Load Eccentricity of Compressed Composite Z-Columns in Non-Linear State

Abstract

1. Introduction

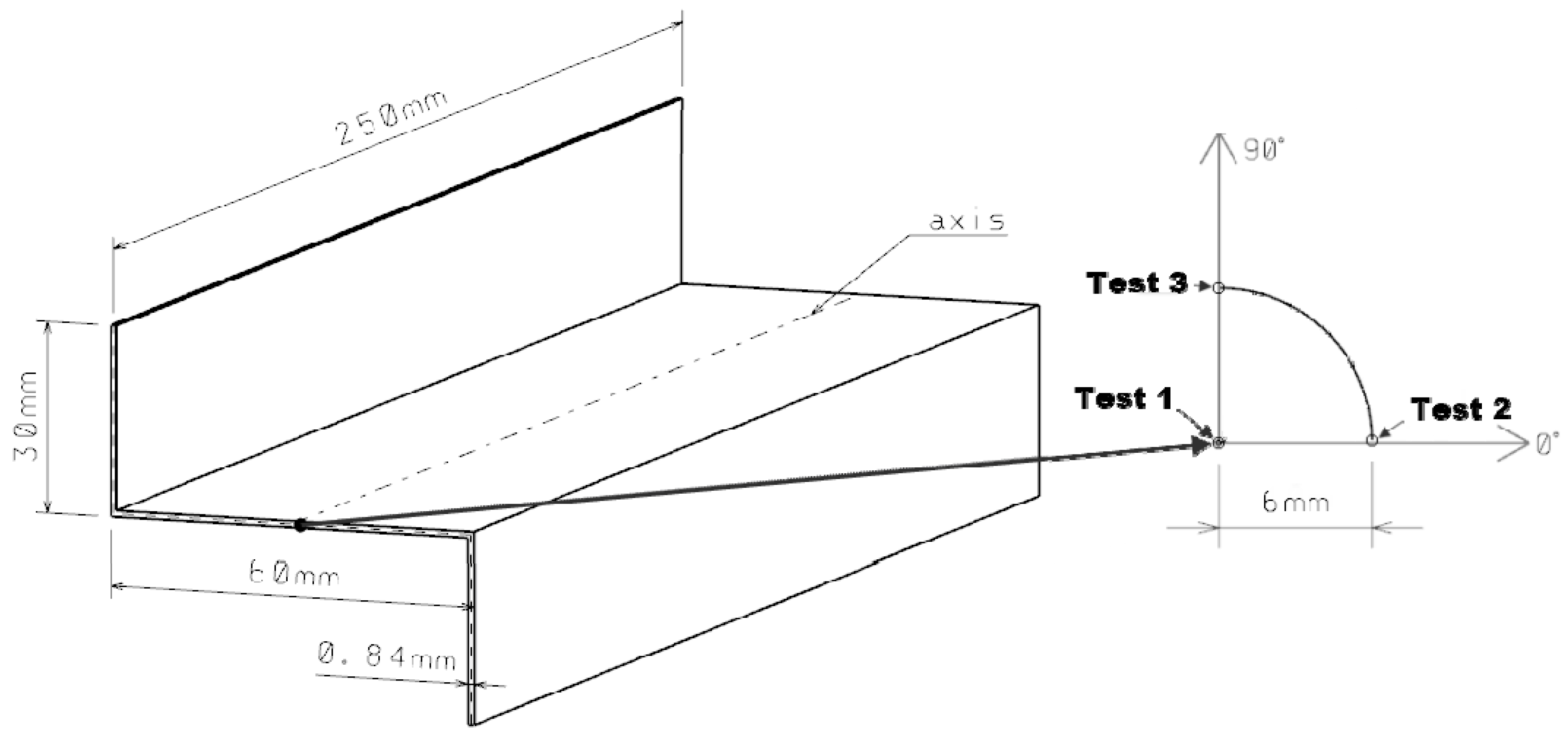

2. The Test Object

3. Methodology

4. Experimental Test

5. Numerical Model

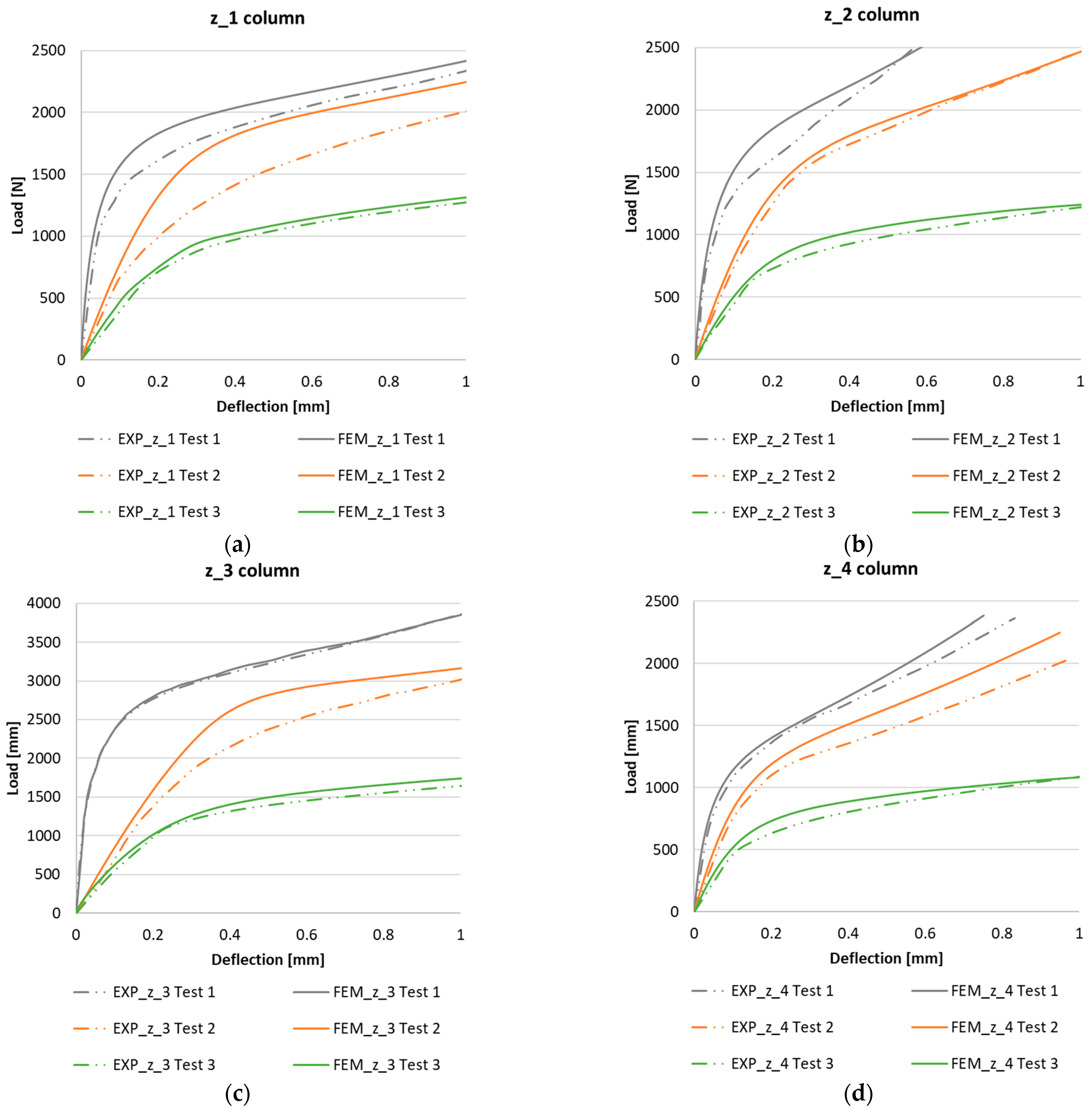

6. Results

7. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Carlsson, L.A.; Adams, D.F.; Pipes, R.B. Experimental Characterization of Advanced Composite Materials, 4th ed.; CRC Press: Boca Raton, FL, USA, 2014; ISBN 978-1-4398-4858-6. [Google Scholar]

- Wu, M.Q.; Zhang, W.; Niu, Y. Experimental and Numerical Studies on Nonlinear Vibrations and Dynamic Snap-through Phenomena of Bistable Asymmetric Composite Laminated Shallow Shell under Center Foundation Excitation. Eur. J. Mech.-A/Solids 2021, 89, 104303. [Google Scholar] [CrossRef]

- Yang, S.; Hao, Y.; Zhang, W.; Yang, L.; Liu, L. Nonlinear Vibration of Functionally Graded Graphene Platelet-Reinforced Composite Truncated Conical Shell Using First-Order Shear Deformation Theory. Appl. Math. Mech.-Engl. Ed. 2021, 42, 981–998. [Google Scholar] [CrossRef]

- Yang, S.W.; Hao, Y.X.; Zhang, W.; Yang, L.; Liu, L.T. Free Vibration and Buckling of Eccentric Rotating FG-GPLRC Cylindrical Shell Using First-Order Shear Deformation Theory. Compos. Struct. 2021, 263, 113728. [Google Scholar] [CrossRef]

- Siriguleng, B.; Zhang, W.; Liu, T.; Liu, Y.Z. Vibration Modal Experiments and Modal Interactions of a Large Space Deployable Antenna with Carbon Fiber Material and Ring-Truss Structure. Eng. Struct. 2020, 207, 109932. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, W.; Zhang, Y.; Wang, Q. Nonlinear Dynamics of Composite Laminated Circular Cylindrical Shell With Membranes in Thermal Environment. In Proceedings of the 14th International Conference on Multibody Systems, Nonlinear Dynamics, and Control, American Society of Mechanical Engineers, Quebec City, QC, Canada, 26 August 2018; Volume 6, p. V006T09A031. [Google Scholar]

- Chen, J.E.; Zhang, W.; Guo, X.Y.; Sun, M. Theoretical and Experimental Studies on Nonlinear Oscillations of Symmetric Cross-Ply Composite Laminated Plates. Nonlinear Dyn. 2013, 73, 1697–1714. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Cedolin, L.; World Scientific (Firm). Stability of Structures: Elastic, Inelastic, Fracture and Damage Theories; World Scientific Pub. Co.: Singapore; Hackensack, NJ, USA, 2010; ISBN 978-981-4317-04-7. [Google Scholar]

- Singer, J.; Arbocz, J.; Weller, T. Buckling Experiments: Experimental Methods in Buckling of Thin-Walled Structures; Wiley: Chichester, UK; New York, NY, USA, 1998; ISBN 978-0-471-95661-7. [Google Scholar]

- Kopecki, T.; Lis, T.; Mazurek, P. Post-Critical Deformation of Thin-Walled Load-Bearing Aircraft Structure Representing Fragment of the One-Way Torsion Box. Adv. Sci. Technol. Res. J. 2018, 12, 203–209. [Google Scholar] [CrossRef]

- Kopecki, T.; Mazurek, P.; Lis, T.; Chodorowska, D. Post-Buckling Deformation States of Semi-Monocoque Cylindrical Structures with Large Cut-Outs under Operating Load Conditions. Numerical Analysis and Experimental Tests. EiN 2016, 18, 16–24. [Google Scholar] [CrossRef]

- Fascetti, A.; Feo, L.; Nisticò, N.; Penna, R. Web-Flange Behavior of Pultruded GFRP I-Beams: A Lattice Model for the Interpretation of Experimental Results. Compos. Part B Eng. 2016, 100, 257–269. [Google Scholar] [CrossRef]

- Feo, L.; Latour, M.; Penna, R.; Rizzano, G. Pilot Study on the Experimental Behavior of GFRP-Steel Slip-Critical Connections. Compos. Part B Eng. 2017, 115, 209–222. [Google Scholar] [CrossRef]

- Berardi, V.P.; Perrella, M.; Feo, L.; Cricrì, G. Creep Behavior of GFRP Laminates and Their Phases: Experimental Investigation and Analytical Modeling. Compos. Part B Eng. 2017, 122, 136–144. [Google Scholar] [CrossRef]

- Rozylo, P.; Wysmulski, P. Failure Analysis of Thin-Walled Composite Profiles Subjected to Axial Compression Using Progressive Failure Analysis (PFA) and Cohesive Zone Model (CZM). Compos. Struct. 2021, 262, 113597. [Google Scholar] [CrossRef]

- Kubiak, T.; Kolakowski, Z.; Swiniarski, J.; Urbaniak, M.; Gliszczynski, A. Local Buckling and Post-Buckling of Composite Channel-Section Beams—Numerical and Experimental Investigations. Compos. Part B Eng. 2016, 91, 176–188. [Google Scholar] [CrossRef]

- Debski, H.; Samborski, S.; Rozylo, P.; Wysmulski, P. Stability and Load-Carrying Capacity of Thin-Walled FRP Composite Z-Profiles under Eccentric Compression. Materials 2020, 13, 2956. [Google Scholar] [CrossRef] [PubMed]

- Madukauwa-David, I.D.; Drissi-Habti, M. Numerical Simulation of the Mechanical Behavior of a Large Smart Composite Platform under Static Loads. Compos. Part B Eng. 2016, 88, 19–25. [Google Scholar] [CrossRef]

- Chróścielewski, J.; Miśkiewicz, M.; Pyrzowski, Ł.; Sobczyk, B.; Wilde, K. A Novel Sandwich Footbridge—Practical Application of Laminated Composites in Bridge Design and in Situ Measurements of Static Response. Compos. Part B Eng. 2017, 126, 153–161. [Google Scholar] [CrossRef]

- Wysmulski, P. The Analysis of Buckling and Post Buckling in the Compressed Composite Columns. Arch. Mater. Sci. Eng. 2017, 85, 35–41. [Google Scholar] [CrossRef]

- Różyło, P. Experimental-Numerical Test of Opensection Composite Columns Stabilitysubjected to Axial Compression. Arch. Mater. Sci. Eng. 2017, 84, 58–64. [Google Scholar] [CrossRef]

- Gliszczynski, A.; Kubiak, T.; Wawer, K. Barely Visible Impact Damages of GFRP Laminate Profiles—An Experimental Study. Compos. Part B Eng. 2019, 158, 10–17. [Google Scholar] [CrossRef]

- Rozylo, P.; Debski, H. Effect of Eccentric Loading on the Stability and Load-Carrying Capacity of Thin-Walled Composite Profiles with Top-Hat Section. Compos. Struct. 2020, 245, 112388. [Google Scholar] [CrossRef]

- Debski, H.; Teter, A. Numerical and Experimental Studies on the Limit State of Fibre-Reinforced Composite Columns with a Lipped Channel Section under Quasi-Static Compression. Compos. Struct. 2015, 133, 1–7. [Google Scholar] [CrossRef]

- Debski, H.; Kubiak, T.; Teter, A. Experimental Investigation of Channel-Section Composite Profiles’ Behavior with Various Sequences of Plies Subjected to Static Compression. Thin-Walled Struct. 2013, 71, 147–154. [Google Scholar] [CrossRef]

- Debski, H.; Rozylo, P.; Wysmulski, P. Stability and Load-Carrying Capacity of Short Open-Section Composite Columns under Eccentric Compression Loading. Compos. Struct. 2020, 252, 112716. [Google Scholar] [CrossRef]

- Rozylo, P.; Falkowicz, K.; Wysmulski, P.; Debski, H.; Pasnik, J.; Kral, J. Experimental-Numerical Failure Analysis of Thin-Walled Composite Columns Using Advanced Damage Models. Materials 2021, 14, 1506. [Google Scholar] [CrossRef]

- Banat, D.; Kolakowski, Z.; Mania, R.J. Investigations of Fml Profile Buckling and Post-Buckling Behaviour under Axial Compression. Thin-Walled Struct. 2016, 107, 335–344. [Google Scholar] [CrossRef]

- Ascione, F. Influence of Initial Geometric Imperfections in the Lateral Buckling Problem of Thin Walled Pultruded GFRP I-Profiles. Compos. Struct. 2014, 112, 85–99. [Google Scholar] [CrossRef]

- Li, Z.-M.; Qiao, P. Buckling and Postbuckling Behavior of Shear Deformable Anisotropic Laminated Beams with Initial Geometric Imperfections Subjected to Axial Compression. Eng. Struct. 2015, 85, 277–292. [Google Scholar] [CrossRef]

- Urbaniak, M.; Teter, A.; Kubiak, T. Influence of Boundary Conditions on the Critical and Failure Load in the GFPR Channel Cross-Section Columns Subjected to Compression. Compos. Struct. 2015, 134, 199–208. [Google Scholar] [CrossRef]

- Debski, H.; Rozylo, P.; Wysmulski, P.; Falkowicz, K.; Ferdynus, M. Experimental Study on the Effect of Eccentric Compressive Load on the Stability and Load-Carrying Capacity of Thin-Walled Composite Profiles. Compos. Part B Eng. 2021, 226, 109346. [Google Scholar] [CrossRef]

- Wysmulski, P.; Debski, H. Post-Buckling and Limit States of Composite Channel-Section Profiles under Eccentric Compression. Compos. Struct. 2020, 245, 112356. [Google Scholar] [CrossRef]

- Paszkiewicz, M.; Kubiak, T. Selected Problems Concerning Determination of the Buckling Load of Channel Section Beams and Columns. Thin-Walled Struct. 2015, 93, 112–121. [Google Scholar] [CrossRef]

- Falkowicz, K.; Ferdynus, M.; Rozylo, P. Experimental and Numerical Analysis of Stability and Failure of Compressed Composite Plates. Compos. Struct. 2021, 263, 113657. [Google Scholar] [CrossRef]

- Rzeczkowski, J.; Samborski, S.; Paśnik, J. Experimental Verification of the DCB Test Configuration Applicability to Mechanically Coupled Composite Laminates. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012055. [Google Scholar] [CrossRef]

- Wysmulski, P.; Debski, H. The Analysis of Sensitivity to Eccentric Load of Compressed Thin-Walled Laminate Columns. In AIP Conference Proceedings; AIP Publishing LLC: Depok, Indonesia, 2019; p. 020006. [Google Scholar]

- Wysmulski, P.; Teter, A.; Debski, H. Effect of Load Eccentricity on the Buckling of Thin-Walled Laminated C-Columns. In AIP Conference Proceedings; AIP Publishing LLC: Lublin, Poland, 2018; p. 080008. [Google Scholar]

- Samborski, S.; Gliszczynski, A.; Rzeczkowski, J.; Wiacek, N. Mode I Interlaminar Fracture of Glass/Epoxy Unidirectional Laminates. Part I: Experimental Studies. Materials 2019, 12, 1607. [Google Scholar] [CrossRef] [PubMed]

- Rogala, M.; Gajewski, J.; Ferdynus, M. The Effect of Geometrical Non-Linearity on the Crashworthiness of Thin-Walled Conical Energy-Absorbers. Materials 2020, 13, 4857. [Google Scholar] [CrossRef] [PubMed]

- Gliszczynski, A.; Samborski, S.; Wiacek, N.; Rzeczkowski, J. Mode I Interlaminar Fracture of Glass/Epoxy Unidirectional Laminates. Part II: Numerical Analysis. Materials 2019, 12, 1604. [Google Scholar] [CrossRef]

- Rzeczkowski, J.; Paśnik, J.; Samborski, S. Mode III Numerical Analysis of Composite Laminates with Elastic Couplings in Split Cantilever Beam Configuration. Compos. Struct. 2021, 265, 113751. [Google Scholar] [CrossRef]

- Rogala, M.; Gajewski, J.; Gawdzińska, K. Crashworthiness Analysis of Thin-Walled Aluminum Columns Filled with Aluminum–Silicon Carbide Composite Foam. Compos. Struct. 2022, 299, 116102. [Google Scholar] [CrossRef]

- Samborski, S.; Rzeczkowski, J. Numerical Modeling and Experimental Testing of the DCB Laminated Composite Beams with Mechanical Couplings. In AIP Conference Proceedings; AIP Publishing LLC: Lublin, Poland, 2018; p. 080010. [Google Scholar]

- Rogala, M.; Gajewski, J. Numerical Analysis of Porous Materials Subjected to Oblique Crushing Force. J. Phys. Conf. Ser. 2021, 1736, 012025. [Google Scholar] [CrossRef]

- Zhou, Y.; Fei, Q. Evaluating Deformation Modes of Sandwich Serpentine Structures for High Stretchability. Thin-Walled Struct. 2020, 157, 107087. [Google Scholar] [CrossRef]

- Urbanowicz, K.; Bergant, A.; Grzejda, R.; Stosiak, M. About Inverse Laplace Transform of a Dynamic Viscosity Function. Materials 2022, 15, 4364. [Google Scholar] [CrossRef]

- Grzejda, R.; Warzecha, M.; Urbanowicz, K. Determination of the Preload of Bolts for Structural Health Monitoring of a Multi-Bolted Joint: FEM Approach. Lubricants 2022, 10, 75. [Google Scholar] [CrossRef]

- Jonak, J.; Karpiński, R.; Wójcik, A.; Siegmund, M.; Kalita, M. Determining the Effect of Rock Strength Parameters on the Breakout Area Utilizing the New Design of the Undercut/Breakout Anchor. Materials 2022, 15, 851. [Google Scholar] [CrossRef] [PubMed]

- Nozdrzykowski, K.; Grządziel, Z.; Grzejda, R.; Warzecha, M.; Stępień, M. An Analysis of Reaction Forces in Crankshaft Support Systems. Lubricants 2022, 10, 151. [Google Scholar] [CrossRef]

- Grzejda, R. Thermal Strength Analysis of a Steel Bolted Connection under Bolt Loss Conditions. EiN 2022, 24, 269–274. [Google Scholar] [CrossRef]

- Jonak, J.; Karpiński, R.; Wójcik, A. Influence of the Undercut Anchor Head Angle on the Propagation of the Failure Zone of the Rock Medium. Materials 2021, 14, 2371. [Google Scholar] [CrossRef]

- Jonak, J.; Karpiński, R.; Wójcik, A. Numerical Analysis of Undercut Anchor Effect on Rock. J. Phys. Conf. Ser. 2021, 2130, 012011. [Google Scholar] [CrossRef]

- Jonak, J.; Karpiński, R.; Wójcik, A. Numerical Analysis of the Effect of Embedment Depth on the Geometry of the Cone Failure. J. Phys. Conf. Ser. 2021, 2130, 012012. [Google Scholar] [CrossRef]

- Jaszak, P.; Skrzypacz, J.; Borawski, A.; Grzejda, R. Methodology of Leakage Prediction in Gasketed Flange Joints at Pipeline Deformations. Materials 2022, 15, 4354. [Google Scholar] [CrossRef]

- Falkowicz, K.; Debski, H. Stability Analysis of Thin-Walled Composite Plate in Unsymmetrical Configuration Subjected to Axial Load. Thin-Walled Struct. 2021, 158, 107203. [Google Scholar] [CrossRef]

- Wysmulski, P.; Falkowicz, K.; Filipek, P. Buckling State Analysis of Compressed Composite Plates with Cut-Out. Compos. Struct. 2021, 274, 114345. [Google Scholar] [CrossRef]

- Falkowicz, K.; Debski, H. The Work of a Compressed, Composite Plate in Asymmetrical Arrangement of Layers. In AIP Conference Proceedings; AIP Publishing LLC: Depok, Indonesia, 2019; p. 020005. [Google Scholar]

- Falkowicz, K. Composite Plate Analysis Made in an Unsymmetric Configuartion. J. Phys. Conf. Ser. 2021, 2130, 012014. [Google Scholar] [CrossRef]

- Falkowicz, K. Buckling Numerical Analysis of Composite Plate Element in Asymmetrical Configuration. J. Phys. Conf. Ser. 2021, 1736, 012029. [Google Scholar] [CrossRef]

- Wysmulski, P.; Debski, H. Stability Analysis of Composite Columns under Eccentric Load. Appl. Compos. Mater. 2019, 26, 683–692. [Google Scholar] [CrossRef]

- Wysmulski, P. The Effect of Load Eccentricity on the Compressed CFRP Z-Shaped Columns in the Weak Post-Critical State. Compos. Struct. 2022, 301, 116184. [Google Scholar] [CrossRef]

- Gawryluk, J.; Teter, A. Experimental-Numerical Studies on the First-Ply Failure Analysis of Real, Thin Walled Laminated Angle Columns Subjected to Uniform Shortening. Compos. Struct. 2021, 269, 114046. [Google Scholar] [CrossRef]

- Tsai, S.W.; Wu, E.M. A General Theory of Strength for Anisotropic Materials. J. Compos. Mater. 1971, 5, 58–80. [Google Scholar] [CrossRef]

- Wysmulski, P.; Debski, H.; Falkowicz, K. Sensitivity of Compressed Composite Channel Columns to Eccentric Loading. Materials 2022, 15, 6938. [Google Scholar] [CrossRef]

- Falkowicz, K. Numerical Investigations of Perforated CFRP Z-Cross-Section Profiles, under Axial Compression. Materials 2022, 15, 6874. [Google Scholar] [CrossRef]

- Motamedi, D.; Mohammadi, S. Fracture Analysis of Composites by Time Independent Moving-Crack Orthotropic XFEM. Int. J. Mech. Sci. 2012, 54, 20–37. [Google Scholar] [CrossRef]

- Duarte, A.P.C.; Díaz Sáez, A.; Silvestre, N. Comparative Study between XFEM and Hashin Damage Criterion Applied to Failure of Composites. Thin-Walled Struct. 2017, 115, 277–288. [Google Scholar] [CrossRef]

- Nagashima, T.; Suemasu, H. X-FEM Analyses of a Thin-Walled Composite Shell Structure with a Delamination. Comput. Struct. 2010, 88, 549–557. [Google Scholar] [CrossRef]

- Feerick, E.M.; Liu, X.; McGarry, P. Anisotropic Mode-Dependent Damage of Cortical Bone Using the Extended Finite Element Method (XFEM). J. Mech. Behav. Biomed. Mater. 2013, 20, 77–89. [Google Scholar] [CrossRef] [PubMed]

- Jonak, J.; Karpiński, R.; Wójcik, A. Influence of the Undercut Anchor Head Angle on the Propagation of the Failure Zone of the Rock Medium—Part II. Materials 2021, 14, 3880. [Google Scholar] [CrossRef]

- Jonak, J.; Karpiński, R.; Wójcik, A.; Siegmund, M. The Influence of the Physical-Mechanical Parameters of Rock on the Extent of the Initial Failure Zone under the Action of an Undercut Anchor. Materials 2021, 14, 1841. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Kazemi, M.T.; Hasegawa, T.; Mazars, J. Size Effect in Brazilian Split-Cylinder Tests: Measurements and Fracture Analysis. ACI Mater. J. 1991, 88, 325–332. [Google Scholar] [CrossRef]

- Jonak, J.; Karpinski, R.; Wojcik, A.; Siegmund, M. The Effect of Undercut Anchor Diameter on the Rock Failure Cone Area in Pullout Tests. Adv. Sci. Technol. Res. J. 2022, 16, 261–270. [Google Scholar] [CrossRef]

- Jonak, J.; Karpiński, R.; Siegmund, M.; Wójcik, A.; Jonak, K. Analysis of the Rock Failure Cone Size Relative to the Group Effect from a Triangular Anchorage System. Materials 2020, 13, 4657. [Google Scholar] [CrossRef]

- Szklarek, K.; Kotełko, M.; Ferdynus, M. Crashworthiness Performance of Thin-Walled Hollow and Foam-Filled Prismatic Frusta—FEM Parametric Studies—Part 1. Thin-Walled Struct. 2022, 181, 110046. [Google Scholar] [CrossRef]

- Ferdynus, M.; Szklarek, K.; Kotełko, M. Crashworthiness Performance of Thin-Walled Hollow and Foam-Filled Prismatic Frusta, Part 2: Experimental Study. Thin-Walled Struct. 2022, 181, 110070. [Google Scholar] [CrossRef]

- Liu, P.F.; Gu, Z.P.; Peng, X.Q.; Zheng, J.Y. Finite Element Analysis of the Influence of Cohesive Law Parameters on the Multiple Delamination Behaviors of Composites under Compression. Compos. Struct. 2015, 131, 975–986. [Google Scholar] [CrossRef]

- Wysmulski, P.; Debski, H.; Falkowicz, K. Stability Analysis of Laminate Profiles under Eccentric Load. Compos. Struct. 2020, 238, 111944. [Google Scholar] [CrossRef]

- Banat, D.; Mania, R.J. Failure Assessment of Thin-Walled FML Profiles during Buckling and Postbuckling Response. Compos. Part B Eng. 2017, 112, 278–289. [Google Scholar] [CrossRef]

- Sohn, M.S.; Hu, X.Z.; Kim, J.K.; Walker, L. Impact Damage Characterisation of Carbon Fibre/Epoxy Composites with Multi-Layer Reinforcement. Compos. Part B Eng. 2000, 31, 681–691. [Google Scholar] [CrossRef]

- Rozylo, P.; Falkowicz, K. Stability and Failure Analysis of Compressed Thin-Walled Composite Structures with Central Cut-out, Using Three Advanced Independent Damage Models. Compos. Struct. 2021, 273, 114298. [Google Scholar] [CrossRef]

- Rozylo, P. Comparison of Failure for Thin-Walled Composite Columns. Materials 2021, 15, 167. [Google Scholar] [CrossRef]

- Batra, R.C.; Gopinath, G.; Zheng, J.Q. Damage and Failure in Low Energy Impact of Fiber-Reinforced Polymeric Composite Laminates. Compos. Struct. 2012, 94, 540–547. [Google Scholar] [CrossRef]

- Rozylo, P.; Debski, H. Failure Study of Compressed Thin-Walled Composite Columns with Top-Hat Cross-Section. Thin-Walled Struct. 2022, 180, 109869. [Google Scholar] [CrossRef]

- Hu, H.; Niu, F.; Dou, T.; Zhang, H. Rehabilitation Effect Evaluation of CFRP-Lined Prestressed Concrete Cylinder Pipe under Combined Loads Using Numerical Simulation. Math. Probl. Eng. 2018, 2018, 3268962. [Google Scholar] [CrossRef]

- Barbero, E.J.; Cosso, F.A. Determination of Material Parameters for Discrete Damage Mechanics Analysis of Carbon-Epoxy Laminates. Compos. Part B Eng. 2014, 56, 638–646. [Google Scholar] [CrossRef]

- Li, W.; Cai, H.; Li, C.; Wang, K.; Fang, L. Progressive Failure of Laminated Composites with a Hole under Compressive Loading Based on Micro-Mechanics. Adv. Compos. Mater. 2014, 23, 477–490. [Google Scholar] [CrossRef]

| Specimen | Configuration |

|---|---|

| z_1 | [0/-45/45/90]s |

| z_2 | [90/-45/45/0/]s |

| z_3 | [45/-45/90/0/]s |

| z_4 | [90/0/90/0]s |

| E1 (0°) | E2 (90°) | G1,2 | ν12 | FT1 (0°) | FT2 (90°) | Fs (45°) | FC1 (0°) | FC2 (90°) |

|---|---|---|---|---|---|---|---|---|

| GPa | MPa | MPa | - | MPa | MPa | MPa | MPa | MPa |

| 143 | 5826 | 3846 | 0.36 | 2221 | 49 | 84 | 641 | 114 |

| Difference | Column—z_1 | Column—z_2 | Column—z_3 | Column—z_4 | ||||

|---|---|---|---|---|---|---|---|---|

| EXP | FEM | EXP | FEM | EXP | FEM | EXP | FEM | |

| Test 1 to Test 02 | 12% | 8% | 22% | 19% | 21% | 18% | 20% | 19% |

| Test 1 to Test 3 | 46% | 43% | 64% | 61% | 58% | 55% | 53% | 52% |

| Test 1 | Test 3 | ||

|---|---|---|---|

| z_1 | EXP | 7374 N | 1497 N |

| FEM | 7496 N (7) | 1504 N (2) | |

| difference | 1.60% | 0.50% | |

| z_2 | EXP | 7992 N | 1349 N |

| FEM | 8229 N (2) | 1466 N (1) | |

| difference | 2.90% | 8% | |

| z_3 | EXP | 7417 N | 1762 N |

| FEM | 7802 N (8) | 1875 N (7) | |

| difference | 4.90% | 6% | |

| z_4 | EXP | 9141 N | 1349 N |

| FEM | 9301 N (2) | 1381 N (7) | |

| difference | 1.70% | 2.30% | |

| Difference | Sample—z_1 | Sample—z_2 | Sample—z_3 | Sample—z_4 | ||||

|---|---|---|---|---|---|---|---|---|

| EXP | FEM | EXP | FEM | EXP | FEM | EXP | FEM | |

| Test 1 to Test 3 | 79.7% | 79.9% | 83.1% | 82.2% | 76.2% | 76% | 85.2% | 85% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wysmulski, P. Load Eccentricity of Compressed Composite Z-Columns in Non-Linear State. Materials 2022, 15, 7631. https://doi.org/10.3390/ma15217631

Wysmulski P. Load Eccentricity of Compressed Composite Z-Columns in Non-Linear State. Materials. 2022; 15(21):7631. https://doi.org/10.3390/ma15217631

Chicago/Turabian StyleWysmulski, Pawel. 2022. "Load Eccentricity of Compressed Composite Z-Columns in Non-Linear State" Materials 15, no. 21: 7631. https://doi.org/10.3390/ma15217631

APA StyleWysmulski, P. (2022). Load Eccentricity of Compressed Composite Z-Columns in Non-Linear State. Materials, 15(21), 7631. https://doi.org/10.3390/ma15217631