Mechanical Behavior and Constitutive Modeling of the Mg-Zn-Y Alloy in an Electrically Assisted Tensile Test

Abstract

:1. Introduction

2. Experimental Materials and Procedures

2.1. Experimental Materials

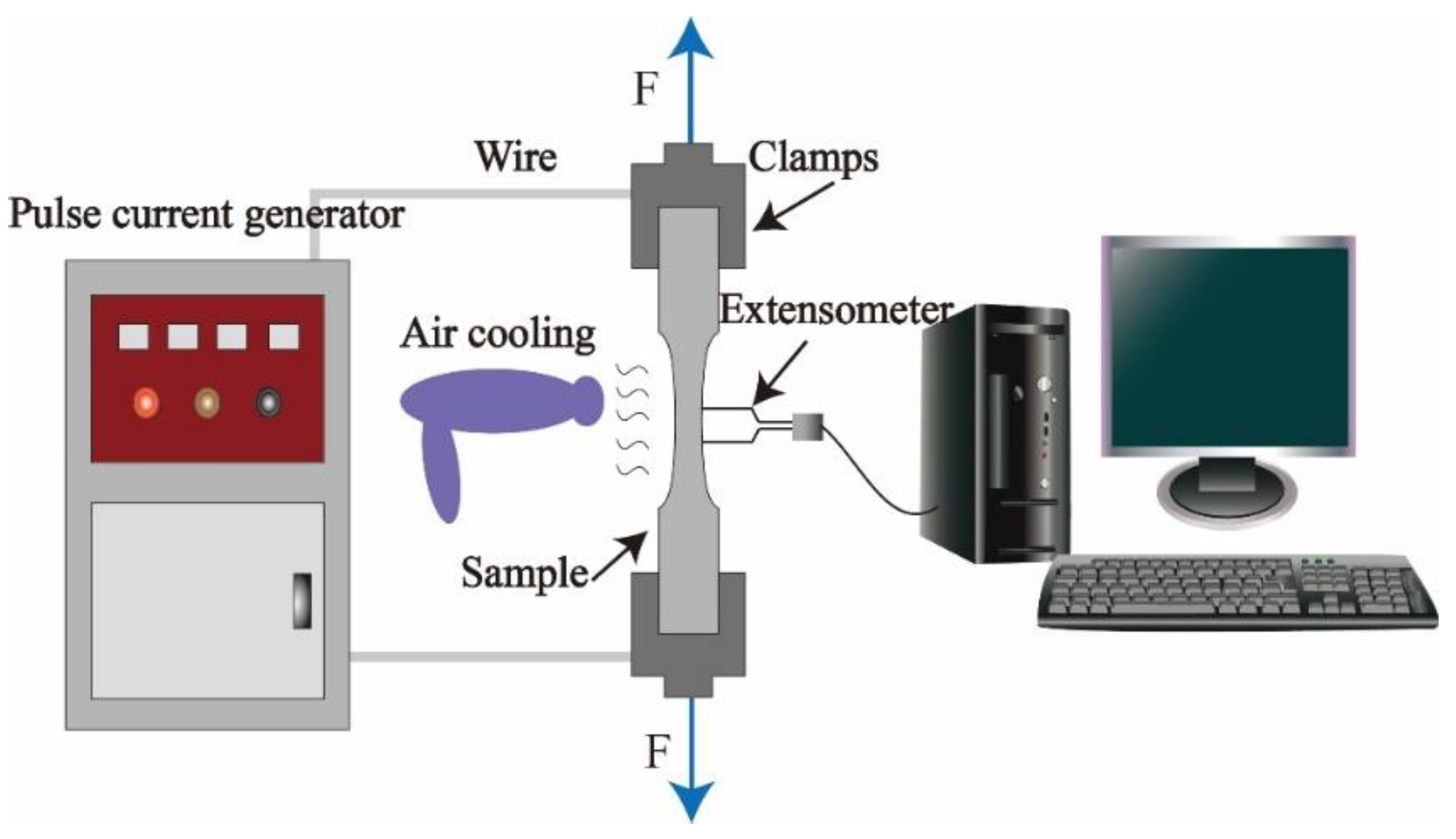

2.2. Experimental Procedures

3. Results and Discussion

3.1. Flow Stress Behavior

3.2. Microstructure of Samples after the Tensile Test

3.3. Establishment of Constitutive Equation

3.4. Finite Element Model and Simulation Results

4. Conclusions

- (1)

- The results obtained from the tensile tests at elevated temperatures show that the deformation temperature and strain rate are sensitive factors affecting the flow behavior of the Mg98.5Zn0.5Y1 alloy. Under the condition of high strain rate, the generation and propagation of dislocations are accelerated and the flow stress increases accordingly. When the deformation temperature increases, more slip systems will be activated. Hence, the flow stress inevitably decreases with the increasing temperature.

- (2)

- The peak stress of the material decreases with the increase in current density. Compared with the current density, the effects of duty ratio and pulse frequency on the mechanical properties of the Mg98.5Zn0.5Y1 alloy can be almost ignored. When the current is applied, more recrystallized grains appear in the alloy and the basal texture is weakened.

- (3)

- The constitutive equation of the Mg98.5Zn0.5Y1 alloy coupling with flow stress, temperature, and pulse current parameters was established. It can be obtained as follows:

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.H.; Liu, S.J.; Wu, R.Z.; Hou, L.G.; Zhang, M.L. Recent developments in high-strength Mg-RE-based alloys: Focusing on Mg-Gd and Mg-Y systems. J. Magnes. Alloys 2018, 6, 277–291. [Google Scholar] [CrossRef]

- Drozdenko, D.; Yamasaki, M.; Máthis, K.; Dobroň, P.; Lukáč, P.; Kizu, N.; Inoue, S.; Kawamura, Y. Optimization of mechanical properties of dilute Mg-Zn-Y alloys prepared by rapid solidification. J. Mater. Des. 2019, 181, 107984. [Google Scholar] [CrossRef]

- Shao, X.H.; Yang, Z.Q.; Ma, X.L. Strengthening and toughening mechanisms in Mg-Zn-Y alloy with a long period stacking ordered structure. J. Acta Mater. 2010, 58, 4760–4771. [Google Scholar] [CrossRef]

- Xu, Z.C.; Zhu, C.; Guo, X.F.; Yang, W.P.; Cui, H.B.; Wang, Y. Effect of multi-pass equal channel angular pressing on the microstructure and mechanical properties of a directional solidification Mg98.5Zn0.5Y1 Alloy. J. Mater. Trans. 2019, 60, 2361–2367. [Google Scholar] [CrossRef]

- Okayasu, M.; Takeuchi, S.; Matsushita, M.; Tada, N.; Yamasaki, M.; Kawamura, Y. Mechanical properties and failure characteristics of cast and extruded Mg97Y2Zn1 alloys with LPSO phase. J. Mater. Sci. Eng. 2016, 652, 14–29. [Google Scholar] [CrossRef]

- Abazari, S.; Shamsipur, A.; Bakhsheshi-Rad, H.R.; Ismail, A.F.; Sharif, S.; Razzaghi, M.; Ramakrishna, S.; Berto, F. Carbon nanotubes (CNTs)-reinforced magnesium-based matrix composites: A comprehensive review. Materials 2020, 13, 4421. [Google Scholar] [CrossRef]

- Abazari, S.; Shamsipur, A.; Bakhsheshi-Rad, H.R.; Ramakrishna, S.; Berto, F. Graphene family nanomaterial reinforced magnesium-based matrix composites for biomedical application: A comprehensive review. Metals 2020, 10, 1002. [Google Scholar] [CrossRef]

- Khorashadizade, F.; Abazari, S.; Rajabi, M.; Bakhsheshi-Rad, H.; Ismail, A.F.; Sharif, S.; Ramakrishna, S.; Berto, F. Overview of magnesium-ceramic composites: Mechanical, corrosion and biological properties. J. Mater. Res. Technol. 2021, 15, 6034–6066. [Google Scholar] [CrossRef]

- Badkoobeh, F.; Mostaan, H.; Rafiei, M.; Bakhsheshi-Rad, H.R.; Berto, F. Friction Stir Welding/Processing of Mg-Based Alloys: A Critical Review on Advancements and Challenges. Materials 2021, 14, 6726. [Google Scholar] [CrossRef]

- Wang, K.; Wang, J.F.; Peng, X.; Gao, S.Q.; Hu, H.; Zeng, L.J.; Pan, F.S. Microstructure and mechanical properties of Mg-Gd-Y-Zn-Mn alloy sheets processed by large-strain high-efficiency rolling. J. Mater. Sci. Eng. 2019, 748, 100–107. [Google Scholar] [CrossRef]

- Conrad, H.; Sprecher, A.F.; Cao, W.D.; Lu, X.P. Electroplasticity—The effect of electricity on the mechanical properties of metals. J. JOM 1990, 42, 28–33. [Google Scholar] [CrossRef]

- Liu, K.; Dong, X.; Xie, H.; Peng, F. Effect of pulsed current on the deformation behavior of AZ31B magnesium alloy. Mater. Sci. Eng. A 2015, 623, 97–103. [Google Scholar] [CrossRef]

- Xu, Z.T.; Jiang, T.H.; Huang, J.H.; Peng, L.F.; Lai, X.M.; Fu, M.W. Electroplasticity in electrically-assisted forming: Process phenomena, performances and modelling. J. Int. J. Mach. Tools Manuf. 2022, 175, 103871. [Google Scholar] [CrossRef]

- Liu, X.; Lan, S.; Ni, J. Experimental study of Electro-Plastic Effect on Advanced High Strength Steels. Mater. Sci. Eng. A 2013, 582, 211–218. [Google Scholar] [CrossRef]

- Salandro, W.A.; Jones, J.J.; McNeal, T.A.; Roth, J.T.; Hong, S.-T.; Smith, M.T. Formability of Al 5xxx Sheet Metals Using Pulsed Current for Various Heat Treatments. J. Manuf. Sci. Eng. 2010, 132, 051016. [Google Scholar] [CrossRef]

- Ross, C.D.; Irvin, D.B.; Roth, J.T. Manufacturing Aspects Relating to the Effects of Direct Current on the Tensile Properties of Metals. J. Eng. Mater. Technol. 2007, 129, 342–347. [Google Scholar] [CrossRef]

- Xu, X.L.; Zheng, G.G.; Wang, H.D.; Wang, T. Research progress on the application of electro-plastic effect in materials processing. J. Plast Eng. 2017, 24, 1–7. [Google Scholar]

- Kim, M.J.; Jeong, H.J.; Park, J.W.; Hong, S.T.; Han, H.N. Modified Johnson-Cook model incorporated with electroplasticity for uniaxial tension under a pulsed electric current. J. Met. Mater. Int. 2018, 24, 42–50. [Google Scholar] [CrossRef]

- Roh, J.-H.; Seo, J.-J.; Hong, S.-T.; Kim, M.-J.; Han, H.N.; Roth, J.T. The mechanical behavior of 5052-H32 aluminum alloys under a pulsed electric current. Int. J. Plast. 2014, 58, 84–99. [Google Scholar] [CrossRef]

- Li, H.-W.; Yan, S.-L.; Zhan, M.; Zhang, X. Eddy current induced dynamic deformation behaviors of aluminum alloy during EMF: Modeling and quantitative characterization. J. Mater. Process. Technol. 2018, 263, 423–439. [Google Scholar] [CrossRef]

- Yang, X.; Zhou, X.; Yu, S.; Zhang, J.; Lu, X.; Chen, X.; Lu, L.; Huang, W.; Liu, Y. Tensile behavior at various temperatures of the Mg-Gd-Y-Zn-Zr alloys with different initial morphologies of LPSO phases prior to extrusion. Mater. Sci. Eng. A 2022, 851, 143634. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, C.; Zhang, X.; Dai, H.; Jia, J.; Bai, Z. Dynamic recrystallization kinetics and microstructure evolution of an AZ91D magnesium alloy during hot compression. Mater. Charact. 2018, 145, 39–52. [Google Scholar] [CrossRef]

- Kou, Y.; Wang, J.; Fu, Q.; Mei, D.; Sun, Y.; Wang, J.; Wang, L.; Zhu, S.; Guan, S. Simulation of dynamic recrystallization behavior of hot extruded Mg-Zn-Y-Nd alloy tubes by the finite element method. Mater. Today Commun. 2021, 27, 102384. [Google Scholar] [CrossRef]

- Chen, T.; Chen, Z.; Shao, J.; Wang, R.; Mao, L.; Liu, C. The role of long period stacking ordered phase in dynamic recrystallization of a Mg–Zn–Y alloy during hot compression. J. Alloys Compd. 2019, 818, 152814. [Google Scholar] [CrossRef]

- Wu, H.; Xu, W.C.; Wang, S.B.; Yang, Z.Z.; Chen, Y.; Teng, B.G.; Shan, D.B.; Guo, B. A cellular automaton coupled FEA model for hot deformation behavior of AZ61 magnesium alloys. J. Alloys Compd. 2020, 816, 152562. [Google Scholar] [CrossRef]

- Tang, W.R.; Liu, S.M.; Liu, Z.; Kang, S.; Mao, P.L.; Guo, H. High strain rate compression deformation mechanism and constitutive equation of fine grained Mg–7Gd–5Y–1.2Nd–0.5Zr alloy at different temperatures. J. Mater. Sci. Eng. A 2020, 780, 139208. [Google Scholar] [CrossRef]

- Sellars, C.; McTegart, W. On the mechanism of hot deformation. Acta Met. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Xu, R. The thermal stability and activation energy of the nanocrystalline Mg-Zn-Y alloy obtained by high pressure torsion. Mater. Lett. 2020, 268, 127607. [Google Scholar] [CrossRef]

- Papillon, J.; Salero, P.; Mercier, F.; Fabrègue, D.; Maire, É. Compressive deformation behavior of dendritic Mg–Ca(–Zn) alloys at high temperature. Mater. Sci. Eng. A 2019, 763, 138180. [Google Scholar] [CrossRef]

- Zhi, C.; Ma, L.; Jia, W.; Huo, X.; Fan, Q.; Huang, Z.; Le, Q.; Lin, J. Dependence of deformation behaviors on temperature for twin-roll casted AZ31 alloy by processing maps. J. Mater. Res. Technol. 2019, 8, 5217–5232. [Google Scholar] [CrossRef]

- Kwak, T.Y.; Lim, H.K.; Kim, W.J. Hot compression behavior of the ignition-resistant Mg-5Y-2.5Zn-1.2Ca alloy with long-period stacking ordered structures. J. Alloys Compd. 2015, 632, 417–428. [Google Scholar] [CrossRef]

- Lv, B.J.; Peng, J.; Zhu, L.L.; Wang, Y.J.; Tang, A.T. The effect of 14H LPSO phase on dynamic recrystallization behavior and hot workability of Mg–2.0Zn–0.3Zr–5.8Y alloy. J. Mater. Sci. Eng. A 2014, 599, 150–159. [Google Scholar] [CrossRef]

- Somekawa, H.; Nakasuji, Y.; Yuasa, M.; Miyamoto, H.; Yamasaki, M.; Kawamura, Y. Hot compression deformation behavior of Mg–Y–Zn alloys containing LPSO phase. J. Mater. Sci. Eng. A 2020, 792, 139777. [Google Scholar] [CrossRef]

- Li, L.; Wang, Y.; Li, H.; Jiang, W.; Wang, T.; Zhang, C.C.; Wang, F.; Garmestani, H. Effect of the Zener-Hollomon parameter on the dynamic recrystallization kinetics of Mg–Zn–Zr–Yb magnesium alloy. J. Comput. Mater. Sci. 2019, 166, 221–229. [Google Scholar] [CrossRef]

- Molotskii, M.; Fleurov, V. Magnetic effects in electroplasticity of metals. J. Phys. Rev. B 1995, 52, 15829. [Google Scholar] [CrossRef]

- Abaqus, V. 6.14 Documentation; Dassault Systemes Simulia Corporation: Providence, RI, USA, 2014; Volume 651, p. 6.2. [Google Scholar]

- Hu, L.; Lang, M.W.; Shi, L.X.; Li, M.G.; Zhou, T.; Bao, C.L.; Yang, M.B. Study on hot deformation behavior of homogenized Mg-8.5Gd-4.5Y-0.8Zn-0.4Zr alloy using a combination of strain-compensated Arrhenius constitutive model and finite element simulation method. J. Magnes. Alloy 2021. [Google Scholar] [CrossRef]

| Nominal Alloy | Actual Composition (at. %) | |||

|---|---|---|---|---|

| Mg | Zn | Y | Y/Zn | |

| Mg98.5Zn0.5Y1 | 98.5 | 0.5 | 1 | 2 |

| Category | Temperature T/°C | Strain Rate/s−1 | Duty Ratio d/% | Current Density j/A∙mm−2 | Pulse Frequency f/Hz |

|---|---|---|---|---|---|

| Thermally assisted test | 200, 250 300, 350 | 0.001 | —— | —— | —— |

| 200, 250 300, 350 | 0.01 | —— | —— | —— | |

| 200, 250 300, 350 | 0.1 | —— | —— | —— | |

| 200, 250 300, 350 | 1 | —— | —— | —— | |

| Electrically assisted test | 250 | 0.1 | 22.6 | 44.25 | 30.7 |

| 250 | 0.1 | 32.9 | 44.21 | 30.7 | |

| 250 | 0.1 | 43.5 | 44.35 | 30.7 | |

| 250 | 0.1 | 22.6 | 44.25 | 30.7 | |

| 250 | 0.1 | 22.6 | 44.31 | 58 | |

| 250 | 0.1 | 22.6 | 44.29 | 79.6 | |

| 200 | 0.1 | 22.6 | 26.58 | 30.7 | |

| 250 | 0.1 | 22.6 | 44.25 | 30.7 | |

| 300 | 0.1 | 22.6 | 56.74 | 30.7 | |

| 350 | 0.1 | 22.6 | 68.95 | 30.7 |

| Temperature/K | 473 | 523 | 573 | 623 |

|---|---|---|---|---|

| 145,782.6 | 112,759.4 | 63,741.62 | 50,132.58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Yang, W.; Fan, J.; Wu, T.; Gao, Z. Mechanical Behavior and Constitutive Modeling of the Mg-Zn-Y Alloy in an Electrically Assisted Tensile Test. Materials 2022, 15, 7203. https://doi.org/10.3390/ma15207203

Xu Z, Yang W, Fan J, Wu T, Gao Z. Mechanical Behavior and Constitutive Modeling of the Mg-Zn-Y Alloy in an Electrically Assisted Tensile Test. Materials. 2022; 15(20):7203. https://doi.org/10.3390/ma15207203

Chicago/Turabian StyleXu, Zhichao, Wenju Yang, Jianfeng Fan, Tao Wu, and Zeng Gao. 2022. "Mechanical Behavior and Constitutive Modeling of the Mg-Zn-Y Alloy in an Electrically Assisted Tensile Test" Materials 15, no. 20: 7203. https://doi.org/10.3390/ma15207203

APA StyleXu, Z., Yang, W., Fan, J., Wu, T., & Gao, Z. (2022). Mechanical Behavior and Constitutive Modeling of the Mg-Zn-Y Alloy in an Electrically Assisted Tensile Test. Materials, 15(20), 7203. https://doi.org/10.3390/ma15207203