Microstructural Features, Defects, and Corrosion Behaviour of 316L Stainless Steel Clads Deposited on Wrought Material by Powder- and Laser-Based Direct Energy Deposition with Relevance to Repair Applications

Abstract

1. Introduction

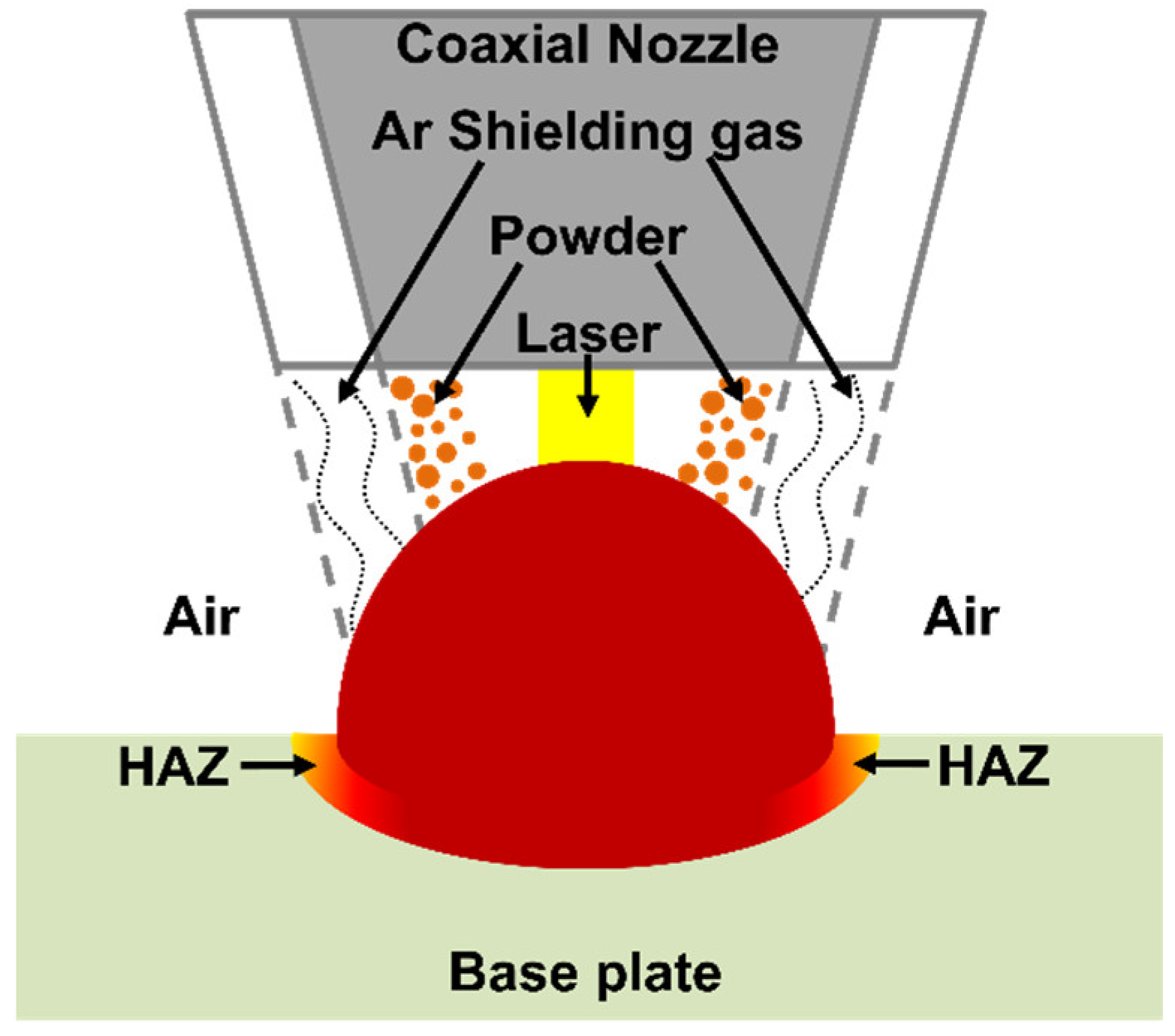

2. Experimental Section

3. Results and Discussion

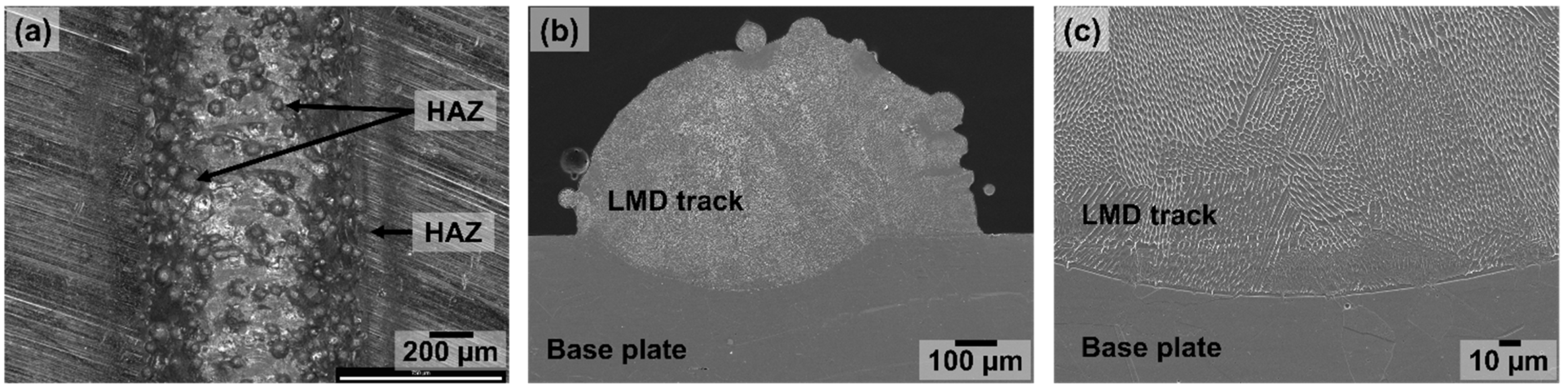

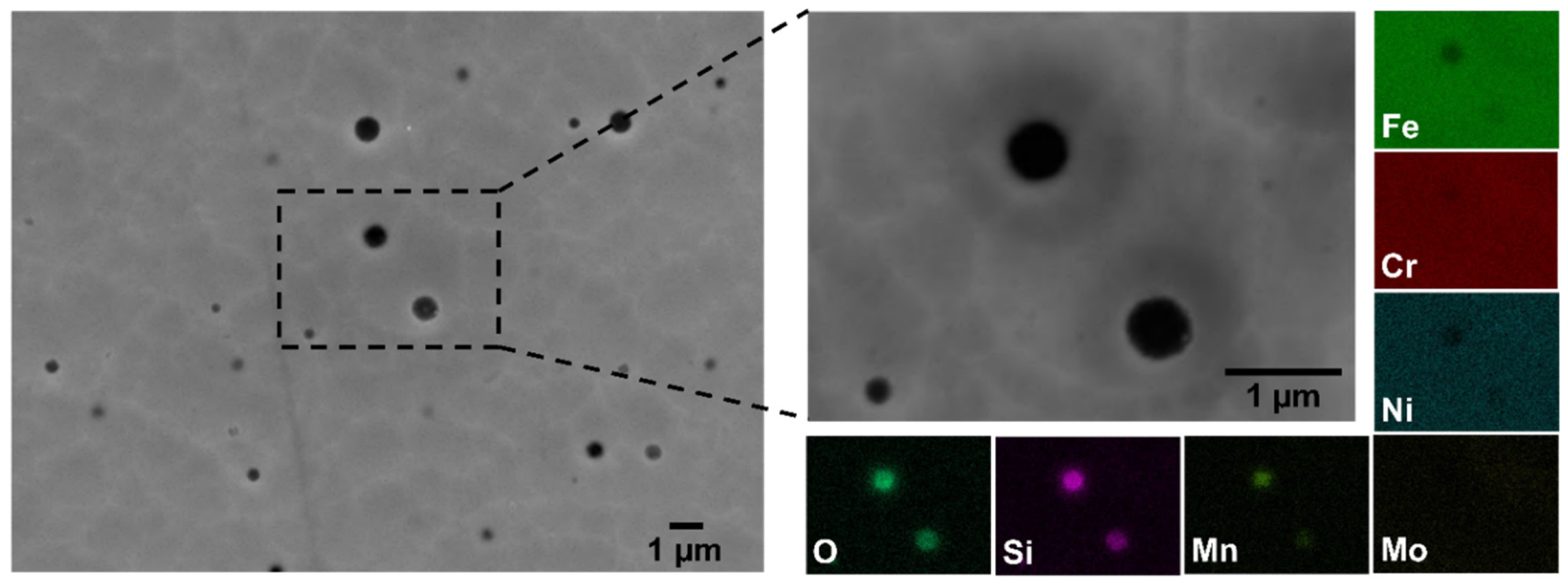

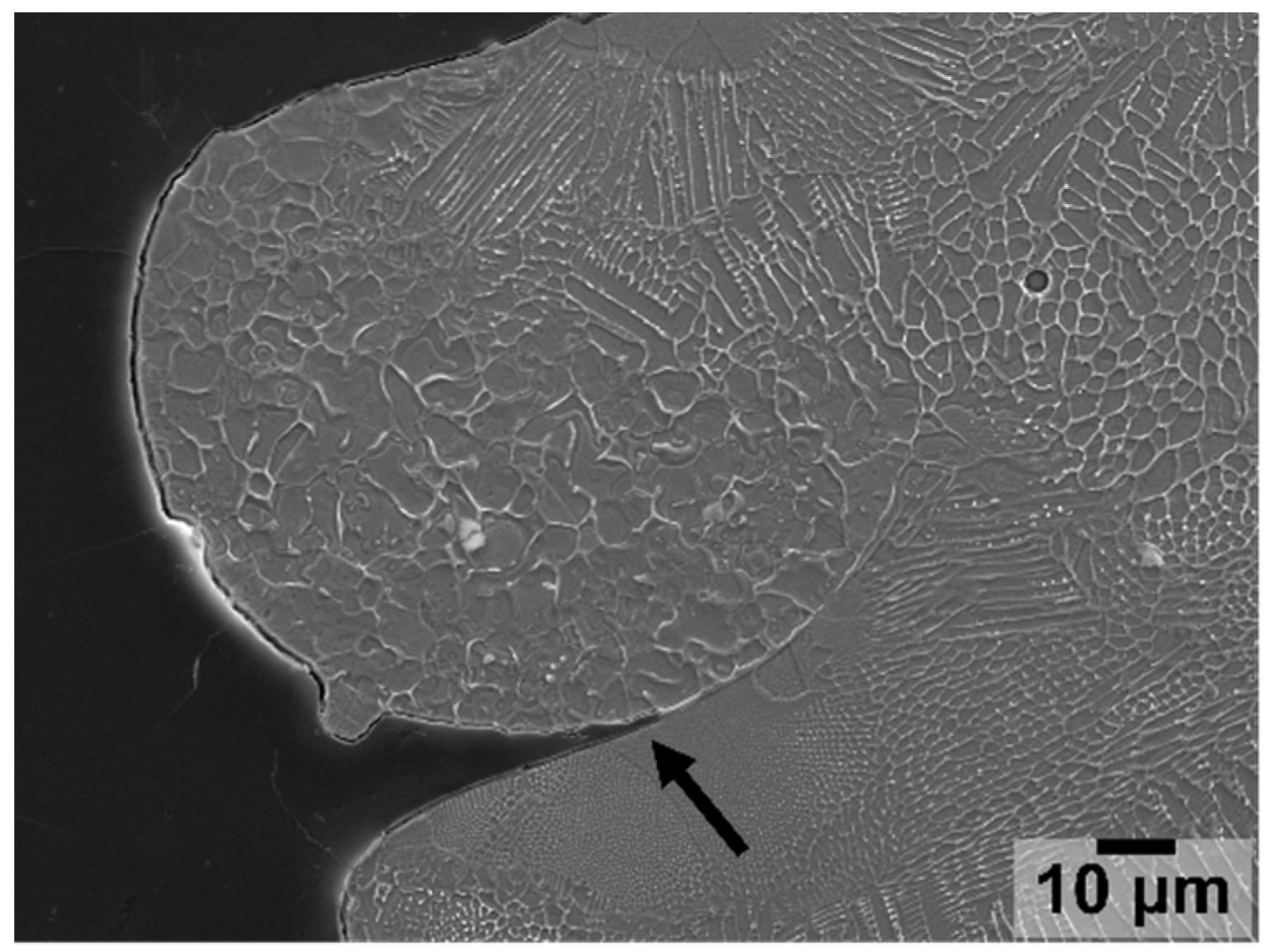

3.1. Microstructure, Special Features, and Defects

3.2. Microstructure

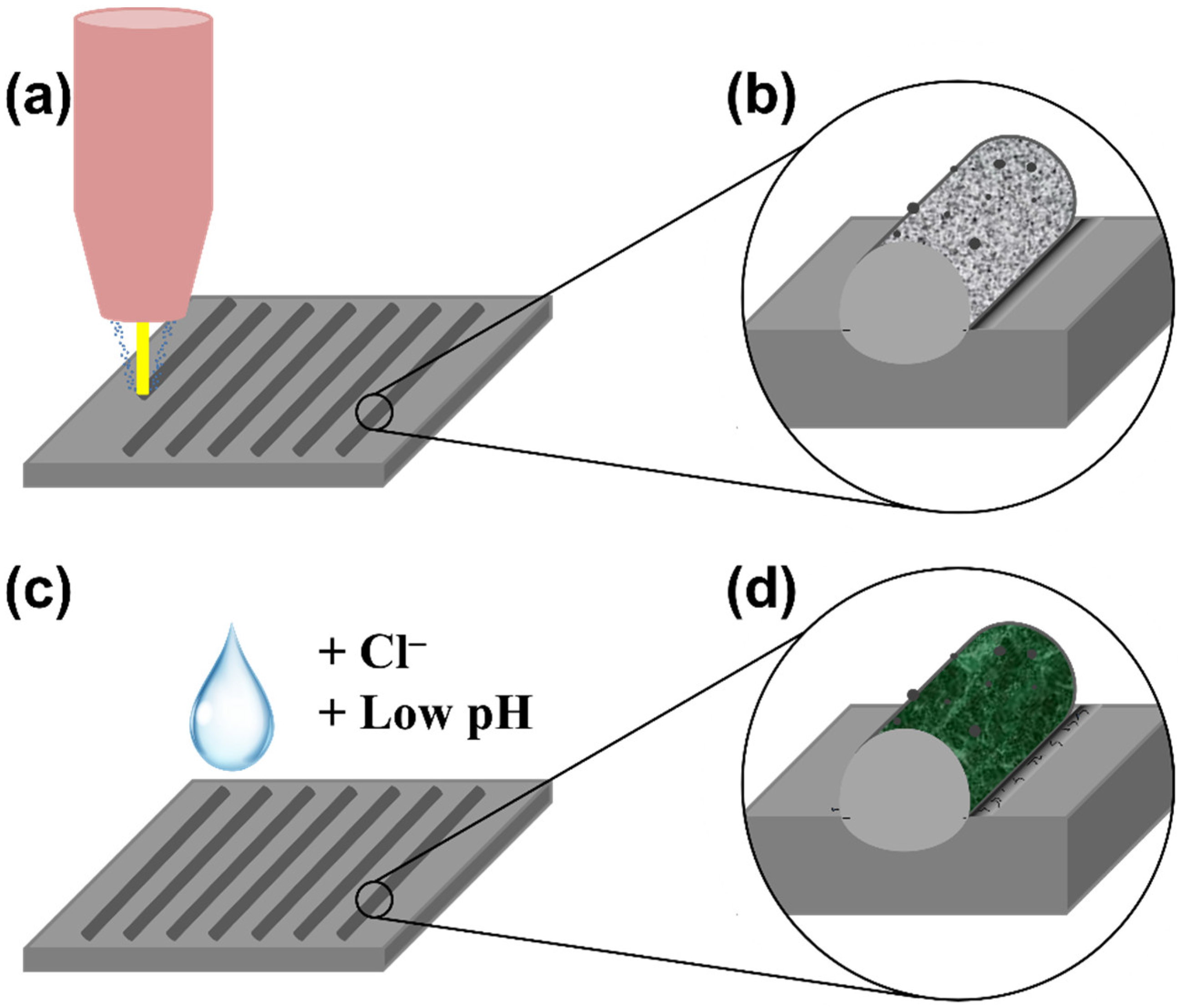

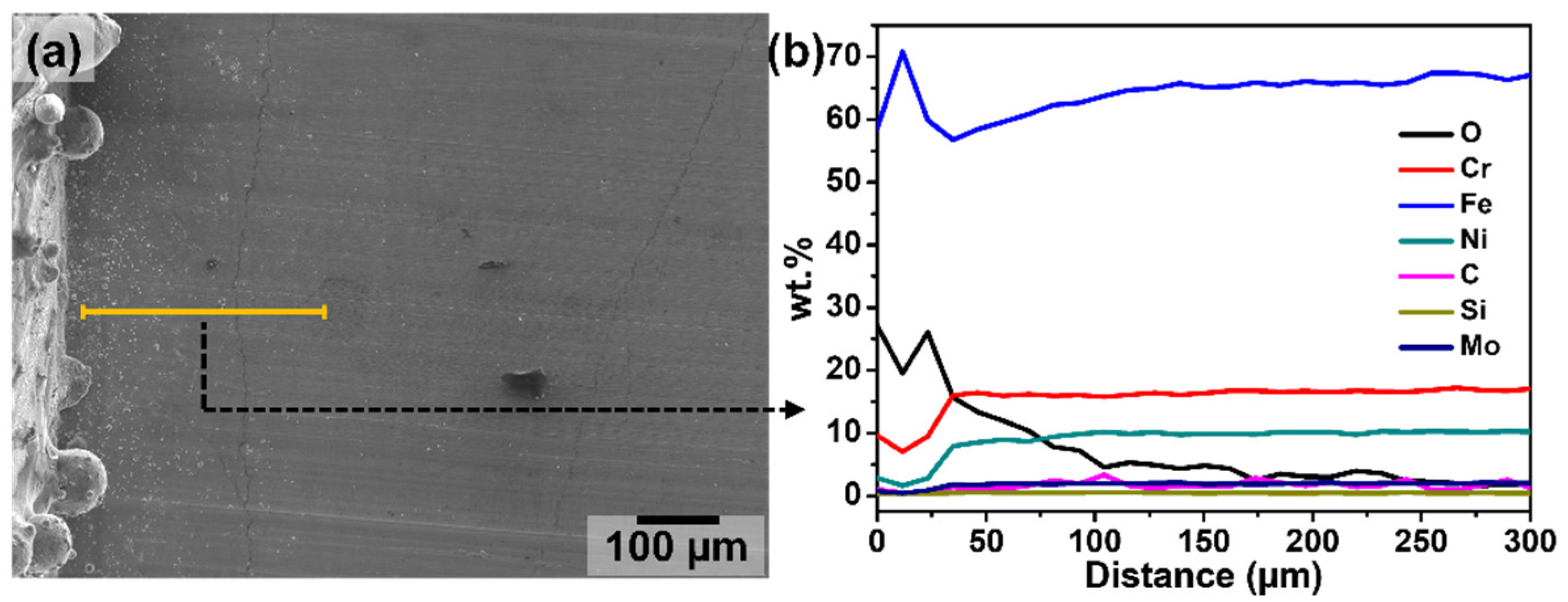

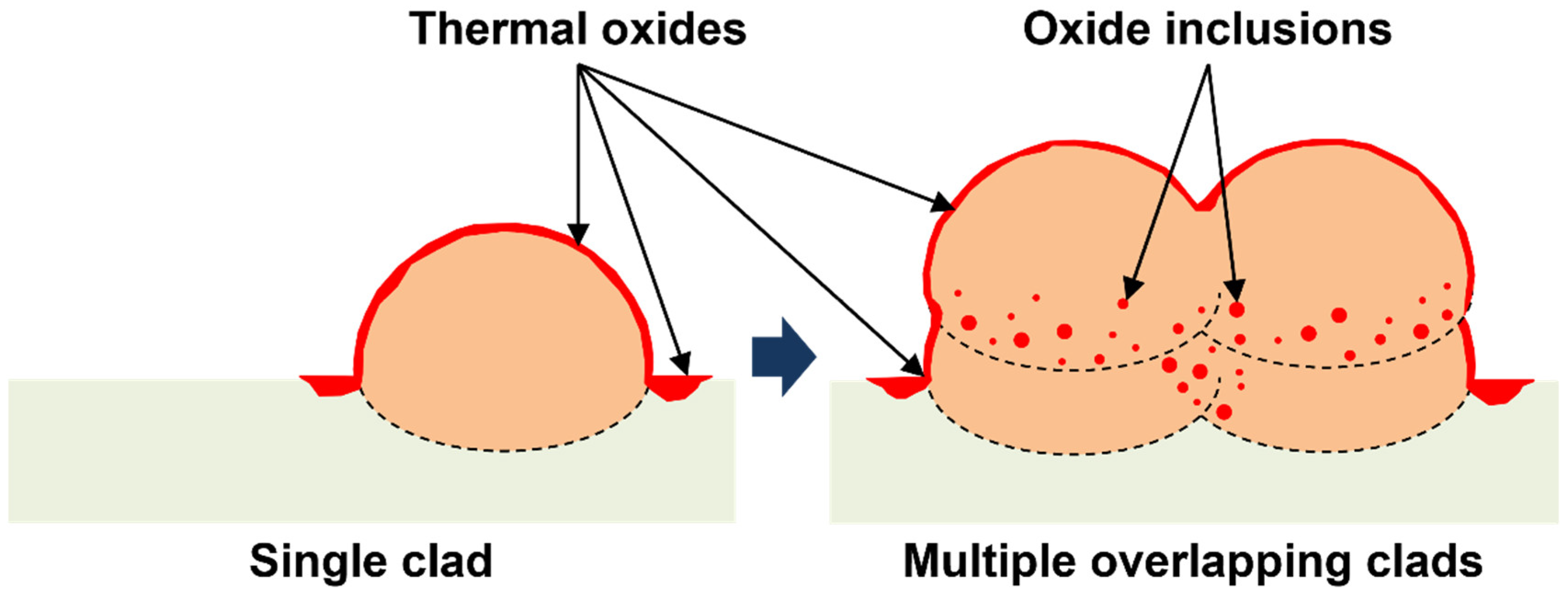

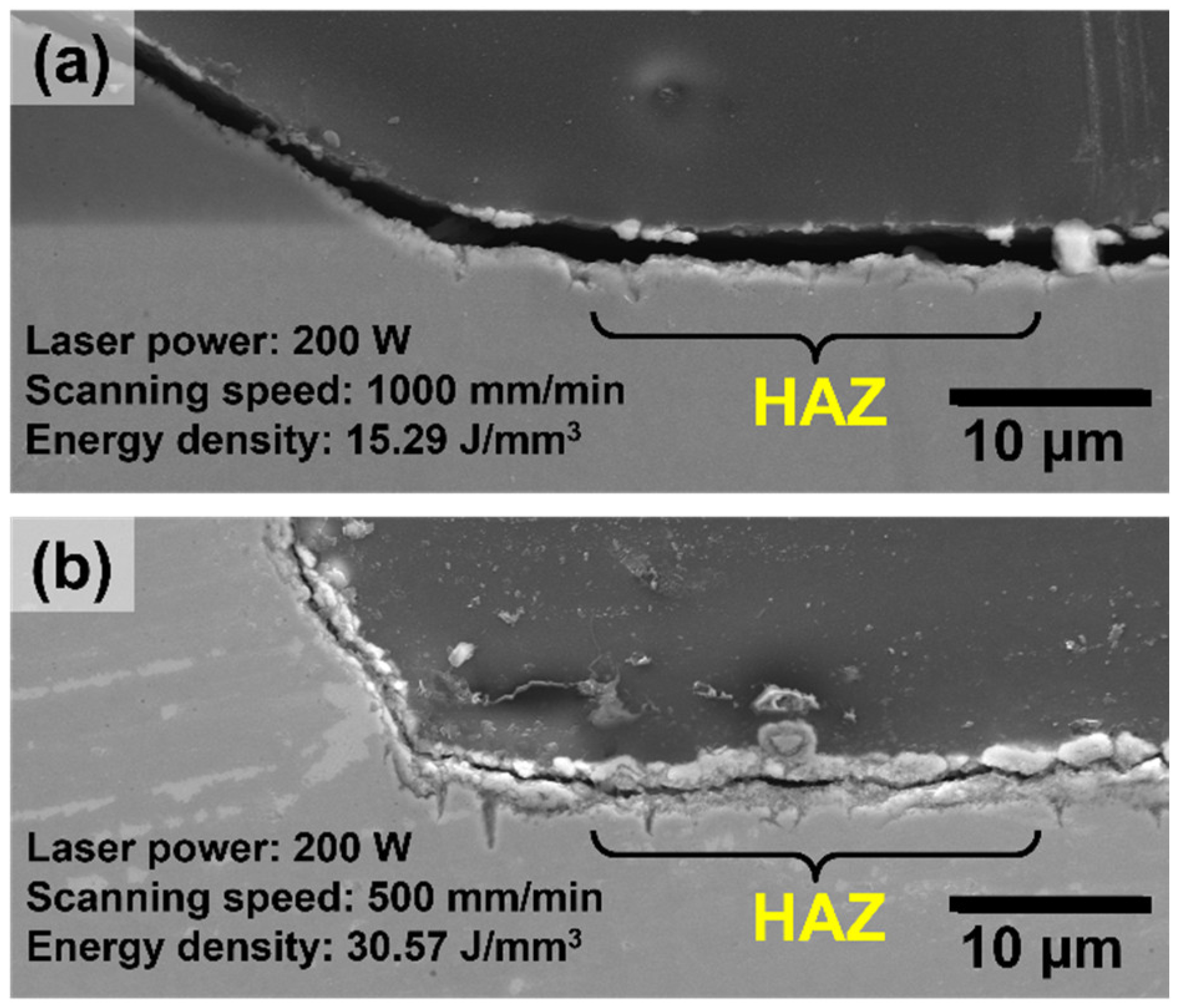

3.3. Heat-Affected Zone (HAZ) and Thermal Oxides

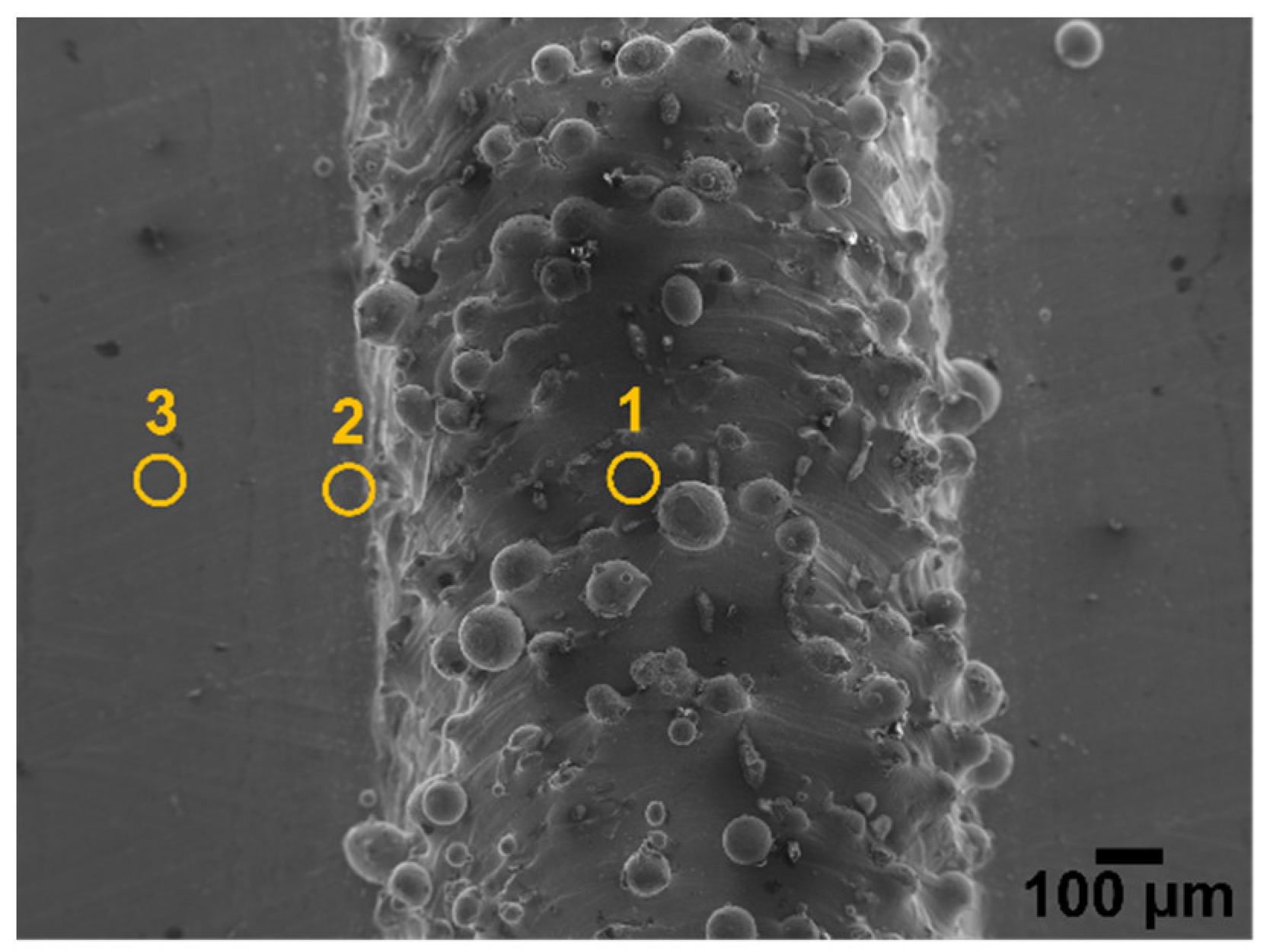

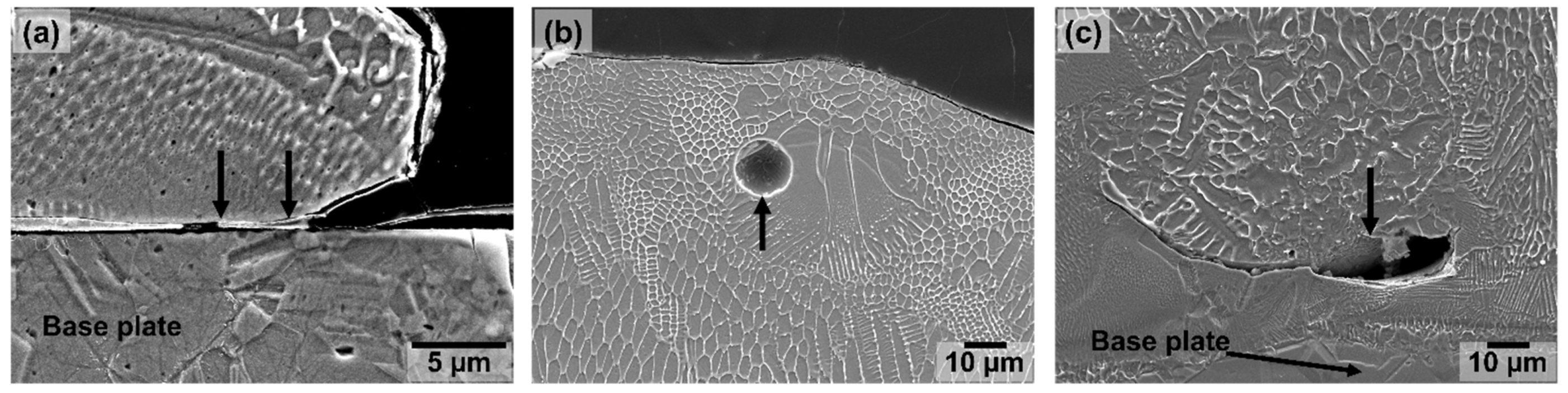

3.4. Un-Melted Powder Particles

3.5. Voids and Pores

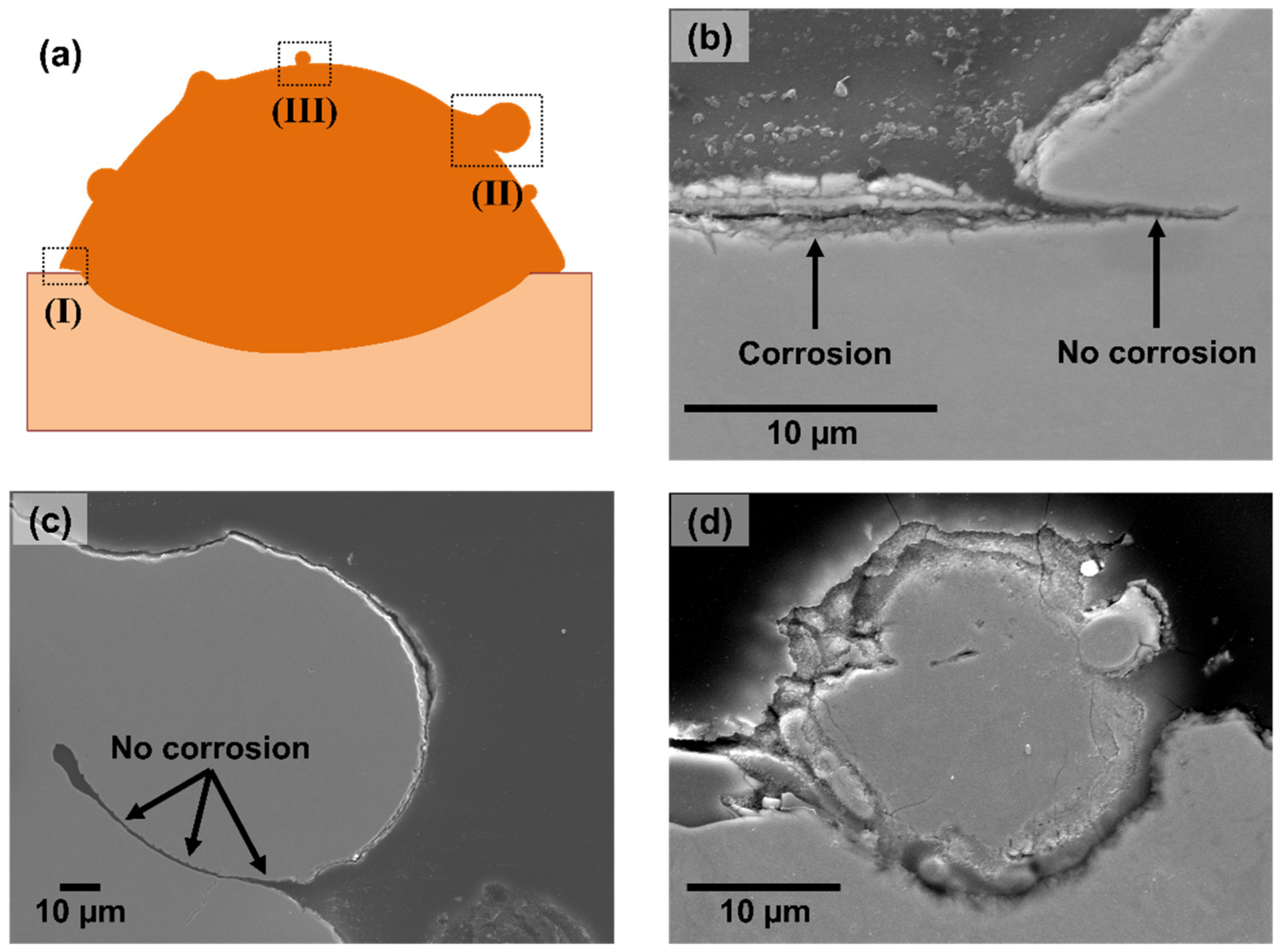

3.6. Corrosion Behaviour

3.7. Considerations towards Improving Corrosion Performance of LMD 316L SS Parts for Repair Applications

4. Conclusions

- Heat-affected zones along the deposited clads (in their close vicinity) were characterised by a large depletion of alloying elements, while containing a high oxygen content due to thermally driven oxidation. Depletion of Cr and Mo in these regions provoked a significant decrease in the pitting resistance of the heat-affected zone, resulting in these regions being the primary contributor to the corrosion activity of the LMD-deposited clads.

- Samples prepared using a relatively higher laser energy density presented a more severe corrosion attack along the heat-affected zone than clads manufactured with relatively low laser energy input.

- From the partially un-melted powder particles scattered across the surface of the deposited clads, almost exclusively powder particles with a relatively small diameter (generally <30 µm) and a highly irregular shape were actively affected by corrosion.

- Due to the exposure to ambient air of the HAZ and the surface of the printed clad left behind by the moving nozzle, a relatively high level of thermal oxidation was observed on these regions. These high contents of thermal oxides formed during the DED manufacturing process on the HAZ and on the surface of the printed clads can be the source of the high number of oxide inclusions often found in multi-layered DED 316L stainless steel parts.

- This work highlights the need for more investigations on as-built surfaces of additively manufactured parts to better understand the performance of the materials closer to their final applications, demonstrating that the surface defects resulting from the additive manufacturing process play a predominant role in the corrosion behaviour of the system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The role of Additive Manufacturing in the era of industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Gorsse, S.; Hutchinson, C.; Goune, M.; Banerjee, R. Additive manufacturing of metals: A brief review of the characteristic microstructures and properties of steels, Ti-6Al-4V and high-entropy alloys. Sci. Technol. Adv. Mater. 2017, 18, 584–610. [Google Scholar] [CrossRef] [PubMed]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Saeidi, K.; Gao, X.; Lofaj, F.; Kvetkova, L.; Shen, Z.J. Transformation of austenite to duplex austenite-ferrite assembly in annealed stainless steel 316L consolidated by laser melting. J. Alloys Compd. 2015, 633, 463–468. [Google Scholar] [CrossRef]

- Saeidi, K.; Gao, X.; Zhong, Y.; Shen, Z.J. Hardened austenite steel with columnar sub-grain structure formed by laser melting. Mater. Sci. Eng. A 2015, 625, 221–229. [Google Scholar] [CrossRef]

- Kurzynowski, T.; Gruber, K.; Stopyra, W.; Kuznicka, B.; Chlebus, E. Correlation between process parameters, microstructure and properties of 316L stainless steel processed by selective laser melting. Mater. Sci. Eng. A 2018, 718, 64–73. [Google Scholar] [CrossRef]

- Godec, M.; Zaefferer, S.; Podgornik, B.; Šinko, M.; Tchernychova, E. Quantitative multiscale correlative microstructure analysis of additive manufacturing of stainless steel 316L processed by selective laser melting. Mater. Charact. 2020, 160, 110074. [Google Scholar] [CrossRef]

- Barkia, B.; Aubry, P.; Haghi-Ashtiani, P.; Auger, T.; Gosmain, L.; Schuster, F.; Maskrot, H. On the origin of the high tensile strength and ductility of additively manufactured 316L stainless steel: Multiscale investigation. J. Mater. Sci. Technol. 2020, 41, 209–218. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Bosio, F.; Bassini, E.; Librera, E.; de Chirico, M.; Biamino, S.; Ugues, D.; Fino, P.; Lombardi, M. An investigation on the effect of powder recycling on the microstructure and mechanical properties of AISI 316L produced by Directed Energy Deposition. Mater. Sci. Eng. A 2019, 766, 138360. [Google Scholar] [CrossRef]

- Revilla, R.I.; van Calster, M.; Raes, M.; Arroud, G.; Andreatta, F.; Pyl, L.; Guillaume, P.; de Graeve, I. Microstructure and corrosion behavior of 316L stainless steel prepared using different additive manufacturing methods: A comparative study bringing insights into the impact of microstructure on their passivity. Corros. Sci. 2020, 176, 108914. [Google Scholar] [CrossRef]

- Sander, G.; Tan, J.; Balan, P.; Gharbi, O.; Feenstra, D.R.; Singer, L.; Thomas, S.; Kelly, R.G.; Scully, J.R.; Birbilis, N. Corrosion of additively manufactured alloys: A review. Corrosion 2018, 74, 1318–1350. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Ni, X.; Li, X. Corrosion of metallic materials fabricated by selective laser melting. NPJ Mater. Degrad. 2019, 3, 24. [Google Scholar] [CrossRef]

- Ko, G.; Kim, W.; Kwon, K.; Lee, T.-K. The corrosion of stainless steel made by additive manufacturing: A review. Metals 2021, 11, 516. [Google Scholar] [CrossRef]

- Andreatta, F.; Lanzutti, A.; Vaglio, E.; Totis, G.; Sortino, M.; Fedrizzi, L. Corrosion behaviour of 316L stainless steel manufactured by selective laser melting. Mater. Corros. 2019, 70, 1633–1645. [Google Scholar] [CrossRef]

- Lodhi, M.J.K.; Deen, K.M.; Greenlee-Wacker, M.C.; Haider, W. Additively manufactured 316L stainless steel with improved corrosion resistance and biological response for biomedical applications. Addit. Manuf. 2019, 27, 8–19. [Google Scholar] [CrossRef]

- Lodhi, M.J.K.; Deen, K.M.; Haider, W. Corrosion behavior of additively manufactured 316L stainless steel in acidic media. Materialia 2018, 2, 111–121. [Google Scholar] [CrossRef]

- Trelewicz, J.R.; Halada, G.P.; Donaldson, O.K.; Manogharan, G. Microstructure and corrosion resistance of laser additively manufactured 316L stainless steel. J. Mater. 2016, 68, 850–859. [Google Scholar] [CrossRef]

- Sun, Y.; Moroz, A.; Alrbaey, K. Sliding wear characteristics and corrosion behaviour of selective laser melted 316L stainless steel. J. Mater. Eng. Perform. 2014, 23, 518–526. [Google Scholar] [CrossRef]

- Kong, D.; Ni, X.; Dong, C.; Zhang, L.; Man, C.; Yao, J.; Xiao, K.; Li, X. Heat treatment effect on the microstructure and corrosion behavior of 316L stainless steel fabricated by selective laser melting for proton exchange membrane fuel cells. Electrochim. Acta 2018, 276, 293–303. [Google Scholar] [CrossRef]

- Laleh, M.; Hughes, A.E.; Xua, W.; Haghdadi, N.; Wang, K.; Cizek, P.; Gibson, I.; Tan, M.Y. On the unusual intergranular corrosion resistance of 316L stainless steel additively manufactured by selective laser melting. Corros. Sci. 2019, 161, 108189. [Google Scholar] [CrossRef]

- Ni, X.; Kong, D.; Wu, W.; Zhang, L.; Dong, C.; He, B.; Lu, L.; Wu, K.; Zhu, D. Corrosion Behavior of 316L Stainless Steel Fabricated by Selective Laser Melting Under Different Scanning Speeds. J. Mater. Eng. Perform. 2018, 27, 3667–3677. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Yan, Q.; Zhang, L.; Wang, M.; Song, B.; Shi, Y. Amorphous alloy strengthened stainless steel manufactured by selective laser melting: Enhanced strength and improved corrosion resistance. Scr. Mater. 2018, 148, 20–23. [Google Scholar] [CrossRef]

- Chao, Q.; Cruz, V.; Thomas, S.; Birbilis, N.; Collins, P.; Taylor, A.; Hodgson, P.D.; Fabijanic, D. On the enhanced corrosion resistance of a selective laser melted austenitic stainless steel. Scr. Mater. 2017, 141, 94–98. [Google Scholar] [CrossRef]

- Sun, S.H.; Ishimoto, T.; Hagihara, K.; Tsutsumi, Y.; Hanawa, T.; Nakano, T. Excellent mechanical and corrosion properties of austenitic stainless steel with a unique crystallographic lamellar microstructure via selective laser melting. Scr. Mater. 2019, 159, 89–93. [Google Scholar] [CrossRef]

- Sander, G.; Thomas, S.; Cruz, V.; Jurg, M.; Birbilis, N.; Gao, X.; Brameld, M.; Hutchinson, C.R. On the corrosion and metastable pitting characteristics of 316L stainless steel produced by selective laser melting. J. Electrochem. Soc. 2017, 164, C250–C257. [Google Scholar] [CrossRef]

- Man, C.; Dong, C.; Liu, T.; Kong, D.; Wang, D.; Li, X. The enhancement of microstructure on the passive and pitting behaviors of selective laser melting 316L SS in simulated body fluid. Appl. Surf. Sci. 2019, 467–468, 193–205. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Ni, X.; Zhang, L.; Luo, H.; Li, R.; Wang, L.; Man, C.; Li, X. The passivity of selective laser melted 316L stainless steel. Appl. Surf. Sci. 2020, 504, 144495. [Google Scholar] [CrossRef]

- Revilla, R.I.; Wouters, B.; Andreatta, F.; Lanzutti, A.; Fedrizzi, L.; de Graeve, I. EIS comparative study and critical Equivalent Electrical Circuit (EEC) analysis of the native oxide layer of additive manufactured and wrought 316L stainless steel. Corros. Sci. 2020, 167, 108480. [Google Scholar] [CrossRef]

- Zietala, M.; Durejko, T.; Polanski, M.; Kunce, I.; Plocinski, T.; Zielinski, W.; Lazinska, M.; Stepniowski, W.; Czujko, T.; Kurzydlowski, K.J.; et al. The microstructure, mechanical properties and corrosion resistance of 316L stainless steel fabricated using laser engineered net shaping. Mater. Sci. Eng. A 2016, 677, 1–10. [Google Scholar] [CrossRef]

- Ganesh, P.; Giri, R.; Kaul, R.; Sankar, P.R.; Tiwari, P.; Atulkar, A.; Porwal, R.K.; Dayal, R.K.; Kukreja, L.M. Studies on pitting corrosion and sensitization in laser rapid manufactured specimens of type 316L stainless steel. Mater. Des. 2012, 39, 509–521. [Google Scholar] [CrossRef]

- Majumdar, J.D.; Pinkerton, A.; Liu, Z.; Manna, I.; Li, L. Mechanical and electrochemical properties of multiple-layer diode laser cladding of 316L stainless steel. Appl. Surf. Sci. 2005, 247, 373–377. [Google Scholar] [CrossRef]

- Sun, G.F.; Shen, X.T.; Wang, Z.D.; Zhan, M.J.; Yao, S.; Zhou, R.; Ni, Z.H. Laser metal deposition as repair technology for 316L stainless steel: Influence of feeding powder compositions on microstructure and mechanical properties. Opt. Laser Technol. 2019, 109, 71–83. [Google Scholar] [CrossRef]

- Zhan, M.J.; Sun, G.F.; Wang, Z.D.; Shen, X.T.; Yan, Y.; Ni, Z.H. Numerical and experimental investigation on laser metal deposition as repair technology for 316L stainless steel. Opt. Laser Technol. 2019, 118, 84–92. [Google Scholar] [CrossRef]

- Oh, W.J.; Lee, W.J.; Kim, M.S.; Jeon, J.B.; Shim, D.S. Repairing additive-manufactured 316L stainless steel using direct energy deposition. Opt. Laser Technol. 2019, 117, 6–17. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of directed energy deposition-based additive manufacturing in repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- Lei, X.; Nuam, V.L.; Deng, Y.; Yuan, Y.; Liu, M.; Yao, W.; Wang, N. Insight into the passivation and corrosion behavior of additive manufacturing repaired single crystal superalloy. Corros. Sci. 2022, 203, 110340. [Google Scholar] [CrossRef]

- Vishnukumar, M.; Pramod, R.; Kannan, A.R. Wire arc additive manufacturing for repairing aluminium structures in marine applications. Mater. Lett. 2021, 299, 130112. [Google Scholar] [CrossRef]

- Ertveldt, J.; Guillaume, P.; Helsen, J. MiCLAD as a platform for real-time monitoring and machine learning in laser metal deposition. Procedia CIRP 2020, 94, 456–461. [Google Scholar] [CrossRef]

- Ahmad, Z. Selection of materials for corrosive environment. In Principles of Corrosion Engineering and Corrosion Control; Elsevier: Amsterdam, The Netherlands, 2006; Chapter 9; pp. 479–549. [Google Scholar] [CrossRef]

- Klueh, R.L.; King, J.F. Austenitic stainless steel-ferritic steel weld joint failures. Weld. J. Res. Suppl. 1982, 61, 302s–311s. [Google Scholar]

- Ogawa, T.; Koseki, T. Effect of composition profiles on metallurgy and corrosion behavior of duplex stainless steel weld metals. Weld. J. Res. Suppl. 1989, 68, 181s–191s. [Google Scholar]

- Rashid, R.A.R.; Abaspour, S.; Palanisamy, S.; Matthews, N.; Dargusch, M.S. Metallurgical and geometrical characterisation of 316L stainless steel clad deposited on a mild steel substrate. Surf. Coat. Technol. 2017, 327, 174–184. [Google Scholar] [CrossRef]

- Graf, B.; Gumenyuk, A.; Rethmeier, M. Laser metal deposition as repair technology for stainless steel and titanium alloys. Phys. Procedia 2012, 39, 376–381. [Google Scholar] [CrossRef]

- Saboori, A.; Toushekhah, M.; Aversa, A.; Lai, M.; Lombardi, M.; Biamino, S.; Fino, P. Critical features in the microstructural analysis of AISI 316L produced by metal additive manufacturing. Metallogr. Microstruct. Anal. 2020, 9, 92–96. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Microstructure and mechanical properties of AISI 316L produced by directed energy deposition-based additive manufacturing: A review. Appl. Sci. 2020, 10, 3310. [Google Scholar] [CrossRef]

- Meier, C.; Weissbach, R.; Weinberg, J.; Wall, W.A.; Hart, A.J. Modelling and characterization of cohesion in fine metal powders with a focus on additive manufacturing process simulation. Powder Technol. 2019, 343, 855–866. [Google Scholar] [CrossRef]

| Cr | Ni | Mo | Mn | Si | S | C | N | P |

|---|---|---|---|---|---|---|---|---|

| 16.0–18.0 | 10.0–14.0 | 2.0–3.0 | <2.0 | <0.75 | <0.03 | <0.03 | <0.1 | <0.05 |

| Wt.% | ||||||||

|---|---|---|---|---|---|---|---|---|

| Fe | O | Cr | Ni | Mo | Si | Mn | S | |

| Spectrum 1 | 53.9 | 15.6 | 16.3 | 10.2 | 2.5 | 0.5 | 1 | – |

| Spectrum 2 | 57.1 | 21.2 | 13.6 | 5.3 | 0.9 | 0.3 | 1.4 | 0.1 |

| Spectrum 3 | 68.2 | 1.3 | 16.6 | 10.0 | 2.0 | 0.5 | 1.5 | – |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Revilla, R.I.; De Graeve, I. Microstructural Features, Defects, and Corrosion Behaviour of 316L Stainless Steel Clads Deposited on Wrought Material by Powder- and Laser-Based Direct Energy Deposition with Relevance to Repair Applications. Materials 2022, 15, 7181. https://doi.org/10.3390/ma15207181

Revilla RI, De Graeve I. Microstructural Features, Defects, and Corrosion Behaviour of 316L Stainless Steel Clads Deposited on Wrought Material by Powder- and Laser-Based Direct Energy Deposition with Relevance to Repair Applications. Materials. 2022; 15(20):7181. https://doi.org/10.3390/ma15207181

Chicago/Turabian StyleRevilla, Reynier I., and Iris De Graeve. 2022. "Microstructural Features, Defects, and Corrosion Behaviour of 316L Stainless Steel Clads Deposited on Wrought Material by Powder- and Laser-Based Direct Energy Deposition with Relevance to Repair Applications" Materials 15, no. 20: 7181. https://doi.org/10.3390/ma15207181

APA StyleRevilla, R. I., & De Graeve, I. (2022). Microstructural Features, Defects, and Corrosion Behaviour of 316L Stainless Steel Clads Deposited on Wrought Material by Powder- and Laser-Based Direct Energy Deposition with Relevance to Repair Applications. Materials, 15(20), 7181. https://doi.org/10.3390/ma15207181