Comparative Studies of c- and m-Plane AlN Seeds Grown by Physical Vapor Transport

Abstract

1. Introduction

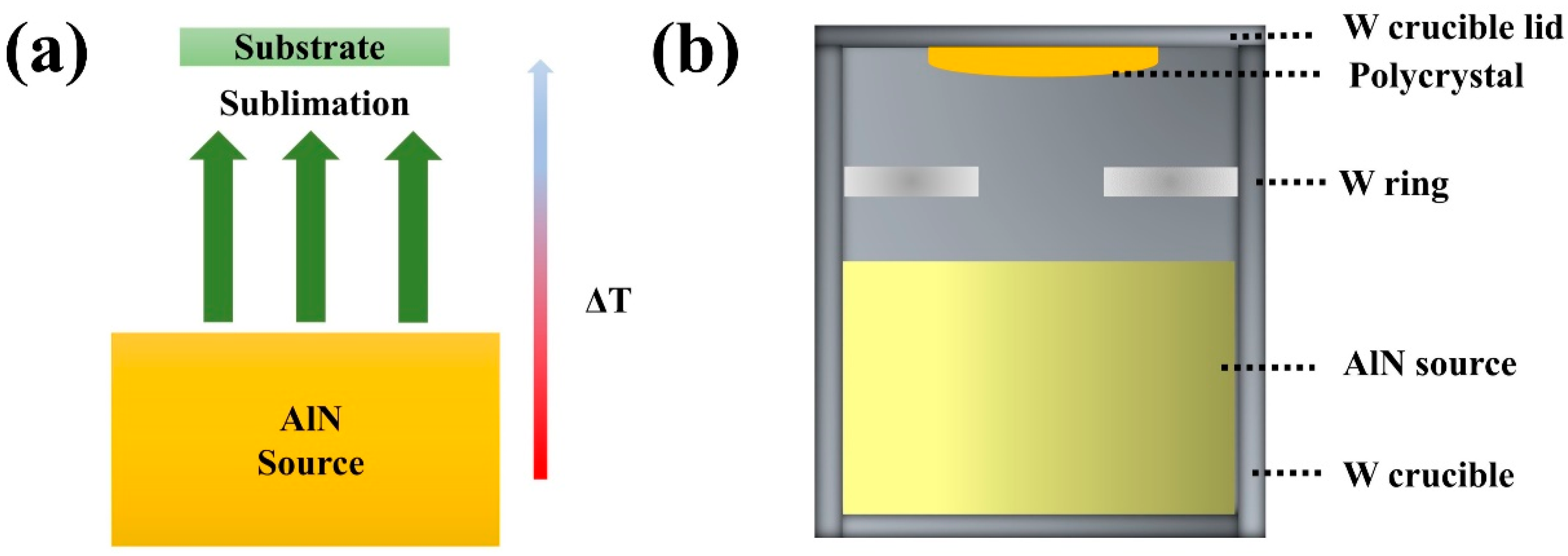

2. Experimental Section

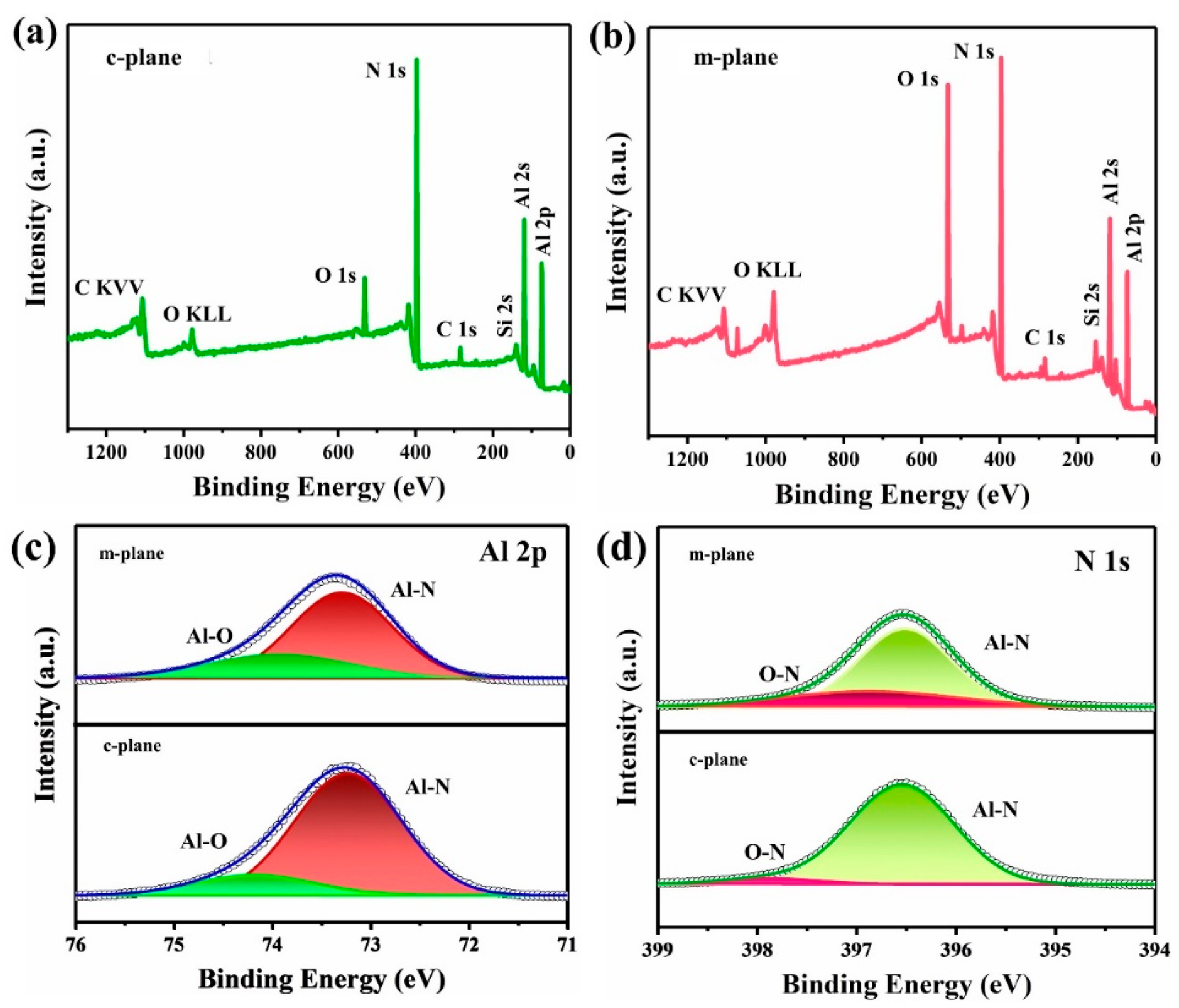

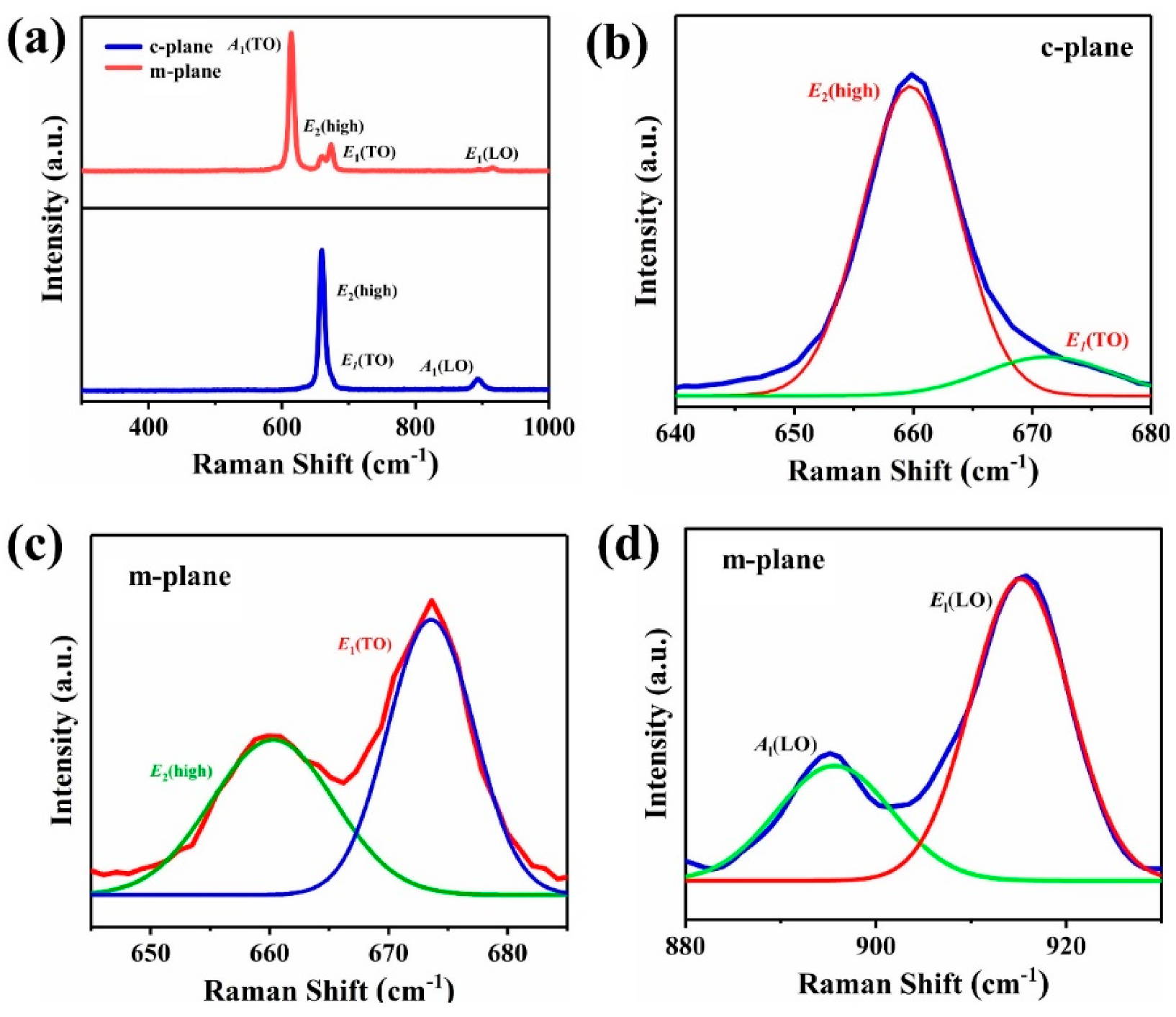

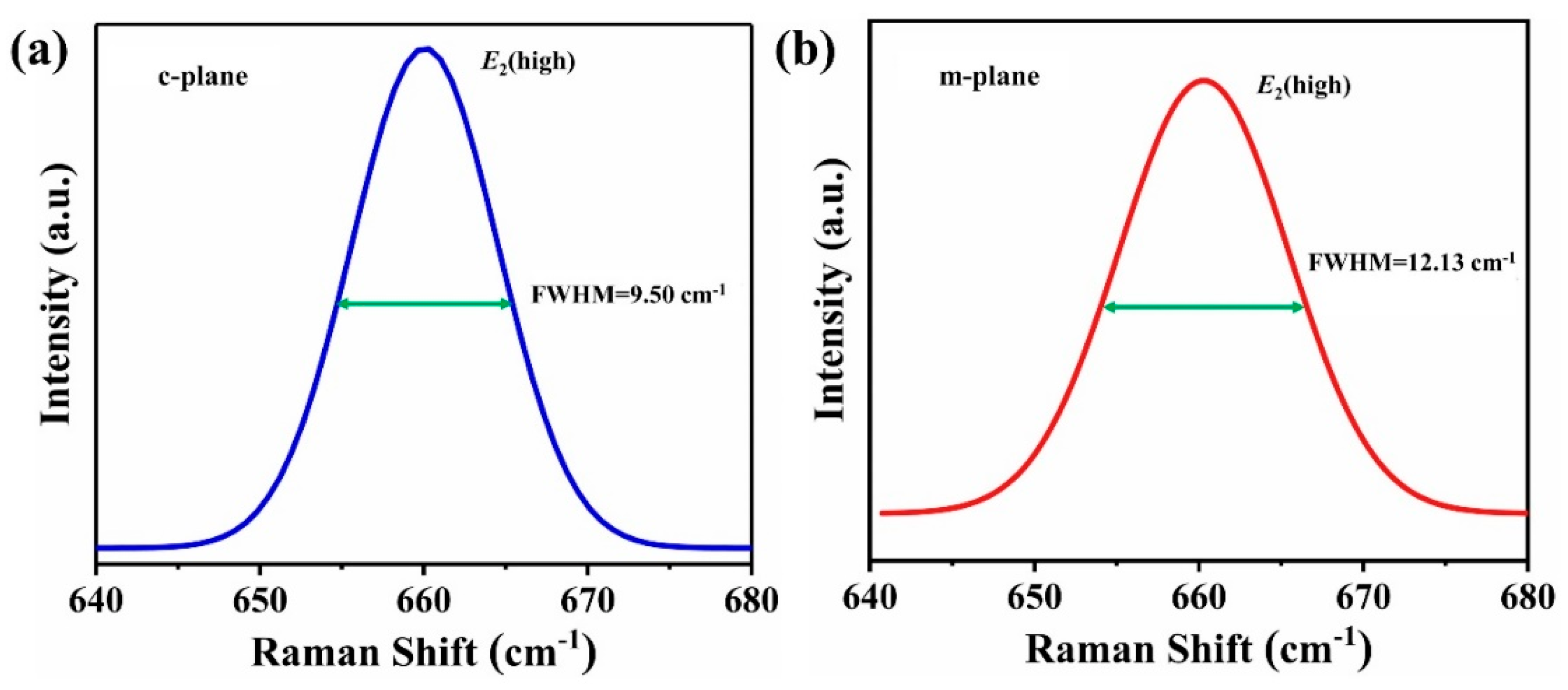

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Yang, J.; Zhao, D.; Liang, F.; Chen, P.; Liu, Z. High-quality AlN growth on flat sapphire at relatively low temperature by crystal island shape control method. Appl. Surf. Sci. 2022, 606, 154919. [Google Scholar] [CrossRef]

- Kumar, U.; Yadav, D.; Thakur, A.K.; Srivastav, K.K.; Upadhyay, S. Investigation on phase formation of Sr2SnO4 and effect of La-doping on its structural and optical properties. J. Therm. Anal. Calorim. 2019, 135, 1987–1999. [Google Scholar] [CrossRef]

- Hu, S.; Fang, H.; Liu, Y.; Peng, H.; Cheng, Q.; Chen, Z.; Dalmau, R.; Britt, J.; Schlesser, R.; Raghothamachar, B. Characterization of prismatic slip in PVT-grown AlN crystals. J. Cryst. Growth 2022, 584, 126548. [Google Scholar] [CrossRef]

- Cheema, H.; Kumar, S.; Alvi, P.A.; Choudhary, B.L.; Kumar, U. Synthesis and physical properties of nanopowder and electrical properties of bulk samples of ZnFe2-xNixO4 (x: 0, 0.05, 0.10). Adv. Powder Technol. 2020, 31, 4241–4252. [Google Scholar] [CrossRef]

- Yao, X.; Wang, G.; Tu, H.; Liu, S.; Yang, M.; Kong, Z.; Shao, Y.; Wu, Y.; Hao, X. Crystallographic orientation and strain distribution in AlN seeds grown on 6H-SiC substrates by the PVT method. Crystengcomm 2021, 23, 4946–4953. [Google Scholar] [CrossRef]

- Yin, J.; Chen, D.; Yang, H.; Liu, Y.; Talwar, D.N.; He, T.; Ferguson, I.T.; He, K.; Wan, L.; Feng, Z.C. Comparative spectroscopic studies of MOCVD grown AlN films on Al2O3 and 6H–SiC. J. Alloys Compd. 2021, 857, 157487. [Google Scholar] [CrossRef]

- Fu, D.; Wang, Q.; Zhang, G.; Zhu, R.; Liu, H.; Li, Z.; Wu, L. Modelling and simulation of oxygen transport during AlN crystal growth by the PVT method. J. Cryst. Growth 2020, 551, 125902. [Google Scholar] [CrossRef]

- Fu, D.; Lei, D.; Li, Z.; Zhang, G.; Huang, J.; Sun, X.; Wang, Q.; Li, D.; Wang, J.; Wu, L. Toward Φ56 mm Al-Polar AlN Single Crystals Grown by the Homoepitaxial PVT Method. Cryst. Growth Des. 2022, 22, 3462–3470. [Google Scholar] [CrossRef]

- Besisa, D.H.A.; Ewais, E.M.; Ahmed, Y.M.; Elhosiny, F.I.; Kuznetsov, D.V.; Fend, T. Densification and characterization of SiC-AlN composites for solar energy applications. Renew. Energy 2018, 129, 201–213. [Google Scholar] [CrossRef]

- Wang, F.; Xiao, F.; Song, D.; Qian, L.; Feng, Y.; Fu, B.; Dong, K.; Li, C.; Zhang, K. Research of micro area piezoelectric properties of AlN films and fabrication of high frequency SAW devices. Microelectron. Eng. 2018, 199, 63–68. [Google Scholar] [CrossRef]

- Liu, G.; Zhou, G.; Qin, Z.; Zhou, Q.; Zheng, R.; Wu, H.; Sun, Z. Luminescence characterizations of freestanding bulk single crystalline aluminum nitride towards optoelectronic application. CrystEngComm 2017, 19, 5522–5527. [Google Scholar] [CrossRef]

- Besleaga, C.; Dumitru, V.; Trinca, L.; Popa, A.; Negrila, C.; Kołodziejczyk, A.; Luculescu, C.; Ionescu, G.; Ripeanu, R.; Vladescu, A.; et al. Mechanical, Corrosion and Biological Properties of Room-Temperature Sputtered Aluminum Nitride Films with Dissimilar Nanostructure. Nanomaterials 2017, 7, 394. [Google Scholar] [CrossRef] [PubMed]

- Jeon, H.; Jeon, I.; Lee, G.S.; Bae, S.G.; Ahn, H.S.; Yang, M.; Yi, S.N.; Yu, Y.M.; Honda, Y.; Sawaki, N.; et al. AlN and AlGaN layers grown on Si (111) substrate by mixed-source hydride vapor phase epitaxy method. Jpn. J. Appl. Phys. 2016, 56, 01AD07. [Google Scholar] [CrossRef]

- Fleischmann, S.; Richter, E.; Mogilatenko, A.; Weyers, M.; Tränkle, G. Influence of AlN buffer layer on growth of AlGaN by HVPE. Phys. Status Solidi 2017, 254, 1600696. [Google Scholar] [CrossRef]

- Chaudhuri, R.; Bader, S.J.; Chen, Z.; Muller, D.A.; Xing, H.G.; Jena, D. A polarization-induced 2D hole gas in undoped gallium nitride quantum wells. Science 2019, 365, 1454–1457. [Google Scholar] [CrossRef]

- Chen, J.; Huang, J.; Su, X.; Niu, M.; Xu, K. Influence comparison of N2 and NH3 nitrogen sources on AlN films grown by halide vapor phase epitaxy. Chin. Phys. B 2020, 29, 076802. [Google Scholar] [CrossRef]

- E, Y.; Hao, Z.; Yu, J.; Wu, C.; Wang, L.; Xiong, B.; Wang, J.; Han, Y.; Sun, C.; Luo, Y. Studies on the nucleation of MBE grown III-nitride nanowires on Si. Chin. Phys. B 2017, 26, 016103. [Google Scholar]

- Zhao, Q.; Zhu, X.; Han, T.; Wang, Z.; Wu, J.; Yu, T. Realizing overgrowth in the homo-PVT process for 2 inch AlN single crystals. Crystengcomm 2022, 24, 1719–1724. [Google Scholar] [CrossRef]

- Wang, G.; Chen, C.; Shao, Y.; Chen, F.; Zhang, L.; Wu, Y.; Hao, X. High-aspect-ratio single-crystalline AlN nanowires: Free-catalytic PVT growth and field-emission studies. J. Alloys Compd. 2019, 794, 171–177. [Google Scholar] [CrossRef]

- Lu, P.; Collazo, R.; Dalmau, R.F.; Durkaya, G.; Dietz, N.; Raghothamachar, B.; Dudley, M.; Sitar, Z. Seeded growth of AlN bulk crystals in m- and c-orientation. J. Cryst. Growth 2009, 312, 58–63. [Google Scholar] [CrossRef]

- Li, H.; Wang, W.J.; Song, B.; Wu, R.; Li, J.; Sun, Y.F.; Zheng, Y.F.; Jian, J.K. Catalyst-free synthesis, morphology evolution and optical property of one-dimensional aluminum nitride nanostructure arrays. J. Alloys Compd. 2010, 503, 34–39. [Google Scholar] [CrossRef]

- Sumathi, R.R. Common issues in the hetero-epitaxial seeding on SiC substrates in the sublimation growth of AlN crystals. Appl. Phys. A-Mater. 2021, 127, 622. [Google Scholar] [CrossRef]

- Hartmann, C.; Matiwe, L.; Wollweber, J.; Gamov, I.; Irmscher, K.; Bickermann, M.; Straubinger, T. Favourable growth conditions for the preparation of bulk AlN single crystals by PVT. Crystengcomm 2020, 22, 1762–1768. [Google Scholar] [CrossRef]

- Zhang, L.; Qi, H.; Cheng, H.; Shi, Y.; Lai, Z.; Luo, M. Morphology and crystalline property of an AlN single crystal grown on AlN seed. J. Semicond. 2021, 42, 52101. [Google Scholar] [CrossRef]

- Cheng, H.; Jin, L.; Wu, H.; Qi, H.; Wang, Z.; Shi, Y.; Zhang, L. Growth Behavior of AlN Single Crystal. J. Synth. Cryst. 2020, 49, 2200. [Google Scholar]

- Hartmann, C.; Wollweber, J.; Dittmar, A.; Irmscher, K.; Kwasniewski, A.; Langhans, F.; Neugut, T.; Bickermann, M. Preparation of Bulk AlN Seeds by Spontaneous Nucleation of Freestanding Crystals. Jpn. J. Appl. Phys. 2013, 52, 6–8. [Google Scholar] [CrossRef]

- Chen, W.; Qin, Z.; Tian, X.; Zhong, X.; Sun, Z.; Li, B.; Zheng, R.; Guo, Y.; Wu, H. The Physical Vapor Transport Method for Bulk AlN Crystal Growth. Molecules 2019, 24, 1562. [Google Scholar] [CrossRef]

- Noveski, V.; Schlesser, R.; Mahajan, S.; Beaudoin, S.; Sitar, Z. Mass transfer in AlN crystal growth at high temperatures. J. Cryst. Growth 2004, 264, 369–378. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, L.; Wang, Y.; Shao, Y.; Chen, C.; Liu, G.; Yao, X.; Wu, Y.; Hao, X. Growth and Stress Analysis of Spontaneous Nucleationc-Plane Bulk AlN Crystals by a PVT Method. Cryst. Res. Technol. 2020, 55, 2000118. [Google Scholar] [CrossRef]

- Hartmann, C.; Dittmar, A.; Wollweber, J.; Bickermann, M. Bulk AlN growth by physical vapour transport. Semicond. Sci. Technol. 2014, 29, 084002. [Google Scholar] [CrossRef]

- Motamedi, P.; Cadien, K. XPS analysis of AlN thin films deposited by plasma enhanced atomic layer deposition. Appl. Surf. Sci. 2014, 315, 104–109. [Google Scholar] [CrossRef]

- Alexander, M.R.; Thompson, G.E.; Zhou, X.; Beamson, G.; Fairley, N. Quantification of oxide film thickness at the surface of aluminium using XPS. Surf. Interface Anal. 2002, 34, 485–489. [Google Scholar] [CrossRef]

- Davydov, V.Y.; Kitaev, Y.E.; Goncharuk, I.N.; Tsaregorodtsev, A.M.; Smirnov, A.N.; Lebedev, A.O.; Botnaryk, V.M.; Zhilyaev, Y.V.; Smirnov, M.B.; Mirgorodsky, A.P.; et al. Phonon spectrum of wurtzite GaN and AlN experiment and theory. J. Cryst. Growth 1998, 189–190, 656–660. [Google Scholar] [CrossRef]

- Filip, O.; Epelbaum, B.M.; Bickermann, M.; Heimann, P.; Nagata, S.; Winnacker, A. Seeded Growth of AlN on (0001)-Plane 6H-SiC Substrates. Mater. Sci. Forum 2009, 615–617, 983–986. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, W.; He, C.; Zhang, K.; He, L.; Chen, Z. Growth of high quality AlN/sapphire templates with high growth rate using a medium-temperature layer. Superlattice. Microst. 2019, 125, 343–347. [Google Scholar] [CrossRef]

- Zhang, L.; Qi, H.; Cheng, H.; Jin, L.; Shi, Y. Preparation and characterization of AlN seeds for homogeneous growth. J. Semicond. 2019, 40, 102801. [Google Scholar] [CrossRef]

- Sumathi, R.R.; Gille, P. Role of SiC substrate polarity on the growth and properties of bulk AlN single crystals. J. Mater. Sci. Mater. Electron. 2014, 25, 3733–3741. [Google Scholar] [CrossRef]

- Sarua, A.; Kuball, M.; Van Nostrand, J.E. Deformation potentials of the E2(high) phonon mode of AlN. Appl. Phys. Lett. 2002, 81, 1426–1428. [Google Scholar] [CrossRef]

| Phonon Symmetry | c-Plane | m-Plane | PVT on SiC [5] | PVT on W-Substrate [27] | CHVPE on a-Al2O3 [27] | Free-Stress [33] |

|---|---|---|---|---|---|---|

| E2(low) | - | - | 247.4 | 239 | 249 | 248.6 |

| A1(TO) | - | 614.13 | --- | 610 | 611 | 611.0 |

| E2(high) | 659.74 | 660.29 | 655.3 | 658 | 657 | 657.4 |

| E1(TO) | 671.28 | 673.56 | - | 670 | 671 | 670.8 |

| A1(LO) | 893.13 | 895.64 | 902.7 | - | 890 | 890.0 |

| E1(LO) | - | 915.22 | - | 914 | 912 | 912.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, X.; Kong, Z.; Liu, S.; Wang, Y.; Shao, Y.; Wu, Y.; Hao, X. Comparative Studies of c- and m-Plane AlN Seeds Grown by Physical Vapor Transport. Materials 2022, 15, 8791. https://doi.org/10.3390/ma15248791

Yao X, Kong Z, Liu S, Wang Y, Shao Y, Wu Y, Hao X. Comparative Studies of c- and m-Plane AlN Seeds Grown by Physical Vapor Transport. Materials. 2022; 15(24):8791. https://doi.org/10.3390/ma15248791

Chicago/Turabian StyleYao, Xiaogang, Zhen Kong, Shengfu Liu, Yong Wang, Yongliang Shao, Yongzhong Wu, and Xiaopeng Hao. 2022. "Comparative Studies of c- and m-Plane AlN Seeds Grown by Physical Vapor Transport" Materials 15, no. 24: 8791. https://doi.org/10.3390/ma15248791

APA StyleYao, X., Kong, Z., Liu, S., Wang, Y., Shao, Y., Wu, Y., & Hao, X. (2022). Comparative Studies of c- and m-Plane AlN Seeds Grown by Physical Vapor Transport. Materials, 15(24), 8791. https://doi.org/10.3390/ma15248791