(Cr1−xAlx)N Coating Deposition by Short-Pulse High-Power Dual Magnetron Sputtering

Abstract

1. Introduction

2. Materials and Methods

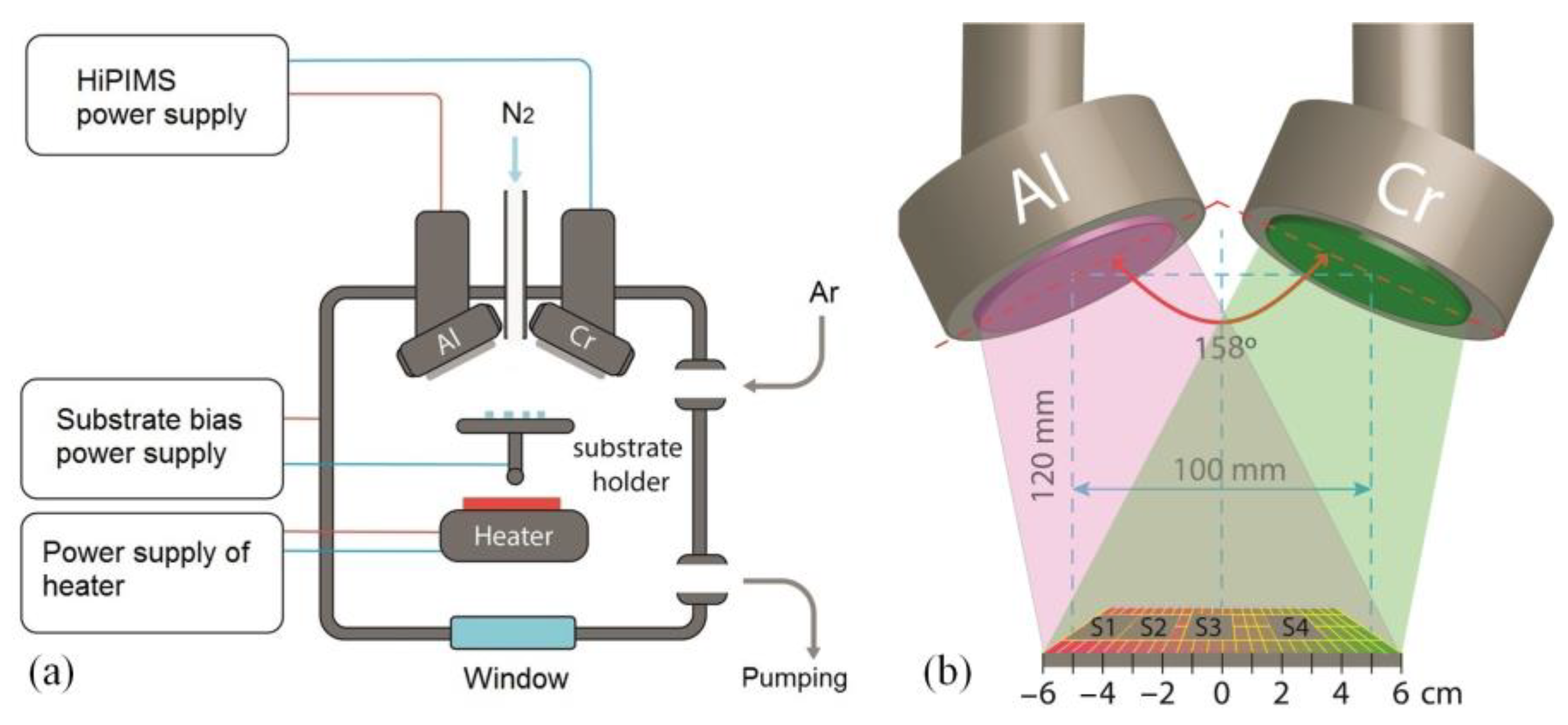

2.1. Preparation of (Cr1−xAlx)N Coatings

2.2. Surface Characterization

3. Results and Discussion

3.1. Chemical Composition

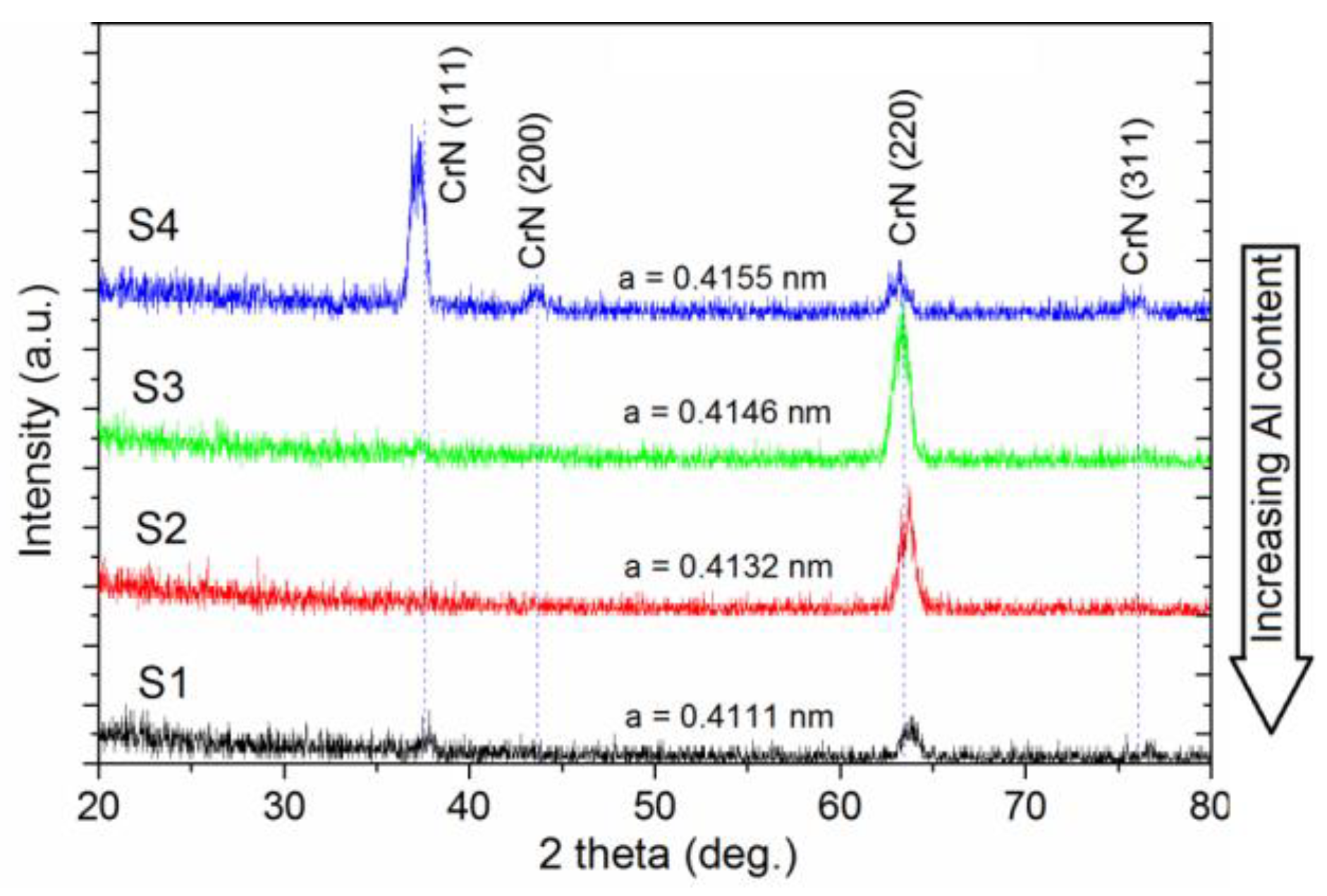

3.2. Phase Composition of the (Cr1−xAlx)N Coating

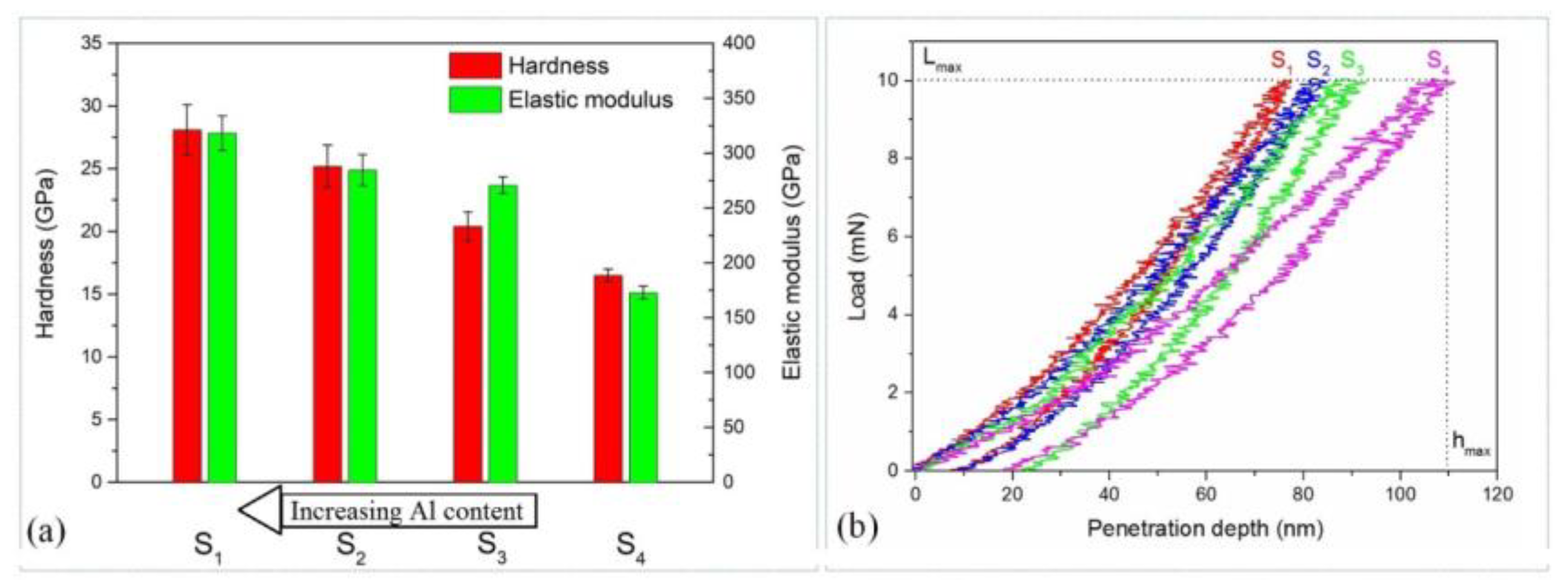

3.3. Mechanical Properties of the (Cr1−xAlx)N Coating

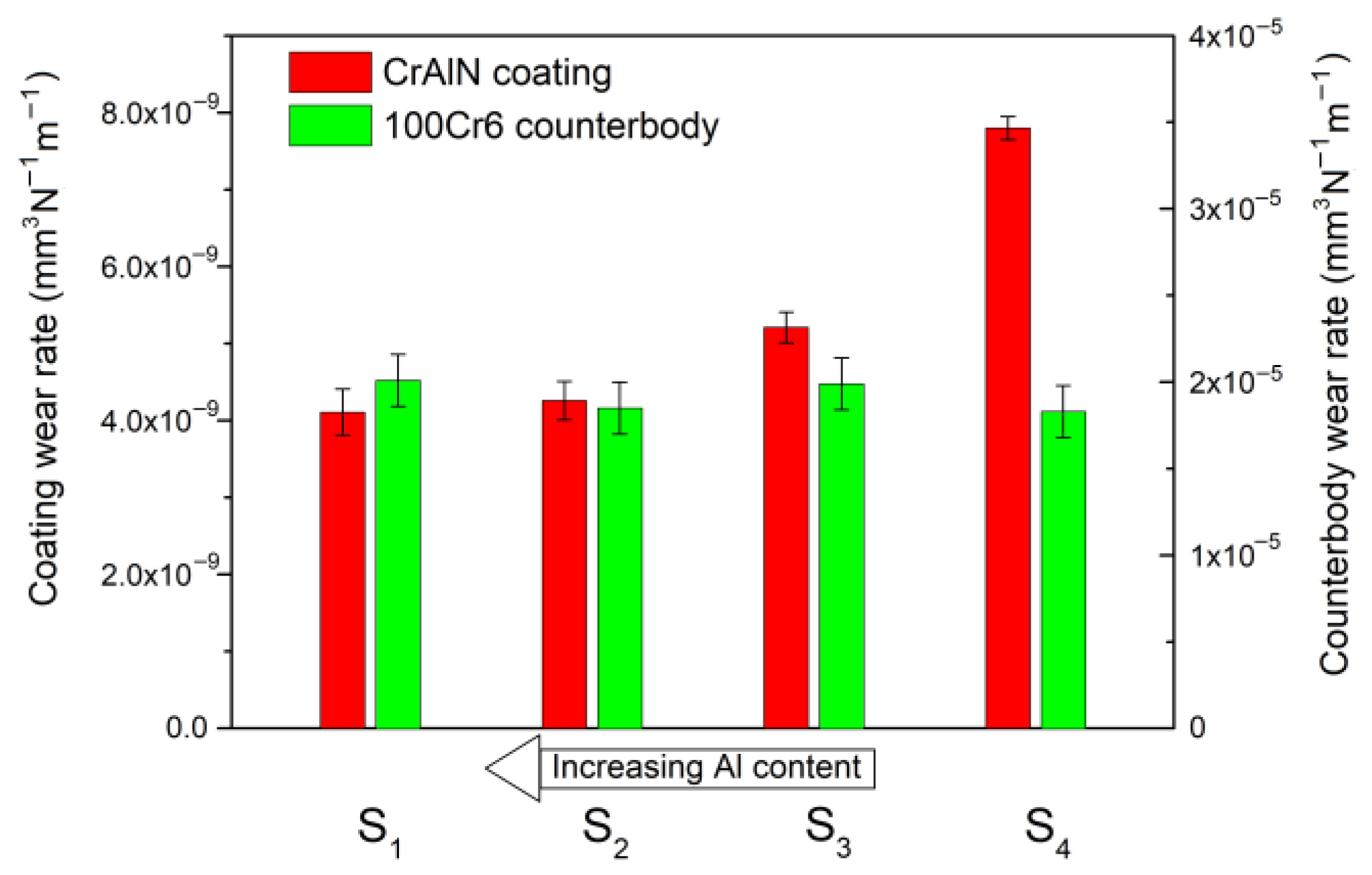

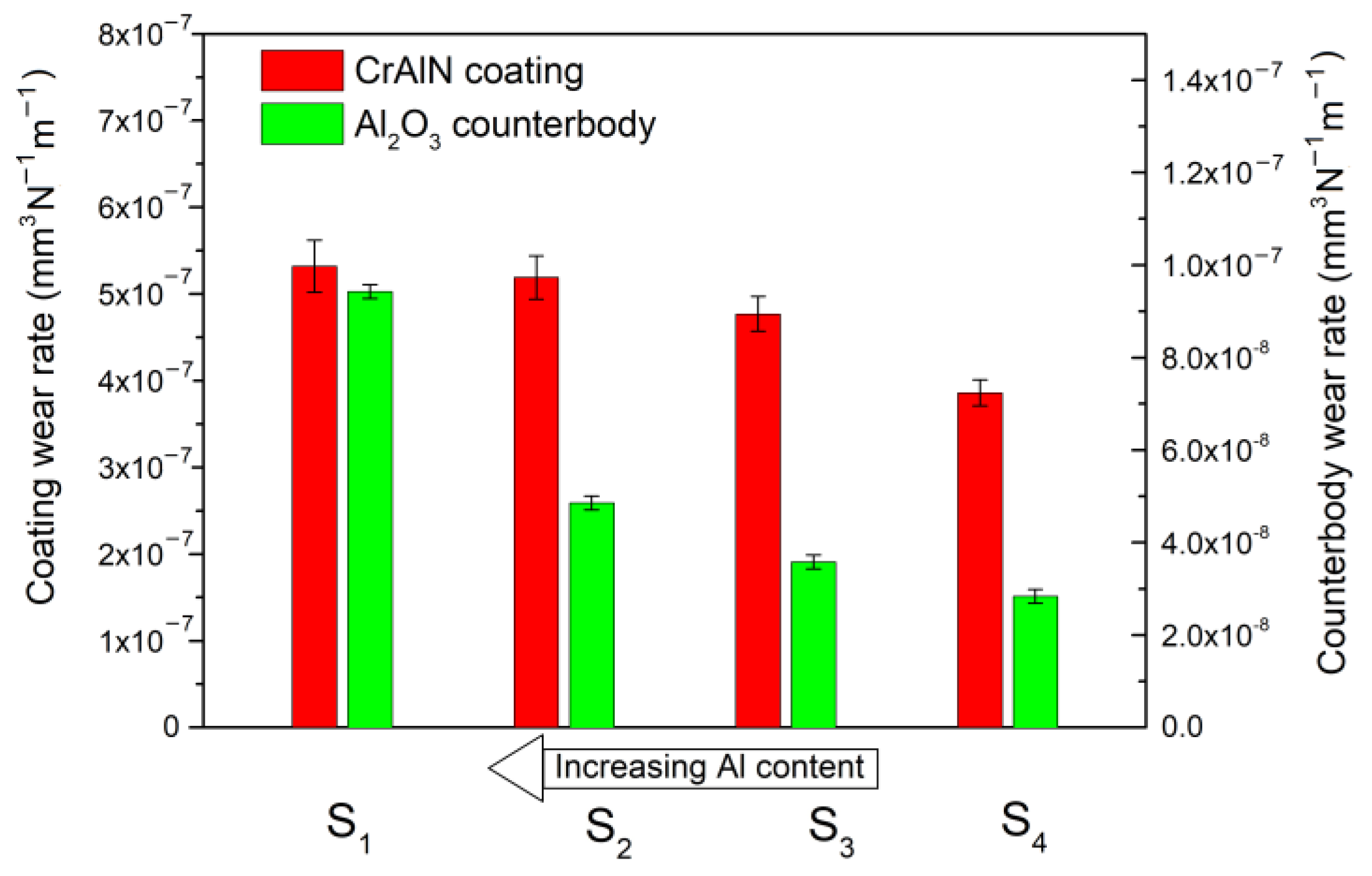

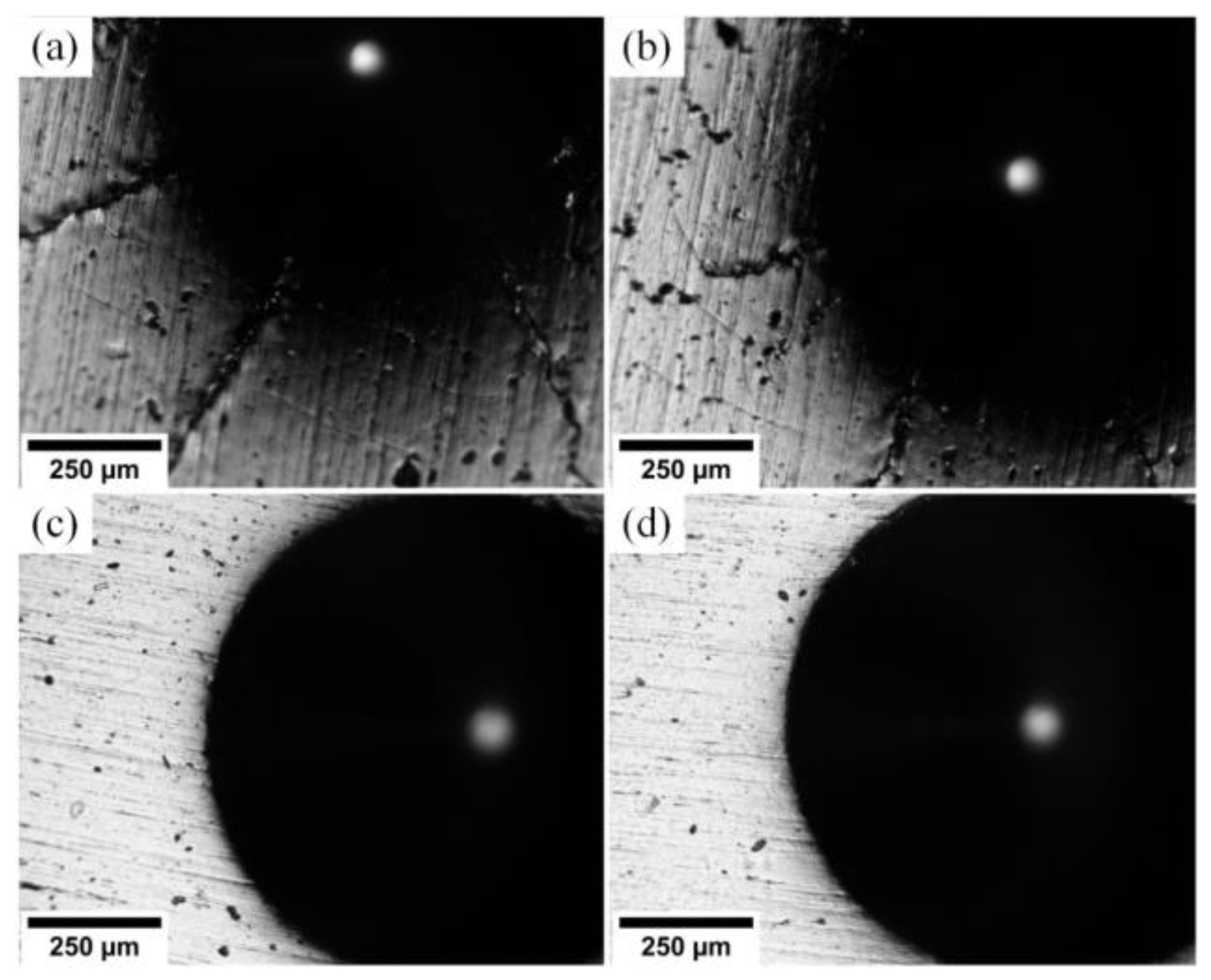

3.4. Wear Resistance of (Cr1−xAlx)N/100Cr6 Sliding Pair

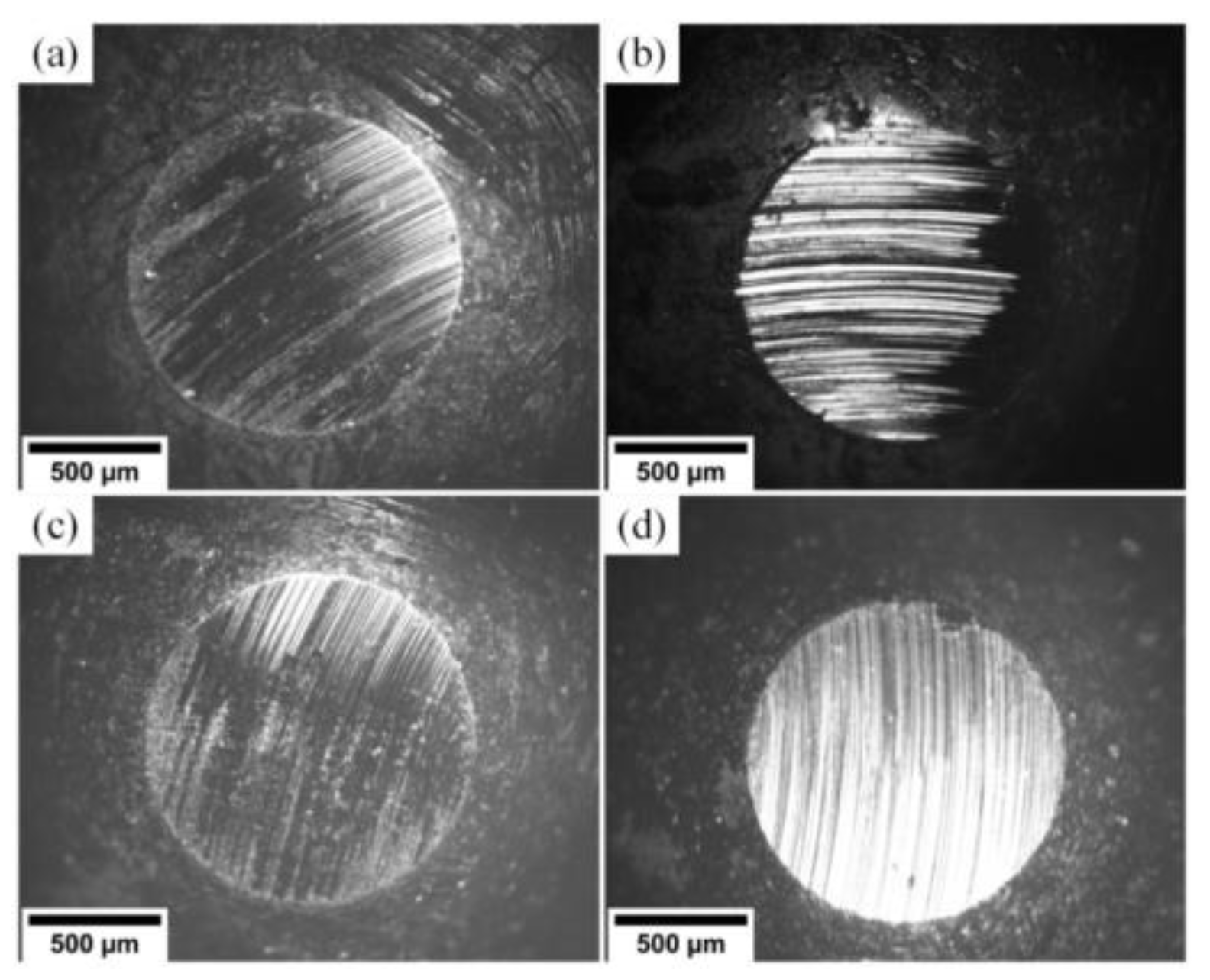

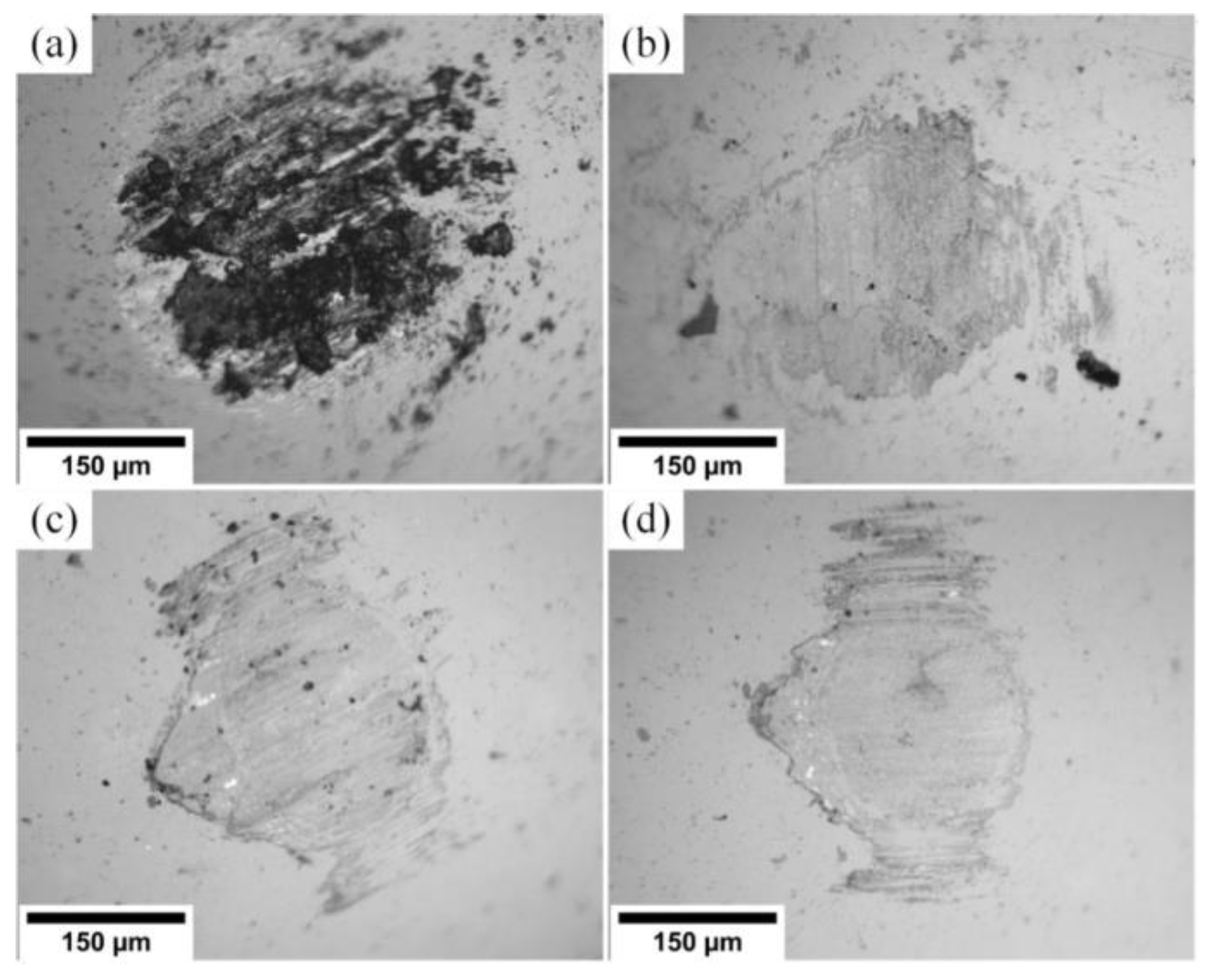

3.5. Wear Resistance of (Cr1−xAlx)N/Al2O3 Sliding Pair

3.6. Friction Coefficient of the (Cr1−xAlx)N Coating

3.7. Adhesive Strength Measurement

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Das, S.; Guha, S.; Ghadai, R.; Swain, B.P. A comparative analysis over different properties of TiN, TiAlN and TiAlSiN thin film coatings grown in nitrogen gas atmosphere. Mater. Chem. Phys. 2021, 258, 123866. [Google Scholar] [CrossRef]

- Huang, X.; Etsion, I.; Shao, T. Effects of elastic modulus mismatch between coating and substrate on the friction and wear properties of TiN and TiAlN coating systems. Wear 2015, 338–339, 54–61. [Google Scholar] [CrossRef]

- Tlili, B.; Mustapha, N.; Nouveau, C.; Benlatreche, Y.; Guillemot, G.; Lambertin, M. Correlation between thermal properties and aluminum fractions in CrAlN layers deposited by PVD technique. Vacuum 2010, 84, 1067–1074. [Google Scholar] [CrossRef]

- Chim, Y.C.; Ding, X.Z.; Zeng, X.T.; Zhang, S. Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateral rotating cathode arc. Thin Solid Film. 2009, 517, 4845–4849. [Google Scholar] [CrossRef]

- Polcar, T.; Cavaleiro, A. High temperature properties of CrAlN, CrAlSiN and AlCrSiN coatings—Structure and oxidation. Mater. Chem. Phys. 2011, 129, 195–201. [Google Scholar] [CrossRef]

- Hu, C.; Xu, Y.X.; Chen, L.; Pei, F.; Du, Y. Mechanical properties, thermal stability and oxidation resistance of Ta-doped CrAlN coatings. Surf. Coat. Technol. 2019, 368, 25–32. [Google Scholar] [CrossRef]

- Fan, Q.X.; Zhang, J.J.; Wu, Z.H.; Liu, Y.M.; Zhang, T.; Yan, B.; Wang, T.G. Influence of Al Content on the Microstructure and Properties of the CrAlN Coatings Deposited by Arc Ion Plating. Acta Metall. Sin. (Engl. Lett.) 2017, 30, 1221–1230. [Google Scholar] [CrossRef]

- Kang, M.C.; Je, S.K.; Kim, K.H.; Shin, B.S.; Kwon, D.H.; Kim, J.S. Cutting performance of CrN-based coatings tool deposited by hybrid coating method for micro drilling applications. Surf. Coat. Technol. 2008, 202, 5629–5632. [Google Scholar] [CrossRef]

- Romero, J.; Gómez, M.A.; Esteve, J.; Montalà, F.; Carreras, L.; Grifol, M.; Lousa, A. CrAlN coatings deposited by cathodic arc evaporation at different substrate bias. Thin Solid Film. 2006, 515, 113–117. [Google Scholar] [CrossRef]

- Li, M.; Wang, F. Effects of nitrogen partial pressure and pulse bias voltage on (Ti,Al)N coatings by arc ion plating. Surf. Coat. Technol. 2003, 167, 197–202. [Google Scholar] [CrossRef]

- Alhafian, M.-R.; Chemin, J.-B.; Fleming, Y.; Bourgeois, L.; Penoy, M.; Useldinger, R.; Soldera, F.; Mücklich, F.; Choquet, P. Comparison on the structural, mechanical and tribological properties of TiAlN coatings deposited by HiPIMS and Cathodic Arc Evaporation. Surf. Coat. Technol. 2021, 423, 127529. [Google Scholar] [CrossRef]

- Zhao, Y.; Lin, G.; Xiao, J.; Lang, W.; Dong, C.; Gong, J.; Sun, C. Synthesis of titanium nitride thin films deposited by a new shielded arc ion plating. Appl. Surf. Sci. 2011, 257, 5694–5697. [Google Scholar] [CrossRef]

- Chunyan, Y.; Linhai, T.; Yinghui, W.; Shebin, W.; Tianbao, L.; Bingshe, X. The effect of substrate bias voltages on impact resistance of CrAlN coatings deposited by modified ion beam enhanced magnetron sputtering. Appl. Surf. Sci. 2009, 255, 4033–4038. [Google Scholar] [CrossRef]

- Mohammadpour, E.; Jiang, Z.T.; Altarawneh, M.; Xie, Z.; Zhou, Z.; Mondinos, N.; Kimpton, J.; Dlugogorski, B.Z. Predicting high temperature mechanical properties of CrN and CrAlN coatings from in-situ synchrotron radiation X-ray diffraction. Thin Solid Film. 2016, 599, 98–103. [Google Scholar] [CrossRef]

- Ding, X.Z.; Zeng, X.T. Structural, mechanical and tribological properties of CrAlN coatings deposited by reactive unbalanced magnetron sputtering. Surf. Coat. Technol. 2005, 200, 1372–1376. [Google Scholar] [CrossRef]

- Drnovšek, A.; Vo, H.T.; Rebelo de Figueiredo, M.; Kolozsvári, S.; Hosemann, P.; Franz, R. High temperature fracture toughness of single-layer CrAlN and CrAlSiN hard coatings. Surf. Coat. Technol. 2021, 409, 126909. [Google Scholar] [CrossRef]

- Tillmann, W.; Hagen, L.; Stangier, D.; Dias, N.F.L.; Görtz, J.; Kensy, M.D. Lapping and polishing of additively manufactured 316L substrates and their effects on the microstructural evolution and adhesion of PVD CrAlN coatings. Surf. Coat. Technol. 2021, 428, 127905. [Google Scholar] [CrossRef]

- Kitamika, Y.; Hasegawa, H. Mechanical, tribological, and oxidation properties of Si-containing CrAlN films. Vacuum 2019, 164, 29–33. [Google Scholar] [CrossRef]

- Nouveau, C.; Labidi, C.; Ferreira Martin, J.-P.; Collet, R.; Djouadi, A. Application of CrAlN coatings on carbide substrates in routing of MDF. Wear 2007, 263, 1291–1299. [Google Scholar] [CrossRef]

- Bai, Y.; Xi, Y.; Gao, K.; Yang, H.; Pang, X.; Volinsky, A.A. Residual stress control in CrAlN coatings deposited on Ti alloys. Ceram. Int. 2018, 44, 4653–4659. [Google Scholar] [CrossRef]

- Barshilia, H.C.; Selvakumar, N.; Deepthi, B.; Rajam, K.S. A comparative study of reactive direct current magnetron sputtered CrAlN and CrN coatings. Surf. Coat. Technol. 2006, 201, 2193–2201. [Google Scholar] [CrossRef]

- Xingrun, R.; Zhu, H.; Meixia, L.; Jiangao, Y.; Hao, C. Comparison of Microstructure and Tribological Behaviors of CrAlN and CrN Film Deposited by DC Magnetron Sputtering. Rare Metal Mat. Eng. 2018, 47, 1100–1106. [Google Scholar] [CrossRef]

- Hsiao, Y.C.; Lee, J.W.; Yang, Y.C.; Lou, B.S. Effects of duty cycle and pulse frequency on the fabrication of AlCrN thin films deposited by high power impulse magnetron sputtering. Thin Solid Film. 2013, 549, 281–291. [Google Scholar] [CrossRef]

- Liu, L.; Ruan, Q.; Wu, Z.; Li, D.; Huang, C.; Wu, Y.; Li, T.; Wu, Z.; Tian, X.; Fu, R.K.Y.; et al. Fabrication and cutting performance of CrAlN/CrAl multilayer coatings deposited by continuous high-power magnetron sputtering. Ceram. Int. 2022, 48, 14528–14536. [Google Scholar] [CrossRef]

- Gui, B.; Zhou, H.; Zheng, J.; Liu, X.; Feng, X.; Zhang, Y.; Yang, L. Microstructure and properties of TiAlCrN ceramic coatings deposited by hybrid HiPIMS/DC magnetron co-sputtering. Ceram. Int. 2021, 47, 8175–8183. [Google Scholar] [CrossRef]

- Rojas, T.C.; Caro, A.; Lozano, G.; Sánchez-López, J.C. High-temperature solar-selective coatings based on Cr(Al)N. Part 1: Microstructure and optical properties of CrNy and Cr1-xAlxNy films prepared by DC/HiPIMS. Sol. Energy Mater. Sol. Cells 2021, 223, 110951. [Google Scholar] [CrossRef]

- Lattemann, M.; Ehiasarian, A.P.; Bohlmark, J.; Persson, P.Å.O.; Helmersson, U. Investigation of high power impulse magnetron sputtering pretreated interfaces for adhesion enhancement of hard coatings on steel. Surf. Coat. Technol. 2006, 200, 6495–6499. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Drnovšek, A.; Rebelo de Figueiredo, M.; Vo, H.; Xia, A.; Vachhani, S.J.; Kolozsvári, S.; Hosemann, P.; Franz, R. Correlating high temperature mechanical and tribological properties of CrAlN and CrAlSiN hard coatings. Surf. Coat. Technol. 2019, 372, 361–368. [Google Scholar] [CrossRef]

- Li, W.; Zheng, K.; Liu, P.; Zhu, P.; Zhang, K.; Ma, F.; Liu, X.; Chen, X.; He, D. Microstructure and superhardness effect of CrAlN/SiO2 nanomultilayered film synthesized by reactive magnetron sputtering. Mater. Charact. 2016, 118, 79–84. [Google Scholar] [CrossRef]

- Weirather, T.; Czettl, C.; Polcik, P.; Kathrein, M.; Mitterer, C. Industrial-scale sputter deposition of Cr1−xAlxN coatings with 0.21 ≤ x ≤ 0.74 from segmented targets. Surf. Coat. Technol. 2013, 232, 303–310. [Google Scholar] [CrossRef]

- Bagcivan, N.; Bobzin, K.; Theiß, S. (Cr1−xAlx)N: A comparison of direct current, middle frequency pulsed and high power pulsed magnetron sputtering for injection molding components. Thin Solid Film. 2013, 528, 180–186. [Google Scholar] [CrossRef]

- PalDey, S.; Deevi, S.C. Single layer and multilayer wear resistant coatings of (Ti, Al)N: A review. Mater. Sci. Eng. A 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Gibson, D.R.; Brinkley, I.; Waddell, E.M.; Walls, J.M. Closed field magnetron sputtering: New generation sputtering process for optical coatings. In Proceedings of the SPIE 7101 Advances in Optical Thin Films III, Glasgow, UK, 2–5 September 2008; Volume 7101, p. 710108. [Google Scholar] [CrossRef]

- Oskirko, V.O.; Zakharov, A.N.; Pavlov, A.P.; Solovyev, A.A.; Semenov, V.A.; Rabotkin, S.V. Hybrid HIPIMS+MFMS power supply for dual magnetron sputtering systems. Vacuum 2020, 181, 109670. [Google Scholar] [CrossRef]

- Oskirko, V.O.; Zakharov, A.N.; Semenov, V.A.; Pavlov, A.P.; Grenadyorov, A.S.; Rabotkin, S.V.; Solovyev, A.A. Short-pulse high-power dual magnetron sputtering. Vacuum 2022, 200, 111026. [Google Scholar] [CrossRef]

- Tiron, V.; Velicu, I.L.; Cristea, D.; Lupu, N.; Stoian, G.; Munteanu, D. Influence of ion-to-neutral flux ratio on the mechanical and tribological properties of TiN coatings deposited by HiPIMS. Surf. Coat. Technol. 2018, 352, 690–698. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Liang, Q.; Stanishevsky, A.; Vohra, Y.K. Tribological properties of undoped and boron-doped nanocrystalline diamond films. Thin Solid Film. 2008, 517, 800–804. [Google Scholar] [CrossRef]

- Ramadoss, R.; Kumar, N.; Pandian, R.; Dash, S.; Ravindran, T.R.; Arivuoli, D.; Tyagi, A.K. Tribological properties and deformation mechanism of TiAlN coating sliding with various counterbodies. Tribol. Int. 2013, 66, 143–149. [Google Scholar] [CrossRef]

- Vidakis, N.; Antoniadis, A.; Bilalis, N. The VDI 3198 indentation test evaluation of a reliable qualitative control for layeredcompounds. J. Mater. Process. Technol. 2003, 143–144, 481–485. [Google Scholar] [CrossRef]

- Banakh, O.; Schmid, P.E.; Sanjines, R.; Levy, F. High-temperature oxidation resistance of Cr1-xAlxN thin films deposited by reactive magnetron sputtering. Surf. Coat. Technol. 2003, 163–164, 57–61. [Google Scholar] [CrossRef]

- Kawate, M.; Kimura Hashimoto, A.; Suzuki, T. Oxidation resistance of Cr1−XAlXN and Ti1−XAlXN films. Surf. Coat. Technol. 2003, 165, 163–167. [Google Scholar] [CrossRef]

- Kimura, A.; Kawate, M.; Hasegawa, H.; Suzuki, T. Anisotropic lattice expansion and shrinkage of hexagonal TiAlN and CrAlN films. Surf. Coat. Technol. 2003, 169–170, 367–370. [Google Scholar] [CrossRef]

- Hirai, M.; Ueno, Y.; Suzuki, T.; Jiang, W.; Grigoriu, C.; Yatsui, K. Characteristics of (Cr1-x, Alx)N Films Prepared by Pulsed Laser Deposition. Jpn. J. Appl. Phys. 2001, 40, 1056–1060. [Google Scholar] [CrossRef]

- Łępicka, M.; Grądzka-Dahlke, M.; Pieniak, D.; Pasierbiewicz, K.; Kryńska, K.; Niewczas, A. Tribological performance of titanium nitride coatings: A comparative study on TiN-coated stainless steel and titanium alloy. Wear 2019, 422–423, 68–80. [Google Scholar] [CrossRef]

- Cai, J.B.; Wang, X.L.; Bai, W.Q.; Zhao, X.Y.; Wang, T.Q.; Tu, J.P. Bias-graded deposition and tribological properties of Ti-contained a-C gradient composite film on Ti6Al4V alloy. Appl. Surf. Sci. 2013, 279, 450–457. [Google Scholar] [CrossRef]

- Mo, J.L.; Zhu, M.H.; Leyland, A.; Matthews, A. Impact wear and abrasion resistance of CrN, AlCrN and AlTiN PVD coatings. Surf. Coat. Technol. 2013, 215, 170–177. [Google Scholar] [CrossRef]

- Krysina, O.V.; Prokopenko, N.A.; Ivanov, Y.F.; Tolkachev, O.S.; Shugurov, V.V.; Petrikova, E.A. Multi-layered gradient (Zr,Nb)N coatings deposited by the vacuum-arc method. Surf. Coat. Technol. 2020, 393, 125759. [Google Scholar] [CrossRef]

- Zok, F.W.; Miserez, A. Property maps for abrasion resistance of materials. Acta Mater. 2007, 55, 6365–6371. [Google Scholar] [CrossRef]

- Reiter, A.E.; Derflinger, V.H.; Hanselmann, B.; Bachmann, T.; Sartory, B. Investigation of the properties of Al1-xCrxN coatings prepared by cathodic arc evaporation. Surf. Coat. Technol. 2005, 200, 2114–2122. [Google Scholar] [CrossRef]

- Łępicka, M.; Grądzka-Dahlke, M.; Pieniak, D.; Pasierbiewicz, K.; Niewczas, A. Effect of mechanical properties of substrate and coating on wear performance of TiN- or DLC-coated 316LVM stainless steel. Wear 2017, 382–383, 62–70. [Google Scholar] [CrossRef]

- Sánchez-López, J.C.; Contreras, A.; Domínguez-Meister, S.; García-Luis, A.; Brizuela, M. Tribological behaviour at high temperature of hard CrAlN coatings doped with Y or Zr. Thin Solid Film. 2014, 550, 413–420. [Google Scholar] [CrossRef]

- Lin, J.; Mishra, B.; Moore, J.J.; Sproul, W.D.; Rees, J.A. Effects of the substrate to chamber wall distance on the structure and properties of CrAlN films deposited by pulsed closed field unbalanced magnetron sputtering (P-CFUBMS). Surf. Coat. Technol. 2007, 201, 6960–6969. [Google Scholar] [CrossRef]

- Sidelev, D.V.; Voronina, E.D.; Kashkarov, E.B. Duplex treatment of AISI 420 steel by RF-ICP nitriding and CrAlN coating deposition: The role of nitriding duration. Coatings 2022, 12, 1709. [Google Scholar] [CrossRef]

- Reiter, A.E.; Mitterer, C.; Rebelo de Figueiredo, M.; Franz, R. Abrasive and adhesive wear behavior of arc-evaporated Al1-xCrxN hard coatings. Tribol. Lett. 2010, 37, 605–611. [Google Scholar] [CrossRef]

- Falsafein, M.; Ashrafizadeh, F.; Kheirandish, A. Influence of thickness on adhesion of nanostructured multilayer CrN/CrAlN coatings to stainless steel substrate. Surf. Interfaces 2018, 13, 178–185. [Google Scholar] [CrossRef]

- Heinke, W.; Leyland, A.; Matthews, A.; Berg, G.; Friedrich, C.; Broszeit, E. Evaluation of PVD nitride coatings, using impact, scratch and Rockwell-C adhesion tests. Thin Solid Film. 1995, 270, 431–438. [Google Scholar] [CrossRef]

- Zhang, X.; Tian, X.; Gong, C.; Liu, X.; Li, J.; Zhu, J.; Lin, H. Effect of plasma nitriding ion current density on tribological properties of composite CrAlN coatings. Ceram. Int. 2022, 48, 3954–3962. [Google Scholar] [CrossRef]

| Counter Body | H, GPa | E, GPa | δ, g∙cm−3 | υ, a.u. | H3/E2, MPa |

|---|---|---|---|---|---|

| 100Cr6 | 2.7 ± 0.2 | 185 ± 17 | 7.8 | 0.30 | 0.57 |

| Al2O3 | 26 ± 2.3 | 382 ± 32 | 3.9 | 0.24 | 120.4 |

| Substrate | 2.5 ± 0.1 | 182 ± 7 | 7.7 | - | 0.47 |

| Substrates | H, GPa | E, GPa | H/E | H3/E2, MPa | We, % |

|---|---|---|---|---|---|

| S1 | 28 | 318 | 0.088 | 219 | 89.1 |

| S2 | 25 | 284 | 0.089 | 198 | 88.5 |

| S3 | 20 | 271 | 0.075 | 115 | 74.1 |

| S4 | 17 | 173 | 0.095 | 150 | 83.4 |

| Methods | Substrate | Al/Cr Ratio | Hardness (GPa) | Wear Rate (mm3N−1m−1) | COF (a.u.) | Counter Bodies | Literature |

|---|---|---|---|---|---|---|---|

| RF sputtering | Si, stainless steel | 1.4 | 30.9 | - | 0.4–0.8 | SiC | [18] |

| DC sputtering | AISI 304 | - | - | 3.7 × 10−6 | 0.4–0.9 | Si3N4 | [22] |

| DC sputtering | M2 HSS | 1 | 28 | - | 0.57 | Al2O3 | [53] |

| C-HPMS | Si, cemented carbide | - | 35.6 | - | 0.76 | Si3N4 | [24] |

| HiPIMS/DC co-sputtering | 9Cr18 stainless steel | 1.3 | 20.7 | 8 × 10−7 | 0.5 | Al2O3 | [25] |

| CFUMS | High speed steel | 0.2 | 23 | 6 × 10−7 | - | Al2O3 | [15] |

| CFUMS | AISI 304 | 0.4 | 27.4 | 3.69 × 10−6 | 0.41 | WC-Co (6%) | [54] |

| MF MS * | AISI 420 | 2 | 23 | 4 × 10−6 | - | Al2O3 | [55] |

| Short-pulse dual HiPIMS | AISI 430 | 1.2 | 28 | 5.3 × 10−7 | 0.6–0.63 | Al2O3 | Our work |

| 0.2 | 17 | 3.9 × 10−7 | 0.42–0.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grenadyorov, A.; Oskirko, V.; Zakharov, A.; Oskomov, K.; Solovyev, A. (Cr1−xAlx)N Coating Deposition by Short-Pulse High-Power Dual Magnetron Sputtering. Materials 2022, 15, 8237. https://doi.org/10.3390/ma15228237

Grenadyorov A, Oskirko V, Zakharov A, Oskomov K, Solovyev A. (Cr1−xAlx)N Coating Deposition by Short-Pulse High-Power Dual Magnetron Sputtering. Materials. 2022; 15(22):8237. https://doi.org/10.3390/ma15228237

Chicago/Turabian StyleGrenadyorov, Alexander, Vladimir Oskirko, Alexander Zakharov, Konstantin Oskomov, and Andrey Solovyev. 2022. "(Cr1−xAlx)N Coating Deposition by Short-Pulse High-Power Dual Magnetron Sputtering" Materials 15, no. 22: 8237. https://doi.org/10.3390/ma15228237

APA StyleGrenadyorov, A., Oskirko, V., Zakharov, A., Oskomov, K., & Solovyev, A. (2022). (Cr1−xAlx)N Coating Deposition by Short-Pulse High-Power Dual Magnetron Sputtering. Materials, 15(22), 8237. https://doi.org/10.3390/ma15228237