Experimental and Numerical Research of Delamination Process in CFRP Laminates with Bending-Twisting Elastic Couplings

Abstract

1. Introduction

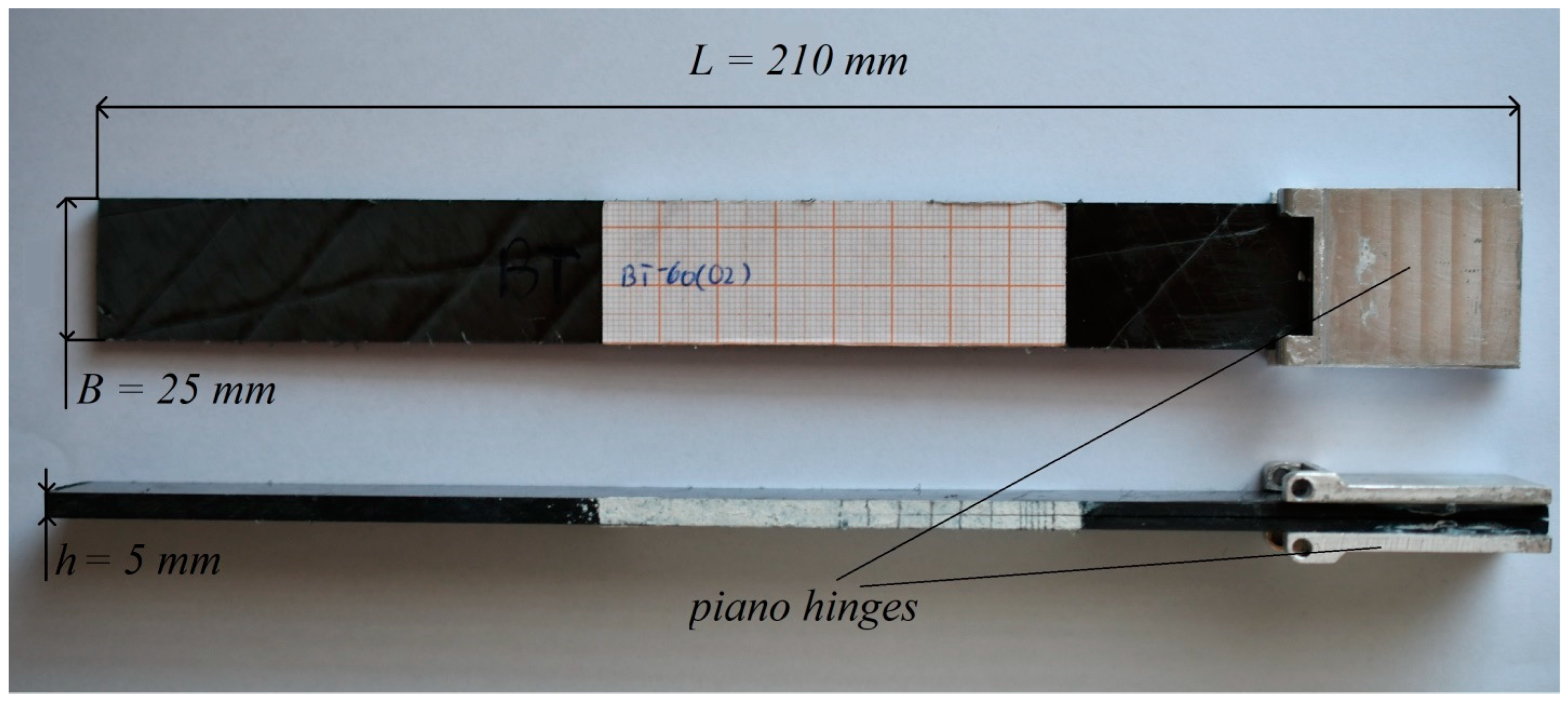

2. Tested Laminates

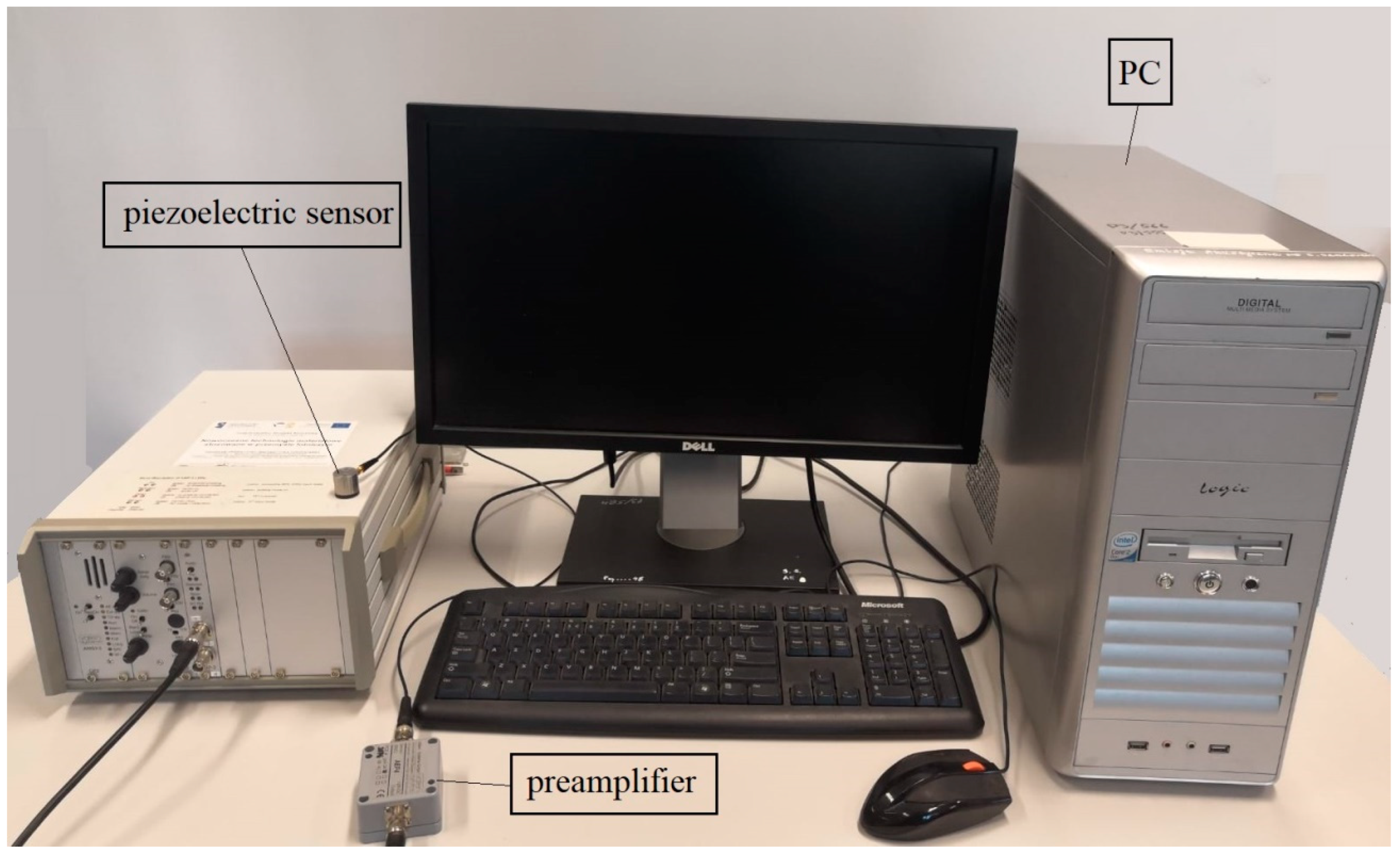

3. Experimental Procedures

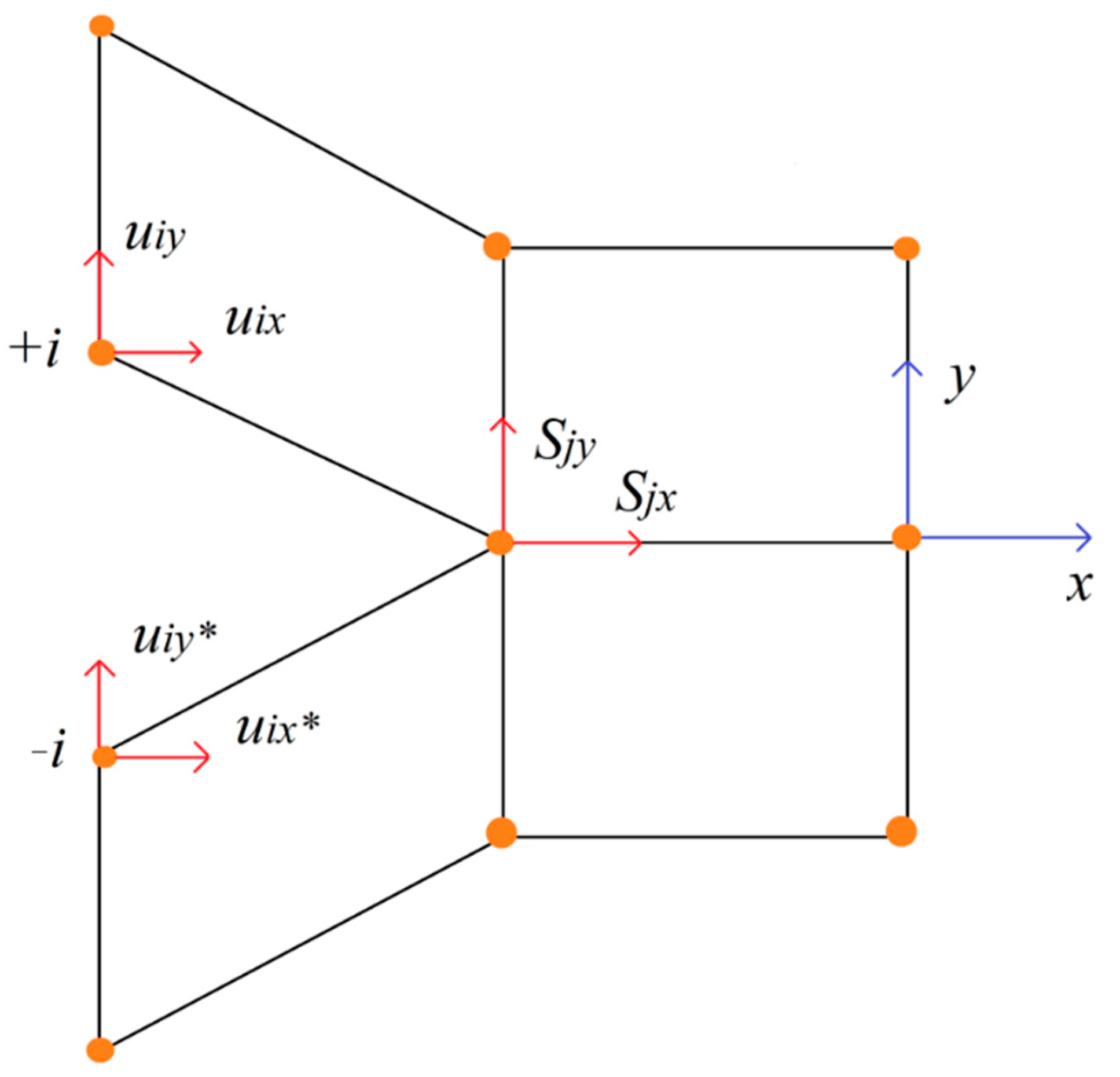

4. Analytical Determination of Energy Release Rates

5. Numerical Analysis

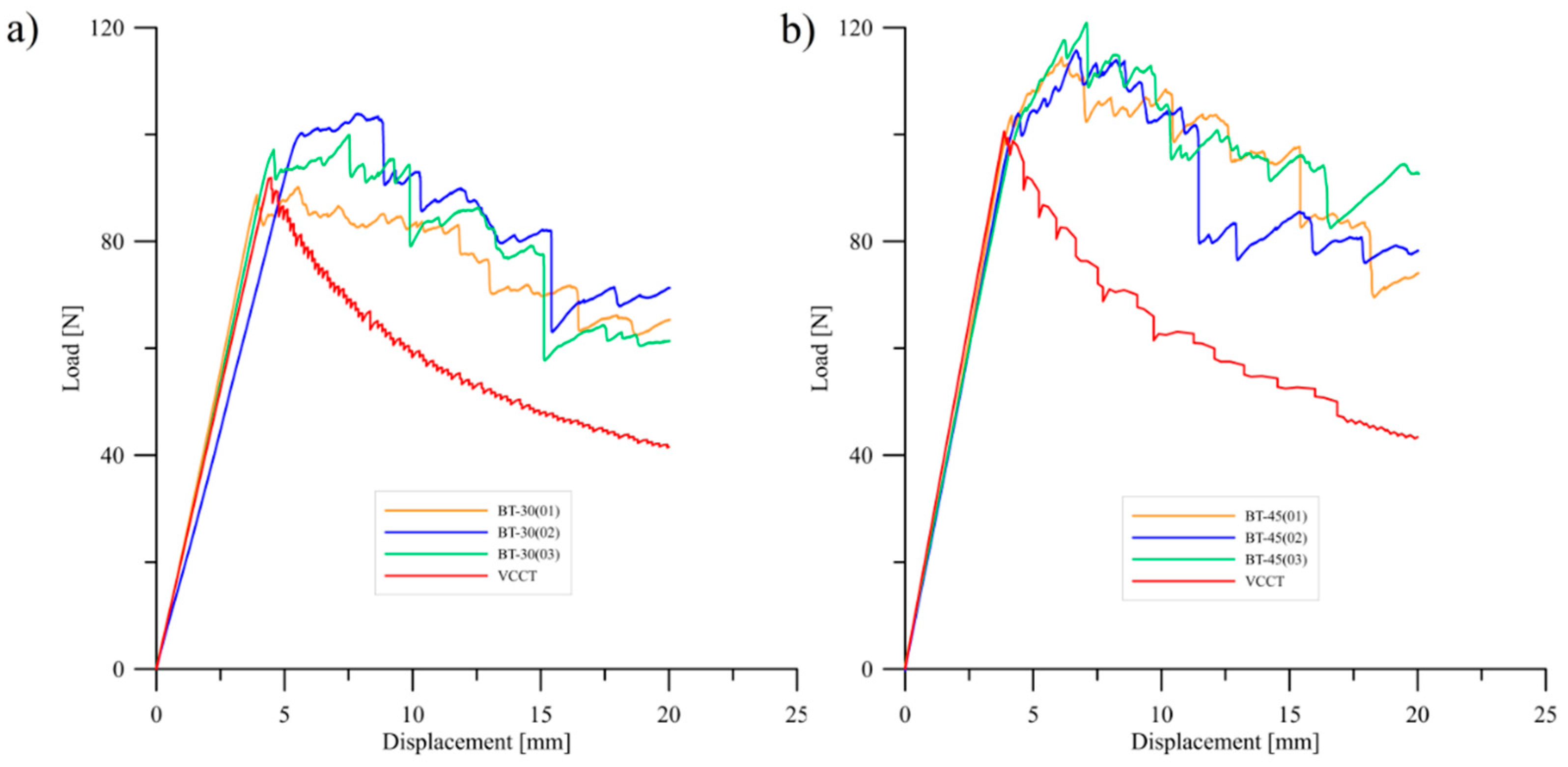

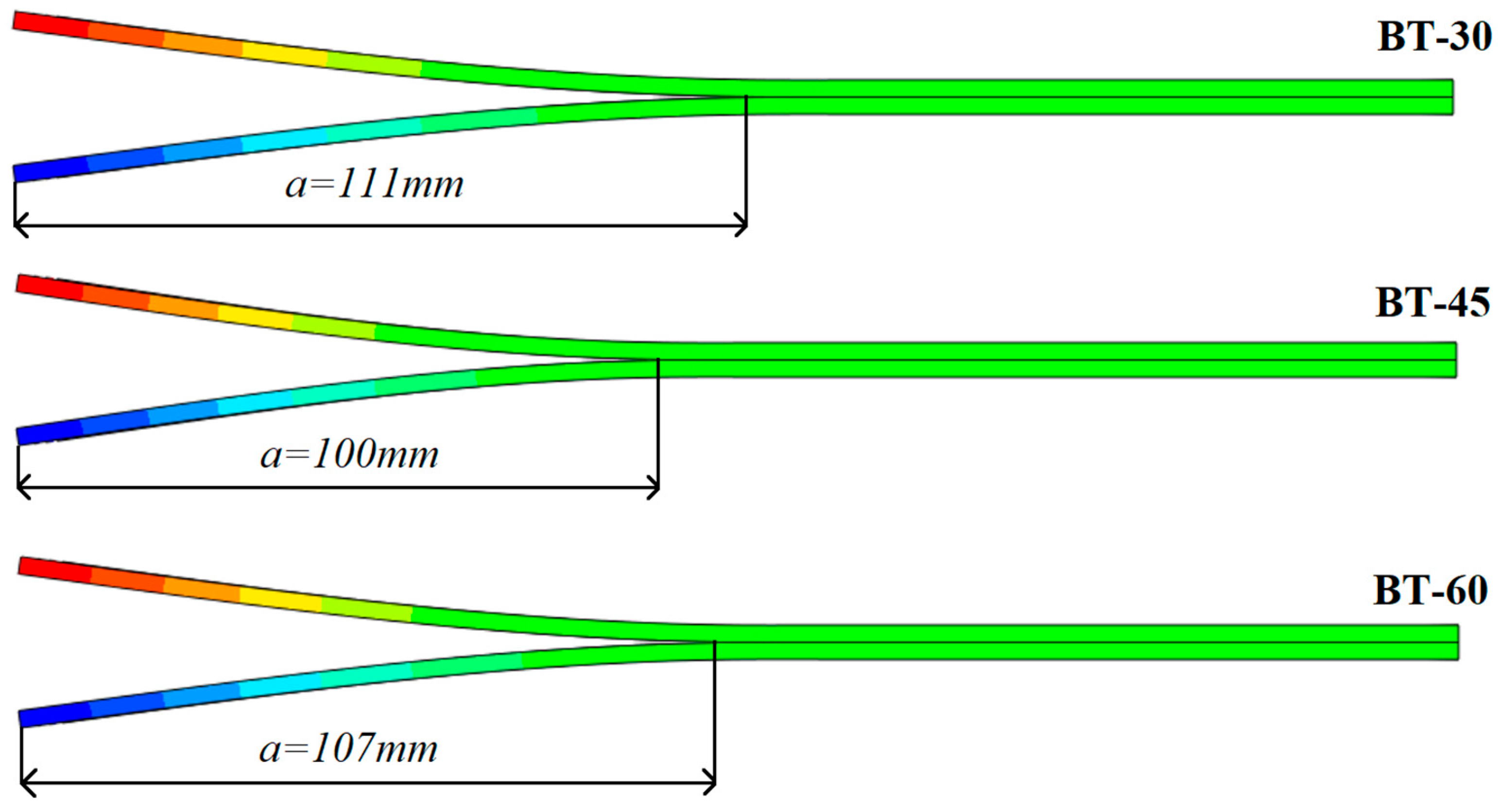

6. Results and Discussion

7. Conclusions

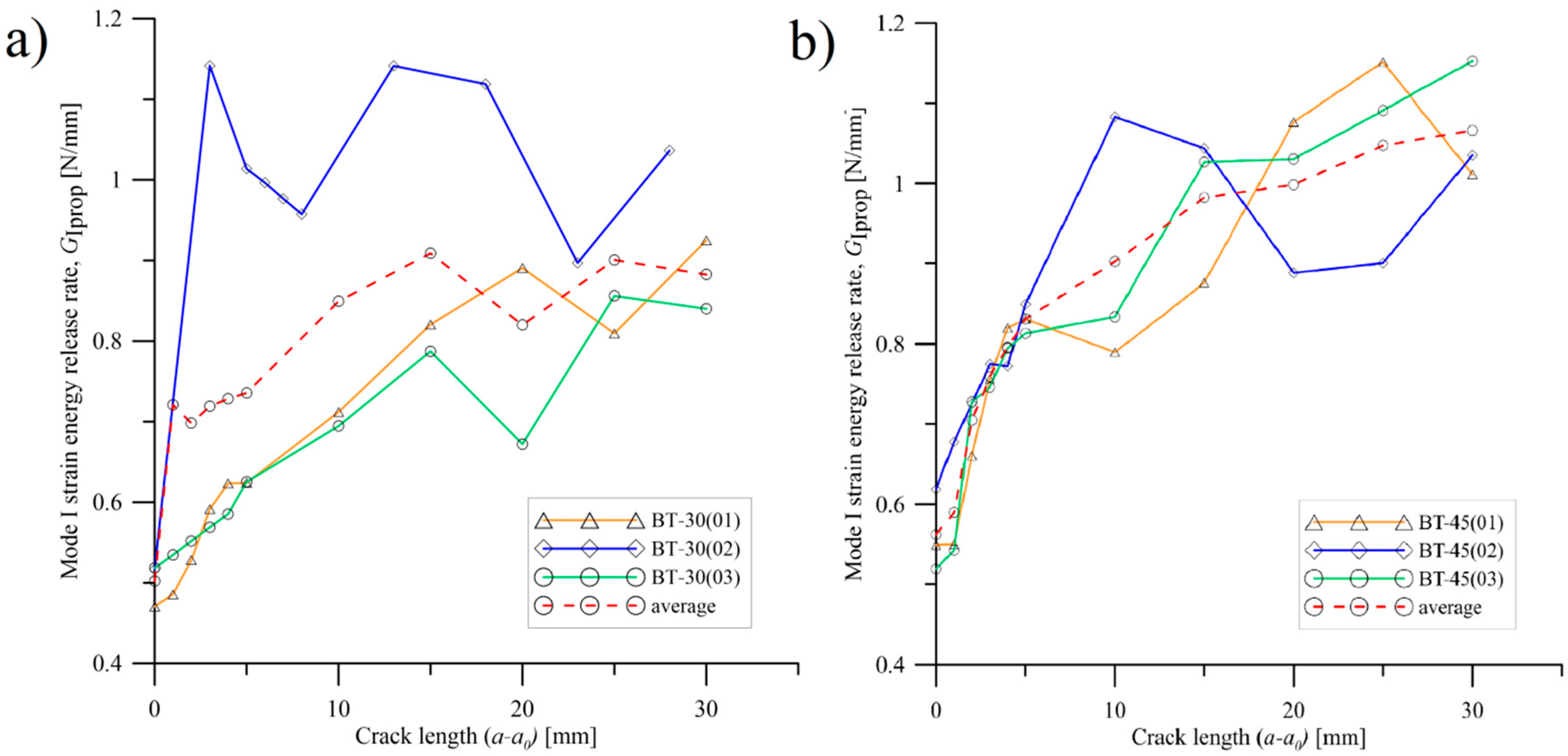

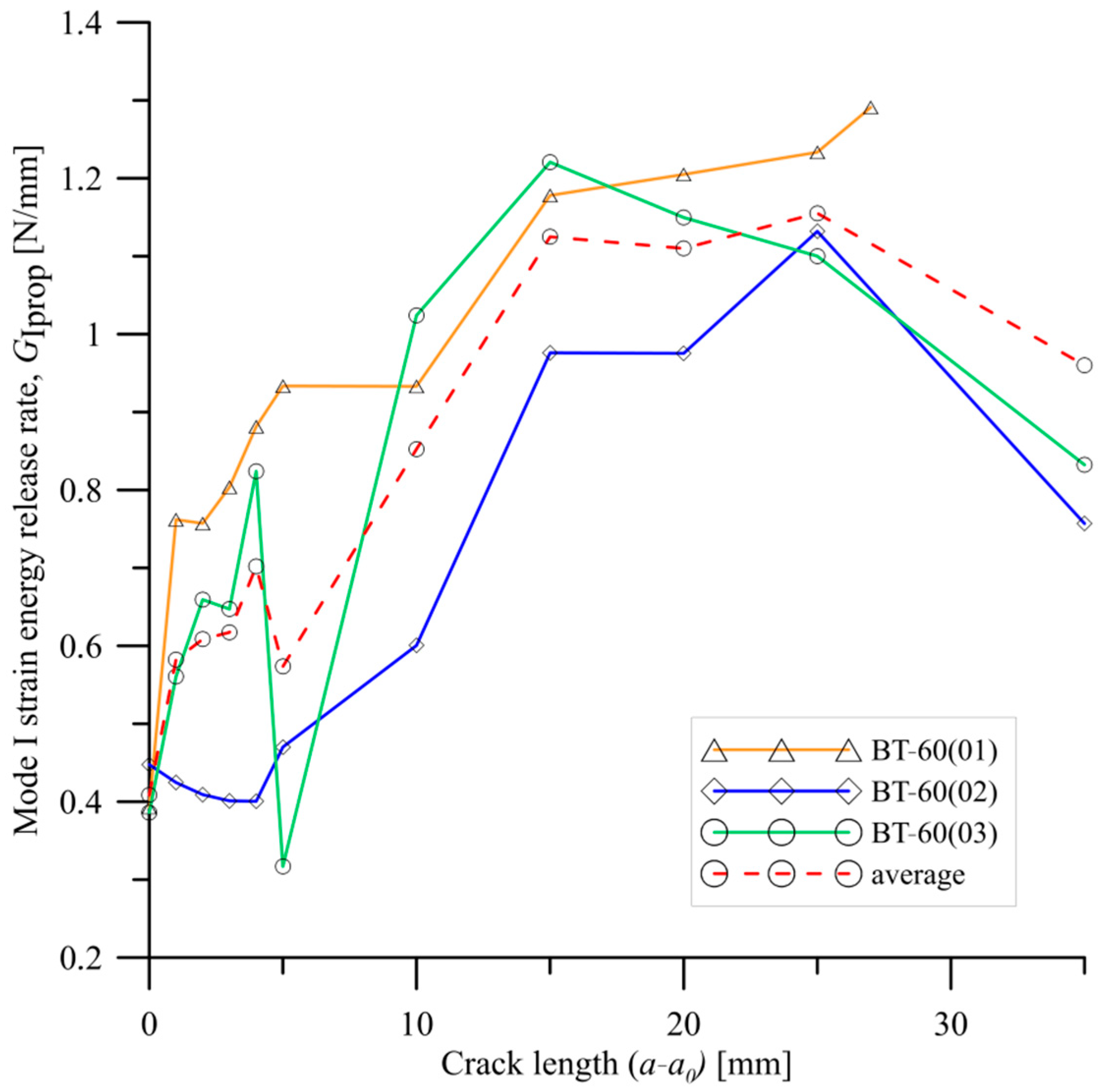

- The greatest value of the GIC equal to 0.56 N/mm was obtained for BT45 laminate. On the other hand, the lowest mode I c-SERR determined for BT60 laminate was equal to 0.41 N/mm. In case of the BT30 specimens, the mode I fracture toughness reached 0.51 N/mm. Moreover, the differences between delamination resistance values determined by using three different methods were slight.

- For all tested laminates, an extensive fiber bridging was observed during delamination process. It influenced the unstable crack propagation and the discrepancies in propagation strain energy release rate values.

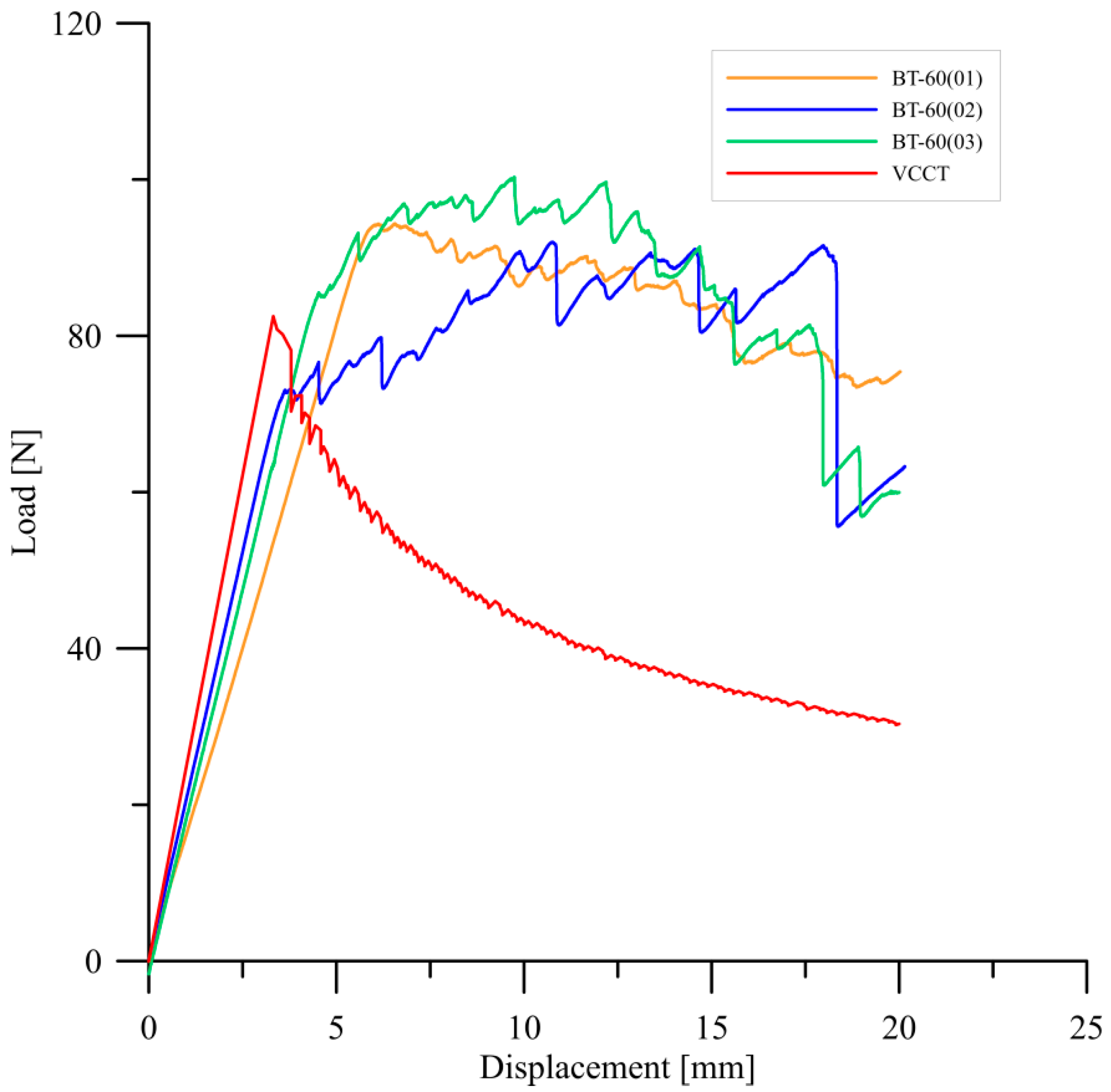

- Numerically obtained load versus displacement plots were in agreement with experimental data only in initial stage of delamination. For propagation stage, the fiber bridging phenomenon influenced on differences between numerically and experimentally obtained P-δ curves. Nevertheless, application of the VCCT technique to simulate delamination in elastically coupled laminates was found out to be a sufficient tool, in particular for modeling the initial stage of delamination.

- Prevailing contribution of the mode I fracture scheme in delamination process was affected by the constraints imposed by the piano hinges.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cañas, J.; Justo, J.; París, F. Evaluation of the interlaminar fracture toughness on composite materials using DCB test on symmetric and unsymmetric configurations. Compos. Struct. 2022, 297, 115944. [Google Scholar] [CrossRef]

- Gong, Y.; Chen, X.; Li, W.; Zhao, L.; Tao, J.; Zhang, J.; Hu, N. Delamination in carbon fiber epoxy DCB laminates with different stacking sequences: R-curve behavior and bridging traction-separation relation. Compos. Struct. 2021, 262, 113605. [Google Scholar] [CrossRef]

- Gong, Y.; Chen, X.; Tao, J.; Zhao, L.; Zhang, J.; Hu, N. A simple procedure for determining the mode I bridging stress of composite DCB laminates without measuring the crack opening displacement. Compos. Struct. 2020, 243, 112147. [Google Scholar] [CrossRef]

- Heidari-Rarani, M.; Sayedain, M. Finite element modeling strategies for 2D and 3D delamination propagation in composite DCB specimens using VCCT, CZM and XFEM approaches. Theor. Appl. Fract. Mech. 2019, 103, 102246. [Google Scholar] [CrossRef]

- Jia, R.; Zhao, L.; Curti, R.; Gong, X. Determination of pure mode-I fracture toughness of multidirectional composite DCB specimens. Eng. Fract. Mech. 2021, 252, 107776. [Google Scholar] [CrossRef]

- Rekbi, F.M.L.; Hecini, M.; Khechai, A. Experimental and numerical analysis of mode-I interlaminar fracture of composite pipes. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 185. [Google Scholar] [CrossRef]

- Gong, Y.; Tian, D.; Cao, T.; Zhao, L.; Zhang, J.; Hu, N.; Zhang, C. An R-curve effect-included delamination growth criterion for mixed-mode I/II delamination predictions of composite laminates. Compos. Struct. 2022, 295, 115846. [Google Scholar] [CrossRef]

- Hu, P.; Tao, R.; Li, X.; Lubineau, G. Decomposing the coupling damage in mode I multidirectional delamination. Compos. Sci. Technol. 2022, 229, 109684. [Google Scholar] [CrossRef]

- Low, K.O.; Johar, M.; Sung, A.N.; Mohd Nasir, M.N.; Rahimian Koloor, S.S.; Petrů, M.; AhmadIsrar, H.; JyeWong, K. Displacement rate effects on mixed-mode I/II delamination of laminated carbon/epoxy composites. Polym. Test. 2022, 108, 107512. [Google Scholar] [CrossRef]

- D30 Committee. Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Fibre-Reinforced Plastic Composites. Determination of Mode I Interlaminar Fracture Toughness, Gic, for Unidirectionally Reinforced Materials; BSI British Standards: London, UK, 2016. [Google Scholar]

- Valvo, P.S. On the calculation of energy release rate and mode mixity in delaminated laminated beams. Eng. Fract. Mech. 2016, 165, 114–139. [Google Scholar] [CrossRef]

- York, C.B.; de Almeida, S.F.M. On Extension-Shearing Bending-Twisting coupled laminates. Compos. Struct. 2017, 164, 10–22. [Google Scholar] [CrossRef]

- Fukunaga, H.; Sekine, H. A Laminate Design for Elastic Properties of Symmetric Laminates with Extension-Shear or Bending-Twisting Coupling. J. Compos. Mater. 1994, 28, 708–731. [Google Scholar] [CrossRef]

- Baker, D.J. Response of Damaged and Undamaged Tailored Extension-Shear-Coupled Composite Panels. J. Aircr. 2006, 43, 517–527. [Google Scholar] [CrossRef]

- Samborski, S. Analysis of the end-notched flexure test configuration applicability for mechanically coupled fiber reinforced composite laminates. Compos. Struct. 2017, 163, 342–349. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Heidari-Rarani, M.; Rahimi, S. Influence of curved delamination front on toughness of multidirectional DCB specimens. Compos. Struct. 2012, 94, 1359–1365. [Google Scholar] [CrossRef]

- Rzeczkowski, J.; Samborski, S.; Valvo, P.S. Effect of stiffness matrices terms on delamination front shape in laminates with elastic couplings. Compos. Struct. 2020, 233, 111547. [Google Scholar] [CrossRef]

- Samborski, S. Prediction of delamination front’s advancement direction in the CFRP laminates with mechanical couplings subjected to different fracture toughness tests. Compos. Struct. 2018, 202, 643–650. [Google Scholar] [CrossRef]

- Jiang, Z.; Wan, S.; Zhong, Z.; Li, S.; Shen, K. Effect of curved delamination front on mode-I fracture toughness of adhesively bonded joints. Eng. Fract. Mech. 2015, 138, 73–91. [Google Scholar] [CrossRef]

- Davidson, B.D.; Krüger, R.; König, M. Effect of stacking sequence on energy release rate distributions in multidirectional dcb and enf specimens. Eng. Fract. Mech. 1996, 55, 557–569. [Google Scholar] [CrossRef]

- Alhussein, M.; Ameer, Z.; Hamzah, A. Simulation of the effect laminate sequence on delamination mode-I with elastic couplings. Diagnostyka 2022, 23, 1–12. [Google Scholar] [CrossRef]

- Samborski, S. Numerical analysis of the DCB test configuration applicability to mechanically coupled Fiber Reinforced Laminated Composite beams. Compos. Struct. 2016, 152, 477–487. [Google Scholar] [CrossRef]

- de Gracia, J.; Boyano, A.; Arrese, A.; Mujika, F. Analysis of the DCB test of angle-ply laminates including residual stresses. Theor. Appl. Fract. Mech. 2018, 94, 197–204. [Google Scholar] [CrossRef]

- Sun, C.T.; Zheng, S. Delamination characteristics of double-cantilever beam and end-notched flexure composite specimens. Compos. Sci. Technol. 1996, 56, 451–459. [Google Scholar] [CrossRef]

- D30 Committee. Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- D30 Committee. Test Method for In-Plane Shear Response of Polymer Matrix Composite Materials by Tensile Test of a 45 Laminate; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Paul, S.C.; Pirskawetz, S.; van Zijl, G.P.A.G.; Schmidt, W. Acoustic emission for characterising the crack propagation in strain-hardening cement-based composites (SHCC). Cem. Concr. Res. 2015, 69, 19–24. [Google Scholar] [CrossRef]

- Huo, X.; Luo, Q.; Li, Q.; Zheng, G.; Sun, G. On characterization of cohesive zone model (CZM) based upon digital image correlation (DIC) method. Int. J. Mech. Sci. 2022, 215, 106921. [Google Scholar] [CrossRef]

- Din, I.U.; Naresh, K.; Umer, R.; Khan, K.A.; Drzal, L.T.; Haq, M.; Cantwell, W.J. Processing and out-of-plane properties of composites with embedded graphene paper for EMI shielding applications. Compos. Part A Appl. Sci. Manuf. 2020, 134, 105901. [Google Scholar] [CrossRef]

- Rzeczkowski, J. An experimental analysis of the end-notched flexure composite laminates beams with elastic couplings. Contin. Mech. Thermodyn. 2021, 33, 2331–2343. [Google Scholar] [CrossRef]

- Rzeczkowski, J.; Paśnik, J.; Samborski, S. Mode III numerical analysis of composite laminates with elastic couplings in split cantilever beam configuration. Compos. Struct. 2021, 265, 113751. [Google Scholar] [CrossRef]

- Rzeczkowski, J.; Samborski, S.; de Moura, M. Experimental Investigation of Delamination in Composite Continuous Fiber-Reinforced Plastic Laminates with Elastic Couplings. Materials 2020, 13, 5146. [Google Scholar] [CrossRef]

- De Moura MF, S.F.; Campilho, R.D.; Amaro, A.M.; Reis PN, B. Interlaminar and intralaminar fracture characterization of composites under mode I loading. Compos. Struct. 2010, 92, 144–149. [Google Scholar] [CrossRef]

| E1 [GPa] | S.D. [%] | E2 [GPa] | S.D. [%] | ν12 | S.D. [%] | G [GPa] | S.D. [%] |

|---|---|---|---|---|---|---|---|

| 112.105 | 3.56 | 7.421 | 2.61 | 0.27 | 8.28 | 3.338 | 2.18 |

| Specimens | Stacking Sequence (for One Branch) | Bt [-] | Dc [-] |

|---|---|---|---|

| BT30 | 30/0°/30/30/0°/−30/0°/−30/−30/−30/−30/0°/−30/30/0°/0°/30/30 | 0.2238 | 0.2208 |

| BT45 | 45/0°/45/45/0°/−45/0°/−45/−45/−45/−45/0°/−45/45/0°/0°/45/45 | 0.2363 | 0.2384 |

| BT60 | 60/0°/60/60/0°/−60/0°/−60/−60/−60/−60/0°/−60/60/0°/0°/60/60 | 0.1341 | 0.0990 |

| E11 [MPa] | E22 = E33 [MPa] | G12 = G13 [MPa] | G23 [MPa] | ν12 = ν13 [-] | ν23 [-] | GIC [N/mm] | GIIC [N/mm] | GIIIC [N/mm] | η [-] | |

|---|---|---|---|---|---|---|---|---|---|---|

| BT30 | 112,105 | 7421 | 3338 | 2769 | 0.27 | 0.34 | 0.51 | 0.7 | 0.7 | 1.685 |

| BT45 | 0.56 | |||||||||

| BT60 | 0.41 |

| Laminate | BT30 | BT45 | BT60 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| GIC [N/mm] | GIC [N/mm] | GIC [N/mm] | |||||||

| CCM | MBT | MCC | CCM | MBT | MCC | CCM | MBT | MCC | |

| 1 | 0.48 | 0.48 | 0.47 | 0.56 | 0.55 | 0.55 | 0.39 | 0.39 | 0.39 |

| 2 | 0.52 | 0.52 | 0.54 | 0.62 | 0.62 | 0.62 | 0.45 | 0.45 | 0.45 |

| 3 | 0.53 | 0.52 | 0.52 | 0.53 | 0.52 | 0.51 | 0.39 | 0.39 | 0.39 |

| average | 0.51 | 0.51 | 0.51 | 0.57 | 0.56 | 0.56 | 0.41 | 0.41 | 0.41 |

| BT30 | BT45 | BT60 | |

|---|---|---|---|

| GI/GT | 99 % | 99% | 99% |

| GII/GT | 0.6% | 0.8% | 0.85% |

| GIII/GT | 0.4% | 0.2% | 0.15% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rzeczkowski, J.; Samborski, S. Experimental and Numerical Research of Delamination Process in CFRP Laminates with Bending-Twisting Elastic Couplings. Materials 2022, 15, 7745. https://doi.org/10.3390/ma15217745

Rzeczkowski J, Samborski S. Experimental and Numerical Research of Delamination Process in CFRP Laminates with Bending-Twisting Elastic Couplings. Materials. 2022; 15(21):7745. https://doi.org/10.3390/ma15217745

Chicago/Turabian StyleRzeczkowski, Jakub, and Sylwester Samborski. 2022. "Experimental and Numerical Research of Delamination Process in CFRP Laminates with Bending-Twisting Elastic Couplings" Materials 15, no. 21: 7745. https://doi.org/10.3390/ma15217745

APA StyleRzeczkowski, J., & Samborski, S. (2022). Experimental and Numerical Research of Delamination Process in CFRP Laminates with Bending-Twisting Elastic Couplings. Materials, 15(21), 7745. https://doi.org/10.3390/ma15217745