Influence of the Stainless-Steel Microstructure on Tribological Behavior and Surface Integrity after Ball Burnishing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Chemical Composition and Material Processing

2.1.2. Microstructural Characterization

2.1.3. Hardness

2.1.4. Surface Roughness

2.2. Experimental Methods

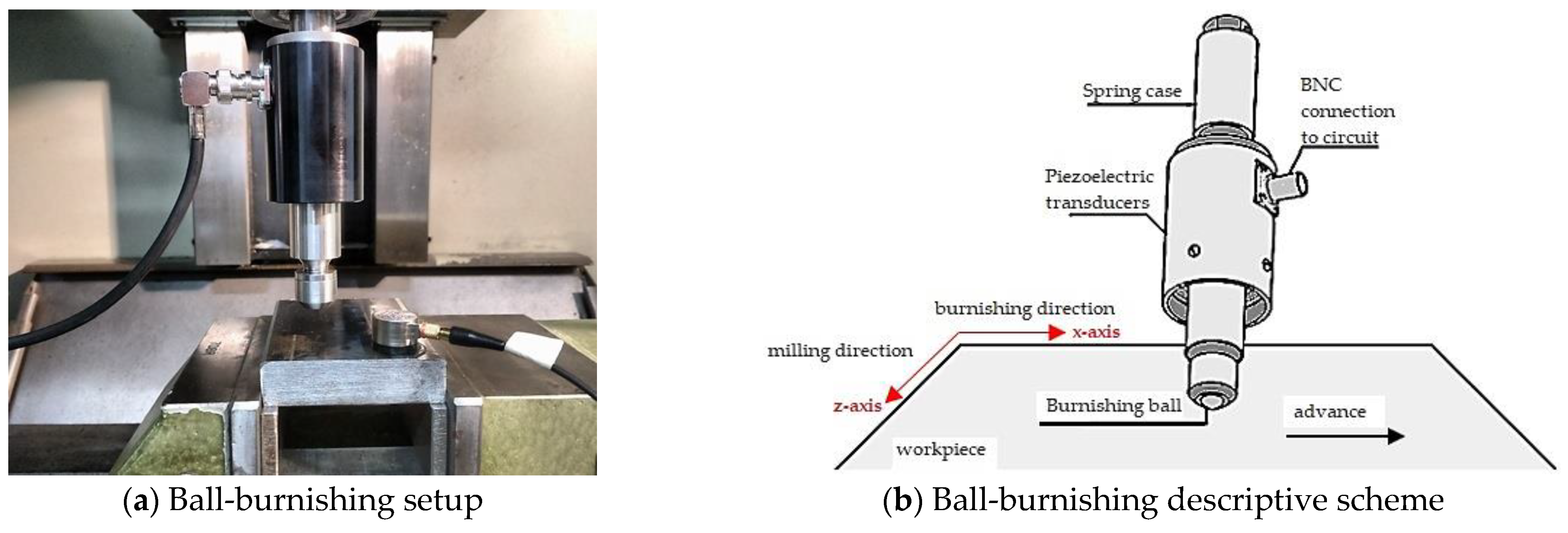

2.2.1. Ball-Burnishing Process

2.2.2. Uniaxial Tensile Properties

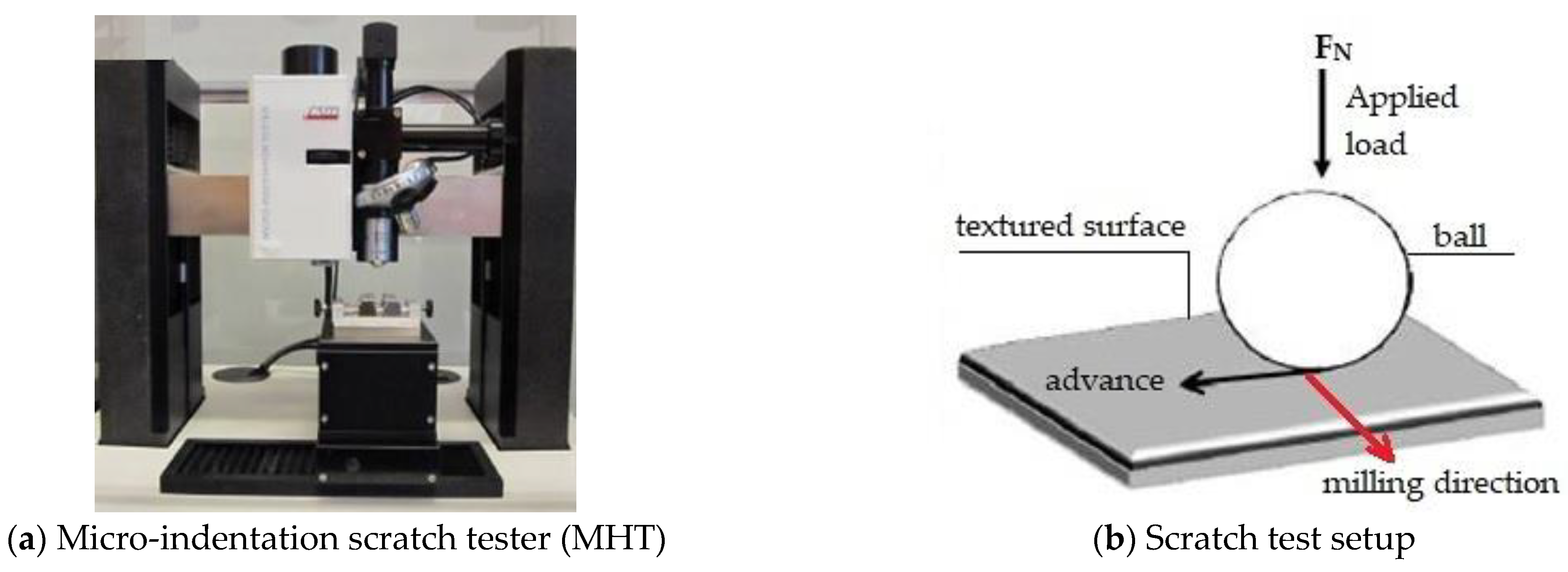

2.2.3. Friction Coefficient

2.2.4. Surface Integrity Characterization

Residual Stresses

3. Results

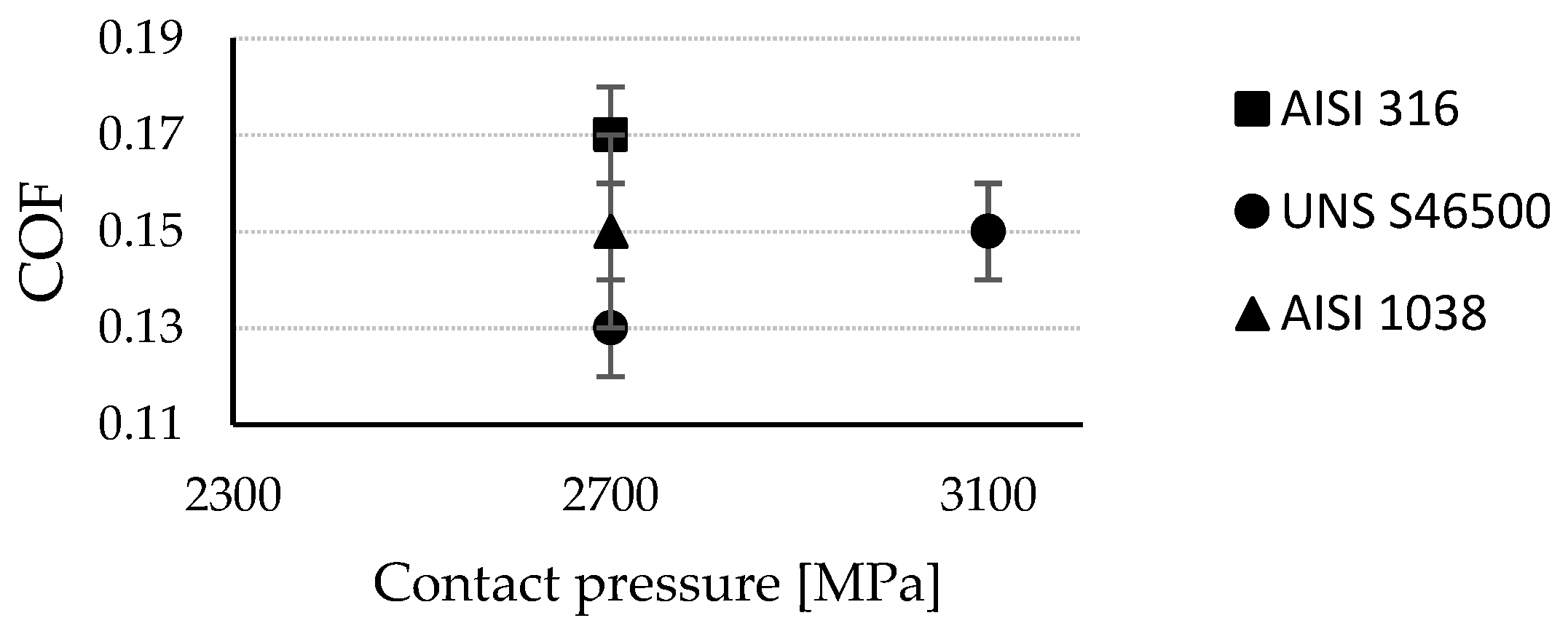

3.1. Friction

3.2. Surface Integrity

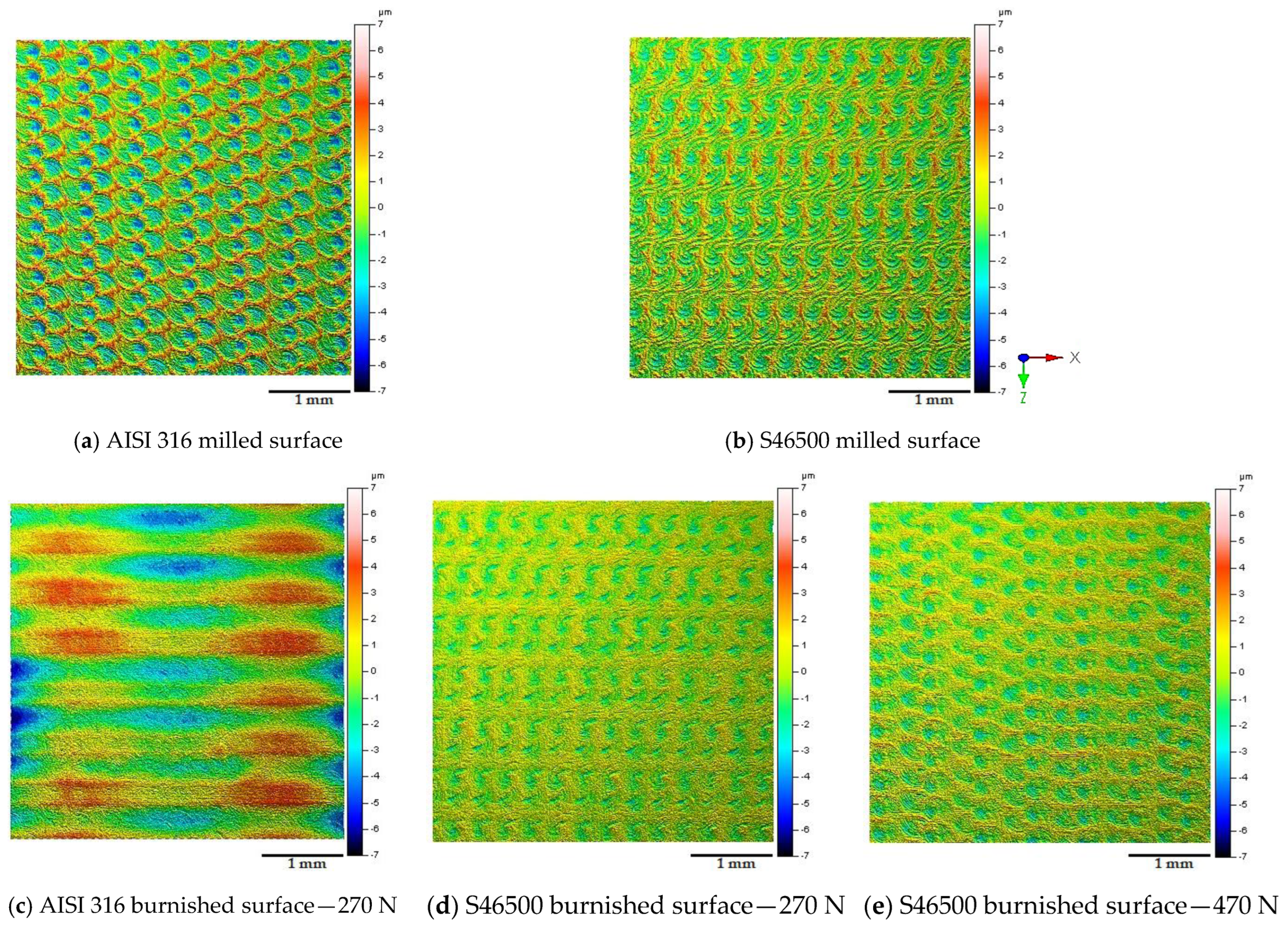

3.2.1. Surface Roughness

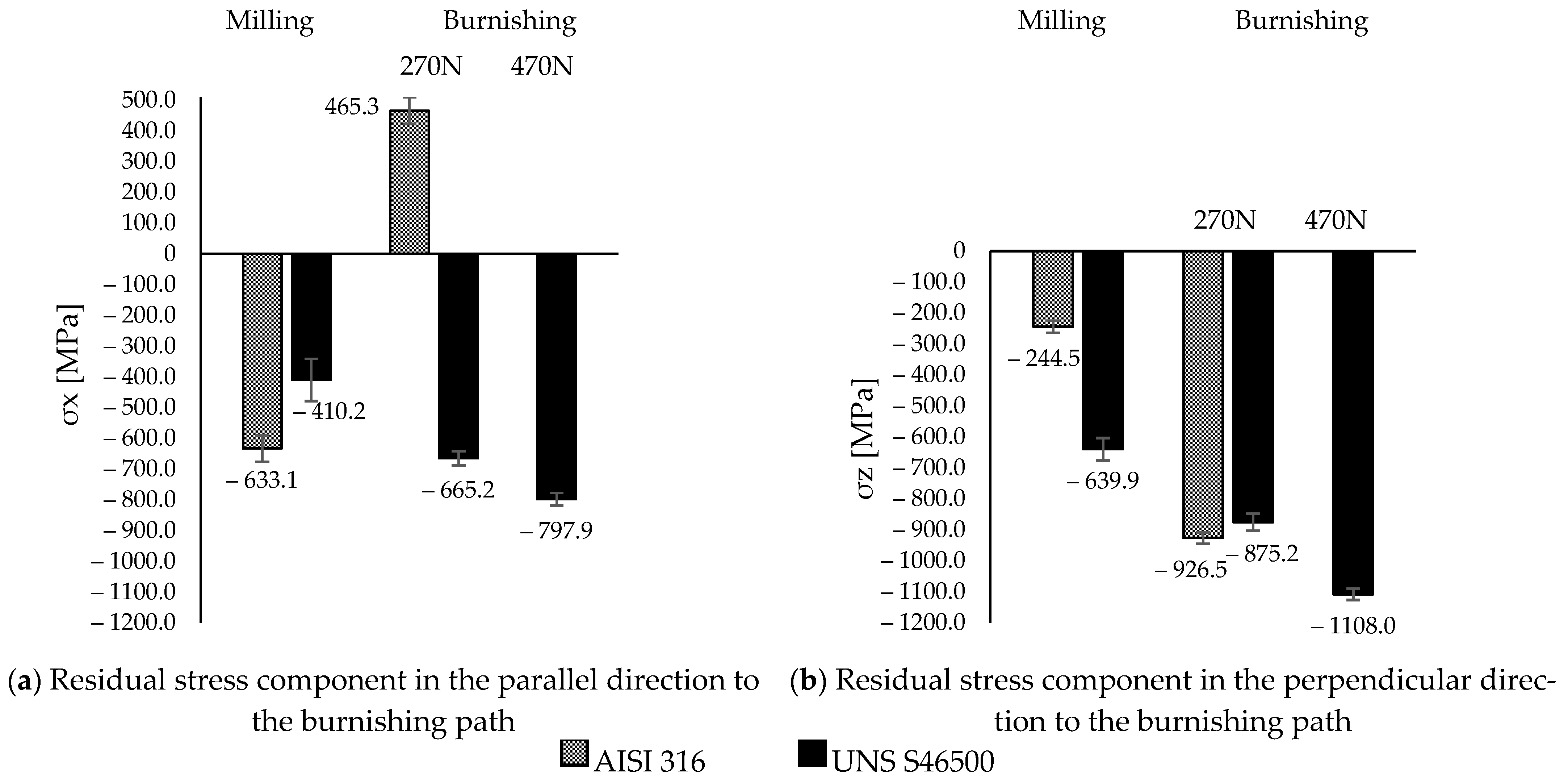

3.2.2. X-ray Difracction

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Ssk | Skewness |

| XRD | X-ray diffraction |

| Sa | Arithmetical mean height |

| Sq | Root mean square height |

| Sku | Kurtosis |

| Str | Texture aspect ratio |

| S10z | Ten-point height |

| Lc | Parallel length |

| E | Young’s modulus |

| ν | Poisson coefficient |

| σ0.2 | Yield strength |

| UTS | Ultimate tensile strength |

| n | Self-hardening coefficient |

| p0 | Pressure in the center of the contact region |

| F | Normal force |

| R | Indenter radius |

| E* | Reduced elastic modulus |

| ASM | American Society of Materials |

| COF | Coefficient of friction |

References

- Kumar, N.; Kumar, M.; Sharma, N.; Shah, P.; Ranganath, M.S.; Mishra, R.S. Mechanical Properties and Microstructural Analysis of AISI 316 During Different Types of Welding Processes: A Review Manufacturing; IJAPIE: New Delhi, India, 2017. [Google Scholar]

- Magnabosco, R.; Alonso-falleiros, N. Effect of Aging Heat Treatment H950 and H1000 on Mechanical and Pitting Corrosion Properties of UNS S46500 Stainless Steel. Mater. Res. 2018, 22, 1–9. [Google Scholar] [CrossRef]

- El-Tayeb, N.S.M.; Low, K.O.; Brevern, P.V. Influence of roller burnishing contact width and burnishing orientation on surface quality and tribological behaviour of Aluminium 6061. J. Mater. Process. Technol. 2007, 186, 272–278. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering, 9th ed.; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

- Michael, A.; Shercliff, H.; Cebon, D. Materials: Engineering, Science, Processing and Design, 1st ed.; Butterworth-Heinemann: Cambridge, UK, 2007; ISBN 978-0-7506-8391-3. [Google Scholar]

- Yang, S.; Li, W. Surface Finishing Theory and New Technology; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Bouzid Saï, W.; Lebrun, J.L. Influence of finishing by burnishing on surface characteristics. J. Mater. Eng. Perform. 2003, 12, 37–40. [Google Scholar] [CrossRef]

- Konefał, K.; Korzyński, M.; Byczkowska, Z.; Korzyńska, K. Improved corrosion resistance of stainless steel X6CrNiMoTi17-12-2 by slide diamond burnishing. J. Mater. Process. Technol. 2013, 213, 1997–2004. [Google Scholar] [CrossRef]

- Kułakowska, A.; Patyk, R.; Bohdal, Ł.; Kałduński, P.; Chodór, J.; Koszalińska, P. Wybrane aspekty ekoinnowacyjnej obróbki nagniataniem, Środkowo-Pomorskie Towarzystwo Naukowe Ochrony Środowiska. Rocz. Ochr. Sr. 2016, Tom 18, 478–492. [Google Scholar]

- Balland, P.; Tabourot, L.; Degre, F.; Moreau, V. Mechanics of the burnishing process. Precis. Eng. 2013, 37, 129–134. [Google Scholar] [CrossRef]

- Jerez-Mesa, R. Study and Characterization of Surface Integrity Modification after Ultrasonic Vibration-Assisted Ball Burnishing; Mechanics of materials [physics.class-ph]; Université Paul Sabatier, Toulouse III: Toulouse, France, 2018. [Google Scholar]

- Kuznetsov, V.P.; Smolin, I.Y.; Dmitriev, A.I.; Tarasov, S.Y.; Gorgots, V.G. Toward control of subsurface strain accumulation in nanostructuring burnishing on thermostrengthened steel. Surf. Coat. Technol. 2016, 285, 171–178. [Google Scholar] [CrossRef]

- Chomienne, V.; Valiorgue, F.; Rech, J.; Verdu, C. CIRP Journal of Manufacturing Science and Technology Influence of ball burnishing on residual stress profile of a 15-5PH stainless steel. CIRP J. Manuf. Sci. Technol. 2016, 13, 90–96. [Google Scholar] [CrossRef]

- Jerez-Mesa, R.; Fargas, G.; Roa, J.J.; Llumà, J.; Travieso-Rodriguez, J.A. Superficial effects of ball burnishing on trip steel AISI 301LN sheets. Metals 2021, 11, 82. [Google Scholar] [CrossRef]

- Zaborski, A.; Tubielewicz, K.; Major, B. Contribution of burnishing to the microstructure and texture in surface layers of carbon steel. Arch. Metall 2000, 45, 333–341. [Google Scholar]

- Capilla-González, G.; Martínez-Ramírez, I.; Díaz-Infante, D.; Hernández-Rodríguez, E.; Alcántar-Camarena, V.; Saldaña-Robles, A. Effect of the ball burnishing on the surface quality and mechanical properties of a TRIP steel sheet. Int. J. Adv. Manuf. Technol. 2021, 116, 3953–3964. [Google Scholar] [CrossRef]

- Mahajan, D.; Tajane, R. A Review on Ball Burnishing Process. Int. J. Sci. Res. Publ. 2013, 3, 1–8. [Google Scholar]

- Malleswara Rao, J.N.; Chenna Kesava Reddy, A.; Rama Rao, P.V. The effect of roller burnishing on surface hardness and surface roughness on mild steel specimens. Int. J. Appl. Eng. Research. 2011, 1, 777–785. [Google Scholar]

- Dzierwa, A.; Markopoulos, A.P. Influence of ball-burnishing process on surface topography parameters and tribological properties of hardened steel. Machines 2019, 7, 11. [Google Scholar] [CrossRef]

- Zhang, T.; Bugtai, N.; Marinescu, I.D. Burnishing of aerospace alloy: A theoretical—experimental approach. J. Manuf. Syst. 2015, 37, 472–478. [Google Scholar]

- Amini, C.; Jerez-Mesa, R.; Travieso-Rodriguez, J.A.; Llumà, J.; Estevez-Urra, A. Finite element analysis of ball burnishing on ball-end milled surfaces considering their original topology and residual stress. Metals 2020, 10, 638. [Google Scholar] [CrossRef]

- Jerez-mesa, R.; Travieso-rodríguez, J.A.; Landon, Y.; Dessein, G.; Lluma-fuentes, J. Comprehensive analysis of surface integrity modi fi cation of ball-end milled Ti-6Al-4V surfaces through vibration-assisted ball burnishing. J. Mater. Process. Technol. 2019, 267, 230–240. [Google Scholar] [CrossRef]

- Travieso-Rodríguez, J.A.; Jerez-Mesa, R.; Gómez-Gras, G.; Llumà-Fuentes, J.; Casadesús-Farràs, O.; Madueño-Guerrero, M. Hardening effect and fatigue behavior enhancement through ball burnishing on AISI 1038. J. Mater Res. Technol. 2019, 8, 5639–5646. [Google Scholar] [CrossRef]

- Jerez-Mesa, R.; Landon, Y.; Travieso-Rodriguez, J.A.; Dessein, G.; Llumà, J.; Wagner, V. Topological surface integrity modification of AISI 1038 alloy after vibration-assisted ball burnishing. Surf. Coat. Technol. 2018, 349, 364–377. [Google Scholar] [CrossRef]

- Mesa, R.J.; Gómez, G.; Travieso-Rodríguez, J.A.; Llumà, J.; Casadesús, O.; Madueño, M. Estudio Experimental del Efecto de Bruñido Sobre la Vida a Fatiga de Probetas de Acero AISI 1038; Mecánica: Elche, Spain, 2016. [Google Scholar]

- ISO 25178-2:2016; Geometrical Product Specifications (GPS)—Surface Quality Texture: Areal—Part 21: Terms, Definitions and Surface Quality Parameters Indication of Surface Texture. ISO: Geneva, Switzerland, 2016.

- Jerez-Mesa, R.; Gómez Gras, G.; Travieso-Rodriguez, J.A.; Llumà, J. Ultrasonic Vibration-Assisted Ball Burnishing Tool; Universitat Politècnica de Catalunya: Barcelona, Spain, 2018. [Google Scholar]

- ISO 6892-1:2009; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature, European Committee for Standardization. ISO: Geneva, Switzerland, 2009.

- Popov, V.L. Tratamiento riguroso del contacto—El Contacto Hertziano. In Principios y Aplicaciones de la Mecánica de Contacto en Tribología, Fricción y Adherencia, 3rd ed.; Martín-Martínez, J.M., Moreno-Flores, S., Eds.; Publicacions de la Universitat d’Alacant: Alicante, España, 2015; pp. 79–85. [Google Scholar]

- Gresham, R.M. ASM HANDBOOK Volume 18: Friction, Lubrication, and Wear Technology; Tribology & Lubrication Technology; Totten, G.E., Ed.; Portland State University: Portland, OR, USA, 2018; Volume 74, p. 84. [Google Scholar]

| Material | Fe | C | Mn | Ti | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|

| AISI 316 | 68.50 ± 0.03 | 0.02 ± 2 × 10−4 | 1.25 ± 4 × 10−3 | 0.01 ± 1 × 10−4 | 16.69 ± 0.01 | 9.92 ± 0.02 | 2.21 ± 0.005 |

| UNS S46500 | 74.40 ± 0.02 | 0.01 ± 6 × 10−4 | 0.03 ± 3 × 10−4 | 1.70 ± 0.02 | 11.69 ± 0.03 | 10.89 ± 0.01 | 1.01 ± 6 × 10−3 |

| Tool | Ball Mill UT Coating ø 10 [mm]—Two Teeth |

|---|---|

| Lateral pass width | 0.30 [mm] |

| Depth of cut | 0.20 [mm] |

| Feed rate | 600 [mm/min] |

| Cutting speed | 2000 [rpm] |

| Load | 270 [N]/470 [N] |

| Feed rate | 600 [mm/min] |

| Lateral pass width | 0.30 [mm] |

| Vibration-assistance | No |

| Material | E [GPa] | ν | σ0.2 [MPa] | UTS [MPa] | n |

|---|---|---|---|---|---|

| AISI 316 | 203.6 ± 0.4 | 0.287 ± 6 × 10−4 | 327 ± 2 | 588 ± 1 | 0.307 ± 8 × 10−4 |

| UNS S46500 | 198.8 ± 0.4 | 0.294 ± 2 × 10−4 | 1571 ± 8 | 1656 ± 5 | 0.029 ± 0.002 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torres, A.; Cuadrado, N.; Llumà, J.; Vilaseca, M.; Travieso-Rodriguez, J.A. Influence of the Stainless-Steel Microstructure on Tribological Behavior and Surface Integrity after Ball Burnishing. Materials 2022, 15, 8829. https://doi.org/10.3390/ma15248829

Torres A, Cuadrado N, Llumà J, Vilaseca M, Travieso-Rodriguez JA. Influence of the Stainless-Steel Microstructure on Tribological Behavior and Surface Integrity after Ball Burnishing. Materials. 2022; 15(24):8829. https://doi.org/10.3390/ma15248829

Chicago/Turabian StyleTorres, Alejandra, Nuria Cuadrado, Jordi Llumà, Montserrat Vilaseca, and J. Antonio Travieso-Rodriguez. 2022. "Influence of the Stainless-Steel Microstructure on Tribological Behavior and Surface Integrity after Ball Burnishing" Materials 15, no. 24: 8829. https://doi.org/10.3390/ma15248829

APA StyleTorres, A., Cuadrado, N., Llumà, J., Vilaseca, M., & Travieso-Rodriguez, J. A. (2022). Influence of the Stainless-Steel Microstructure on Tribological Behavior and Surface Integrity after Ball Burnishing. Materials, 15(24), 8829. https://doi.org/10.3390/ma15248829