Determination of Two-Stage Heat Treatment Parameters in Industrial Conditions in Order to Obtain a TRIP Structure in Low-Alloy Carbon Steel Wires

Abstract

1. Introduction

2. Materials and Methods

- (a)

- A passive disc unwinder with a friction brake with adjustable clamping force of the rotating disc, which reduces excessive wire overhang during the unwinding process;

- (b)

- An arrangement of drawing rollers with individual drive and a set of stress-relieving rollers mounted in two planes, which reduce the intrinsic stresses of the wire;

- (c)

- An induction coil capable of achieving the required temperature (850 °C) in less than 5 s;

- (d)

- A high-temperature pass-through furnace No. I (850 °C);

- (e)

- A through cooler with adjustable compressed air blow to achieve the required cooling speed;

- (f)

- A low-temperature pass-through furnace II (440 °C);

- (g)

- A winder with a smooth adjustment of the rotational speed of the drum with a diameter of 1000 mm.

3. Results and Discussion

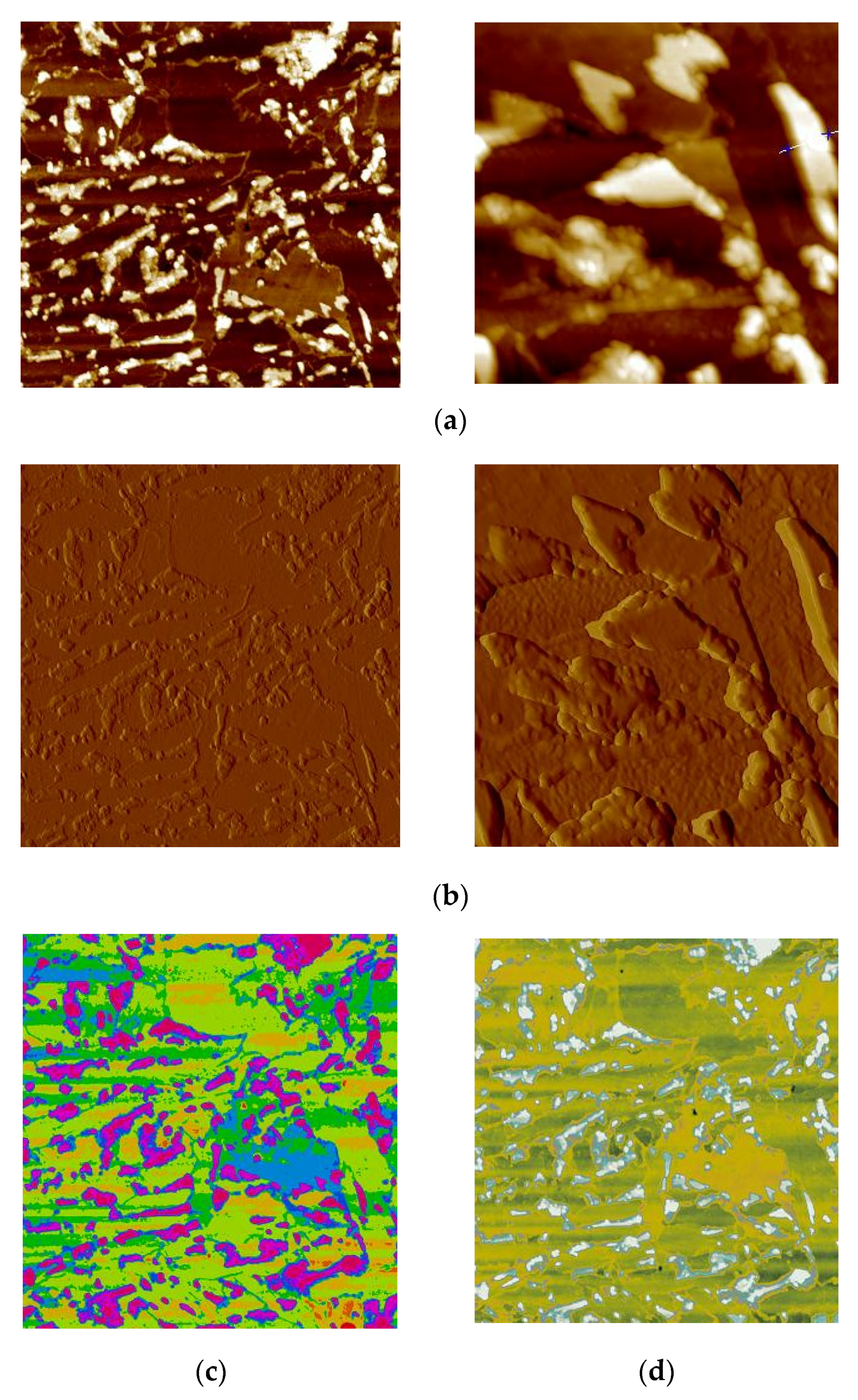

3.1. Qualitative Metallographic Analysis of Heat-Treated Wires with JEOL 2100 Plus Electron Microscope

3.2. Quantitative Analysis of the Share of Retained Austenite in the Structure of Wires Subjected to Two-Stage Heat Treatment Type TRIP

3.3. Analysis of the Results of Mechanical Properties

4. Conclusions

- The applied parameters of the two-stage TRIP heat treatment process on the demonstration line for the analyzed steel grades allowed us to obtain wires with up to 5.50 mm diameters with a volume fraction of retained austenite in the structure, meeting the assumed requirements: ≥60×%C in steel.

- Wires after TRIP-type heat treatment process have higher values of tensile strength in comparison to unheated wires with ferritic–pearlitic structure.

- The conducted two-stage TRIP-type heat treatment process and the subsequent calibration drawing process allowed us to obtain the material with an appropriate plasticity reserve (Re/Rm at the level of 0.84–0.87); that is, raw material for the production of screws.

- The successive stages of shaping the screw in the plastic deformation processes will result in the transformation of the retained austenite into martensite, which will increase the mechanical properties and obtaining a fastener in property class 8.8 without conducting heat treatment on the finished product.

- The techniques of determining the share of retained austenite used in the presented work, both stereological and X-ray structural methods, offer high consistency in the obtained values and can be used interchangeably.

- The applied parameters of the two-stage TRIP type heat treatment process allowed us to obtain a material with 11% of the volume fraction of retained austenite in the structure for steel grade S355J2 and 7% for steel grade G4Si1.

- A technological line developed in industrial conditions for conducting a two-stage TRIP heat treatment process for wires with diameters below 5.50 mm gives the possibility of producing semi-finished products, such as wires for ropes used in the construction of protective barriers on motorways.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Ethical Statement

References

- Grajcar, A.; Kozłowska, A.; Radwański, K.; Skowronek, A. Quantitative Analysis of Microstructure Evolution in Hot-Rolled Multiphase Steel Subjected to Interrupted Tensile Test. Metals 2019, 9, 1304. [Google Scholar] [CrossRef]

- Gronostajski, Z.; Niechajowicz, A.; Kuziak, R.; Krawczyk, J.; Polak, S. The Effect of the Strain Rate on the Stress-Strain Curve and Microstructure of AHSS. J. Mater. Process. Technol. 2017, 242, 246–259. [Google Scholar] [CrossRef]

- Vercruysse, F.; Cerda, F.M.C.; Verleysen, P.; Petrov, R.H. Behavior of Ultrafast Annealed Advanced High Strength Steels Under Static and Dynamic Conditions. Mater. Sci. Eng. A 2020, 780, 139–168. [Google Scholar] [CrossRef]

- Raabe, D.; Sun, B.; da Silva, A.K.; Gault, B.; Yen, H.W.; Sedighiani, K.; Sukumar, P.H.; Filho, I.R.S.; Katnagallu, S.; Jagle, E.; et al. Current Challenges and Opportunities in Mi-crostructure-Related Properties of Advanced High- Strength Steels. Metall. Mater. Trans. A 2020, 51, 5517–5586. [Google Scholar] [CrossRef]

- Bordone, M.; Monsalve, A.; Ipina, J.P. Fracture toughness of High-Manganese steels with TWIP/TRIP effects. Eng. Fract. Mech. 2022, 275, 108837. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Mitter, W. Umwandlungsplastizität und ihre Berücksichtigung bei der Berechnung von Eigenspannungen, Metallkundliche- Technische Reihe 7; Gebrüder Borntraeger: Berlin, Germany, 1987. [Google Scholar]

- Zackay, V.F.; Parker, E.R.; Fahr, D.; Bush, R. The enhancement of ductility in high-strength steels. Trans. Am. Soc. Met. 1967, 60, 252. [Google Scholar]

- Berrahmoune, M.R.; Berveiller, S.; Inal, K.; Moulin, A.; Patoor, E. Analysis of the martensitic transformation at various scales in TRIP steel. Mater. Sci. Eng. A 2004, 378, 304–307. [Google Scholar] [CrossRef]

- Grajcar, A.; Kilarski, A.; Kozłowska, A.; Radwański, K. Microstructure Evolution and Mechanical Stability of Retained Austenite in Thermomechanically Processed Medium-Mn Steel. Materials 2019, 50, 501. [Google Scholar] [CrossRef]

- Eres-Castellanos, A.; Caballero, F.G.; Garcia-Mateo, C. Stress or Strain Induced Martensitic and Bainitic transformations during ausforming processes. Acta Mater. 2020, 198, 60–72. [Google Scholar] [CrossRef]

- Frolova, A.V.; Stolyarov, V.V.; Kumar, J.V.T.; Sudha, J. Features of TRIP steel deformation at low and moderate temperatures. Mater. Sci. Eng. 2021, 1129, 012003. [Google Scholar] [CrossRef]

- Qiu, J.; Zhang, M.; Liu, X.; Zhang, X.; Tan, Z. Characterization of Retained Austenite in a Low Carbon High Strength Mn-Si-Cr Steel. Mater. Sci. Eng. A 2020, 797, 139985. [Google Scholar] [CrossRef]

- Long, X.; Zhao, G.; Zhang, F.; Xu, S.; Yang, Z.; Du, G.; Branco, R. Evolution of Tensile Properties with Transformation Temperature in Medium-Carbon Carbidefree Bainitic steel. Mater. Sci. Eng. A 2020, 775, 138964. [Google Scholar] [CrossRef]

- Vercruysse, F.; Celada-Casero, C.; Linke, B.M.; Verleysen, P.; Petrov, R.H. Temperature Dependence of the Static and Dynamic Behaviour in a Quenching and Partitioning Processed Low-Si Steel. Metals 2020, 10, 509. [Google Scholar] [CrossRef]

- Lloyd, J.T.; Magagnosc, D.J.; Meredith, C.S.; Limmer, K.R.; Field, D.M. Improved dynamic strength of TRIP steel via pre-straining. Scr. Mater. 2022, 220, 114941. [Google Scholar] [CrossRef]

- Prosvirnin, D.V.; Kolmakov, A.G.; Larionov, M.D.; Pivovarchik, S.V. Peculiarities of deformation of thin-sheet TRIP steel under static and fatigue loading. J. Phys. Conf. Ser. 2021, 1758, 012042. [Google Scholar] [CrossRef]

- Kozłowska, A.; Grajcar, A.; Radwański, K.; Opara, J.; Matus, K.; Nuckowski, P.M. Microstructure and temperature-dependent mechanical behavior of hot-rolled TRIP-assisted microalloyed steel. Mater. Charact. 2022, 186, 111804. [Google Scholar] [CrossRef]

- Kozłowska, A.; Grajcar, A. Effect of Elevated Deformation Temperatures on Microstructural and Tensile Behavior of Si-Al Alloyed TRIP-Aided Steel. Materials 2020, 13, 5284. [Google Scholar] [CrossRef]

- Girault, E.; Mertes, A.; Jacques, P.; Houbaert, Y.; Verlinden, B.; Humbeeck, J. Comparison of the effects of silicon and aluminium on the tensile behavior of multiphase TRIP-assisted steels. Scr. Mater. 2001, 44, 885–892. [Google Scholar] [CrossRef]

- Covarrubias, O.; Guerrero, M.P.; Colás, R.; Petrov, R.; Kestens, L.; Houbaert, Y. Transformation behaviour of Si and Mn bearing low carbon steels. In Proceeding of the TRIP—International Conference on TRIP-Aided High Strength Ferrous Alloys, Ghent, Belgium, 19–21 June 2002; pp. 227–230. [Google Scholar]

- Oja, O.; Saastamoinen, A.; Patnamsetty, M.; Honkanen, M.; Peura, P.; Järvenpää, M. Microstructure and Mechanical Properties of Nb and V Microalloyed TRIP-Assisted Steels. Metals 2019, 9, 887. [Google Scholar] [CrossRef]

- Salinas, A.; Artigas, A.; Perez-Ipiña, J.; Castro-Cerda, F.; Garza-Montes-de-Oca, N.; Colás, R.; Petrov, R.; Monsalve, A. Effects of Heat Treatment on Morphology, Texture, and Mechanical Properties of a MnSiAl Multiphase Steel with TRIP Behavior. Metals 2018, 8, 1021. [Google Scholar] [CrossRef]

- Wiewiórowska, S.; Muskalski, Z. The influence of partial single reduction on mechanical properties wires made from TRIP steel with 0.43%C. Metalurgija 2015, 54, 184–186. [Google Scholar]

- Suliga, M.; Muskalski, Z. Wiewiórowska, The influence of drawing speed on fatigue strength TRIP steel wires. Arch. Civ. Mech. Eng. 2009, 9, 97–107. [Google Scholar] [CrossRef]

- Siemiński, M.; Wiewiórowska, S.; Muskalski, Z. Examination of the Effect of Variation in Stress Magnitude on the Amount of Transformed Retained Austenite in the Structure of TRIP Steel Wires. Key Eng. Mater. 2016, 716, 311–316. [Google Scholar] [CrossRef]

- Wiewiórowska, S.; Muskalski, Z.; Siemiński, M. The analysis of “hot” drawing process of TRIP steel wires at different initial temperatures. Arch. Metall. Mater. 2016, 61, 1991–1994. [Google Scholar] [CrossRef]

- Wiewiórowska, S.; Muskalski, Z.; Michalczyk, J. The Influence of Hot Dip Galvanizing Process on Trip Steel Wire Structure and Properties. Arch. Metall. Mater. 2019, 64, 129–132. [Google Scholar] [CrossRef]

- Kucharska, M.; Wiewiórowska, S.; Michalczyk, J.; Gontarz, A. The Influence of the Drawing Process on the Mechanical Properties of TRIP Steel Wires with 0.4% C Content. Materials 2020, 13, 5769. [Google Scholar] [CrossRef]

- Tomita, Y.; Morioka, K. Effect of microstructure on Transformation-Induced-Plasticity of silicon-containing low-alloy steel. Mater. Charact. 1997, 38, 243–250. [Google Scholar] [CrossRef]

- Ostash, O.P.; Kulyk, V.V.; Poznyakov, V.D.; Gaivorons’kyi, О.А.; Vira, V.V. Influence of the Modes of Heat Treatment on the Strength and Cyclic Crack-Growth Resistance of 65G Steel. Mater. Sci. 2019, 54, 776–782. [Google Scholar] [CrossRef]

- Xu, B.; Chen, P.; Li, Z.; Wu, D.; Wang, G.; Guo, J.; Liu, R.; Misra, R.D.K.; Yi, H. The Significance of Optimizing Mn-Content in Tuning the Microstructure and Mechanical Properties of δ-TRIP Steels. Metals 2021, 11, 523. [Google Scholar] [CrossRef]

- ASM Handbook Committee. Properties and Selection: Irons Steels and High Performance Alloys; ASM International the Materials Information Company: Materials Park, OH, USA, 2002; Volume 1. [Google Scholar]

| Grade of Steel | C % | Mn % | Si % | P % | S % | Cr % |

|---|---|---|---|---|---|---|

| G4Si1 | 0.08 | 1.44 | 0.84 | 0.008 | 0.019 | 0.03 |

| S355J2 | 0.18 | 1.39 | 0.22 | 0.011 | 0.008 | 0.03 |

| Drawn No. | Φ mm | Gp, % | Gc, % |

|---|---|---|---|

| 0 | 5.50 | - | - |

| 1 | 5.20 | 10.61 | 10.61 |

| 2 | 5.00 | 7.54 | 17.35 |

| 3 | 4.80 | 7.84 | 23.83 |

| Wire Diameter | Ambient Temp. | Temp. after the Inductor Coil | Temp. T1 | Temp. at the Exit of Furnace No.1 | Temp. after the Cooler | Temp. T2 | Temp. at the Exit of Furnace No.2 |

|---|---|---|---|---|---|---|---|

| mm | °C | °C | °C | °C | °C | °C | °C |

| 4.8 | 15 | 862 | 860 | 860 | 431 | 430 | 430 |

| 4.8 | 15 | 858 | 850 | 851 | 417 | 420 | 421 |

| 4.8 | 17 | 873 | 870 | 872 | 455 | 450 | 453 |

| 5.0 | 16 | 824 | 820 | 821 | 416 | 440 | 440 |

| 5.0 | 17 | 847 | 840 | 844 | 457 | 460 | 461 |

| Variant | Wire Diameter | Temp. after the Inductor Coil | Temp. T1 | Wire Speed, v | Temp. after the Cooler | Temp. T2 | Grade of Steel | |

|---|---|---|---|---|---|---|---|---|

| mm | °C | °C | cm/s | °C | °C | |||

| 1 | assumed parameters | 4.8 | 770 | 750 | 6 | 350 | 350 | S355J2 |

| real parameters | 4.8 | 772 | 750 | 6 | 349 | 350 | ||

| 2 | assumed parameters | 5.0 | 770 | 750 | 6 | 350 | 350 | |

| real parameters | 5.0 | 771 | 750 | 6 | 348 | 350 | ||

| 3 | assumed parameters | 5.0 | 790 | 790 | 6 | 370 | 370 | G4Si1 |

| real parameters | 5.0 | 791 | 790 | 6 | 365 | 370 |

| Variant No. | Quantity of Retained Austenite Determined in Accordance with Quantitative Methods % | Amount of Retained Austenite Determined in Accordance with Atomic Force Microscope % | The Amount of Retained Austenite Determined in Accordance with X-ray Diffraction % |

|---|---|---|---|

| 1 | 11.2 | 10.4 | 11.9 |

| 2 | 10.9 | 10.6 | 11.4 |

| 3 | 6.9 | 6.60 | 7.06 |

| Variant No. | Wire Diameter mm | Rm, MPa | Re, MPa | Re/Rm | A50, % |

|---|---|---|---|---|---|

| Pre-treatment wires prior to the two-stage TRIP process | |||||

| 1 | 4.8 | 550 | 423 | 0.76 | 15.36 |

| 2 | 5.0 | 530 | 415 | 0.78 | 13.24 |

| 3 | 5.0 | 520 | 402 | 0.77 | 14.23 |

| Wire following a two-stage TRIP heat treatment process | |||||

| 1 | 4.8 | 623 | 402 | 0.64 | 29.66 |

| 2 | 5.0 | 623 | 358 | 0.57 | 30.27 |

| 3 | 5.0 | 583 | 386 | 0.66 | 34.36 |

| Variant No. | Steel Grade | Initial Diameter, mm | Final Diameter, mm | Rm, MPa | Re, MPa | Re/Rm | A50, % |

|---|---|---|---|---|---|---|---|

| 1 | S355J2 | 4.80 | 4.55 | 720 | 605 | 0.84 | 15.2 |

| 2 | S355J2 | 5.00 | 4.55 | 750 | 642 | 0.86 | 18.2 |

| 3 | G4Si1 | 5.00 | 4.55 | 730 | 635 | 0.87 | 14.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wiewiórowska, S.; Siemiński, M.; Śleboda, T.; Łukaszek-Sołek, A.; Dyl, T.; Koczurkiewicz, B. Determination of Two-Stage Heat Treatment Parameters in Industrial Conditions in Order to Obtain a TRIP Structure in Low-Alloy Carbon Steel Wires. Materials 2022, 15, 8965. https://doi.org/10.3390/ma15248965

Wiewiórowska S, Siemiński M, Śleboda T, Łukaszek-Sołek A, Dyl T, Koczurkiewicz B. Determination of Two-Stage Heat Treatment Parameters in Industrial Conditions in Order to Obtain a TRIP Structure in Low-Alloy Carbon Steel Wires. Materials. 2022; 15(24):8965. https://doi.org/10.3390/ma15248965

Chicago/Turabian StyleWiewiórowska, Sylwia, Marek Siemiński, Tomasz Śleboda, Aneta Łukaszek-Sołek, Tomasz Dyl, and Bartosz Koczurkiewicz. 2022. "Determination of Two-Stage Heat Treatment Parameters in Industrial Conditions in Order to Obtain a TRIP Structure in Low-Alloy Carbon Steel Wires" Materials 15, no. 24: 8965. https://doi.org/10.3390/ma15248965

APA StyleWiewiórowska, S., Siemiński, M., Śleboda, T., Łukaszek-Sołek, A., Dyl, T., & Koczurkiewicz, B. (2022). Determination of Two-Stage Heat Treatment Parameters in Industrial Conditions in Order to Obtain a TRIP Structure in Low-Alloy Carbon Steel Wires. Materials, 15(24), 8965. https://doi.org/10.3390/ma15248965