Deposition of Sol–Gel ZnO:Mg Films and Investigation of Their Structural and Optical Properties

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussions

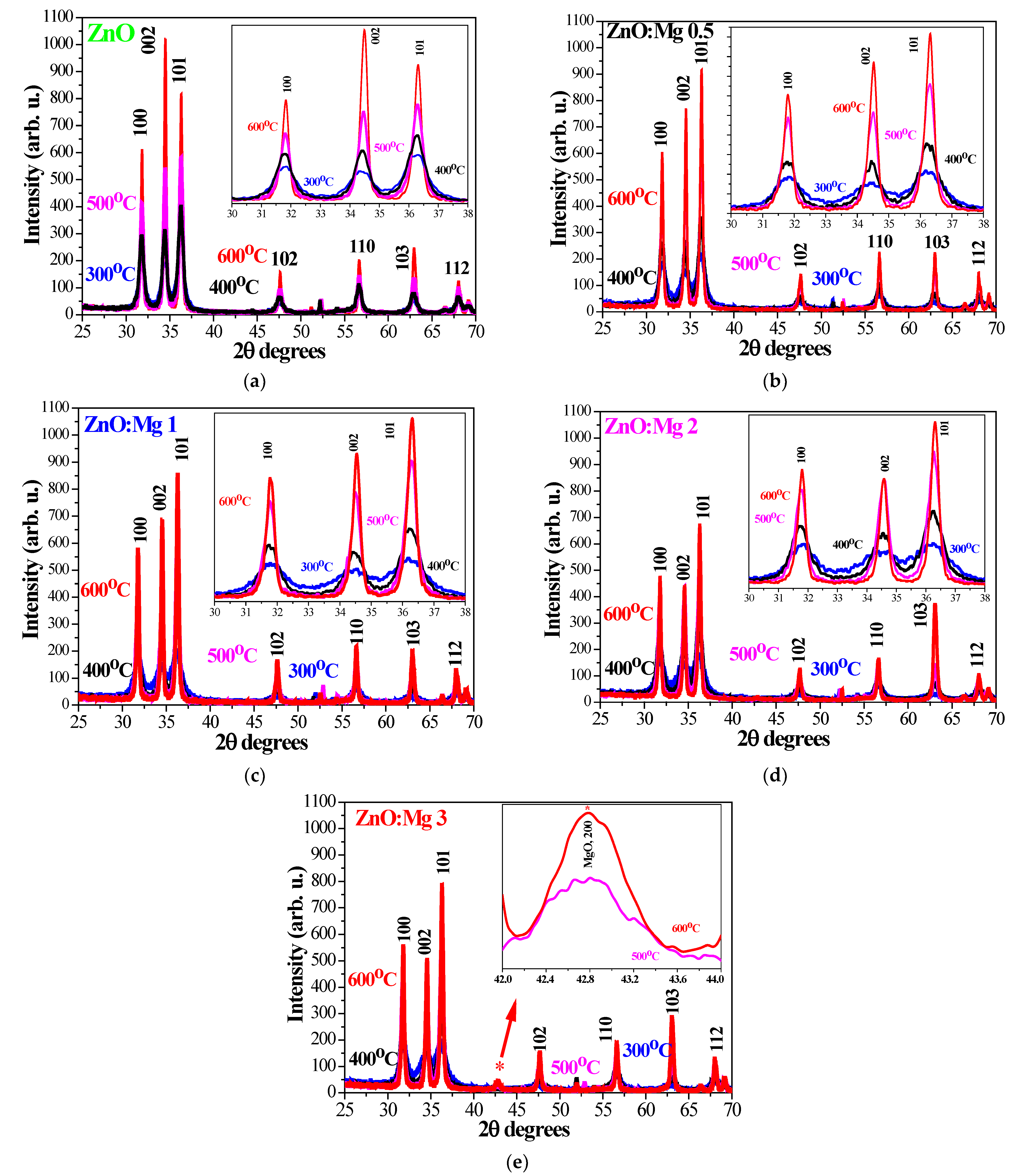

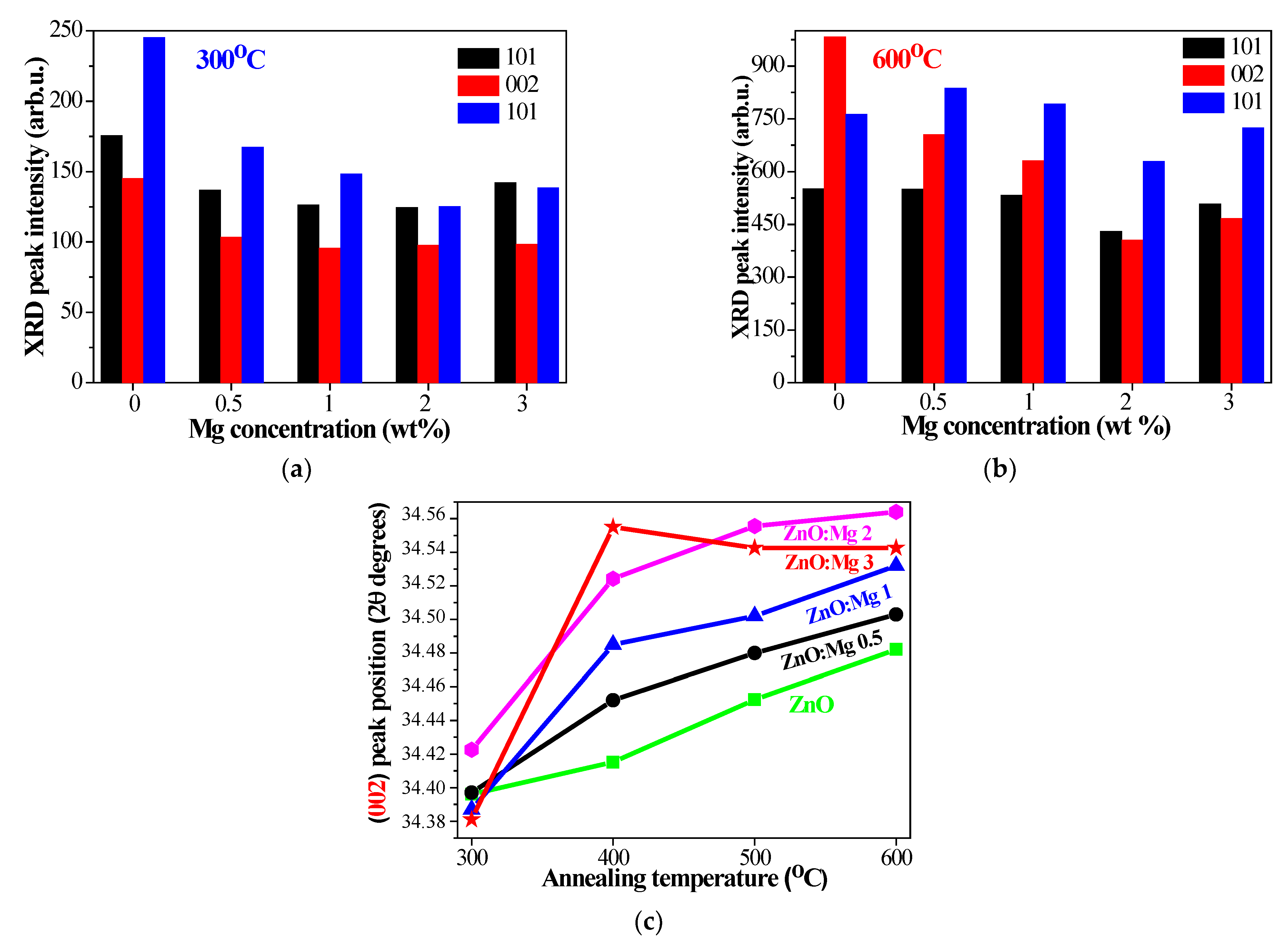

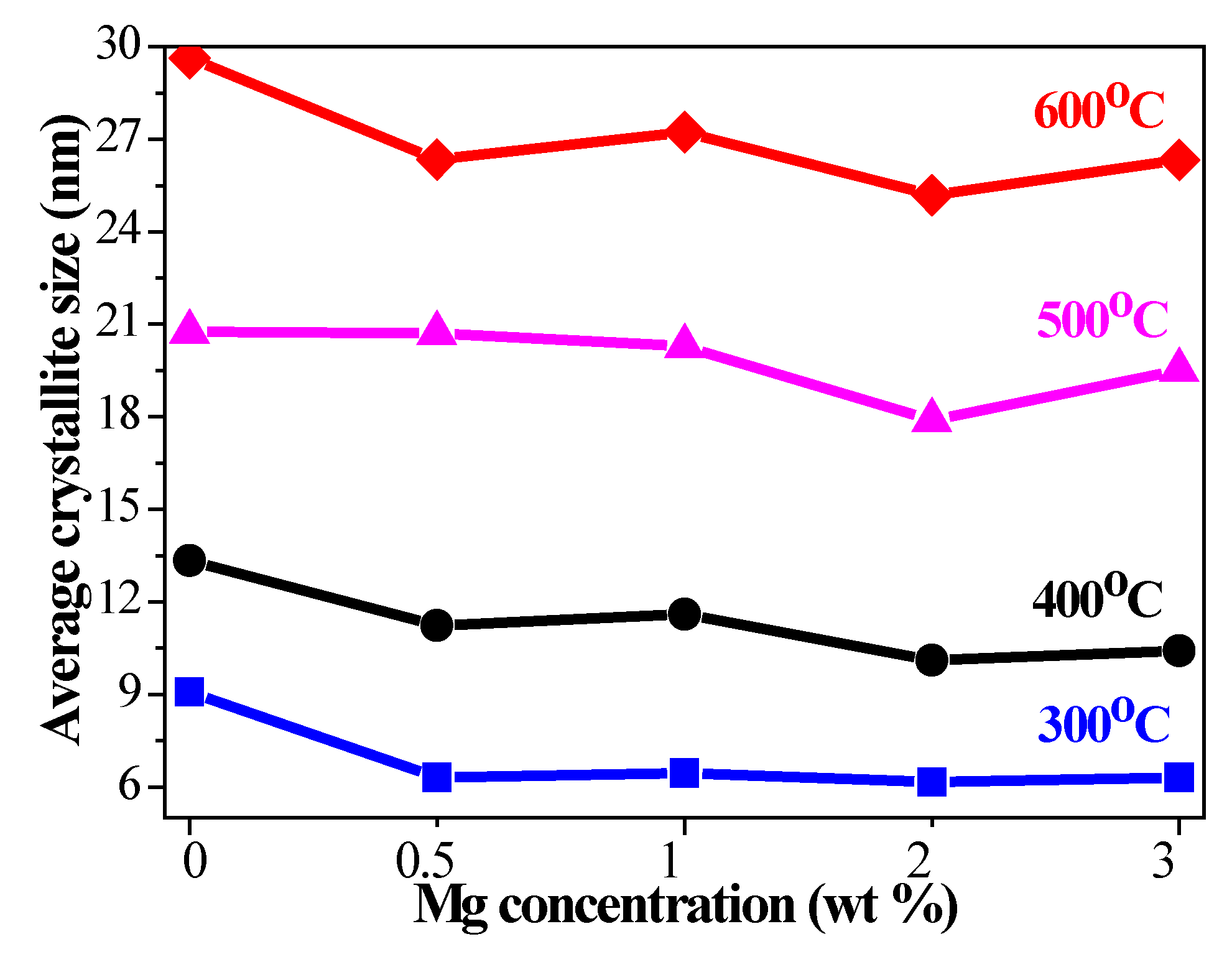

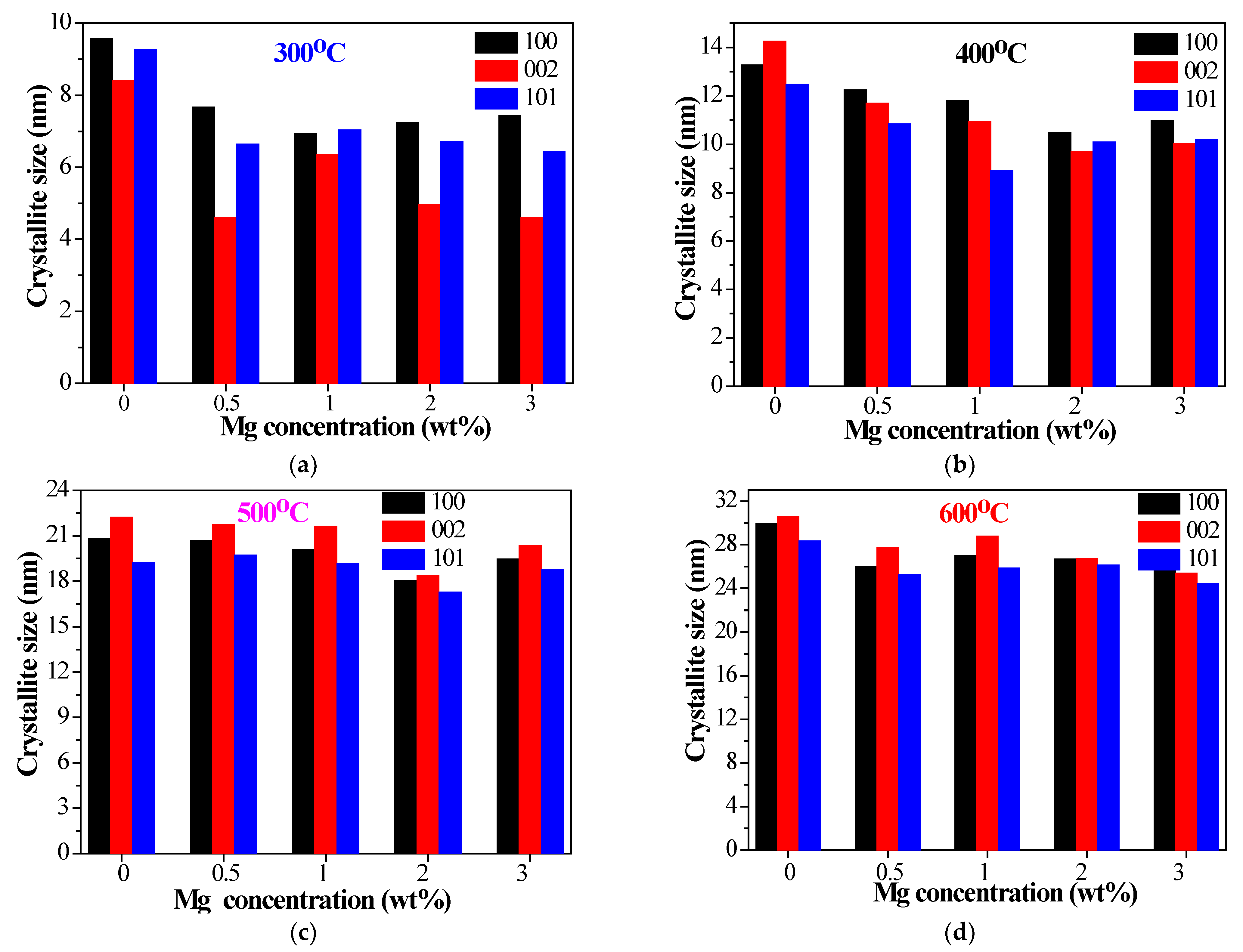

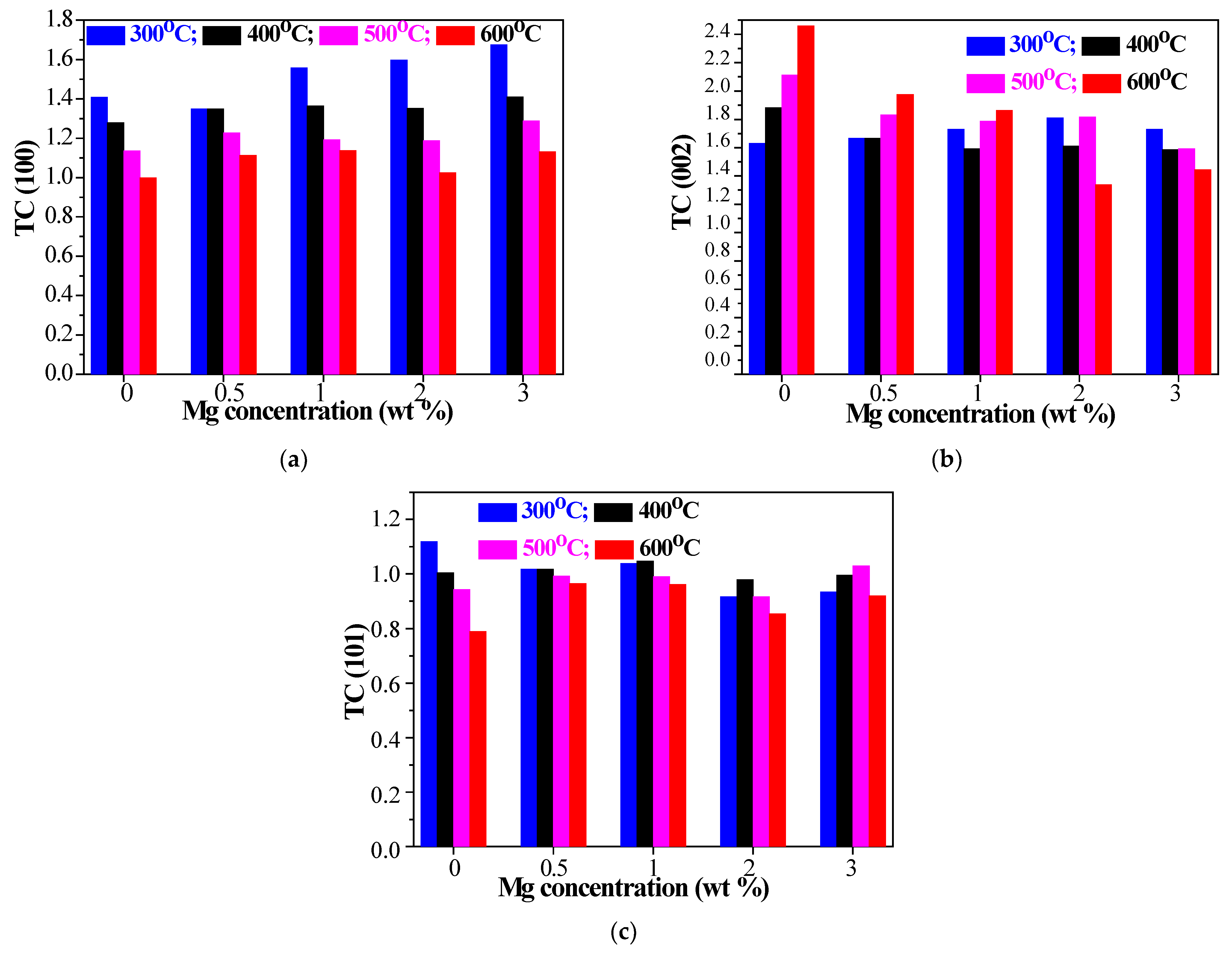

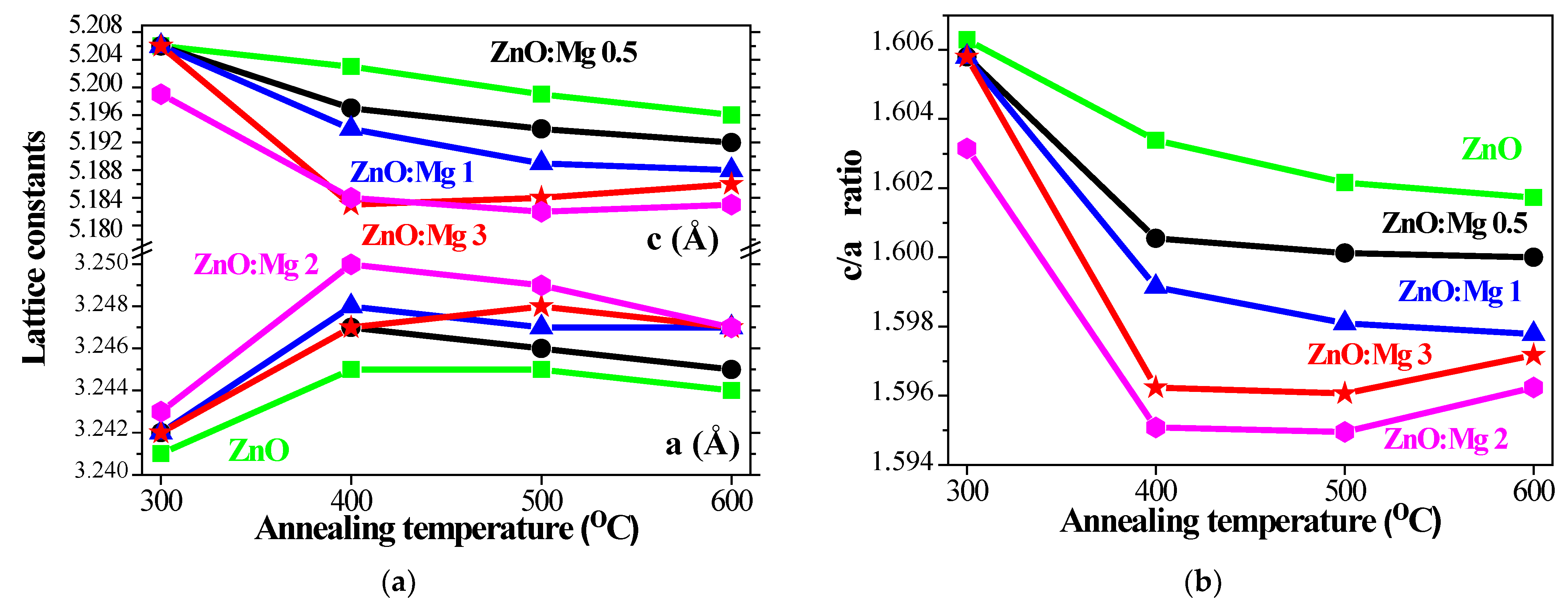

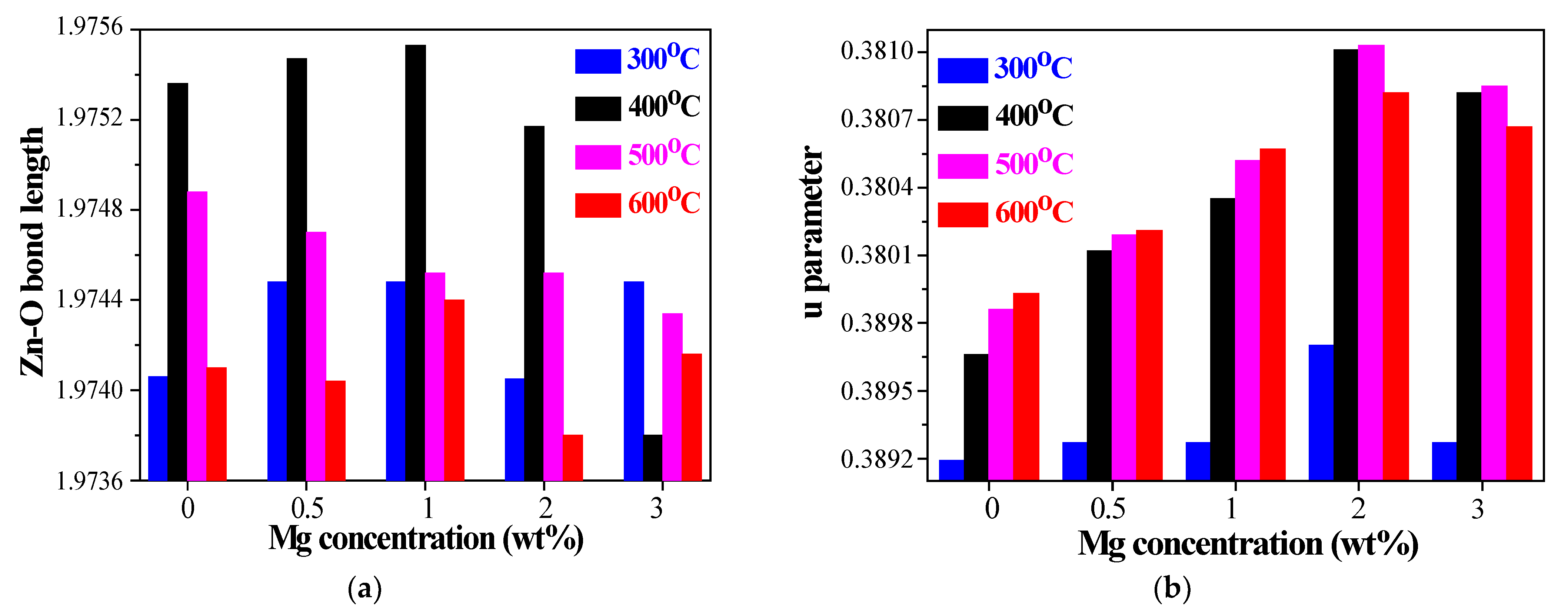

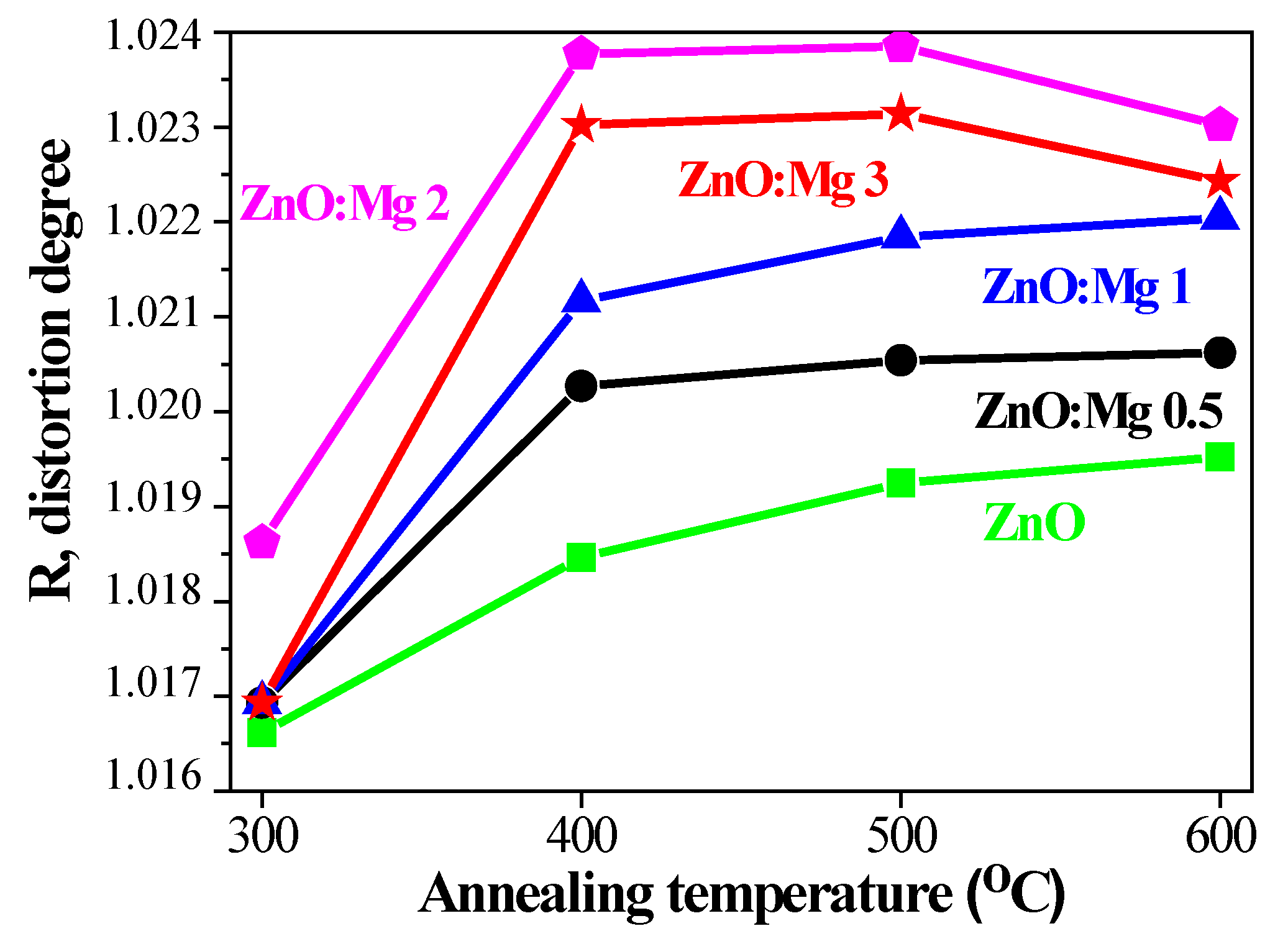

3.1. XRD Study—Crystalization Behavior

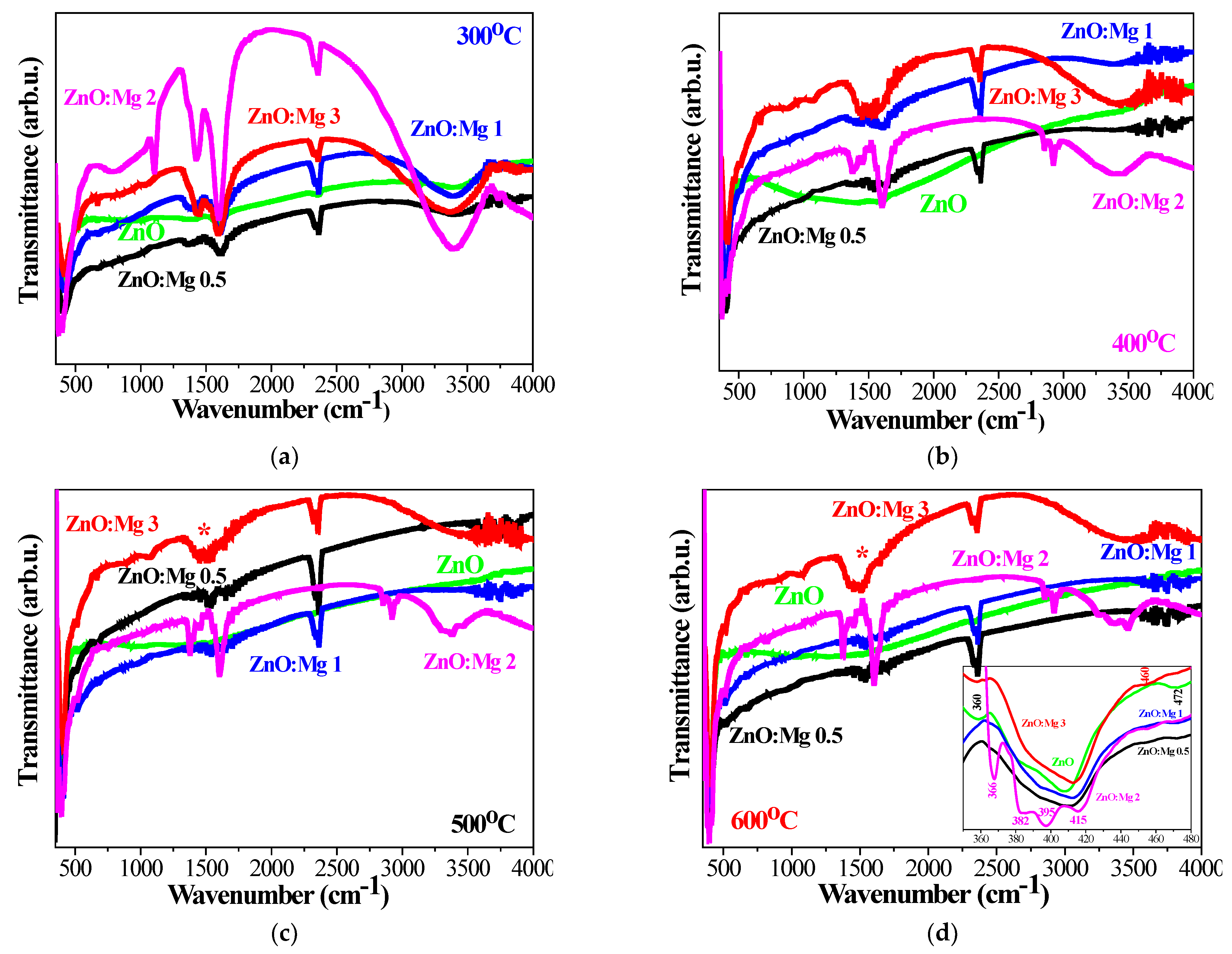

3.2. FTIR Spectroscopy—Vibrational Properties

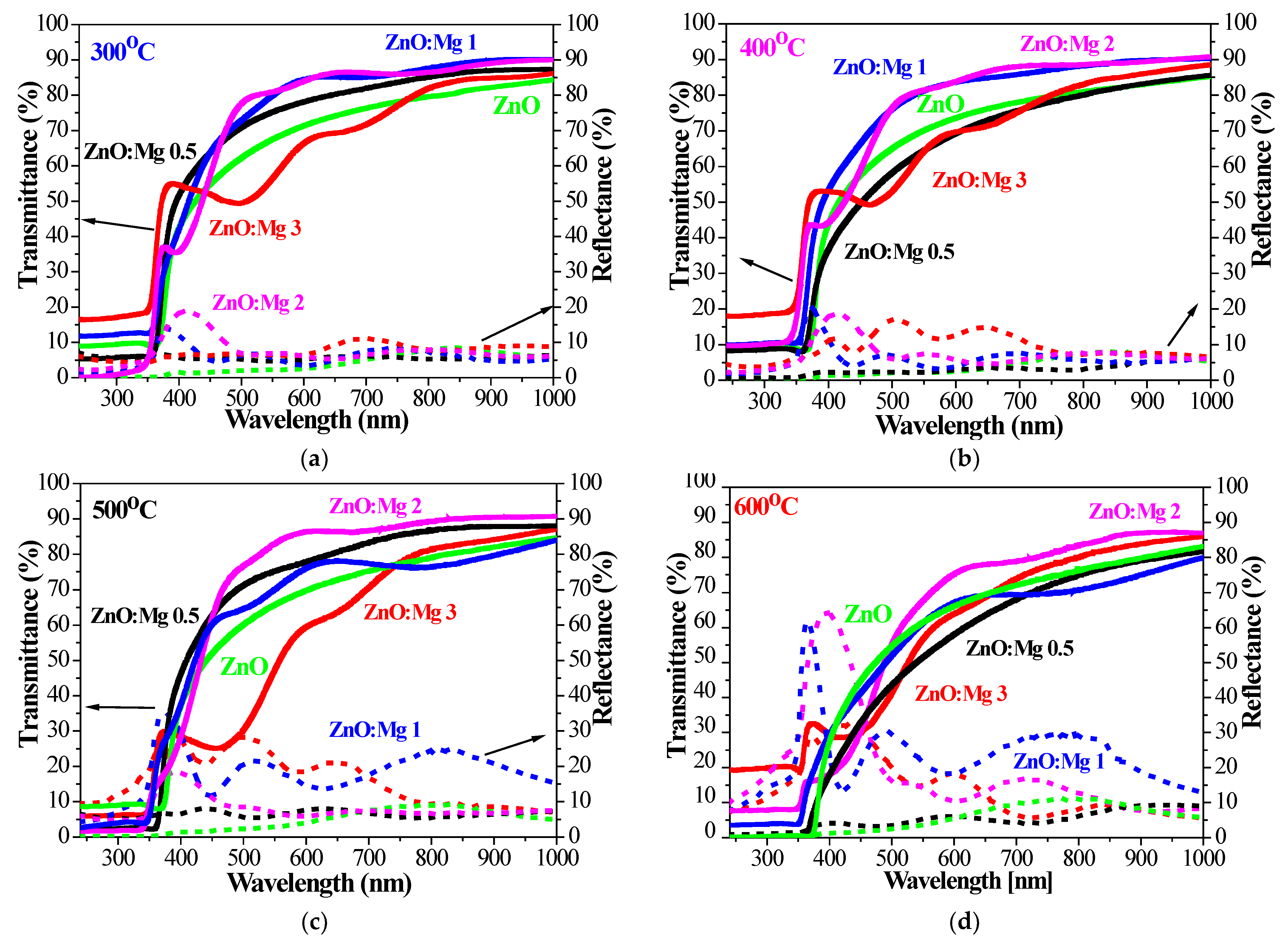

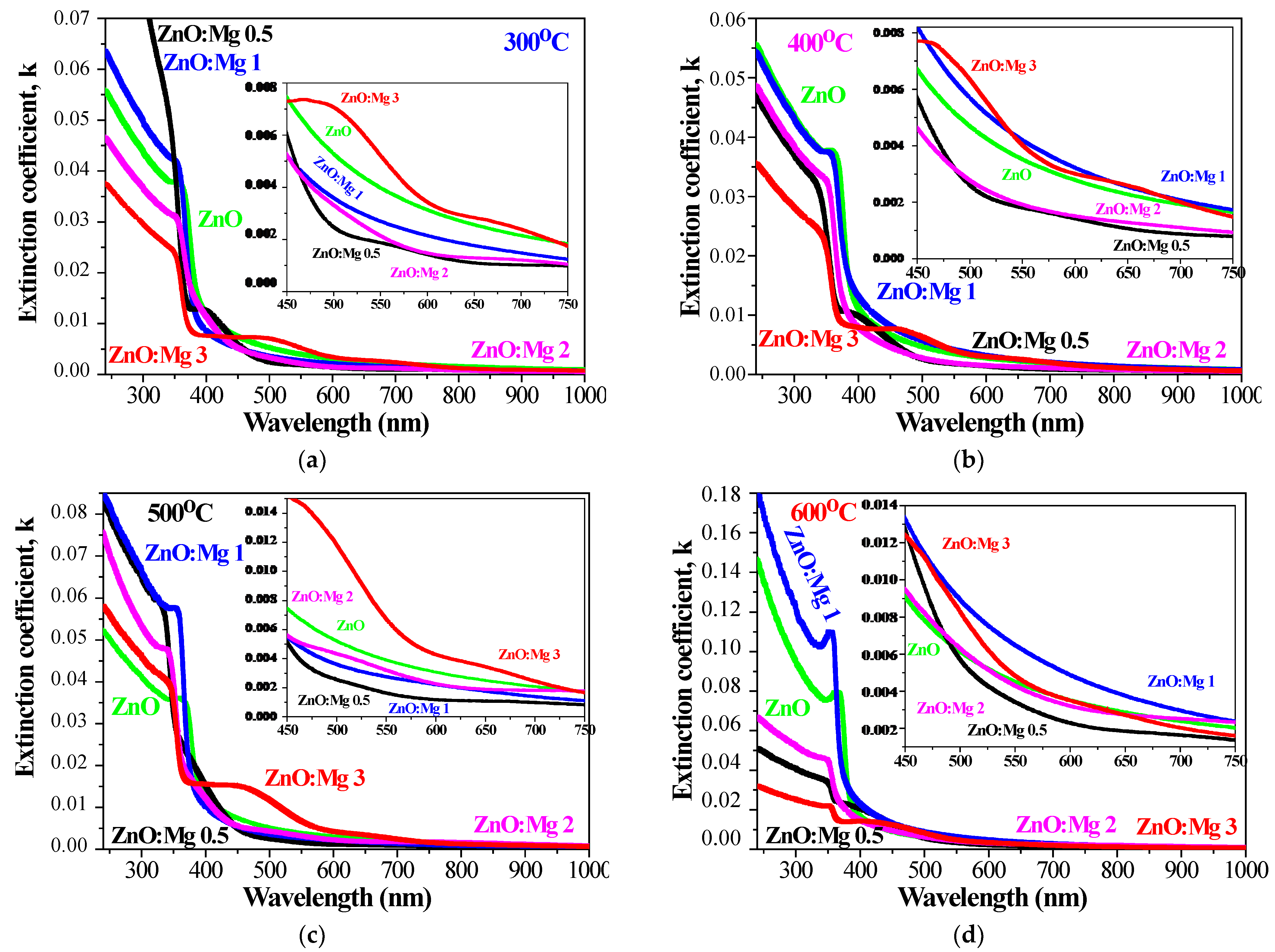

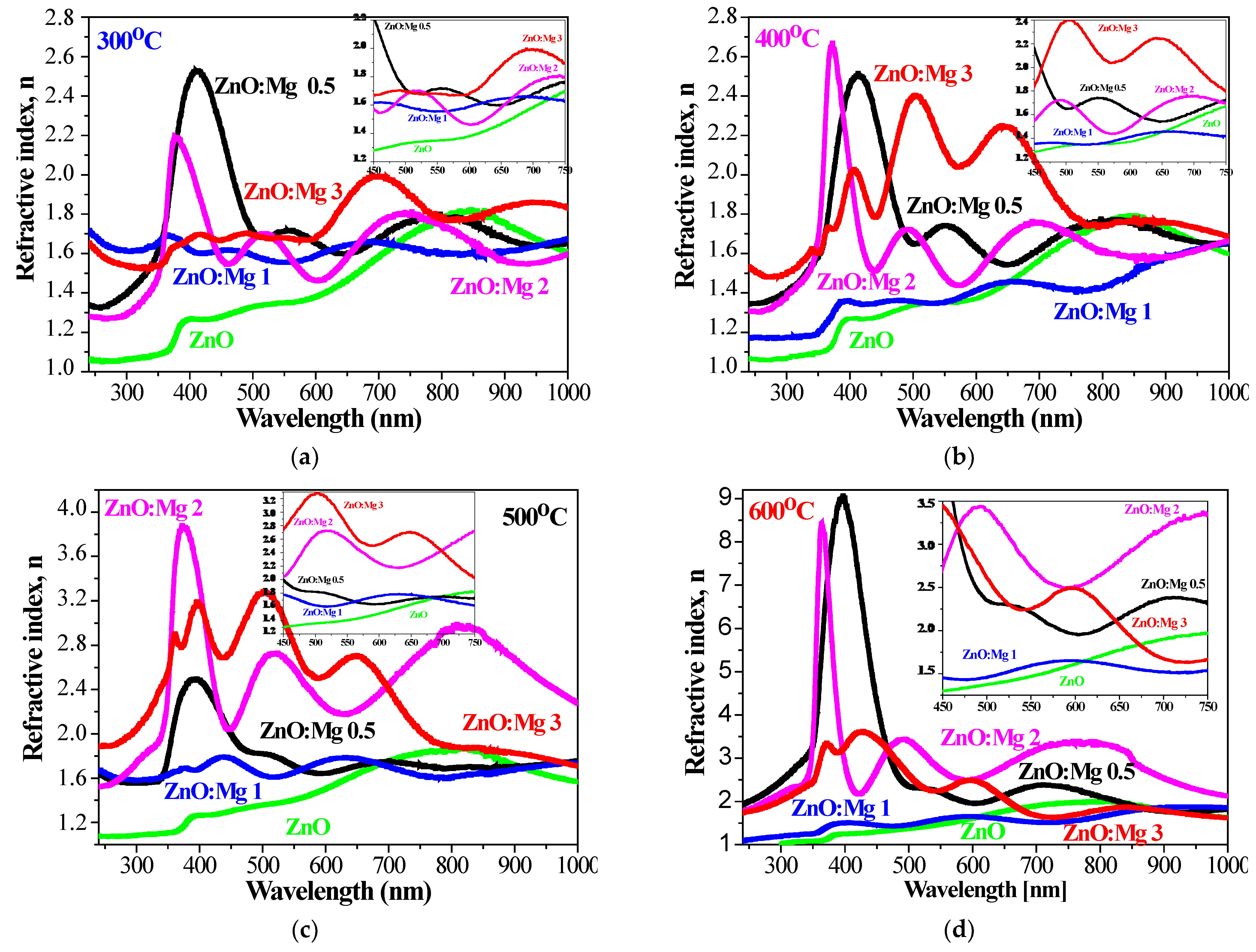

3.3. UV–VIS Spectroscopy—Optical Characterization

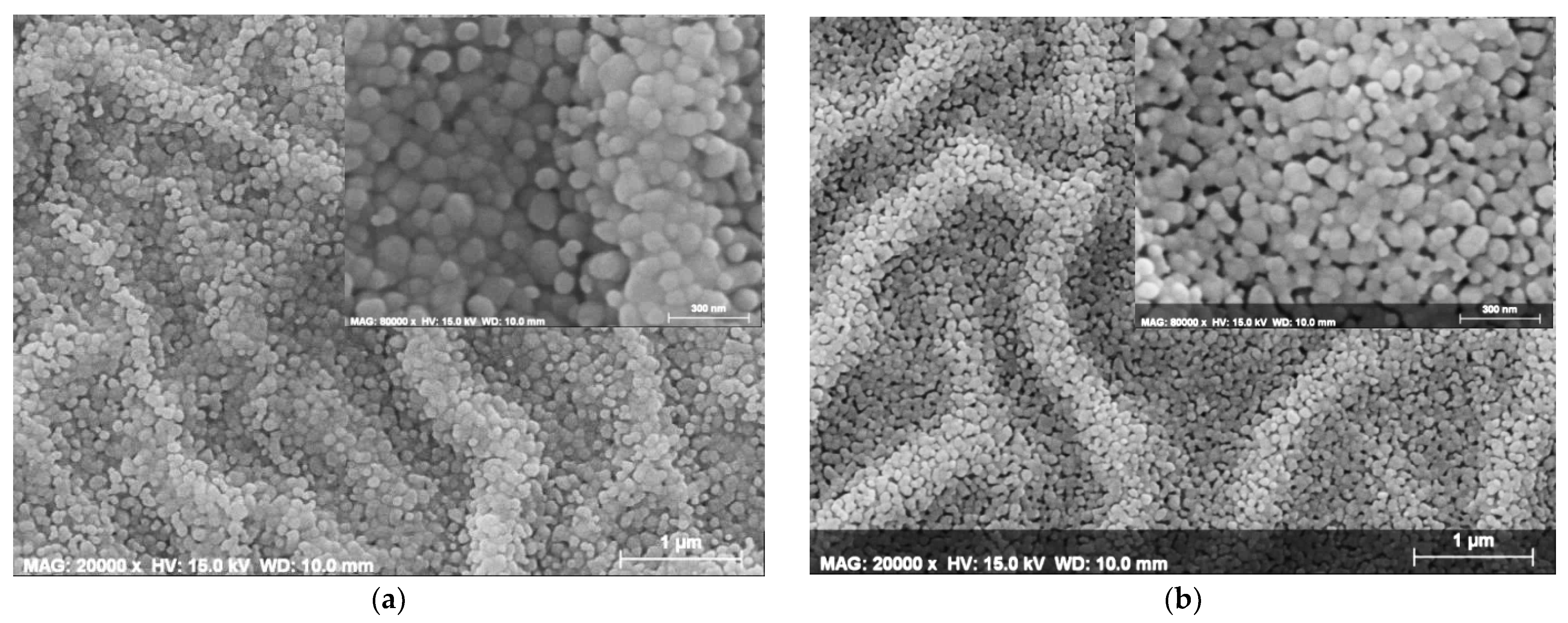

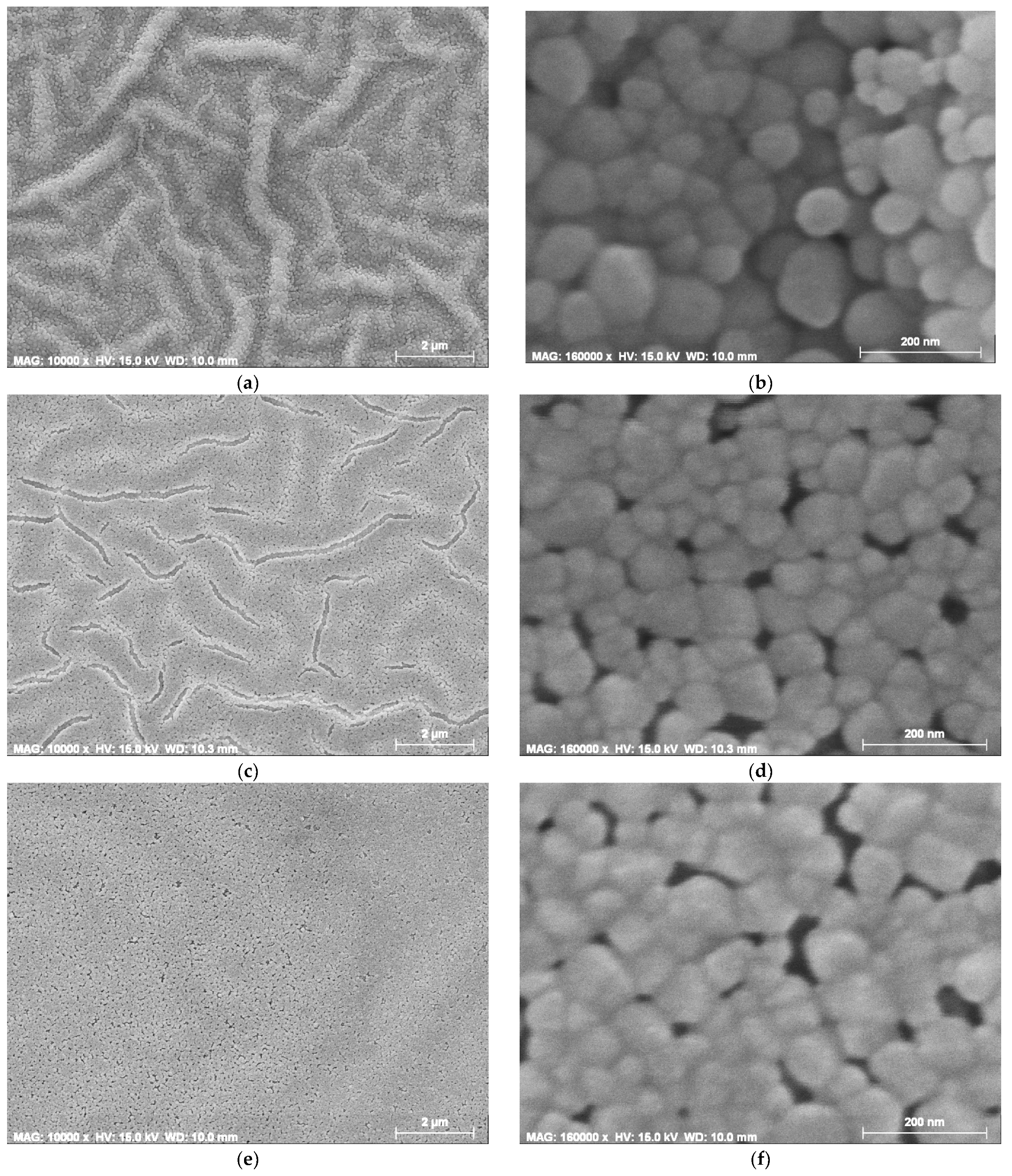

3.4. FESEM Microscopy—Film Morphology

3.5. Figure of Merit (FOM)—Electrical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Popielarski, P.; Mosinska, L.; Bala, W.; Paprocki, K.; Zorenko, Y.; Zorenko, T.; Sypniewska, M. Persistent photoconductivity in ZnO thin films grown on Si substrate by spin coating method. Opt. Mater. 2019, 97, 109343. [Google Scholar] [CrossRef]

- Xu, L.; Zheng, G.; Xian, F.; Su, J. The morphological evolution of ZnO thin films by Sn ions doping and its influence on the surface energy and photocatalytic activity. Mater. Chem. Phys. 2019, 229, 215–225. [Google Scholar] [CrossRef]

- Hurma, T. Effect of boron doping concentration on structural optical electrical properties of nanostructured ZnO films. J. Mol. Struct. 2019, 1189, 1–7. [Google Scholar] [CrossRef]

- Makuku, O.; Mbaiwa, F.; Sathiaraj, T.S. Structural, optical and electrical properties of low temperature grown undoped and (Al, Ga) co-doped ZnO thin films by spray pyrolysis. Ceram. Int. 2016, 42, 14581–14586. [Google Scholar] [CrossRef]

- Theerthagiri, J.; Salla, S.; Senthil, R.A.; Nithyadharseni, P.; Madankumar, A.; Arunachalam, P.; Maiyalagan, T.; Kim, H.S. A review on ZnO nanostructured materials: Energy, environmental and biological applications. Nanotechn. 2019, 30, 392001. [Google Scholar] [CrossRef]

- Abed, C.; Fernández, S.; Aouida, S.; Elhouichet, H.; Priego, F.; Castro, Y.; Gómez-Mancebo, M.B.; Munuera, C. Processing and study of optical and electrical properties of (Mg, Al) co-doped ZnO thin films prepared by rf magnetron sputtering for photovoltaic application. Materials 2020, 13, 2146. [Google Scholar] [CrossRef]

- Kun, T.; Shulin, G.; Jiandong, Y.; Shunming, Z.; Rong, Z.; Youdou, Z. High-quality ZnO growth, doping, and polarization effect. J. Semicond. 2016, 37, 031001. [Google Scholar] [CrossRef][Green Version]

- Ayinde, S.A.; Fasakin, O.; Olofinjana, B.; Adedeji, A.V.; Oyedare, P.O.; Eleruja, M.A.; Ajayi, E.O.B. Optical, Structural and Electrical Properties of Aluminum Doped Zinc Oxide Thin Films by MOCVD Technique. J. Electron. Mater. 2019, 48, 3655–3661. [Google Scholar] [CrossRef]

- Yildirim, O.A.; Arslan, H.; Sönmezoğlu, S. Facile synthesis of cobalt-doped zinc oxide thin films for highly efficient visible light photocatalysts. Appl. Surf. Sci. 2016, 390, 111–121. [Google Scholar] [CrossRef]

- Boujnah, M.; Boumdyan, M.; Naji, S.; Benyoussef, A.; El Kenz, A.; Loulidi, M. High efficiency of transmittance and electrical conductivity of V doped ZnO used in solar cells applications. J. Alloys Comp. 2016, 671, 560–565. [Google Scholar] [CrossRef]

- Fan, J.C.; Sreekanth, K.M.; Xie, Z.; Chang, S.L.; Rao, K.V. p-Type ZnO materials: Theory, growth, properties and devices. Prog. Mater. Sci. 2013, 58, 874–985. [Google Scholar] [CrossRef]

- Daksh, D.; Agrawal, Y.K. Rare Earth-Doped Zinc Oxide Nanostructures: A Review. Rev. Nanosc. Nanotech. 2016, 5, 1–27. [Google Scholar] [CrossRef]

- Schelonka, D.; Tolasz, J.; Štengl, V. Doping of Zinc Oxide with Selected First Row Transition Metals for Photocatalytic Applications. Photochem. Photobiol. 2015, 91, 1071–1077. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Li, J.; Yu, Z.; Li, W.; Zhu, M.; Jin, H.; Liu, Y.; Li, Y.; Skotnicova, K. Study on the high magnetic field processed ZnO based diluted magnetic semiconductors. Ceram. Int. 2019, 45, 19583–19595. [Google Scholar] [CrossRef]

- Lardjane, S.; Yazdi, M.A.P.; Martin, N.; Bellouard, C.; Fenineche, N.; Schuler, A.; Merad, G.; Billard, A. Structural, electrical and magnetic characterization of in-situ crystallized ZnO:Co thin films synthesized by reactive magnetron sputtering. Mater. Chem. Phys. 2015, 161, 26–34. [Google Scholar] [CrossRef]

- Saadi, H.; Benzarti, Z.; Rhouma, F.I.H.; Sanguino, P.; Guermazi, S.; Khirouni, K.; Vieira, M.T. Enhancing the electrical and dielectric properties of ZnO nanoparticles through Fe doping for electric storage applications. J. Mater. Sci. Mater. Electron. 2021, 32, 1536–1556. [Google Scholar] [CrossRef]

- Ye, Z.; He, H.; Jiang, L. Co-doping: An effective strategy for achieving stable p-type ZnO thin films. Nano Energy 2018, 52, 527–540. [Google Scholar] [CrossRef]

- Saadi, H.; Benzarti, Z.; Sanguino, P.; Hadouch, Y.; Mezzane, D.; Khirouni, K.; Abdelmoula, N.; Khemakhem, H. Improving the optical, electrical and dielectric characteristics of ZnO nanoparticles through (Fe + Al) addition for optoelectronic applications. Appl. Phys. A 2022, 128, 691. [Google Scholar] [CrossRef]

- Cheng, H.-W.; Raghunath, P.; Wang, K.; Cheng, P.; Haung, T.; Wu, Q.; Yang, Y. Potassium-presenting Zinc Oxide Surfaces Induce Vertical Phase Separation in Fullerene-free Organic Photovoltaics. Nano Lett. 2020, 20, 715–721. [Google Scholar] [CrossRef]

- Wang, X.H.; Huang, L.Q.; Niu, L.J.; Li, R.B.; Fan, D.H.; Zhang, F.B.; Chen, Z.W.; Wang, X.; Guo, Q.X. The impacts of growth temperature on morphologies, compositions and optical properties of Mg-doped ZnO nanomaterials by chemical vapor deposition. J. Alloys Comp. 2015, 622, 440–445. [Google Scholar] [CrossRef]

- Goktas, A.; Tumbul, A.; Aba, Z.; Durgun, M. Mg doping levels and annealing temperature induced structural, optical and electrical properties of highly c-axis oriented ZnO:Mg thin films and Al/ZnO:Mg/p-Si/Al heterojunction diode. Thin Solid Film. 2019, 680, 20–30. [Google Scholar] [CrossRef]

- Mia, M.N.H.; Pervez, M.F.; Hossain, M.K.; Rahman, M.R.; Uddin, M.J.; Al Mashud, M.A.; Ghosh, H.K.; Hoq, M. Influence of Mg content on tailoring optical bandgap of Mg-doped ZnO thin film prepared by sol-gel method. Results Phys. 2017, 7, 2683–2691. [Google Scholar] [CrossRef]

- Quan, Z.; Liu, X.; Qi, Y.; Song, Z.; Qi, S.; Zhou, G.; Xu, X. Robust room temperature ferromagnetism and band gap tuning in nonmagnetic Mg doped ZnO films. Appl. Surf. Sci. 2017, 399, 751–757. [Google Scholar] [CrossRef]

- Duan, F.L.; Yang, Z.; Ji, Z.; Weng, H.; Xie, Z.; Shen, A.; Mi, S.; Chen, X.; Chen, Y.; Liu, Q. Process optimization and device variation of Mg-doped ZnO FBARs. Solid-State Electron. 2019, 151, 11–17. [Google Scholar] [CrossRef]

- Loeza-Poot, M.; Mis-Fernández, R.; Rimmaudo, I.; Camacho-Espinosa, E.; Peña, J.L. Novel sputtering method to obtain wide band gap and low resistivity in as-deposited magnesium doped zinc oxide films. Mater. Sci. Semicon. Proc. 2019, 104, 104646. [Google Scholar] [CrossRef]

- Vijayalakshmi, K.; Renitt, A.; Karthick, K. Growth of high quality ZnO:Mg films on ITO coated glass substrates for enhanced H2 sensing. Ceram. Int. 2014, 40, 6171–6177. [Google Scholar] [CrossRef]

- Tsay, C.Y.; Chen, S.T.; Fan, M.T. Solution-Processed Mg-Substituted ZnO Thin Films for Metal-Semiconductor-Metal Visible-Blind Photodetectors. Coatings 2019, 9, 277. [Google Scholar] [CrossRef]

- Chen, S.; Brahma, Y.J.; Liu, C.P.; Huang, J.L. Enhancement of the piezoelectric coefficient in hexagonal MgxZn1-xO films at lower Mg compositions. J. Alloys. Comp. 2017, 728, 1248–1253. [Google Scholar] [CrossRef]

- Murkute, P.; Ghadi, H.; Sreedhara, S.; Chakrabarti, S. Detailed investigation of photoluminescence, structural, and elemental properties of ZnO thin films under various annealing ambient. Superlattices Microstruct. 2019, 136, 106310. [Google Scholar] [CrossRef]

- Jiamprasertboon, A.; Dixon, S.C.; Sathasivam, S.; Powell, M.J.; Lu, Y.; Siritanon, T.; Carmalt, C.J. Low-Cost One-Step Fabrication of Highly Conductive ZnO:Cl Transparent Thin Films with Tunable Photocatalytic Properties via Aerosol-Assisted Chemical Vapor Deposition. ACS Appl. Electron. Mater. 2019, 1, 1408–1417. [Google Scholar] [CrossRef]

- Aksay, S. Effects of Al dopant on XRD, FT-IR and UV–vis properties of MgO films. Physica B Condens. Matter 2019, 570, 280–284. [Google Scholar] [CrossRef]

- Nateq, M.H.; Ceccato, R. Enhanced Sol–Gel Route to Obtain a Highly Transparent and Conductive Aluminum-Doped Zinc Oxide Thin Films. Materials 2019, 12, 1744. [Google Scholar] [CrossRef] [PubMed]

- Siregar, N.; Motlan; Panggabean, J. The effect magnesium (Mg) on structural and optical properties of ZnO:Mg thin film by sol-gel spin coating method. J. Phys. Conf. Ser. 2020, 1428, 012026. [Google Scholar] [CrossRef]

- Varghese, J.; Saji, S.K.; Aswathy, N.R.; Vinodkumar, R. Influence of Mg doping on structural, optical and dielectric properties of sol–gel spin coated ZnO thin films. Eur. Phys. J. Plus 2021, 136, 1206. [Google Scholar] [CrossRef]

- Matur, U.C.; Duru, I.P.; Akcan, D. Tracking optical properties of ZnO:Mg thin films: Experimental and first principles calculations. Ceram. Int. 2022, 48, 19090–19097. [Google Scholar] [CrossRef]

- Ţălu, S.; Boudour, S.; Bouchama, I.; Astinchap, B.; Ghanbaripour, H.; Akhtar, M.S.; Zahra, S. Multifractal analysis of Mg-doped ZnO thin films deposited by sol-gel spin coating method. Microsc. Res. Tech. 2022, 85, 1213–1223. [Google Scholar] [CrossRef]

- Ivanova, T.; Harizanova, A.; Koutzarova, T.; Vertruyen, B.; Stefanov, B. Structural and morphological characterization of sol-gel ZnO:Ga films: Effect of annealing temperatures. Thin Solid Films 2018, 646, 132–142. [Google Scholar] [CrossRef]

- Singh, J.P.; Kim, S.H.; Won, S.O.; Lee, I.J.; Chae, K.H. Atomic-scale investigation of MgO growth on fused quartz using angle-dependent NEXAFS measurements. RSC Adv. 2018, 8, 31275–31286. [Google Scholar] [CrossRef]

- Lin, C.F.; Kao, C.H.; Lin, C.Y.; Liu, Y.W.; Wang, C.H. The electrical and physical characteristics of Mg-doped ZnO sensing membrane in EIS (electrolyte–insulator–semiconductor) for glucose sensing applications. Results Phys. 2020, 16, 102976. [Google Scholar] [CrossRef]

- Huang, K.; Tang, Z.; Zhang, L.; Yu, J.; Lv, J.; Liu, X.; Liu, F. Preparation and characterization of Mg-doped ZnO thin films by sol–gel method. Appl. Surf. Sci. 2012, 258, 3710–3713. [Google Scholar] [CrossRef]

- Shkir, M.; Arif, M.; Ganesh, V.; Manthrammel, M.A.; Singh, A.; Yahia, I.S.; Maidur, S.R.; Patil, P.S.; AlFaify, S. Investigation on structural, linear, nonlinear and optical limiting properties of sol-gel derived nanocrystalline Mg doped ZnO thin films for optoelectronic applications. J. Mol. Struct. 2018, 1173, 375–384. [Google Scholar] [CrossRef]

- Manzhi, P.; Kumari, R.; Alam, M.B.; Umapathy, G.R.; Krishna, R.; Ojha, S.; Srivastava, R.; Sinha, O.P. Mg-doped ZnO nanostructures for efficient Organic Light Emitting Diode. Vacuum 2019, 166, 370–376. [Google Scholar] [CrossRef]

- Kim, T.H.; Park, J.J.; Nam, S.H.; Park, H.S.; Cheong, N.R.; Song, J.K.; Park, S.M. Fabrication of Mg-doped ZnO thin films by laser ablation of Zn:Mg target. Appl. Surf. Sci. 2009, 255, 5264–5266. [Google Scholar] [CrossRef]

- Debye, P.; Scherrer, P. Interference of irregularly oriented particles in x-rays. Phys. Zeit. 1916, 17, 277–283. [Google Scholar]

- Suwanboon, S.; Amornpitoksuk, P.; Sukolrat, A. Dependence of optical properties on doping metal, crystallite size and defect concentration of M-doped ZnO nanopowders (M = Al, Mg, Ti). Ceram. Int. 2017, 37, 1359–1365. [Google Scholar] [CrossRef]

- Shaban, M.; Zayed, M.; Hamdy, H. Nanostructured ZnO thin films for self-cleaning applications. RSC Adv. 2017, 7, 617–631. [Google Scholar] [CrossRef]

- Novak, G.; Colville, A. A practical interactive least-squares cell-parameter program using an electronic spreadsheet and a personal computer. Am. Mineral. 1989, 74, 488–490. [Google Scholar]

- Singh, J.; Hudson, M.S.L.; Pandey, S.K.; Tiwari, R.S.; Srivastava, O.N. Structural and hydrogenation studies of ZnO and Mg doped ZnO nanowires. Int. J. Hydrogen Energy 2012, 37, 3748–3754. [Google Scholar] [CrossRef]

- Araújo Júnior, E.A.; Nobre, F.X.; da Silva Sousa, G.; Cavalcante, L.S.M.; Santos, R.d.M.C.; Souza, F.L.; de Matos, J.M.E. Synthesis, growth mechanism, optical properties and catalytic activity of ZnO microcrystals obtained via hydrothermal processing. RSC Adv. 2017, 7, 24263–24281. [Google Scholar] [CrossRef]

- Özgür, Ü.; Alivov, Y.I.; Liu, C.; Teke, A.; Reshchikov, M.A.; Doğan, S.; Avrutin, V.; Cho, S.J.; Morkoç, H. A comprehensive review of ZnO materials and devices. J. Appl. Phys. 2005, 98, 041301. [Google Scholar] [CrossRef]

- Algarni, H.; Gueddim, A.; Bouarissa, N.; Ajmal Khan, M.; Ziani, H. Crystal structure and electronic properties of wurtzite MgxZn1-xO: Ab initio study. Results Phys. 2019, 15, 102694. [Google Scholar] [CrossRef]

- Caglar, Y.; Ilican, S.; Caglar, M. FESEM, XRD and DRS studies of electrochemically deposited boron doped ZnO films. Mater. Sci. Poland 2017, 35, 824–829. [Google Scholar] [CrossRef][Green Version]

- Petrovic, Z.; Ristic, M.; Music, S. Development of ZnO microstructures produced by rapid hydrolysis of zinc acetylacetonate. Ceram. Int. 2014, 40, 10953–10959. [Google Scholar] [CrossRef]

- Khan, Z.R.; Khan, M.S.; Zulfequar, M.; Khan, M.S. Optical and Structural Properties of ZnO Thin Films Fabricated by Sol-Gel Method. Mater. Sci. Appl. 2011, 2, 340–345. [Google Scholar] [CrossRef]

- Noei, H.; Qiu, H.; Wang, Y.; Löffler, E.; Wöll, C.; Muhler, M. The identification of hydroxyl groups on ZnO nanoparticles by infrared spectroscopy. Phys. Chem. Chem. Phys. 2008, 10, 7092–7097. [Google Scholar] [CrossRef]

- Gordeeva, A.; Hsu, Y.J.; Jenei, I.Z.; Carvalho, P.H.B.B.; Simak, S.I.; Andersson, O.; Häussermann, U. The identification of hydroxyl groups on ZnO nanoparticles by infrared spectroscopy. ACS Omega 2020, 5, 17617–17627. [Google Scholar] [CrossRef]

- Marikutsa, A.; Rumyantseva, M.; Gaskov, A.; Batuk, M.; Hadermann, J.; Sarmadian, N.; Saniz, R.; Partoens, B.; Lamoen, D. Effect of Zinc Oxide Modification by Indium Oxide on Microstructure, Adsorbed Surface Species, and Sensitivity to CO. Front. Mater. 2019, 6, 43. [Google Scholar] [CrossRef]

- Wang, X.; Li, Q.Q.; Liu, Z.B.; Zhang, J.; Liu, Z.F.; Wang, R.M. Low-temperature growth and properties of ZnO nanowires. Appl. Phys. Lett. 2004, 84, 4941–4943. [Google Scholar] [CrossRef]

- Ajala, F.; Hamrouni, A.; Houas, A.; Lachheb, H.; Megna, B.; Palmisano, L.; Parrino, F. The influence of Al doping on the photocatalytic activity of nanostructured ZnO: The role of adsorbed water. Appl. Surf. Sci. 2018, 445, 376–382. [Google Scholar] [CrossRef]

- Fernández-Pérez, A.; Rodríguez-Casado, V.; Valdés-Solís, T.; Marbán, G. Room temperature sintering of polar ZnO nanosheets: II-mechanism. Phys. Chem. Chem. Phys. 2017, 19, 16413–16425. [Google Scholar] [CrossRef]

- Ning, G.H.; Zhao, X.P.; Li, J. Structure and optical properties of MgxZn1−xO nanoparticles prepared by sol–gel method. Opt. Mater. 2004, 27, 1–5. [Google Scholar] [CrossRef]

- Alam, M.S.; Manzoor, U.; Mujahid, M.; Bhatti, A.S. Highly Responsive UV Light Sensors Using Mg-Doped ZnO Nanoparticles. J. Sensors 2016, 2016, 8296936. [Google Scholar] [CrossRef]

- Suresh, J.; Pradheesh, G.; Alexramani, V.; Sundrarajan, M.; Hong, S.I. Green synthesis and characterization of zinc oxide nanoparticle using insulin plant (Costus pictus D. Don) and investigation of its antimicrobial as well as anticancer activities. Adv. Nat. Sci. Nanosci. Nanotechn. 2018, 9, 015008. [Google Scholar] [CrossRef]

- Zerdali, M.; Hanizaoui, S.; Teheran, F.H.; Rogers, P. Growth of ZnO thin film on SiO2/Si substrate by pulsed laser deposition and study of their physical properties. Mater. Lett. 2006, 60, 504–508. [Google Scholar] [CrossRef]

- Tamilselvi, P.; Yelilarasi, A.; Hema, M.; Anbarasan, R. Synthesis of hierarchical structured MgO by sol-gel method. Nano Bull. 2013, 2, 130106. [Google Scholar]

- Khaleel, W.A.; Sadeq, S.A.; Alani, I.A.M.; Ahmed, M.H.M. Magnesium oxide (MgO) thin film as saturable absorber for passively mode locked erbium-doped fiber laser. Optics Laser Techn. 2019, 115, 331–336. [Google Scholar] [CrossRef]

- Devaraja, B.; Avadhani, D.N.; Prashantha, S.C.; Nagabhushana, H.; Sharma, S.C.; Nagabhushana, B.M.; Nagaswarupa, H.P. Synthesis, structural and luminescence studies of magnesium oxide nanopowder. Spectroch. Acta A 2014, 118, 847–851. [Google Scholar] [CrossRef] [PubMed]

- Güney, H.; İskenderoğlu, D. Synthesis of MgO thin films grown by SILAR technique. Ceram. Int. 2018, 44, 7788–7793. [Google Scholar] [CrossRef]

- Salam, S.; Islam, M.; Akram, A. Sol–gel synthesis of intrinsic and aluminum-doped zinc oxide thin films as transparent conducting oxides for thin film solar cell. Thin Solid Films 2013, 529, 242–247. [Google Scholar] [CrossRef]

- Tsay, C.Y.; Wang, M.C.; Chiang, S.C. Effects of Mg additions on microstructure and optical properties of sol- gel derived ZnO thin films. Mater. Trans. 2008, 49, 1186–1191. [Google Scholar] [CrossRef]

- Ng, Z.N.; Chan, K.Y.; Tohsophon, T. Effects of annealing temperature on ZnO and AZO films prepared by sol-gel technique. Appl. Surf. Sci. 2012, 258, 9604–9609. [Google Scholar] [CrossRef]

- Zak, A.K.; Yousefi, R.; Majid, W.H.A.; Muhamad, M.R. Facile synthesis and X-ray peak broadening studies of Zn1−xMgxO nanoparticles. Ceram. Int. 2012, 38, 2059–2064. [Google Scholar] [CrossRef]

- Singh, A.; Kumar, D.; Khann, P.K.; Kumar, A.; Kumar, M.; Kumar, M. Anomalous behavior in ZnMgO thin films deposited by sol–gel method. Thin Solid Films 2011, 519, 5826–5830. [Google Scholar] [CrossRef]

- Hussain, F.; Imran, M.; Khalil, R.M.A.; Niaz, N.A.; Rana, A.M.; Sattar, M.A.; Ismail, M.; Majid, A.; Kim, S.; Iqbal, F.; et al. An insight of Mg doped ZnO thin films: A comparative experimental and first-principle investigations. Physica E 2020, 115, 113658. [Google Scholar] [CrossRef]

- Chen, X.; Liu, J.; Ni, J.; Zhao, Y.; Zhang, X. Wide-spectrum Mg and Ga co-doped ZnO TCO thin films for solar cells grown via magnetron sputtering with H2 introduction. Appl. Surf. Sci. 2015, 328, 193–197. [Google Scholar] [CrossRef]

- Rao, L.S.; Rao, T.V.; Naheed, S.; Rao, P.V. Structural and optical properties of zinc magnesium oxide nanoparticles synthesized by chemical co-precipitation. Mater. Chem. Phys. 2018, 203, 133–140. [Google Scholar] [CrossRef]

- Kumar, P.; Malik, H.K.; Ghosh, A.; Thangavel, R.; Asokan, K. Bandgap tuning in highly c-axis oriented Zn1−xMgxO thin films. Appl. Phys. Lett. 2013, 102, 221903. [Google Scholar] [CrossRef]

- Al-Kuhaili, M.F.S.; Durrani, M.A.; El-Said, A.S.; Heller, R. Enhancement of the refractive index of sputtered zinc oxide thin films through doping with Fe2O3. J. Alloys Compd. 2017, 690, 453–460. [Google Scholar] [CrossRef]

- Goktas, A.; Aslan, F.; Tumbul, A.; Gunduz, S.H. Tuning of structural, optical and dielectric constants by various transition metal doping in ZnO:TM (TM = Mn, Co, Fe) nanostructured thin films: A comparative study. Ceram. Int. 2007, 43, 704–713. [Google Scholar] [CrossRef]

- Salah, A.; Saad, A.M.; Aboud, A.A. Effect of Co-doping level on physical properties of ZnO thin films. Opt. Mater. 2021, 113, 110812. [Google Scholar] [CrossRef]

- Alsaad, A.M.; Al-Bataineh, Q.M.; Ahmad, A.A.; Albataineh, Z.; Telfah, A. Optical band gap and refractive index dispersion parameters of boron-doped ZnO thin films: A novel derived mathematical model from the experimental transmission spectra. Optik 2020, 211, 164641. [Google Scholar] [CrossRef]

- Badawi, A.; Althobaiti, M.G.; Ali, E.E.; Alharthi, S.S.; Alharbi, A.N. A comparative study of the structural and optical properties of transition metals (M = Fe, Co, Mn, Ni) doped ZnO films deposited by spray-pyrolysis technique for optoelectronic applications. Opt. Mater. 2022, 124, 112055. [Google Scholar] [CrossRef]

- Mimouni, R.; Kamoun, O.; Yumak, A.; Mhamdi, A.; Boubaker, K.; Petkova, P.; Amlouk, M. Effect of Mn content on structural, optical, opto-thermal and electrical properties of ZnO:Mn sprayed thin films compounds. J. Alloys Compd. 2015, 645, 100–111. [Google Scholar] [CrossRef]

- Lekoui, F.; Amrani, R.; Filali, W.; Garoudja, E.; Sebih, L.; Bakouk, I.E.; Akkari, H.; Hassani, S.; Saoula, N.; Oussalah, S.; et al. Investigation of the effects of thermal annealing on the structural, morphological and optical properties of nanostructured Mn doped ZnO thin films. Opt. Mater. 2021, 118, 111236. [Google Scholar] [CrossRef]

- Hoggas, K.; Nouveau, C.; Djelloul, A.; Bououdina, M. Structural, microstructural, and optical properties of Zn1–xMgxO thin films grown onto glass substrate by ultrasonic spray pyrolysis. Appl. Phys. A 2015, 120, 745–755. [Google Scholar] [CrossRef]

- Singh, S.K.; Hazra, P.; Tripathi, S.; Chakrabarti, P. Optical characterization of Mg-doped ZnO thin films deposited by RF magnetron sputtering technique. AIP Conf. Proc. 2016, 1728, 020168. [Google Scholar] [CrossRef]

- Wang, L.W.; Wu, F.; Tian, D.X.; Li, W.J.; Fang, L.; Kong, C.Y.; Zhou, M. Effects of Na content on structural and optical properties of Na-doped ZnO thin films prepared by sol-gel method. J. Alloys Compd. 2015, 623, 367–373. [Google Scholar] [CrossRef]

- Serbetci, Z.; El-Nasser, H.M.; Yakuphanoglu, F. Photoluminescence and refractive index dispersion properties of ZnO nanofibers grown by sol-gel method. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2012, 86, 405–409. [Google Scholar] [CrossRef]

- Wang, C.; Ying, M.J.; Lian, J.; Wei, M.Y.; Jiang, Q.; Xu, Z.; Zhang, Y.; Wang, Y. Structural, optical and half-metallic properties of Mn and As co-implanted ZnO thin films. Appl. Surf. Sci. 2022, 575, 151703. [Google Scholar] [CrossRef]

- Ali, G.A.; Emam-Ismail, M.; El-Hagary, M.; Shaaban, E.R.; Moustafa, S.H.; Amer, M.I.; Shaban, H. Optical and microstructural characterization of nanocrystalline Cu doped ZnO diluted magnetic semiconductor thin film for optoelectronic applications. Opt. Mater. 2021, 119, 111312. [Google Scholar] [CrossRef]

- Othman, Z.J.; Matoussi, A. Morphological and optical studies of zinc oxide doped MgO. J. Alloys Compd. 2016, 671, 366–371. [Google Scholar] [CrossRef]

- Miller, J.B.; Hsie, H.J.; Howard, B.H.; Broitman, E. Microstructural evolution of sol–gel derived ZnO thin films. Thin Solid Films 2010, 518, 6792–6798. [Google Scholar] [CrossRef]

- Navin, K.; Kurchania, R. Structural, morphological and optical studies of ripple-structured ZnO thin films. Appl. Phys. A 2015, 121, 1155–1161. [Google Scholar] [CrossRef]

- Bu, I.Y.Y. Self-assembled, wrinkled zinc oxide for enhanced solar cell performances. Mater. Lett. 2014, 122, 55–57. [Google Scholar] [CrossRef]

- Anand, A.; Islam, M.M.; Meitzner, R.; Schubert, U.S.; Hoppe, H. Introduction of a Novel Figure of Merit for the Assessment of Transparent Conductive Electrodes in Photovoltaics: Exact and Approximate Form. Adv. Energy Mater. 2021, 11, 2100875. [Google Scholar] [CrossRef]

- Wang, F.H.; Chen, M.S.; Jiang, Y.L.; Liu, H.W.; Kang, T.K. Fabrication and characterization of sputtered Mg and F co-doped ZnO thin films with different substrate temperature for silicon thin-film solar cell applications. J. Alloys Comp. 2022, 897, 163174. [Google Scholar] [CrossRef]

- Mahajan, C.M.; Pendharkar, M.; Chaudhari, Y.A.; Sawant, S.S.; Ankamwar, B.; Takwale, M.G. Spray deposited nanocrystalline ZnO transparent electrodes: Role of Precursor Solvent. J. Nano-Electron. Phys. 2016, 8, 02026. [Google Scholar] [CrossRef]

- Das, A.; Das, G.; Kabiraj, D.; Basak, D. High conductivity along with high visible light transparency in Al implanted sol-gel ZnO thin film with an elevated figure of merit value as a transparent conducting layer. J. Alloys Comp. 2020, 835, 155221. [Google Scholar] [CrossRef]

- Mahajan, C.M.; Takwale, M.G. Precursor molarity dependent growth rate, microstructural, optical and electrical properties of spray pyrolytically deposited transparent conducting ZnO thin films. Micro Nanostr. 2022, 163, 107131. [Google Scholar] [CrossRef]

- Rahman, M.R.; Uddin, M.N.; Hoq, M. A comprehensive optical and electrical properties analysis of Mg doped ZnO nanocrystalline thin-films for optoelectronic applications. In Proceedings of the 2020 IEEE International Conference on Advent Trends in Multidisciplinary Research and Innovation (ICATMRI), Buldhana, India, 30 December 2020; pp. 1–6. [Google Scholar] [CrossRef]

| Material | Deposition Method | Spectral Range (nm) | n | Reference |

|---|---|---|---|---|

| ZnO | Sol–gel spin coating | 450–700 | 1.28–1.90 | This work |

| ZnO:Mg | 4.31–1.62 | |||

| Bulk ZnO | 500 | 2.047–2.063 | [78] | |

| ZnO | Various | 500 | 1.67–2.20 | [78] |

| ZnO | Sol–gel spin coating | 350–700 | 1.55–1.93 | [82] |

| Zno:MnO | Sputtering | visible | 2.40 | [79] |

| ZnO:Mn | Chemical spray technique | 600–1800 | 2.2–2.6 | [83] |

| ZnO:Mn | Rapid thermal evaporation | 600 | 2.07–2.148 | [84] |

| ZnO | Ultrasonic spray pyrolysis | 598 | 1.779 | [85] |

| Zn1–xMg xO x = 0.10–0.16 | 595 | 1.647–1.885 | [85] | |

| ZnO:Mg, Mg 5–10% | RF magnetron sputtering | 300–600 | 4.5–2.5 | [86] |

| ZnO, ZnO:Na | Sol–gel spin coating | 450–700 | 2.4–3.6 | [87] |

| ZnO | Sol–gel, nanofibers | 400–800 | 1.65–1.90 | [88] |

| ZnO | Molecular beam epitaxy | 300–1000 | 1.10–1.71 | [89] |

| ZnO | e-beam | 450–1100 | 2.7–2.2 | [90] |

| (ZnO)1−x(MgO)x powder | Solid state sintering | 300–1500 | 4.7–2.0 | [91] |

| Zn1-xCuxO | E-beam evaporation | 450–1000 | 2.7–2.2 | [78] |

| ZnO-MgO:Al2O3 | RF magnetron sputtering | 400–600 | 2.91–2.59 | [6] |

| Annealing at 500 °C | Annealing at 600 °C | |||||

|---|---|---|---|---|---|---|

| Material | Taverage (%) | Rsheet (Ω/sq) | FOM × 10−4 (Ω−1) | Taverage (%) | Rsheet (Ω/sq) | FOM × 10−4 (Ω−1) |

| ZnO | 74.59 | 685 | 0.78 | 70.48 | 688 | 0.44 |

| ZnO:Mg 0.5 | 83.62 | 350 | 4.78 | 62.75 | 520 | 0.18 |

| ZnO:Mg 1 | 78.97 | 694 | 1.36 | 75.10 | 730 | 0.78 |

| ZnO:Mg 2 | 89.14 | 370 | 8.56 | 71.05 | 240 | 1.37 |

| ZnO:Mg 3 | 60.11 | 689 | 0.089 | 66.22 | 680 | 0.24 |

| Material | Fabrication Method | Taverage (%) | Rsheet (Ω/sq) | FOM (Ω−1) | Reference |

|---|---|---|---|---|---|

| ZnO:Mg, F | Sputtering | 90.7 | 1.36 × 10−2 | [96] | |

| ZnO | Spray pyrolysis | 94.4 | 117 | 4.9 × 10−3 | [97] |

| ZnO:Al | Sol–gel | 82.0 | 156 | 90.3 × 10−3 | [98] |

| ZnO | Spray pyrolysis | 96.3 | 388 | 1.76 × 10−3 | [99] |

| ZnO:Mg | Sol–gel, spin coating | 97.0 | 1725 | 4.75 × 10−4 | [100] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ivanova, T.; Harizanova, A.; Koutzarova, T.; Vertruyen, B.; Closset, R. Deposition of Sol–Gel ZnO:Mg Films and Investigation of Their Structural and Optical Properties. Materials 2022, 15, 8883. https://doi.org/10.3390/ma15248883

Ivanova T, Harizanova A, Koutzarova T, Vertruyen B, Closset R. Deposition of Sol–Gel ZnO:Mg Films and Investigation of Their Structural and Optical Properties. Materials. 2022; 15(24):8883. https://doi.org/10.3390/ma15248883

Chicago/Turabian StyleIvanova, Tatyana, Antoaneta Harizanova, Tatyana Koutzarova, Benedicte Vertruyen, and Raphael Closset. 2022. "Deposition of Sol–Gel ZnO:Mg Films and Investigation of Their Structural and Optical Properties" Materials 15, no. 24: 8883. https://doi.org/10.3390/ma15248883

APA StyleIvanova, T., Harizanova, A., Koutzarova, T., Vertruyen, B., & Closset, R. (2022). Deposition of Sol–Gel ZnO:Mg Films and Investigation of Their Structural and Optical Properties. Materials, 15(24), 8883. https://doi.org/10.3390/ma15248883