Seed Layer Optimisation for Ultra-Thin Sb2Se3 Solar Cells on TiO2 by Vapour Transport Deposition

Abstract

1. Introduction

2. Materials and Methods

3. Results

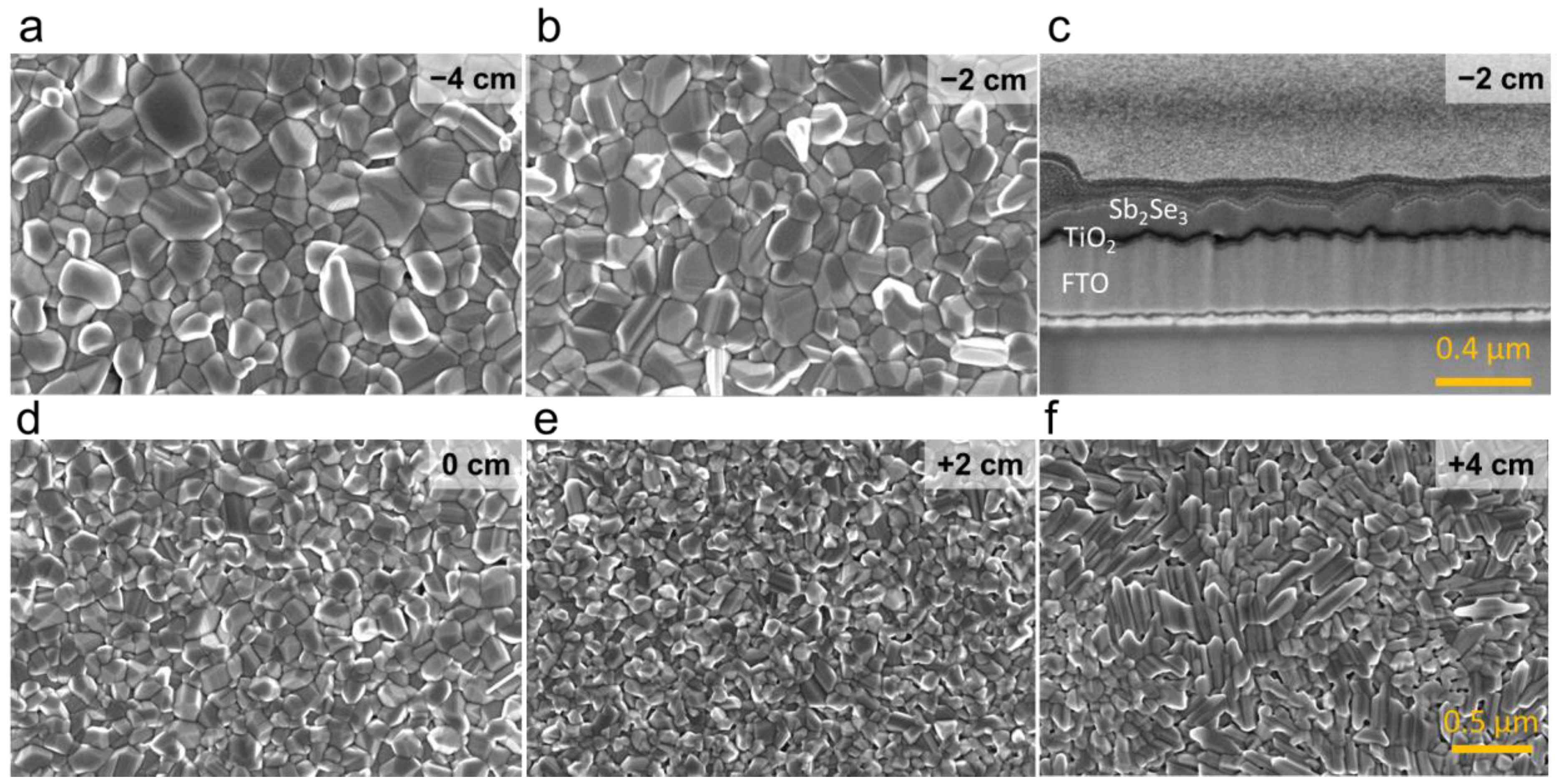

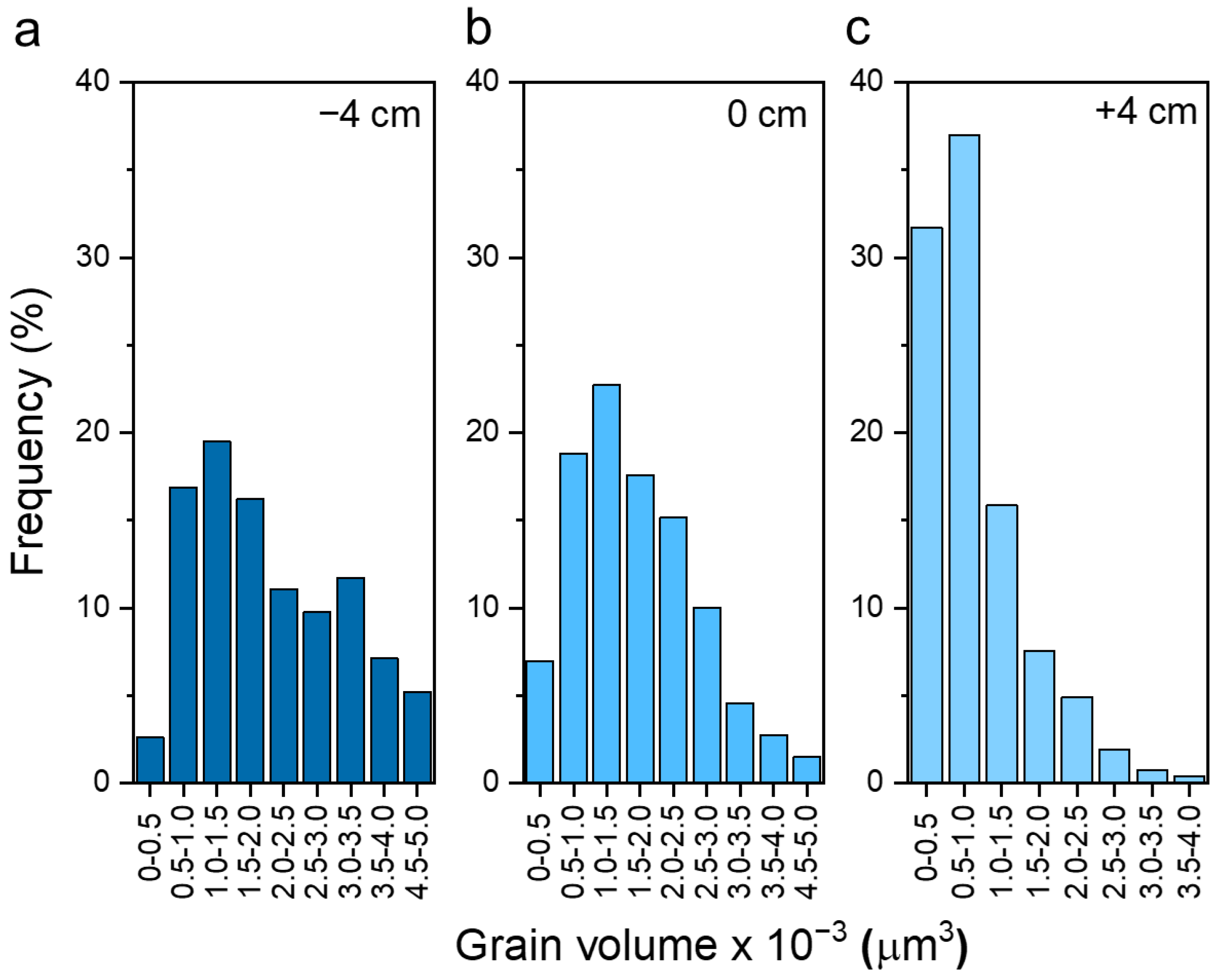

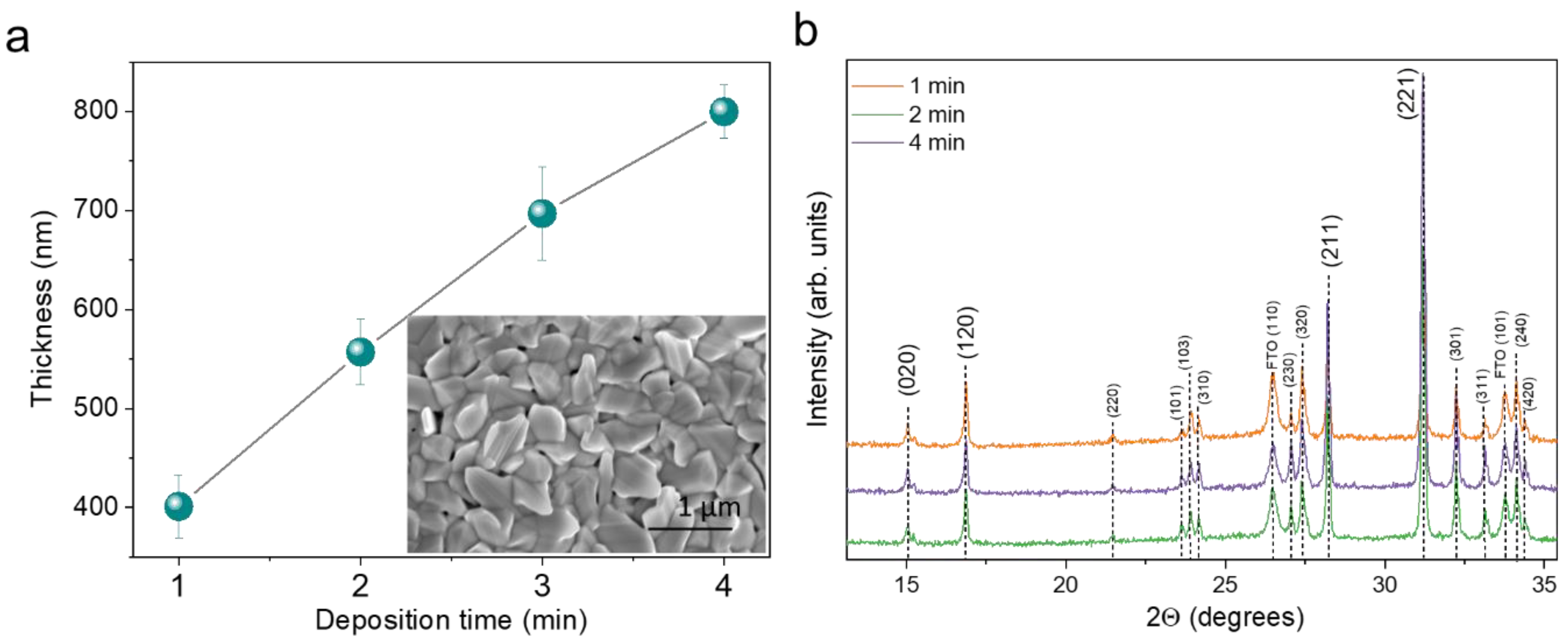

3.1. Optimization of the Seed Layer

3.2. Solar Cell Fabrication and Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nakamura, M.; Yamaguchi, K.; Kimoto, Y.; Yasaki, Y.; Kato, T.; Sugimoto, H. Cd-Free Cu(In, Ga)(Se, S)2 Thin-Film Solar Cell with Record Efficiency of 23.35%. IEEE J. Photovolt. 2019, 9, 1863–1867. [Google Scholar] [CrossRef]

- Green, M.; Dunlop, E.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Hao, X. Solar cell efficiency tables (version 57). Prog. Photovolt. Res. Appl. 2021, 29, 3–15. [Google Scholar] [CrossRef]

- Sharma, R.; Sharma, A.; Agarwal, S.; Dhaka, M.S. Stability and efficiency issues, solutions and advancements in perovskite solar cells: A review. Sol. Energy 2022, 244, 516–535. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, L.; Chen, S.; Qin, S.; Liu, X.; Chen, J.; Xue, D.-J.; Luo, M.; Cao, Y.; Cheng, Y.; et al. Thin-film Sb2Se3 photovoltaics with oriented one-dimensional ribbons and benign grain boundaries. Nat. Photonics 2015, 9, 409–415. [Google Scholar] [CrossRef]

- Duan, Z.; Liang, X.; Feng, Y.; Ma, H.; Liang, B.; Wang, Y.; Luo, S.; Wang, S.; Schropp, R.E.I.; Mai, Y.; et al. Sb2Se3 Thin-Film Solar Cells Exceeding 10% Power Conversion Efficiency Enabled by Injection Vapor Deposition Technology. Adv. Mater. 2022, 34, 2202969. [Google Scholar] [CrossRef]

- Mamta; Maurya, K.K.; Singh, V.N. Influence of buffer layers on antimony selenide based solar cell. Opt. Mater. 2022, 126, 112240. [Google Scholar] [CrossRef]

- Spalatu, N.; Katerski, A. Effect of TiO2 Annealing Conditions on the Performance of Antimony Selenide Thin Film Solar Cell. Master’s Thesis, Tallinn University of Technology, Tallinn, Estonia, 2021. [Google Scholar]

- Fleck, N. The Role of Surfaces, Interfaces and Oxides in Antimony Selenide Photovoltaics; University of Liverpool: Liverpool, UK, 2021. [Google Scholar]

- Zhang, Z.; Hu, M.; Jia, T.; Du, J.; Chen, C.; Wang, C.; Liu, Z.; Shi, T.; Tang, J.; Leng, Y. Suppressing the Trapping Process by Interfacial Charge Extraction in Antimony Selenide Heterojunctions. ACS Energy Lett. 2021, 6, 1740–1748. [Google Scholar] [CrossRef]

- Luo, Y.-D.; Chen, M.-d.; Tang, R.; Azam, M.; Chen, S.; Zheng, Z.-H.; Su, Z.-H.; Fan, P.; Ma, H.-L.; Liang, G.-X. Energy band alignment for Cd-free antimony triselenide substrate structured solar cells by Co-sputtering ZnSnO buffer layer. Sol. Energy Mater. Sol. Cells 2022, 240, 111721. [Google Scholar] [CrossRef]

- Guo, H.; Chen, Z.; Wang, X.; Cang, Q.; Ma, C.; Jia, X.; Yuan, N.; Ding, J. Significant increase in efficiency and limited toxicity of a solar cell based on Sb2Se3 with SnO2 as a buffer layer. J. Mater. Chem. C 2019, 7, 14350–14356. [Google Scholar] [CrossRef]

- Hobson, T.D.C.; Phillips, L.J.; Hutter, O.S.; Shiel, H.; Swallow, J.E.N.; Savory, C.N.; Nayak, P.K.; Mariotti, S.; Das, B.; Bowen, L.; et al. Isotype Heterojunction Solar Cells Using n-Type Sb2Se3 Thin Films. Chem. Mater. 2020, 32, 2621–2630. [Google Scholar] [CrossRef]

- Li, K.; Chen, C.; Lu, S.; Wang, C.; Wang, S.; Lu, Y.; Tang, J. Orientation Engineering in Low-Dimensional Crystal-Structural Materials via Seed Screening. Adv. Mater. 2019, 31, 1903914. [Google Scholar] [CrossRef] [PubMed]

- Kondrotas, R.; Zhang, J.; Wang, C.; Tang, J. Growth mechanism of Sb2Se3 thin films for photovoltaic application by vapor transport deposition. Sol. Energy Mater. Sol. Cells 2019, 199, 16–23. [Google Scholar] [CrossRef]

- Hutter, O.S.; Phillips, L.J.; Yates, P.J.; Major, J.D.; Durose, K. CSS Antimony Selenide Film Morphology and High Efficiency PV Devices. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018; pp. 27–31. [Google Scholar]

- Spalatu, N.; Krautmann, R.; Katerski, A.; Karber, E.; Josepson, R.; Hiie, J.; Acik, I.O.; Krunks, M. Screening and optimization of processing temperature for Sb2Se3 thin film growth protocol: Interrelation between grain structure, interface intermixing and solar cell performance. Sol. Energy Mater. Sol. Cells 2021, 225, 111045. [Google Scholar] [CrossRef]

- Wang, W.; Cao, Z.; Wu, L.; Chen, G.; Ao, J.; Luo, J.; Zhang, Y. Interface Etching Leads to the Inversion of the Conduction Band Offset between the CdS/Sb2Se3 Heterojunction and High-Efficient Sb2Se3 Solar Cells. ACS Appl. Energy Mater. 2022, 5, 2531–2541. [Google Scholar] [CrossRef]

- Wen, X.; Chen, C.; Lu, S.; Li, K.; Kondrotas, R.; Zhao, Y.; Chen, W.; Gao, L.; Wang, C.; Zhang, J.; et al. Vapor transport deposition of antimony selenide thin film solar cells with 7.6% efficiency. Nat. Commun. 2018, 9, 2179. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Zhao, Y.; Lu, S.; Li, K.; Li, Y.; Yang, B.; Chen, W.; Wang, L.; Li, D.; Deng, H. Accelerated optimization of TiO2/Sb2Se3 thin film solar cells by high-throughput combinatorial approach. Adv. Energy Mater. 2017, 7, 1700866. [Google Scholar] [CrossRef]

- Zhang, H.; Yuan, S.; Deng, H.; Ishaq, M.; Yang, X.; Hou, T.; Shah, U.A.; Song, H.; Tang, J. Controllable orientations for Sb2S3 solar cells by vertical VTD method. Prog. Photovolt. Res. Appl. 2020, 28, 823–832. [Google Scholar] [CrossRef]

- Lei, H.; Chen, J.; Tan, Z.; Fang, G. Review of Recent Progress in Antimony Chalcogenide-Based Solar Cells: Materials and Devices. Sol. RRL 2019, 3, 1900026. [Google Scholar] [CrossRef]

- Wang, C.; Lu, S.; Li, S.; Wang, S.; Lin, X.; Zhang, J.; Kondrotas, R.; Li, K.; Chen, C.; Tang, J. Efficiency improvement of flexible Sb2Se3 solar cells with non-toxic buffer layer via interface engineering. Nano Energy 2020, 71, 104577. [Google Scholar] [CrossRef]

- Wang, W.; Yao, L.; Dong, J.; Wu, L.; Cao, Z.; Hui, L.; Chen, G.; Luo, J.; Zhang, Y. Interface Modification Uncovers the Potential Application of SnO2/TiO2 Double Electron Transport Layer in Efficient Cadmium-Free Sb2Se3 Devices. Adv. Mater. Interfaces 2022, 9, 2102464. [Google Scholar] [CrossRef]

- Heriche, H.; Rouabah, Z.; Bouarissa, N. High-efficiency CIGS solar cells with optimization of layers thickness and doping. Optik 2016, 127, 11751–11757. [Google Scholar] [CrossRef]

- Bouarissa, A.; Gueddim, A.; Bouarissa, N.; Maghraoui-Meherezi, H. Modeling of ZnO/MoS2/CZTS photovoltaic solar cell through window, buffer and absorber layers optimization. Mater. Sci. Eng. B 2021, 263, 114816. [Google Scholar] [CrossRef]

- Gupta, A.; Parikh, V.; Compaan, A.D. High efficiency ultra-thin sputtered CdTe solar cells. Sol. Energy Mater. Sol. Cells 2006, 90, 2263–2271. [Google Scholar] [CrossRef]

- Wang, K.; Chen, C.; Liao, H.; Wang, S.; Tang, J.; Beard, M.C.; Yang, Y. Both Free and Trapped Carriers Contribute to Photocurrent of Sb2Se3 Solar Cells. J. Phys. Chem. Lett. 2019, 10, 4881–4887. [Google Scholar] [CrossRef] [PubMed]

- Kashiwaya, S.; Morasch, J.; Streibel, V.; Toupance, T.; Jaegermann, W.; Klein, A. The Work Function of TiO2. Surfaces 2018, 1, 73–89. [Google Scholar] [CrossRef]

- Shiel, H.; Hutter, O.S.; Phillips, L.J.; Swallow, J.E.N.; Jones, L.A.H.; Featherstone, T.J.; Smiles, M.J.; Thakur, P.K.; Lee, T.-L.; Dhanak, V.R.; et al. Natural Band Alignments and Band Offsets of Sb2Se3 Solar Cells. ACS Appl. Energy Mater. 2020, 3, 11617–11626. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, S.; Che, B.; Li, C.; Chen, X.; Chen, H.; Tang, R.; Wang, X.; Chen, G.; Wang, T. Regulating Deposition Kinetics via A Novel Additive-assisted Chemical Bath Deposition Technology Enables 10.57%-efficient Sb2Se3 Solar Cells. Energy Environ. Sci. 2022. [Google Scholar] [CrossRef]

- Shen, K.; Ou, C.; Huang, T.; Zhu, H.; Li, J.; Li, Z.; Mai, Y. Mechanisms and modification of nonlinear shunt leakage in Sb2Se3 thin film solar cells. Sol. Energy Mater. Sol. Cells 2018, 186, 58–65. [Google Scholar] [CrossRef]

| Deposition Time | JSC, mA/cm2 | VOC, mV | FF, % | PCE, % | Thickness, nm | Limit JSC, mA/cm2 |

|---|---|---|---|---|---|---|

| 1 min Peak cell | 29.4 ± 1.6 31.6 | 286 ± 6 282 | 47.8 ± 0.8 48.6 | 4.0 ± 0.25 4.33 | 400 ± 32 | 36.5 |

| 2 min Peak cell | 27.2 ± 3.9 30.5 | 282 ± 8 289 | 47 ± 1.0 47.9 | 3.6 ± 0.6 4.23 | 557 ± 33 | 38.1 |

| 3 min Peak cell | 30.2 ± 1.8 32.6 | 316 ± 7 311 | 48.4 ± 0.5 47.8 | 4.6 ± 0.2 4.86 | 697 ± 47 | 39.1 |

| 4 min Peak cell | 24.5 ± 3.4 29.4 | 292 ± 2 292 | 47.6 ± 0.5 47.2 | 3.4 ± 0.45 4.05 | 800 ± 27 | 39.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Juškėnas, R.; Naujokaitis, A.; Drabavičius, A.; Pakštas, V.; Vainauskas, D.; Kondrotas, R. Seed Layer Optimisation for Ultra-Thin Sb2Se3 Solar Cells on TiO2 by Vapour Transport Deposition. Materials 2022, 15, 8356. https://doi.org/10.3390/ma15238356

Juškėnas R, Naujokaitis A, Drabavičius A, Pakštas V, Vainauskas D, Kondrotas R. Seed Layer Optimisation for Ultra-Thin Sb2Se3 Solar Cells on TiO2 by Vapour Transport Deposition. Materials. 2022; 15(23):8356. https://doi.org/10.3390/ma15238356

Chicago/Turabian StyleJuškėnas, Remigijus, Arnas Naujokaitis, Audrius Drabavičius, Vidas Pakštas, Deividas Vainauskas, and Rokas Kondrotas. 2022. "Seed Layer Optimisation for Ultra-Thin Sb2Se3 Solar Cells on TiO2 by Vapour Transport Deposition" Materials 15, no. 23: 8356. https://doi.org/10.3390/ma15238356

APA StyleJuškėnas, R., Naujokaitis, A., Drabavičius, A., Pakštas, V., Vainauskas, D., & Kondrotas, R. (2022). Seed Layer Optimisation for Ultra-Thin Sb2Se3 Solar Cells on TiO2 by Vapour Transport Deposition. Materials, 15(23), 8356. https://doi.org/10.3390/ma15238356