The Effect of Molten Salt Infiltration on 2D SiCf/SiC Composite by Chemical Vapour Infiltration

Abstract

1. Introduction

2. Materials and Methods

2.1. Description of 2D Composite Material

2.2. Experimental Methods

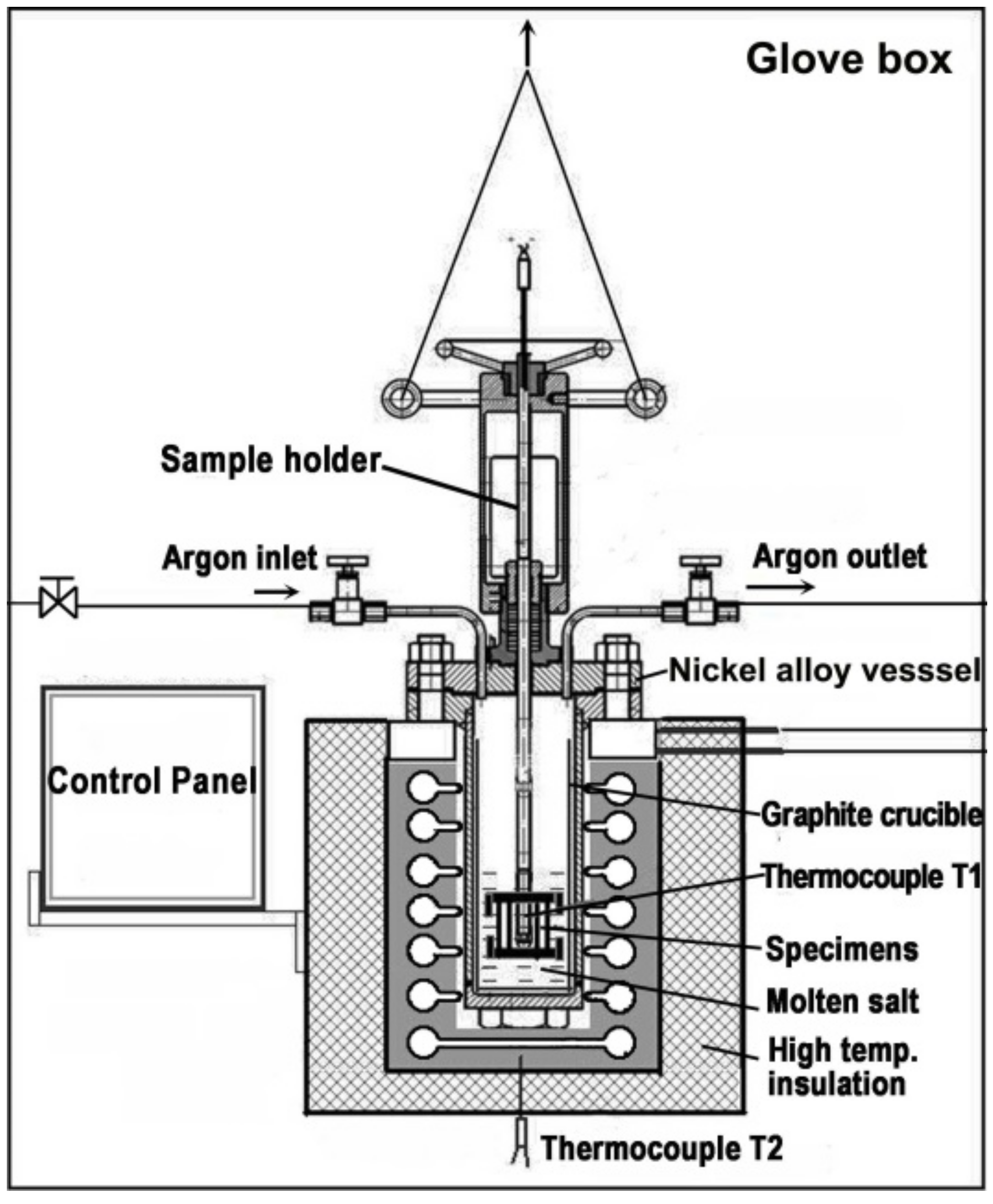

2.2.1. Molten Salt Infiltration Experiment

2.2.2. SEM and X-ray Computed Tomography

2.2.3. XRD Characterization

3. Results and Discussions

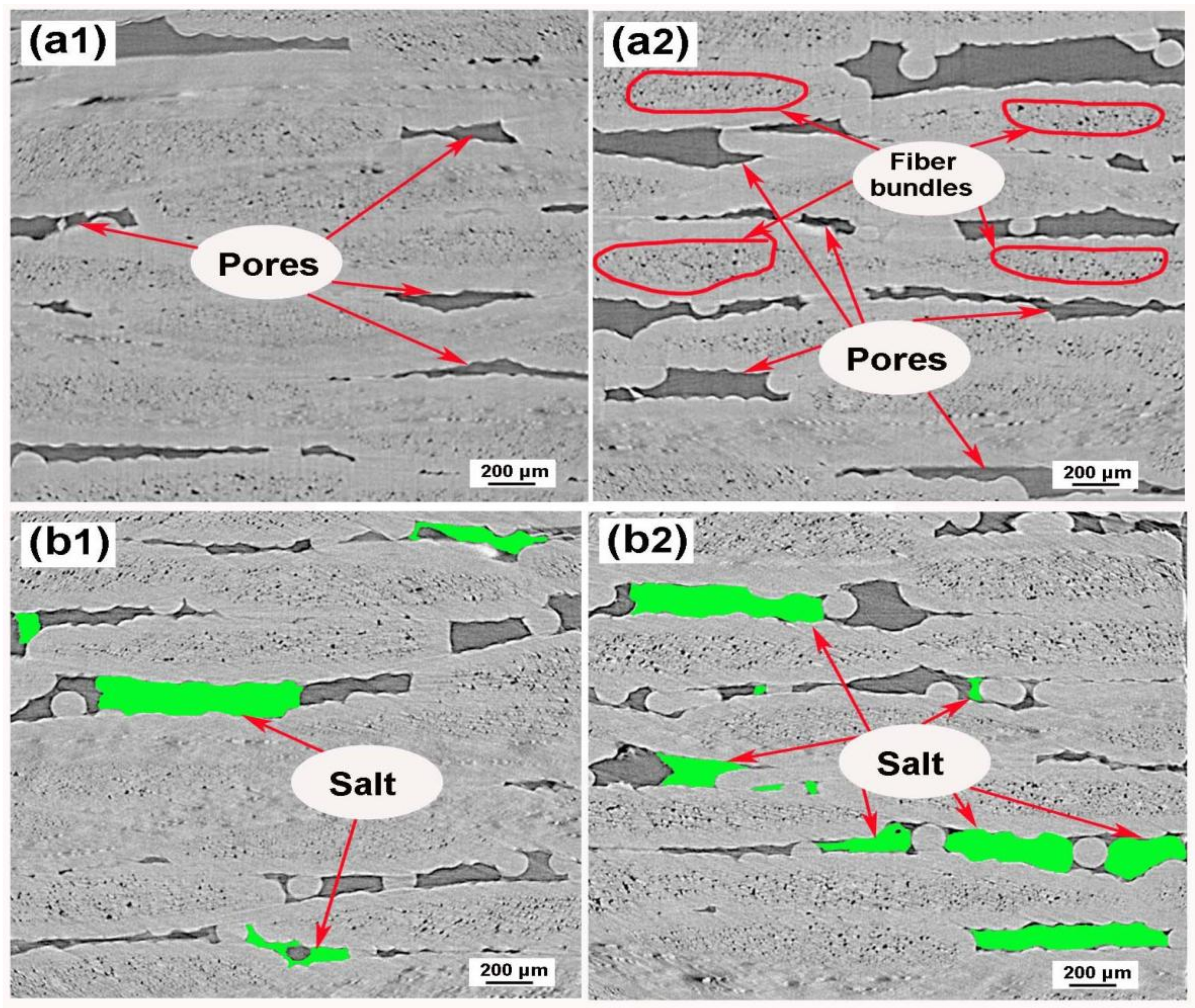

3.1. Morphology Characterization of SiCf/SiC Composite by SEM

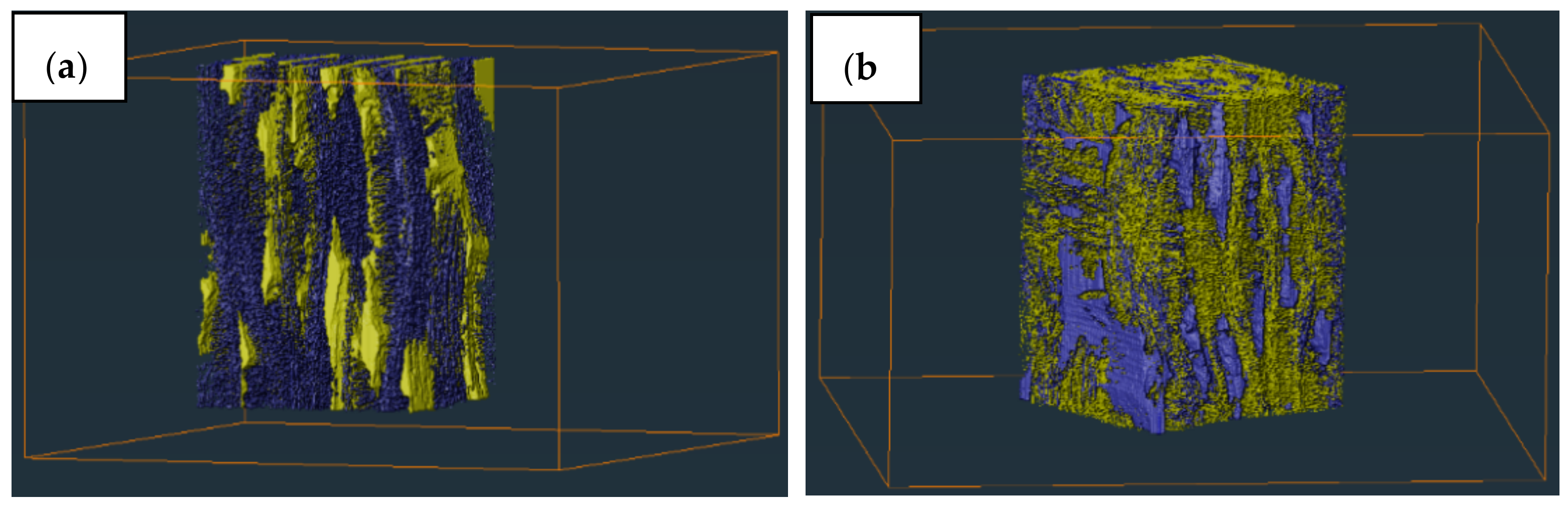

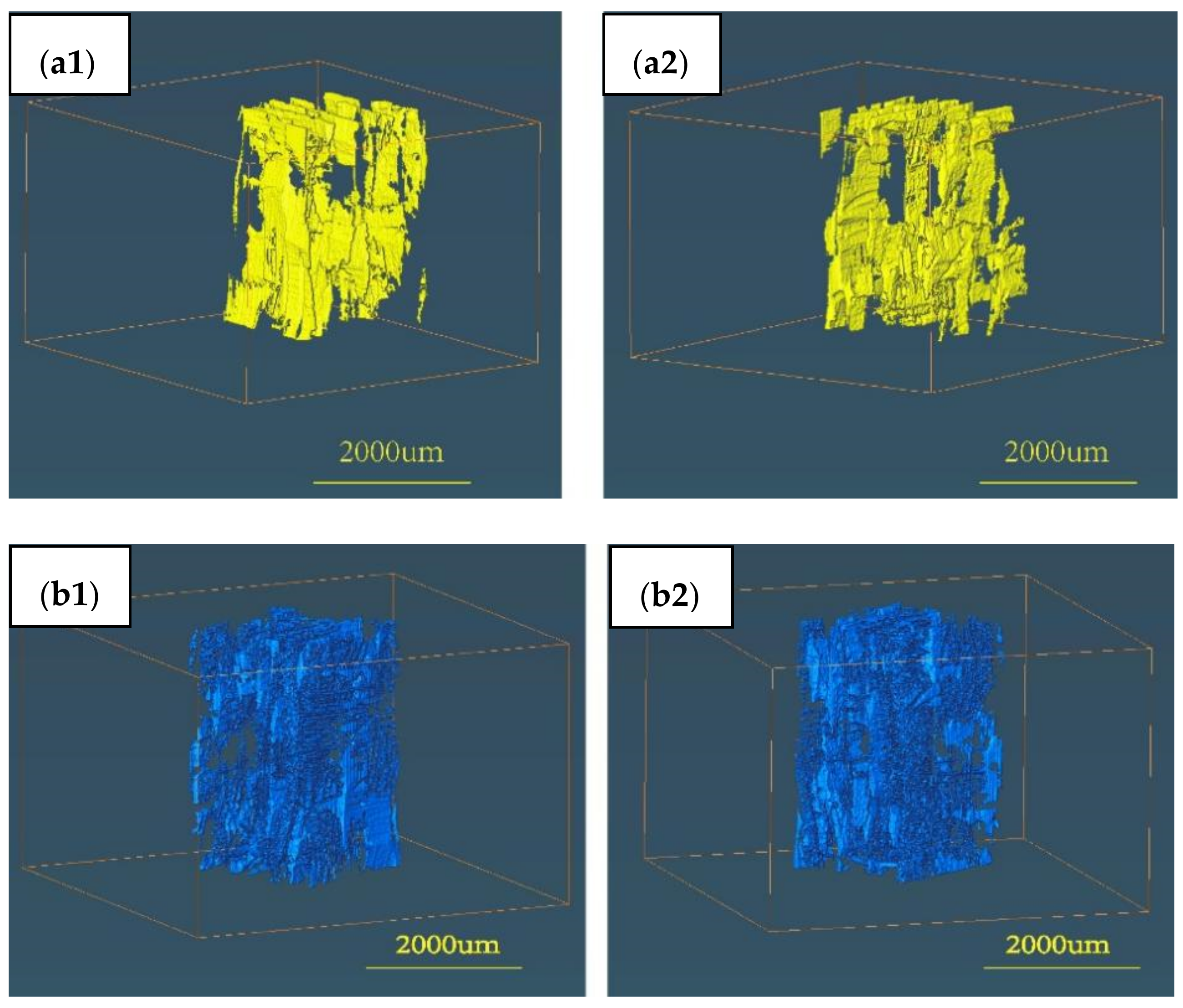

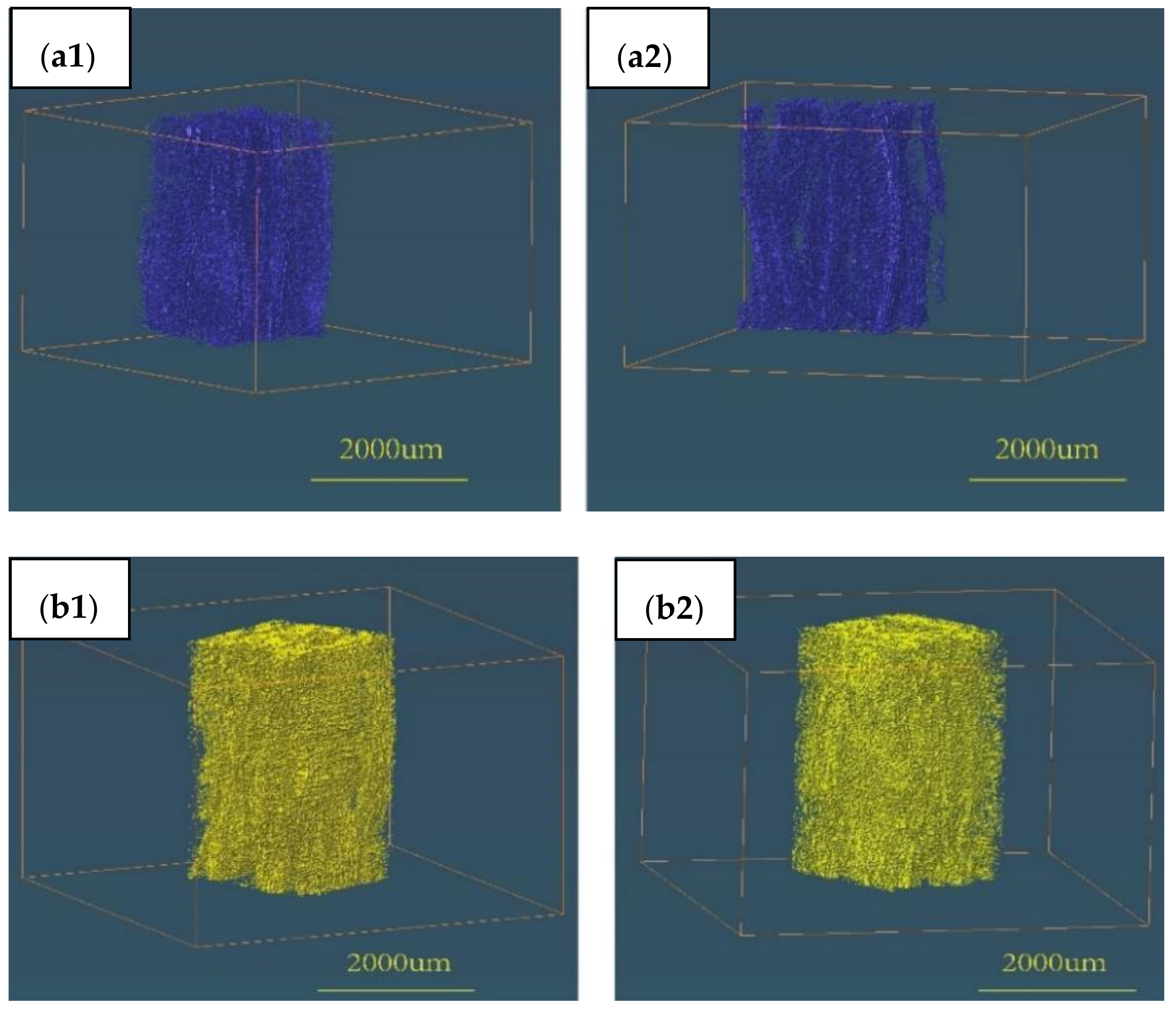

3.2. Microstructure SR-CT Characterization of SiCf/SiC Composite without and with Molten Salt Treatment

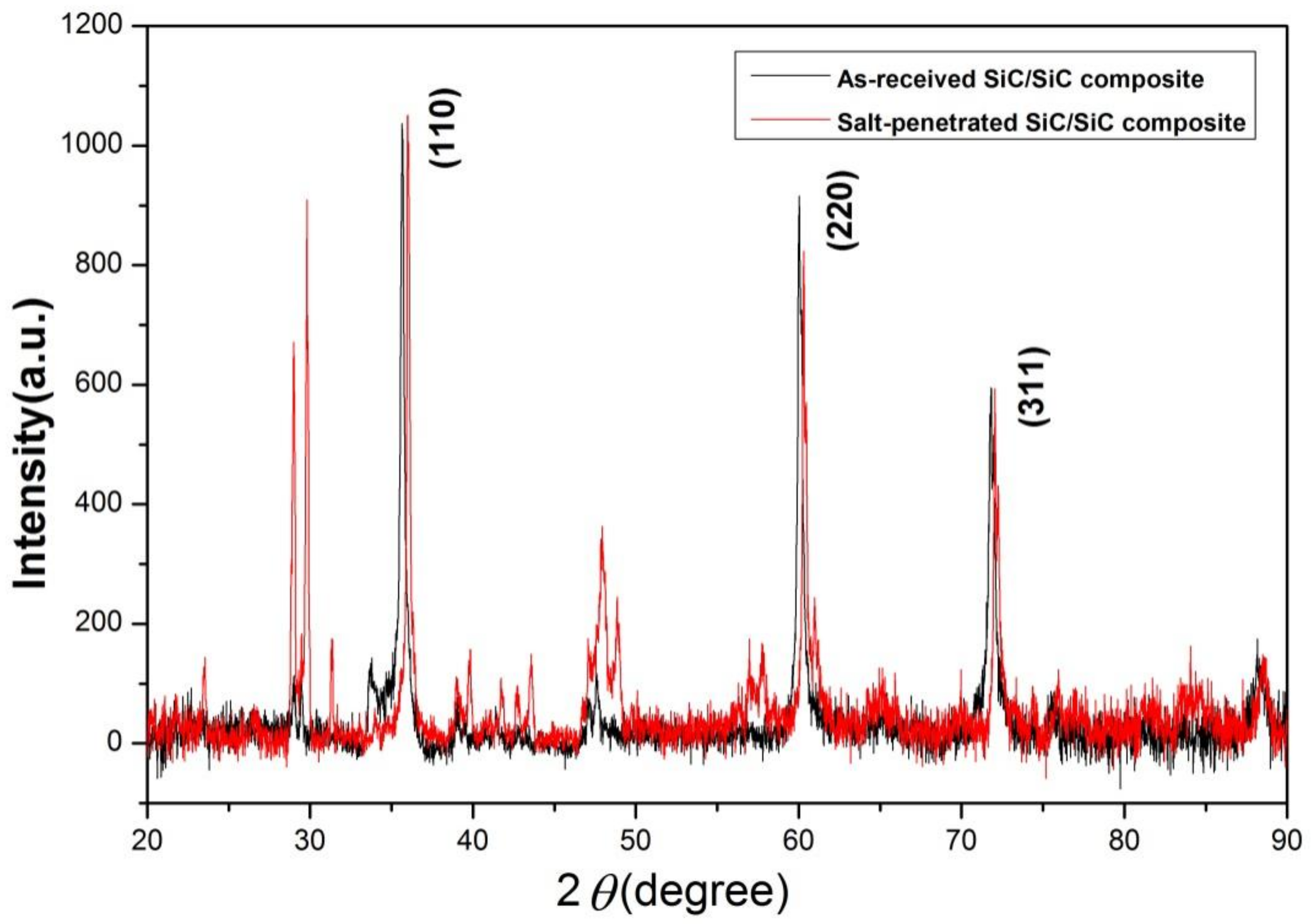

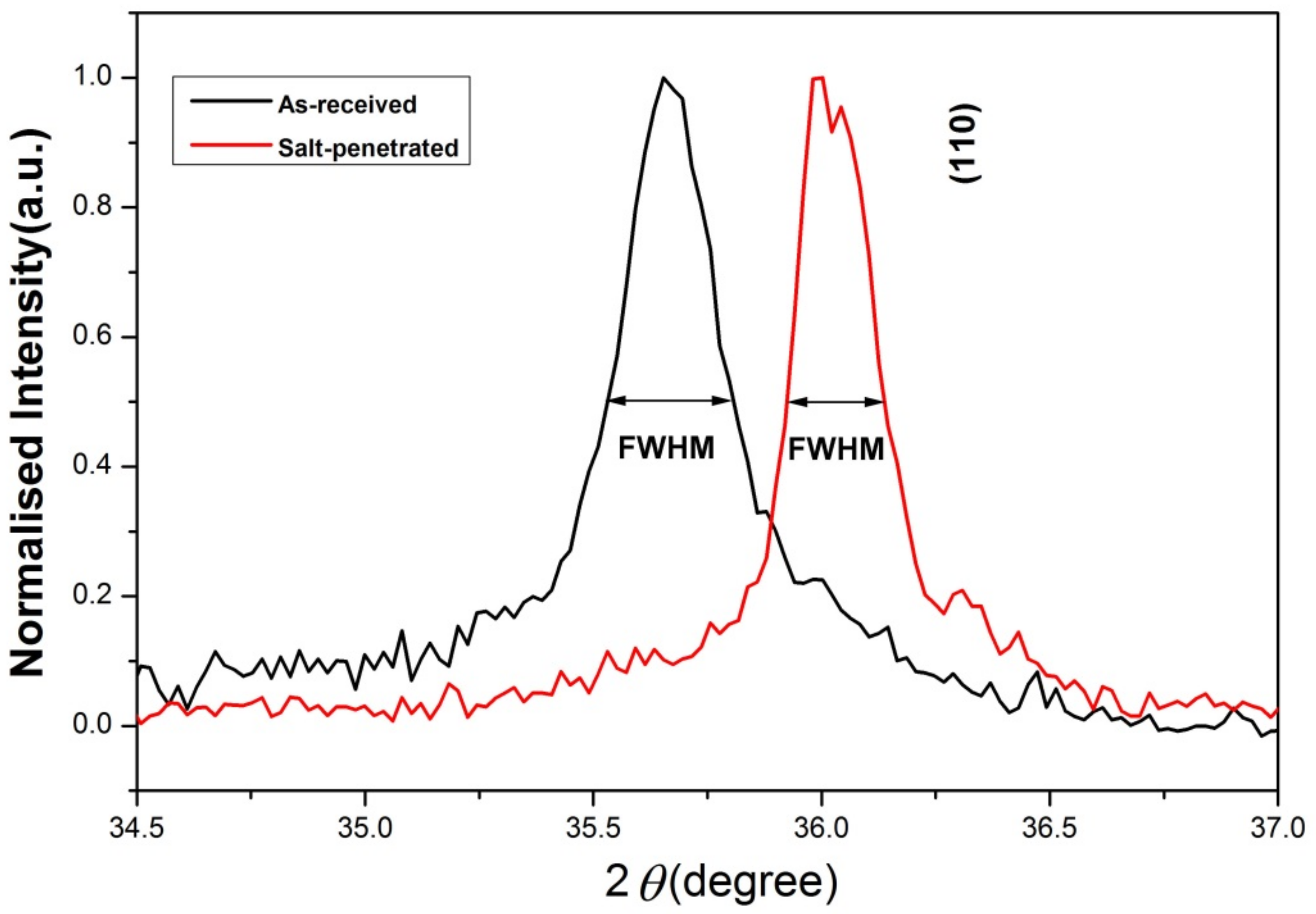

3.3. X-ray Diffraction Analysis

3.4. Comparative Analysis of Pore Structures in SiCf/SiC Composite before and after Molten Salt Infiltration

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclatures

| SiCf/SiC composites | SiC fibre reinforced SiC matrix composites; |

| CT | computed tomography; |

| SR-CT | synchrotron radiation X-ray computed tomography; |

| XRD | X-ray diffraction; |

| SEM | scanning electron microscopy; |

| CVI | chemical vapour infiltration; |

| MSR | Molten Salt Reactor; |

| PyC | pyrolytic carbon |

| the pressure difference inside and outside of pores; | |

| D | the diameter of the infiltrated pore; |

| the surface tension of infiltration liquid; | |

| the contact angle between infiltration liquid and solid. | |

| FWHM | the full width at half maximum |

References

- Zhou, X.G.; Wang, H.L.; Zhao, S. Research Progress in Nuclear SiCf/SiC Composites. Adv. Ceram. 2016, 37, 151–167. [Google Scholar]

- Kohyama, A.; Kotani, M.; Katoh, Y.; Nakayasu, T.; Sato, M.; Yamamura, T.; Okamura, K. High-performance SiC/SiC composites by improved PIP processing with new precursor polymers. J. Nucl. Mater. 2000, 283–287, 565–569. [Google Scholar] [CrossRef]

- Suzuki, M.; Inoue, Y.; Sato, M.; Ishikawa, T.; Goda, K. Fabrication and High-Temperature Flexural Strength of a Sintered SiC Fiber Reinforced SiC Composite. J. Soc. Mater. Sci. Jpn. 2003, 52, 681–687. [Google Scholar] [CrossRef][Green Version]

- Serp, J.; Allibert, M.; Beneš, O.; Delpech, S.; Feynberg, O.; Ghetta, V.; Heuer, D.; Holcomb, D.; Ignatiev, V.; Kloosterman, J.L.; et al. The molten salt reactor (MSR) in generation IV: Overview and perspectives. Prog. Nucl. Energy 2014, 77, 308–319. [Google Scholar] [CrossRef]

- LeBlanc, D. Molten salt reactors: A new beginning for an old idea. Nucl. Eng. Des. 2010, 240, 1644–1656. [Google Scholar] [CrossRef]

- Zheng, G.; Kelleher, B.; Cao, G.; Anderson, M.; Allen, T.; Sridharan, K. Corrosion of 316 stainless steel in high temperature molten Li2BeF4 (FLiBe) salt. J. Nucl. Mater. 2015, 461, 143–150. [Google Scholar] [CrossRef]

- Abram, T.; Ion, S. Generation-IV nuclear power: A review of the state of the science. Energy Policy 2008, 36, 4323–4330. [Google Scholar] [CrossRef]

- Katoh, Y.; Ozawa, K.; Shih, C.; Nozawa, T.; Shinavski, R.J.; Hasegawa, A.; Snead, L.L. Continuous SiC fiber, CVI SiC matrix composites for nuclear applications: Properties and irradiation effects. J. Nucl. Mater. 2014, 448, 448–476. [Google Scholar] [CrossRef]

- Zhang, D.S.; Xia, H.H.; Yang, X.M.; Feng, S.L.; Song, J.L.; Zhou, X.T. The influence of FLiNaK salt impregnation on the mechanical properties of a 2D woven C/C composite. J. Nucl. Mater. 2017, 485, 74–79. [Google Scholar] [CrossRef]

- Schiro, M.; Agudo, E.R.; Navarro, C.R. Damage mechanisms of porous materials due to in-pore salt crystallization. Phys. Rev. Lett. 2012, 109, 265503. [Google Scholar] [CrossRef]

- Flatt, R.J. Salt damage in porous materials: How high supersaturations are generated. J. Cryst. Growth 2002, 242, 435–454. [Google Scholar] [CrossRef]

- La Iglesia, A.; González, V.; López-Acevedo, V.; Viedma, C. Salt crystallization in porous construction materials I: Estimation of crystallization pressure. J. Cryst. Growth 1997, 177, 111–118. [Google Scholar] [CrossRef]

- Tatlisu, H.; Bastuerk, M.; Rauch, H.; Trinker, M. Structural investigation of SiCf/SiC composites. Mater. Struct. 2008, 15, 13–16. [Google Scholar]

- Thaulow, N.; Sahu, S. Mechanism of concrete deterioration due to salt crystallization. Mater. Charact. 2004, 53, 123–127. [Google Scholar] [CrossRef]

- Gao, Y.; Zhou, H.; Liu, M.; Ye, L.; Xia, H. Mechanical and thermal properties of chemical vapor infiltration engineered 2D-woven and 3D-braided carbon silicate composites. Ceram. Int. 2015, 41, 10949–10956. [Google Scholar] [CrossRef]

- Yang, W.; Noda, T.; Araki, H.; Yu, J.; Kohyama, A. Mechanical properties of several advanced Tyranno-SA fiber reinforced CVI-SiC matrix composites. Mater. Sci. Eng. A 2003, 345, 28–35. [Google Scholar] [CrossRef]

- Nozawa, T.; Ozawa, K.; Asakura, Y.; Kohyama, A.; Tanigawa, H. Evaluation of damage accumulation behavior and strength anisotropy of NITE SiCf/SiC composites by acoustic emission, digital image correlation and electrical resistivity monitoring. J. Nucl. Mater. 2014, 455, 549–553. [Google Scholar] [CrossRef]

- Gao, Y.; Hu, W.; Xin, S.; Sun, L. A review of applications of CT imaging on fiber reinforced composites. J. Compos. Mater. 2022, 56, 133–164. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, Y.; Yang, X.; Liu, M.; Xia, H.; Huai, P.; Zhou, X. Synchrotron X-ray tomographic characterization of CVI engineered 2D-woven and 3D-braided SiCf/SiC composites. Ceram. Int. 2016, 42, 17137–17147. [Google Scholar] [CrossRef]

- Bale, H.A.; Haboub, A.; MacDowell, A.A.; Nasiatka, J.R.; Parkinson, D.Y.; Cox, B.N.; Marshall, D.B.; Ritchie, R.O. Real-time quantitative imaging of failure events in materials under load at temperatures above 1600 °C. Nat. Mater. 2013, 12, 40–46. [Google Scholar] [CrossRef]

- Li, T.; Fan, D.; Lu, L.; Huang, J.Y.; Zhao, F.; Qi, M.L.; Sun, T.; Fezzaa, K.; Xiao, X.H.; Zhou, X.M.; et al. Dynamic fracture of C/SiC composites under high strain-rate loading: Microstructures and mechanisms. Carbon 2015, 91, 468–478. [Google Scholar] [CrossRef]

- Chateau, C.; Gélébart, L.; Bornert, M.; Crépin, J.; Boller, E.; Sauder, C.; Ludwig, W. In-Situ X-ray microtomography characterization of damage in SiCf/SiC minicomposites. Compos. Sci. Technol. 2011, 71, 916–924. [Google Scholar] [CrossRef]

- Tang, H.; Qi, W.; He, Z.; Xia, H.; Huang, Q.; Zhang, C.; Wang, X.; Song, J.; Huai, P.; Zhou, X. Infiltration of graphite by molten 2LiF–BeF2 salt. J. Mater. Sci. 2017, 52, 11346–11359. [Google Scholar] [CrossRef]

- Rabiei, M.; Palevicius, A.; Monshi, A.; Nasiri, S.; Vilkauskas, A.; Janusas, G. Comparing Methods for Calculating Nano Crystal Size of Natural Hydroxyapatite Using X-Ray Diffraction. Nanomaterials 2020, 10, 1627. [Google Scholar] [CrossRef] [PubMed]

| 2θ (°) As Received | 2θ (°) Salt-Penetrated | FWHM (°) As Received | FWHM (°) Salt-Penetrated |

|---|---|---|---|

| 35.6540 | 36.0019 | 0.2757 | 0.2131 |

| Less than 10 μm | More than 10 μm | |

|---|---|---|

| Proportion of pores before infiltration | 71.36% | 28.64% |

| Proportion of pores after infiltration | 80.17% | 19.83% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Tang, H.; Li, K.; Yan, H. The Effect of Molten Salt Infiltration on 2D SiCf/SiC Composite by Chemical Vapour Infiltration. Materials 2022, 15, 7182. https://doi.org/10.3390/ma15207182

Gao Y, Tang H, Li K, Yan H. The Effect of Molten Salt Infiltration on 2D SiCf/SiC Composite by Chemical Vapour Infiltration. Materials. 2022; 15(20):7182. https://doi.org/10.3390/ma15207182

Chicago/Turabian StyleGao, Yantao, Hui Tang, Ke Li, and Hao Yan. 2022. "The Effect of Molten Salt Infiltration on 2D SiCf/SiC Composite by Chemical Vapour Infiltration" Materials 15, no. 20: 7182. https://doi.org/10.3390/ma15207182

APA StyleGao, Y., Tang, H., Li, K., & Yan, H. (2022). The Effect of Molten Salt Infiltration on 2D SiCf/SiC Composite by Chemical Vapour Infiltration. Materials, 15(20), 7182. https://doi.org/10.3390/ma15207182