High Piezoelectric Output Voltage from Blue Fluorescent N,N-Dimethyl-4-nitroaniline Nano Crystals in Poly-L-Lactic Acid Electrospun Fibers

Abstract

1. Introduction

2. Materials and Methods

2.1. Solution Preparation

2.2. Electrospinning of Microfibers

2.3. Characterization Techniques

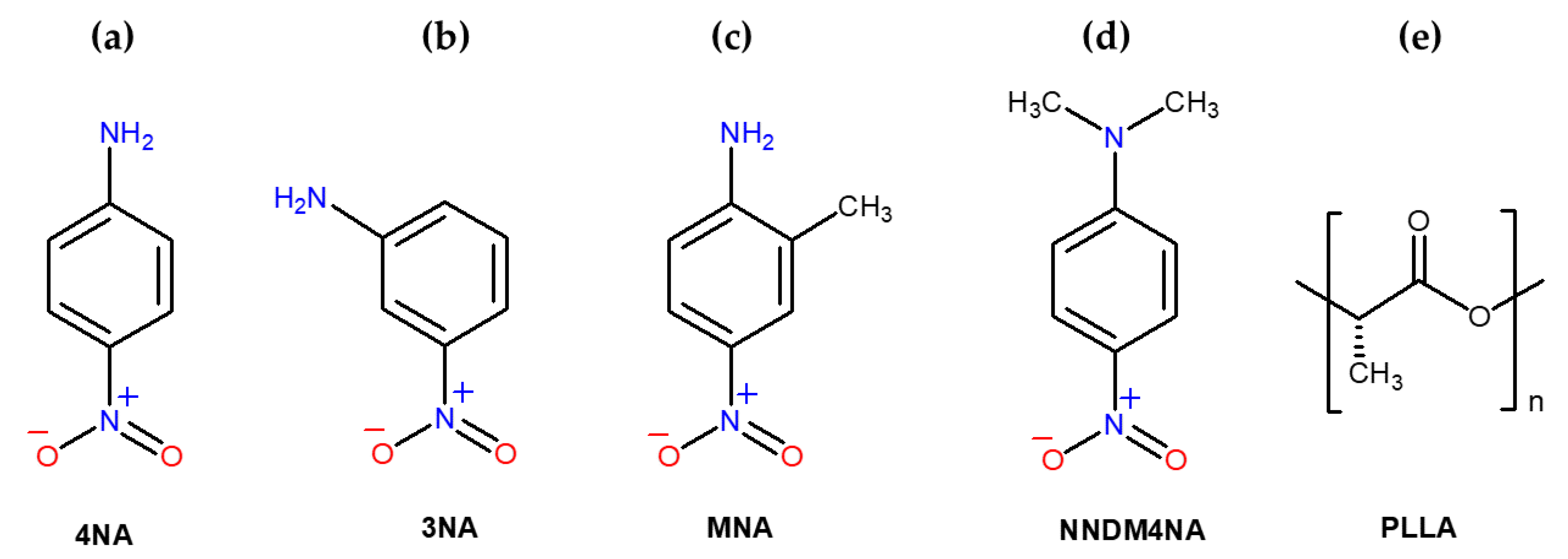

3. Results and Discussion

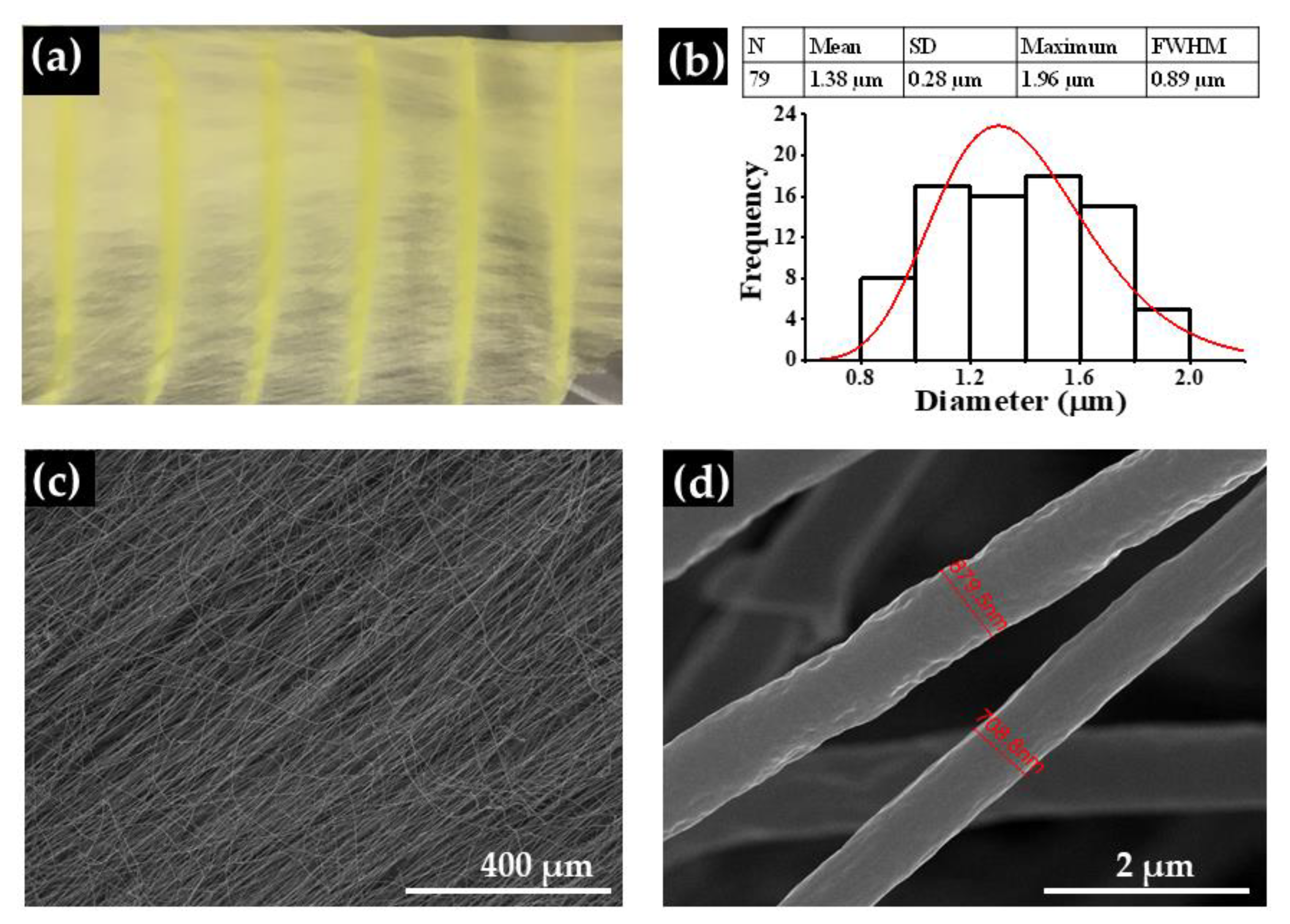

3.1. Fiber Morphology and Crystallinity

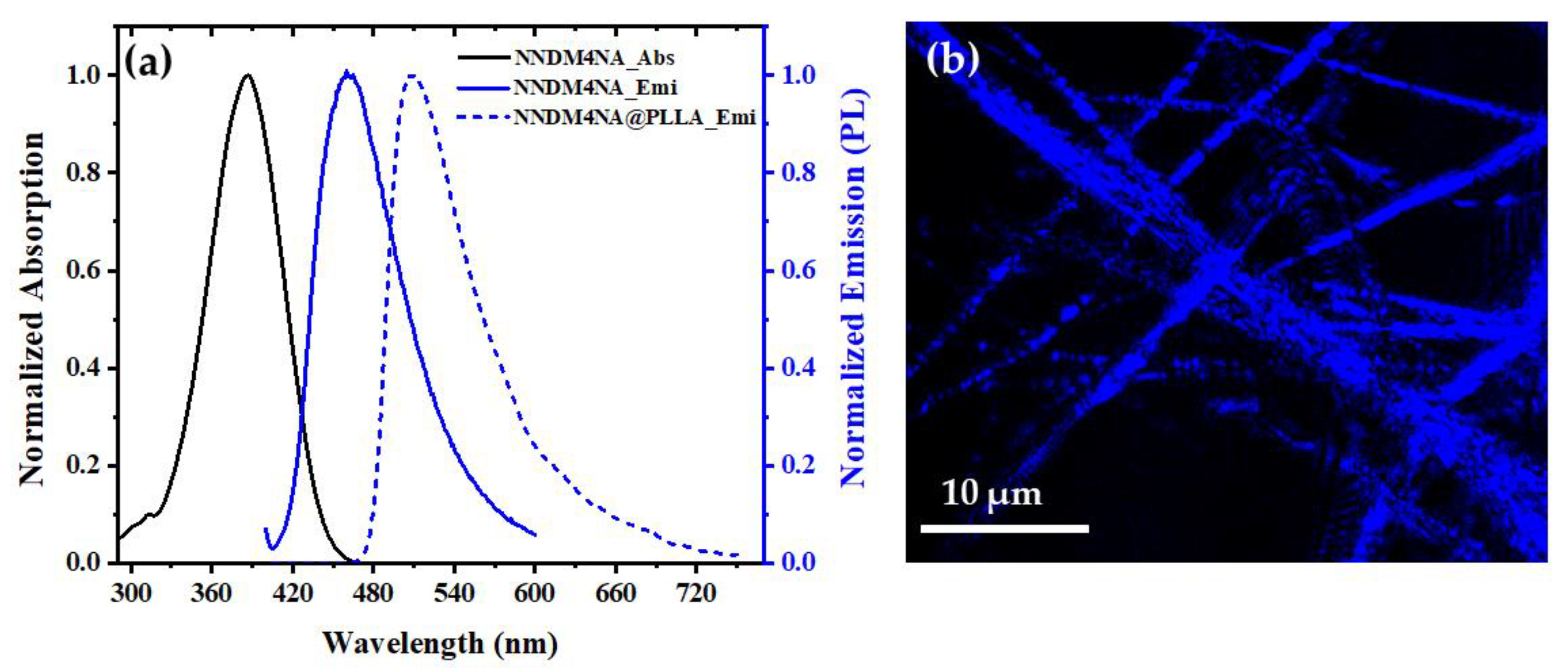

3.2. Optical Absorption and Luminescence

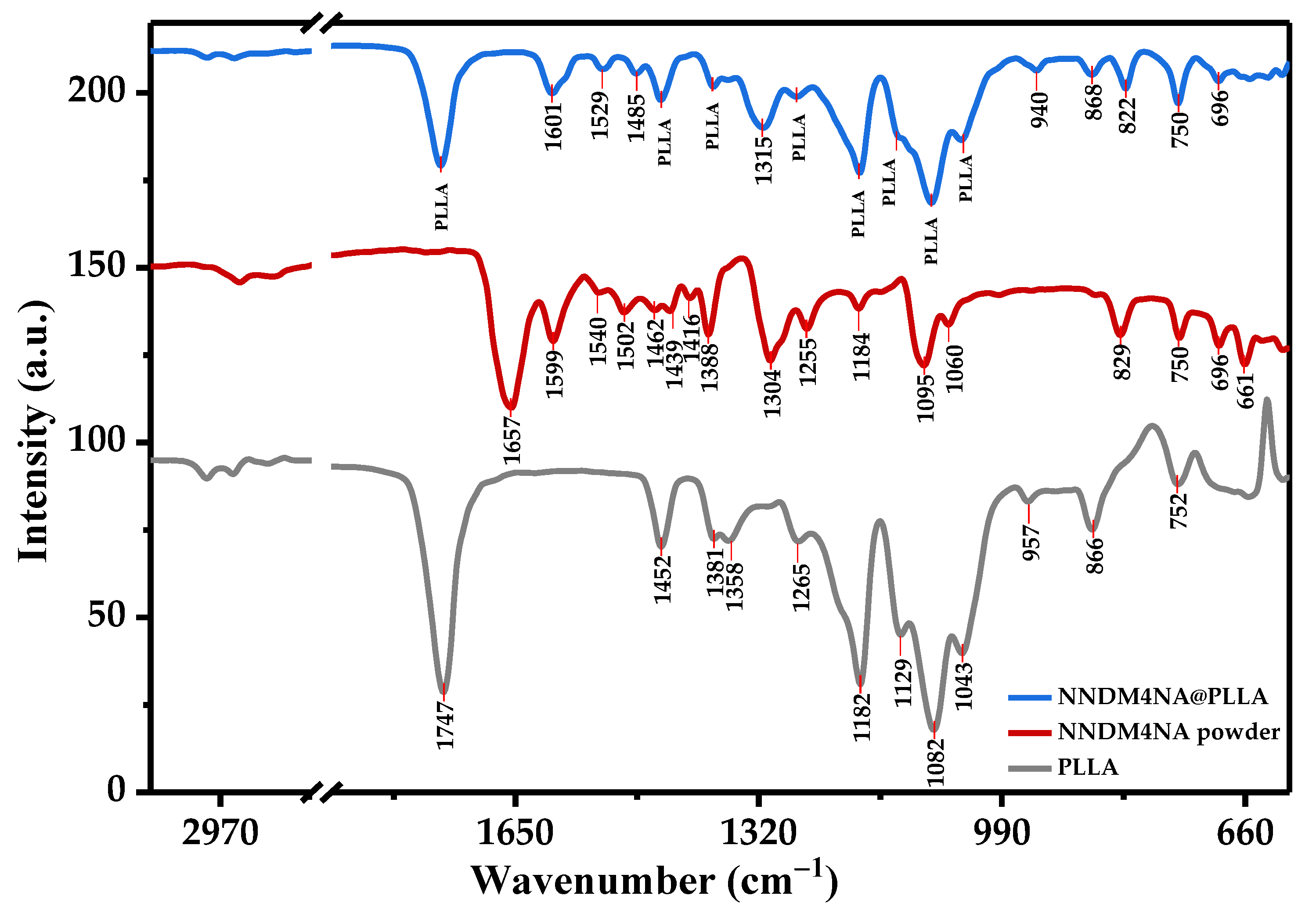

3.3. Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy (FTIR-ATR)

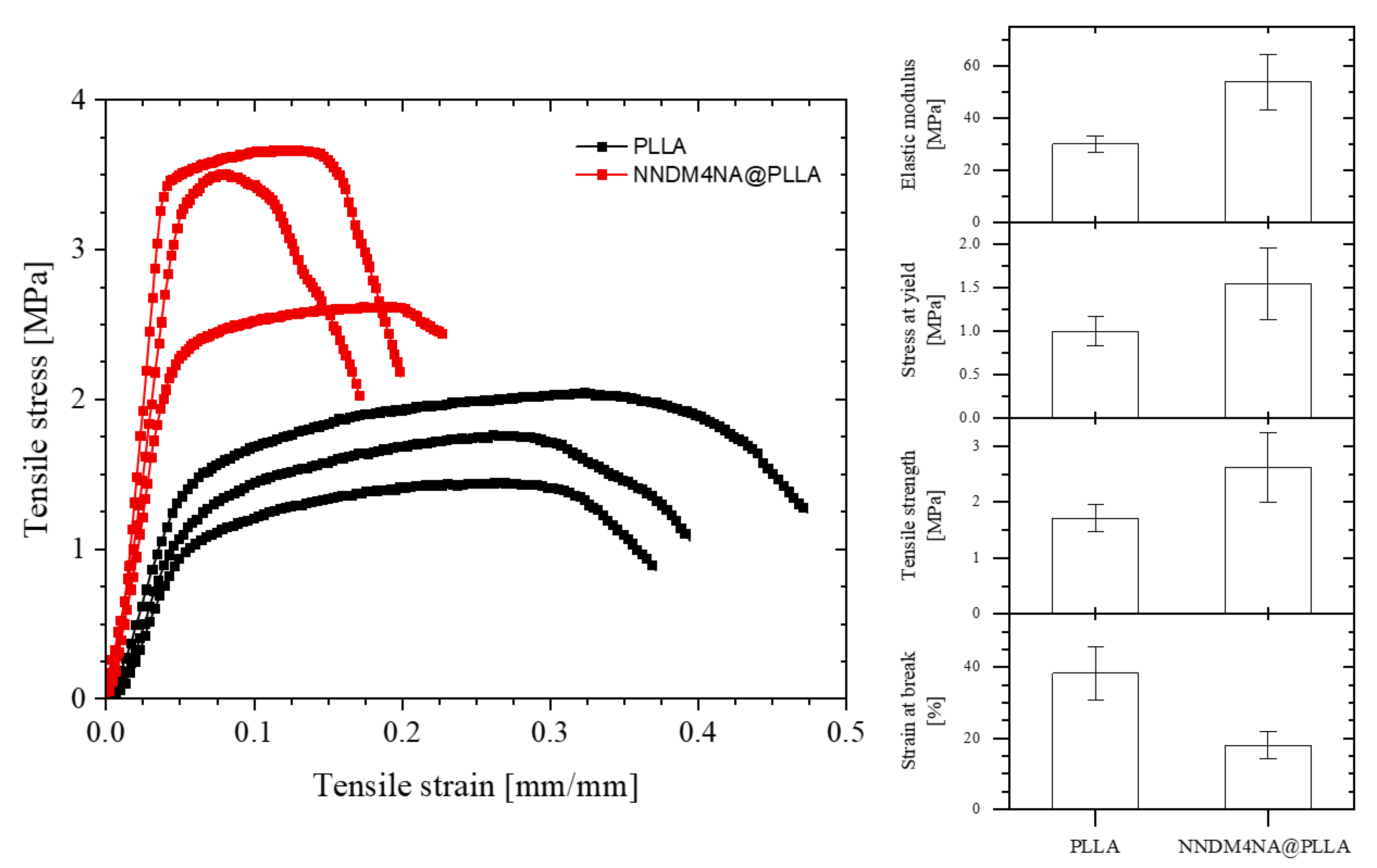

3.4. Mechanical Performance

3.5. Dielectric Permittivity

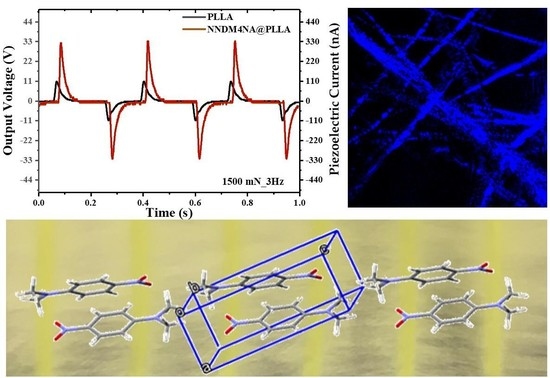

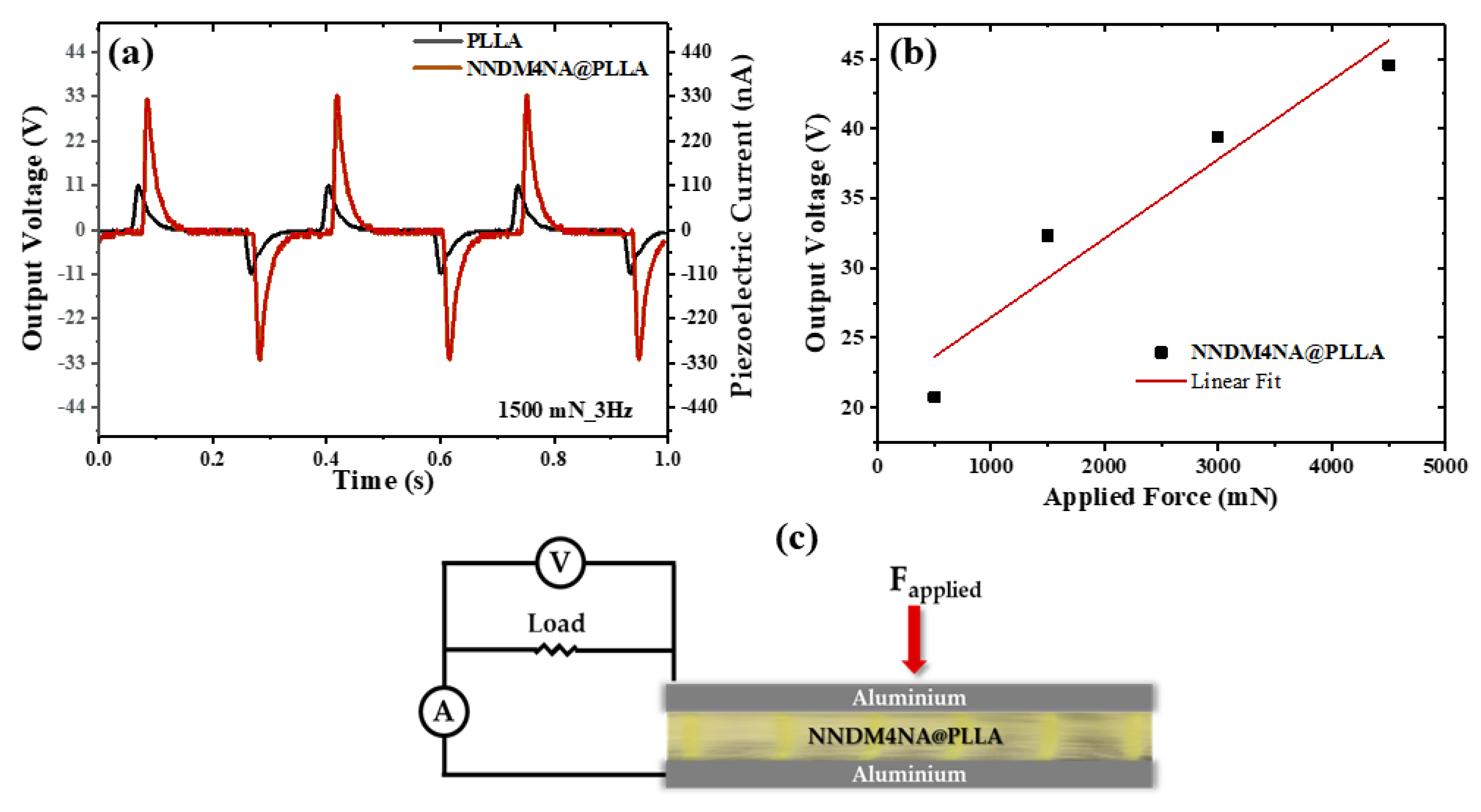

3.6. Microfibers Piezoelectric Voltage

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Xu, J.L.; Semin, S.; Rasing, T.; Rowan, A.E. Organized chromophoric assemblies for nonlinear optical materials: Towards (sub)wavelength scale architectures. Small 2015, 11, 1113–1129. [Google Scholar] [CrossRef] [PubMed]

- Bosshard, C.; Hulliger, J.; Florsheimer, M.; Gunter, P. Organic Nonlinear Optical Materials; CRC Press: Boca Raton, FL, USA, 2001. [Google Scholar]

- Garito, A.; Singer, K.; Teng, C. Molecular Optics: Nonlinear Optical Properties of Organic and Polymeric Crystals; ACS Publications: Washington, DC, USA, 1983. [Google Scholar]

- Nalwa, H.S.; Miyata, S. Nonlinear Optics of Organic Molecules and Polymers; CRC Press: Boca Raton, FL, USA, 1996. [Google Scholar]

- Hashimoto, H.; Okada, Y.; Fujimura, H.; Morioka, M.; Sugihara, O.; Okamoto, N.; Matsushima, R. Second-harmonic generation from single crystals of n-substituted 4-nitroanilines. Jpn. J. Appl. Phys. 1997, 36, 6754–6760. [Google Scholar] [CrossRef]

- Trueblood, K.N.; Goldish, E.; Donohue, J. A three-dimensional refinement of the crystal structure of 4-nitroaniline. Acta Crystallogr. 1961, 14, 1009–1017. [Google Scholar] [CrossRef]

- Ayers, S.; Faktor, M.M.; Marr, D.; Stevenson, J.L. Growth of single crystals of meta-nitroaniline and the evaluation of its electro-optic properties. J. Mater. Sci. 1972, 7, 31–33. [Google Scholar] [CrossRef]

- Bain, A.M.; El-Korashy, N.; Gilmour, S.; Pethrick, R.A.; Sherwood, J.N. Ultrasonic and piezoelectric investigations on single crystals of 3-nitroaniline. Philos. Mag. B 1992, 66, 293–305. [Google Scholar] [CrossRef]

- Davis, D.; Sreekumar, K.; Sajeev, Y.; Pal, S. Optimization of nonlinear optical properties by substituent position, geometry and symmetry of the molecule: An ab initio study. J. Phys. Chem. B 2005, 109, 14093–14101. [Google Scholar] [CrossRef] [PubMed]

- Howard, S.T.; Hursthouse, M.B.; Lehmann, C.W.; Mallinson, P.R.; Frampton, C.S. Experimental and theoretical-study of the charge-density in 2-methyl-4-nitroaniline. J. Chem. Phys. 1992, 97, 5616–5630. [Google Scholar] [CrossRef]

- Paturle, A.; Graafsma, H.; Sheu, H.S.; Coppens, P.; Becker, P. Measurement of the piezoelectric tensor of an organic crystal by the X-ray method: The nonlinear optical crystal 2-methyl 4-nitroaniline. Phys. Rev. B 1991, 43, 14683–14691. [Google Scholar] [CrossRef]

- Levine, B.F.; Bethea, C.G.; Thurmond, C.D.; Lynch, R.T.; Bernstein, J.L. An organic crystal with an exceptionally large optical second-harmonic coefficient: 2-Methyl-4-nitroaniline. J. Appl. Phys. 1979, 50, 2523–2527. [Google Scholar] [CrossRef]

- Dmitriev, V.G.; Gurzadyan, G.G.; Nikogosyan, D.N. Handbook of Nonlinear Optical Crystals; Springer: Berlin/Heidelberg, Germany, 2013; Volume 64. [Google Scholar]

- Frazier, C.C.; Cockerham, M.P.; Chauchard, E.A.; Lee, C.H. Second-harmonic generation in aromatic organic compounds. J. Opt. Soc. Am. B 1987, 4, 1899–1903. [Google Scholar] [CrossRef]

- Mak, T.C.W.; Trotter, J. The crystal and molecular structure of N,N-dimethyl-p-nitroaniline. Acta Crystallogr. 1965, 18, 68–74. [Google Scholar] [CrossRef]

- Borbulevych, O.Y.; Clark, R.D.; Romero, A.; Tan, L.; Antipin, M.Y.; Nesterov, V.N.; Cardelino, B.H.; Moore, C.E.; Sanghadasa, M.; Timofeeva, T.V. Experimental and theoretical study of the structure of N,N-dimethyl-4-nitroaniline derivatives as model compounds for non-linear optical organic materials. J. Mol. Struct. 2002, 604, 73–86. [Google Scholar] [CrossRef]

- Takamizawa, S.; Takasaki, Y.; Sasaki, T.; Ozaki, N. Superplasticity in an organic crystal. Nat. Commun. 2018, 9, 3984. [Google Scholar] [CrossRef] [PubMed]

- Edington, J.W.; Melton, K.N.; Cutler, C.P. Superplasticity. Prog. Mater. Sci. 1976, 21, 61–170. [Google Scholar] [CrossRef]

- Langdon, T.G. Grain boundary sliding revisited: Developments in sliding over four decades. J. Mater. Sci. 2006, 41, 597–609. [Google Scholar] [CrossRef]

- Krishna, G.R.; Devarapalli, R.; Lal, G.; Reddy, C.M. Mechanically flexible organic crystals achieved by introducing weak interactions in structure: Supramolecular shape synthons. J. Am. Chem. Soc. 2016, 138, 13561–13567. [Google Scholar] [CrossRef]

- Gupta, P.; Allu, S.; Karothu, D.P.; Panda, T.; Nath, N.K. Organic molecular crystals with dual stress-induced mechanical response: Elastic and plastic flexibility. Cryst. Growth Des. 2021, 21, 1931–1938. [Google Scholar] [CrossRef]

- Saha, S.; Mishra, M.K.; Reddy, C.M.; Desiraju, G.R. From molecules to interactions to crystal engineering: Mechanical properties of organic solids. Acc. Chem. Res. 2018, 51, 2957–2967. [Google Scholar] [CrossRef]

- Ghosh, S.; Mishra, M.K. Elastic molecular crystals: From serendipity to design to applications. Cryst. Growth Des. 2021, 21, 2566–2580. [Google Scholar] [CrossRef]

- Ahmed, E.; Karothu, D.P.; Naumov, P. Crystal Adaptronics: Mechanically Reconfigurable Elastic and Superelastic Molecular Crystals. Angew. Chem. Int. Ed. 2018, 57, 8837–8846. [Google Scholar] [CrossRef]

- Greiner, A.; Wendorff, J.H. Electrospinning: A fascinating method for the preparation of ultrathin fibers. Angew. Chem. Int. Ed. 2007, 46, 5670–5703. [Google Scholar] [CrossRef] [PubMed]

- Reneker, D.H.; Yarin, A.L.; Fong, H.; Koombhongse, S. Bending instability of electrically charged liquid jets of polymer solutions in electrospinning. J. Appl. Phys. 2000, 87, 4531–4547. [Google Scholar] [CrossRef]

- Jana, S.; Cooper, A.; Ohuchi, F.; Zhang, M. Uniaxially aligned nanofibrous cylinders by electrospinning. ACS Appl. Mater. Inter. 2012, 4, 4817–4824. [Google Scholar] [CrossRef]

- Laramée, A.W.; Lanthier, C.; Pellerin, C. Electrospinning of highly crystalline polymers for strongly oriented fibers. ACS Appl. Polym. Mater. 2020, 2, 5025–5032. [Google Scholar] [CrossRef]

- Ding, J.; Zhang, J.; Li, J.; Li, D.; Xiao, C.; Xiao, H.; Yang, H.; Zhuang, X.; Chen, X. Electrospun polymer biomaterials. Prog. Polym. Sci. 2019, 90, 1–34. [Google Scholar] [CrossRef]

- Isakov, D.V.; de Matos Gomes, E.; Vieira, L.G.; Dekola, T.; Belsley, M.S.; Almeida, B.G. Oriented single-crystal-like molecular arrangement of optically nonlinear 2-methyl-4-nitroaniline in electrospun nanofibers. ACS Nano 2011, 5, 73–78. [Google Scholar] [CrossRef]

- Baptista, R.M.F.; Bernardo, C.R.; Belsley, M.S.; de Matos Gomes, E. Electrospun fibers with highly polarized second harmonic light from 2-amino-4-nitroaniline and 3-nitroaniline nanocrystals embedded in poly-L-lactic acid polymer. Opt. Mater. 2021, 116, 111089. [Google Scholar] [CrossRef]

- Baptista, R.M.F.; de Matos Gomes, E.; Raposo, M.M.M.; Costa, S.P.G.; Lopes, P.E.; Almeida, B.; Belsley, M.S. Self-assembly of dipeptide Boc-diphenylalanine nanotubes inside electrospun polymeric fibers with strong piezoelectric response. Nanoscale Adv. 2019, 1, 4339–4346. [Google Scholar] [CrossRef]

- Baptista, R.M.F.; Isakov, D.; Raposo, M.M.M.; Belsley, M.; Bdikin, I.; Kholkin, A.L.; Costa, S.P.G.; de Matos Gomes, E. Ferroelectric nanofibers with an embedded optically nonlinear benzothiazole derivative. J. Nanopart. Res. 2014, 16, 2502. [Google Scholar] [CrossRef]

- Bernardo, C.R.; Baptista, R.M.F.; de Matos Gomes, E.; Lopes, P.E.; Raposo, M.M.M.; Costa, S.P.G.; Belsley, M.S. Anisotropic PCL nanofibers embedded with nonlinear nanocrystals as strong generators of polarized second harmonic light and piezoelectric currents. Nanoscale Adv. 2020, 2, 1206–1213. [Google Scholar] [CrossRef]

- Papkov, D.; Delpouve, N.; Delbreilh, L.; Araujo, S.; Stockdale, T.; Mamedov, S.; Maleckis, K.; Zou, Y.; Andalib, M.N.; Dargent, E.; et al. Quantifying polymer chain orientation in strong and tough nanofibers with low crystallinity: Toward next generation nanostructured superfibers. ACS Nano 2019, 13, 4893–4927. [Google Scholar] [CrossRef] [PubMed]

- Persano, L.; Camposeo, A.; Tekmen, C.; Pisignano, D. Industrial upscaling of electrospinning and applications of polymer nanofibers: A Review. Macromol. Mater. Eng. 2013, 298, 504–520. [Google Scholar] [CrossRef]

- Chang, J.; Dommer, M.; Chang, C.; Lin, L. Piezoelectric nanofibers for energy scavenging applications. Nano Energy 2012, 1, 356–371. [Google Scholar] [CrossRef]

- Kobayashi, J.; Asahi, T.; Ichiki, M.; Oikawa, A.; Suzuki, H.; Watanabe, T.; Fukada, E.; Shikinami, Y. Structural and optical properties of poly lactic acids. J. Appl. Phys. 1995, 77, 2957–2973. [Google Scholar] [CrossRef]

- Smith, M.; Calahorra, Y.; Jing, Q.; Kar-Narayan, S. Direct observation of shear piezoelectricity in poly-l-lactic acid nanowires. APL Mater. 2017, 5, 074105. [Google Scholar] [CrossRef]

- Chen, X.-G.; Song, X.-J.; Zhang, Z.-X.; Li, P.-F.; Ge, J.-Z.; Tang, Y.-Y.; Gao, J.-X.; Zhang, W.-Y.; Fu, D.-W.; You, Y.-M.; et al. Two-Dimensional Layered Perovskite Ferroelectric with Giant Piezoelectric Voltage Coefficient. J. Am. Chem. Soc. 2020, 142, 1077–1082. [Google Scholar] [CrossRef]

- Raghavender, A.T.; Samantilleke, A.P.; Sa, P.; Almeida, B.G.; Vasilevskiy, M.I.; Hong, N.H. Simple way to make Anatase TiO2 films on FTO glass for promising solar cells. Mater. Lett. 2012, 69, 59–62. [Google Scholar] [CrossRef]

- Kolev, T.; Koleva, B.B.; Spiteller, M.; Mayer-Figge, H.; Sheldrick, W.S. 2-Amino-4-nitroaniline, a known compound with unexpected properties. J. Phys. Chem. A 2007, 111, 10084–10089. [Google Scholar] [CrossRef]

- Khalil, O.S.; Seliskar, C.J.; McGlynn, S.P. Electronic spectroscopy of highly-polar aromatics. * II. Luminescence of nitroanilines. J. Chem. Phys. 1973, 58, 1607–1612. [Google Scholar] [CrossRef]

- Campoy-Quiles, M.; Ishii, Y.; Sakai, H.; Murata, H. Highly polarized luminescence from aligned conjugated polymer electrospun nanofibers. Appl. Phys. Lett. 2008, 92, 213305. [Google Scholar] [CrossRef]

- Camposeo, A.; Persano, L.; Pisignano, D. Light-emitting electrospun nanofibers for nanophotonics and optoelectronics. Macromol. Mater. Eng. 2013, 298, 487–503. [Google Scholar] [CrossRef]

- Meng, Y.; Fang, Y.; Yuan, C.; Du, C.; Wang, K.-P.; Chen, S.; Hu, Z.-Q. 2-Aryloxybenzo[d]oxazoles as deep blue solid-state emitters: Synthesis, aggregation-induced emission properties and crystal structure. Dye. Pigment. 2021, 187, 109127. [Google Scholar] [CrossRef]

- Li, Q.; Li, Z. Molecular Packing: Another Key Point for the Performance of Organic and Polymeric Optoelectronic Materials. Acc. Chem. Res. 2020, 53, 962–973. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.-B.; Li, Y.; Tang, B.Z.; Yoon, J. Assembly strategies of organic-based imaging agents for fluorescence and photoacoustic bioimaging applications. Chem. Soc. Rev. 2020, 49, 21–31. [Google Scholar] [CrossRef]

- Kozich, V.; Werncke, W.; Dreyer, J.; Brzezinka, K.W.; Rini, M.; Kummrow, A.; Elsaesser, T. Vibrational excitation and energy redistribution after ultrafast internal conversion in 4-nitroaniline. J. Chem. Phys. 2002, 117, 719–726. [Google Scholar] [CrossRef]

- Wang, W.C.; Shigeto, S. Infrared Electroabsorption Spectroscopy of N,N-Dimethyl-p-nitroaniline in Acetonitrile/C2Cl4: Solvation of the Solute and Self-Association of Acetonitrile. J. Phys. Chem. A 2011, 115, 4448–4456. [Google Scholar] [CrossRef]

- Kimura, Y.; Hamamoto, T.; Terazima, M. Raman spectroscopic study on the solvation of N,N-Dimethyl-p-nitroaniline in room-temperature ionic liquids. J. Phys. Chem. A 2007, 111, 7081–7089. [Google Scholar] [CrossRef]

- Szostak, M.M. A polarized infrared and Raman spectroscopic study of the electrooptic crystal m-nitroaniline. I—Assignments of internal vibrations. J. Raman Spectrosc. 1979, 8, 43–49. [Google Scholar] [CrossRef]

- Szostak, M.M. Vibronic couplings in vibrational spectra and nonlinear electrooptic properties of meta-nitroaniline crystal. Chem. Phys. 1988, 121, 449–456. [Google Scholar] [CrossRef]

- Bhuvaneswari, G.; Prabavathi, N.; Guru, P.L. Crystal growth, experimental, and theoretical investigation of organic NLO material n,n-dimethyl-4-nitroaniline. Int. J. Curr. Adv. Res. 2018, 7, 16442–16448. [Google Scholar]

- Okwieka, U.; Szostak, M.M.; Misiaszek, T.; Turowska-Tyrk, I.; Natkaniec, I.; Pavlukojć, A. Spectroscopic, structural and theoretical studies of 2-methyl-4-nitroaniline (MNA) crystal. Electronic transitions in IR. J. Raman Spectrosc. 2008, 39, 849–862. [Google Scholar] [CrossRef]

- Lee, D.W.; De Los Santos, V.L.; Seo, J.W.; Felix, L.L.; Bustamante, D.A.; Cole, J.M.; Barnes, C.H.W. The Structure of Graphite Oxide: Investigation of Its Surface Chemical Groups. J. Phys. Chem. B 2010, 114, 5723–5728. [Google Scholar] [CrossRef] [PubMed]

- Molares, M.E.T.; Buschmann, V.; Dobrev, D.; Neumann, R.; Scholz, R.; Schuchert, I.U.; Vetter, J. Single-crystalline copper nanowires produced by electrochemical deposition in polymeric ion track membranes. Adv. Mater. 2001, 13, 62–65. [Google Scholar] [CrossRef]

- Bognitzki, M.; Czado, W.; Frese, T.; Schaper, A.; Hellwig, M.; Steinhart, M.; Greiner, A.; Wendorff, J.H. Nanostructured Fibers via Electrospinning. Adv. Mater. 2001, 13, 70–72. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Nye, J.F. Physical Properties of Crystals: Their Representation by Tensors and Matrices; Oxford University Press: Oxford, UK, 1985. [Google Scholar]

- You, Y.-M.; Liao, W.-Q.; Zhao, D.; Ye, H.-Y.; Zhang, Y.; Zhou, Q.; Niu, X.; Wang, J.; Li, P.-F.; Fu, D.-W.; et al. An organic-inorganic perovskite ferroelectric with large piezoelectric response. Science 2017, 357, 306. [Google Scholar] [CrossRef]

- Pan, Q.; Xiong, Y.-A.; Sha, T.-T.; You, Y.-M. Recent progress in the piezoelectricity of molecular ferroelectrics. Mater. Chem. Front. 2021, 5, 44–59. [Google Scholar] [CrossRef]

- Li, M.; Wondergem, H.J.; Spijkman, M.-J.; Asadi, K.; Katsouras, I.; Blom, P.W.M.; de Leeuw, D.M. Revisiting the δ-phase of poly(vinylidene fluoride) for solution-processed ferroelectric thin films. Nat. Mater. 2013, 12, 433–438. [Google Scholar] [CrossRef]

- Li, Y.; Liao, C.; Tjong, S.C. Electrospun Polyvinylidene Fluoride-Based Fibrous Scaffolds with Piezoelectric Characteristics for Bone and Neural Tissue Engineering. Nanomaterials 2019, 9, 952. [Google Scholar] [CrossRef]

- Ji, W.; Xue, B.; Arnon, Z.A.; Yuan, H.; Bera, S.; Li, Q.; Zaguri, D.; Reynolds, N.P.; Li, H.; Chen, Y.; et al. Rigid Tightly Packed Amino Acid Crystals as Functional Supramolecular Materials. ACS Nano 2019, 13, 14477–14485. [Google Scholar] [CrossRef]

- Baptista, R.M.F.; Lopes, P.E.; Rodrigues, A.R.O.; Cerca, N.; Belsley, M.S.; de Matos Gomes, E. Self-assembly of Boc-p-nitro-L-phenylalanyl-p-nitro-L-phenylalanine and Boc-L-phenylalanyl-L-tyrosine in solution and into piezoelectric electrospun fibers. Mater. Adv. 2022, 3, 2934–2944. [Google Scholar] [CrossRef]

- Mishra, S.; Unnikrishnan, L.; Nayak, S.K.; Mohanty, S. Advances in Piezoelectric Pol-ymer Composites for Energy Harvesting Applications: A Systematic Review. Macromol. Mater. Eng. 2019, 304, 1800463. [Google Scholar] [CrossRef]

- Wasanasuk, K.; Tashiro, K.; Hanesaka, M.; Ohhara, T.; Kurihara, K.; Kuroki, R.; Tamada, T.; Ozeki, T.; Kanamoto, T. Crystal Structure Analysis of Poly(L-lactic Acid) α Form On the basis of the 2-Dimensional Wide-Angle Synchrotron X-ray and Neutron Diffraction Measurements. Macromolecules 2011, 44, 6441–6452. [Google Scholar] [CrossRef]

- Hammond, C. The Basics of Crystallography and Diffraction, 3rd ed.; International Union of Crystallography Texts on Crystallography: Chester, UK, 2015. [Google Scholar]

- Esteves, G.; Ramos, K.; Fancher, C.M.; Jones, J.L. LIPRAS: Line-Profile Analysis Software; MathWorks: Natick, MA, USA, 2017. [Google Scholar]

| Sample | λabs [nm] | λaexc [nm] | λemi [nm] | Stokes Shift [nm] |

|---|---|---|---|---|

| NNDM4NA | 386 | 386 | 460 | 74 |

| NNDM4NA@PLLA | — | 386 | 510 | 124 |

| Active System | Force/Area [Nm2] | Vout [V] | deff [pCN−1] | geff [VmN−1] | Ref. |

|---|---|---|---|---|---|

| NNDM4NA (Fiber array) | 4 × 103 | 33 | 147 | 4.1 | This work |

| 3NA (Fiber array) | 4 × 103 | 7 | 37 | 1.2 | [34] |

| (ATHP)2PbBr4 (Thin film) | — | — | — | 0.67 | [40] |

| PVDF (Thin film) | — | — | — | 0.29 (g33) | [63] |

| PVDF (Fiber array) | — | — | 25 (d33) | — | [64] |

| L-Tyrosine Film | 86 × 104 | 0.5 | — | — | [65] |

| Boc-PhePhe (Fiber array) | 4 × 103 | 30 | 8.4 | 0.3 | [32] |

| Boc-pNPhepNPhe (Fiber array) | 4 × 103 | 58 | 16 | 0.6 | [66] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baptista, R.M.F.; Silva, B.; Oliveira, J.; Isfahani, V.B.; Almeida, B.; Pereira, M.R.; Cerca, N.; Castro, C.; Rodrigues, P.V.; Machado, A.; et al. High Piezoelectric Output Voltage from Blue Fluorescent N,N-Dimethyl-4-nitroaniline Nano Crystals in Poly-L-Lactic Acid Electrospun Fibers. Materials 2022, 15, 7958. https://doi.org/10.3390/ma15227958

Baptista RMF, Silva B, Oliveira J, Isfahani VB, Almeida B, Pereira MR, Cerca N, Castro C, Rodrigues PV, Machado A, et al. High Piezoelectric Output Voltage from Blue Fluorescent N,N-Dimethyl-4-nitroaniline Nano Crystals in Poly-L-Lactic Acid Electrospun Fibers. Materials. 2022; 15(22):7958. https://doi.org/10.3390/ma15227958

Chicago/Turabian StyleBaptista, Rosa M. F., Bruna Silva, João Oliveira, Vahideh B. Isfahani, Bernardo Almeida, Mário R. Pereira, Nuno Cerca, Cidália Castro, Pedro V. Rodrigues, Ana Machado, and et al. 2022. "High Piezoelectric Output Voltage from Blue Fluorescent N,N-Dimethyl-4-nitroaniline Nano Crystals in Poly-L-Lactic Acid Electrospun Fibers" Materials 15, no. 22: 7958. https://doi.org/10.3390/ma15227958

APA StyleBaptista, R. M. F., Silva, B., Oliveira, J., Isfahani, V. B., Almeida, B., Pereira, M. R., Cerca, N., Castro, C., Rodrigues, P. V., Machado, A., Belsley, M., & Gomes, E. d. M. (2022). High Piezoelectric Output Voltage from Blue Fluorescent N,N-Dimethyl-4-nitroaniline Nano Crystals in Poly-L-Lactic Acid Electrospun Fibers. Materials, 15(22), 7958. https://doi.org/10.3390/ma15227958