From Light-Powered Motors, to Micro-Grippers, to Crawling Caterpillars, Snails and Beyond—Light-Responsive Oriented Polymers in Action

Abstract

1. Introduction

- How to design the mechanics to overcome all the problems with friction, van der Waals forces, fluid viscosity and moving with very low Reynolds numbers [4]? The laws governing mechanics and motion in the micro-world are different from those we are used to: gravity and the electromagnetic forces are governed by the same constants, but their relations change with scale. As a result, new challenges as well as new opportunities arise: crawling on an upside-down glass ceiling is easy for a millimeter-scale snail robot [5], while a micron-size walker may struggle to lift its legs, glued to the surface by van der Waals forces [6,7];

- How to fabricate motors, gears and other elements on the sub-millimeter and smaller scales, reliably and cheaply?

- How to supply the mechanisms with energy, either remotely or from an onboard source?

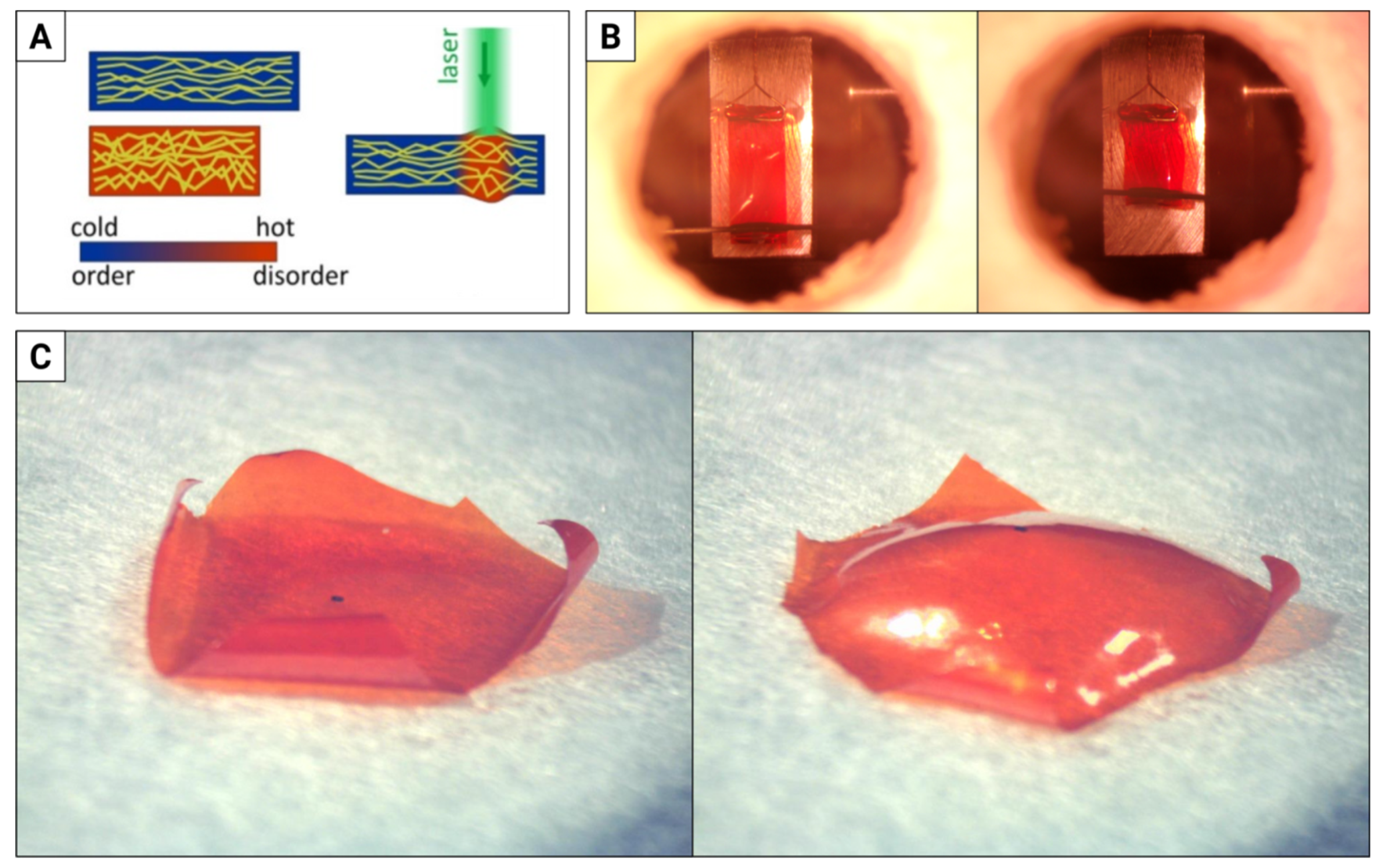

1.1. Liquid Crystal Elastomers as Light-Powered Actuators

1.2. LCE Fabrication in Different Scales

1.3. Problems Yet to Be Solved

- light absorption in the LCE films decreasing over time, mainly due to the light-absorbing dye bleaching; this can be potentially bypassed by using quantum dots or other, more robust absorbers, well known from fluorescence microscopy, where dye bleaching has been studied and addressed for some time;

- the wear and tear of the actuator after many cycles of operation; this calls for further insights into the mechanical properties of the light-responsive elements, probably at the level of polymer chemistry.

2. Micro-Motors—Direct Conversion of Light Energy into Mechanical Work

2.1. Rotary Motor

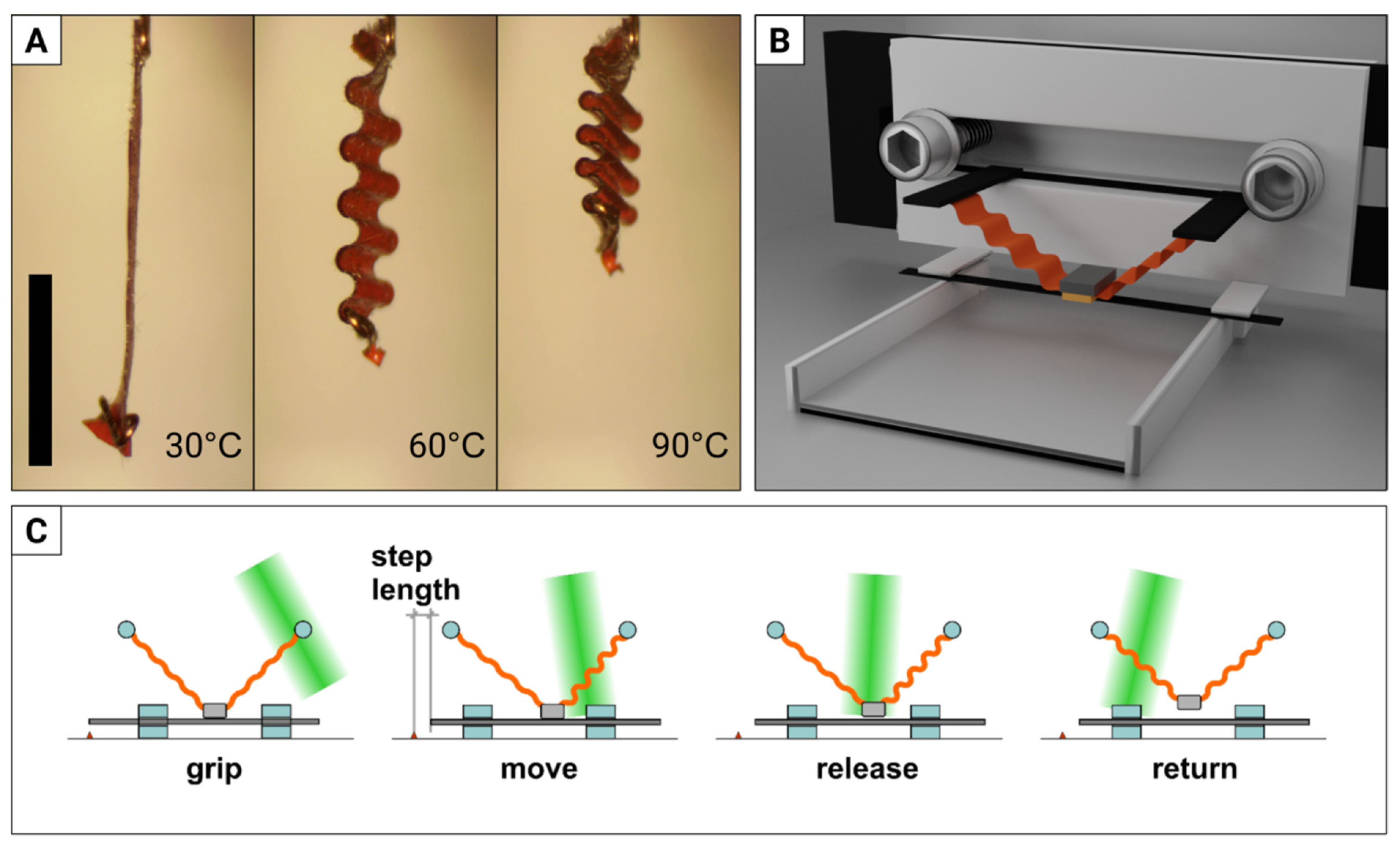

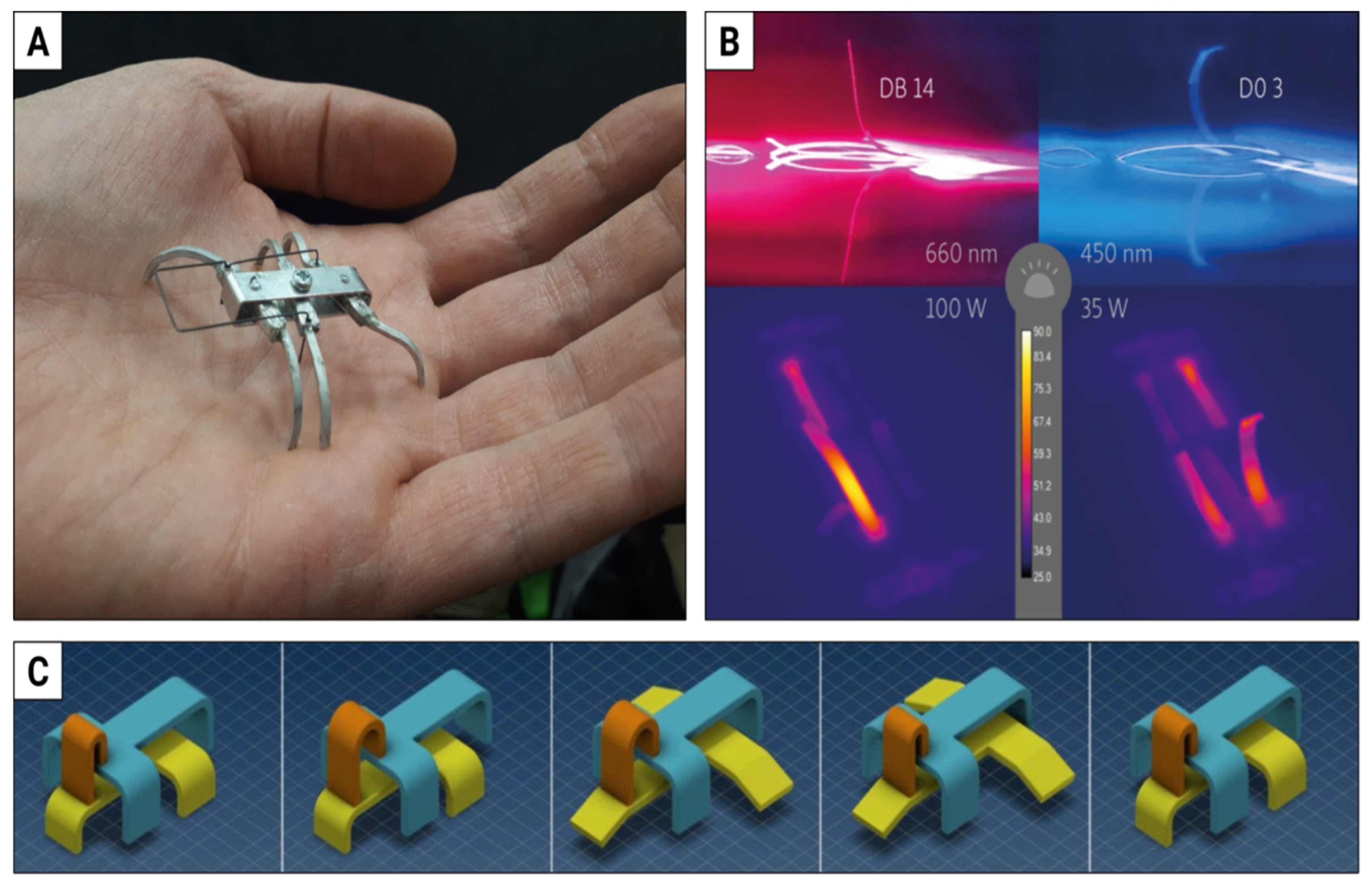

2.2. Linear Stepping Inchworm Motor

3. Bio-Inspired Millimeter-Scale Robots

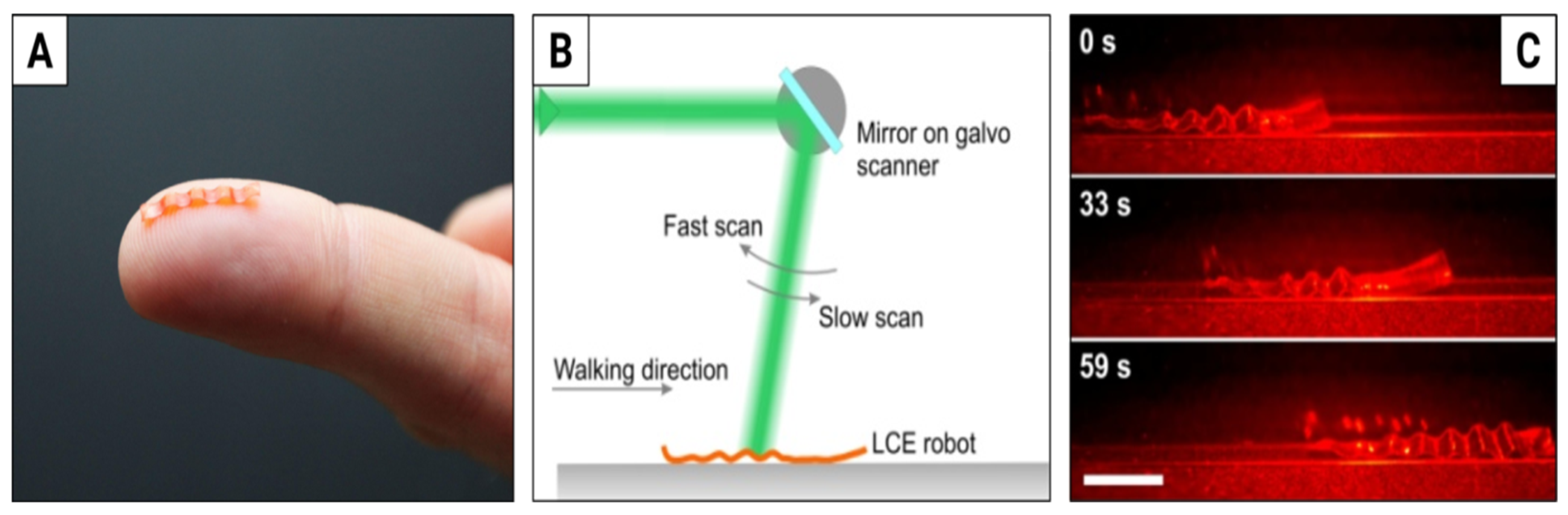

3.1. The Caterpillar

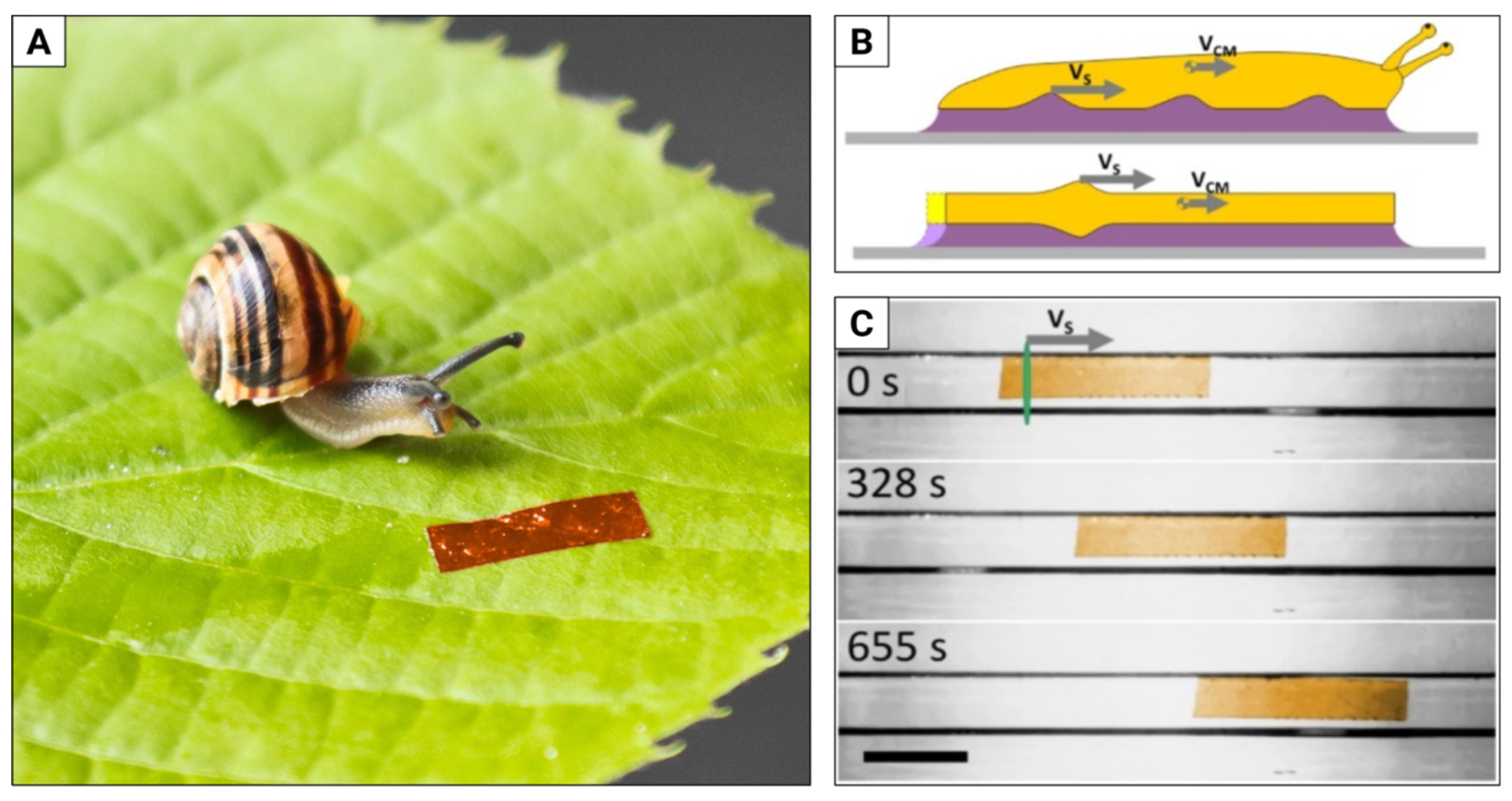

3.2. The Snail

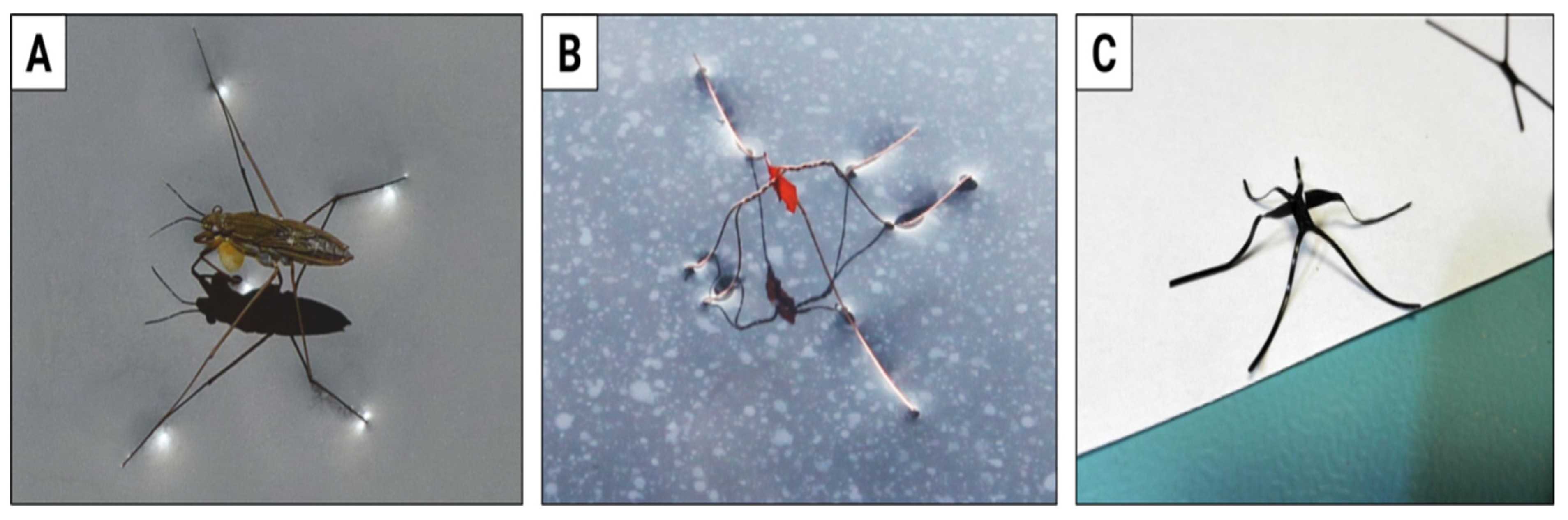

3.3. The Water Strider

3.4. The Ant

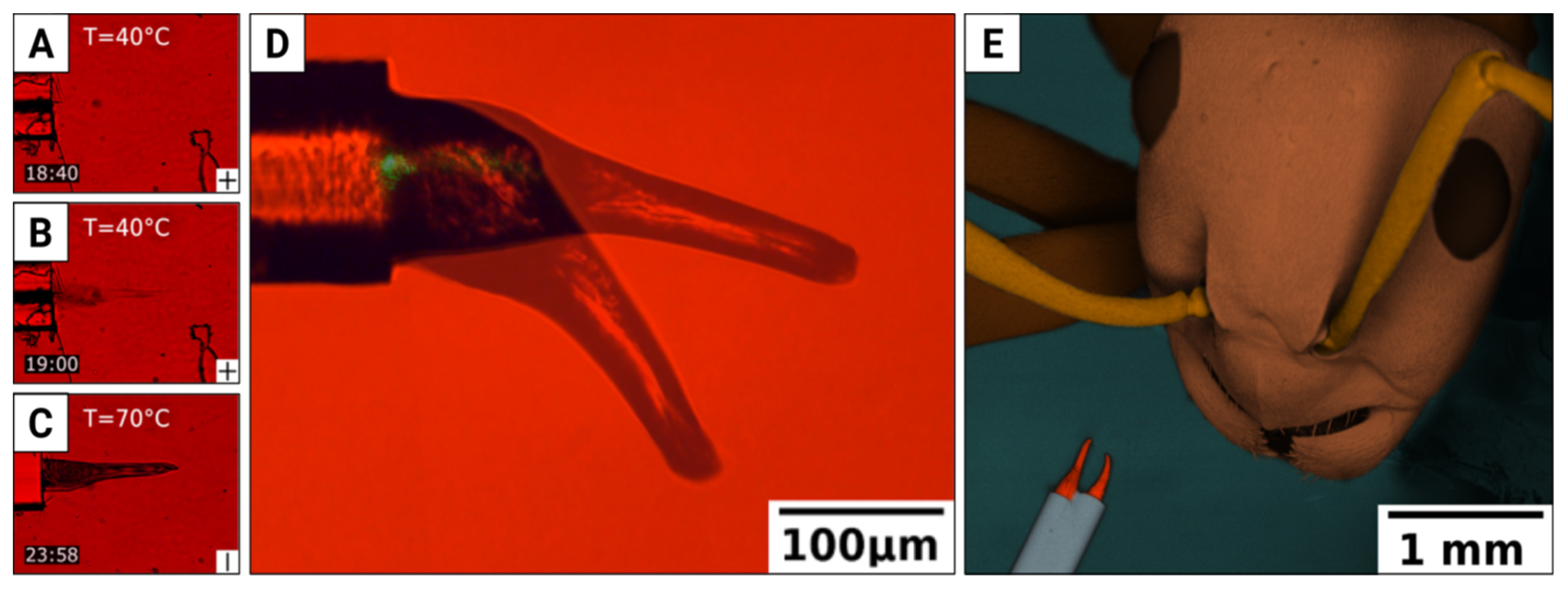

4. Micrometer-Scale Light-Power Tools

5. Conclusions and Outlook

- Orienting LCE with the electric field during laser photolithography [96]. If successful, this technology will open up the ultimate realm of 5D photo-mechanical microstructures: the 3D-printed shape (with sub-micron resolution) with two angles of director orientation, programmable over the entire volume;

- Orienting LCE molecules with writing direction in laser photolithography. This method is somehow similar to orienting by squeezing through a small nozzle in 3D printing of LCEs [97], but on a much smaller scale. As it does not require any photo aligning layers or electrodes, it can be used with minute substrates, such as the end face of an optical fiber;

- Exploring the theme of “materials as machines” [98], we have developed a conveyor belt with LCE-sorting mechanisms, where small objects can be sorted into a number of buckets with LCE stripes (levers) that respond to their different colors and push them from the belt, without any sensors, data processing or separate actuators;

- Since our lab has its origins in photonics and optics, we are constantly playing with ideas of combining LCE structures with optical elements, e.g., optical fibers. We have tested several approaches to fiber switches, either with self-standing light-responsive actuators or with LCE micro-structures grown on the fiber tip.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kistemaker, J.C.M.; Lubbe, A.S.; Feringa, B.L. Exploring Molecular Motors. Mater. Chem. Front. 2021, 5, 2900–2906. [Google Scholar] [CrossRef]

- Challenge for the World’s Smallest|History of Namiki DC Coreless Motor|Adamant Namiki Precision Jewel Co., Ltd. Available online: https://www.ad-na.com/en/product/dccorelessmotor/micromotor.html (accessed on 26 August 2022).

- Jafferis, N.T.; Helbling, E.F.; Karpelson, M.; Wood, R.J. Untethered Flight of an Insect-Sized Flapping-Wing Microscale Aerial Vehicle. Nature 2019, 570, 491–495. [Google Scholar] [CrossRef]

- Purcell, E.M. Life at Low Reynolds Number. Am. J. Phys. 1977, 45, 3–11. [Google Scholar] [CrossRef]

- Rogóż, M.; Dradrach, K.; Xuan, C.; Wasylczyk, P. A Millimeter-Scale Snail Robot Based on a Light-Powered Liquid Crystal Elastomer Continuous Actuator. Macromol. Rapid Commun. 2019, 40, 1900279. [Google Scholar] [CrossRef]

- Zeng, H.; Wasylczyk, P.; Parmeggiani, C.; Martella, D.; Burresi, M.; Wiersma, D.S. Light-Fueled Microscopic Walkers. Adv. Mater. 2015, 27, 3883–3887. [Google Scholar] [CrossRef]

- Zeng, H.; Wasylczyk, P.; Wiersma, D.S.; Priimagi, A. Light Robots: Bridging the Gap between Microrobotics and Photomechanics in Soft Materials. Adv. Mater. 2018, 30, 1703554. [Google Scholar] [CrossRef]

- Hines, L.; Petersen, K.; Lum, G.Z.; Sitti, M. Soft Actuators for Small-Scale Robotics. Adv. Mater. 2017, 29, 1603483. [Google Scholar] [CrossRef]

- Rosset, S.; Niklaus, M.; Dubois, P.; Shea, H.R. Mechanical Characterization of a Dielectric Elastomer Microactuator with Ion-Implanted Electrodes. Sens. Actuators A Phys. 2008, 144, 185–193. [Google Scholar] [CrossRef]

- Brochu, P.; Pei, Q. Advances in Dielectric Elastomers for Actuators and Artificial Muscles. Macromol. Rapid Commun. 2010, 31, 10–36. [Google Scholar] [CrossRef]

- Bay, L.; West, K.; Sommer-Larsen, P.; Skaarup, S.; Benslimane, M. A Conducting Polymer Artificial Muscle with 12% Linear Strain. Adv. Mater. 2003, 15, 310–313. [Google Scholar] [CrossRef]

- Must, I.; Kaasik, F.; Põldsalu, I.; Mihkels, L.; Johanson, U.; Punning, A.; Aabloo, A. Ionic and Capacitive Artificial Muscle for Biomimetic Soft Robotics: Ionic and Capacitive Artificial Muscle for Biomimetic Soft Robotics. Adv. Eng. Mater. 2015, 17, 84–94. [Google Scholar] [CrossRef]

- Lum, G.Z.; Ye, Z.; Dong, X.; Marvi, H.; Erin, O.; Hu, W.; Sitti, M. Shape-Programmable Magnetic Soft Matter. Proc. Natl. Acad. Sci. USA 2016, 113, E6007–E6015. [Google Scholar] [CrossRef]

- Diller, E.; Zhuang, J.; Zhan Lum, G.; Edwards, M.R.; Sitti, M. Continuously Distributed Magnetization Profile for Millimeter-Scale Elastomeric Undulatory Swimming. Appl. Phys. Lett. 2014, 104, 174101. [Google Scholar] [CrossRef]

- Grinthal, A.; Aizenberg, J. Adaptive All the Way down: Building Responsive Materials from Hierarchies of Chemomechanical Feedback. Chem. Soc. Rev. 2013, 42, 7072. [Google Scholar] [CrossRef] [PubMed]

- De Volder, M.; Reynaerts, D. Pneumatic and Hydraulic Microactuators: A Review. J. Micromech. Microeng. 2010, 20, 043001. [Google Scholar] [CrossRef]

- Paek, J.; Cho, I.; Kim, J. Microrobotic Tentacles with Spiral Bending Capability Based on Shape-Engineered Elastomeric Microtubes. Sci. Rep. 2015, 5, 10768. [Google Scholar] [CrossRef]

- De Gennes, P.-G. One Type of Nematic Polymers. C. R. Seances Acad. Sci. Ser. B 1975, 281, 101–103. [Google Scholar]

- Sawa, Y.; Urayama, K.; Takigawa, T.; DeSimone, A.; Teresi, L. Thermally Driven Giant Bending of Liquid Crystal Elastomer Films with Hybrid Alignment. Macromolecules 2010, 43, 4362–4369. [Google Scholar] [CrossRef]

- Yu, Y.; Nakano, M.; Ikeda, T. Directed Bending of a Polymer Film by Light. Nature 2003, 425, 145. [Google Scholar] [CrossRef]

- Braun, L.; Linder, T.; Hessberger, T.; Zentel, R. Influence of a Crosslinker Containing an Azo Group on the Actuation Properties of a Photoactuating LCE System. Polymers 2016, 8, 435. [Google Scholar] [CrossRef]

- Pevnyi, M.; Moreira-Fontana, M.; Richards, G.; Zheng, X.; Palffy-Muhoray, P. Studies of Photo-Thermal Deformations of Liquid Crystal Elastomers under Local Illumination. Mol. Cryst. Liquid Cryst. 2017, 647, 228–234. [Google Scholar] [CrossRef]

- Yang, H.; Buguin, A.; Taulemesse, J.-M.; Kaneko, K.; Méry, S.; Bergeret, A.; Keller, P. Micron-Sized Main-Chain Liquid Crystalline Elastomer Actuators with Ultralarge Amplitude Contractions. J. Am. Chem. Soc. 2009, 131, 15000–15004. [Google Scholar] [CrossRef] [PubMed]

- Urayama, K.; Honda, S.; Takigawa, T. Electrooptical Effects with Anisotropic Deformation in Nematic Gels. Macromolecules 2005, 38, 3574–3576. [Google Scholar] [CrossRef]

- Spillmann, C.M.; Ratna, B.R.; Naciri, J. Anisotropic Actuation in Electroclinic Liquid Crystal Elastomers. Appl. Phys. Lett. 2007, 90, 021911. [Google Scholar] [CrossRef]

- Urayama, K. Selected Issues in Liquid Crystal Elastomers and Gels. Macromolecules 2007, 40, 2277–2288. [Google Scholar] [CrossRef]

- Kumar, K.; Knie, C.; Bléger, D.; Peletier, M.A.; Friedrich, H.; Hecht, S.; Broer, D.J.; Debije, M.G.; Schenning, A.P.H.J. A Chaotic Self-Oscillating Sunlight-Driven Polymer Actuator. Nat. Commun. 2016, 7, 11975. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, T.; Li, X.; Zhang, Y.; Yu, H. NIR–Vis–UV Light-Responsive Actuator Films of Polymer-Dispersed Liquid Crystal/Graphene Oxide Nanocomposites. ACS Appl. Mater. Interfaces 2015, 7, 27494–27501. [Google Scholar] [CrossRef]

- Tabiryan, N.; Serak, S.; Dai, X.-M.; Bunning, T. Polymer Film with Optically Controlled Form and Actuation. Opt. Express 2005, 13, 7442. [Google Scholar] [CrossRef]

- Martella, D.; Nocentini, S.; Micheletti, F.; Wiersma, D.S.; Parmeggiani, C. Polarization-Dependent Deformation in Light Responsive Polymers Doped by Dichroic Dyes. Soft Matter 2019, 15, 1312–1318. [Google Scholar] [CrossRef]

- Gelebart, A.H.; Jan Mulder, D.; Varga, M.; Konya, A.; Vantomme, G.; Meijer, E.W.; Selinger, R.L.B.; Broer, D.J. Making Waves in a Photoactive Polymer Film. Nature 2017, 546, 632–636. [Google Scholar] [CrossRef]

- Liu, X.; Kim, S.-K.; Wang, X. Thermomechanical Liquid Crystalline Elastomer Capillaries with Biomimetic Peristaltic Crawling Function. J. Mater. Chem. B 2016, 4, 7293–7302. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Z.; Ma, S.; Zhang, Y.; Huang, S.; Chen, Y.; Yu, H. Photomechanical Motion of Liquid-Crystalline Fibers Bending Away from a Light Source. Macromolecules 2017, 50, 8317–8324. [Google Scholar] [CrossRef]

- Ge, F.; Zhao, Y. Microstructured Actuation of Liquid Crystal Polymer Networks. Adv. Funct. Mater. 2020, 30, 1901890. [Google Scholar] [CrossRef]

- Finkelmann, H.; Kock, H.-J.; Rehage, G. Investigations on Liquid Crystalline Polysiloxanes Liquid Crystalline Elastomers—A New Type of Liquid Crystalline Material. Makromol. Chem. Rapid Commun. 1981, 2, 317–322. [Google Scholar] [CrossRef]

- Küpfer, J.; Finkelmann, H. Nematic Liquid Single Crystal Elastomers. Makromol. Chem. Rapid Commun. 1991, 12, 717–726. [Google Scholar] [CrossRef]

- Yoon, H.-H.; Kim, D.-Y.; Jeong, K.-U.; Ahn, S. Surface Aligned Main-Chain Liquid Crystalline Elastomers: Tailored Properties by the Choice of Amine Chain Extenders. Macromolecules 2018, 51, 1141–1149. [Google Scholar] [CrossRef]

- Barnes, M.; Cetinkaya, S.; Ajnsztajn, A.; Verduzco, R. Understanding the Effect of Liquid Crystal Content on the Phase Behavior and Mechanical Properties of Liquid Crystal Elastomers. Soft Matter 2022, 18, 5074–5081. [Google Scholar] [CrossRef]

- Herbert, K.M.; Fowler, H.E.; McCracken, J.M.; Schlafmann, K.R.; Koch, J.A.; White, T.J. Synthesis and Alignment of Liquid Crystalline Elastomers. Nat. Rev. Mater. 2022, 7, 23–38. [Google Scholar] [CrossRef]

- Finkelmann, H.; Nishikawa, E.; Pereira, G.G.; Warner, M. A New Opto-Mechanical Effect in Solids. Phys. Rev. Lett. 2001, 87, 015501. [Google Scholar] [CrossRef]

- Sánchez-Ferrer, A.; Merekalov, A.; Finkelmann, H. Opto-Mechanical Effect in Photoactive Nematic Side-Chain Liquid-Crystalline Elastomers: Opto-Mechanical Effect in Photoactive. Macromol. Rapid Commun. 2011, 32, 671–678. [Google Scholar] [CrossRef]

- Ahn, S.; Ware, T.H.; Lee, K.M.; Tondiglia, V.P.; White, T.J. Photoinduced Topographical Feature Development in Blueprinted Azobenzene-Functionalized Liquid Crystalline Elastomers. Adv. Funct. Mater. 2016, 26, 5819–5826. [Google Scholar] [CrossRef]

- Mehta, K.; Peeketi, A.R.; Liu, L.; Broer, D.; Onck, P.; Annabattula, R.K. Design and Applications of Light Responsive Liquid Crystal Polymer Thin Films. Appl. Phys. Rev. 2020, 7, 041306. [Google Scholar] [CrossRef]

- Marshall, J.E.; Ji, Y.; Torras, N.; Zinoviev, K.; Terentjev, E.M. Carbon-Nanotube Sensitized Nematic Elastomer Composites for IR-Visible Photo-Actuation. Soft Matter 2012, 8, 1570–1574. [Google Scholar] [CrossRef]

- Liu, X.; Wei, R.; Hoang, P.T.; Wang, X.; Liu, T.; Keller, P. Reversible and Rapid Laser Actuation of Liquid Crystalline Elastomer Micropillars with Inclusion of Gold Nanoparticles. Adv. Funct. Mater. 2015, 25, 3022–3032. [Google Scholar] [CrossRef]

- Hauser, A.W.; Liu, D.; Bryson, K.C.; Hayward, R.C.; Broer, D.J. Reconfiguring Nanocomposite Liquid Crystal Polymer Films with Visible Light. Macromolecules 2016, 49, 1575–1581. [Google Scholar] [CrossRef]

- He, Q.; Wang, Z.; Wang, Y.; Wang, Z.; Li, C.; Annapooranan, R.; Zeng, J.; Chen, R.; Cai, S. Electrospun Liquid Crystal Elastomer Microfiber Actuator. Sci. Robot. 2021, 6, eabi9704. [Google Scholar] [CrossRef] [PubMed]

- Lahikainen, M.; Zeng, H.; Priimagi, A. Reconfigurable Photoactuator through Synergistic Use of Photochemical and Photothermal Effects. Nat. Commun. 2018, 9, 4148. [Google Scholar] [CrossRef]

- Cheng, Y.; Lu, H.; Lee, X.; Zeng, H.; Priimagi, A. Soft Actuators: Kirigami-Based Light-Induced Shape-Morphing and Locomotion (Adv. Mater. 7/2020). Adv. Mater. 2020, 32, 2070047. [Google Scholar] [CrossRef]

- Rogóż, M.; Zeng, H.; Xuan, C.; Wiersma, D.S.; Wasylczyk, P. Light-Driven Soft Robot Mimics Caterpillar Locomotion in Natural Scale. Adv. Opt. Mater. 2016, 4, 1689–1694. [Google Scholar] [CrossRef]

- Ware, T.H.; McConney, M.E.; Wie, J.J.; Tondiglia, V.P.; White, T.J. Voxelated Liquid Crystal Elastomers. Science 2015, 347, 982–984. [Google Scholar] [CrossRef]

- Rogóż, M.; Haberko, J.; Wasylczyk, P. Light-Driven Linear Inchworm Motor Based on Liquid Crystal Elastomer Actuators Fabricated with Rubbing Overwriting. Materials 2021, 14, 6688. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Waters, J.T.; Shneidman, A.V.; Cui, J.; Wang, X.; Mandsberg, N.K.; Li, S.; Balazs, A.C.; Aizenberg, J. Multiresponsive Polymeric Microstructures with Encoded Predetermined and Self-Regulated Deformability. Proc. Natl. Acad. Sci. USA 2018, 115, 12950–12955. [Google Scholar] [CrossRef] [PubMed]

- Wehner, M.; Truby, R.L.; Fitzgerald, D.J.; Mosadegh, B.; Whitesides, G.M.; Lewis, J.A.; Wood, R.J. An Integrated Design and Fabrication Strategy for Entirely Soft, Autonomous Robots. Nature 2016, 536, 451–455. [Google Scholar] [CrossRef]

- Truby, R.L.; Lewis, J.A. Printing Soft Matter in Three Dimensions. Nature 2016, 540, 371–378. [Google Scholar] [CrossRef]

- Zeng, H.; Wasylczyk, P.; Cerretti, G.; Martella, D.; Parmeggiani, C.; Wiersma, D.S. Alignment Engineering in Liquid Crystalline Elastomers: Free-Form Microstructures with Multiple Functionalities. Appl. Phys. Lett. 2015, 106, 111902. [Google Scholar] [CrossRef]

- Grabowski, P.; Haberko, J.; Wasylczyk, P. Photo-Mechanical Response Dynamics of Liquid Crystal Elastomer Linear Actuators. Materials 2020, 13, 2933. [Google Scholar] [CrossRef]

- Yamada, M.; Kondo, M.; Mamiya, J.; Yu, Y.; Kinoshita, M.; Barrett, C.J.; Ikeda, T. Photomobile Polymer Materials: Towards Light-Driven Plastic Motors. Angew. Chem. Int. Ed. 2008, 47, 4986–4988. [Google Scholar] [CrossRef]

- Wang, H.; Pumera, M. Fabrication of Micro/Nanoscale Motors. Chem. Rev. 2015, 115, 8704–8735. [Google Scholar] [CrossRef]

- Xu, L.; Mou, F.; Gong, H.; Luo, M.; Guan, J. Light-Driven Micro/Nanomotors: From Fundamentals to Applications. Chem. Soc. Rev. 2017, 46, 6905–6926. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, Q.; Du, X. Light-Powered Micro/Nanomotors. Micromachines 2018, 9, 41. [Google Scholar] [CrossRef]

- Bisoyi, H.K.; Li, Q. Light-Driven Liquid Crystalline Materials: From Photo-Induced Phase Transitions and Property Modulations to Applications. Chem. Rev. 2016, 116, 15089–15166. [Google Scholar] [CrossRef] [PubMed]

- Ahn, C.; Li, K.; Cai, S. Light or Thermally Powered Autonomous Rolling of an Elastomer Rod. ACS Appl. Mater. Interfaces 2018, 10, 25689–25696. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Guo, S.; Tong, X.; Xia, H.; Zhao, Y. Tunable Photocontrolled Motions Using Stored Strain Energy in Malleable Azobenzene Liquid Crystalline Polymer Actuators. Adv. Mater. 2017, 29, 1606467. [Google Scholar] [CrossRef]

- Dradrach, K.; Rogóż, M.; Grabowski, P.; Xuan, C.; Węgłowski, R.; Konieczkowska, J.; Schab-Balcerzak, E.; Piecek, W.; Wasylczyk, P. Traveling Wave Rotary Micromotor Based on a Photomechanical Response in Liquid Crystal Polymer Networks. ACS Appl. Mater. Interfaces 2020, 12, 8681–8686. [Google Scholar] [CrossRef] [PubMed]

- Morita, T. Miniature Piezoelectric Motors. Sens. Actuators A Phys. 2003, 103, 291–300. [Google Scholar] [CrossRef]

- Oh, J.-H.; Jung, H.-E.; Lee, J.; Lim, K.-J.; Kim, H.-H.; Ryu, B.-H.; Park, D.-H. Design and Performances of High Torque Ultrasonic Motor for Application of Automobile. J. Electroceram. 2009, 22, 150–155. [Google Scholar] [CrossRef]

- Spanner, K.; Koc, B. Piezoelectric Motors, an Overview. Actuators 2016, 5, 6. [Google Scholar] [CrossRef]

- Traveling Wave Rotary Micromotor. Available online: https://www.youtube.com/watch?v=2w5vf_kfO5Y&ab_channel=PNaF (accessed on 1 October 2022).

- Smits, J.G. Design Considerations of a Piezoelectric-on-Silicon Microrobot. Sens. Actuators A Phys. 1992, 35, 129–135. [Google Scholar] [CrossRef]

- Bexell, M.; Tiensuu, A.-L.; Schweitz, J.-Å.; Söderkvist, J.; Johansson, S. Characterization of an Inchworm Prototype Motor. Sens. Actuators A Phys. 1994, 43, 322–329. [Google Scholar] [CrossRef]

- Montazami, R.; Spillmann, C.M.; Naciri, J.; Ratna, B.R. Enhanced Thermomechanical Properties of a Nematic Liquid Crystal Elastomer Doped with Gold Nanoparticles. Sens. Actuators A Phys. 2012, 178, 175–178. [Google Scholar] [CrossRef]

- Han, W.C.; Sim, G.W.; Kim, Y.B.; Kim, D.S. Reversible Curvature Reversal of Monolithic Liquid Crystal Elastomer Film and Its Smart Valve Application. Macromol. Rapid Commun. 2021, 42, 2100404. [Google Scholar] [CrossRef]

- Inchworm Motor Based on Liquid Crystal Elastomer Actuators Fabricated with Rubbing Overwriting. Available online: https://www.youtube.com/watch?v=PhxzyFMsWJU&ab_channel=PNaF (accessed on 1 October 2022).

- Lombardero, M.; Yllera, M. del M. Leonardo Da Vinci’s Animal Anatomy: Bear and Horse Drawings Revisited. Animals 2019, 9, 435. [Google Scholar] [CrossRef]

- Kim, S.; Laschi, C.; Trimmer, B. Soft Robotics: A Bioinspired Evolution in Robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef]

- Pilz da Cunha, M.; Debije, M.G.; Schenning, A.P.H.J. Bioinspired Light-Driven Soft Robots Based on Liquid Crystal Polymers. Chem. Soc. Rev. 2020, 49, 6568–6578. [Google Scholar] [CrossRef] [PubMed]

- Light-Driven Soft Robot Mimics Caterpillar Locomotion in Natural Scale. Available online: https://www.youtube.com/watch?v=mAGK8JG0gVY&ab_channel=PNaF (accessed on 1 October 2022).

- Brackenbury, J. Fast Locomotion in Caterpillars. J. Insect Physiol. 1999, 45, 525–533. [Google Scholar] [CrossRef]

- Wang, C.; Sim, K.; Chen, J.; Kim, H.; Rao, Z.; Li, Y.; Chen, W.; Song, J.; Verduzco, R.; Yu, C. Soft Ultrathin Electronics Innervated Adaptive Fully Soft Robots. Adv. Mater. 2018, 30, 1706695. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Li, K.; He, Q.; Cai, S. A Light-Powered Ultralight Tensegrity Robot with High Deformability and Load Capacity. Adv. Mater. 2019, 31, 1806849. [Google Scholar] [CrossRef] [PubMed]

- Ahn, C.; Liang, X.; Cai, S. Bioinspired Design of Light-Powered Crawling, Squeezing, and Jumping Untethered Soft Robot. Adv. Mater. Technol. 2019, 4, 1900185. [Google Scholar] [CrossRef]

- Snail Soft Robot, Light-Powered, Made of LCE. Available online: https://www.youtube.com/watch?v=u3z3TdB4BT0&ab_channel=PNaF (accessed on 1 October 2022).

- Denny, M. The Role of Gastropod Pedal Mucus in Locomotion. Nature 1980, 285, 160–161. [Google Scholar] [CrossRef]

- Denny, M.W. A Quantitative Model for the Adhesive Locomotion of the Terrestrial Slug, Ariolimax columbianus. J. Exp. Biol. 1981, 91, 195–217. [Google Scholar] [CrossRef]

- Parker, G.H. The Mechanism of Locomotion in Gastropods. J. Morphol. 1911, 22, 155–170. [Google Scholar] [CrossRef]

- Suter, R.; Rosenberg, O.; Loeb, S.; Wildman, H.; Long, J. Locomotion on the Water Surface: Propulsive Mechanisms of the Fisher Spider. J. Exp. Biol. 1997, 200, 2523–2538. [Google Scholar] [CrossRef] [PubMed]

- Hu, D.L.; Chan, B.; Bush, J.W.M. The Hydrodynamics of Water Strider Locomotion. Nature 2003, 424, 663–666. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; van den Berg, J.; Crosby, A.J. Autonomous Snapping and Jumping Polymer Gels. Nat. Mater. 2021, 20, 1695–1701. [Google Scholar] [CrossRef] [PubMed]

- Koh, J.-S.; Yang, E.; Jung, G.-P.; Jung, S.-P.; Son, J.H.; Lee, S.-I.; Jablonski, P.G.; Wood, R.J.; Kim, H.-Y.; Cho, K.-J. Jumping on Water: Surface Tension–Dominated Jumping of Water Striders and Robotic Insects. Science 2015, 349, 517–521. [Google Scholar] [CrossRef]

- Song, Y.S.; Sitti, M. Surface-Tension-Driven Biologically Inspired Water Strider Robots: Theory and Experiments. IEEE Trans. Robot. 2007, 23, 578–589. [Google Scholar] [CrossRef]

- Kudzia, A. Liquid Crystal Elastomer Films as Light-Driven Actuators with the Spectral Degree of Freedom. Bachelor’s Thesis, University of Warsaw, Warsaw, Poland, 2021. [Google Scholar]

- Zmyślony, M.; Dradrach, K.; Haberko, J.; Nałęcz-Jawecki, P.; Rogóż, M.; Wasylczyk, P. Optical Pliers: Micrometer-Scale, Light-Driven Tools Grown on Optical Fibers. Adv. Mater. 2020, 32, 2002779. [Google Scholar] [CrossRef]

- Optical Pliers: Micrometer-Scale, Light-Driven Tools Grown on Optical Fibers. Available online: https://www.youtube.com/watch?v=j-R-SB6EBqs&ab_channel=PNaF (accessed on 1 October 2022).

- Ashkin, A.; Dziedzic, J.M. Optical Trapping and Manipulation of Viruses and Bacteria. Science 1987, 235, 1517–1520. [Google Scholar] [CrossRef]

- Carlotti, M.; Tricinci, O.; den Hoed, F.; Palagi, S.; Mattoli, V. Direct Laser Writing of Liquid Crystal Elastomers Oriented by a Horizontal Electric Field. Open Res. Europe 2021, 1, 129. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, X.; Fei, G.; Wang, Z.; Xia, H.; Zhao, Y. 4D Printing of a Liquid Crystal Elastomer with a Controllable Orientation Gradient. ACS Appl. Mater. Interfaces 2019, 11, 44774–44782. [Google Scholar] [CrossRef]

- McCracken, J.M.; Donovan, B.R.; White, T.J. Materials as Machines. Adv. Mater. 2020, 32, 1906564. [Google Scholar] [CrossRef] [PubMed]

- Wani, O.M.; Zeng, H.; Wasylczyk, P.; Priimagi, A. Programming Photoresponse in Liquid Crystal Polymer Actuators with Laser Projector. Adv. Opt. Mater. 2018, 6, 1700949. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rogóż, M.; Dziekan, Z.; Dradrach, K.; Zmyślony, M.; Nałęcz-Jawecki, P.; Grabowski, P.; Fabjanowicz, B.; Podgórska, M.; Kudzia, A.; Wasylczyk, P. From Light-Powered Motors, to Micro-Grippers, to Crawling Caterpillars, Snails and Beyond—Light-Responsive Oriented Polymers in Action. Materials 2022, 15, 8214. https://doi.org/10.3390/ma15228214

Rogóż M, Dziekan Z, Dradrach K, Zmyślony M, Nałęcz-Jawecki P, Grabowski P, Fabjanowicz B, Podgórska M, Kudzia A, Wasylczyk P. From Light-Powered Motors, to Micro-Grippers, to Crawling Caterpillars, Snails and Beyond—Light-Responsive Oriented Polymers in Action. Materials. 2022; 15(22):8214. https://doi.org/10.3390/ma15228214

Chicago/Turabian StyleRogóż, Mikołaj, Zofia Dziekan, Klaudia Dradrach, Michał Zmyślony, Paweł Nałęcz-Jawecki, Przemysław Grabowski, Bartosz Fabjanowicz, Magdalena Podgórska, Anna Kudzia, and Piotr Wasylczyk. 2022. "From Light-Powered Motors, to Micro-Grippers, to Crawling Caterpillars, Snails and Beyond—Light-Responsive Oriented Polymers in Action" Materials 15, no. 22: 8214. https://doi.org/10.3390/ma15228214

APA StyleRogóż, M., Dziekan, Z., Dradrach, K., Zmyślony, M., Nałęcz-Jawecki, P., Grabowski, P., Fabjanowicz, B., Podgórska, M., Kudzia, A., & Wasylczyk, P. (2022). From Light-Powered Motors, to Micro-Grippers, to Crawling Caterpillars, Snails and Beyond—Light-Responsive Oriented Polymers in Action. Materials, 15(22), 8214. https://doi.org/10.3390/ma15228214