Cooling Subgrade Effectiveness by L-Shaped Two-Phase Closed Thermosyphons with Different Inclination Angles and XPS Insulation Boards in Permafrost Regions

Abstract

1. Introduction

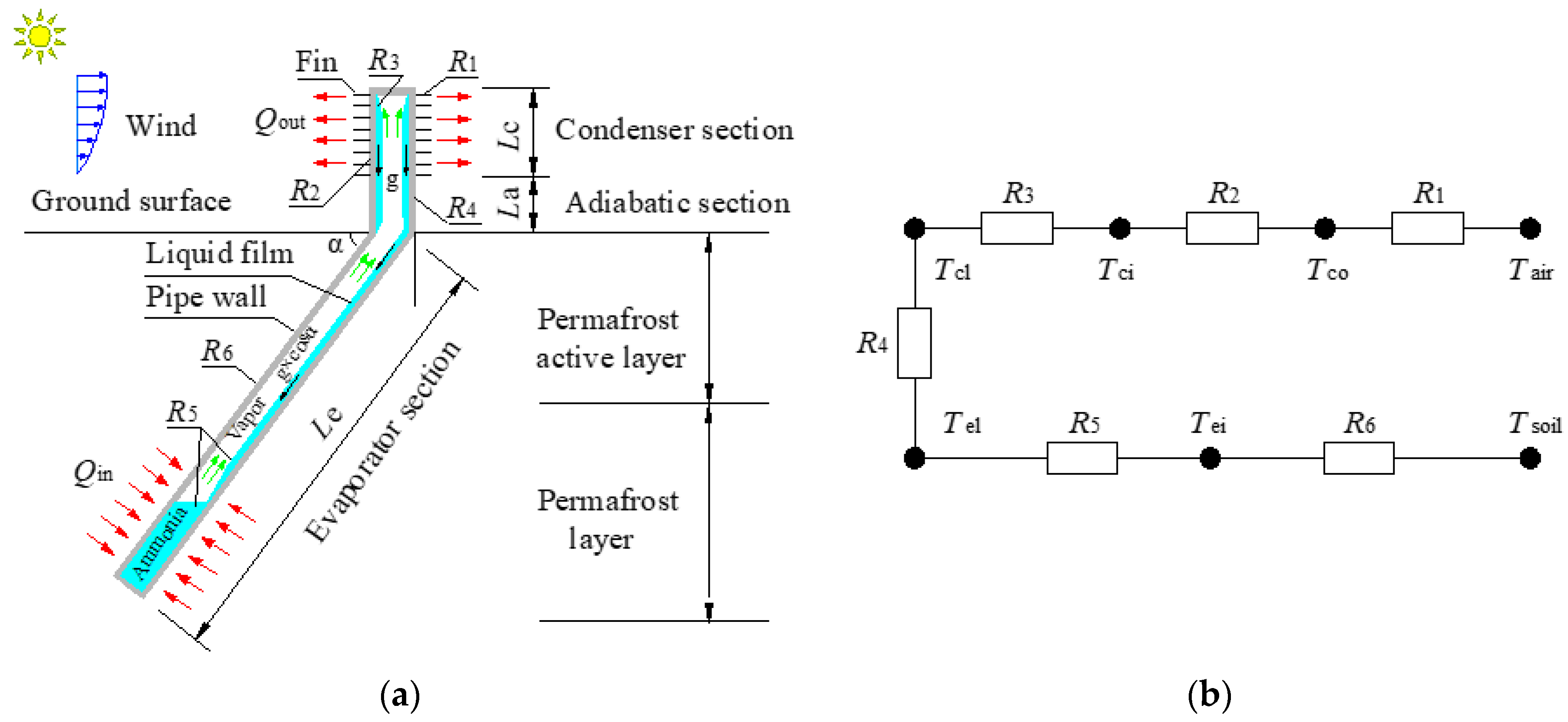

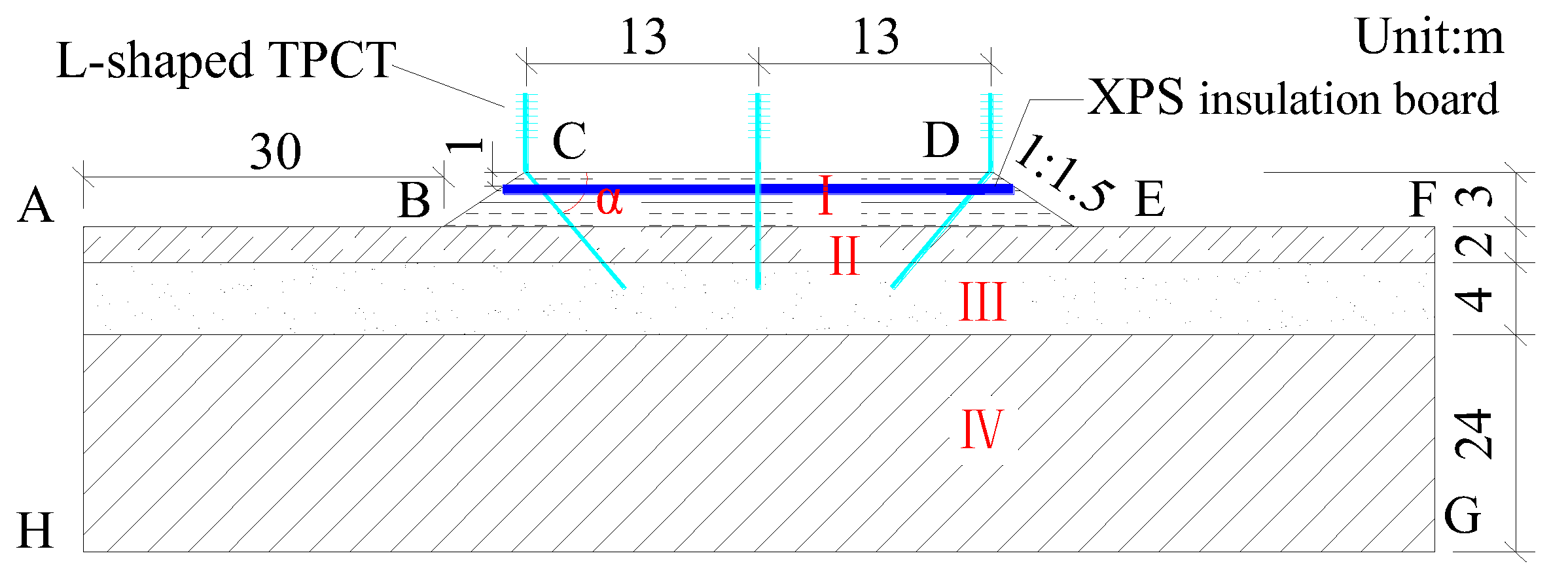

2. Heat Transfer Model of the Subgrade with L-Shaped TPCTs

2.1. Heat Conduction Equation of Soil

2.2. Coupled Air Temperature—L-Shaped TPCT—Subgrade Soil Heat Transfer Model

- (1)

- Condenser section

- (2)

- Adiabatic section

- (3)

- Evaporator section

3. Finite Element Calculation Model and Verification

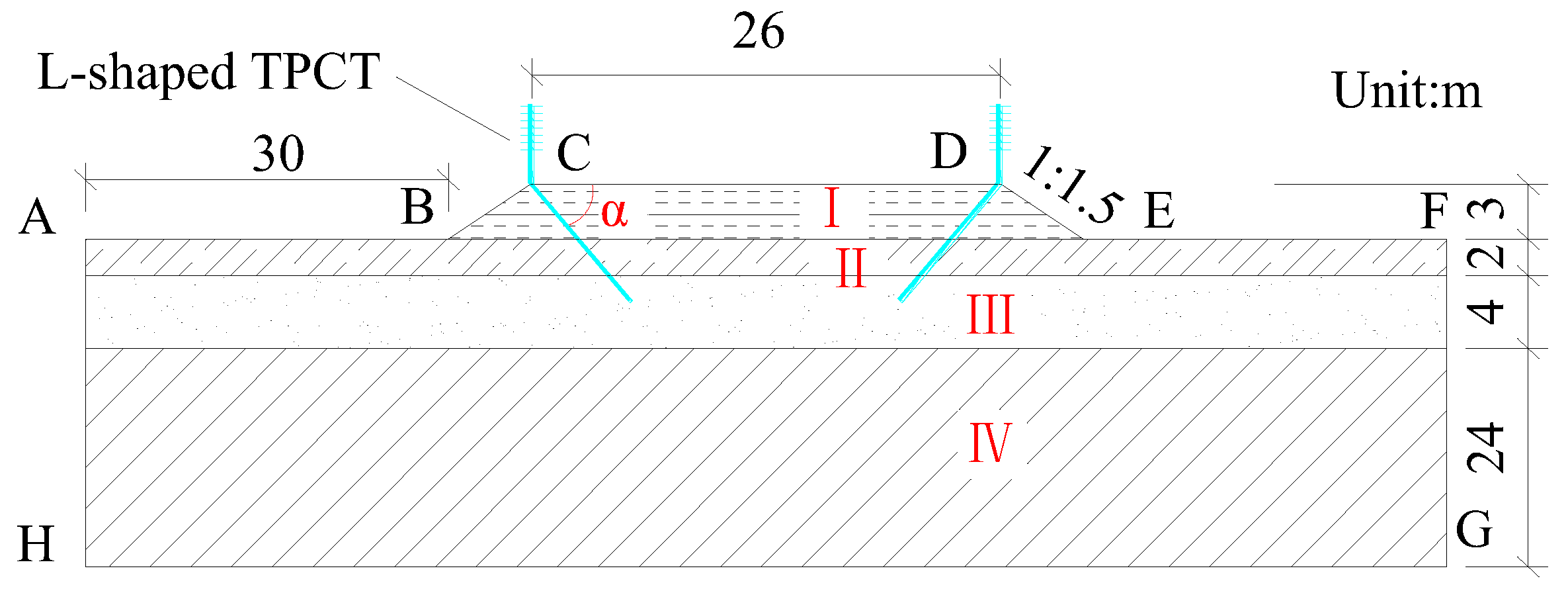

3.1. Model Establishment and Boundary Conditions

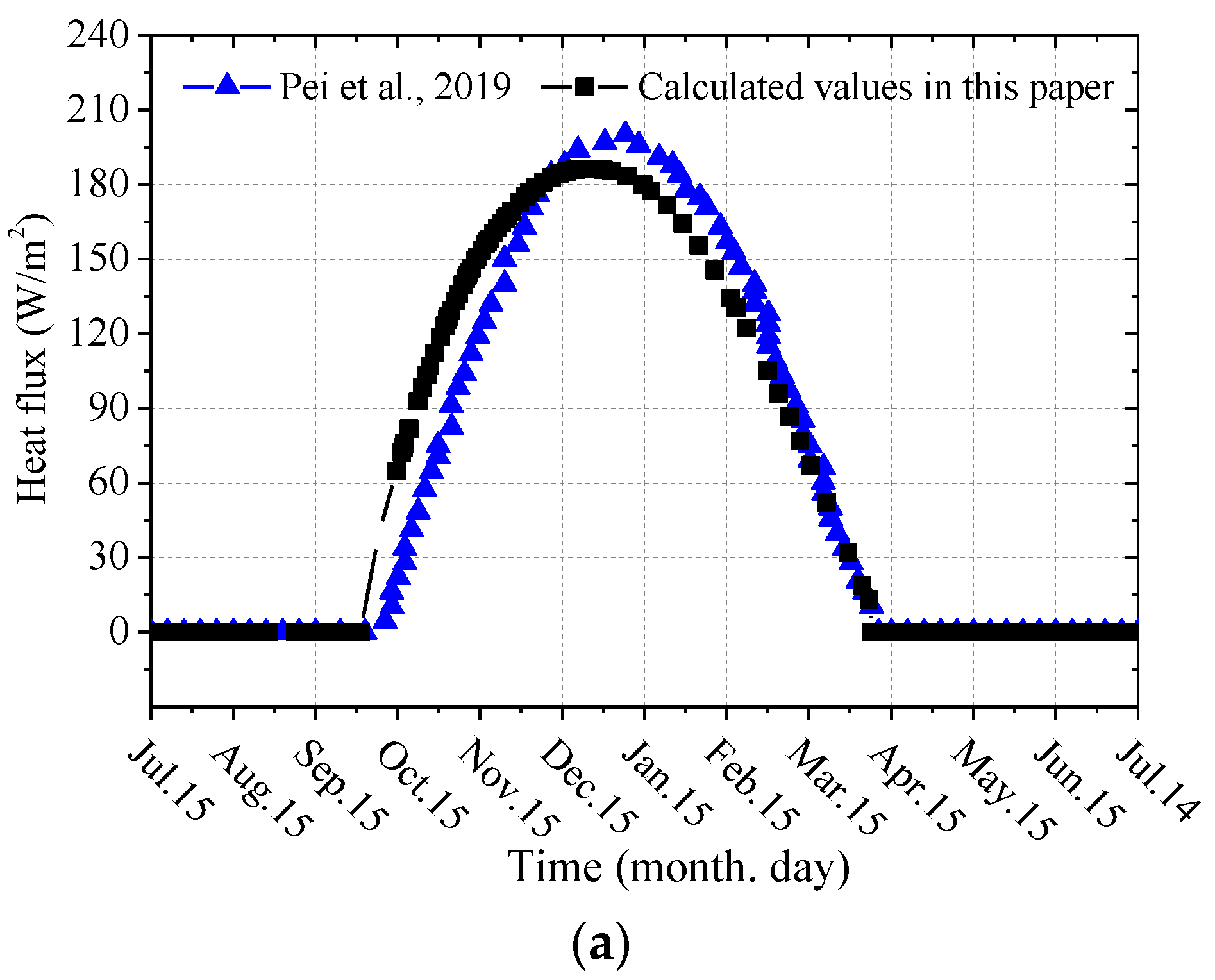

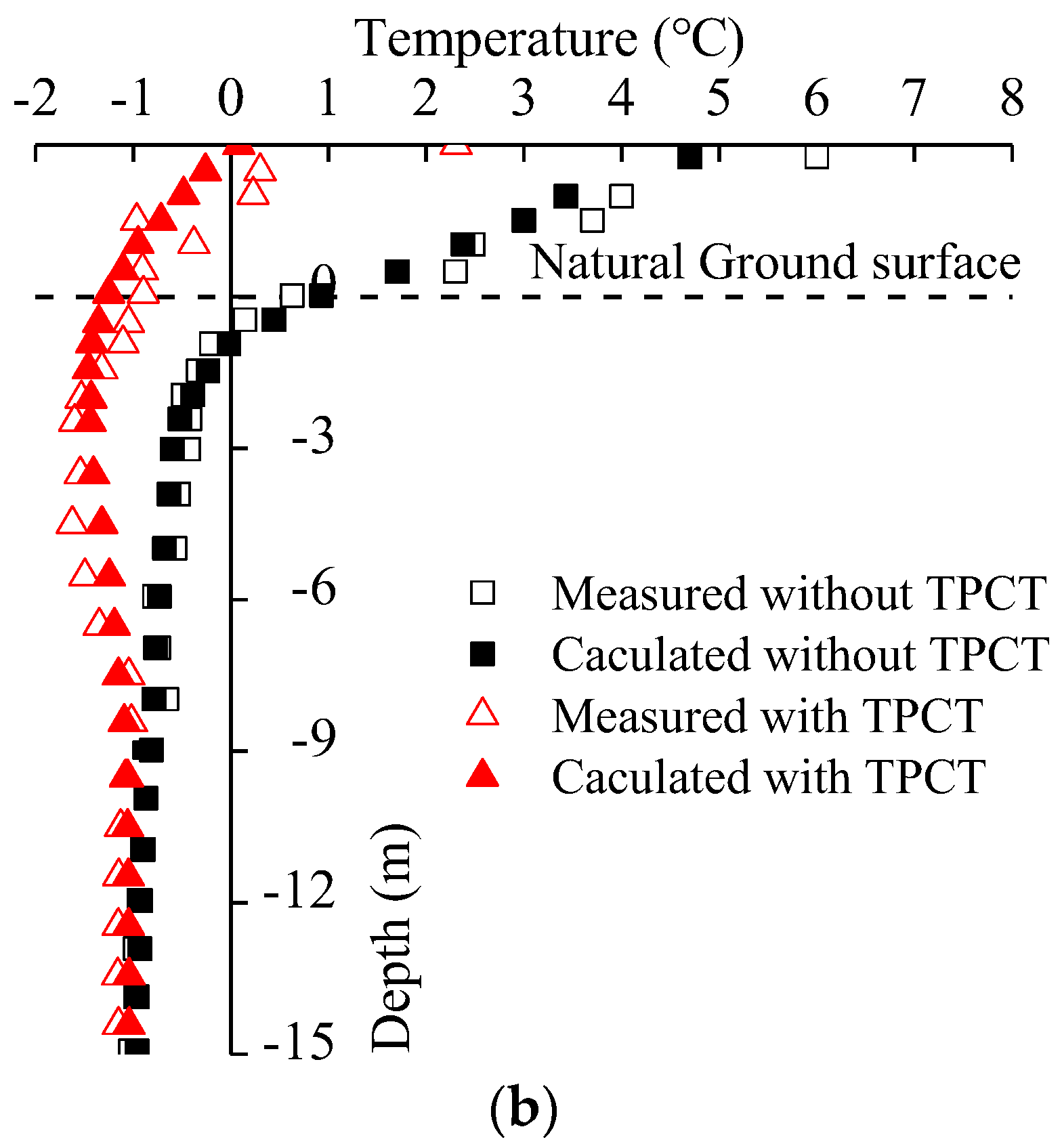

3.2. Model Validation

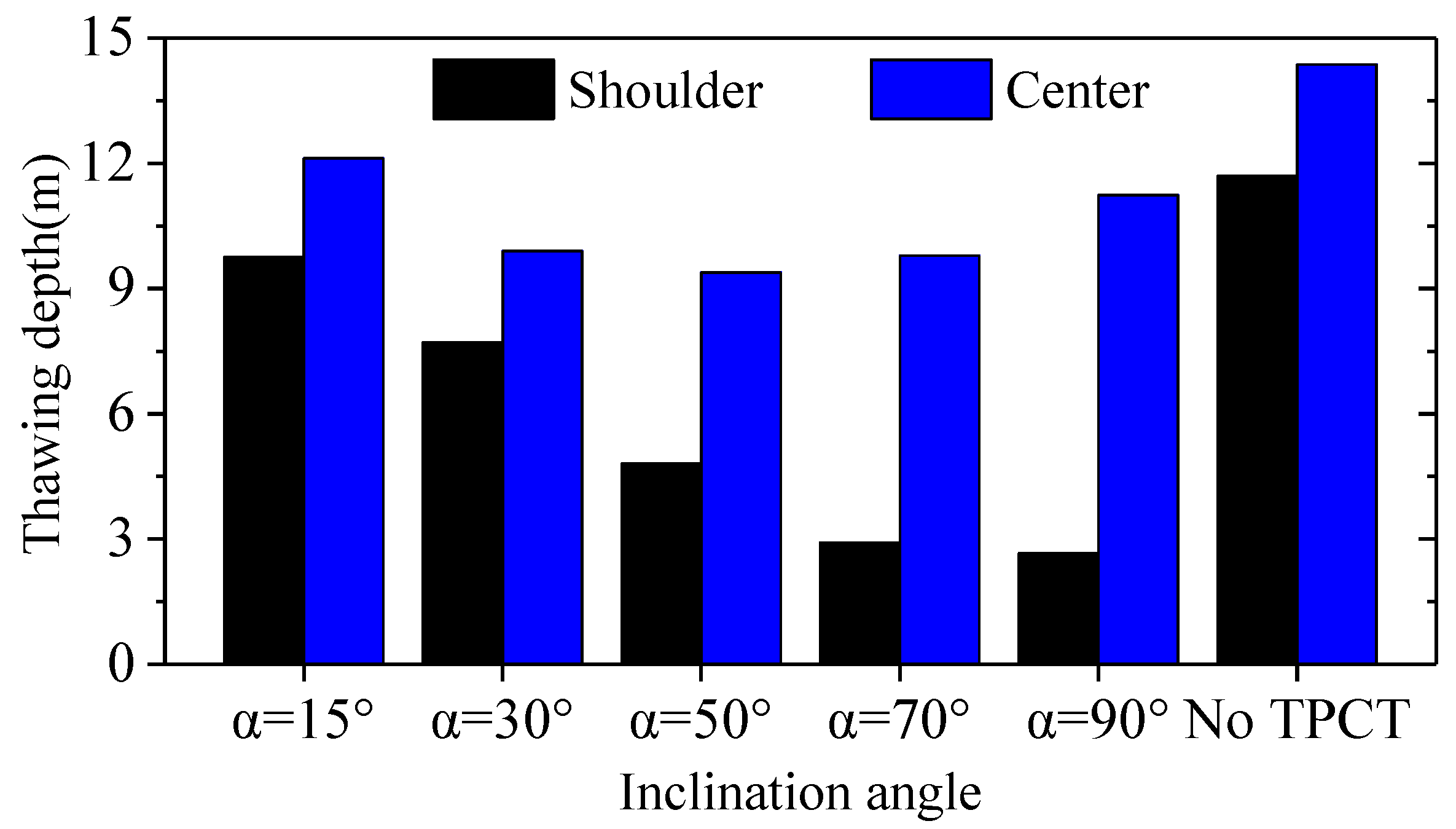

4. Influence of Evaporator Section Inclinations on the Cooling Effectiveness

4.1. Heat-Transfer Characteristics of L-Shaped TPCTs

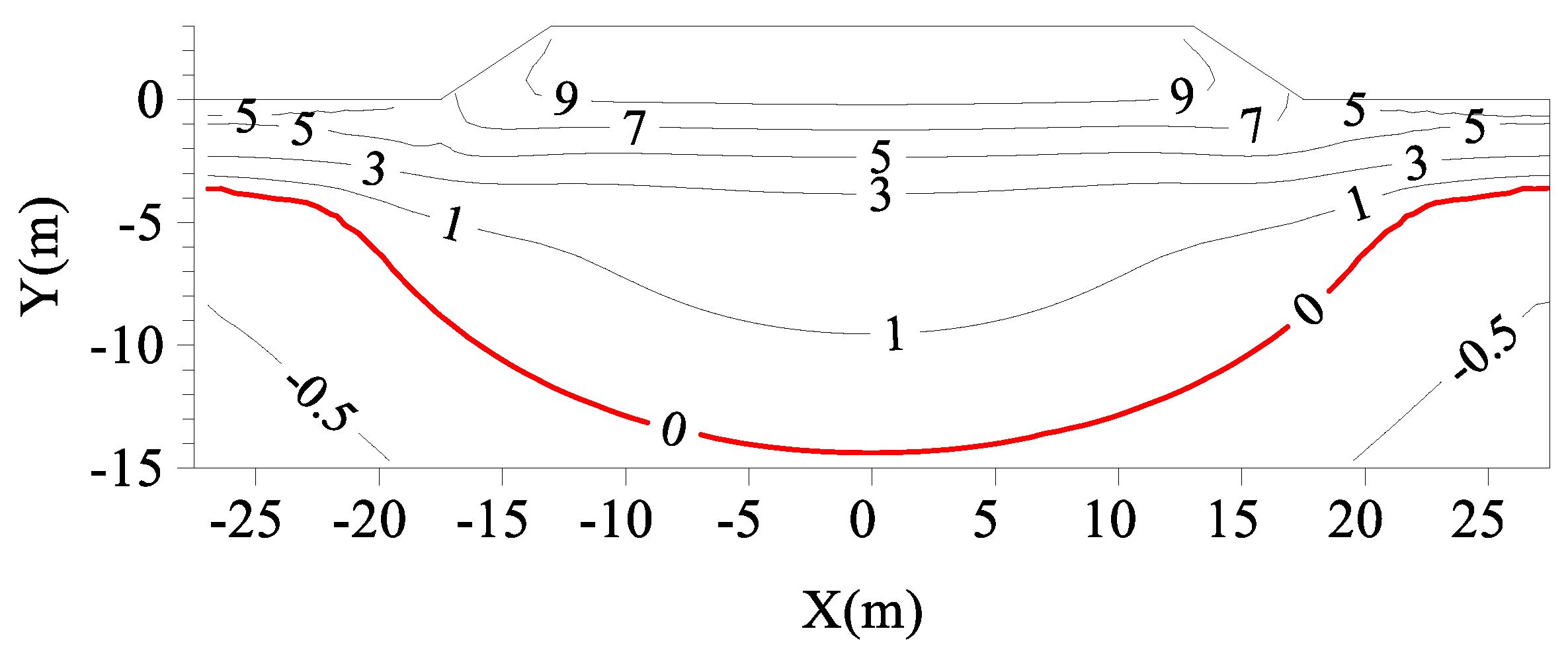

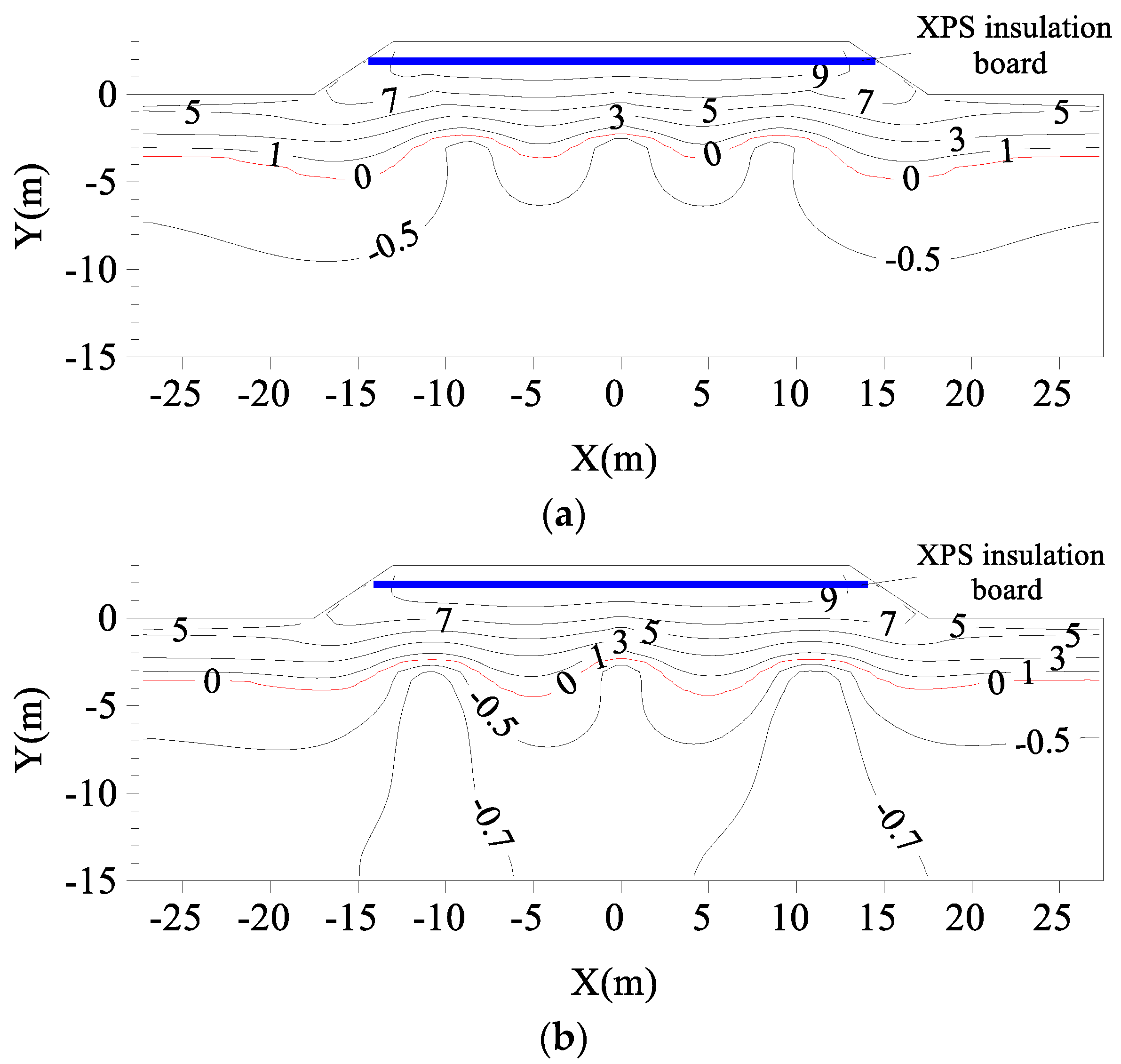

4.2. Geotemperature Distribution in the Subgrade

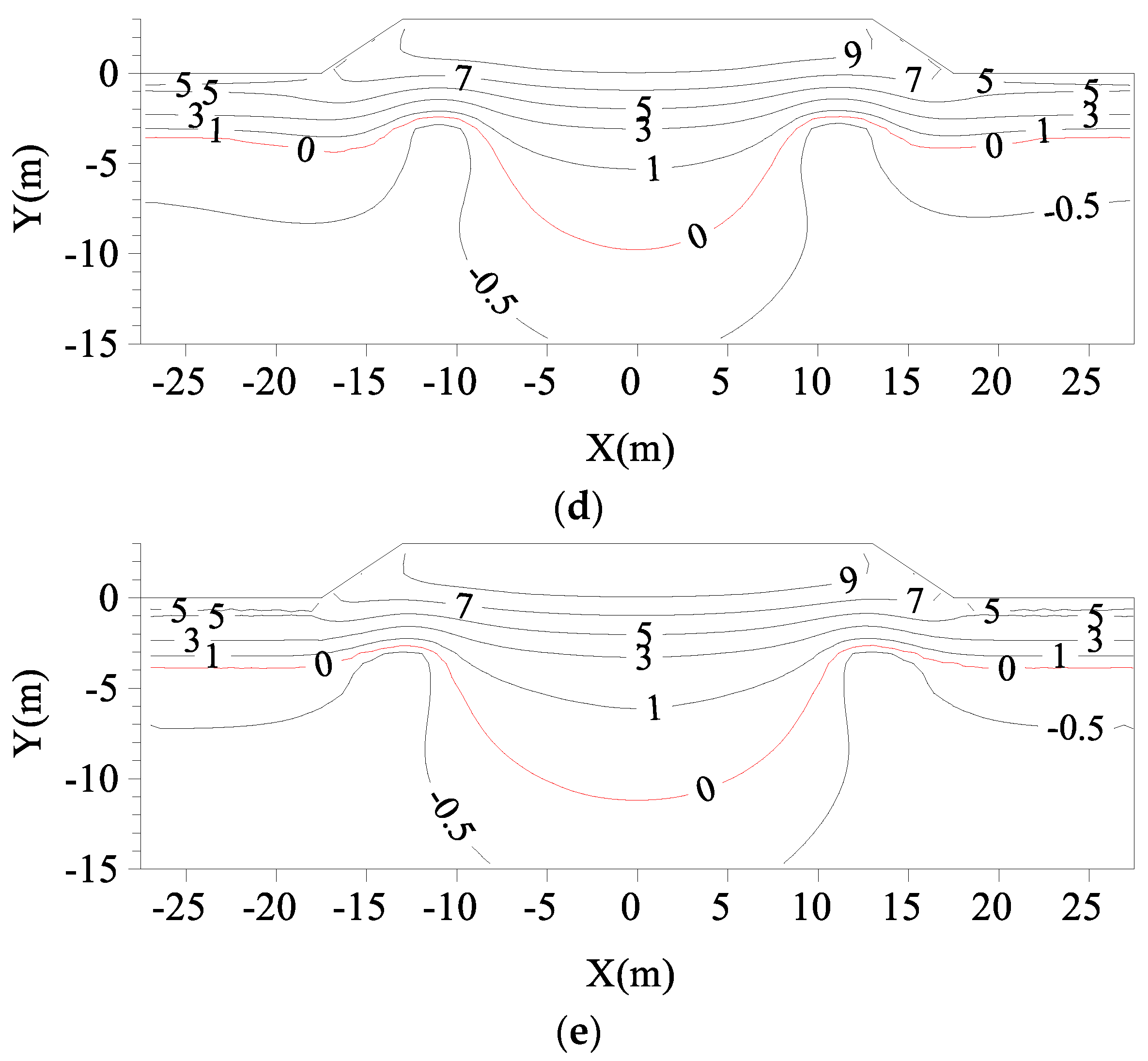

5. Composite Subgrades with an L-Shaped TPCTs/Vertical TPCT/XPS Insulation Board System

6. Conclusions

- A coupled heat transfer calculation model of air temperature–L-shaped TPCT–subgrade soil, considering the changes in the evaporator section inclination angles of the L-shaped TPCT, was proposed. The comparison between the calculated results and the field-measured data showed that the model could simulate the thermal stability of a wide subgrade with L-shaped TPCTs in permafrost regions.

- In comparison to a vertical TPCT, the L-shaped TPCT had a relatively good cooling effect on the subgrade, as a whole, when the inclination angles of the evaporator section were 50° and 70°. However, in the 30th year, the thawing depth at the center of the subgrade with L-shaped TPCTs reached 9.0 m below the ground surface. When the evaporator section inclination angle of the TPCT was 50°, the corresponding heat flux was the largest, reaching a maximum value of 165.7 W·m−2 in January.

- The composite subgrade with L-Shaped TPCTs/vertical TPCT/XPS insulation board system is an effective method to protect the permafrost foundation and improve the long-term thermal stability of a wide subgrade. The maximum heat flux of evaporation section of the L-shaped TPCT and vertical TPCT of the composite subgrade was 196.8 W·m2 and 165.7 W·m2, respectively, throughout the working time, and the maximum heat flux of L-shaped TPCT was increased by 18.8%. However, this paper only studied the influence of L-shaped two-phase closed thermosyphons and XPS insulation boards on the subgrade temperature field, and more studies should be carried out on the deformation of the composite subgrade in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, Q.; Fan, K.; Qian, J.; Guo, L.; You, Y. Key issues of highway construction in permafrost regions in China. Sci. Sin. Technol. 2014, 44, 425–432. [Google Scholar]

- Niu, F.; Luo, J.; Lin, Z.; Fang, J.; Liu, M. Thaw-induced slope failures and stability analyses in permafrost regions of the Qinghai-Tibet Plateau, China. Landslides 2016, 13, 55–65. [Google Scholar] [CrossRef]

- Yu, F.; Qi, J.L.; Lai, Y.M.; Sivasithamparam, N.; Yao, X.L.; Zhang, M.Y.; Liu, Y.Z.; Wu, G.L. Typical embankment settlement/heave patterns of the Qinghai–Tibet highway in permafrost regions: Formation and evolution. Eng. Geol. 2016, 214, 147–156. [Google Scholar] [CrossRef]

- Ma, W.; Mu, Y.H.; Xie, S.B.; Mao, Y.C.; Chen, D. Thermal-mechanical influences and environmental effects of expressway construction on the Qinghai-Tibet permafrost engineering corridor. Adv. Earth Sci. 2017, 32, 459–464. [Google Scholar]

- Zhu, D.; Dong, Y.; Liu, G. Study of the influence of large-width asphalt-concrete pavement on the thermal characteristics of underlying permafrost. J. Glaciol. Geocryol. 2014, 36, 845–853. [Google Scholar]

- Wu, Z.W.; Liu, Y.Z. Frozen Subsoil and Engineering; Ocean Press: Beijing, China, 2005. [Google Scholar]

- Kong, S.; Wen, Z.; Wu, Q.; Wang, D. Applicability evaluation on application of thermosyphon in embankment engineering of expressway in permafrost regions of Qinghai-Tibet plateau. J. Cent. South Univ. (Sci. Technol.) 2019, 50, 1384–1391. [Google Scholar]

- Wen, Z.; Sheng, Y.; Ma, W.; Qi, J. In situ experimental study on thermal protection effects of the insulation method on warm permafrost. Cold Reg. Sci. Technol. 2008, 53, 369–381. [Google Scholar] [CrossRef]

- Heuer, C.E. The Application of Heat Pipes on the Trans-Alaska Pipeline, United States Army Crops of Engineers; Cold Regions Research and Engineering Laboratory: New Hampshire, NH, USA, 1979. [Google Scholar]

- Ma, L.; Shang, L.; Zhong, D.; Ji, Z. Experimental investigation of a two-phase closed thermosyphon charged with hydrocarbon and Freon refrigerants. Appl. Energy 2017, 207, 665–673. [Google Scholar] [CrossRef]

- Gao, J.; Lai, Y.; Zhang, M.; Chang, D. Thermal effect of heating two-phase closed thermosyphons on the high-speed railway embankment in seasonally frozen regions. Appl. Therm. Eng. 2018, 141, 948–957. [Google Scholar] [CrossRef]

- Jiang, D.; Wang, X.; Liu, D.; Qiong, X. Experimental study on stability of thermal pile foundation of transmission tower in permafrost foundation of Qinghai-Tibet railway. Chin. J. Rock Mech. Eng. 2014, 33, 4258–4263. [Google Scholar]

- Song, Y.; Jin, L.; Zhang, J. In-situ study on cooling characteristics of two-phase closed thermosyphon embankment of Qinghai-Tibet Highway in permafrost regions. Cold Reg. Sci. Technol. 2013, 93, 12–19. [Google Scholar] [CrossRef]

- Yu, F.; Zhang, M.; Lai, Y.; Liu, Y.; Qi, J.; Yao, X. formation of a highway embankment installed with two-phase closed thermosyphons in permafrost regions: Field experiment and geothermal modelling. Appl. Therm. Eng. 2017, 115, 670–681. [Google Scholar] [CrossRef]

- Dong, Y.H.; Lai, Y.M.; Chen, W. Cooling effect of combined L-shaped thermosyphon, crushed-rock revetment and insulation for high-grade highways in permafrost regions. Chin. J. Geotech. Eng. 2012, 34, 1043–1049. [Google Scholar]

- Zhang, M.; Lai, Y.; Zhang, J.; Sun, Z. Numerical study on cooling characteristics of two-phase closed thermosyphon embankment in permafrost regions. Cold Reg. Sci. Technol. 2011, 65, 203–210. [Google Scholar] [CrossRef]

- Zhang, M.Y.; Pei, W.S.; Lai, Y.M.; Niu, F.J.; Li, S.Y. Numerical study of the thermal characteristics of a shallow tunnel section with a two-phase closed thermosyphon group in a permafrost region under climate warming. Int. J. Heat Mass Tran. 2017, 104, 952–963. [Google Scholar] [CrossRef]

- Wu, J.J.; Ma, W.; Sun, Z.Z.; Wen, Z. In-situ study on cooling effect of the two-phase closed thermosyphon and insulation combinational embankment of the Qinghai-Tibet Railway. Cold Reg. Sci. Technol. 2010, 60, 234–244. [Google Scholar] [CrossRef]

- Zhang, M.; Lai, Y.; Wu, Q.; Yu, Q.; Zhao, T.; Pei, W.; Zhang, J. A full-scale field experiment to evaluate the cooling performance of a novel composite embankment in permafrost regions. Int. J. Heat Mass Transf. 2016, 95, 1047–1056. [Google Scholar] [CrossRef]

- Mozumder, A.K.; Akon, A.F.; Chowdhury, M.S.H.; Banik, S.C. Performance of heat pipe for different working fluids and fill ratios. J. Mech. Eng. 2010, 41, 96–102. [Google Scholar] [CrossRef]

- Eami, M.R.S.; Noie, S.H.; Khoshnoodi, M. Effect of aspect ratio and filling ratio on thermal performance of an tilted two-phase closed thermosyphon. Iran. J. Sci. Technol. Trans. B Eng. 2008, 32, 39–51. [Google Scholar]

- Cao, X.L.; Cao, S.J.; Zhu, X.J.; Zeng, W.; Wang, F.F.; Li, J.; Chi, D. Experimental investigation on heat transfer characteristics of novel gravity-assisted heat pipe heat exchanger. J. Cent. South Univ. (Sci. Technol.) 2012, 43, 402–406. [Google Scholar]

- Zhang, M.; Lai, Y.; Dong, Y.; Jin, L.; Pei, W.; Harbor, J. Laboratory investigation of the heat transfer characteristics of a two–phase closed thermosyphon. Cold Reg. Sci. Technol. 2013, 95, 67–73. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, S.; Wei, Q. Effect simulation of different declining angles of thermosyphons used in Qinghai-Tibet railway permafrost embankment. China Civ. Eng. J. 2006, 39, 108–113. [Google Scholar]

- Pei, W.; Zhang, M.; Lai, Y.; Yan, Z.; Li, S. Evaluation of the ground heat control capacity of a novel Air-L-Shaped TPCT-Ground (ALTG) cooling system in cold regions. Energy 2019, 179, 655–668. [Google Scholar] [CrossRef]

- Zhou, Y.; Guo, C.; Wang, X.; Jiang, D.; Liu, D.; He, F.; Hu, Y. Prediction of long-term cooling effect of thermal pipe foundation of transmission tower in permafrost regions considering the change of thermal pipe power. Chin. J. Rock Mech. Eng. 2019, 38, 1461–1469. [Google Scholar]

- Zhou, Y.; Wang, X.; Niu, F.; He, F.; Guo, C.; Liu, D.; Jiang, D. Frost jacking characteristics of transmission tower pile foundations with and without thermosyphons in permafrost regions of Qinghai–Tibet plateau. J. Cold Reg. Eng. 2021, 35, 04021004. [Google Scholar] [CrossRef]

- Hou, Y.; Wu, Q.; Dong, J.; Luo, J.; Zhang, M.; Ye, Z. Numerical simulation of efficient cooling by coupled RR and TCPT on railway embankments in permafrost regions. Appl. Therm. Eng. 2018, 133, 351–360. [Google Scholar] [CrossRef]

- Mu, Y.; Yu, Q.; Li, G.; Wei, M.; Mao, Y.-C.; Guo, L. Application of thermosyphons and insulated boards in Qinghai-Tibet DC interconnection project in permafrost regions. Chin. J. Geotech. Eng. 2014, 36, 1896–1907. [Google Scholar]

- Fan, X. Study on heat transfer characteristics of gravity heat pipe and ground source heat pump composite rode snowmelt system. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2017. [Google Scholar]

- Khazaee, I.; Hosseini, R.; Kianifar, A.; Noie, S.H. Experimental consideration and correlation of heat transfer of a two-phase closed thermosyphon due to the inclination angle, filling ratio, and aspect ratio. J. Enhanc. Heat Transf. 2011, 18, 31–40. [Google Scholar] [CrossRef]

- Jin, L.; Wang, S.; Mu, k.; Hui, P. Cooling effect of thermosyhpon subgrade for Qinghai-Tibet highway. J. Traffic Transp. Eng. 2016, 16, 45–58. [Google Scholar]

- JTG 3363–2019; Code for Design of Ground Base and Foundation of Highway Bridges and Culverts. China Communications Press: Beijing, China, 2019.

- She, W.; Chen, Y.Q.; Zhang, Y.S.; Jones, M.R. Characterization and simulation of microstructure and thermal properties of foamed concrete. Constr. Build. Mater. 2013, 47, 1278–1291. [Google Scholar]

- Chen, D. Dynamic three-dimensional heat transfer calculation for uninsulated slab-on-ground constructions. Energy Build. 2013, 60, 420–428. [Google Scholar] [CrossRef]

- Plotnikov, A. Stabilizing the temperature regime of a frozen foundation bed using thermal insulation and cooling mechanisms. Soil Mech. Found. Eng. 2020, 57, 329–335. [Google Scholar] [CrossRef]

| Parameter | λa (W·m−1·°C−1) | ca (J·kg−1·°C−1) | ρa (kg·m−3) | μ (Pa·s) |

|---|---|---|---|---|

| Value | 0.023 | 10040 | 0.641 | 1.75 × 10−5 |

| Parameter | λl (W·m−1·°C−1) | cpa (J·kg−1·°C−1) | ρl (kg·m−3) | ρva (kg·m−3) | μ (Pa·s) | Lr (kJ·kg−1) |

|---|---|---|---|---|---|---|

| Value | 0.298 | 2125 | 638.6 | 3.48 | 2.35 × 10−4 | 1263 |

| Soil Layer | Soil Layer Thickness (m) | Dry Density (kg·m−3) | Thermal Conductivity (W·m−1·°C−1) | Specific Heat Capacity (J·kg−1·°C−1) | Latent Heat (J·m−3) | ||

|---|---|---|---|---|---|---|---|

| Frozen Soils | Unfrozen Soils | Frozen Soils | Unfrozen Soils | ||||

| Subgrade fill | 3 | 2060 | 7128 | 6908 | 928 | 1081 | 2.04 × 107 |

| Gravelly sand | 2 | 1900 | 5944 | 5220 | 960 | 1292 | 2.32 × 107 |

| Clayey loam | 4 | 1600 | 4864 | 4050 | 1174 | 1473 | 6.03 × 107 |

| Mudstone | 24 | 1800 | 6567 | 5306 | 1025 | 1166 | 3.77 × 107 |

| Variable | T0 (°C) | A (°C) |

|---|---|---|

| Air temperature | −3.0 | 10.5 |

| Asphalt pavement surfaces (CD) | 3.5 | 15 |

| Slope surfaces (BC, DE) | 1.7 | 13 |

| Natural ground surfaces (AB, EF) | −0.5 | 12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Wang, X.; Guo, C.; Hu, Y.; He, F.; Liu, D.; Jiang, D. Cooling Subgrade Effectiveness by L-Shaped Two-Phase Closed Thermosyphons with Different Inclination Angles and XPS Insulation Boards in Permafrost Regions. Materials 2022, 15, 8470. https://doi.org/10.3390/ma15238470

Zhou Y, Wang X, Guo C, Hu Y, He F, Liu D, Jiang D. Cooling Subgrade Effectiveness by L-Shaped Two-Phase Closed Thermosyphons with Different Inclination Angles and XPS Insulation Boards in Permafrost Regions. Materials. 2022; 15(23):8470. https://doi.org/10.3390/ma15238470

Chicago/Turabian StyleZhou, Yalong, Xu Wang, Chunxiang Guo, Yuan Hu, Fei He, Deren Liu, and Daijun Jiang. 2022. "Cooling Subgrade Effectiveness by L-Shaped Two-Phase Closed Thermosyphons with Different Inclination Angles and XPS Insulation Boards in Permafrost Regions" Materials 15, no. 23: 8470. https://doi.org/10.3390/ma15238470

APA StyleZhou, Y., Wang, X., Guo, C., Hu, Y., He, F., Liu, D., & Jiang, D. (2022). Cooling Subgrade Effectiveness by L-Shaped Two-Phase Closed Thermosyphons with Different Inclination Angles and XPS Insulation Boards in Permafrost Regions. Materials, 15(23), 8470. https://doi.org/10.3390/ma15238470