Investigation of Microstructure and Mechanical Properties of SLM-Fabricated AlSi10Mg Alloy Post-Processed Using Equal Channel Angular Pressing (ECAP)

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructure

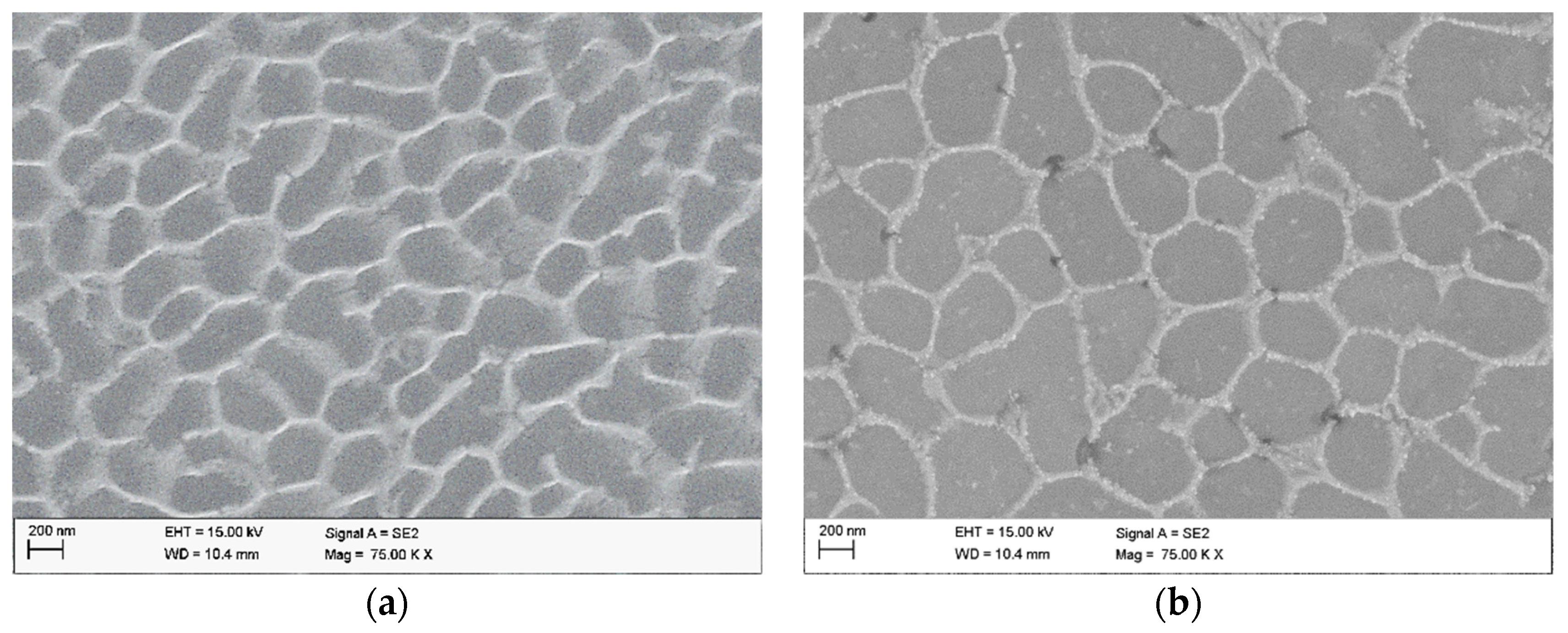

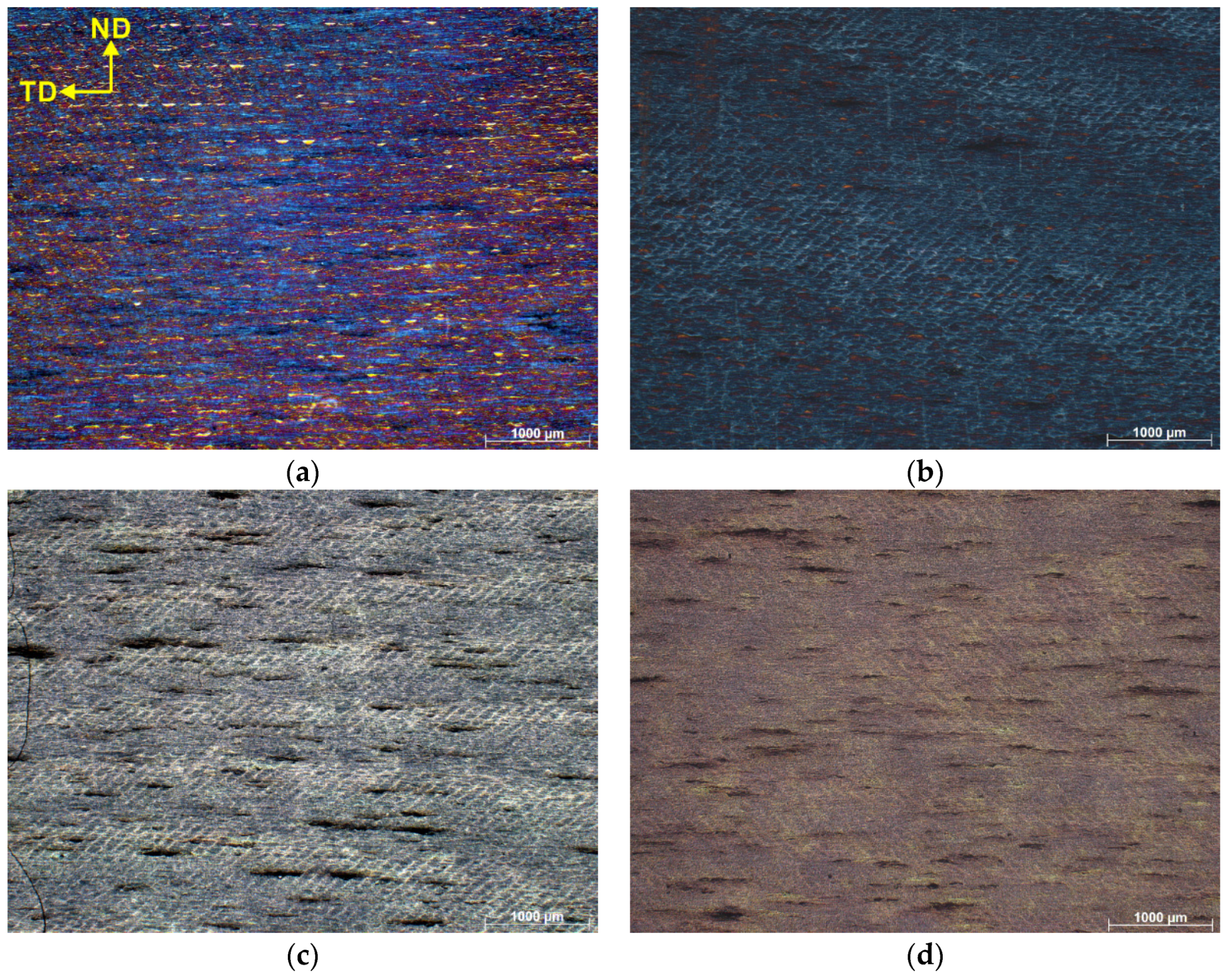

3.1.1. Microstructure Prior to ECAP Processing

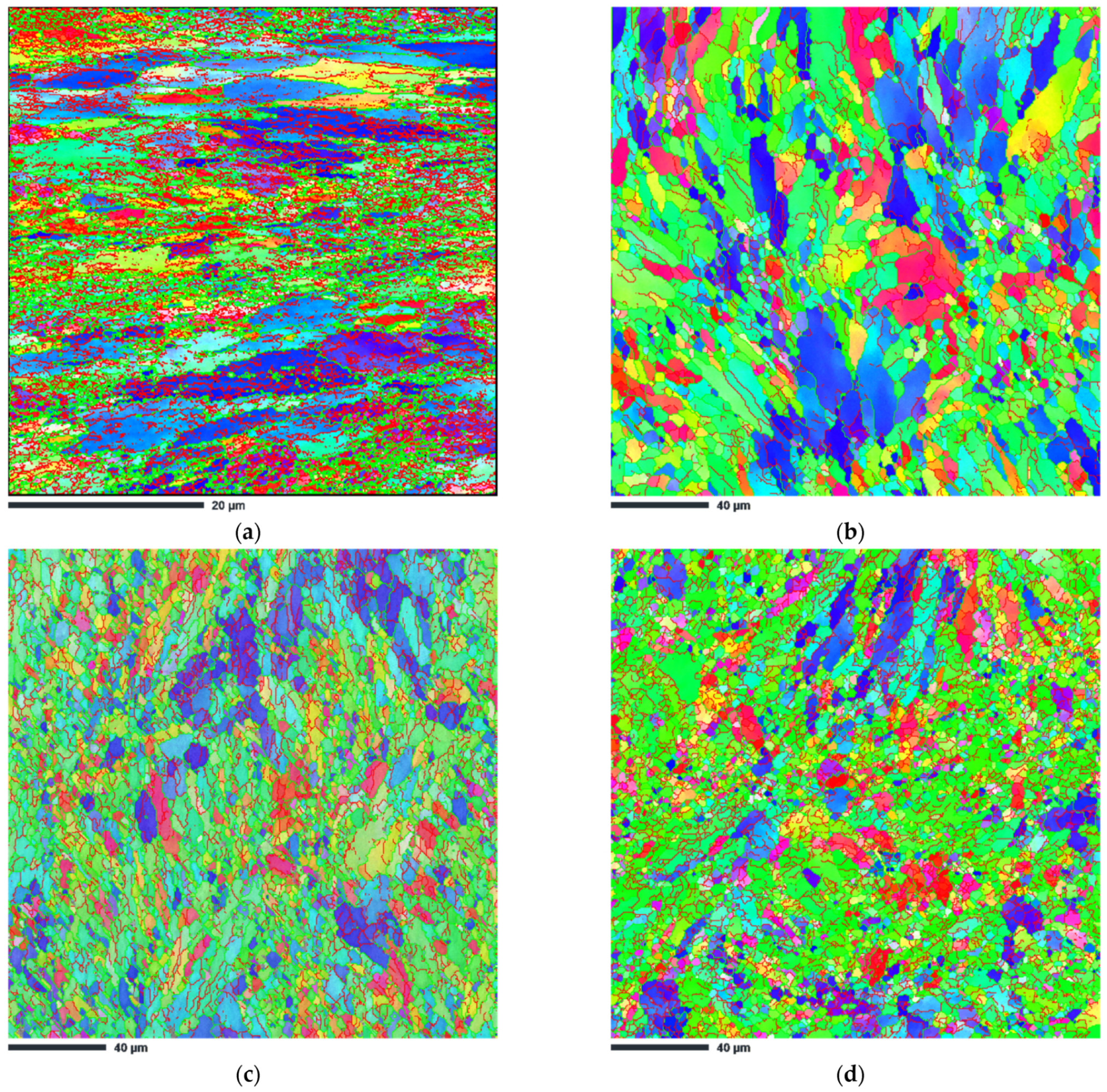

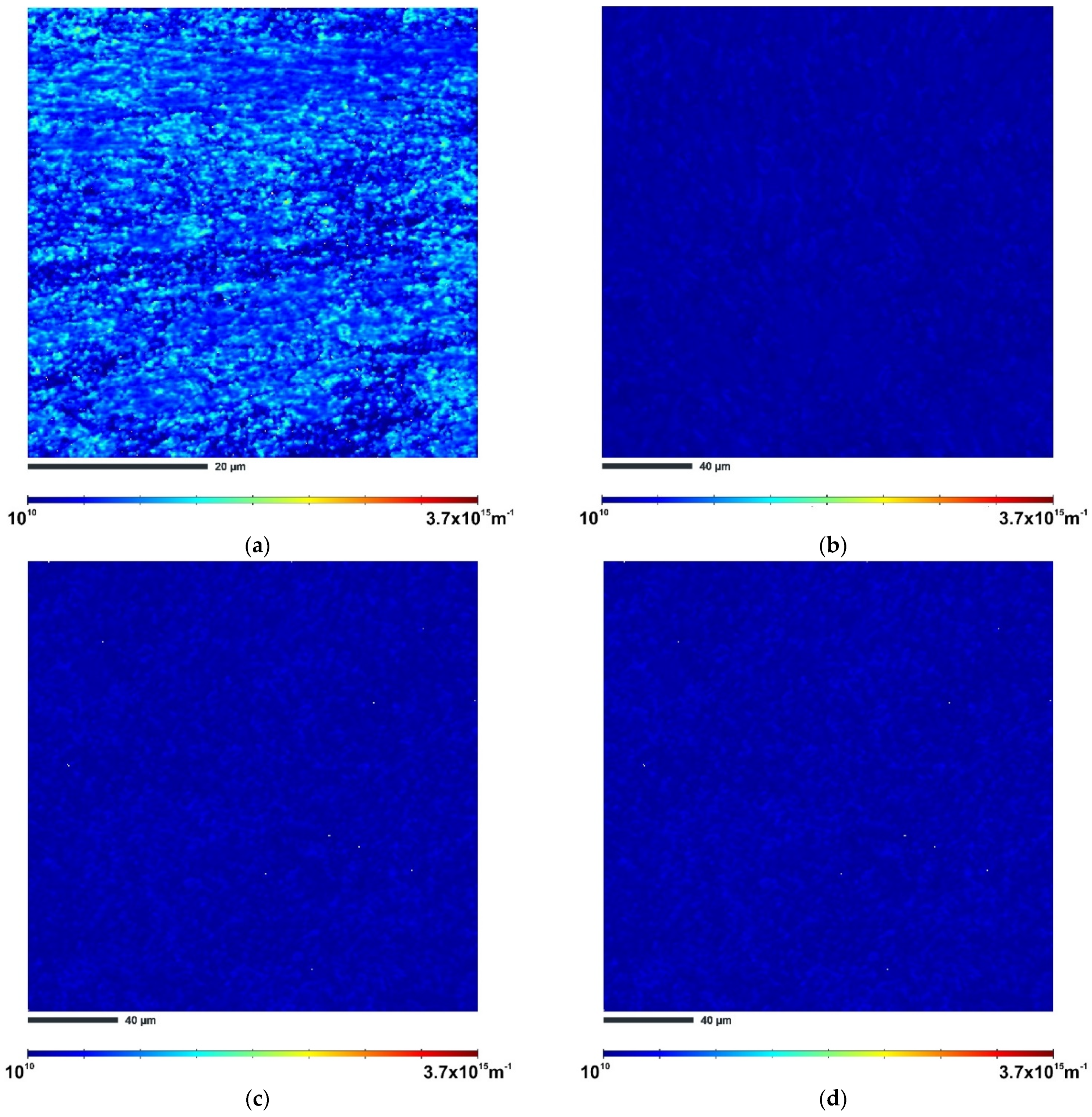

3.1.2. Microstructure after ECAP Processing

3.2. Mechanical Properties

4. Conclusions

- In this work, the effects of ECAP processing on the microstructure and mechanical properties of SLM-fabricated AlSi10Mg alloys were studied under different conditions of post-processing heat treatment and ECAP temperatures. Resulting microstructure and mechanical properties of post-processed SLM samples were compared to that of the as-built alloy and it is observed that post-processing operations significantly affect the performance of the SLM-fabricated alloy.

- Metallographic observations, coupled with SEM investigations, revealed the SLM-fabricated alloys possessed a unique cellular microstructure made up of Si networks surrounding the Al-based matrix phase.

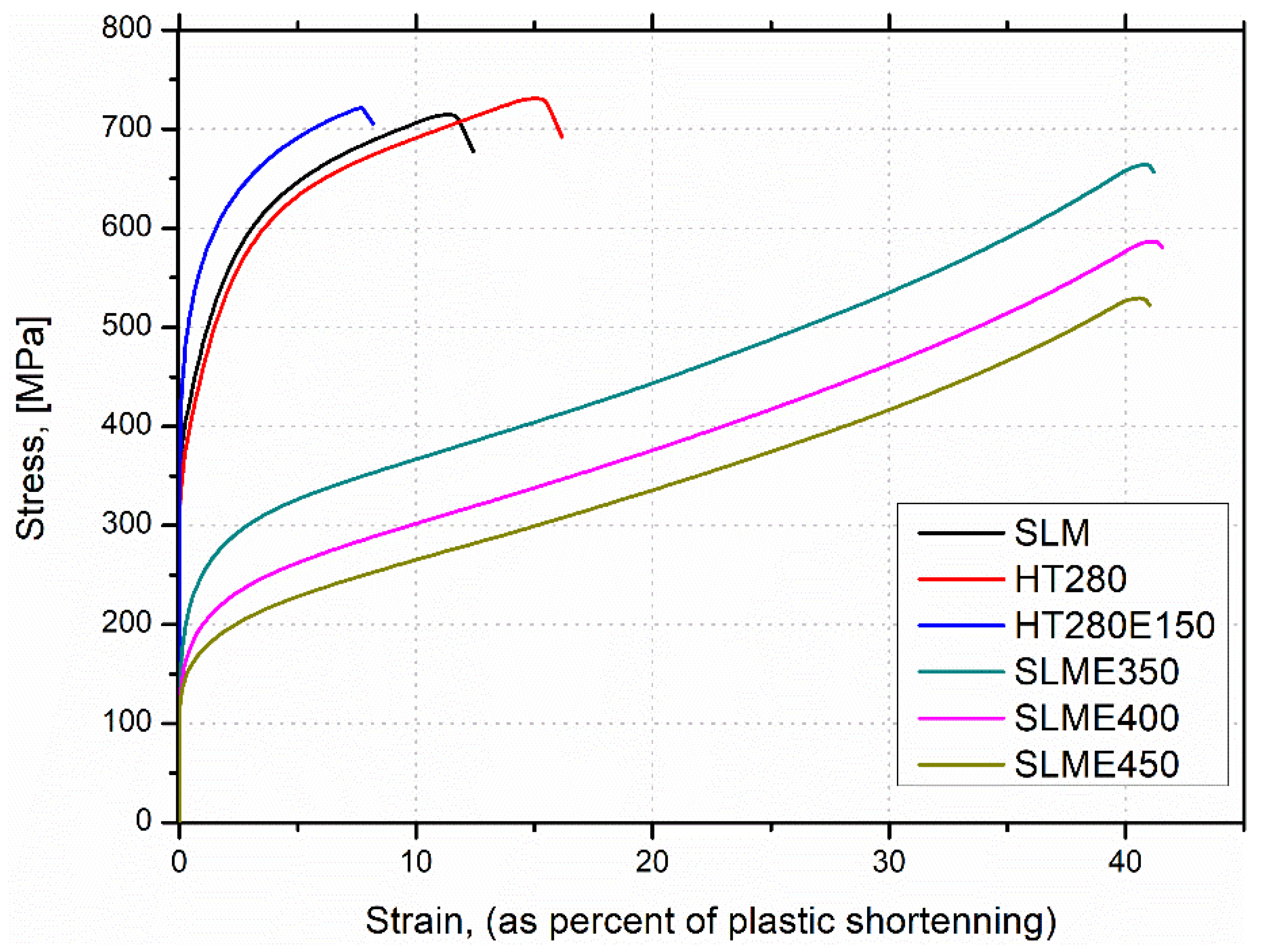

- Low-temperature annealing (LTA) heat treatment, followed by ECAP, processing facilitated microstructural evolution of the alloy with a partial rupture of the Si network and an observed nucleation of β-Si precipitates throughout the Al-based matrix. This resulted in a Vickers microhardness of 153 HV and a yield strength of 415 MPa, which are amongst the highest reported values in the literature for this alloy.

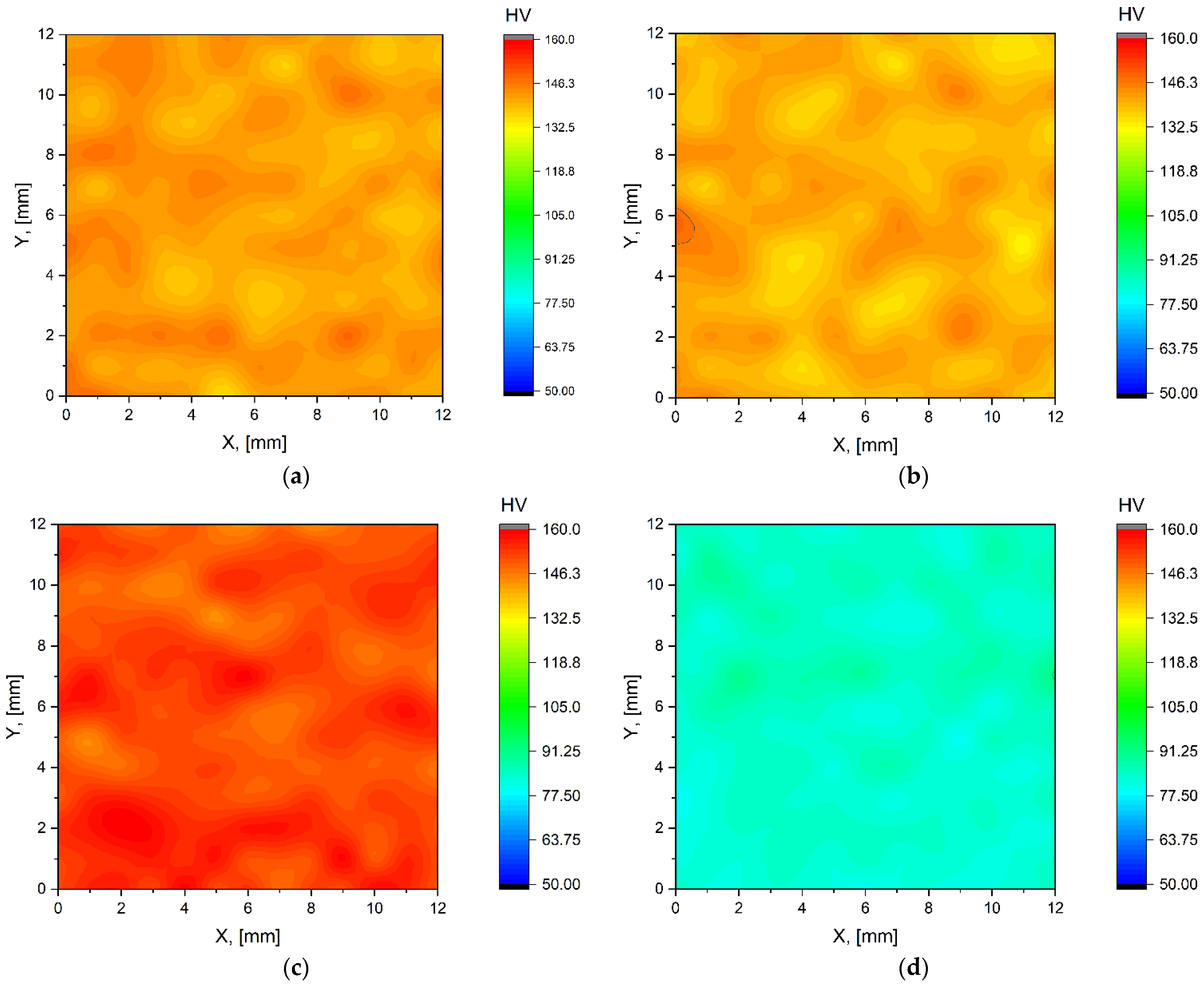

- Increasing the ECAP process temperature of the non-heat-treated alloys resulted in complete rupture and coarsening of the Si phase, resulting in a non-uniform hardness distribution and reducing the mechanical performance of the alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hehr, A.; Norfolk, M. A Comprehensive Review of Ultrasonic Additive Manufacturing. Rapid Prototyp. J. 2020, 26, 445–458. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Binder Jetting. In Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2021; pp. 237–252. [Google Scholar]

- Yap, Y.L.; Wang, C.; Sing, S.L.; Dikshit, V.; Yeong, W.Y.; Wei, J. Material Jetting Additive Manufacturing: An Experimental Study Using Designed Metrological Benchmarks. Precis. Eng. 2017, 50, 275–285. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Easton, M. Powder Bed Fusion Processes: An Overview. In Laser Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2017; pp. 55–77. [Google Scholar]

- Pagac, M.; Hajnys, J.; Ma, Q.-P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of Vat Photopolymerization Technology: Materials, Applications, Challenges, and Future Trends of 3d Printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef]

- Elambasseril, J.; Rogers, J.; Wallbrink, C.; Munk, D.; Leary, M.; Qian, M. Laser Powder Bed Fusion Additive Manufacturing (LPBF-AM): The Influence of Design Features and LPBF Variables on Surface Topography and Effect on Fatigue Properties. Crit. Rev. Solid State Mater. Sci. 2022, 1–37. [Google Scholar] [CrossRef]

- Hojjatzadeh, S.M.H.; Parab, N.D.; Guo, Q.; Qu, M.; Xiong, L.; Zhao, C.; Escano, L.I.; Fezzaa, K.; Everhart, W.; Sun, T. Direct Observation of Pore Formation Mechanisms during LPBF Additive Manufacturing Process and High Energy Density Laser Welding. Int. J. Mach. Tools Manuf. 2020, 153, 103555. [Google Scholar] [CrossRef]

- Safaei, K.; Abedi, H.; Nematollahi, M.; Kordizadeh, F.; Dabbaghi, H.; Bayati, P.; Javanbakht, R.; Jahadakbar, A.; Elahinia, M.; Poorganji, B. Additive Manufacturing of NiTi Shape Memory Alloy for Biomedical Applications: Review of the LPBF Process Ecosystem. JOM 2021, 73, 3771–3786. [Google Scholar] [CrossRef]

- Nandy, J.; Sarangi, H.; Sahoo, S. A Review on Direct Metal Laser Sintering: Process Features and Microstructure Modeling. Lasers Manuf. Mater. Process. 2019, 6, 280–316. [Google Scholar] [CrossRef]

- Gueche, Y.A.; Sanchez-Ballester, N.M.; Cailleaux, S.; Bataille, B.; Soulairol, I. Selective Laser Sintering (SLS), a New Chapter in the Production of Solid Oral Forms (SOFs) by 3D Printing. Pharmaceutics 2021, 13, 1212. [Google Scholar] [CrossRef]

- Del Guercio, G.; Galati, M.; Saboori, A.; Fino, P.; Iuliano, L. Microstructure and Mechanical Performance of Ti–6Al–4V Lattice Structures Manufactured via Electron Beam Melting (EBM): A Review. Acta Metall. Sin. Engl. Lett. 2020, 33, 183–203. [Google Scholar] [CrossRef]

- Rajamani, D.; Balasubramanian, E. Investigation of Sintering Parameters on Viscoelastic Behaviour of Selective Heat Sintered HDPE Parts. J. Appl. Sci. Eng. 2019, 22, 391–402. [Google Scholar]

- Zhang, H.; Zhao, Y.; Huang, S.; Zhu, S.; Wang, F.; Li, D. Manufacturing and Analysis of High-Performance Refractory High-Entropy Alloy via Selective Laser Melting (SLM). Materials 2019, 12, 720. [Google Scholar] [CrossRef] [PubMed]

- Arun, K.; Aravindh, K.; Raja, K.; Naiju, C.D.; Thrinadh, E.; Ranka, S. Characterization of AlSi10Mg Alloy Produced by DMLS Process for Automotive Engine Application; SAE Technical Paper; SAE: Warrendale, PA, USA, 2019. [Google Scholar]

- Li, Z.; Nie, Y.; Liu, B.; Kuai, Z.; Zhao, M.; Liu, F. Mechanical Properties of AlSi10Mg Lattice Structures Fabricated by Selective Laser Melting. Mater. Des. 2020, 192, 108709. [Google Scholar] [CrossRef]

- Chen, B.; Moon, S.; Yao, X.; Bi, G.; Shen, J.; Umeda, J.; Kondoh, K. Strength and Strain Hardening of a Selective Laser Melted AlSi10Mg Alloy. Scr. Mater. 2017, 141, 45–49. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.; Tan, Z.; Xiong, D.-B.; Guo, Q. Stress Relaxation and the Cellular Structure-Dependence of Plastic Deformation in Additively Manufactured AlSi10Mg Alloys. Int. J. Plast. 2020, 127, 102640. [Google Scholar] [CrossRef]

- Ma, R.; Peng, C.; Cai, Z.; Wang, R.; Zhou, Z.; Li, X.; Cao, X. Enhanced Strength of the Selective Laser Melted Al-Mg-Sc-Zr Alloy by Cold Rolling. Mater. Sci. Eng. A 2020, 775, 138975. [Google Scholar] [CrossRef]

- Snopiński, P.; Król, M.; Pagáč, M.; Petrů, J.; Hajnyš, J.; Mikuszewski, T.; Tański, T. Effects of Equal Channel Angular Pressing and Heat Treatments on the Microstructures and Mechanical Properties of Selective Laser Melted and Cast AlSi10Mg Alloys. Arch. Civ. Mech. Eng. 2021, 21, 92. [Google Scholar] [CrossRef]

- Hosseinzadeh, A.; Radi, A.; Richter, J.; Wegener, T.; Sajadifar, S.V.; Niendorf, T.; Yapici, G.G. Severe Plastic Deformation as a Processing Tool for Strengthening of Additive Manufactured Alloys. J. Manuf. Process. 2021, 68, 788–795. [Google Scholar] [CrossRef]

- Snopiński, P.; Matus, K.; Tatiček, F.; Rusz, S. Overcoming the Strength-Ductility Trade-off in Additively Manufactured AlSi10Mg Alloy by ECAP Processing. J. Alloys Compd. 2022, 918, 165817. [Google Scholar] [CrossRef]

- Wang, G.; Song, D.; Zhou, Z.; Liu, Y.; Liang, N.; Wu, Y.; Ma, A.; Jiang, J. Developing High-Strength Ultrafine-Grained Pure Al via Large-Pass ECAP and Post Cryo-Rolling. J. Mater. Res. Technol. 2021, 15, 2419–2428. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Elbestawi, M.; Dosbaeva, G.K.; Veldhuis, S.C. Thermal Post-Processing of AlSi10Mg Parts Produced by Selective Laser Melting Using Recycled Powder. Addit. Manuf. 2018, 21, 234–247. [Google Scholar] [CrossRef]

- Sagbas, B. Post-Processing Effects on Surface Properties of Direct Metal Laser Sintered AlSi10Mg Parts. Met. Mater. Int. 2020, 26, 143–153. [Google Scholar] [CrossRef]

- Zhuo, L.; Wang, Z.; Zhang, H.; Yin, E.; Wang, Y.; Xu, T.; Li, C. Effect of Post-Process Heat Treatment on Microstructure and Properties of Selective Laser Melted AlSi10Mg Alloy. Mater. Lett. 2019, 234, 196–200. [Google Scholar] [CrossRef]

- Snopiński, P.; Woźniak, A.; Pagáč, M. Microstructural Evolution, Hardness, and Strengthening Mechanisms in SLM AlSi10Mg Alloy Subjected to Equal-Channel Angular Pressing (ECAP). Materials 2021, 14, 7598. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Wang, Y.; Wang, J.J.; Ni, D.R.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Achieving Superior Mechanical Properties of Selective Laser Melted AlSi10Mg via Direct Aging Treatment. J. Mater. Sci. Technol. 2022, 108, 226–235. [Google Scholar] [CrossRef]

- Liu, M.; Zheng, R.; Xiao, W.; Li, J.; Li, G.; Peng, Q.; Ma, C. Bulk Nanostructured Al-Si Alloy with Remarkable Improvement in Strength and Ductility. Scr. Mater. 2021, 201, 113970. [Google Scholar] [CrossRef]

- Wei, P.; Chen, Z.; Zhang, S.; Fang, X.; Lu, B.; Zhang, L.; Wei, Z. Effect of T6 Heat Treatment on the Surface Tribological and Corrosion Properties of AlSi10Mg Samples Produced by Selective Laser Melting. Mater. Charact. 2021, 171, 110769. [Google Scholar] [CrossRef]

- Zhao, X.; Yue, Z.; Wang, G.; Li, Z.; Soyarslan, C. Role of GNDs in Bending Strength Gain of Multilayer Deposition Generated Heterostructured Bulk Aluminum. Mater. Des. 2022, 219, 110769. [Google Scholar] [CrossRef]

- Ashby, M. The Deformation of Plastically Non-Homogeneous Materials. Philos. Mag. J. Theor. Exp. Appl. Phys. 1970, 21, 399–424. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. The Microstructure and Mechanical Properties of Selectively Laser Melted AlSi10Mg: The Effect of a Conventional T6-like Heat Treatment. Mater. Sci. Eng. A 2016, 667, 139–146. [Google Scholar] [CrossRef]

- Poncelet, O.; Marteleur, M.; van der Rest, C.; Rigo, O.; Adrien, J.; Dancette, S.; Jacques, P.; Simar, A. Critical Assessment of the Impact of Process Parameters on Vertical Roughness and Hardness of Thin Walls of AlSi10Mg Processed by Laser Powder Bed Fusion. Addit. Manuf. 2021, 38, 101801. [Google Scholar] [CrossRef]

- Patakham, U.; Palasay, A.; Wila, P.; Tongsri, R. MPB Characteristics and Si Morphologies on Mechanical Properties and Fracture Behavior of SLM AlSi10Mg. Mater. Sci. Eng. A 2021, 821, 141602. [Google Scholar] [CrossRef]

- Liu, L.; Ding, Q.; Zhong, Y.; Zou, J.; Wu, J.; Chiu, Y.-L.; Li, J.; Zhang, Z.; Yu, Q.; Shen, Z. Dislocation Network in Additive Manufactured Steel Breaks Strength–Ductility Trade-Off. Mater. Today 2018, 21, 354–361. [Google Scholar] [CrossRef]

| Sample ID | Annealing | ECAP Temperature (°C) |

|---|---|---|

| HT280E150 | LTA at 280 °C | 150 |

| SLME350 | Not annealed | 350 |

| SLME400 | Not annealed | 400 |

| SLME450 | Not annealed | 450 |

| SLM | Not annealed | No ECAP |

| HT280 | LTA at 280 °C | No ECAP |

| Sample | Grain Size, µm | Low Angle Boundaries, % | High Angle Boundaries, % | GNDs Density, m−2 |

|---|---|---|---|---|

| HT280E150 | 0.44 ± 0.06 | 55.2 ± 1.3 | 44.8 ± 1.2 | 6.70 × 1014 ± 0.14 |

| SLME350 | 3.37 ± 0.08 | 37.7 ± 1.1 | 62.3 ± 1.4 | 9.60 × 1013 ± 0.12 |

| SLME400 | 2.11 ± 0.08 | 38.0 ± 1.2 | 62.0 ± 1.3 | 7.69 × 1013 ± 0.16 |

| SLME450 | 2.91 ± 0.07 | 47.5 ± 1.5 | 52.5 ± 1.3 | 6.88 × 1013 ± 0.20 |

| Sample | Hardness, HV | Yield Strength, MPa |

|---|---|---|

| SLM | 142 ± 2.2 | 397 ± 3.0 |

| HT280 | 138 ± 1.8 | 385 ± 2.7 |

| HT280E150 | 153 ± 2.5 | 415 ± 3.2 |

| SLME350 | 86 ± 1.4 | 187 ± 2.4 |

| SLME400 | 69 ± 2.1 | 161 ± 2.7 |

| SLME450 | 60 ± 2.3 | 141 ± 2.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Snopiński, P.; Appiah, A.N.S.; Hilšer, O.; Kotoul, M. Investigation of Microstructure and Mechanical Properties of SLM-Fabricated AlSi10Mg Alloy Post-Processed Using Equal Channel Angular Pressing (ECAP). Materials 2022, 15, 7940. https://doi.org/10.3390/ma15227940

Snopiński P, Appiah ANS, Hilšer O, Kotoul M. Investigation of Microstructure and Mechanical Properties of SLM-Fabricated AlSi10Mg Alloy Post-Processed Using Equal Channel Angular Pressing (ECAP). Materials. 2022; 15(22):7940. https://doi.org/10.3390/ma15227940

Chicago/Turabian StyleSnopiński, Przemysław, Augustine Nana Sekyi Appiah, Ondrej Hilšer, and Michal Kotoul. 2022. "Investigation of Microstructure and Mechanical Properties of SLM-Fabricated AlSi10Mg Alloy Post-Processed Using Equal Channel Angular Pressing (ECAP)" Materials 15, no. 22: 7940. https://doi.org/10.3390/ma15227940

APA StyleSnopiński, P., Appiah, A. N. S., Hilšer, O., & Kotoul, M. (2022). Investigation of Microstructure and Mechanical Properties of SLM-Fabricated AlSi10Mg Alloy Post-Processed Using Equal Channel Angular Pressing (ECAP). Materials, 15(22), 7940. https://doi.org/10.3390/ma15227940