Study on Preparation and Properties of Glass Fibre Fabric Reinforced Polyphenylene Sulphide Composites

Abstract

1. Introduction

2. Experiment

2.1. Materials

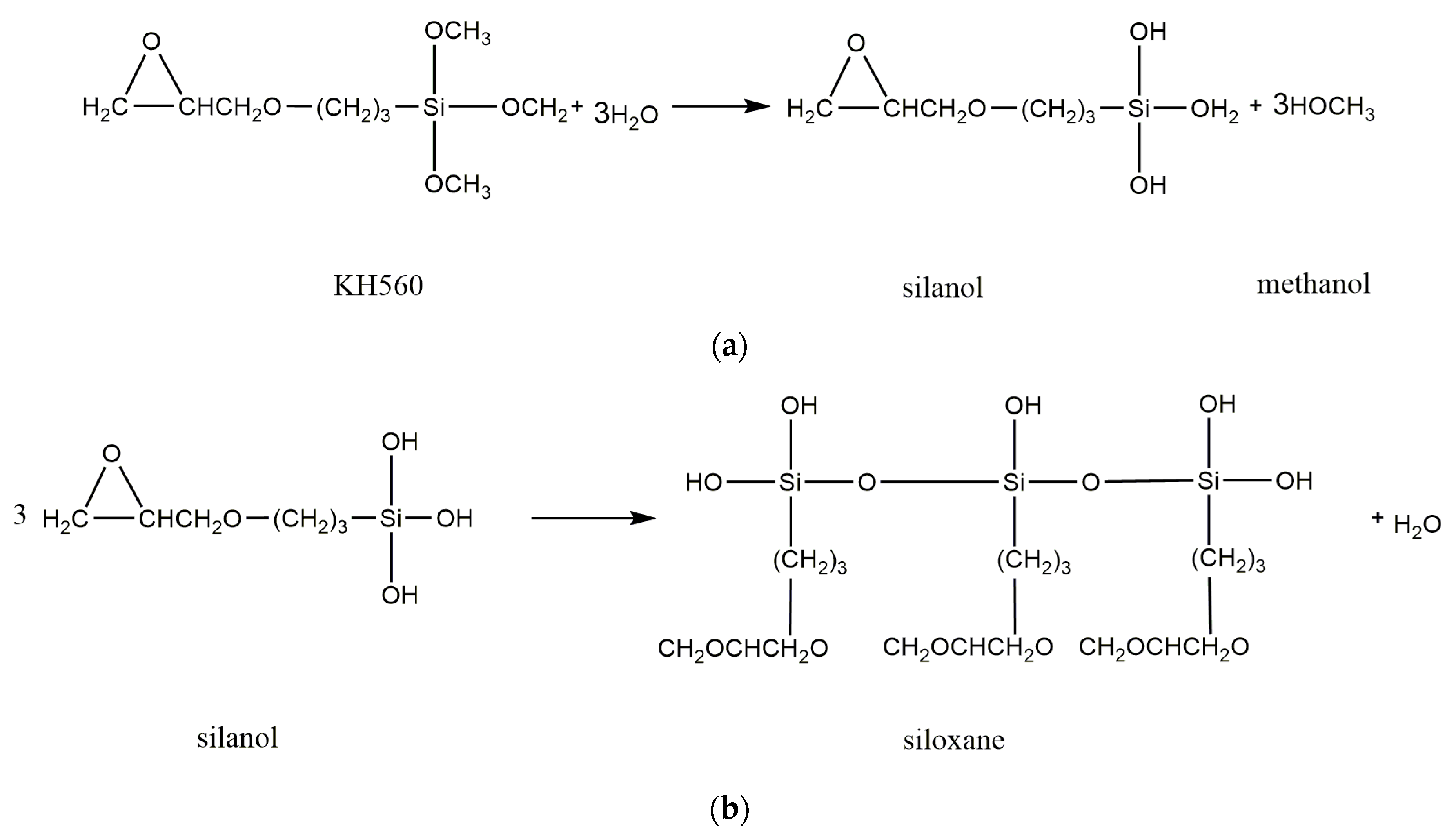

2.2. Silane Coupling Agent Treatment

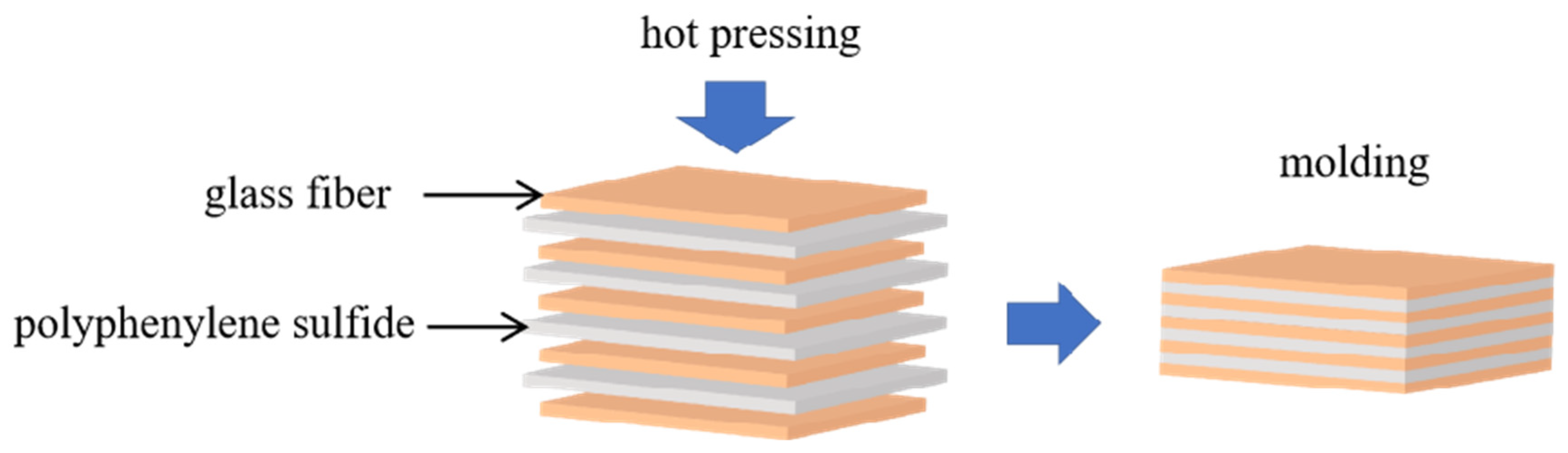

2.3. Preparation of Composite Materials

2.4. Characterization

2.4.1. Surface Morphology

2.4.2. Infrared Spectrum Test

2.4.3. Color Test

2.4.4. Assessment of Tensile Property

2.4.5. Assessment of Bending Strength

3. Results and Discussion

3.1. Effect of Modification of Silane Coupling Agent on Properties

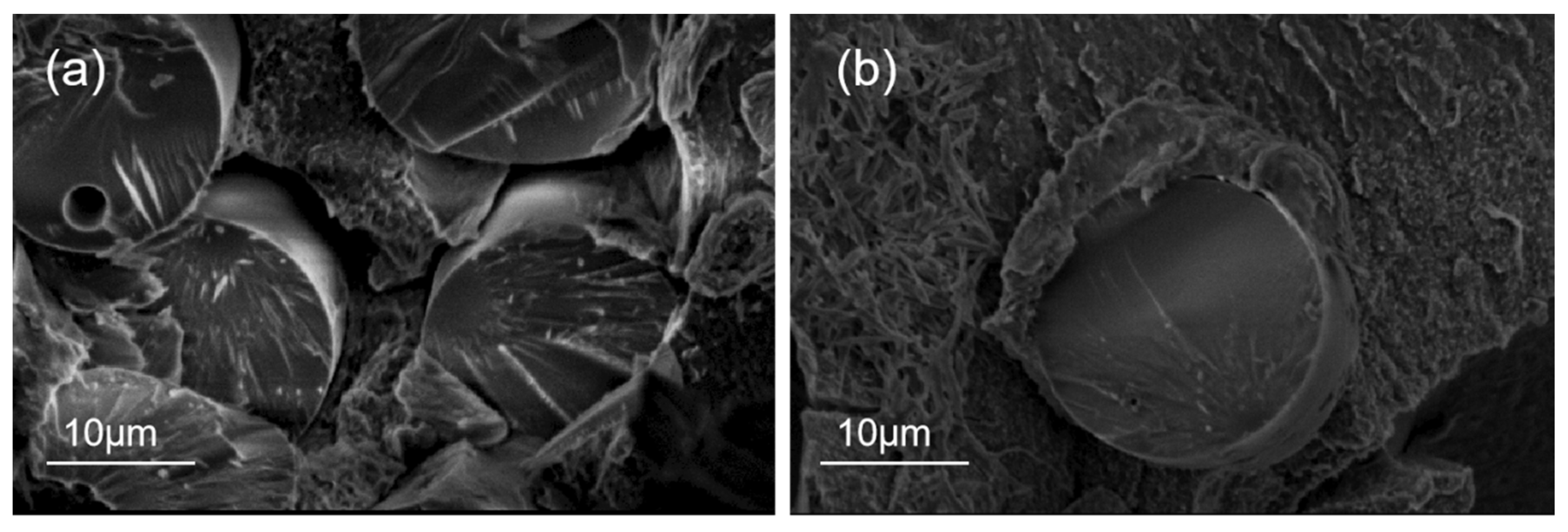

3.1.1. Surface Morphology before and after Silane Coupling Agent Treatment

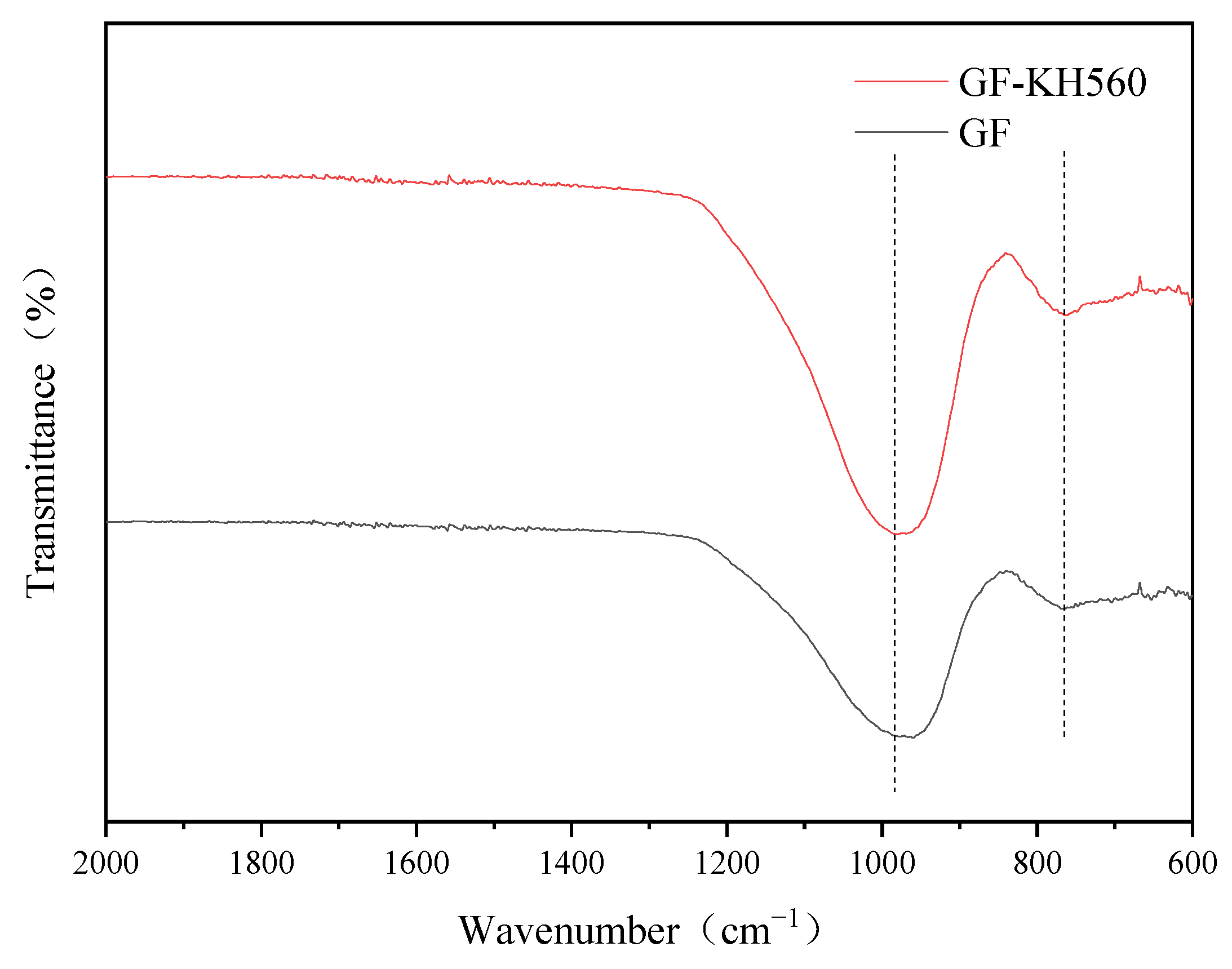

3.1.2. Infrared Spectrum Analysis

3.1.3. Micromorphology of Composites before and after Silane Coupling Agent Treatment

3.2. Effect of Moulding Temperature on Properties of Composites

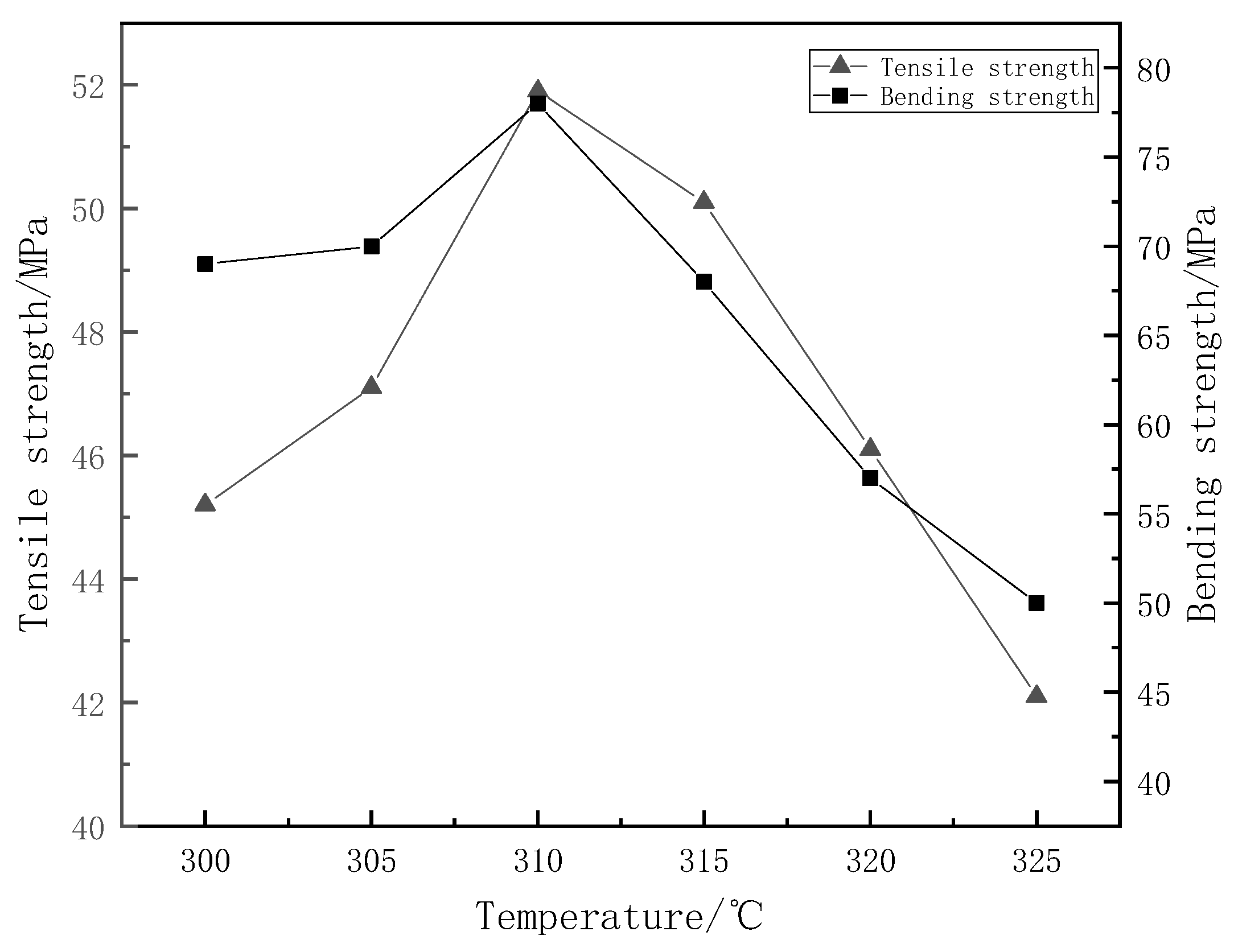

3.2.1. Effect of Forming Temperature on Mechanical Properties of Composites

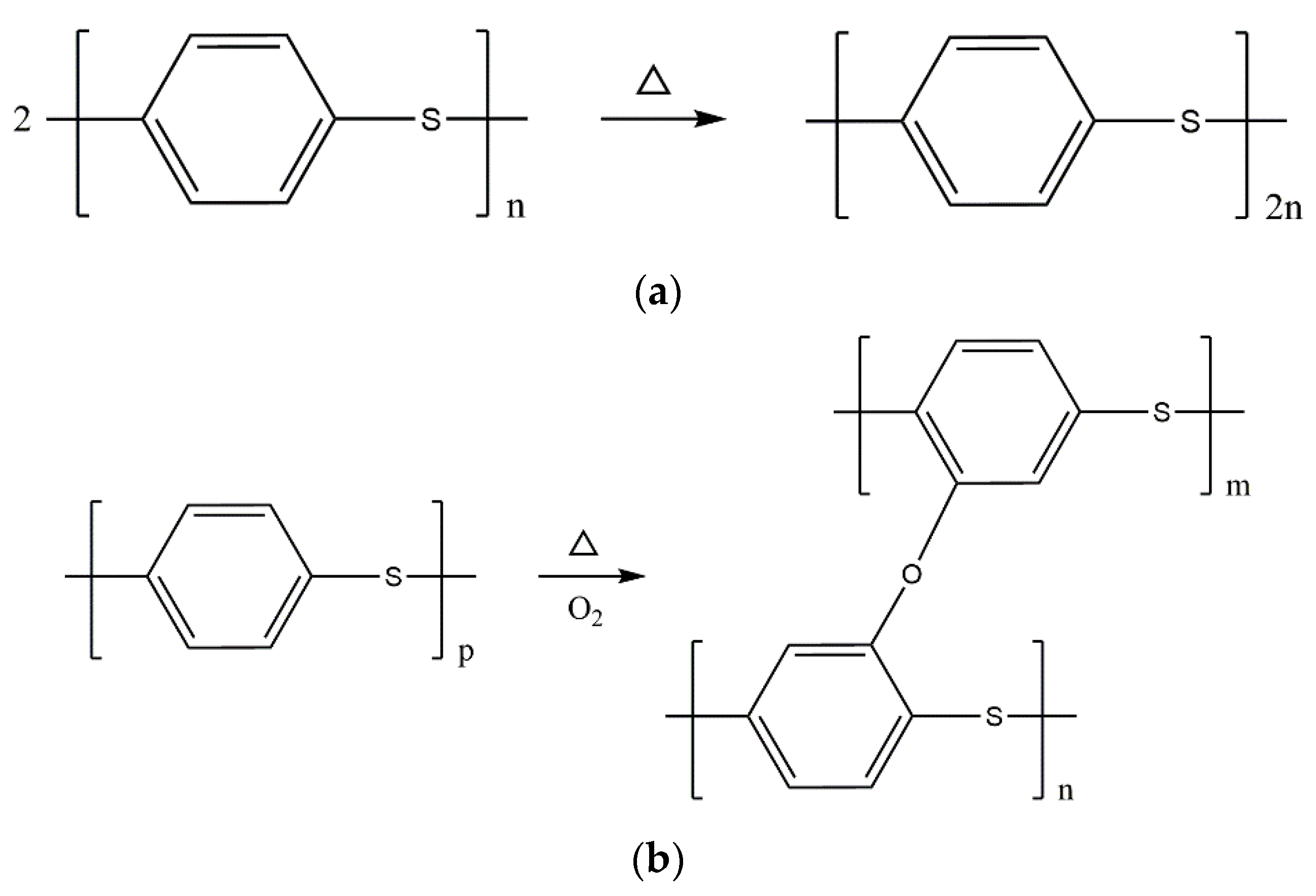

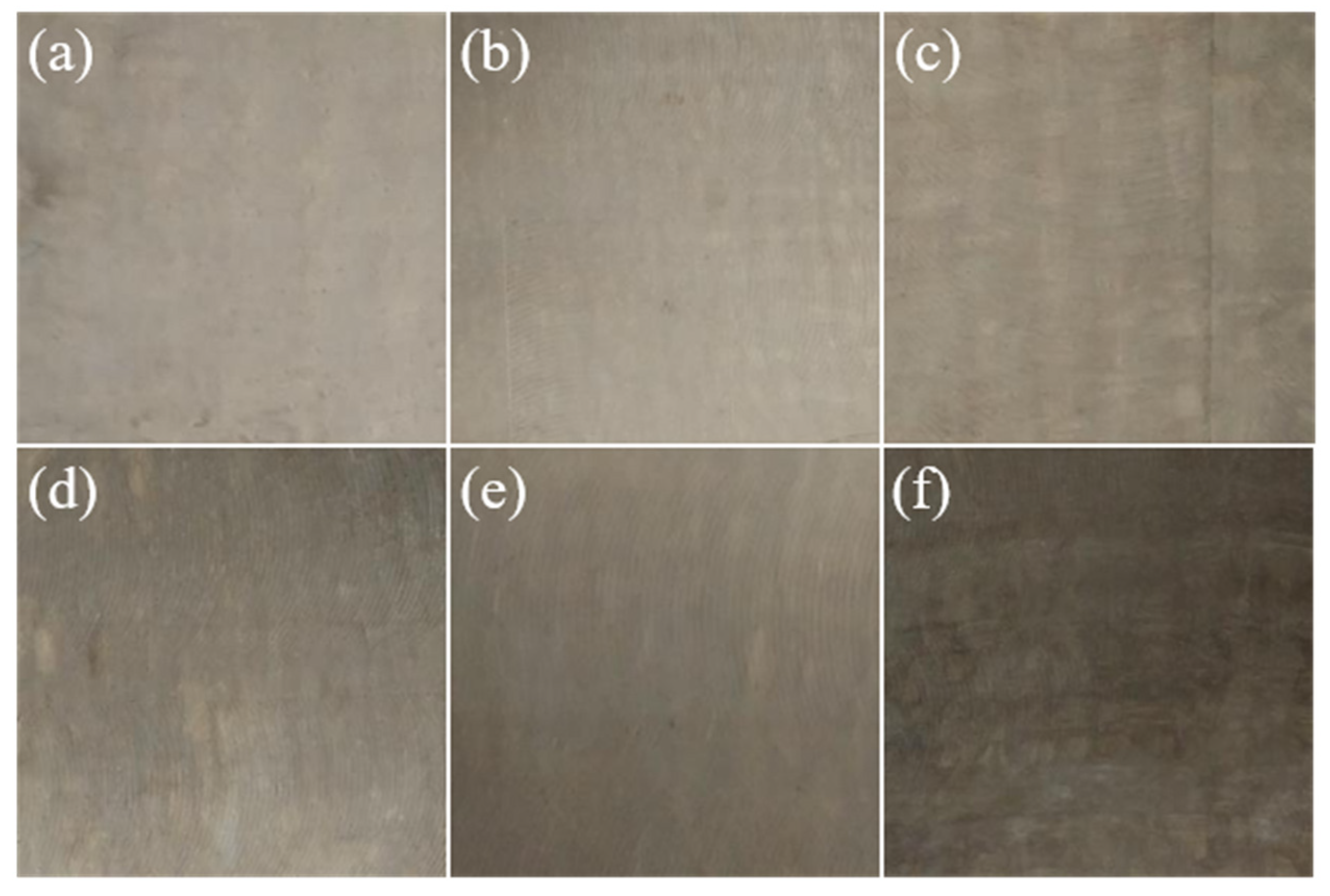

3.2.2. Effect of Forming Temperature on the Surface Color of Composites

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Boborodea, A.; Brookes, A. Characterization of Polyphenylene Sulfide Using Gel Permeation Chromatography with Triple Detection. Int. J. Polym. Anal. Charact. 2015, 20, 172–179. [Google Scholar] [CrossRef]

- Chen, G.W.; Mohanty, A.K.; Misra, M. Progress in research and applications of Polyphenylene Sulfide blends and composites with carbons. Compos. Part B Eng. 2021, 209, 24. [Google Scholar] [CrossRef]

- Yang, R.; Su, Z.T.; Wang, S.; Zhao, Y.F.; Shi, J. Crystallization and mechanical properties of polyphenylene sulfide/multiwalled carbon nanotube composites. J. Thermoplast. Compos. Mater. 2018, 31, 1545–1560. [Google Scholar] [CrossRef]

- Ye, J.J.; Hong, Y.; Wang, Y.K.; Zhai, Z.; Shi, B.Q.; Chen, X.F. The fatigue life study of polyphenylene sulfide composites filled with continuous glass fibers. Mater. Res. Express 2018, 5, 9. [Google Scholar] [CrossRef]

- Cho, M. Friction and wear of a hybrid surface texturing of polyphenylene sulfide-filled micropores. Wear 2016, 346, 158–167. [Google Scholar] [CrossRef]

- Cho, M.H.; Bahadur, S. A study of the thermal, dynamic mechanical, and tribological properties of polyphenylene sulfide composites reinforced with carbon nanofibers. Tribol. Lett. 2007, 25, 237–245. [Google Scholar] [CrossRef]

- Choi, M.; Lee, J.; Ryu, S.; Ku, B.C. Fabrication and Applications of Polyphenylene Sulfide (PPS) Composites: A Short Review. Compos. Res. 2020, 33, 91–100. [Google Scholar] [CrossRef]

- Chukov, D.; Nematulloev, S.; Zadorozhnyy, M.; Tcherdyntsev, V.; Stepashkin, A.; Zherebtsov, D. Structure, Mechanical and Thermal Properties of Polyphenylene Sulfide and Polysulfone Impregnated Carbon Fiber Composites. Polymers 2019, 11, 684. [Google Scholar] [CrossRef]

- Coban, O.; Bora, M.O.; Kutluk, T.; Fidan, S.; Sinmazcelik, T. Effect of Silane as Coupling Agent on Dynamic Mechanical Properties of Volcanic Ash Filled PPS Composites. Acta Phys. Pol. A 2016, 129, 492–494. [Google Scholar] [CrossRef]

- Deng, S.L.; Du, C.M.; Lin, H.B.; Zhu, J.Y.; Lin, Z.D. Isothermal crystallization kinetics and morphology of nanodiamond/polyphenylene sulfide composites. In Proceedings of the International Conference on Materials, Environmental and Biological Engineering (MEBE), Guilin, China, 28–30 March 2015; pp. 97–100. [Google Scholar]

- Di, X.J.; Fang, L.; Lin, Q.F.; Zhang, T.; Zhou, X.D. Synthesis and characterization of silane-grafted polyphenylene sulfide. High Perform. Polym. 2014, 26, 97–105. [Google Scholar] [CrossRef]

- Fan, G.H.; Shi, G.Y.; Ren, H.; Liu, Y.; Fan, R.H. Graphene/polyphenylene sulfide composites for tailorable negative permittivity media by plasmonic oscillation. Mater. Lett. 2019, 257, 4. [Google Scholar] [CrossRef]

- Gao, Y.; Zhou, X.; Zhang, M.; Lyu, L.; Li, Z. Polyphenylene Sulfide-Based Membranes: Recent Progress and Future Perspectives. Membranes 2022, 12, 924. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.Y.; Xu, D.X.; Wang, X.J.; Long, S.R.; Yang, J. Improved interfacial shear strength of carbon fiber/polyphenylene sulfide composites by graphene. High Perform. Polym. 2017, 29, 913–921. [Google Scholar] [CrossRef]

- Yang, J.Z.; Zhao, M. Effect of low temperature plasma treatment on surface properties of polyphenylene sulfide fiber. In Proceedings of the 2nd International Conference on Chemical Engineering and Advanced Materials (CEAM 2012), Guangzhou, China, 13–15 July 2012; pp. 1668–1671. [Google Scholar]

- Zhang, M.L.; Gao, Y.; Zhang, Y.X.; Zhang, M.G.; Gao, Y.; Cheng, B.W.; Li, Z.H. Preparation and properties of polyphenylene sulfide/oxidized-polyphenylene sulfide composite membranes. React. Funct. Polym. 2021, 160, 10. [Google Scholar] [CrossRef]

- Zuo, P.Y.; Fitoussi, J.; Shirinbayan, M.; Bakir, F.; Tcharkhtchi, A. Thermal aging effects on overall mechanical behavior of short glass fiber-reinforced polyphenylene sulfide composites. Polym. Eng. Sci. 2019, 59, 765–772. [Google Scholar] [CrossRef]

- Zuo, P.Y.; Tcharkhtchi, A.; Shirinbayan, M.; Fitoussi, J.; Bakir, F. Overall Investigation of Poly (Phenylene Sulfide) from Synthesis and Process to ApplicationsA Review. Macromol. Mater. Eng. 2019, 304, 27. [Google Scholar] [CrossRef]

- Han, P.D.; Butterfield, J.; Price, M.; Buchanan, S.; Murphy, A. Experimental investigation of thermoforming carbon fibre-reinforced polyphenylene sulphide composites. J. Thermoplast. Compos. Mater. 2015, 28, 529–547. [Google Scholar] [CrossRef]

- Jeong, Y.; Yoo, S.Y.; Jung, C.G.; Lee, J.; Kim, S.H.; Lee, P.C.; Lee, H.W.; Ha, J.U. Comparison of Polyphenylene Sulfide Composites Having Different Processing Temperatures and Glass Fibers. Elastom. Compos. 2019, 54, 308–312. [Google Scholar] [CrossRef]

- Jiang, Z.Y.; Buchanan, S.; McCool, R.; Hornsby, P.; Murphy, A. Preparation and Properties of Polyphenylene Sulfide/Multiwalled Carbon Nanotube Composites. In Proceedings of the 14th International Conference on Material Forming Esaform, Queens University, Belfast, UK, 27–29 April 2011; pp. 996–1001. [Google Scholar]

- Kemmler, B.; Hoffmann, P.; Cremer, M.; Ortner, H.M.; Mennig, G. Quantification of corrosion phenomena in plastic processing machines. Fresenius J. Anal. Chem. 2001, 371, 874–881. [Google Scholar] [CrossRef]

- Khan, S.M.; Gull, N.; Munawar, M.A.; Zia, S.; Anjum, F.; Iqbal, M.S.; Shafiq, M.; Islam, A.; Awais, S.M.; Butt, M.A.; et al. Polyphenylene sulphide/carbon fiber composites: Study on their thermal, mechanical and microscopic properties. Iran. Polym. J. 2016, 25, 475–485. [Google Scholar] [CrossRef]

- Kim, D.K.; Song, K.H.; Hwang, S.S. Effect of Poly(phenylene sulfide) (PPS) as Functional Additive on the Physical Properties of Poly(phenylene ether) (PPE)/PPS Blends. Int. Polym. Process. 2020, 35, 268–280. [Google Scholar] [CrossRef]

- Kutluk, T.; Coban, O.; Bora, M.O.; Fidan, S.; Sinmazcelik, T. Silane Coupling Efficiency on Thermal Properties of Volcanic Ash Filled PPS Composites. Acta Phys. Pol. A 2016, 129, 498–500. [Google Scholar] [CrossRef]

- Liu, B.Y.; Wang, X.J.; Long, S.R.; Yang, J. Interfacial micromechanics of carbon fiber-reinforced polyphenylene sulfide composites. Compos. Interfaces 2014, 21, 359–369. [Google Scholar] [CrossRef]

- Manjunath, A.; Manjushree, H.; Nagaraja, K.C.; Pranesh, K.G. Role of E-glass fiber on mechanical, thermal and electrical properties of polyphenylene sulfide (PPS) composites. In Proceedings of the International Conference on Emerging Trends in Material Science and Technology (ICETMT), Bangalore, India, 10–11 February 2022; pp. 5439–5443. [Google Scholar]

- Mao, Y.H.; Guan, Y.; Zheng, Q.K.; Liu, Q.S.; Feng, X.N.; Wang, X.X. Carrier dyeing of polyphenylene sulphide fabric with disperse dye. Color. Technol. 2013, 129, 39–48. [Google Scholar] [CrossRef]

- Panin, S.V.; Le, T.M.H.; Kornienko, L.A.; Lexenko, V.O.; Ivanova, L.R.; Ovechkin, B.B. Mechanical and Tribotechnical Properties of Polyphenylene Sulfide Composites Reinforced with Carbon Fibers of Various Dimension. In Proceedings of the International Symposium on Hierarchical Materials—Development and Applications for New Technologies and Reliable Structures, Tomsk, Russia, 1–5 October 2018. [Google Scholar]

- Rahate, A.S.; Nemade, K.R.; Waghuley, S.A. Optical Investigation of Polyphenylene Sulfide Composite. In Proceedings of the International Conference on Recent Trends in Applied Physics and Material Science (RAM), Govt Coll Engn & Technol Bikaner, Bikaner, India, 1–2 February 2013; pp. 809–810. [Google Scholar]

- Rahate, A.S.; Nemade, K.R.; Waghuley, S.A. Polyphenylene sulfide (PPS): State of the art and applications. Rev. Chem. Eng. 2013, 29, 471–489. [Google Scholar] [CrossRef]

- Ren, H.H.; Xu, D.X.; Yan, G.M.; Zhang, G.; Wang, X.J.; Long, S.R.; Yang, J. Effect of carboxylic polyphenylene sulfide on the micromechanical properties of polyphenylene sulfide/carbon fiber composites. Compos. Sci. Technol. 2017, 146, 65–72. [Google Scholar] [CrossRef]

- Ribeiro, B.; Pipes, R.B.; Costa, M.L.; Botelho, E.C. Electrical and rheological percolation behavior of multiwalled carbon nanotube-reinforced poly(phenylene sulfide) composites. J. Compos Mater. 2017, 51, 199–208. [Google Scholar] [CrossRef]

- Suresh, A.; Harsha, A.P.; Chosh, M.K. Solid particle erosion studies on polyphenylene sulfide composites and prediction on erosion data using artificial neural networks. Wear 2009, 266, 184–193. [Google Scholar] [CrossRef]

- Chen, C.M.; Hsieh, T.E.; Liu, M.O. Preparation of epoxy-modified polyethylene by graft extrusion and its applications to polyphenylene sulfide alloys as a compatibilizer. React. Funct. Polym. 2008, 68, 1307–1313. [Google Scholar] [CrossRef]

- Wan, J.X.; Qin, Y.F.; Li, S.B.; Wang, X.H. Studies on Preparation and characterization of Anti-oxidizing polyphenylene sulfide. In Proceedings of the International Conference on Textile Engineering and Materials (ICTEM 2011), Tianjin, China, 23–25 September 2011; pp. 1045–1048. [Google Scholar]

- Wang, W.C.; Wu, X.M.; Ding, C.; Huang, X.B.; Ye, N.B.A.; Yu, Q.; Mai, K.C. Thermal aging performance of glass fiber/polyphenylene sulfide composites in high temperature. J. Appl. Polym. Sci. 2021, 138, 10. [Google Scholar] [CrossRef]

- Xiang, P.W.; Zhang, R.P.; Niu, M.; Guo, X.P.; Bai, Q.R. Research on the Rheological Properties of Polyphenylene Sulfide (PPS) Resin. In Proceedings of the International Conference on Textile Engineering and Materials (ICTEM 2011), Tianjin, China, 23–25 September 2011; pp. 949–954. [Google Scholar]

- Zhang, S.Y.; Huang, G.S.; Wang, X.J.; Huang, Y.J.; Yang, J.; Li, G.X. Effect of air plasma treatment on the mechanical properties of polyphenylene sulfide/glass fiber cloth composites. J. Reinf. Plast. Compos. 2013, 32, 786–793. [Google Scholar] [CrossRef]

- Prado, M.; Marques, J.N.; Pereira, G.D.; da Silva, E.M.; Simao, R.A. Evaluation of different surface treatments on fiber post cemented with a self-adhesive system. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 77, 257–262. [Google Scholar] [CrossRef] [PubMed]

- Suarez-Grau, F.J. Theoretical derivation of Darcy’s law for fluid flow in thin porous media. Math. Nachr. 2022, 295, 607–623. [Google Scholar] [CrossRef]

- Bowers, C.A.; Miller, C.T. Generalized Newtonian fluid flow in porous media. Phys. Rev. Fluids 2021, 6, 22. [Google Scholar] [CrossRef]

- Debnath, S.; Wunder, S.L.; McCool, J.I.; Baran, G.R. Silane treatment effects on glass/resin interfacial shear strengths. Dent. Mater. 2003, 19, 441–448. [Google Scholar] [CrossRef]

- Chen, Q.; Su, Y.-l.; Cai, Q.; Bai, Y.-y.; Su, J.; Wang, X.-z. Comparative research for micro-push-out bond strengths of glass fiber posts treated by poly-dopamine or silane coupling agent. Beijing Da Xue Xue Bao Yi Xue Ban J. Peking Univ. Health Sci. 2015, 47, 1005–1009. [Google Scholar]

- Huang, L.; Liu, H.; Wang, C.Z. Preparation and Characterization of Poly(styrene-co-divinylbenzene)/Fiberglass Cation-Exchange Composites. J. Appl. Polym. Sci. 2011, 120, 944–949. [Google Scholar] [CrossRef]

- Yang, G.; Zhang, M.; Su, K.; Li, Z. OPPS Fibers with High Temperature Resistance and Excellent Antioxidant Properties by an Oxidation Method. ACS Appl. Mater. Interfaces 2022, 14, 50225–50234. [Google Scholar] [CrossRef]

- Xing, J.; Xu, Z.Z.; Li, D.W. Preparation and oxidation resistance of polyphenylene sulfide modified by high-temperature antioxidants. Mater. Res. Express 2021, 8, 12. [Google Scholar] [CrossRef]

- Han, W.X.; Lu, J.J.; Ren, J.Y.; Lian, D.D.; Xing, J.D. Preparation of nano-SiO2 compound antioxidant and its antioxidant effect on polyphenylene sulfide. J. Polym. Eng. 2019, 39, 556–564. [Google Scholar] [CrossRef]

| Index | Specification |

|---|---|

| warp density | 34 yarns/10 cm |

| weft density | 25 yarns/10 cm |

| Warp yarn density | 440 tex |

| Weft yarn density | 380 tex |

| GSM | 250 g/m² |

| Thickness | 0.25 mm |

| Sample Number | Variable | Silane Coupling Agent Modification | Temperature/°C |

|---|---|---|---|

| 1 | Silane coupling agent modification | No | 310 |

| 2 | Yes | 310 | |

| 3 | Temperature | Yes | 300 |

| 4 | Yes | 305 | |

| 5 | Yes | 310 | |

| 6 | Yes | 315 | |

| 7 | Yes | 320 | |

| 8 | Yes | 325 |

| Temperature/°C | L | a | b | ΔL | Δa | Δb | ΔE |

|---|---|---|---|---|---|---|---|

| 300 °C | 64 | 1 | 8 | — | — | — | — |

| 305 °C | 63 | 1 | 10 | −1 | 0 | 2 | 2.24 |

| 310 °C | 59 | 2 | 11 | −5 | 1 | 3 | 6.00 |

| 315 °C | 53 | 1 | 9 | −11 | 0 | 1 | 11.05 |

| 320 °C | 48 | 1 | 10 | −16 | 0 | 2 | 14.14 |

| 325 °C | 35 | 2 | 9 | −19 | 1 | 1 | 19.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, L.; Huang, J.; Feng, X.; Sun, Z.; Qiu, Y.; Tian, W.; Zhu, C. Study on Preparation and Properties of Glass Fibre Fabric Reinforced Polyphenylene Sulphide Composites. Materials 2022, 15, 9036. https://doi.org/10.3390/ma15249036

Shao L, Huang J, Feng X, Sun Z, Qiu Y, Tian W, Zhu C. Study on Preparation and Properties of Glass Fibre Fabric Reinforced Polyphenylene Sulphide Composites. Materials. 2022; 15(24):9036. https://doi.org/10.3390/ma15249036

Chicago/Turabian StyleShao, Lingda, Jinbo Huang, Xuhuang Feng, Zeyu Sun, Yingjie Qiu, Wei Tian, and Chengyan Zhu. 2022. "Study on Preparation and Properties of Glass Fibre Fabric Reinforced Polyphenylene Sulphide Composites" Materials 15, no. 24: 9036. https://doi.org/10.3390/ma15249036

APA StyleShao, L., Huang, J., Feng, X., Sun, Z., Qiu, Y., Tian, W., & Zhu, C. (2022). Study on Preparation and Properties of Glass Fibre Fabric Reinforced Polyphenylene Sulphide Composites. Materials, 15(24), 9036. https://doi.org/10.3390/ma15249036