Loading Rate and Temperature Interaction Effects on the Mode I Fracture Response of a Ductile Polyurethane Adhesive Used in the Automotive Industry

Abstract

1. Introduction

2. Experimental

2.1. Material

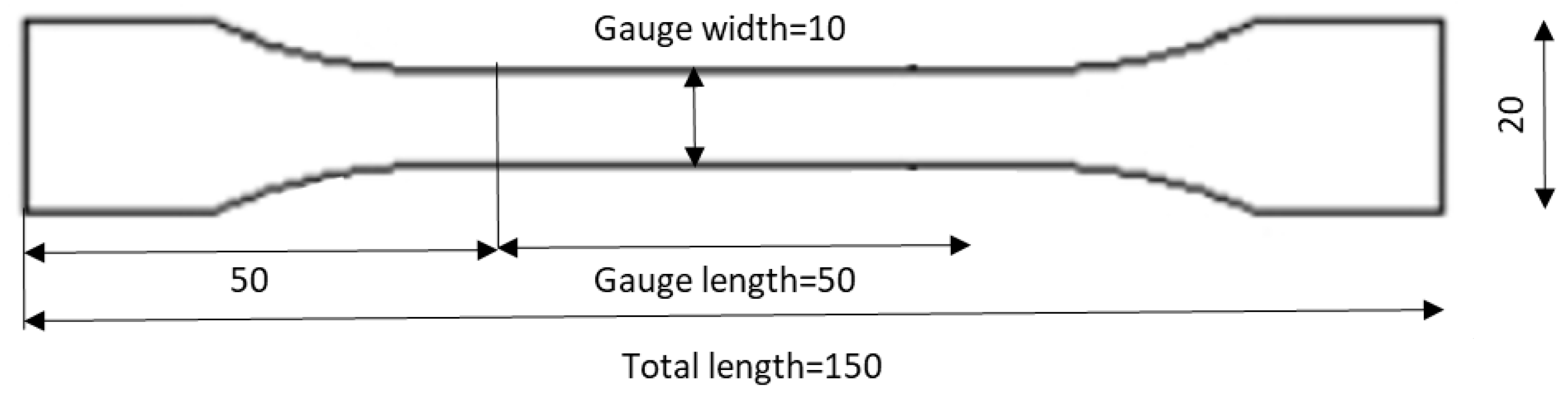

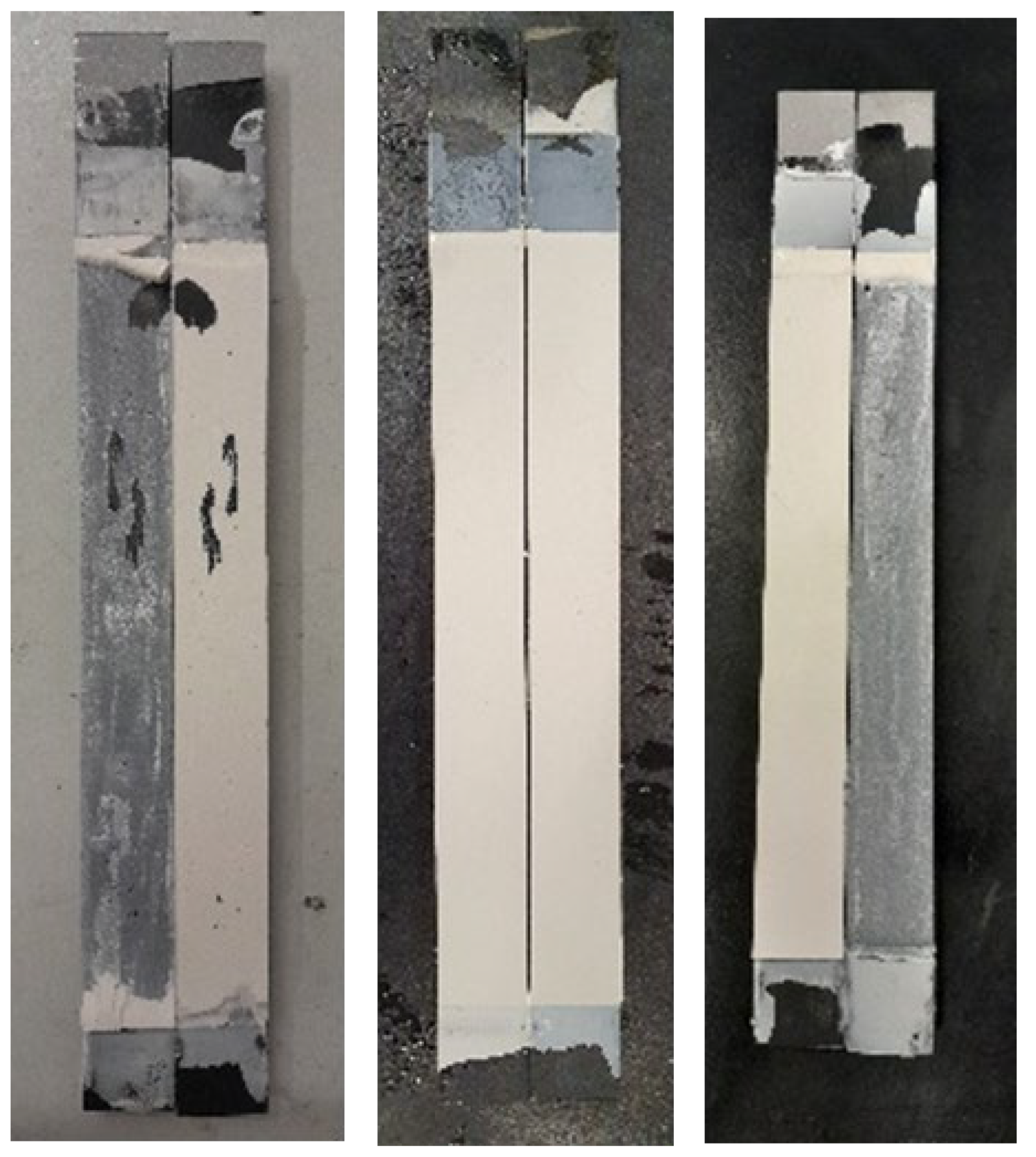

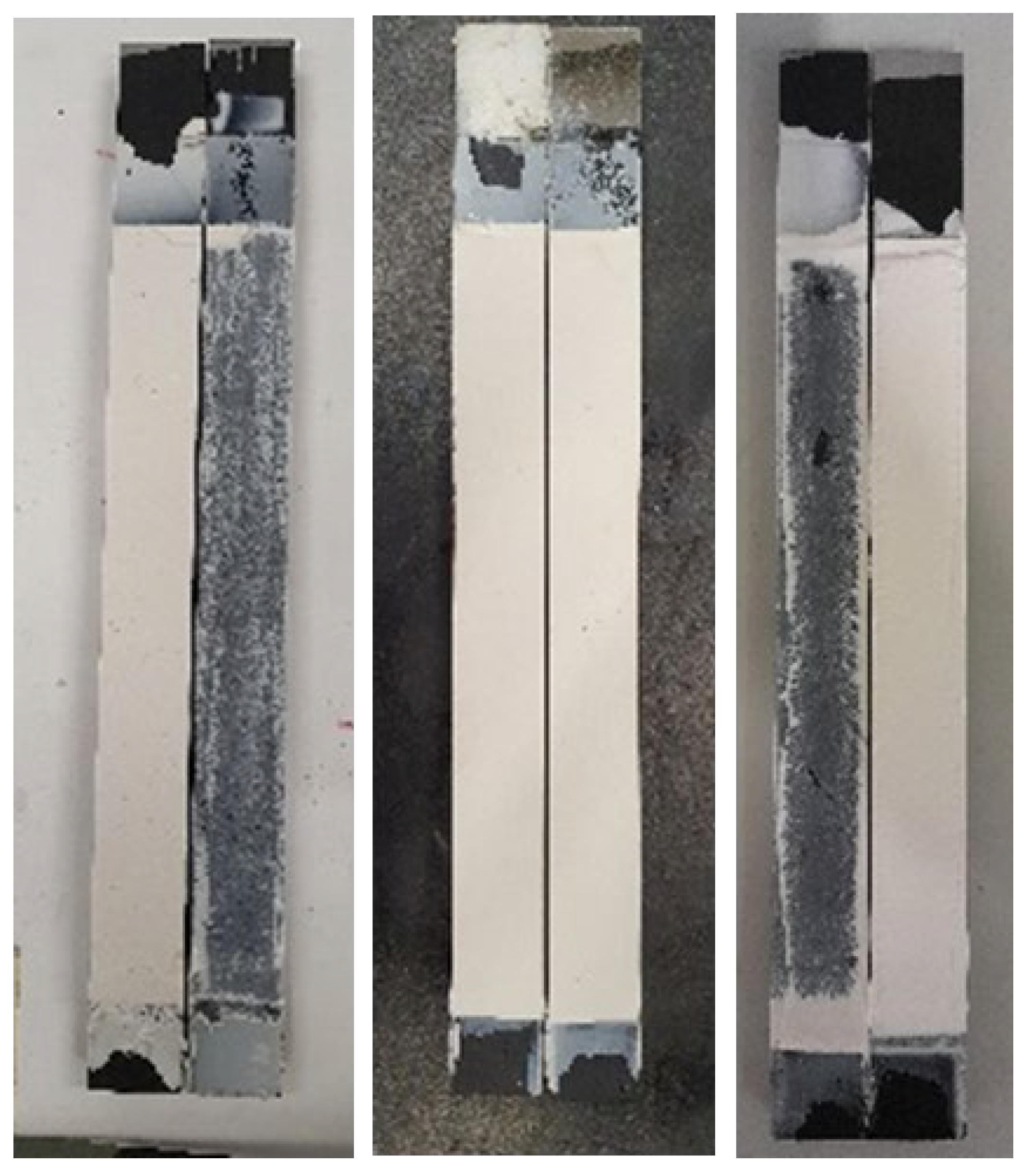

2.2. Geometry and Manufacturing Procedure

2.3. Test Procedures

3. Data Reduction Approach

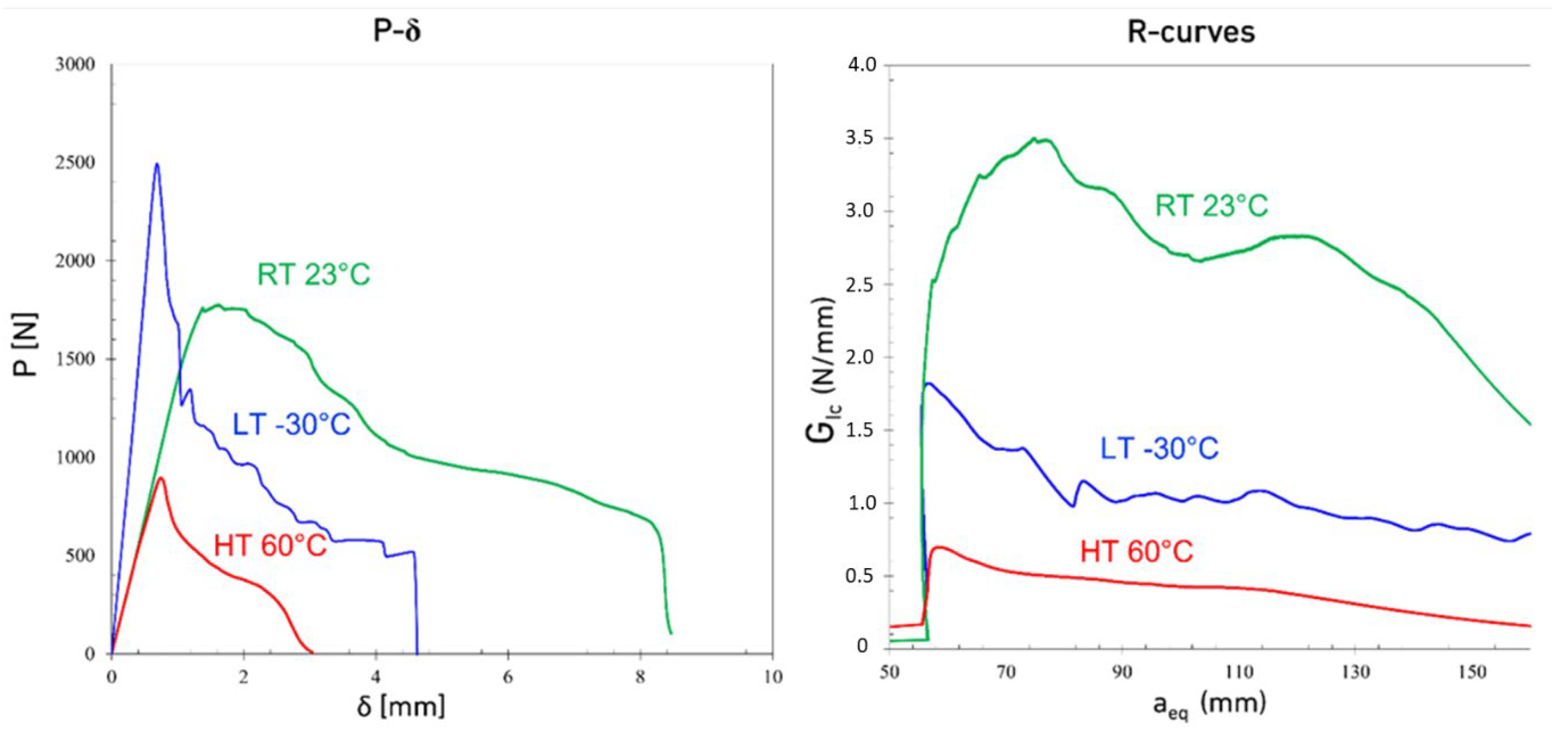

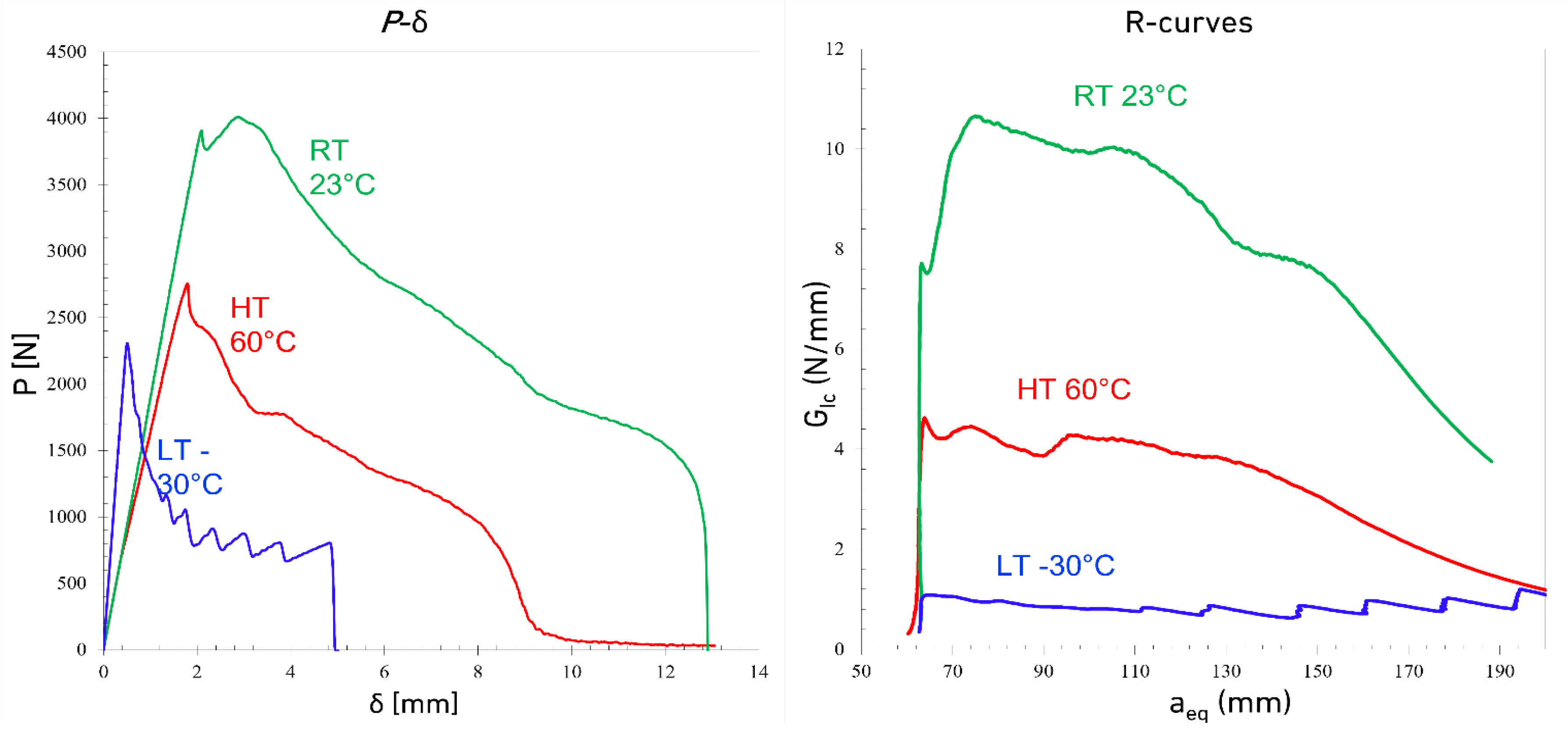

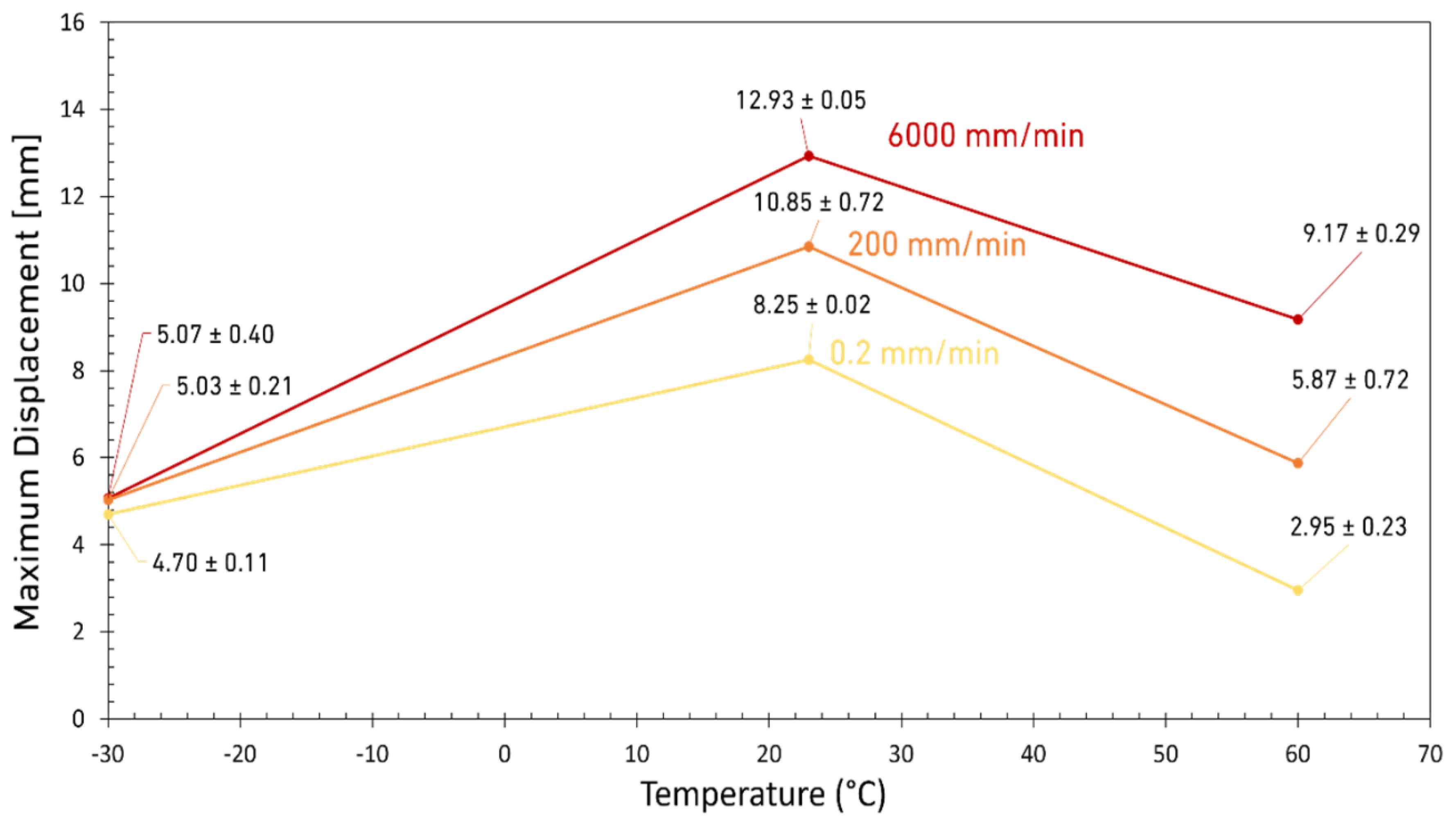

4. Results and Discussions

Fracture Surface Analysis

5. Conclusions

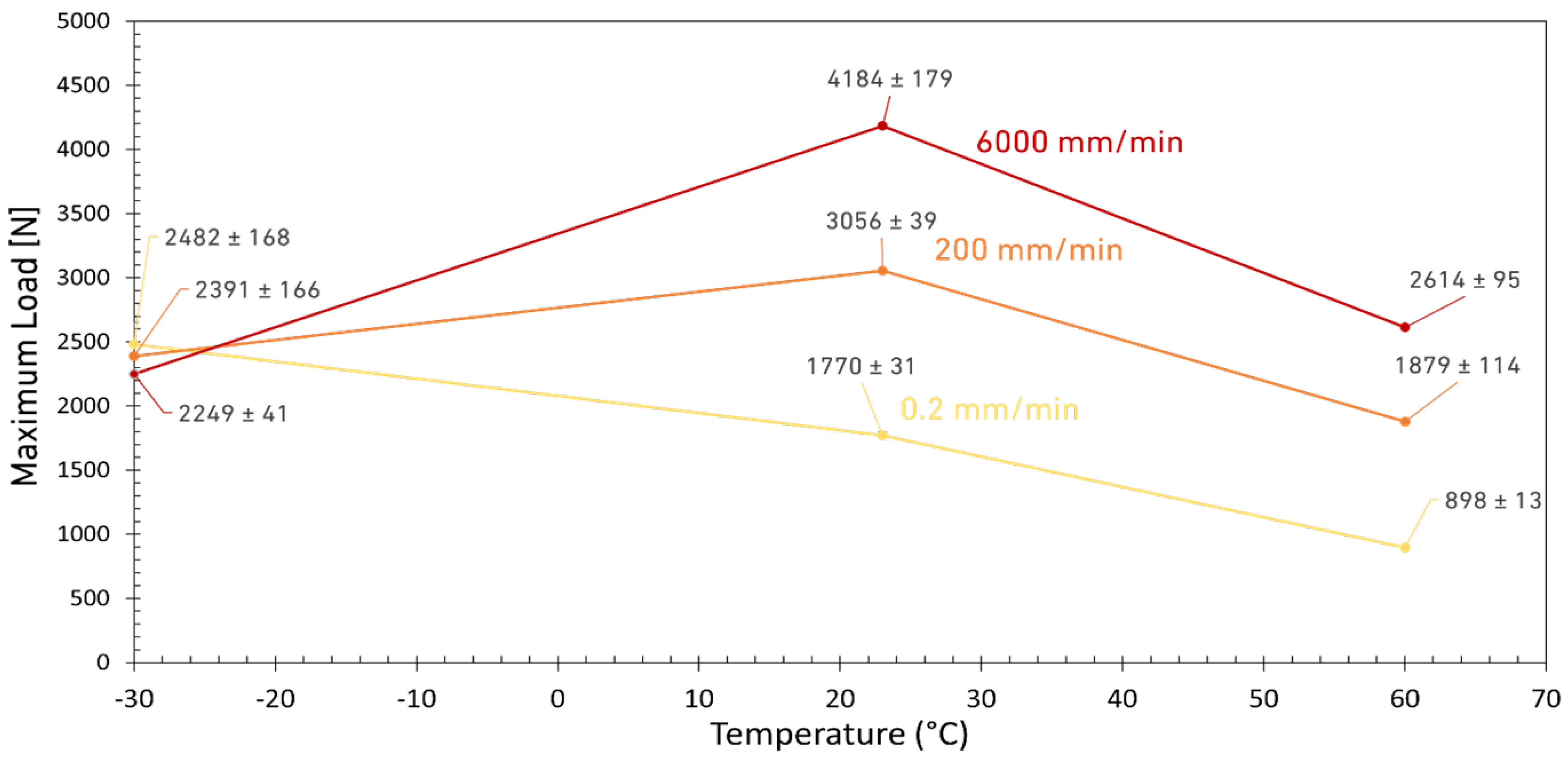

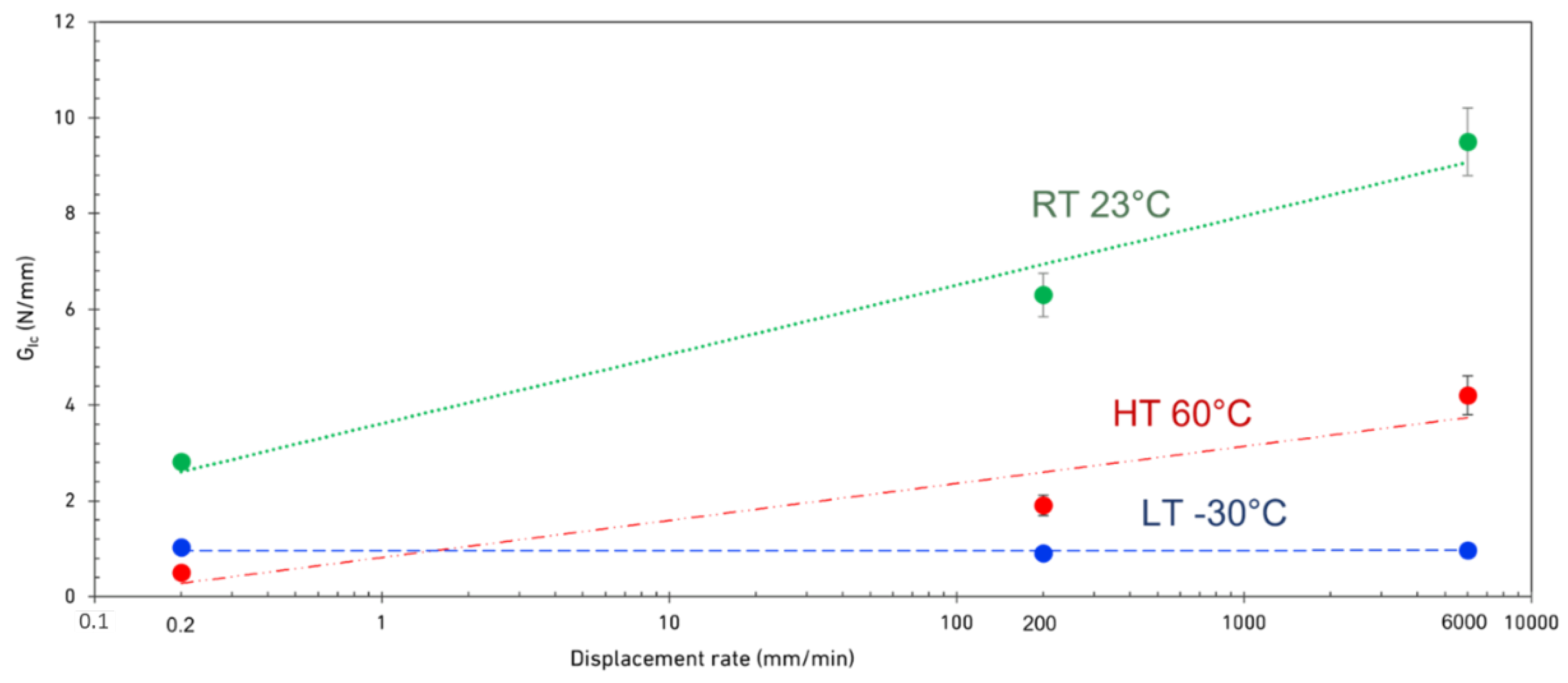

- The adhesive’s mode I fracture behavior and fracture toughness are greatly influenced by service temperature, as the influence of loading rate is quite different when the test is carried out below the Tg or at temperatures above the Tg of the adhesive.

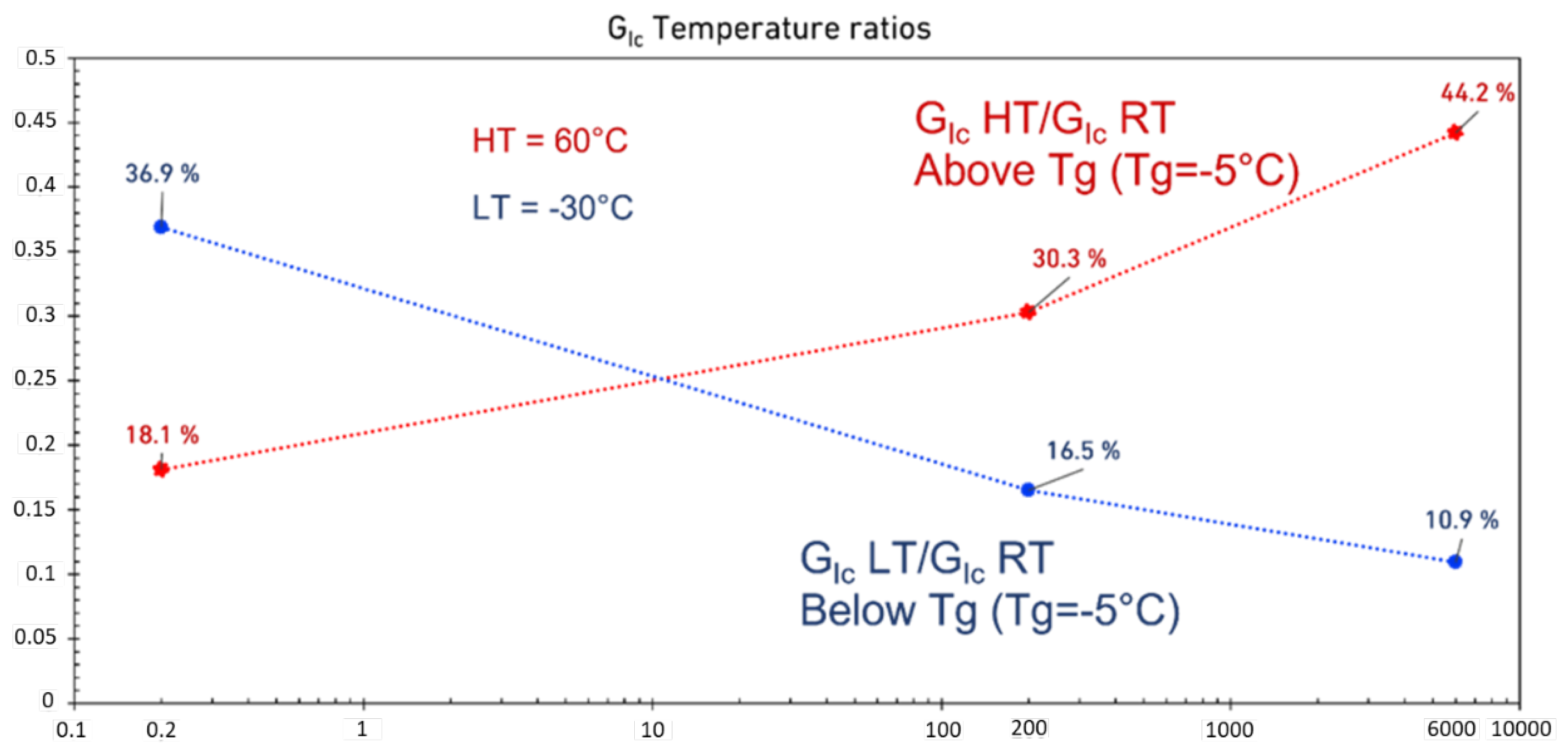

- Above the Tg, the increase in loading rate increases the GIc by a factor of 3.5, while it does not change significantly when the test is running below the Tg.

- It was found that the influence of loading rate is relatively more important for HT than for RT. Based on the results at HT and a high loading rate, the GIc increased by a factor of 10 compared to the factor of 3.5 obtained for RT results.

- When above the Tg, the increase of temperature greatly decreases the GIc, which is less important for higher loading rates.

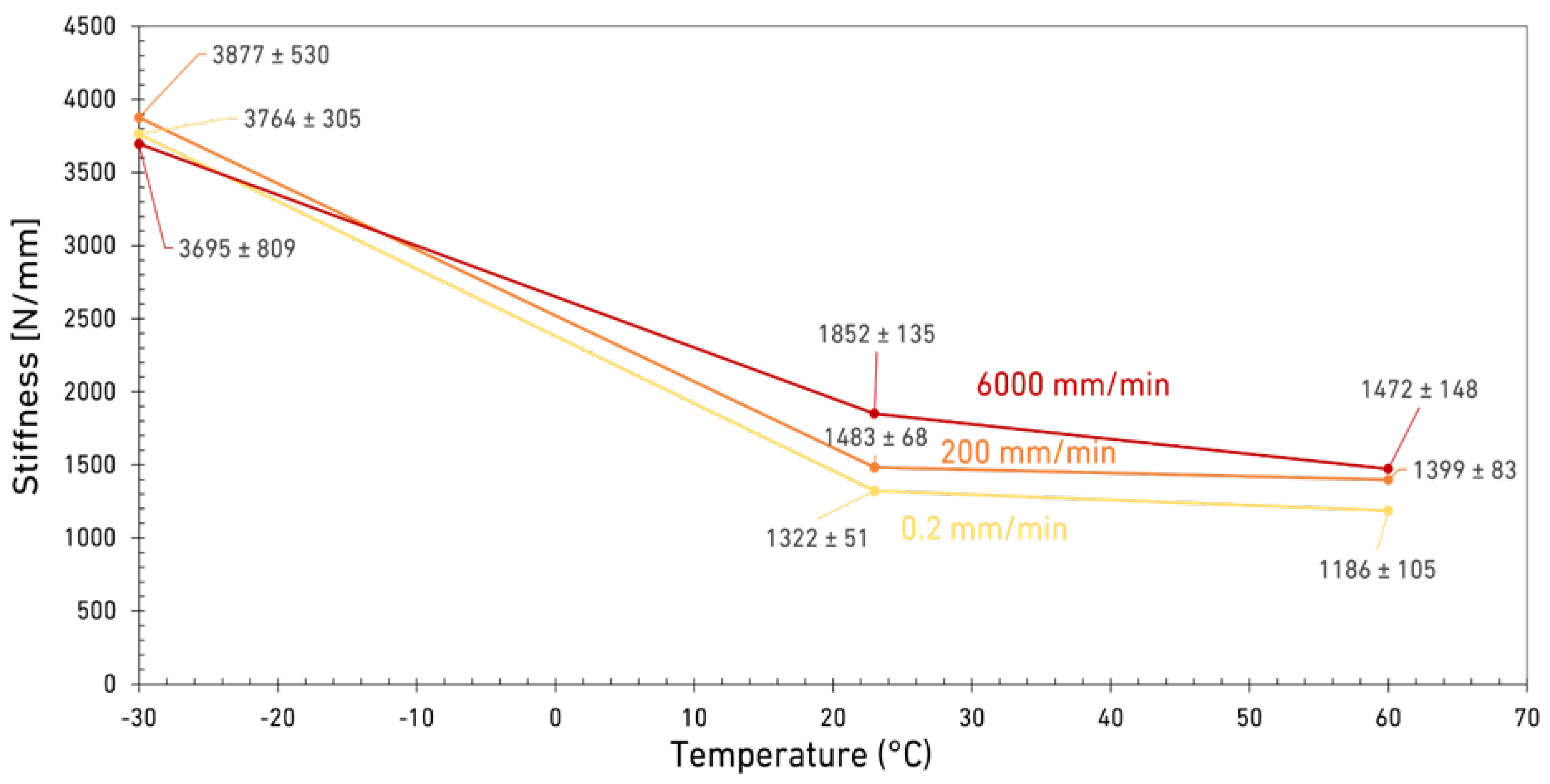

- From the stiffness analysis, it was found that the transition from LT to RT significantly decreases the bond stiffness by 60%, while further temperature increase (from RT to HT) has no significant effect on this parameter.

- Based on the experimental results, the best performance in terms of mode I fracture energy of the adhesive was obtained for RT and at higher loading rates with the GIc of around 9.5 N/mm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Antelo, J.; Akhavan-Safar, A.; Carbas, R.J.C.; Marques, E.A.S.; Goyal, R.; da Silva, L.F.M. Fatigue life evaluation of adhesive joints in a real structural component. Int. J. Fatigue 2021, 153, 106504. [Google Scholar] [CrossRef]

- Minosi, S.; Cocchi, D.; Maccaferri, E.; Pirondi, A.; Zucchelli, A.; Mazzocchetti, L.; Ambrosini, D.; Campanini, F. Exploitation of rubbery electrospun nanofibrous mat for fracture toughness improvement of structural epoxy adhesive bonded joints. J. Adv. Join. Process. 2021, 3, 100050. [Google Scholar] [CrossRef]

- Akhavan-Safar, A.; Salamat-Talab, M.; Delzendehrooy, F.; Zeinolabedin-Beygi, A.; da Silva, L. Effects of natural date palm tree fibres on mode II fracture energy of E-glass/epoxy plain-woven laminated composites. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 457. [Google Scholar] [CrossRef]

- Akhavan-Safar, A.; Beygi, R.; Delzendehrooy, F.; da Silva, L. Fracture energy assessment of adhesives–Part I: Is GIC an adhesive property? A neural network analysis. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 1461–1476. [Google Scholar] [CrossRef]

- Houjou, K.; Shimamoto, K.; Akiyama, H.; Sato, C. Experimental investigations on the effect of a wide range of strain rates on mechanical properties of epoxy adhesives, and prediction of creep and impact strengths. J. Adhes. 2022, 98, 449–463. [Google Scholar] [CrossRef]

- Chen, F.; Pinisetty, D.; Gupta, N. Study of the compressive properties of adhesively bonded carbon fiber laminates at different strain rates. J. Adhes. 2021, 98, 2582–2598. [Google Scholar] [CrossRef]

- Arouche, M.M.; Teixeira de Freitas, S.; de Barros, S. Evaluation of the strain-based partitioning method for mixed-mode I+ II fracture of bi-material cracks. J. Adhes. 2022, 98, 577–605. [Google Scholar] [CrossRef]

- Jalali, S.; Ayatollahi, M.; Akhavan-Safar, A.; da Silva, L. Effects of impact fatigue on residual static strength of adhesively bonded joints. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 1519–1531. [Google Scholar] [CrossRef]

- Akhavan-Safar, A.; Eisaabadi B, G.; Jalali, S.; Beygi, R.; da Silva, L.F.M. Impact fatigue life improvement of bonded structures using the bi-adhesive technique. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 1379–1390. [Google Scholar] [CrossRef]

- Machado, J.J.M.; Nunes, P.D.P.; Marques, E.A.S.; Campilho, R.; da Silva, L.F.M. Numerical study of mode I fracture toughness of carbon-fibre-reinforced plastic under an impact load. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 12–20. [Google Scholar] [CrossRef]

- Bascom, W.; Ting, R.; Moulton, R.; Riew, C.; Siebert, A. The fracture of an epoxy polymer containing elastomeric modifiers. J. Mater. Sci. 1981, 16, 2657–2664. [Google Scholar] [CrossRef]

- Bitner, J.; Rushford, J.; Rose, W.; Hunston, D.; Riew, C. Viscoelastic fracture of structural adhesives. J. Adhes. 1981, 13, 3–28. [Google Scholar] [CrossRef]

- Hunston, D.; Bullman, G. Viscoelastic fracture behaviour for different rubber-modified epoxy adhesive formulations. Int. J. Adhes. Adhes. 1985, 5, 69–74. [Google Scholar] [CrossRef]

- Lataillade, J.; Grapotte, D.; Cayssials, F. The impact resistance of CTBN-modified epoxy adhesive joints. Le J. De Phys. IV 1994, 4, C8-771–C778-776. [Google Scholar] [CrossRef]

- Blackman, B.; Kinloch, A.; Taylor, A.; Wang, Y. The impact wedge-peel performance of structural adhesives. J. Mater. Sci. 2000, 35, 1867–1884. [Google Scholar] [CrossRef]

- Blackman, B.; Kinloch, A.; Sanchez, F.R.; Teo, W.; Williams, J. The fracture behaviour of structural adhesives under high rates of testing. Eng. Fract. Mech. 2009, 76, 2868–2889. [Google Scholar] [CrossRef]

- Raghavan, D.; He, J.; Hunston, D.; Hoffman, D. Strain rate dependence of fracture in a rubber-toughened epoxy system. J. Adhes. 2002, 78, 723–739. [Google Scholar] [CrossRef]

- Karac, A.; Blackman, B.; Cooper, V.; Kinloch, A.; Sanchez, S.R.; Teo, W.; Ivankovic, A. Modelling the fracture behaviour of adhesively-bonded joints as a function of test rate. Eng. Fract. Mech. 2011, 78, 973–989. [Google Scholar] [CrossRef]

- Nunes, P.; Marques, E.; Carbas, R.; Akhavan-Safar, A.; da Silva, L. DCB tests at constant strain rate using crash-resistant epoxy adhesives: A numerical and experimental approach. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 3234–3242. [Google Scholar] [CrossRef]

- May, M.; Voß, H.; Hiermaier, S. Predictive modeling of damage and failure in adhesively bonded metallic joints using cohesive interface elements. Int. J. Adhes. Adhes. 2014, 49, 7–17. [Google Scholar] [CrossRef]

- Kinloch, A.; Kodokian, G.; Jamarani, M. Impact properties of epoxy polymers. J. Mater. Sci. 1987, 22, 4111–4120. [Google Scholar] [CrossRef]

- Biel, A. Constitutive Behaviour and Fracture Toughness of an Adhesive Layer. Ph.D. Thesis, Chalmers Tekniska Högskola, Gothenburg, Sweden, 2005. [Google Scholar]

- Carlberger, T.; Biel, A.; Stigh, U. Influence of temperature and strain rate on cohesive properties of a structural epoxy adhesive. Int. J. Fract. 2009, 155, 155–166. [Google Scholar] [CrossRef]

- Marzi, S.; Hesebeck, O.; Brede, M.; Kleiner, F. A rate-dependent cohesive zone model for adhesively bonded joints loaded in mode I. J. Adhes. Sci. Technol. 2009, 23, 881–898. [Google Scholar] [CrossRef]

- Borges, C.S.P.; Nunes, P.D.P.; Akhavan-Safar, A.; Marques, E.A.S.; Carbas, R.J.C.; Alfonso, L.; Silva, L.F.M. A strain rate dependent cohesive zone element for mode I modeling of the fracture behavior of adhesives. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 610–621. [Google Scholar] [CrossRef]

- Nunes, P.D.P.; Borges, C.S.P.; Marques, E.A.S.; Carbas, R.J.C.; Akhavan-Safar, A.; Antunes, D.P.; Lopes, A.M.; da Silva, L.F.M. Numerical assessment of strain rate in an adhesive layer throughout double cantilever beam and end notch flexure tests. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2020, 234, 415–425. [Google Scholar] [CrossRef]

- Nunes, P.D.P.; Marques, E.A.S.; Carbas, R.J.C.; Akhavan-Safar, A.; da Silva, L.F.M. kQuasi-static and intermediate test speed validation of SHPB specimens for the determination of mode I, mode II fracture toughness of structural epoxy adhesives. Eng. Fract. Mech. 2022, 262, 108231. [Google Scholar] [CrossRef]

- Kumpenza, C.; Pramreiter, M.; Nenning, T.J.; Bliem, P.; Reiterer, R.; Konnerth, J.; Müller, U. Temperature-related tensile modulus of polymer-based adhesive films. J. Adhes. 2021, 99, 259–276. [Google Scholar] [CrossRef]

- Banea, M.; Da Silva, L.; Campilho, R. Mode I fracture toughness of adhesively bonded joints as a function of temperature: Experimental and numerical study. Int. J. Adhes. Adhes. 2011, 31, 273–279. [Google Scholar] [CrossRef]

- Banea, M.; Silva, L.d.; Campilho, R. Effect of temperature on tensile strength and mode I fracture toughness of a high temperature epoxy adhesive. J. Adhes. Sci. Technol. 2012, 26, 939–953. [Google Scholar] [CrossRef]

- Banea, M.; da Silva, L.F.; Campilho, R. Temperature dependence of the fracture toughness of adhesively bonded joints. J. Adhes. Sci. Technol. 2010, 24, 2011–2026. [Google Scholar] [CrossRef]

- Jia, D.; Zheng, J.; Chen, X.; Yu, J. Modeling the temperature-dependent mode I fracture behavior of adhesively bonded joints. J. Adhes. 2017, 93, 481–503. [Google Scholar] [CrossRef]

- Bernasconi, A.; Lima, R.; Cardamone, S.; Campbell, R.; Slocum, A.; Giglio, M. Effect of temperature on cohesive modelling of 3M Scotch-Weld™ 7260 B/A epoxy adhesive. J. Adhes. 2020, 96, 437–460. [Google Scholar] [CrossRef]

- Tang, G.; Liu, M.; Deng, D.; Zhao, R.; Liu, X.; Yang, Y.; Yang, S.; Liu, X. Phosphorus-containing soybean oil-derived polyols for flame-retardant and smoke-suppressant rigid polyurethane foams. Polym. Degrad. Stab. 2021, 191, 109701. [Google Scholar] [CrossRef]

- Tang, G.; Liu, X.; Yang, Y.; Chen, D.; Zhang, H.; Zhou, L.; Zhang, P.; Jiang, H.; Deng, D. Phosphorus-containing silane modified steel slag waste to reduce fire hazards of rigid polyurethane foams. Adv. Powder Technol. 2020, 31, 1420–1430. [Google Scholar] [CrossRef]

- Jia, Z.; Yuan, G.; Hui, D.; Feng, X.; Zou, Y. Effect of high loading rate and low temperature on mode I fracture toughness of ductile polyurethane adhesive. J. Adhes. Sci. Technol. 2019, 33, 79–92. [Google Scholar] [CrossRef]

- Han, X.; Jin, Y.; da Silva, L.F.; Costa, M.; Wu, C. On the effect of adhesive thickness on mode I fracture energy-an experimental and modelling study using a trapezoidal cohesive zone model. J. Adhes. 2020, 96, 490–514. [Google Scholar] [CrossRef]

- Delzendehrooy, F.; Beygi, R.; Akhavan-Safar, A.; da Silva, L.F.M. Fracture energy assessment of adhesives Part II: Is GIIc an adhesive material property? (A neural network analysis). J. Adv. Join. Process. 2021, 3, 100049. [Google Scholar] [CrossRef]

- Akhavan-Safar, A.; Ayatollahi, M.R.; Moazzami, M.; Da Silva, L.F.M. The role of T-stress and stress triaxiality combined with the geometry on tensile fracture energy of brittle adhesives. Int. J. Adhes. Adhes. 2018, 87, 12–21. [Google Scholar] [CrossRef]

- Machado, J.; Hayashi, A.; Nunes, P.; Marques, E.; Carbas, R.; Sato, C.; Da Silva, L. Strain rate dependence of a crash resistant adhesive as a function of temperature for the automotive industry. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 2189–2203. [Google Scholar] [CrossRef]

- Borges, C.; Nunes, P.; Akhavan, A.; Marques, E.; Carbas, R.; Alfonso, L.; Silva, L. Influence of mode mixity and loading rate on the fracture behaviour of crash resistant adhesives. Theor. Appl. Fract. Mech. 2020, 107, 102508. [Google Scholar] [CrossRef]

| Property | Polyol | Isocyanate | Mixed |

|---|---|---|---|

| Specific gravity at 25 °C (g/cm3) | 1.57 | 1.22 | - |

| Viscosity at 25 °C (mPa.s) | 7000 | 20 | 1100 |

| Glass transition temperature (Tg) (°C) | −5 | ||

| Maximum tensile strength (MPa) | 3.4 ± 0.09 | ||

| Maximum tensile strain (%) | 33.4 ± 1.34 | ||

| Young’s Modulus (MPa) | 20.3 ± 1.23 |

| Temperature | LT −30 °C | RT 23 °C | HT 60 °C | |

|---|---|---|---|---|

| Loading Rate | ||||

| Quasi-Static 0.2 mm/min | DCB, mode I fracture test | Tensile test using dogbone bulk samples and mode I fracture test using DCB specimens | DCB, mode I fracture test | |

| Intermediate Speed 200 mm/min | ||||

| High Speed 6000 mm/min | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perez, M.; Akhavan-Safar, A.; Carbas, R.J.C.; Marques, E.A.S.; Wenig, S.; da Silva, L.F.M. Loading Rate and Temperature Interaction Effects on the Mode I Fracture Response of a Ductile Polyurethane Adhesive Used in the Automotive Industry. Materials 2022, 15, 8948. https://doi.org/10.3390/ma15248948

Perez M, Akhavan-Safar A, Carbas RJC, Marques EAS, Wenig S, da Silva LFM. Loading Rate and Temperature Interaction Effects on the Mode I Fracture Response of a Ductile Polyurethane Adhesive Used in the Automotive Industry. Materials. 2022; 15(24):8948. https://doi.org/10.3390/ma15248948

Chicago/Turabian StylePerez, Mael, Alireza Akhavan-Safar, Ricardo J. C. Carbas, Eduardo A. S. Marques, Sabine Wenig, and Lucas F. M. da Silva. 2022. "Loading Rate and Temperature Interaction Effects on the Mode I Fracture Response of a Ductile Polyurethane Adhesive Used in the Automotive Industry" Materials 15, no. 24: 8948. https://doi.org/10.3390/ma15248948

APA StylePerez, M., Akhavan-Safar, A., Carbas, R. J. C., Marques, E. A. S., Wenig, S., & da Silva, L. F. M. (2022). Loading Rate and Temperature Interaction Effects on the Mode I Fracture Response of a Ductile Polyurethane Adhesive Used in the Automotive Industry. Materials, 15(24), 8948. https://doi.org/10.3390/ma15248948