Sol-Gel Derived Silica-Titania Waveguide Films for Applications in Evanescent Wave Sensors—Comprehensive Study

Abstract

1. Introduction

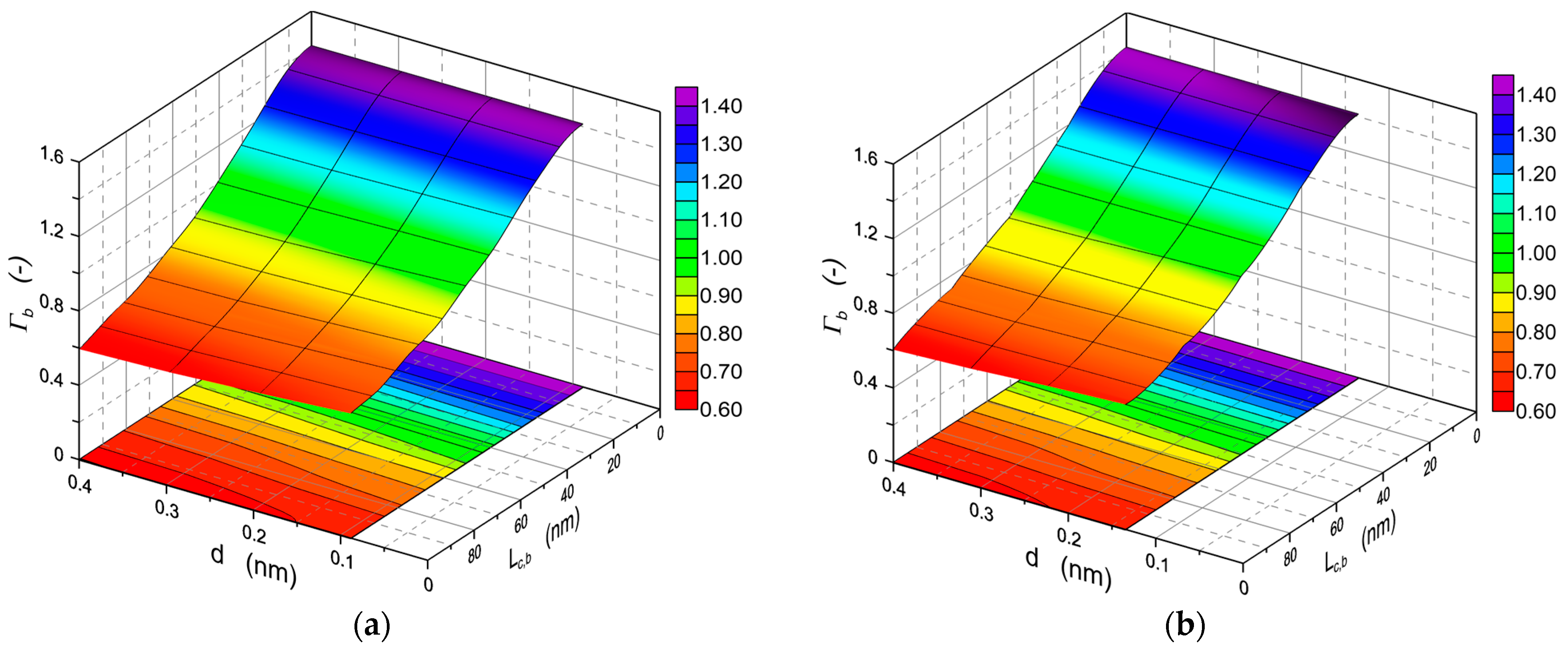

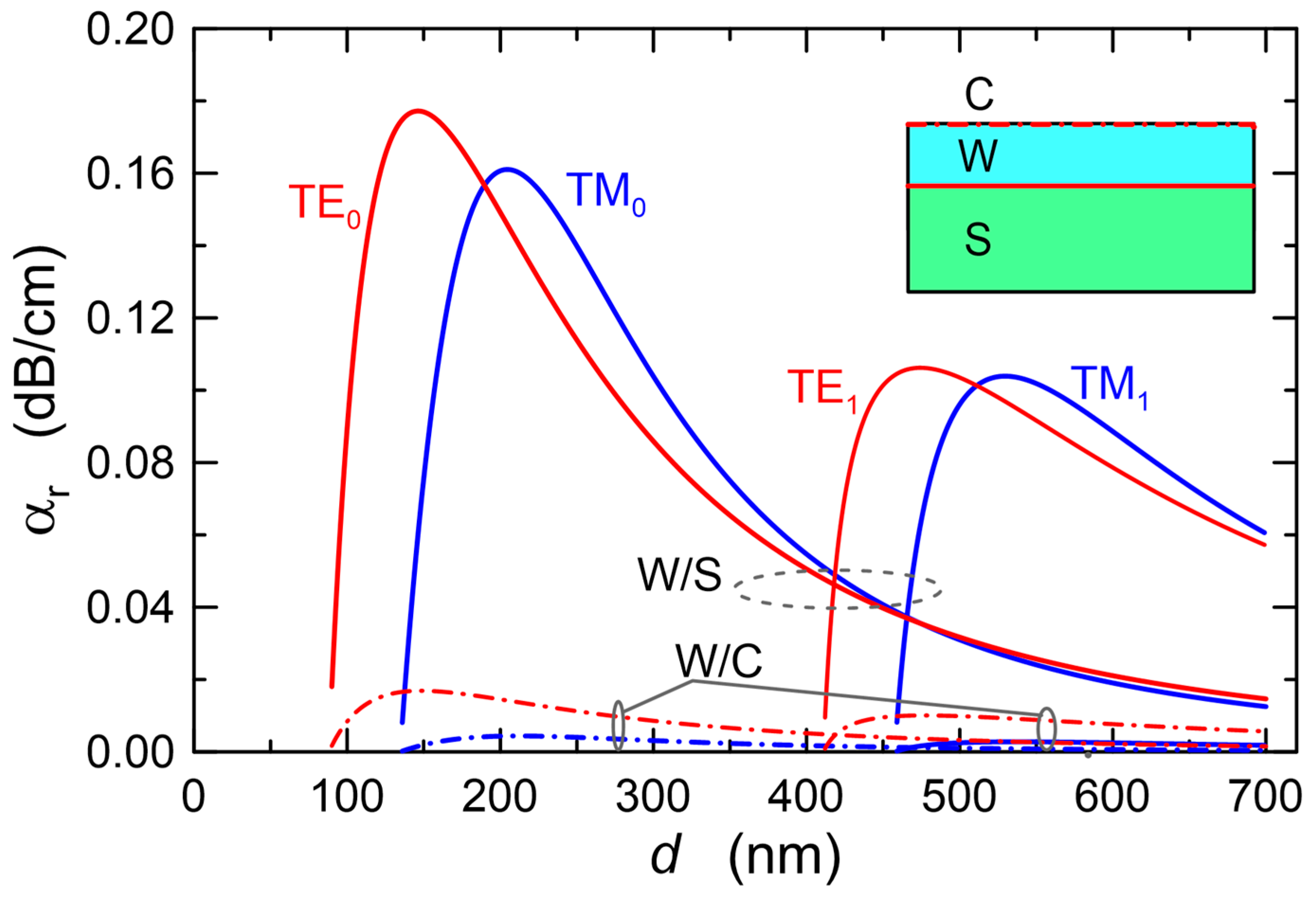

2. Optical Loss—Theoretical Background

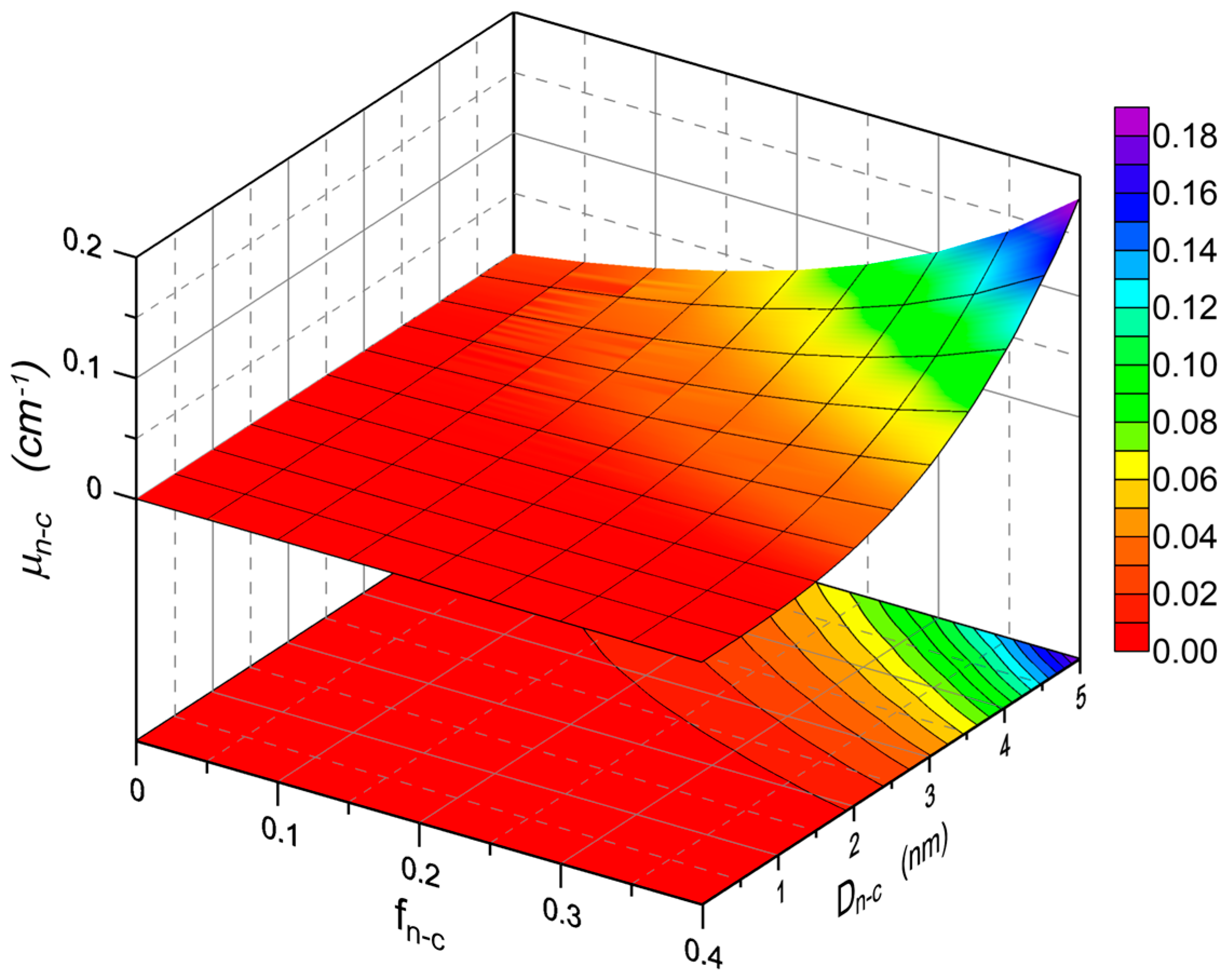

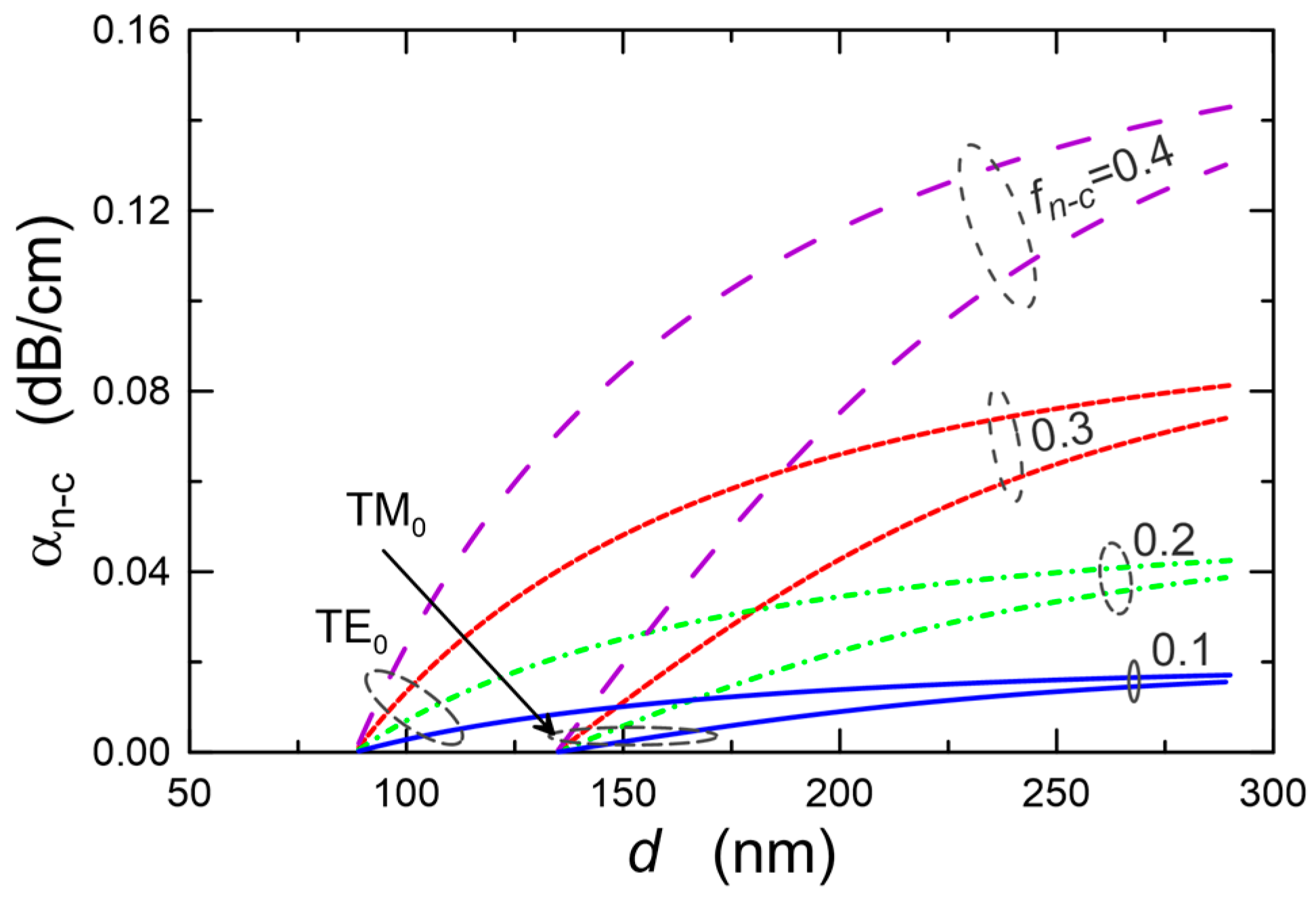

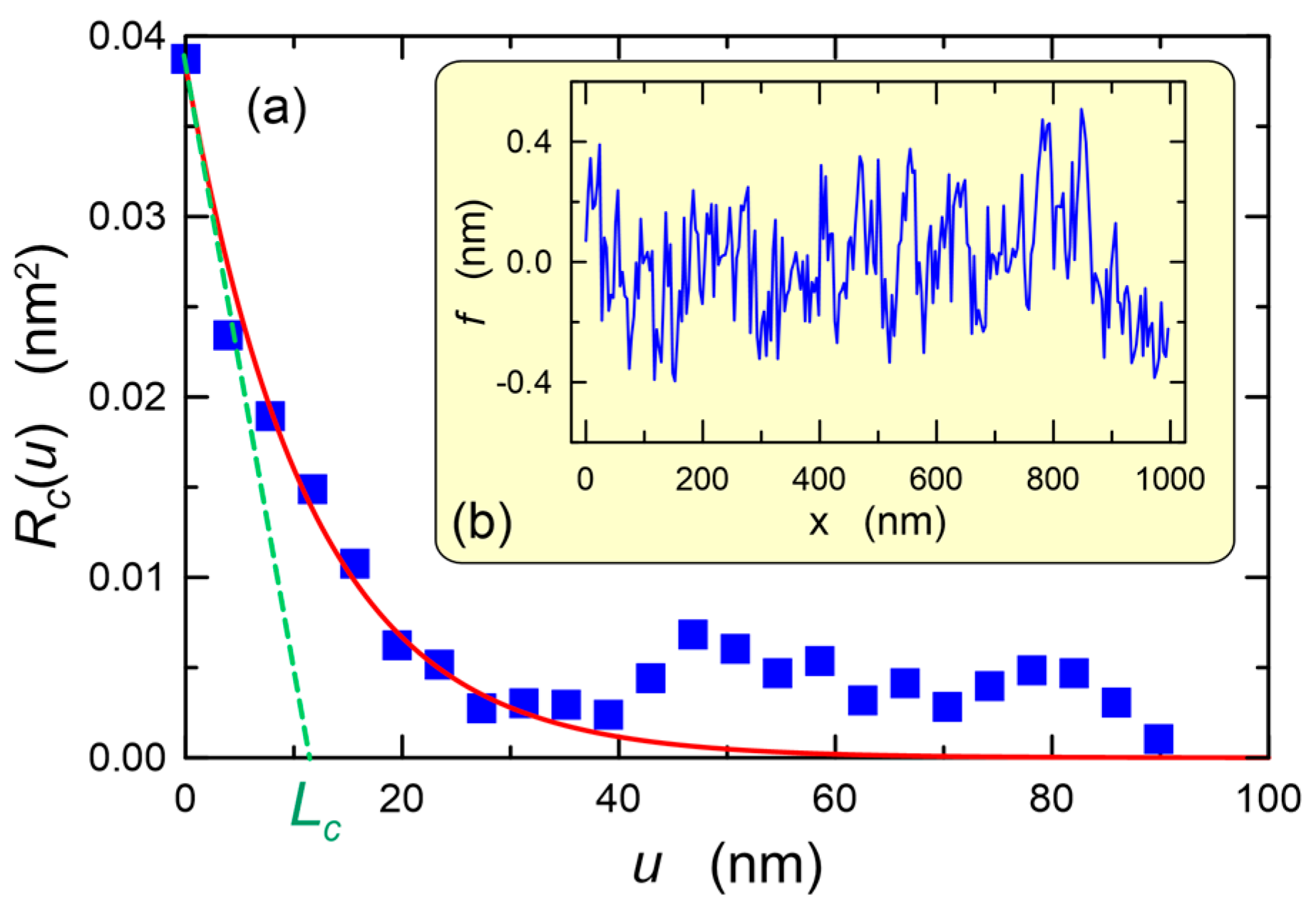

2.1. Model of the Interface Scattering Losses

2.2. Rayleigh-Mie Theory

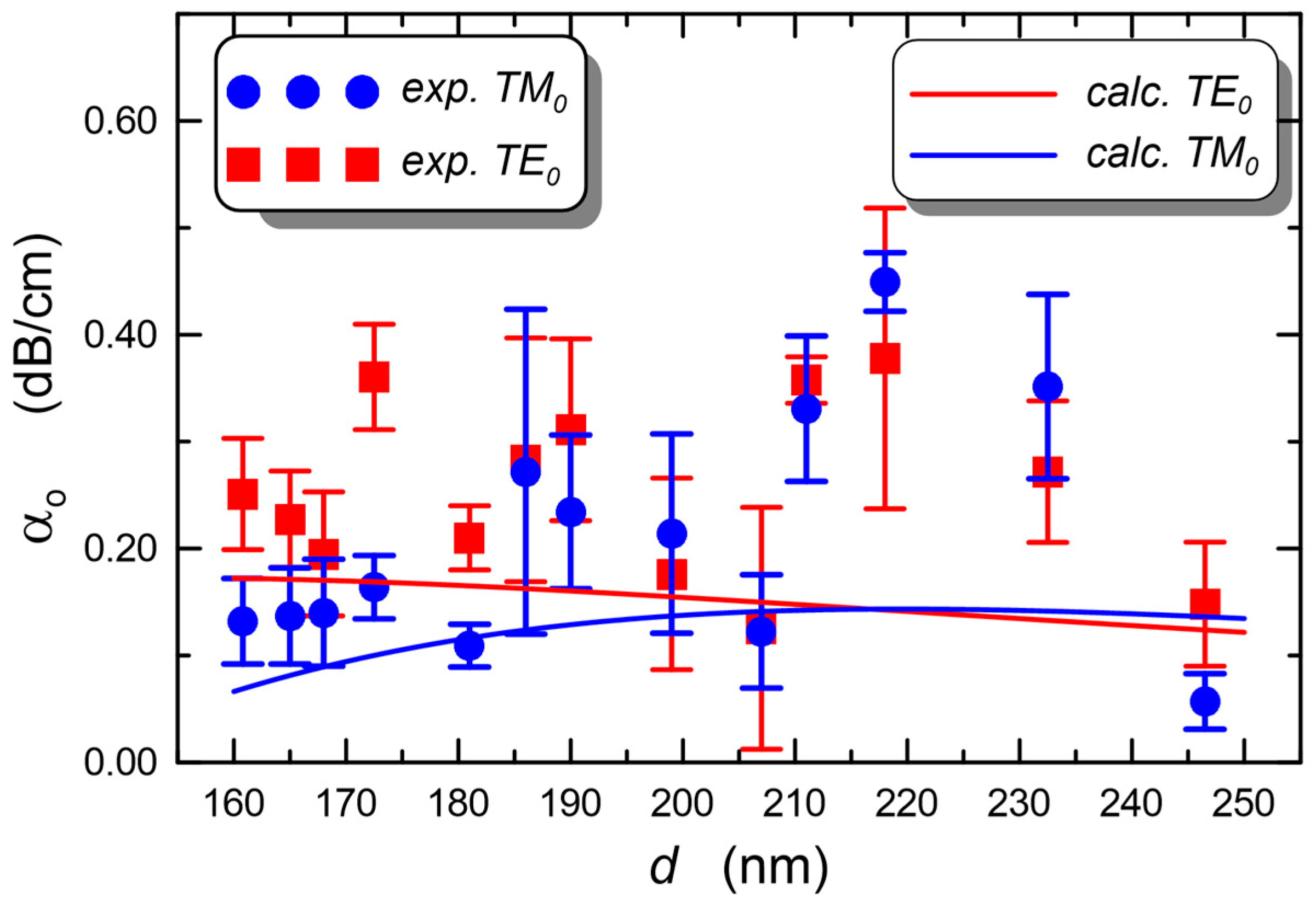

2.3. Optical Loss—Calculation Results

3. Waveguide Film Fabrication

4. Measurements Methods and Instrumentation

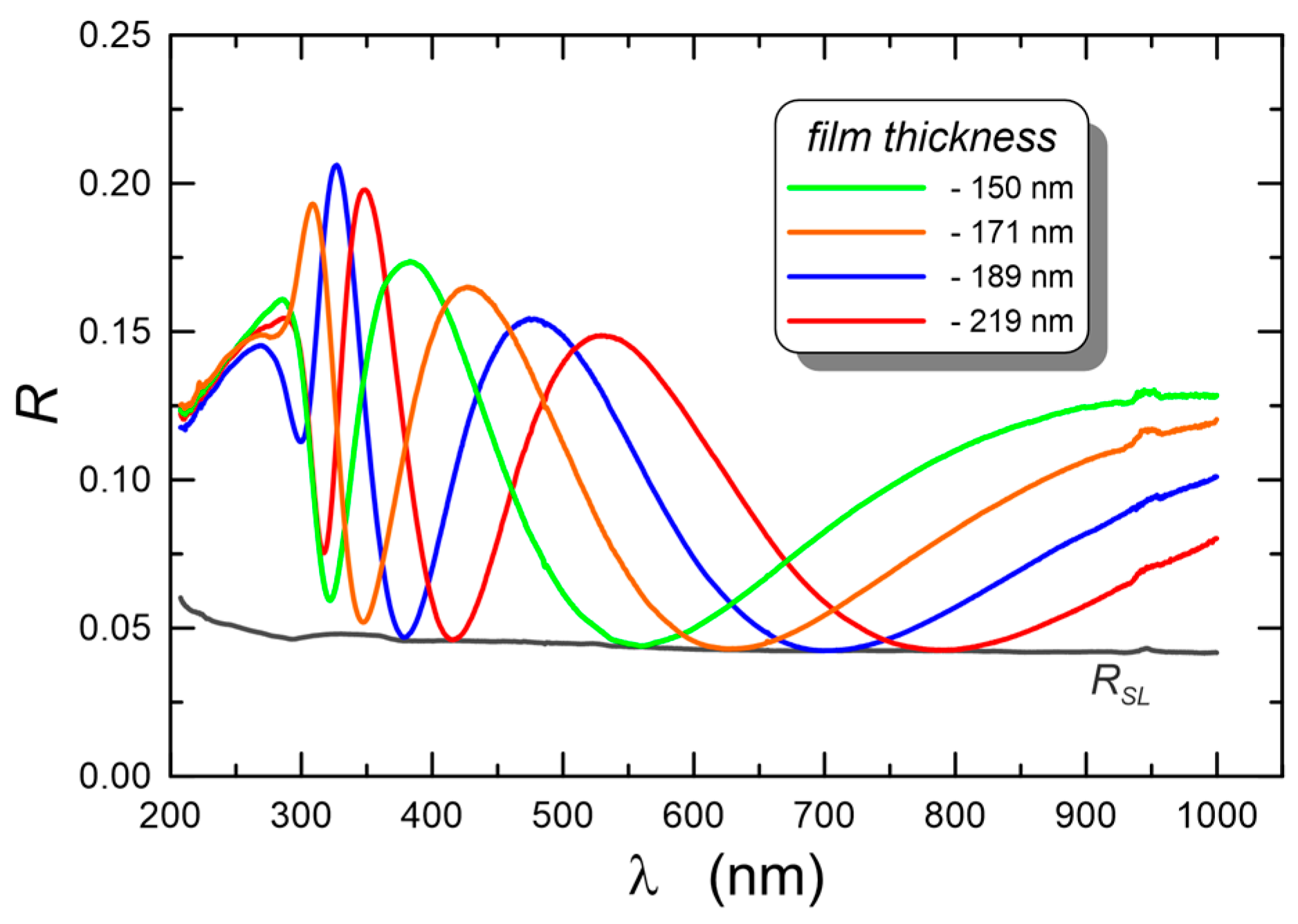

4.1. Thickness and Refractive Index

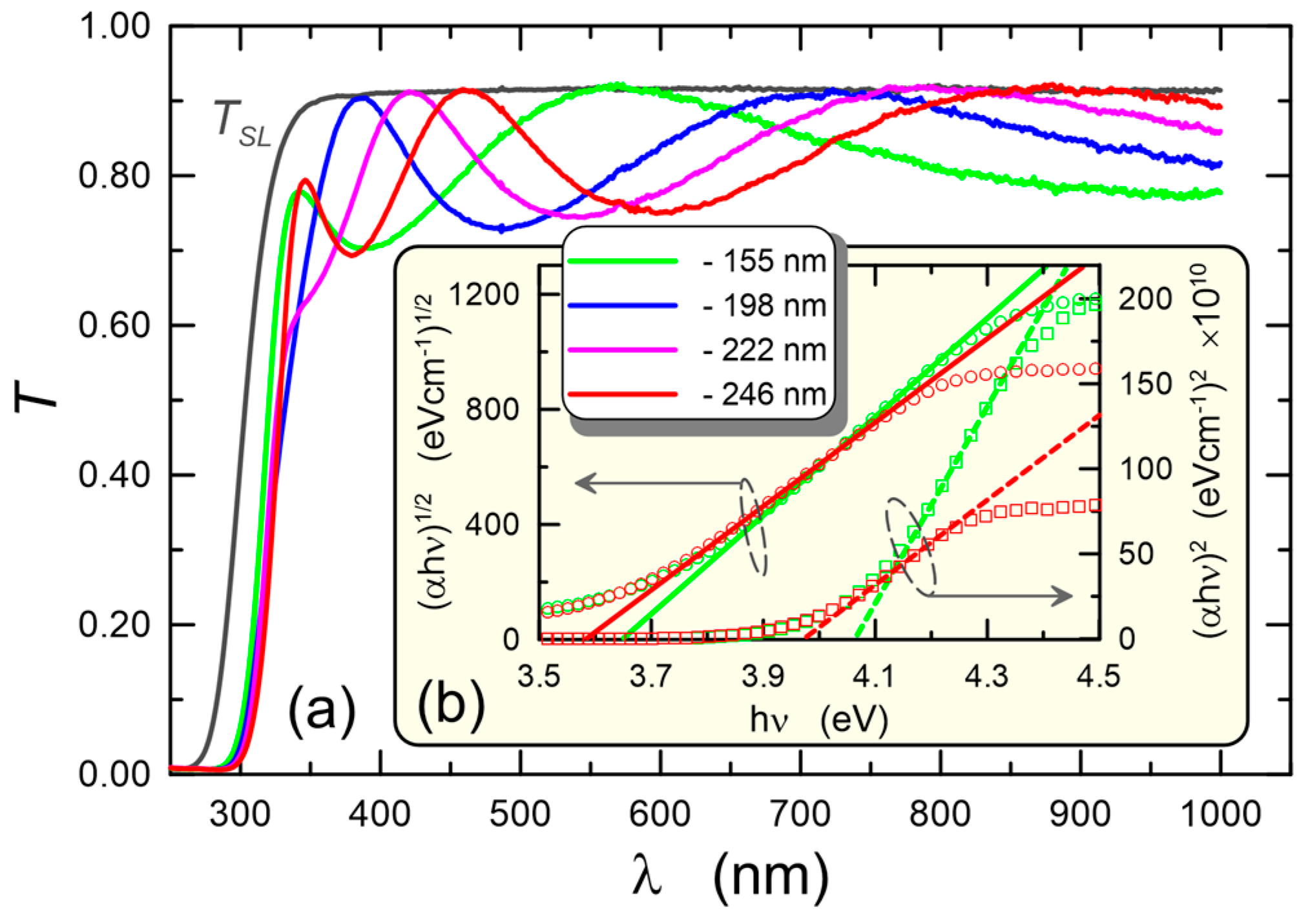

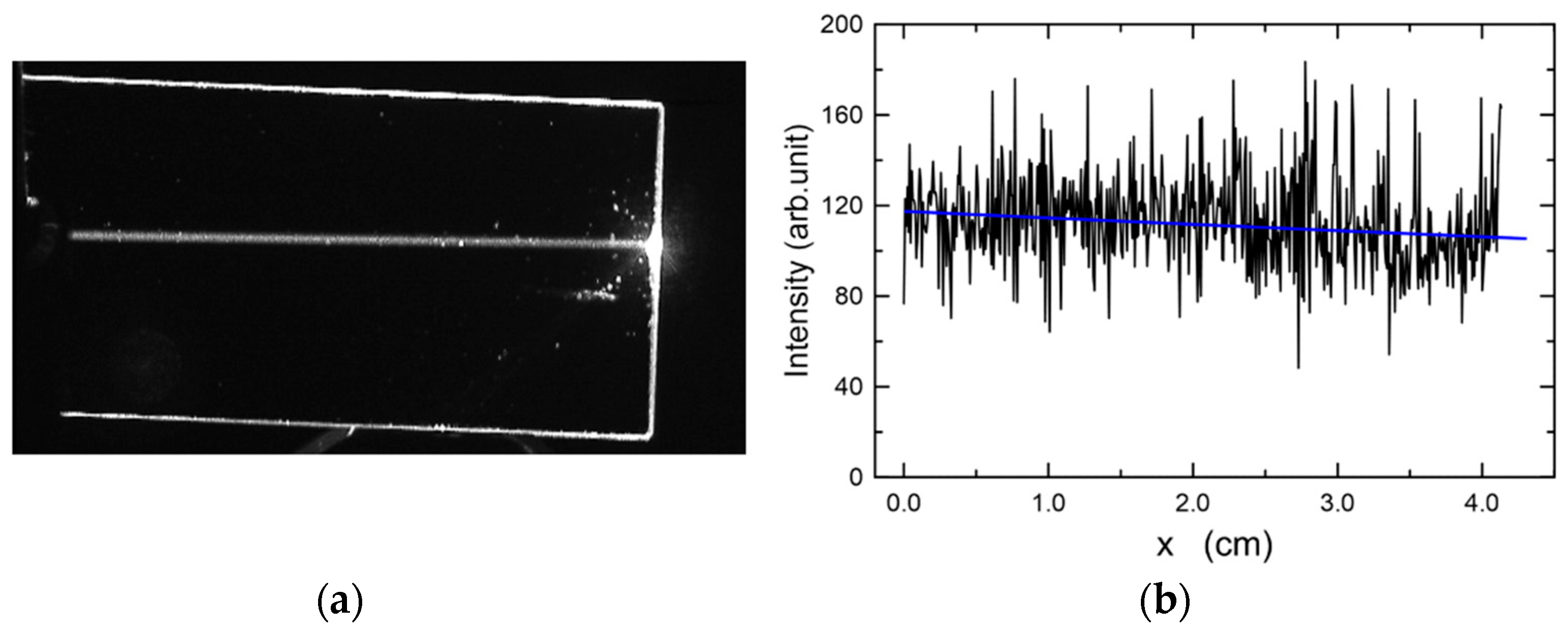

4.2. Transmission Properties, Energy Gap and Optical Homogeneity

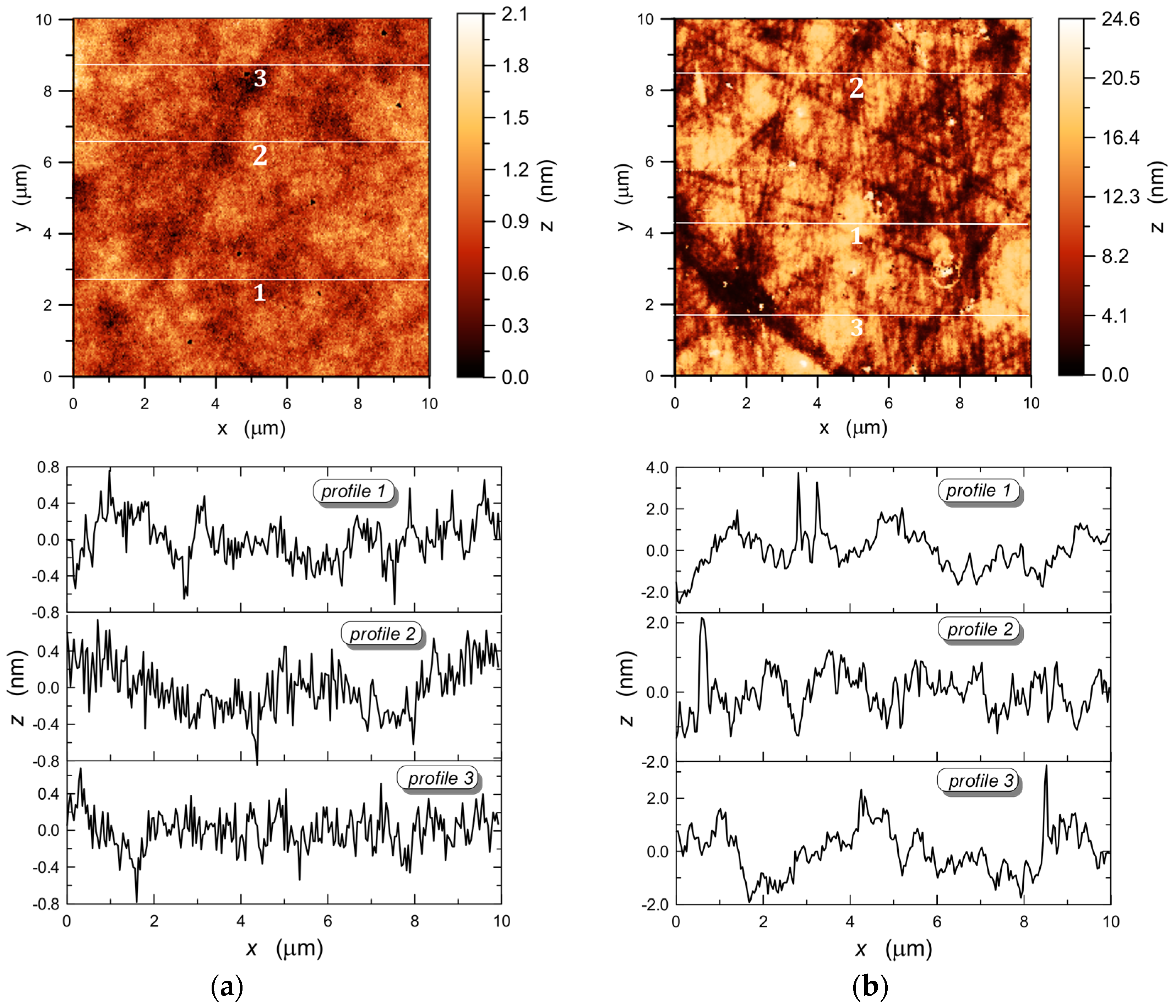

4.3. Morphology of the SiOx:TiOy Composite Films

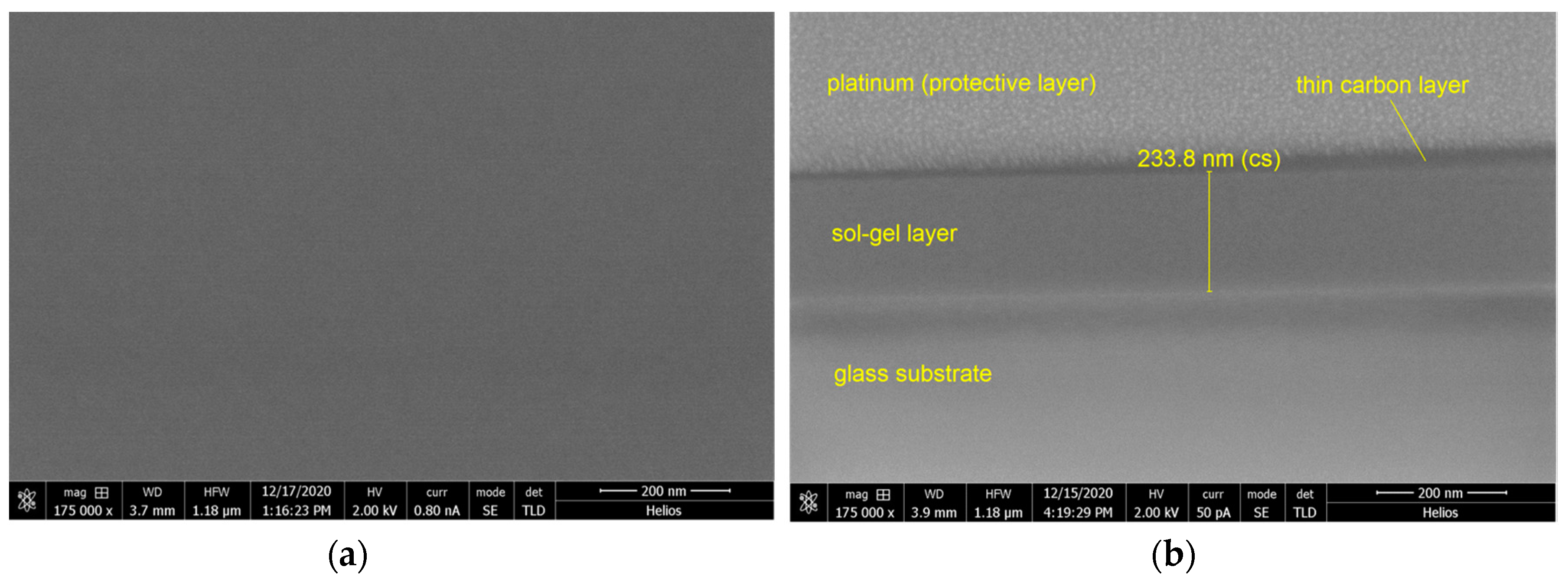

4.3.1. SEM/FIB

4.3.2. TEM Specimen Preparation

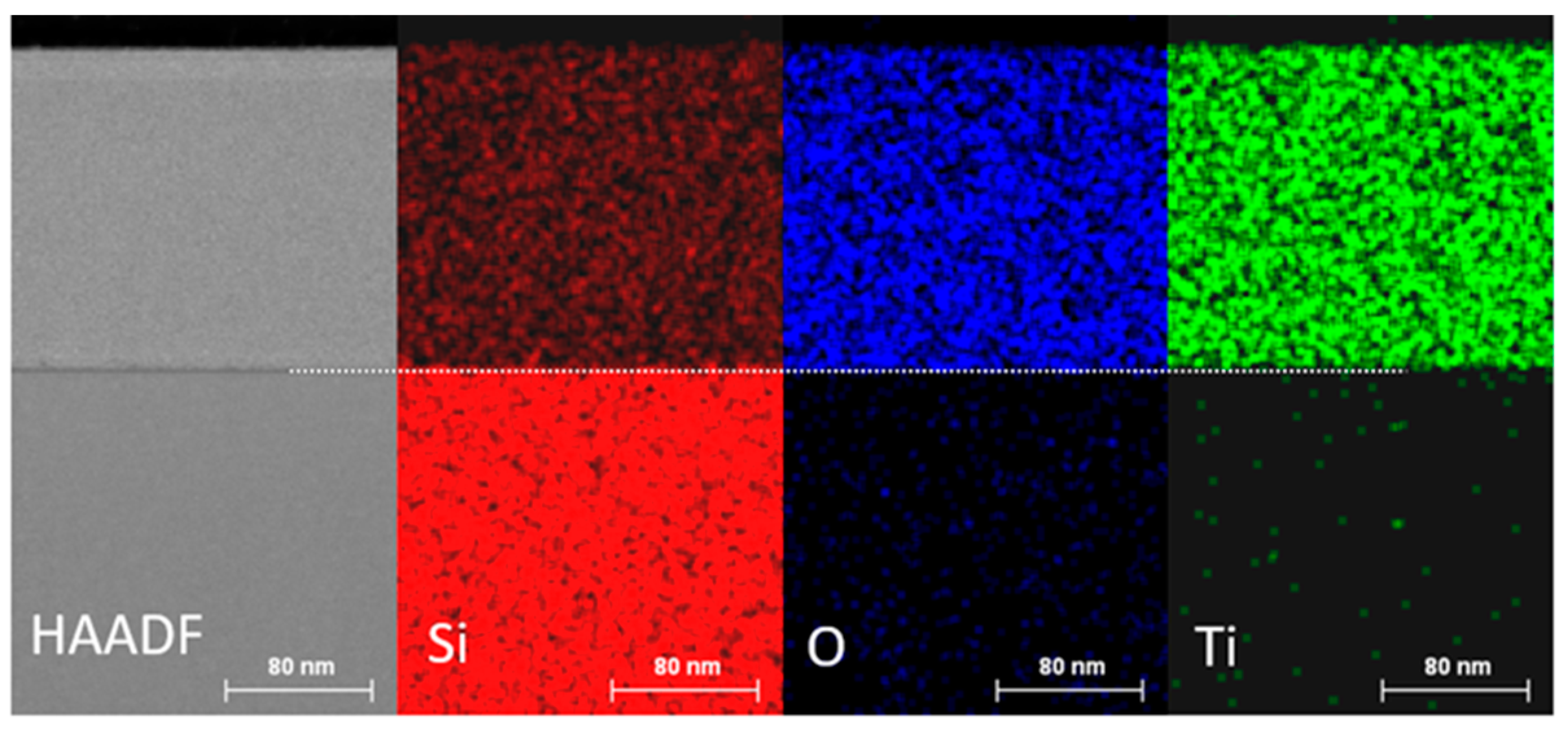

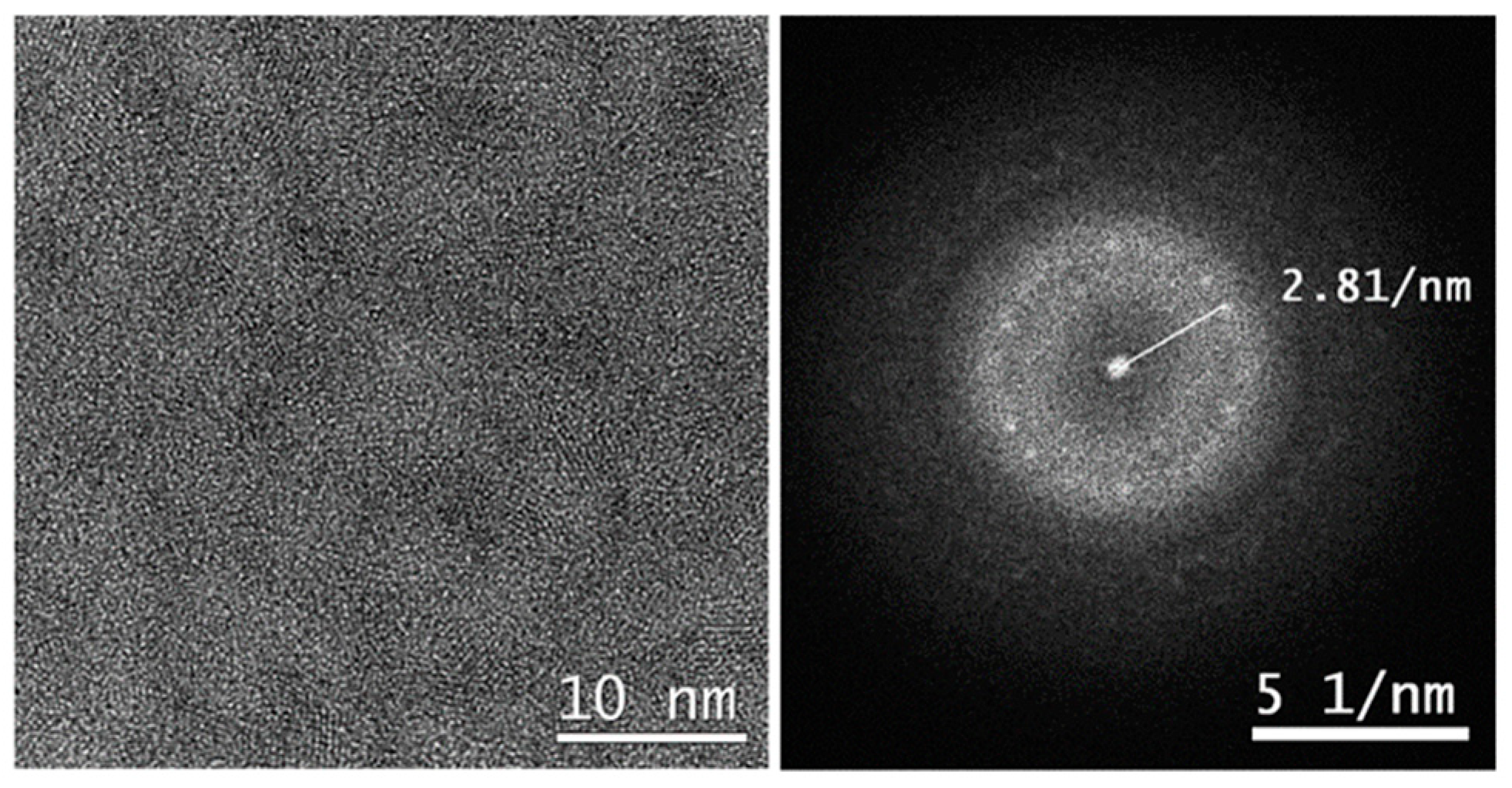

4.3.3. S/TEM Characterization

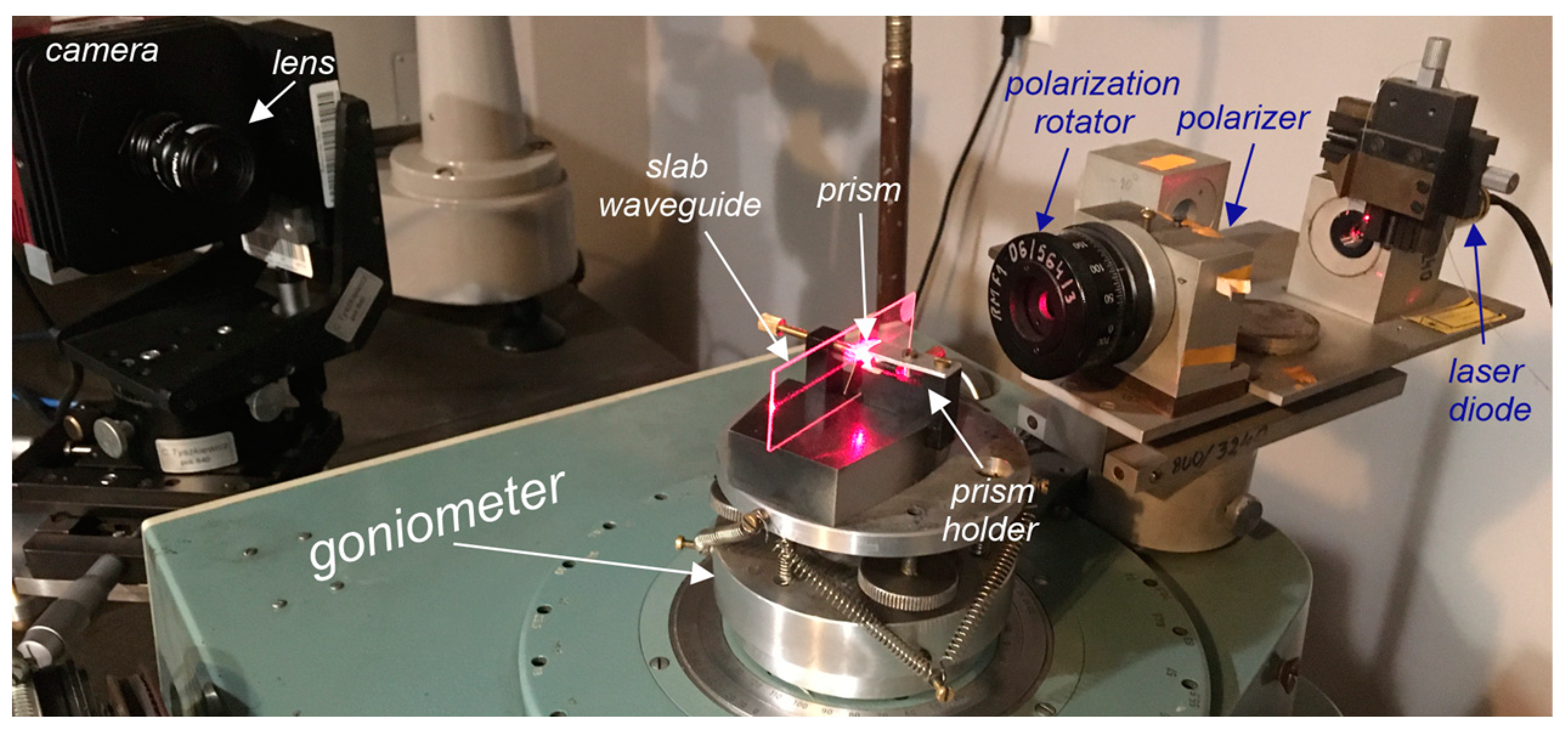

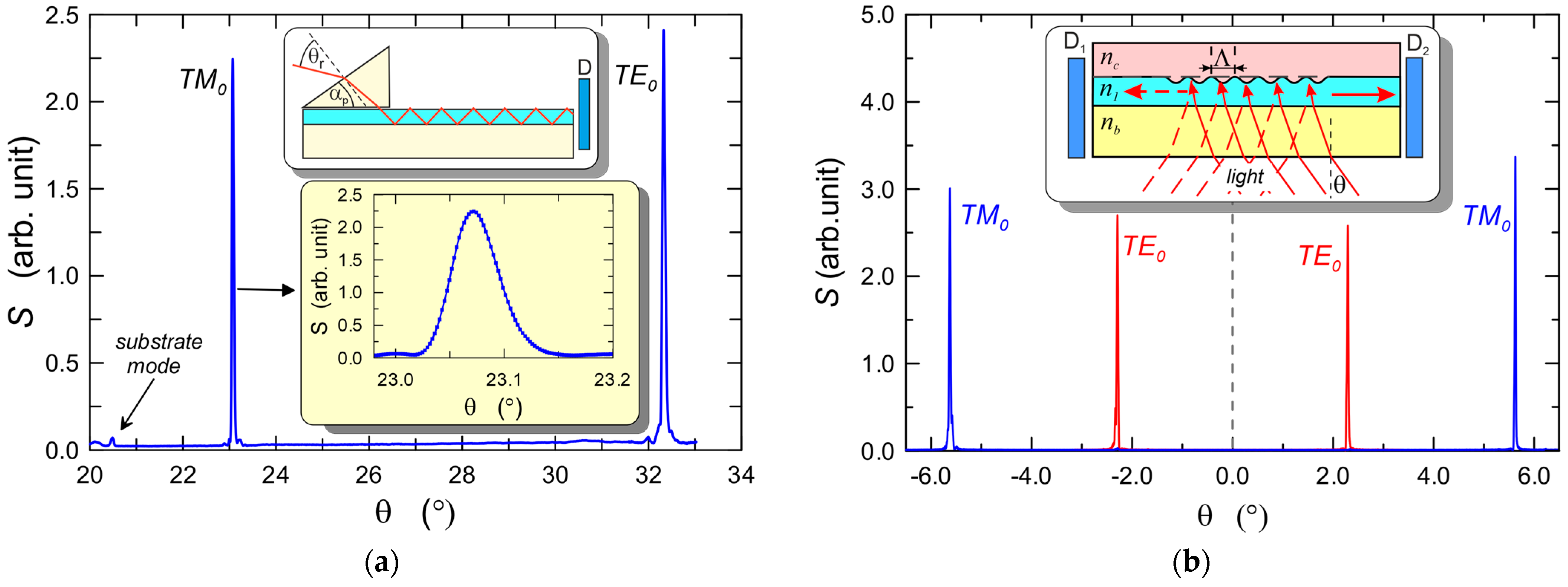

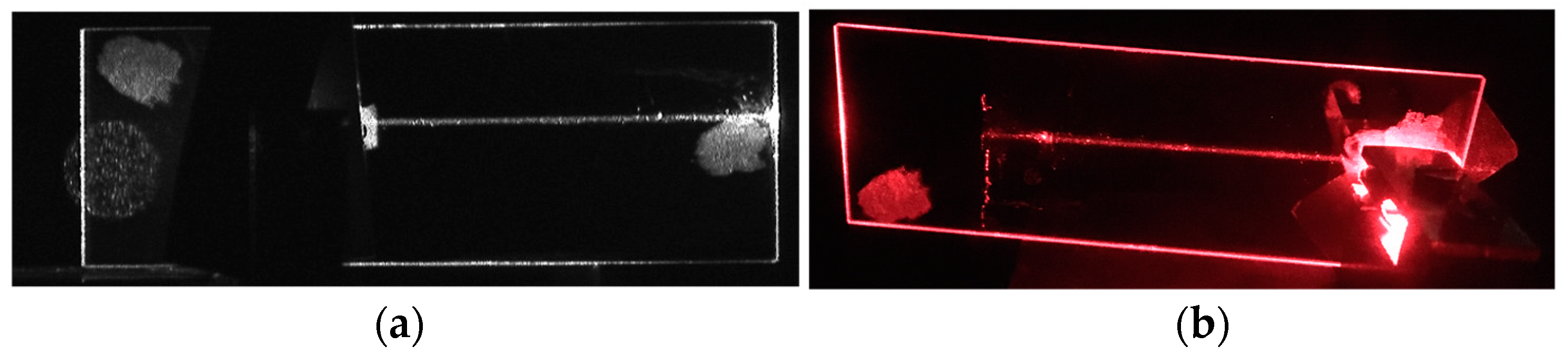

4.4. Waveguide Properties

5. Experimental Results and Discussion

5.1. Film Thickness and Refractive Index versus Substrate Withdrawal Speed

5.2. Optical Band Gap and Homogeneity

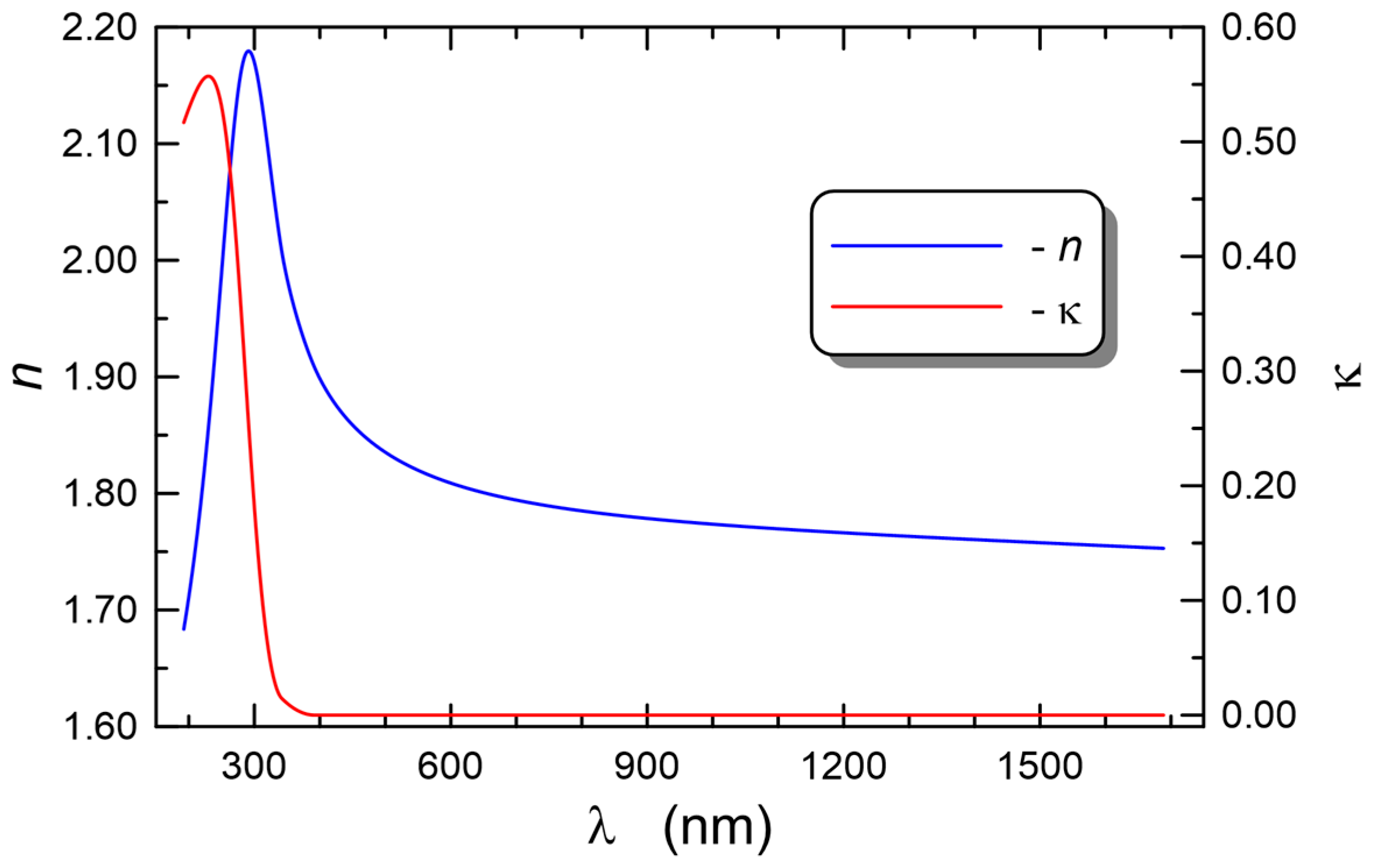

5.3. Complex Refractive Index

5.4. Film Morphology

5.5. Waveguide Properties

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Miller, S.E. Integrated Optics: An Introduction. Bell Syst. Tech. J. 1969, 48, 2059–2069. [Google Scholar] [CrossRef]

- Tien, P.K. Integrated optics and new wave phenomena in optical waveguides. Rev. Mod. Phys. 1977, 49, 361–420. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, R.; Li, X.; Li, T. Development trends in silicon photonics for data centers. Opt. Fiber Technol. 2018, 44, 13–23. [Google Scholar] [CrossRef]

- Bernabé, S.; Wilmart, Q.; Hasharoni, K.; Hassan, K.; Thonnart, Y.; Tissier, P.; Désières, Y.; Olivier, S.; Tekin, T.; Szelag, B. Silicon photonics for terabit/s communication in data centers and exascale computers. Solid-State Electron. 2021, 179, 107928. [Google Scholar] [CrossRef]

- Eldada, L. Optical communication components. Rev. Sci. Instrum. 2004, 75, 575–593. [Google Scholar] [CrossRef]

- Smit, M.; Leijtens, X.; Ambrosius, H.; Bente, E.; Van Der Tol, J.; Smalbrugge, B.; De Vries, T.; Geluk, E.-J.; Bolk, J.; Van Veldhoven, R.; et al. An introduction to InP-based generic integration technology. Semicond. Sci. Technol. 2014, 29, 083001. [Google Scholar] [CrossRef]

- Yamada, K.; Tsuchizawa, T.; Nishi, H.; Kou, R.; Hiraki, T.; Takeda, K.; Fukuda, H.; Ishikawa, Y.; Wada, K.; Yamamoto, T. High-performance silicon photonics technology for telecommunications applications. Sci. Technol. Adv. Mat. 2014, 15, 024603. [Google Scholar] [CrossRef]

- Doerr, C.R. Silicon photonic integration in telecommunications. Front. Phys. 2015, 3, 37. [Google Scholar] [CrossRef]

- Minzioni, P.; Lacava, C.; Tanabe, T.; Dong, J.; Hu, X.; Csaba, G.; Porod, W.; Singh, G.; Willner, A.E.; Almaiman, A.; et al. Roadmap on all-optical processing. J. Opt. 2019, 21, 063001. [Google Scholar] [CrossRef]

- Lambeck, P.V. Integrated optical sensors for the chemical domain. Meas. Sci. Technol. 2006, 17, R93–R116. [Google Scholar] [CrossRef]

- Kozma, P.; Kehl, F.; Ehrentreich-Förster, E.; Stamm, C.; Bier, F.F. Integrated planar optical waveguide interferometer biosensors: A comparative review. Biosens. Bioelectron. 2004, 58, 287–307. [Google Scholar] [CrossRef]

- Benito-Peña, E.; Valdés, M.G.; Glahn-Martínez, B.; Moreno-Bondi, M.C. Fluorescence based fiber optic and planar waveguide biosensors. A review. Anal. Chim. Acta 2016, 943, 17–40. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, J.; Yang, Z.; Wilkinson, J.S.; Zhou, X. Optical biosensors based on refractometric sensing schemes: A review. Biosens. Biolectron. 2019, 144, 111693. [Google Scholar] [CrossRef]

- Vlk, M.; Datta, A.; Alberti, S.; Yallew, H.D.; Mittal, V.; Senthil Murugan, G.; Jágerská, J. Extraordinary evanescent field confinement waveguide sensor for mid-infrared trace gas spectroscopy. Light-Sci. Appl. 2021, 10, 26. [Google Scholar] [CrossRef]

- Lelit, M.; Słowikowski, M.; Filipiak, M.; Juchniewicz, M.; Stonio, B.; Michalak, B.; Pavłov, K.; Myśliwiec, M.; Wiśniewski, P.; Kaźmierczak, A.; et al. Passive Photonic Integrated Circuits Elements Fabricated on a Silicon Nitride Platform. Materials 2022, 15, 1398. [Google Scholar] [CrossRef]

- Barshilia, D.; Chau, L.K.; Chang, G.E. Low-cost planar waveguide-based optofluidic sensor for real-time refractive index sensing. Opt. Express 2020, 28, 27337–27345. [Google Scholar] [CrossRef]

- Demkov, A.A.; Bajaj, C.; Ekerdt, J.G.; Palmstrøm, C.J.; Yoo, S.J.B. Materials for emergent silicon-integrated optical computing. J. Appl. Phys. 2021, 130, 070907. [Google Scholar] [CrossRef]

- Wang, J.; Paesani, S.; Ding, Y.; Santagati, R.; Skrzypczyk, P.; Salavrakos, A.; Tura, J.; Augusiak, R.; Mančinska, L.; Bacco, D.; et al. Multidimensional quantum entanglement with large-scale integrated optics. Science 2018, 360, 285–291. [Google Scholar] [CrossRef]

- Kim, J.H.; Aghaeimeibodi, S.; Carolan, J.; Englund, D.; Waks, E. Hybrid integration methods for on-chip quantum photonics. Optica 2020, 7, 291–308. [Google Scholar] [CrossRef]

- Siew, S.Y.; Li, B.; Gao, F.; Zheng, H.Y.; Zhang, W.; Guo, P.; Xie, S.W.; Song, A.; Dong, B.; Luo, L.W.; et al. Review of Silicon Photonics Technology and Platform Development. J. Lightwave Technol. 2021, 39, 4374–4389. [Google Scholar] [CrossRef]

- Margalit, N.; Xiang, C.; Bowers, S.M.; Bjorlin, A.; Blum, R.; Bowers, J.E. Perspective on the future of silicon photonics and electronics. Appl. Phys. Lett. 2021, 118, 220501. [Google Scholar] [CrossRef]

- Rahim, A.; Goyvaerts, J.; Szelag, B.; Fedeli, J.M.; Absil, P.; Aalto, T.; Harjanne, M.; Littlejohns, C.; Reed, G.; Winzer, G.; et al. Open-access silicon photonics platforms in Europe. IEEE J. Sel. Top. Quant. 2019, 25, 8200818. [Google Scholar] [CrossRef]

- Yan, Z.; Han, Y.; Lin, L.; Xue, Y.; Ma, C.; Ng, W.K.; Wong, K.S.; Lau, K.M. A monolithic InP/SOI platform for integrated photonics. Light Sci. Appl. 2021, 10, 200. [Google Scholar] [CrossRef]

- Bauters, J.F.; Heck, M.J.R.; John, D.; Dai, D.; Tien, M.C.; Barton, J.S.; Leinse, A.; Heideman, R.G.; Blumenthal, D.J.; Bowers, J.E. Ultra-low-loss high-aspect-ratio Si3N4 waveguides. Opt. Express 2011, 19, 3163–3174. [Google Scholar] [CrossRef]

- Wörhoff, K.; Heideman, R.G.; Leinse, A.; Hoekman, M. TriPleX: A versatile dielectric photonic platform. Adv. Opt. Technol. 2015, 4, 189–207. [Google Scholar] [CrossRef]

- Roeloffzen, C.G.H.; Hoekman, M.; Klein, E.J.; Wevers, L.S.; Timens, R.B.; Marchenko, D.; Boller, K.J. Low-Loss Si3N4 TriPleX Optical Waveguides: Technology and Applications Overview. IEEE J. Sel. Top. Quant. 2018, 24, 1–21. [Google Scholar] [CrossRef]

- Butt, M.A.; Tyszkiewicz, C.; Karasiński, P.; Zięba, M.; Kaźmierczak, A.; Zdończyk, M.; Duda, Ł.; Guzik, M.; Olszewski, J.; Martynkien, T.; et al. Optical Thin Films Fabrication Techniques—Towards a Low-Cost Solution for the Integrated Photonic Platform: A Review of the Current Status. Materials 2022, 15, 4591. [Google Scholar] [CrossRef]

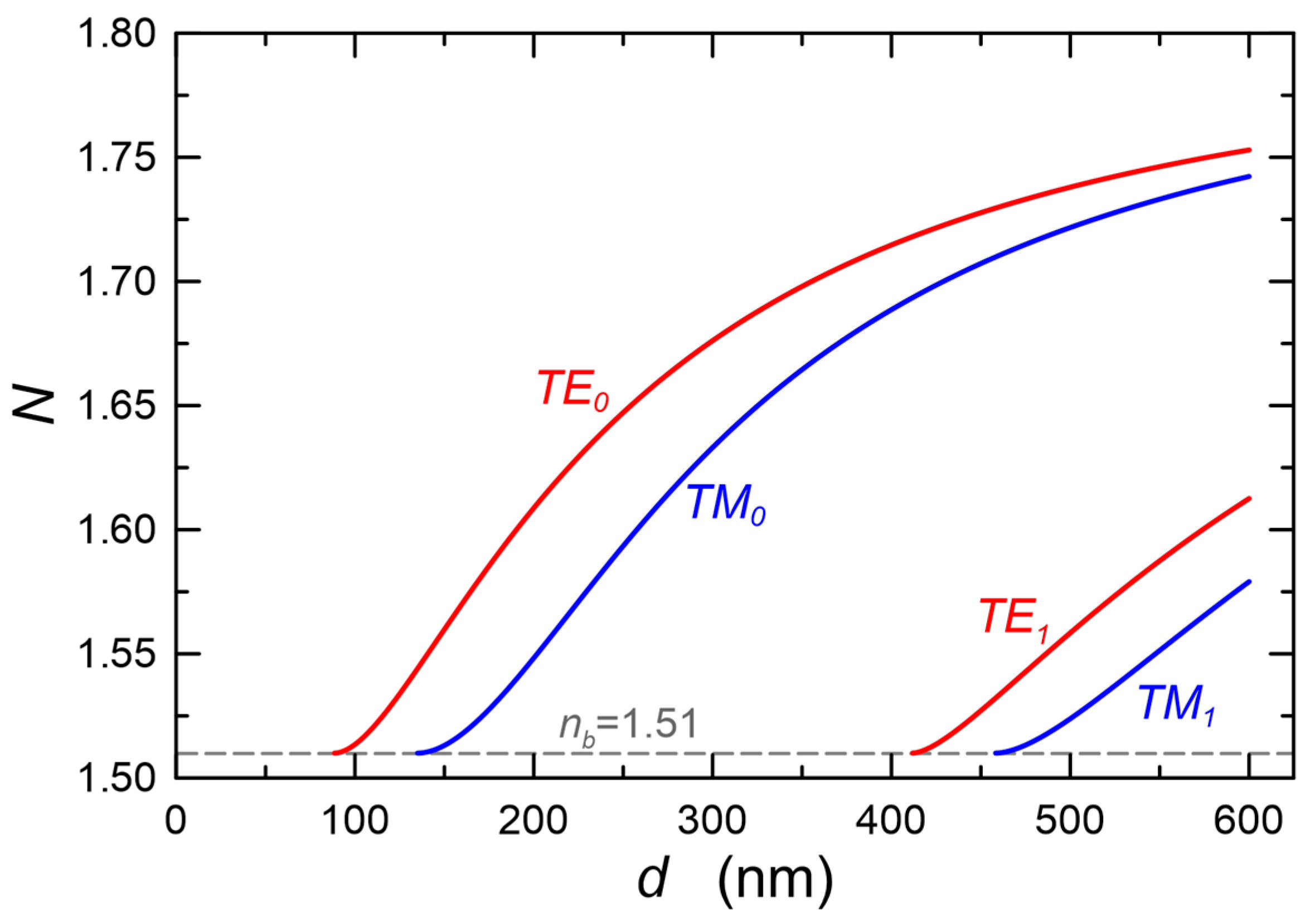

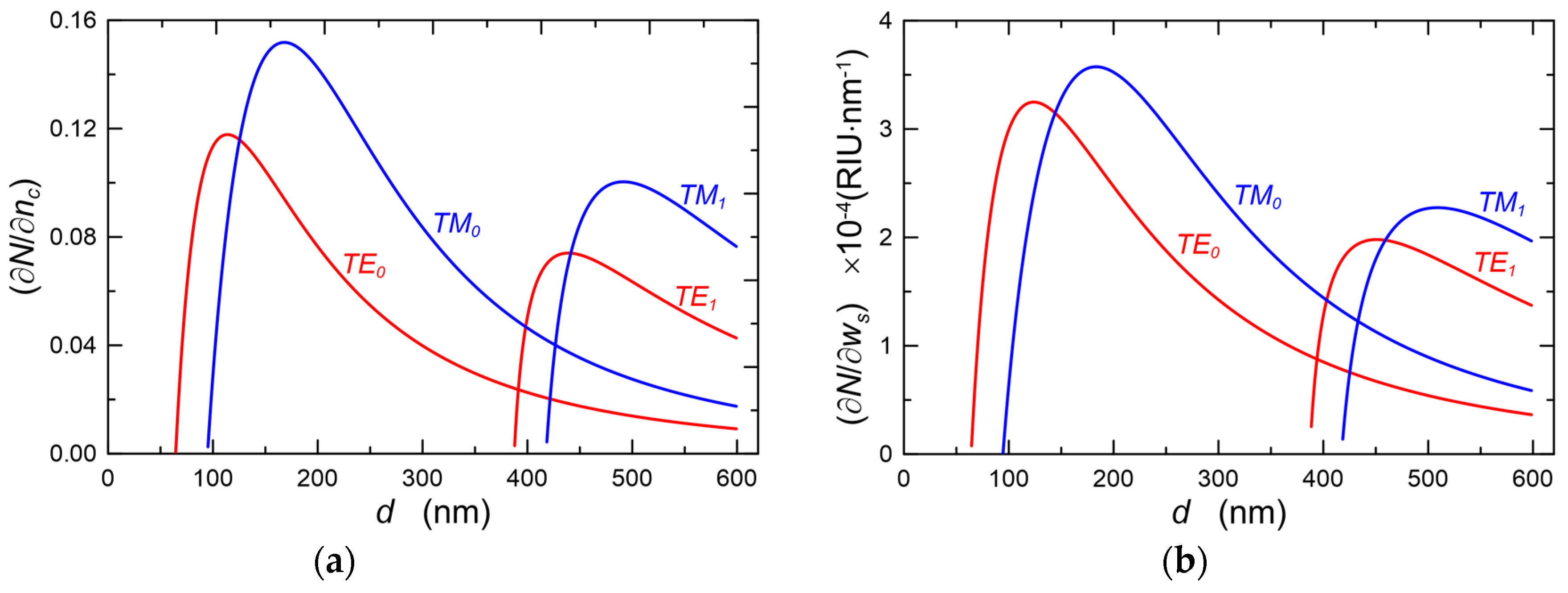

- Parriaux, O.; Veldhuis, G.J. Normalized analysis for the sensitivity optimization of integrated optical evanescent-wave sensors. J. Lightwave Technol. 1998, 16, 573–582. [Google Scholar] [CrossRef]

- Karasiński, P.; Kaźmierczak, A.; Zięba, M.; Tyszkiewicz, C.; Wojtasik, K.; Kielan, P. Highly sensitive sensor structure based on sol-gel waveguide films and grating couplers. Electronics 2021, 10, 1389. [Google Scholar] [CrossRef]

- Kogelnik, H. An Introduction to Integrated Optics. IEEE T Microw Theory 1975, 1, 2–16. [Google Scholar] [CrossRef]

- Ramaswamy, R.V.; Srivastava, R. Ion-exchange glass waveguides: A review. J. Lightwave Technol. 1988, 6, 984–1002. [Google Scholar] [CrossRef]

- Broquin, J.E.; Honkanen, S. Integrated Photonics on Glass: A Review of the Ion-Exchange Technology Achievements. Appl. Sci. 2021, 11, 4472. [Google Scholar] [CrossRef]

- Armenise, M.N. Fabrication techniques of lithium niobate waveguides. IEE Proc. J. 1988, 135, 85–91. [Google Scholar] [CrossRef]

- Nakajima, H. 40 Years Anniversary of Ti:LiNbO3 and Beyond. 2014. Available online: https://www.ecio-conference.org/wp-content/uploads/2016/05/2014/ECIO-2014_We2bTU2.pdf (accessed on 22 September 2022).

- Sun, D.; Zhang, Y.; Wang, D.; Song, W.; Liu, X.; Pang, J.; Geng, D.; Sang, Y.; Liu, H. Microstructure and domain engineering of lithium niobate crystal films for integrated photonic applications. Light Sci. Appl. 2020, 9, 197. [Google Scholar] [CrossRef]

- Karasiński, P.; Rogoziński, R. Characterization and sensor properties of sol–gel SiO2:TiO2 film/ion-exchange glass optical waveguides. Opt. Commun. 2008, 281, 2472–2480. [Google Scholar] [CrossRef]

- Jia, Y.; Wang, L.; Chen, F. Ion-cut lithium niobate on insulator technology: Recent advances and perspectives. Appl. Phys. Rev. 2021, 8, 011307. [Google Scholar] [CrossRef]

- Emerging Waveguide Technology; You, K.Y., Ed.; IntechOpen: London, UK, 2018; Available online: https://www.perlego.com/book/2025423/emerging-waveguide-technology-pdf (accessed on 1 August 2018).

- Prajzler, W.; Arif, S.; Min, K.; Kim, S.; Nekvindova, P. All-polymer silk-fibroin optical planar waveguides. Opt. Mater. 2021, 114, 110932. [Google Scholar] [CrossRef]

- Baudzus, L.; Krummrich, P.M. Low-loss planar optical waveguides based on plasma deposited silicon oxycarbide. Opt. Mater. Express 2019, 9, 2797–2805. [Google Scholar] [CrossRef]

- Sefunc, M.A.; Segerink, F.B.; García-Blanco, S.M. High index contrast passive potassium double tungstate waveguides. Opt. Mater. Express 2018, 8, 629–638. [Google Scholar] [CrossRef]

- Du, X.M.; Almeida, R.M. Sintering kinetics of silica-titania sol-gel films on silicon wafers. J. Mater. Reas. 1996, 11, 353–357. [Google Scholar] [CrossRef]

- Chao, S.; Wang, H.W.; Hsu, M.Y.; Wang, L.C. Characteristics of ion-beam-sputtered high-refractive-index TiO2-SiO2 mixed films. J. Opt. Soc. Am. B 1999, 16, 1477–1483. [Google Scholar] [CrossRef]

- Yang, L.L.; Lai, Y.S.; Chen, J.S.; Tsai, P.H.; Chen, C.L.; Chang, C.J. Compositional tailored sol-gel SiO2–TiO2 Thin Films: Crystallization, Chemical Bonding Configuration, and Optical Properties. J. Mat. Res. 2005, 20, 3141–3149. [Google Scholar] [CrossRef]

- Kermadi, S.; Agoudjil, N.; Sali, S.; Boumaour, M.; Bourgeois, S.M.; De Lucas, M.C. Sol-gel synthesis of xTiO2(100−x)SiO2 nanocomposite thin films: Structure, optical and antireflection properties. Thin Solid Film. 2014, 564, 170–178. [Google Scholar] [CrossRef]

- Brinker, C.J.; Scherer, G.W. Sol-Gel Science, The Physics and Chemistry of Sol-Gel Processing; Academic Press: Cambridge, MA, USA, 1990. [Google Scholar]

- Almeida, R.M.; Martucci, A.; Santos, L.; Hernández, R.E.R. Sol-Gel Derived Optical and Photonic Materials; Woodhead Publishing: Cambridge, UK, 2020. [Google Scholar] [CrossRef]

- Herrmann, P.P.; Wildmann, D. Fabrication of planar dielectric waveguides with high optical damage threshold. IEEE J. Quantum Elect 1983, 12, 1735–1738. [Google Scholar] [CrossRef]

- Tiefenthaler, K.; Briguet, V.; Buser, E.; Horisberger, M.; Lukosz, W. Preparation of planar optical SiO2-TiO2 and LiNbO3 waveguides with a dip coating method and embossing technique for fabricating grating couplers and channel waveguides. Proc. SPIE 1983, 401, 165–173. [Google Scholar]

- Lukosz, W.; Tiefenthaler, K. Embossing technique for fabricating integrated optical components in hard inorganic waveguiding materials. Opt. Lett. 1983, 8, 537–539. [Google Scholar] [CrossRef]

- Tiefenthaler, K.; Lukosz, W. Sensitivity of grating couplers as integrated-optical chemical sensors. J. Opt. Soc. Am. B 1989, 6, 209–220. [Google Scholar] [CrossRef]

- Clerc, D.; Lukosz, W. Direct immunosensing with an integrated-optical output grating coupler. Sensor. Actuat. B-Chem. 1997, 40, 53–58. [Google Scholar] [CrossRef]

- Weisenbacht, L.; Zelinski, B.J.J. The attenuation of sol-gel waveguides measured as a function of wavelength and sample age. Proc. SPIE Sol-Gel Opt. III 1994, 2288, 630–639. [Google Scholar] [CrossRef]

- Yang, L.; Saavedra, S.S.; Armstrong, N.R.; Hayes, J. Fabrication and characterization of low-loss, sol-gel planar waveguides. Anal. Chem. 1994, 66, 1254–1263. [Google Scholar] [CrossRef]

- Jiwei, Z.; Xi, Y.; Liangying, Z. Characterization and optical propagation loss of sol-gel derived TiO2/SiO2 films. J. Phys. D Appl. Phys. 2000, 33, 3013–3017. [Google Scholar] [CrossRef]

- Łukowiak, A.; Dylewicz, R.; Patela, S.; Stręk, W.; Maruszewski, K. Optical properties of SiO2–TiO2 thin film waveguides obtained by the sol–gel method and their applications for sensing purposes. Opt. Mater. 2005, 27, 1501–1505. [Google Scholar] [CrossRef]

- Zaharescu, M.; Cristea, D.; Obreja, P.; Predoana, L.; Gartner, M.; Anastasescu, M. SiO2-TiO2 undoped or (Er3+) doped thin layers for integrate optics prepared by sol-gel method. In Proceedings of the 2007 International Semiconductor Conference, Sinaia, Romania, 15 October–17 September 2007; pp. 215–218. [Google Scholar] [CrossRef]

- Karasiński, P.; Rogoziński, R. Rib waveguides fabricated by means of chemical etching of sol-gel SiO2:TiO2 films. Opt. Commun. 2005, 245, 237–242. [Google Scholar] [CrossRef]

- Karasiński, P. Sensor properties of planar waveguide structures with grating couplers. Opto-Electron. Rev. 2007, 15, 168–178. [Google Scholar] [CrossRef]

- Karasiński, P.; Tyszkiewicz, C.; Rogoziński, R.; Jaglarz, J.; Mazur, J. Optical rib waveguides based on sol-gel derived silica-titania films. Thin Solid Films 2011, 519, 5544–5551. [Google Scholar] [CrossRef]

- Karasiński, P.; Tyszkiewicz, C.; Domanowska, A.; Michalewicz, A.; Mazur, J. Low loss, long time stable sol-gel derived silica-titania waveguide films. Mater. Lett. 2015, 143, 5–7. [Google Scholar] [CrossRef]

- Tyszkiewicz, C.; Karasiński, P.; Rogoziński, R. Directional couplers fabricated via a solgel route and conventional optical lithography. Opt. Quant. Electron. 2016, 48, 19. [Google Scholar] [CrossRef]

- Karasiński, P.; Domanowska, A.; Gondek, E.; Sikora, A.; Tyszkiewicz, C.; Skolik, M. Homogeneity of sol-gel derived silica-titania waveguide films–spectroscopic and AFM studies. Opt. Laser Technol. 2020, 121, 105840. [Google Scholar] [CrossRef]

- Almeida, R.M.; Morais, P.J.; Vasconcelos, H.C. Optical loss mechanisms in nanocomposite sol-gel planar waveguides. Proc. SPIE 1997, 3136, 296–303. [Google Scholar] [CrossRef]

- Pinnow, D.A.; Rich, T.C.; Ostermayer, F.W.; Didomenico, M. Fundamental optical attenuation limits in the liquid and glassy state with application to fiber optical waveguide materials. Appl. Phys. Lett. 1973, 22, 527. [Google Scholar] [CrossRef]

- Tien, P.K. Light waves in thin films and integrated optics. Appl. Opt. 1971, 10, 2395–2413. [Google Scholar] [CrossRef] [PubMed]

- Marcuse, D. Mode conversion caused by surface imperfections of a dielectric slab waveguide. Bell Syst. Tech. J. 1969, 48, 3187–3215. [Google Scholar] [CrossRef]

- Marcuse, D. Theory of Dielectric Optical Waveguides, 1st ed.; Academic Press: London, UK, 1974; pp. 95–97. [Google Scholar]

- Ames, G.H.; Hall, D.G. Attenuation in planar optical waveguides: Comparison of theory end experiment. IEEE J. Quantum Elect. 1983, 5, 845–853. [Google Scholar] [CrossRef]

- Lacey, J.P.R.; Payne, F.P. Radiation loss from planar waveguides with random wall imperfections. IEE Proc-J. 1990, 137, 282–288. [Google Scholar] [CrossRef]

- Payne, F.P.; Lacey, J.P.R. A theoretical analysis of scattering loss from planar optical waveguides. Opt. Quan. Electron. 1994, 26, 977–986. [Google Scholar] [CrossRef]

- Lee, K.K.; Lim, D.R.; Luan, H.-C.; Agarwal, A.; Foresi, J.; Kimerling, L.C. Effect of size and roughness on light transmission in a Si/SiO2 waveguide: Experiments and model. A Phys. Lett. 2000, 77, 1617–1619. [Google Scholar] [CrossRef]

- Yap, K.P.; Delâge, A.; Lapointe, J.; Lamontagne, B.; Schmid, J.H.; Waldron, P.; Syrett, B.A.; Janz, S. Correlation of Scattering Loss, Sidewall Roughness and Waveguide Width in Silicon-on-Insulator (SOI) Ridge Waveguides. J. Lightwave Technol. 2009, 27, 3999–4009. [Google Scholar] [CrossRef]

- Wang, Y.; Kong, M.; Xu, Y.; Zhou, Z. Analysis of scattering loss due to sidewall roughness in slot waveguides by variation of mode effective index. J. Opt. 2018, 20, 025801. [Google Scholar] [CrossRef]

- Shang, H.; Sun, D.; Yu, P.; Wang, B.; Yu, T.; Li, T.; Jiang, H. Investigation for sidewall roughness caused optical scattering loss of silicon-on-insulator waveguides with confocal laser scanning microscopy. Coatings 2020, 10, 236. [Google Scholar] [CrossRef]

- Guglielmi, M.; Zenezini, S. The thickness of sol-gel silica coatings obtained by dipping. J. Non-Cryst. Solids 1990, 121, 303–309. [Google Scholar] [CrossRef]

- Brinker, C.J.; Hurd, A.J.; Schunk, P.R.; Frye, G.C.; Ashley, C.S. Review of sol-gel thin film formation. J. Non-Cryst. Solids 1992, 147–148, 424–436. [Google Scholar] [CrossRef]

- Azzam, R.M.A.; Bashara, N.M. Ellipsometry and Polarized Light; North-Holland: Amsterdam, The Netherlands, 1987. [Google Scholar]

- Jellison, G.E.; Modine, F.A. Parameterization of the optical functions of amorphous materials in the interband region. Appl. Phys. Lett. 1996, 69, 371–373. [Google Scholar] [CrossRef]

- Jellison Jr, G.E.; Merkulov, V.I.; Puretzky, A.A.; Geohegan, D.B.; Eres, G.; Lowndes, D.H.; Caughman, J.B. Characterization of thin-film amorphous semiconductors using spectroscopic ellipsometry. Thin Solid Films 2000, 377–378, 68–73. [Google Scholar] [CrossRef]

- Blanckenhagen, B.; Tonova, D.; Ullmann, J. Application of the Tauc–Lorentz formulation to the interband absorption of optical coating materials. Appl. Opt. 2002, 41, 3137–3141. [Google Scholar] [CrossRef]

- Schmiedova, V.; Heinrichova, P.; Zmeskal, O.; Weiter, M. Characterization of polymeric thin films for photovoltaic applications by spectroscopic ellipsometry. Appl. Surf. Sci. 2015, 349, 582–588. [Google Scholar] [CrossRef]

- Tauc, J.; Grigorovici, R.; Vancu, A. Optical Properties and Electronic Structure of Amorphous Germanium. Phys. Status Solidi B 1966, 15, 627–637. [Google Scholar] [CrossRef]

- Tauc, J. Amorphous and Semiconductors; Plenum: London, UK, 1974. [Google Scholar]

- Karasiński, P.; Gondek, E.; Drewniak, S.; Kityk, I.V. Nano-sized blue spectral shift in sol gel derived mesoporous titania films. J. Sol-Gel Sci. Technol. 2012, 61, 355–361. [Google Scholar] [CrossRef]

- Palik, E.D. Handbook of Optical Constants of Solids, 1st ed.; Academic Press: San Diego, CA, USA, 1998. [Google Scholar]

- Chen, H.Y.; Wu, C.M.; Lai, C.H. A cost-effective modified bright-mode automatic prism coupler for planar optical waveguide characterization. IEEE Trans. Educ. 2019, 62, 40–47. [Google Scholar] [CrossRef]

| Eg1 (eV) | A1 (eV) | E01 (eV) | B1 (eV) | Eg2 (eV) | A2 (eV) | E02 (eV) | B2 (eV) |

|---|---|---|---|---|---|---|---|

| 3.159 ± 0.004 | 38.0 ± 0.9 | 7.0 ± 0.2 | 14.0 ± 1.2 | 3.624 ± 0.003 | 68.5 ± 0.8 | 4.309 ± 0.005 | 1.755 ± 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karasiński, P.; Zięba, M.; Gondek, E.; Nizioł, J.; Gorantla, S.; Rola, K.; Bachmatiuk, A.; Tyszkiewicz, C. Sol-Gel Derived Silica-Titania Waveguide Films for Applications in Evanescent Wave Sensors—Comprehensive Study. Materials 2022, 15, 7641. https://doi.org/10.3390/ma15217641

Karasiński P, Zięba M, Gondek E, Nizioł J, Gorantla S, Rola K, Bachmatiuk A, Tyszkiewicz C. Sol-Gel Derived Silica-Titania Waveguide Films for Applications in Evanescent Wave Sensors—Comprehensive Study. Materials. 2022; 15(21):7641. https://doi.org/10.3390/ma15217641

Chicago/Turabian StyleKarasiński, Paweł, Magdalena Zięba, Ewa Gondek, Jacek Nizioł, Sandeep Gorantla, Krzysztof Rola, Alicja Bachmatiuk, and Cuma Tyszkiewicz. 2022. "Sol-Gel Derived Silica-Titania Waveguide Films for Applications in Evanescent Wave Sensors—Comprehensive Study" Materials 15, no. 21: 7641. https://doi.org/10.3390/ma15217641

APA StyleKarasiński, P., Zięba, M., Gondek, E., Nizioł, J., Gorantla, S., Rola, K., Bachmatiuk, A., & Tyszkiewicz, C. (2022). Sol-Gel Derived Silica-Titania Waveguide Films for Applications in Evanescent Wave Sensors—Comprehensive Study. Materials, 15(21), 7641. https://doi.org/10.3390/ma15217641