Scholar] [CrossRef]

- Patalas, A.; Regus, M.; Peta, K. Studies of thin-walled parts deformation by gripping force during turning process on an example of bearing ring. MATEC Web Conf. 2018, 244, 02010. [Google Scholar] [CrossRef]

- Krajewska-Śpiewak, J.; Gawlik, J.; Piekoszewski, W.; Stachura, K. Identification of Residual Stresses in a Surface Layer of Ti6AL4V and Inconel 718 after Process of Peripheral Milling. Teh. Vjesn. 2018, 25, 88–91. [Google Scholar] [CrossRef]

- Zawada-Michałowska, M.; Kuczmaszewski, J.; Pieśko, P. Pre-Machining of Rolled Plates as an Element of Minimising the Post-Machining Deformations. Materials 2020, 13, 4777. [Google Scholar] [CrossRef]

- Bałon, P.; Rejman, E.; Kiełbasa, B.; Smusz, R. Using HSM technology in machining of thin-walled aircraft structures. Acta Mech. Autom. 2022, 16, 27–33. [Google Scholar] [CrossRef]

- Bałon, P.; Rejman, E.; Swiątoniowski, A.; Kiełbasa, B.; Smusz, R.; Szostak, J.; Cieślik, J.; Kowalski, Ł. Thin-walled Integral Constructions in Aircraft Industry. Procedia Manuf. 2020, 47, 498–504. [Google Scholar] [CrossRef]

- Bere, P.; Dudescu, M.; Neamțu, C.; Cocian, C. Design, Manufacturing and Test of CFRP Front Hood Concepts for a Light-Weight Vehicle. Polymers 2021, 13, 1374. [Google Scholar] [CrossRef]

- Bere, P.; Nemes, O.; Dudescu, C.; Berce, P.; Sabau, E. Design and analysis of carbon/epoxy composite tubular parts. Adv. Eng. Forum 2013, 8, 207–214. [Google Scholar] [CrossRef]

- Kosicka, E.; Borowiec, M.; Kowalczuk, M.; Krzyzak, A.; Szczepaniak, R. Influence of the Selected Physical Modifier on the Dynamical Behavior of the Polymer Composites Used in the Aviation Industry. Materials 2020, 13, 5479. [Google Scholar] [CrossRef]

- Szczepaniak, R.; Komorek, A.; Przybyłek, P.; Krzyżak, A.; Roskowicz, M.; Godzimirski, J.; Pinkiewicz, E.; Jaszczak, W.; Kosicka, E. Research into mechanical properties of an ablative composite on a polymer matrix base with aerogel particles. Compos. Struct. 2022, 280, 114855. [Google Scholar] [CrossRef]

- Bao, Y.; Kang, R.; Dong, Z.; Zhu, X.; Wang, C.; Guo, D. Multipoint support technology for mirror milling of aircraft skins. Mater. Manuf. Process. 2017, 33, 996–1002. [Google Scholar] [CrossRef]

- Wang, X.; Li, Z.; Bi, Q.; Zhu, L.; Ding, H. An accelerated convergence approach for real-time deformation compensation in large thin-walled parts machining. Int. J. Mach. Tools Manuf. 2019, 142, 98–106. [Google Scholar] [CrossRef]

- Zhang, S.; Bi, Q.; Ji, Y.; Wang, Y. Real-time thickness compensation in mirror milling based on modified Smith predictor and disturbance observer. J. Mach. Tools Manuf. 2019, 144, 103427. [Google Scholar] [CrossRef]

- Li, Z.-L.; Zhu, L.-M. Compensation of deformation errors in five-axis flank milling of thin-walled parts via tool path optimization. Precis. Eng. 2019, 55, 77–87. [Google Scholar] [CrossRef]

- Ratchev, S.; Liu, S.; Huang, W.; Becker, A.A. An advanced FEA based force induced error compensation strategy in milling. Int. J. Mach. Tools Manuf. 2006, 46, 542–551. [Google Scholar] [CrossRef]

- Li, Z.-L.; Tuysuz, O.; Zhu, L.-M.; Altintas, Y. Surface form error prediction in five-axis flank milling of thin-walled parts. Int. J. Mach. Tools Manuf. 2018, 128, 21–32. [Google Scholar] [CrossRef]

- Cheng, D.J.; Xu, F.; Xu, S.H.; Zhang, C.-Y.; Zhang, S.-W.; Kim, S.-J. Minimization of Surface Roughness and Machining Deformation in Milling of Al Alloy Thin-Walled Parts. Int. J. Precis. Eng. Manuf. 2022, 21, 1597–1613. [Google Scholar] [CrossRef]

- Kang, Y.-G.; Wang, Z.-Q. Two efficient iterative algorithms for error prediction in peripheral milling of thin-walled workpieces considering the in-cutting chip. J. Mach. Tools Manuf. 2013, 73, 55–61. [Google Scholar] [CrossRef]

- Bi, Q.; Huang, N.; Zhang, S.; Shuai, C.; Wang, Y. Adaptive machining for curved contour on deformed large skin based on on-machine measurement and isometric mapping. J. Mach. Tools Manuf. 2018, 136, 34–44. [Google Scholar] [CrossRef]

- Wang, J.; Ibaraki, S.; Matsubara, A. A cutting sequence optimization algorithm to reduce the workpiece deformation in thin-wall machining. Precis. Eng. 2017, 50, 506–514. [Google Scholar] [CrossRef]

- Zawada-Michałowska, M.; Pieśko, P. Post-Machining Deformations of Thin-Walled Elements Made of EN AW-2024 T351 Aluminium Alloy as Regards the Mechanical Properties of the Applied Rolled Semi-Finished Products. Materials 2021, 14, 7591. [Google Scholar] [CrossRef] [PubMed]

- Bandhu, D.; Thakur, A.; Purohit, R.; Verma, R.K.; Abhishek, K. Characterization & evaluation of Al7075 MMCs reinforced with ceramic particulates and influence of age hardening on their tensile behavior. J. Mech. Sci. Technol. 2018, 32, 3123–3128. [Google Scholar] [CrossRef]

- PN-EN 573-1:2006; Aluminium and Aluminium Alloys—Chemical Composition and Form of Wrought Products—Part 1: Numerical Designation System. Polish Committee for Standardization: Warsaw, Poland, 2006.

- PN-EN 485-2+A1:2018-12; Aluminium and Aluminium Alloys—Sheet, Tape, Plate—Part 2: Mechanical Properties. Polish Committee for Standardization: Warsaw, Poland, 2018.

- ISO 1940-1:2003; Mechanical Vibrations—Balancing of Rigid Rotors—Determination of Permissible Residual Unbalance. ISO Standard: Geneva, Switzerland, 2003.

- SGS Tool Catalogue. Available online: https://www.kyocera-sgstool.com/digital-catalog (accessed on 15 October 2022).

- SEGER Tool Catalogue. Available online: http://segerct.com/wp-content/uploads/2022/08/seger-katalog-2022.pdf (accessed on 15 October 2022).

- Zawada-Michałowska, M.; Pieśko, P.; Józwik, J.; Kukiełka, L.; Legutko, S. A comparison of the geometrical accuracy of thin-walled elements made of different aluminium alloys. Materials 2021, 14, 7242. [Google Scholar] [CrossRef] [PubMed]

| Content of Alloy Elements—EN AW-7075 T651 (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mg | Mn | Fe | Si | Cu | Zn | Cr | Ti | Zr + Ti | Other | Al |

| 2.10–2.90 | ≤0.30 | ≤0.50 | ≤0.40 | 1.20–2.00 | 5.10–6.10 | 0.18–0.28 | ≤0.20 | ≤0.25 | ≤0.05 | Rest |

| Content of Alloy Elements—EN AW-6082 T651 (%) | ||||||||||

| Mg | Mn | Fe | Si | Cu | Zn | Cr | Ti | Zr + Ti | Other | Al |

| 0.60–1.20 | 0.40–1.00 | ≤0.50 | 0.70–1.30 | ≤0.10 | ≤0.20 | ≤0.25 | ≤0.10 | – | ≤0.05 | Rest |

| Technological Parameters | Strategy | |

|---|---|---|

| Conventional Cutting | High Speed Cutting | |

| Depth of cut ap (mm) | 0.2 | 0.2 |

| Cutting speed vc (m/min) | 200 | 900 |

| Feed per tooth fz (mm/tooth) | 0.02 | 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zawada-Michałowska, M.; Kuczmaszewski, J.; Pieśko, P. Effect of the Geometry of Thin-Walled Aluminium Alloy Elements on Their Deformations after Milling. Materials 2022, 15, 9049. https://doi.org/10.3390/ma15249049

Zawada-Michałowska M, Kuczmaszewski J, Pieśko P. Effect of the Geometry of Thin-Walled Aluminium Alloy Elements on Their Deformations after Milling. Materials. 2022; 15(24):9049. https://doi.org/10.3390/ma15249049

Chicago/Turabian StyleZawada-Michałowska, Magdalena, Józef Kuczmaszewski, and Paweł Pieśko. 2022. "Effect of the Geometry of Thin-Walled Aluminium Alloy Elements on Their Deformations after Milling" Materials 15, no. 24: 9049. https://doi.org/10.3390/ma15249049

APA StyleZawada-Michałowska, M., Kuczmaszewski, J., & Pieśko, P. (2022). Effect of the Geometry of Thin-Walled Aluminium Alloy Elements on Their Deformations after Milling. Materials, 15(24), 9049. https://doi.org/10.3390/ma15249049