Microstructure Evolution and Enhanced Hot Workability of TiC/Ti-6Al-4V Composites Fabricated by Melt Hydrogenation

Abstract

1. Introduction

2. Materials and Methods

3. Results

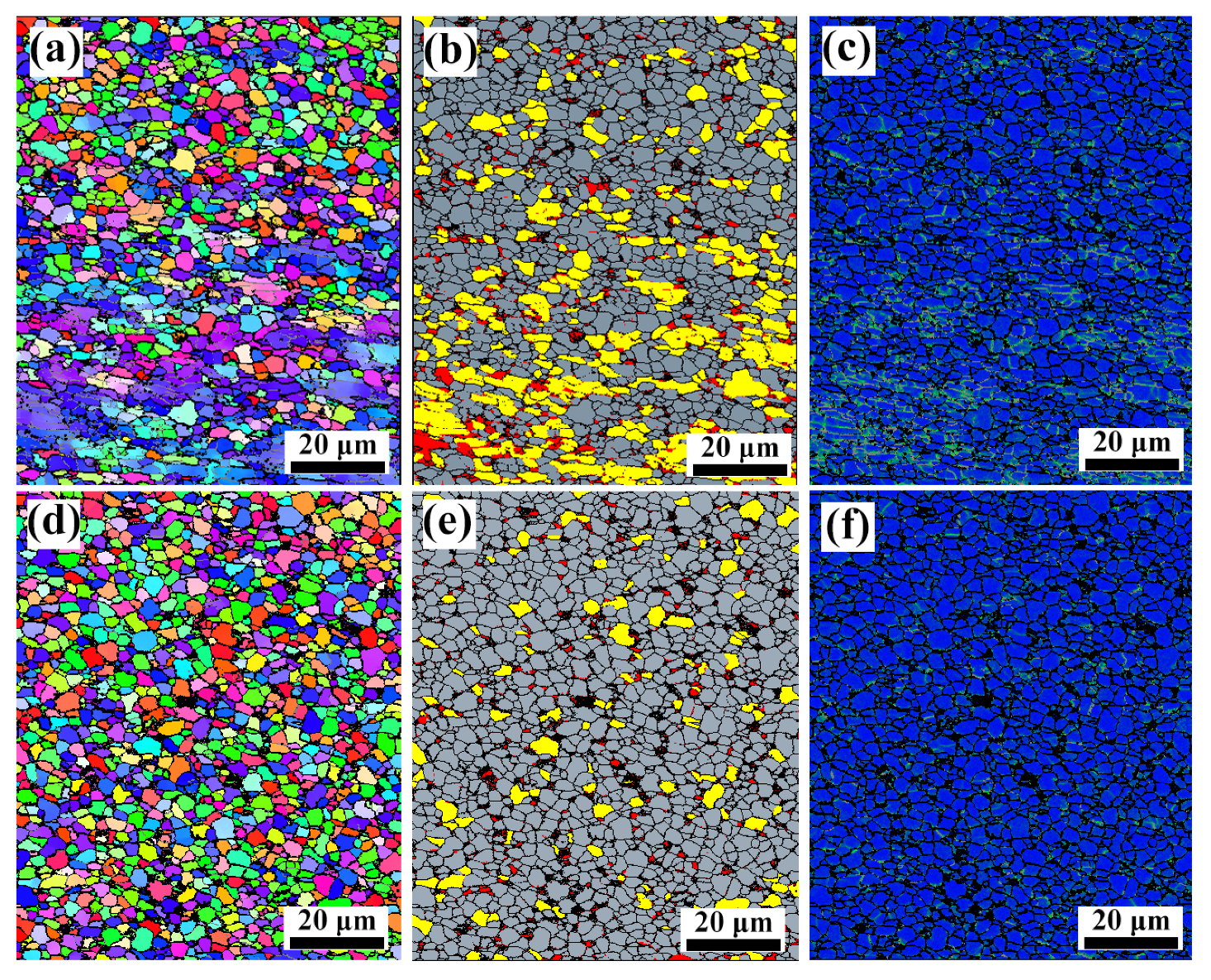

4. Discussion

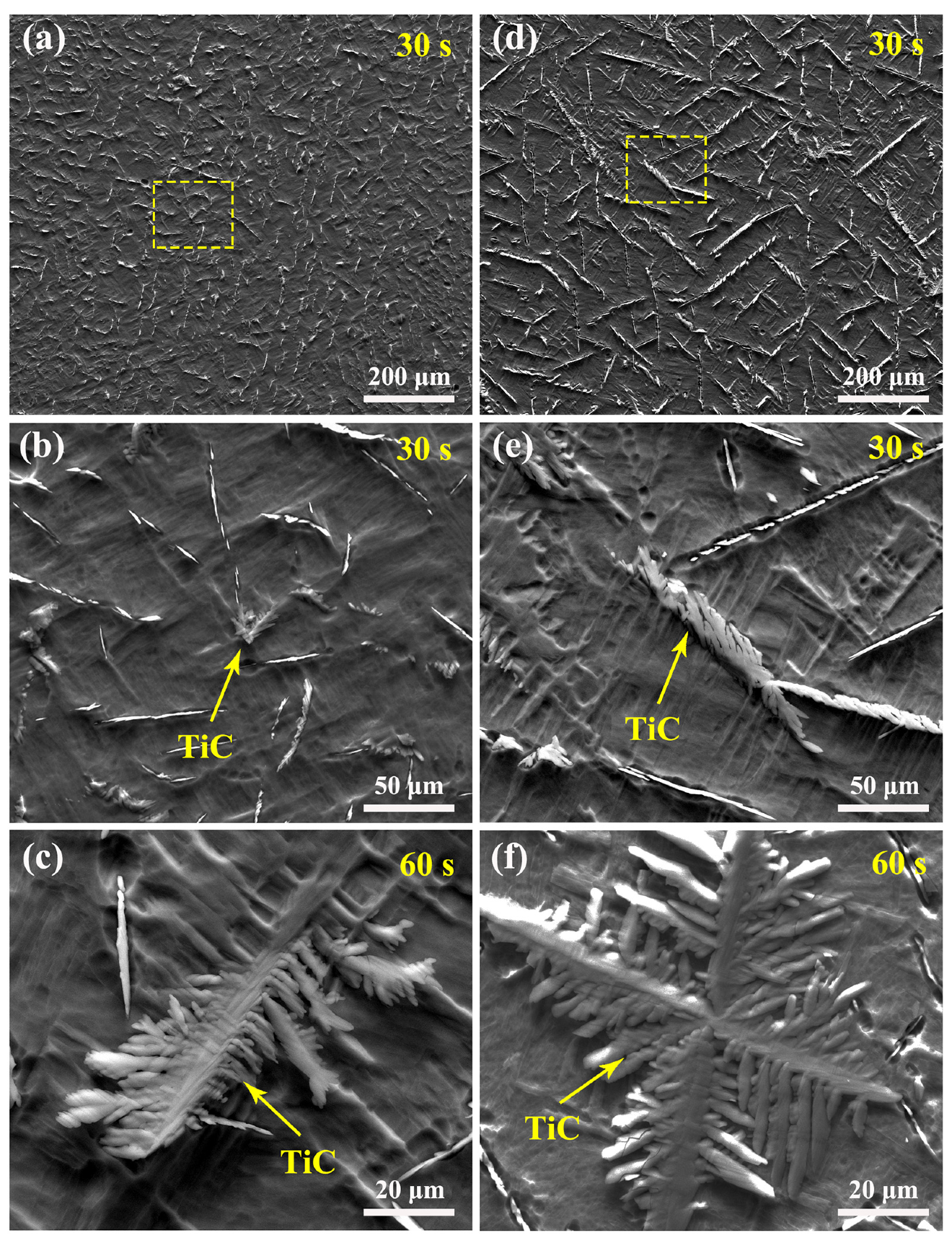

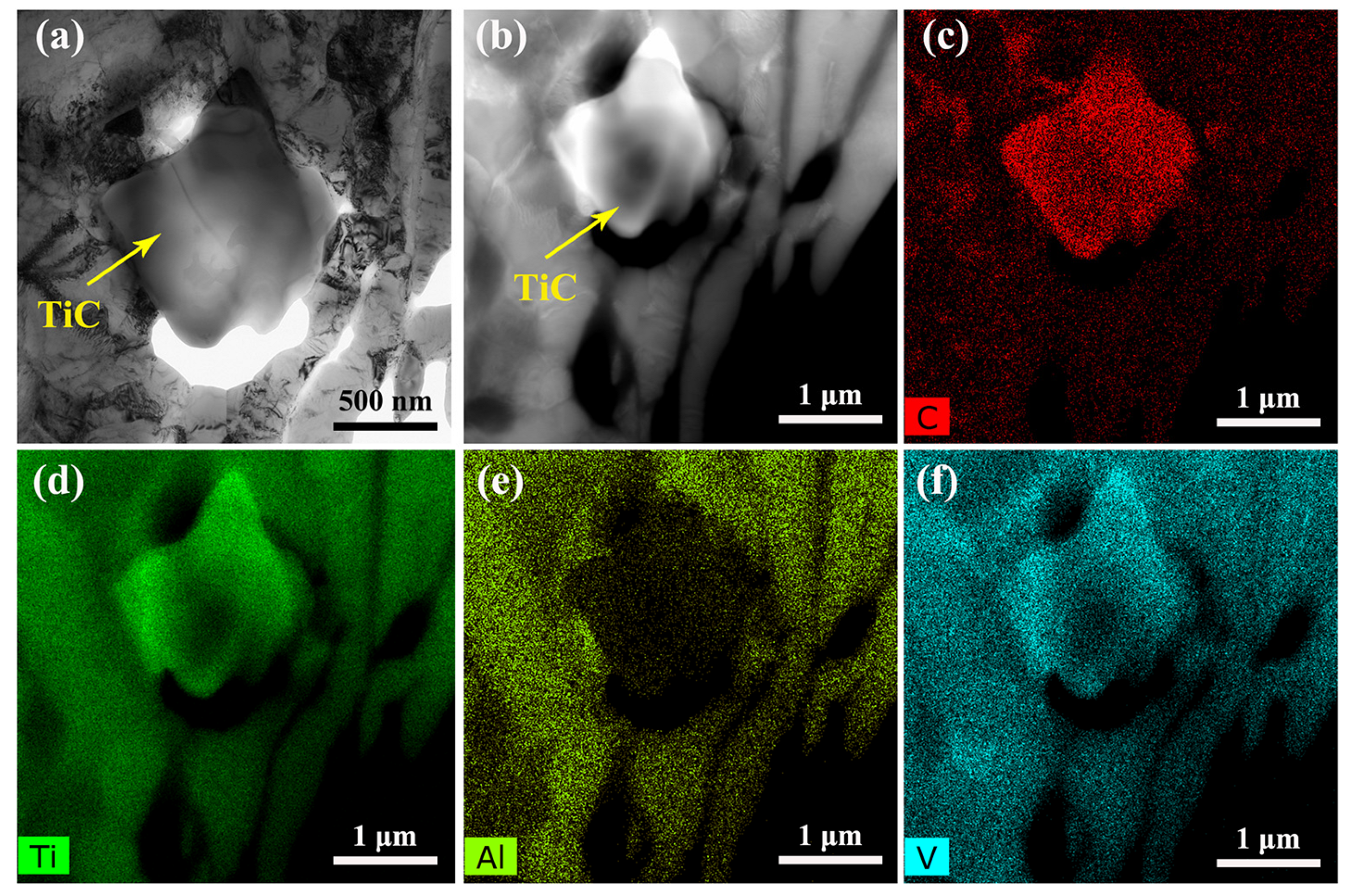

4.1. Effect of Melt Hydrogenation on Distribution and Morphology of TiC

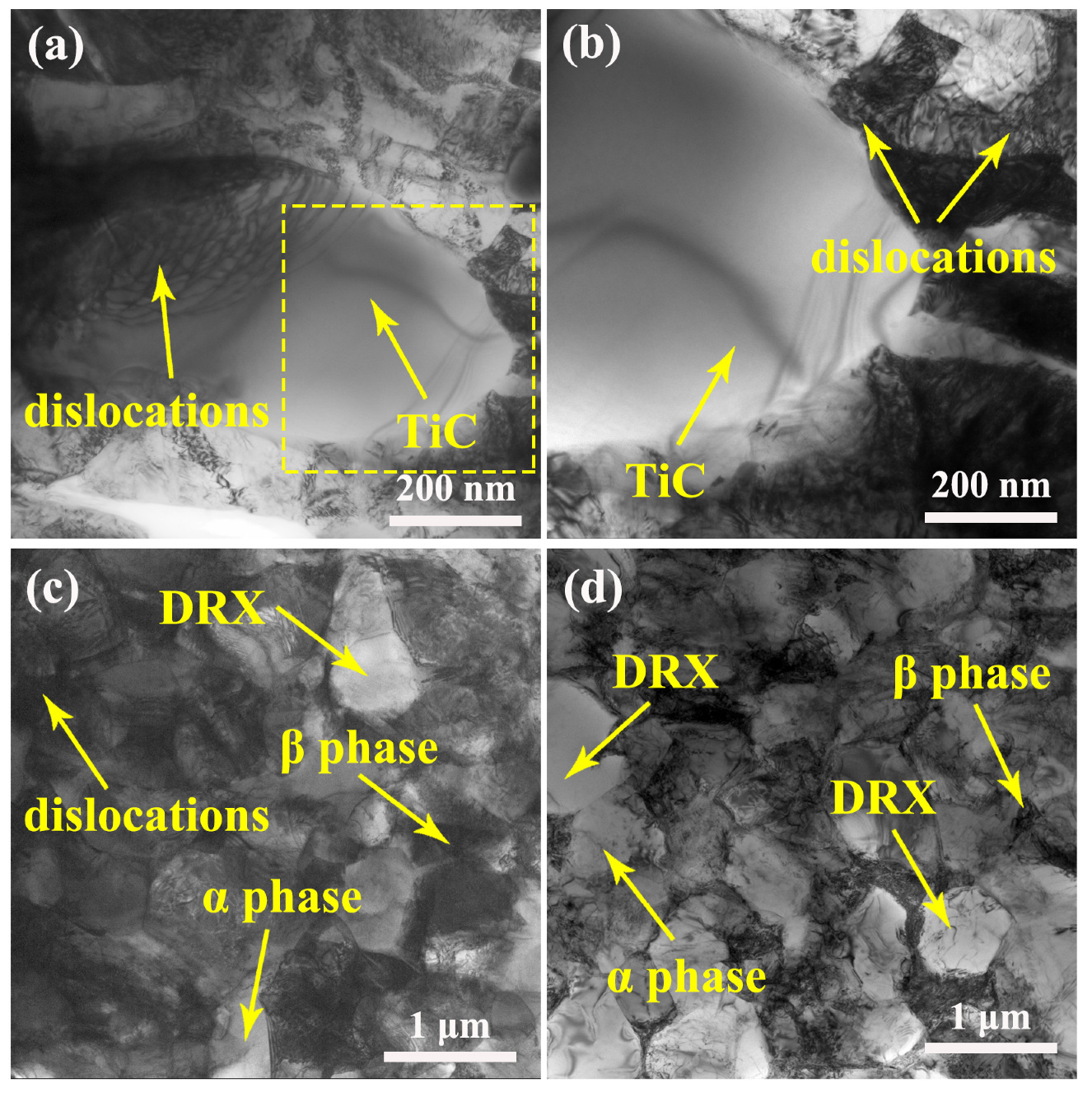

4.2. Effect of Melt Hydrogenation on Hot Workability of TiC/Ti64 Composites

5. Conclusions

- (1)

- Melt hydrogenation did not change the shape of the eutectic TiC phase, but the size of eutectic TiC and the primary β phase were significantly increased. As a result, many large-sized eutectic TiC were distributed along the grain boundaries of primary β grains;

- (2)

- The peak flowing stress of TiC/Ti64 composites in the (α + β) phase region was reduced by melt hydrogenation, most significantly with a strain rate of 0.01 s−1. When compressed at 900 °C/0.01 s−1, the peak stress decreased from 241 ± 9 to 190 ± 8 MPa (decreased by ~51 MPa and 21.2%), and the best improvement of hot workability was obtained;

- (3)

- The decreased atomic bonding force, reduced β/(α + β) transition temperature, higher proportion of DRX, and higher mobility of dislocations by hydrogen atoms all contributed to the enhanced hot workability of TiC/Ti64 composites.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, Y.; Yang, F.; Chen, C.; Shao, Y.; Lu, B.; Sui, Y.; Guo, Z. Mechanical property and microstructure of in-situ TiB/Ti composites via vacuum sintering and hot rolling. J. Alloys Compd. 2022, 911, 165042. [Google Scholar] [CrossRef]

- Xiaolong, C.; Zulei, L.; Yanhua, G.; Zhonggang, S.; Yaoqi, W.; Lian, Z. A study on the grain refinement mechanism of Ti-6Al-4V alloy produced by wire arc additive manufacturing using hydrogenation treatment processes. J. Alloys Compd. 2022, 890, 161634. [Google Scholar] [CrossRef]

- An, Q.; Wang, S.; Huang, L.; Wang, C.; Qian, Q.; Jiang, Y.; Wang, L.; Geng, L. Experimental and first-principles study on TiB/TiC interface in hybrid (TiB + TiC)/Ti6Al4V composite. Ceram. Int. 2022, 48, 22554–22559. [Google Scholar] [CrossRef]

- Ya, B.; Zhou, B.; Yang, H.; Huang, B.; Jia, F.; Zhang, X. Microstructure and mechanical properties of in situ casting TiC/Ti6Al4V composites through adding multi-walled carbon nanotubes. J. Alloys Compd. 2015, 637, 456–460. [Google Scholar] [CrossRef]

- Han, C.; Babicheva, R.; Chua, J.D.Q.; Ramamurty, U.; Tor, S.B.; Sun, C.-N.; Zhou, K. Microstructure and mechanical properties of (TiB + TiC)/Ti composites fabricated in situ via selective laser melting of Ti and B4C powders. Addit. Manuf. 2020, 36, 101466. [Google Scholar] [CrossRef]

- Wei, Z.J.; Cao, L.; Wang, H.W.; Zou, C.M. Microstructure and mechanical properties of TiC/Ti-6Al-4V composites processed by in situ casting route. Mater. Sci. Tech. Ser. 2011, 27, 1321–1327. [Google Scholar] [CrossRef]

- Wang, X.; Wang, L.; Luo, L.; Yan, H.; Li, X.; Chen, R.; Su, Y.; Guo, J.; Fu, H. High temperature deformation behavior of melt hydrogenated (TiB + TiC)/Ti-6Al-4V composites. Mater. Des. 2017, 121, 335–344. [Google Scholar] [CrossRef]

- Wang, X.; Wang, L.; Luo, L.; Liu, X.; Tang, Y.; Li, X.; Chen, R.; Su, Y.; Guo, J.; Fu, H. Hot deformation behavior and dynamic recrystallization of melt hydrogenated Ti-6Al-4V alloy. J. Alloys Compd. 2017, 728, 709–718. [Google Scholar] [CrossRef]

- Zhao, J.W.; Ding, H.; Hou, H.L.; Li, Z.Q. Influence of hydrogen content on hot deformation behavior and microstructural evolution of Ti600 alloy. J. Alloys Compd. 2010, 491, 673–678. [Google Scholar] [CrossRef]

- Wang, X.; Wang, L.; Luo, L.; Xu, Y.; Li, X.; Chen, R.; Su, Y.; Guo, J.; Fu, H. Hydrogen induced softening and hardening for hot workability of (TiB + TiC)/Ti-6Al-4V composites. Int. J. Hydrogen Energy 2017, 42, 3380–3388. [Google Scholar] [CrossRef]

- Wang, X.; Wang, L.; Luo, L.; Liu, X.; Tang, Y.; Yan, H.; Yao, L.; Su, Y.; Guo, J.; Fu, H. Positive effect of hydrogen on interface of in situ synthesized Ti-6Al-4V matrix composites. Mater. Sci. Eng. A 2018, 711, 12–21. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, L.; Luo, L.; Wang, B.; Yan, H.; Chen, R.; Su, Y.; Guo, J.; Fu, H. Effect of melt hydrogenation on microstructure evolution and tensile properties of (TiB + TiC)/Ti-6Al-4V composites. J. Mater. Res. Tech. 2020, 9, 6343–6351. [Google Scholar] [CrossRef]

- Lin, X.; Dong, F.; Zhang, Y.; Yuan, X.; Huang, H.; Zheng, B.; Wang, L.; Wang, X.; Luo, L.; Su, Y.; et al. Hot-deformation behaviour and hot-processing map of melt-hydrogenated Ti 6Al 4V/(TiB+TiC). Int. J. Hydrogen Energy 2019, 44, 8641–8649. [Google Scholar] [CrossRef]

- Bai, M.; Namus, R.; Xu, Y.; Guan, D.; Rainforth, M.W.; Inkson, B.J. In-situ Ti-6Al-4V/TiC composites synthesized by reactive spark plasma sintering: Processing, microstructure, and dry sliding wear behaviour. Wear 2019, 432-433, 202944. [Google Scholar] [CrossRef]

- Wang, X.; Wang, L.; Yang, F.; Luo, L.; Yan, H.; Liu, X.; Li, X.; Chen, R.; Su, Y.; Guo, J.; et al. Hydrogen induced microstructure evolution of titanium matrix composites. Int. J. Hydrogen Energy 2018, 43, 9838–9847. [Google Scholar] [CrossRef]

- Peterson, J.; Issariyapat, A.; Umeda, J.; Kondoh, K. The effects of heat treatment and carbon content on the microstructure and mechanical properties of laser powder bed fusion Ti-6Al-4V with dissolved TiC particles. J. Alloys Compd. 2022, 920, 165930. [Google Scholar] [CrossRef]

- Ochonogor, O.F.; Meacock, C.; Abdulwahab, M.; Pityana, S.; Popoola, A.P.I. Effects of Ti and TiC ceramic powder on laser-cladded Ti–6Al–4V in situ intermetallic composite. Appl. Surf. Sci. 2012, 263, 591–596. [Google Scholar] [CrossRef]

- Oh, J.-M.; Roh, K.-M.; Lim, J.-W. Brief review of removal effect of hydrogen-plasma arc melting on refining of pure titanium and titanium alloys. Int. J. Hydrogen Energy 2016, 41, 23033–23041. [Google Scholar] [CrossRef]

- Wang, X.; Li, S.; Han, Y.; Huang, G.; Mao, J.; Lu, W. Visual assessment of special rod-like α-Ti precipitates within the in situ TiC crystals and the mechanical responses of titanium matrix composites. Compos. Part B Eng. 2022, 230, 109511. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, J.; Vilar, R. Characterization of (TiB+TiC)/TC4 in situ titanium matrix composites prepared by laser direct deposition. J. Mater. Process Tech. 2011, 211, 597–601. [Google Scholar] [CrossRef]

- Senkov, O.N.; Froes, F.H. Thermohydrogen processing of titanium alloys. Int. J. Hydrogen Energy 1999, 24, 565–576. [Google Scholar] [CrossRef]

- Teter, D.F.; Robertson, I.M.; Birnbaum, H.K. The effects of hydrogen on the deformation and fracture of β-titanium. Acta Mater. 2001, 49, 4313–4323. [Google Scholar] [CrossRef]

- Shen, J.; Kotha, S.; Noraas, R.; Venkatesh, V.; Ghosh, S. Developing parametrically upscaled constitutive and crack nucleation models for the α/β Ti64 alloy. Int. J. Plast. 2022, 151, 103182. [Google Scholar] [CrossRef]

- Shen, J.; Sun, Y.; Ning, Y.; Yu, H.; Yao, Z.; Hu, L. Superplasticity induced by the competitive DRX between BCC beta and HCP alpha in Ti-4Al-3V-2Mo-2Fe alloy. Mater. Charact. 2019, 153, 304–317. [Google Scholar] [CrossRef]

- Arun Babu, A.K.; Mozumder, Y.H.; Saha, B.R.; Subramanya Sarma, C.V.; Mandal, A.S. Hot-workability of super-304H exhibiting continuous to discontinuous dynamic recrystallization transition. Mater. Sci. Eng. A 2018, 734, 269–280. [Google Scholar] [CrossRef]

- Shen, J.; Zhang, L.; Hu, L.; Sun, Y.; Gao, F.; Liu, W.; Yu, H. Effect of subgrain and the associated DRX behaviour on the texture modification of Mg-6.63Zn-0.56Zr alloy during hot tensile deformation. Mater. Sci. Eng. A 2021, 823, 141745. [Google Scholar] [CrossRef]

- Chen, Y.Z.; Barth, H.P.; Deutges, M.; Borchers, C.; Liu, F.; Kirchheim, R. Increase in dislocation density in cold-deformed Pd using H as a temporary alloying addition. Scr. Mater. 2013, 68, 743–746. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, B. Effects of hydrogen as a solid solution element on the deformation behavior of a near-alpha titanium alloy. Mater. Sci. Eng. A 2021, 815, 141269. [Google Scholar] [CrossRef]

| NO. | Hydrogen Percentagein Gas Mixture (%) | Hydrogen Content (wt.%) | β/(α + β) Transition Temperature (°C) |

|---|---|---|---|

| unhydrogenated | 0 | 0 | 1024 ± 9 |

| hydrogenated | 20 | 0.0503 ± 0.0027 | 998 ± 7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Chen, S.; Tan, Y.; Yao, L.; Wang, L.; Su, Y.; Guo, J. Microstructure Evolution and Enhanced Hot Workability of TiC/Ti-6Al-4V Composites Fabricated by Melt Hydrogenation. Materials 2022, 15, 8884. https://doi.org/10.3390/ma15248884

Wang X, Chen S, Tan Y, Yao L, Wang L, Su Y, Guo J. Microstructure Evolution and Enhanced Hot Workability of TiC/Ti-6Al-4V Composites Fabricated by Melt Hydrogenation. Materials. 2022; 15(24):8884. https://doi.org/10.3390/ma15248884

Chicago/Turabian StyleWang, Xuan, Siyu Chen, Yingmei Tan, Longhui Yao, Liang Wang, Yanqing Su, and Jingjie Guo. 2022. "Microstructure Evolution and Enhanced Hot Workability of TiC/Ti-6Al-4V Composites Fabricated by Melt Hydrogenation" Materials 15, no. 24: 8884. https://doi.org/10.3390/ma15248884

APA StyleWang, X., Chen, S., Tan, Y., Yao, L., Wang, L., Su, Y., & Guo, J. (2022). Microstructure Evolution and Enhanced Hot Workability of TiC/Ti-6Al-4V Composites Fabricated by Melt Hydrogenation. Materials, 15(24), 8884. https://doi.org/10.3390/ma15248884