Calculation and Analysis of Temperature Damage of Shimantan Concrete Gravity Dam Based on Macro–Meso Model

Abstract

1. Introduction

2. Establishment of Concrete Random Aggregate Model

2.1. Application of Monte Carlo Method

2.2. Fuller Aggregate Gradation Curve

2.3. Walraven Formula

2.4. Determination of the Centroid Coordinates and Radius of Spherical Aggregate Particles

3. Random Aggregate Generation Based on ANSYS

3.1. 2D Random Aggregate Model

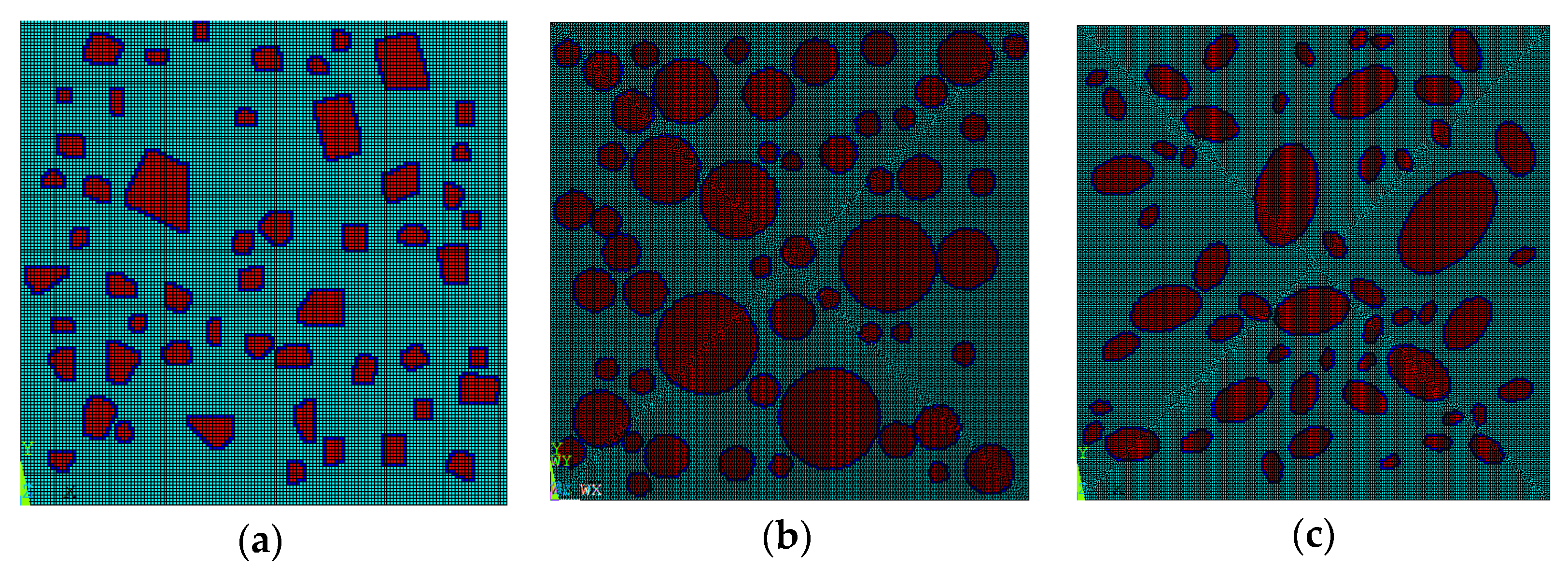

3.1.1. Polygonal Aggregates

- esel,s,cent,x,agv(i,1) − agv(i,3), agv(i,1)+agv(i,3),0.1

- esel,r,cent,y,agv(i,2) − agv(i,3), agv(i,2)+agv(i,3),0.1

- local,11,0,agv(i,1),agv(i,2),0,rand(0,90)

- dsys,11

- esel,r,cent,x,-agv(i,3),agv(i,3),0.1

- mpchg,2,all

- allsel,all

- csdele,all

- nsel,s,ext

- nplot,0

- esln,s,1

- eplot

- mpchg,3,all

3.1.2. Circular Aggregates

- wpave,agv(i,1),agv(i,2)

- cswpla,11,1,1,1

- nsel,s,loc,x,0,agv(i,3),0.1

- esln,s,1

- mpchg,2,all

- allsel,all

- csdele,all

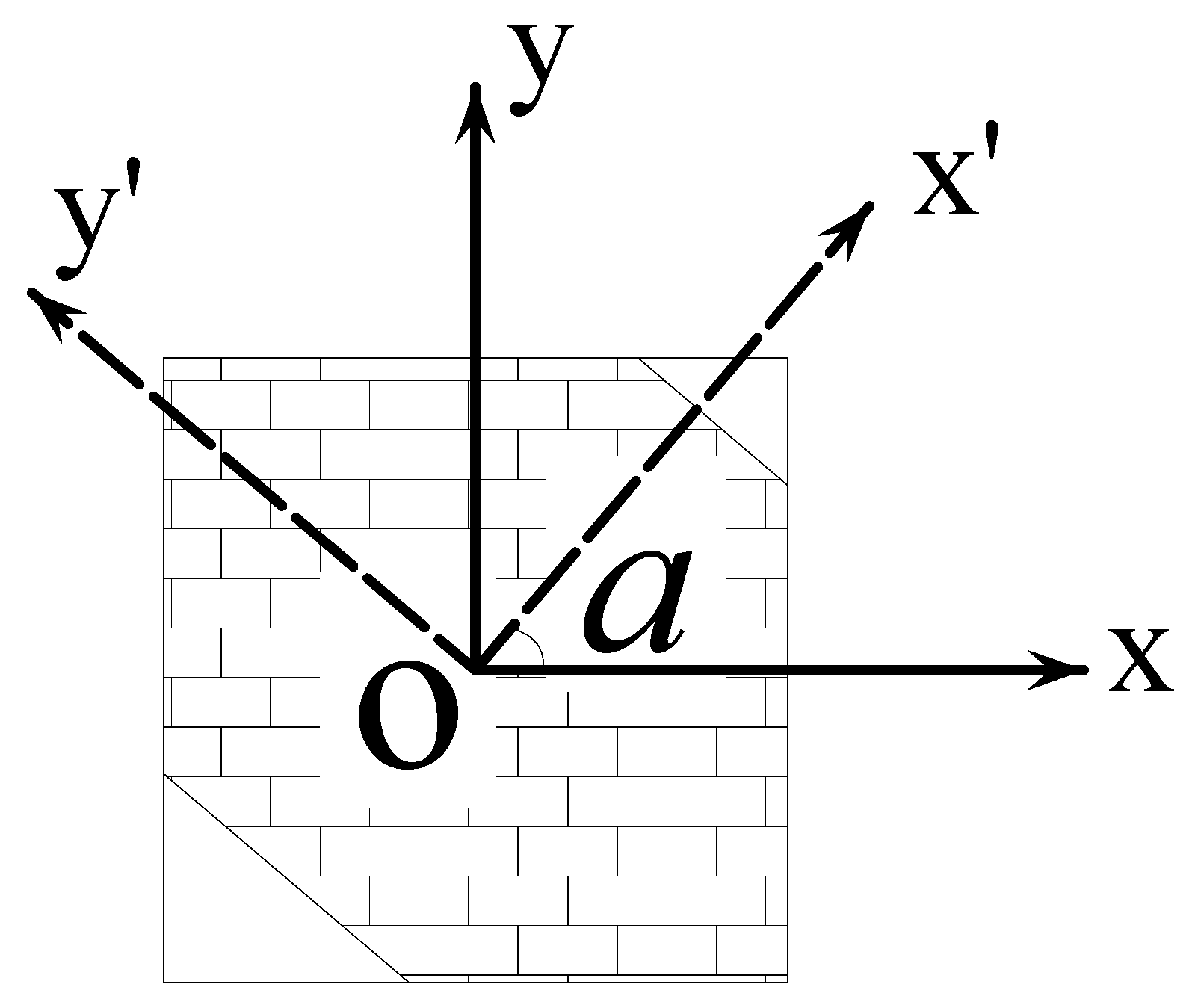

3.1.3. Elliptical Aggregates

- local,11,1,agv(i,1),agv(i,2),0,rand(0,180),,,0.6

- dsys,11

- nsel,s,loc,x,0,agv(i,3),0.1

- esln,s,1

- mpchg,2,all

- allsel,all

- csdele,all

3.1.4. Verification of Aggregate Placement Effect

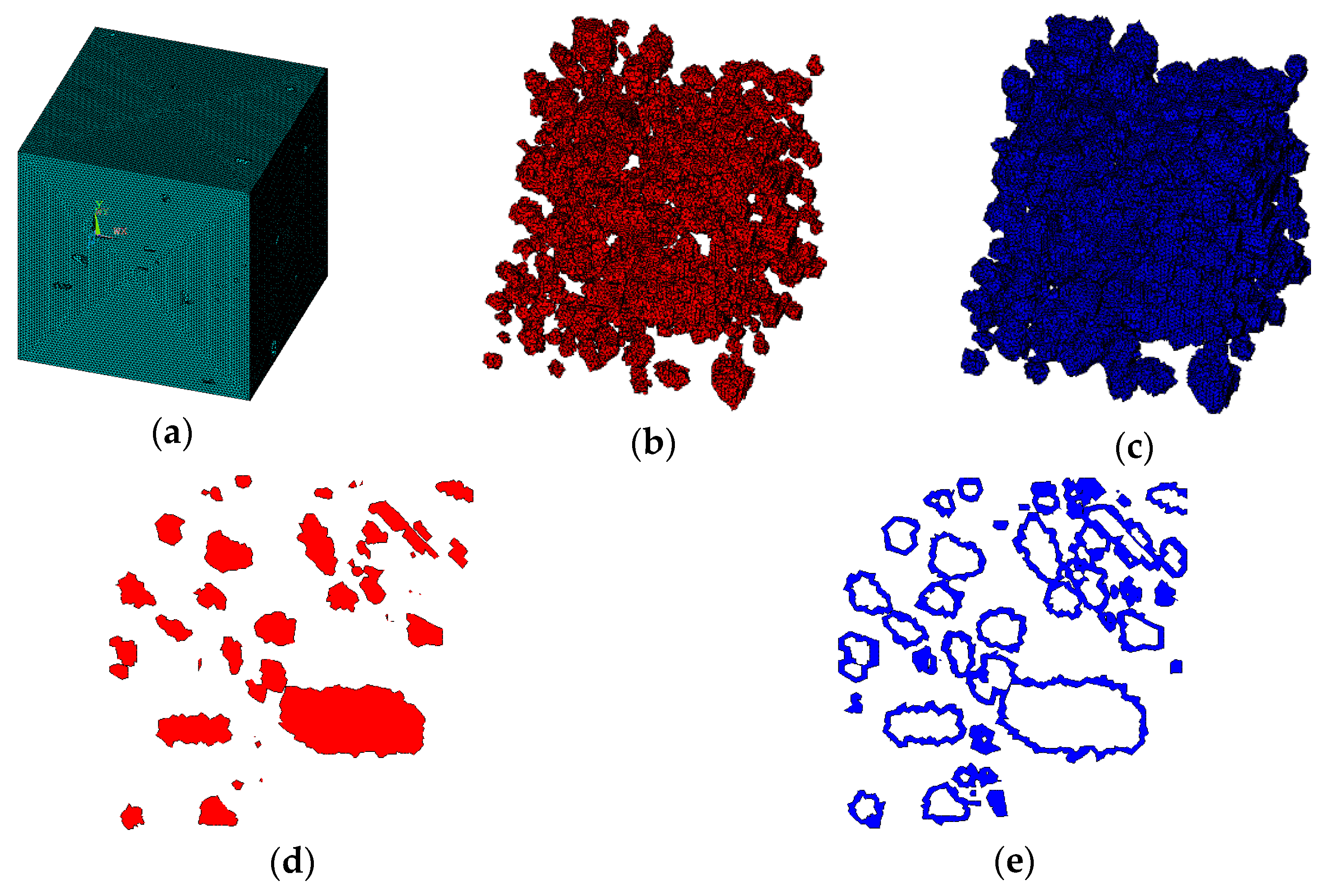

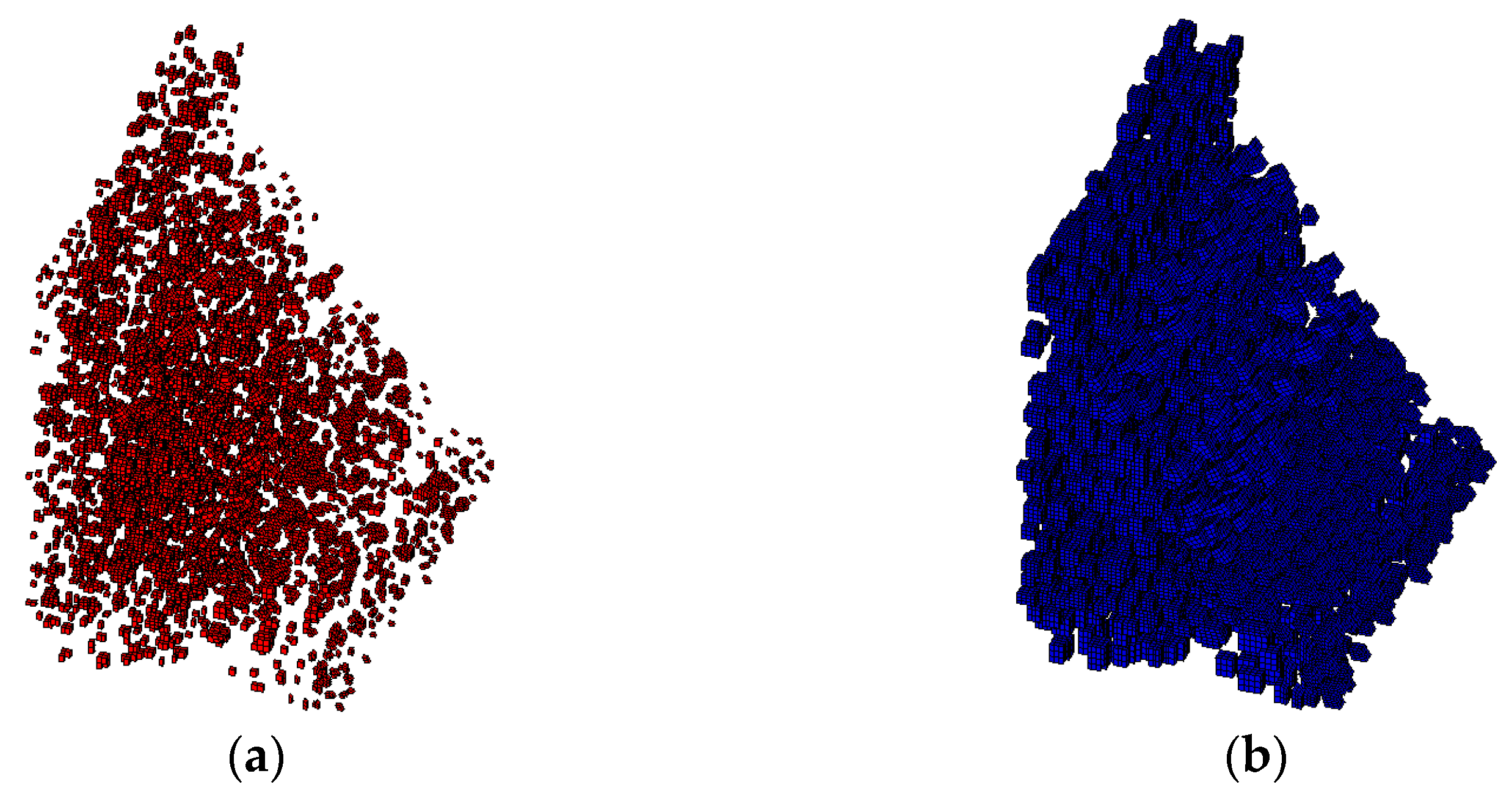

3.2. 3D Random Aggregate Model

- local,11,2,agv(i,1),agv(i,2),agv(i,3),rand(0,180),rand(0,180),rand(0,180),0.6,0.6

4. Material Constitutive Model

- 1.

- When all principal stresses are positive, i.e., tension–tension–tension mode, then can be expressed as follows:

- 2.

- When two principal stresses are positive and one principal stress is negative, i.e., tension–tension–compression mode, it can be seen from Equation (30) that the strain corresponding to the direction of compressive stress must be negative. As mentioned above, the damage in the compression direction is mainly caused by the lateral tensile strain due to the Poisson effect. The damage direction is orthogonal to the compression direction, and the microcrack propagation direction is parallel to the loading direction. Because the lateral deformation caused by the tensile stress is usually compressive deformation, which makes little contribution to the damage in the direction of compressive stress. Therefore, it is assumed that the damage in the direction of compression under the tension-tension-compression state is only related to the tension strain caused by the Poisson effect in the orthogonal direction but not to the strains in the other two directions. In addition, then can be expressed as follows:

- 3.

- When one principal stress is positive and the other two principal stresses are negative, i.e., tension–compression–compression mode, the damage in one compressive direction is mainly caused by the combined action of lateral deformation caused by the Poisson effect in the other two directions. In addition, in this case, the other compressive direction contributes to lateral tensile deformation while the direction of tensile stress contributes to lateral contraction deformation. In this state, the following equation is used to express in this paper:

- 4.

- When all three principal stresses are negative, i.e., compression–compression–compression mode, the damage in one direction is mainly caused by the combined action of lateral deformation caused by the Poisson effect in the other two directions. The other two compressive directions contribute to lateral tensile deformation in this direction. Therefore, in this state, can be expressed as follows:

5. Calculation and Analysis of Temperature Damage of Concrete Gravity Dam

5.1. Project Overview

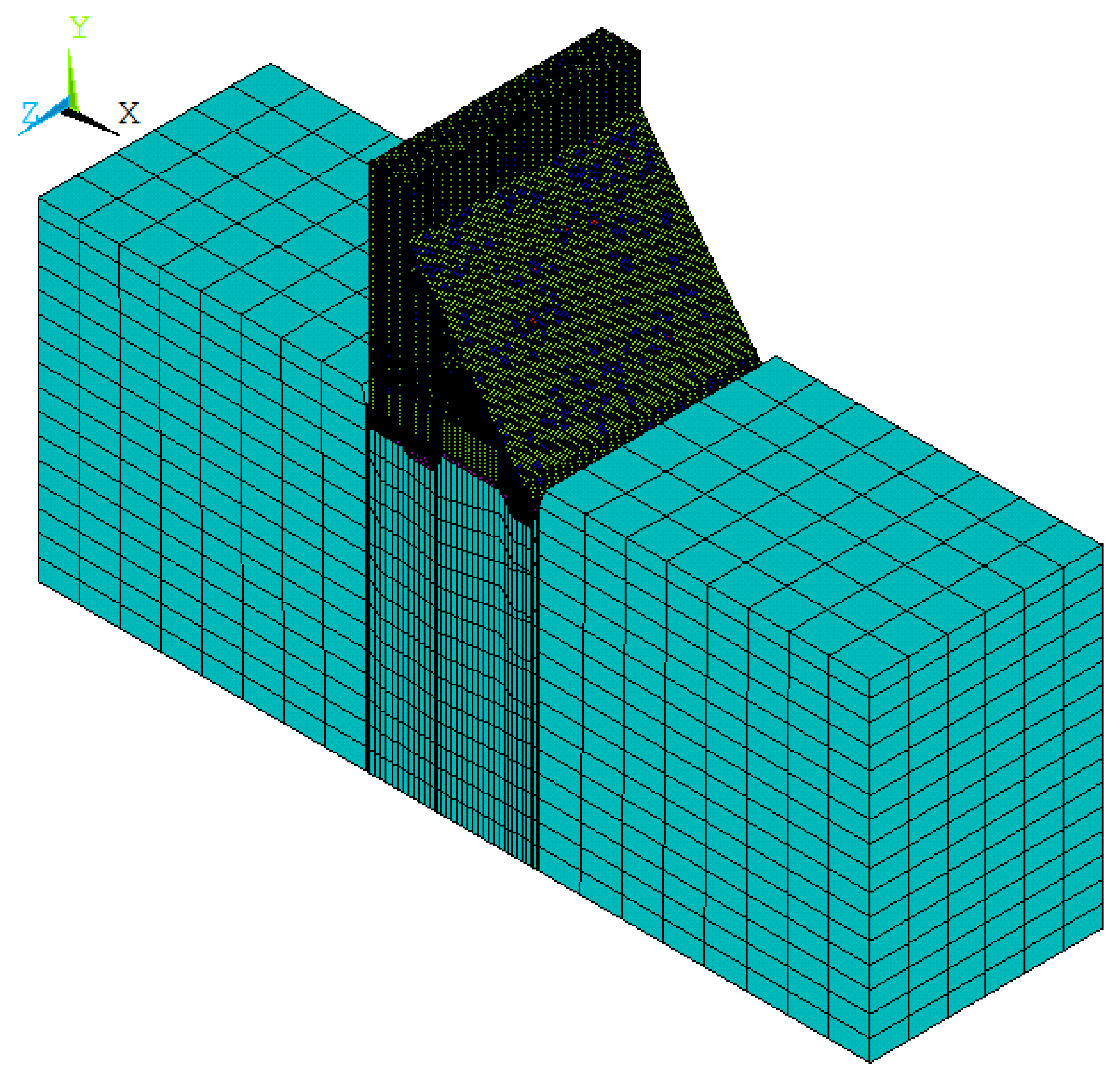

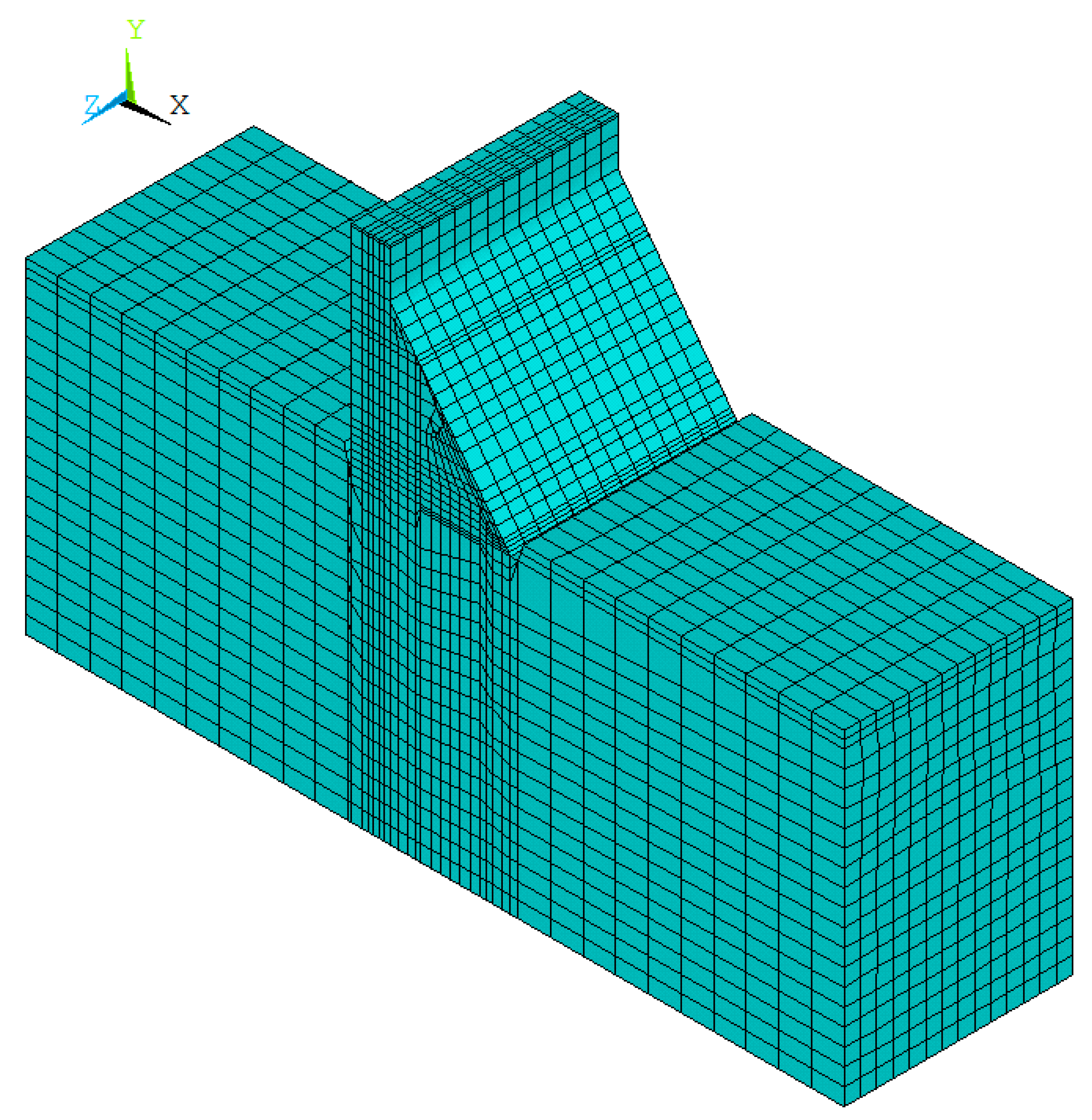

5.2. 3D Finite Element Model

5.3. Boundary Conditions and Calculation Working Conditions

5.4. Calculation Parameters

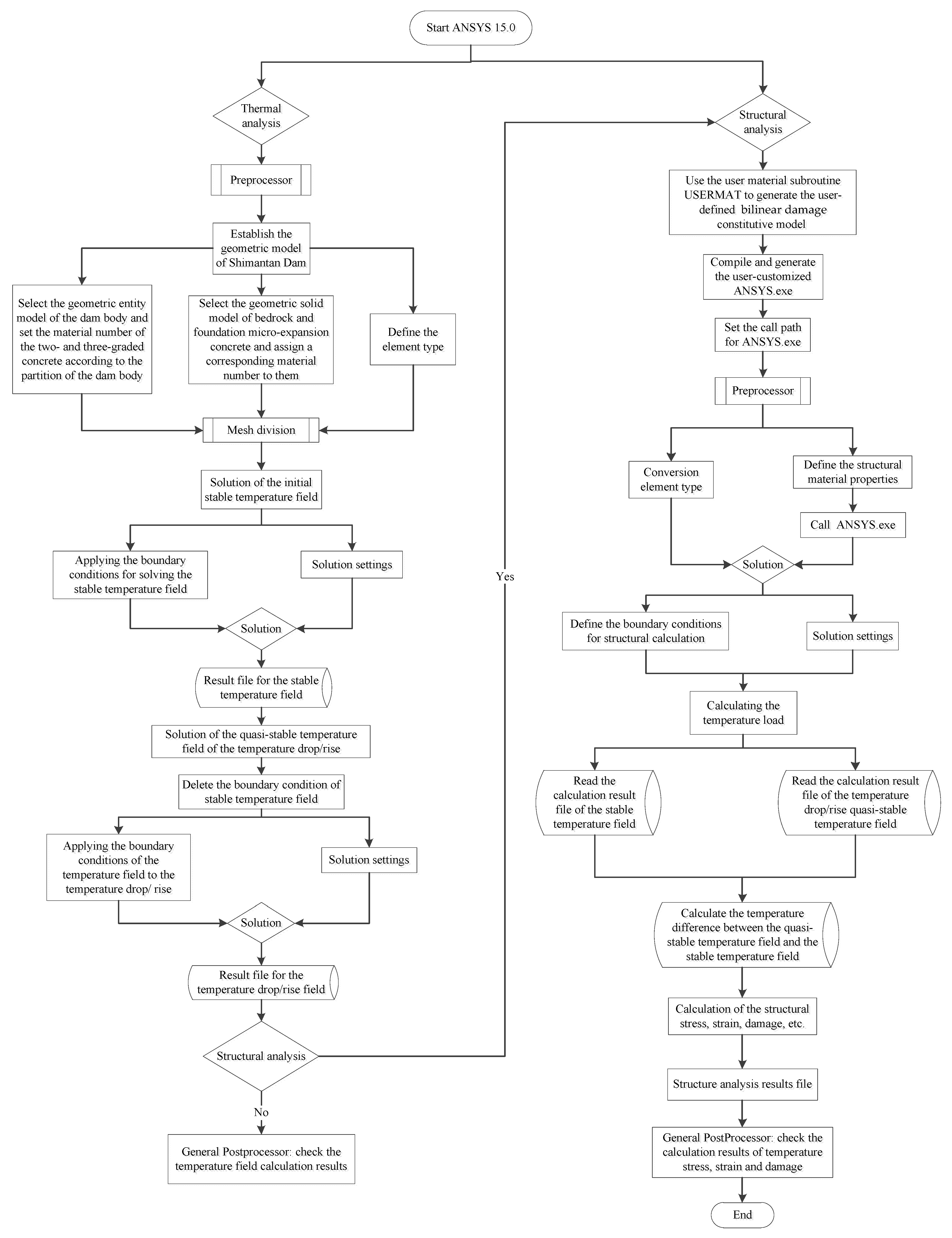

5.5. ANSYS Model Establishment and Solution

5.6. Analysis of Calculation Results

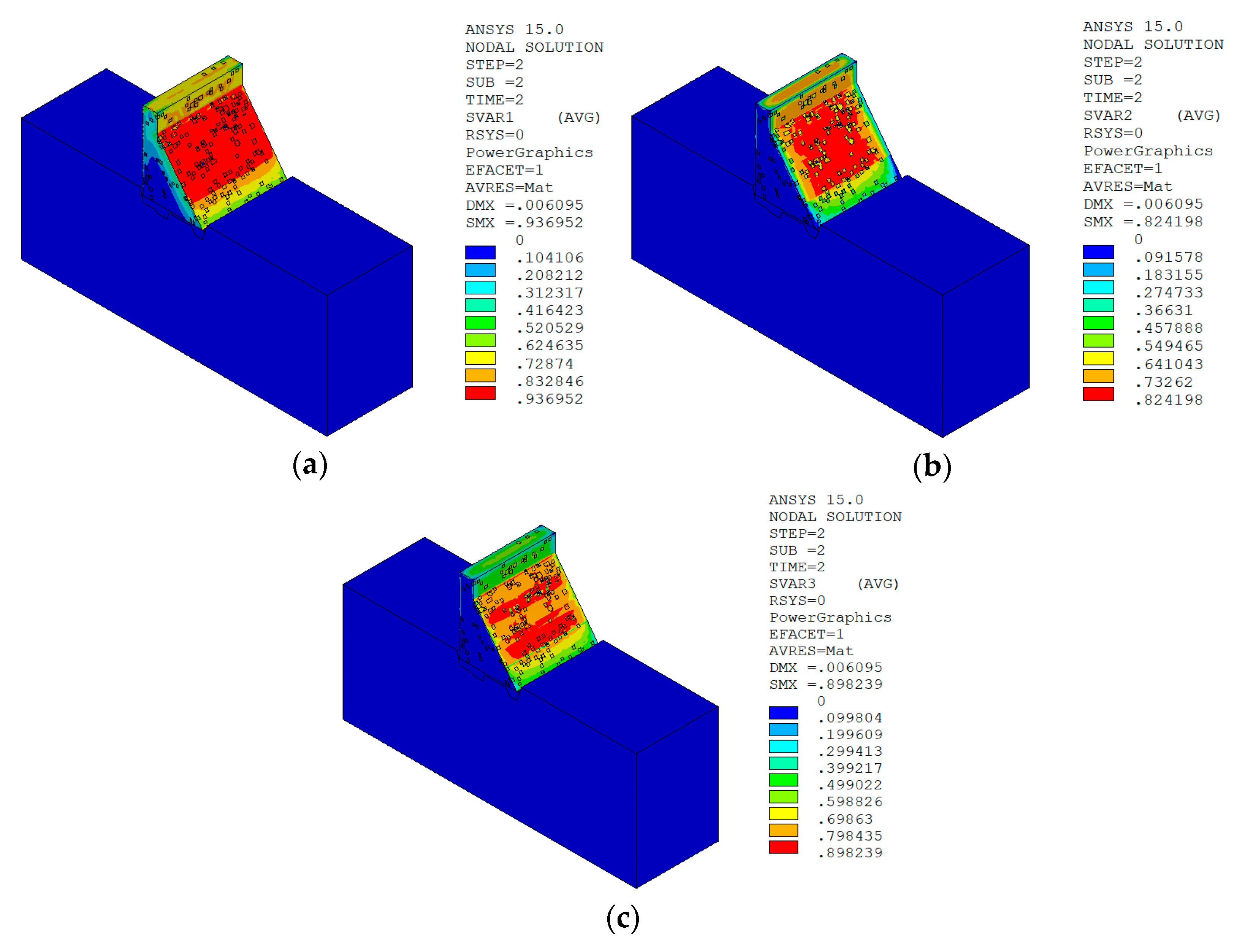

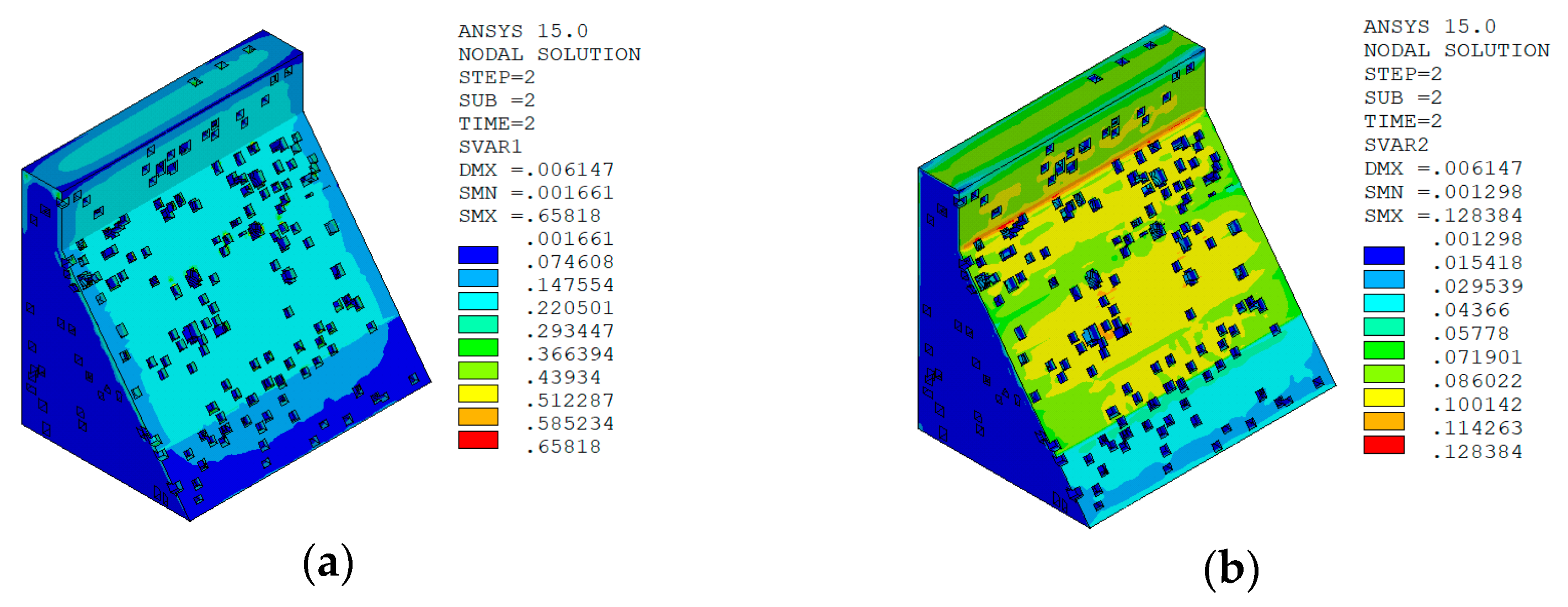

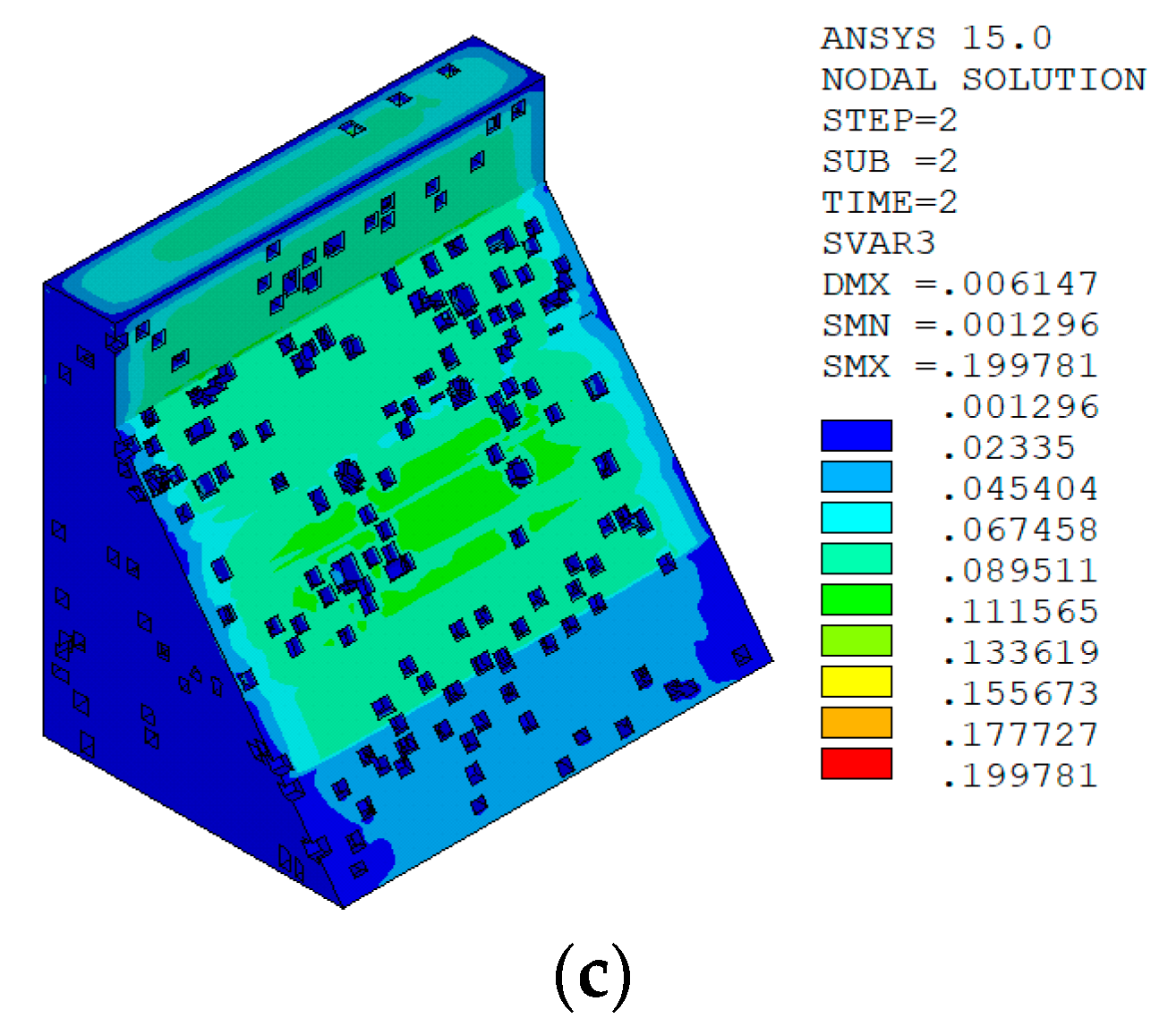

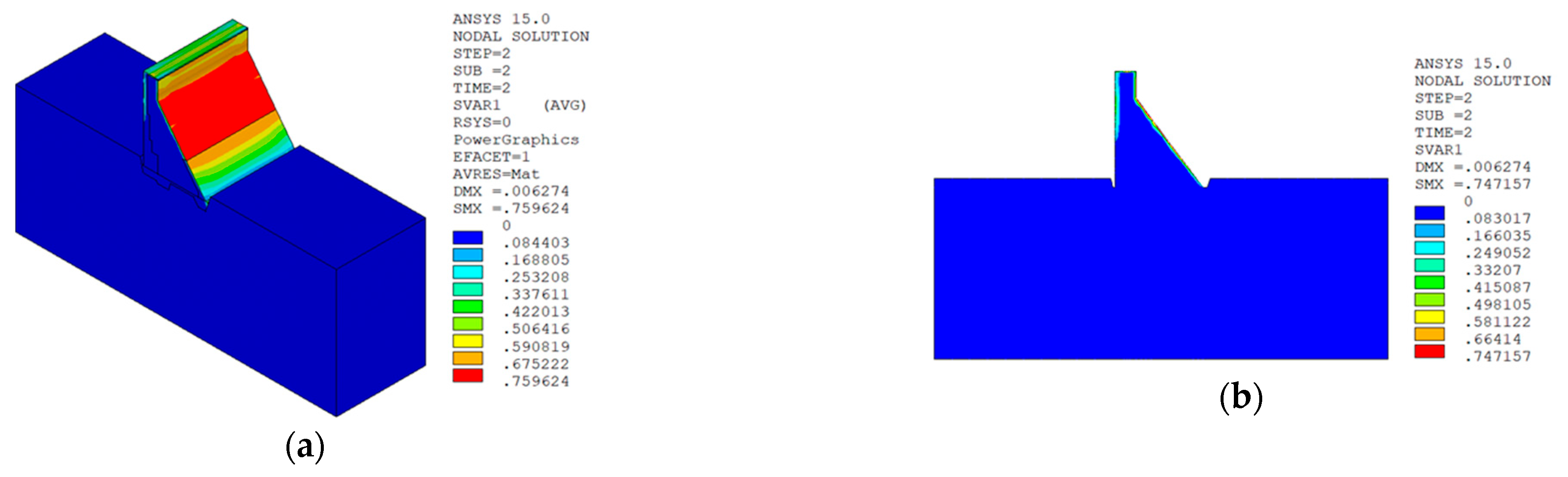

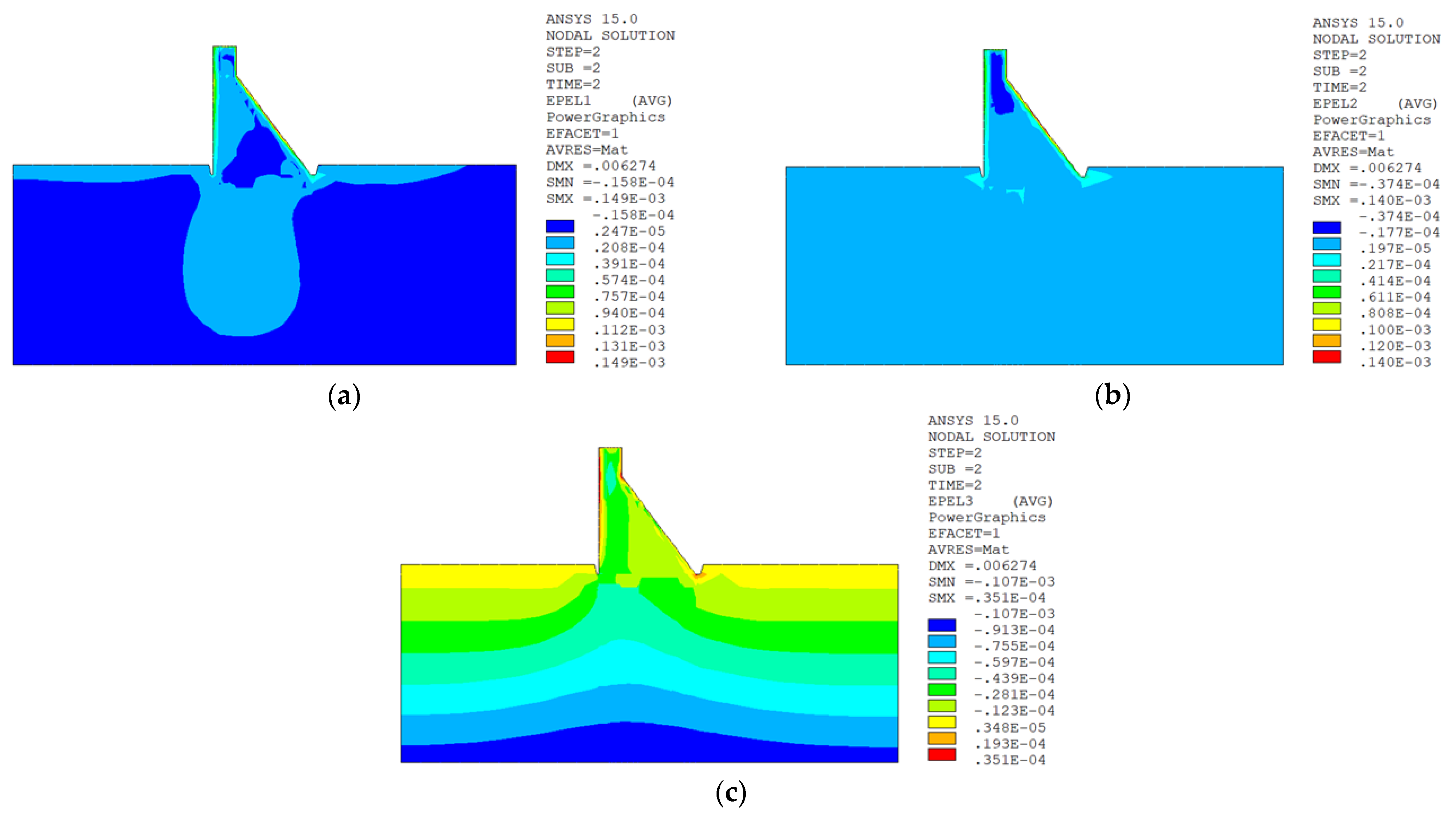

5.6.1. Calculation RESULTS of Macro–Meso Model

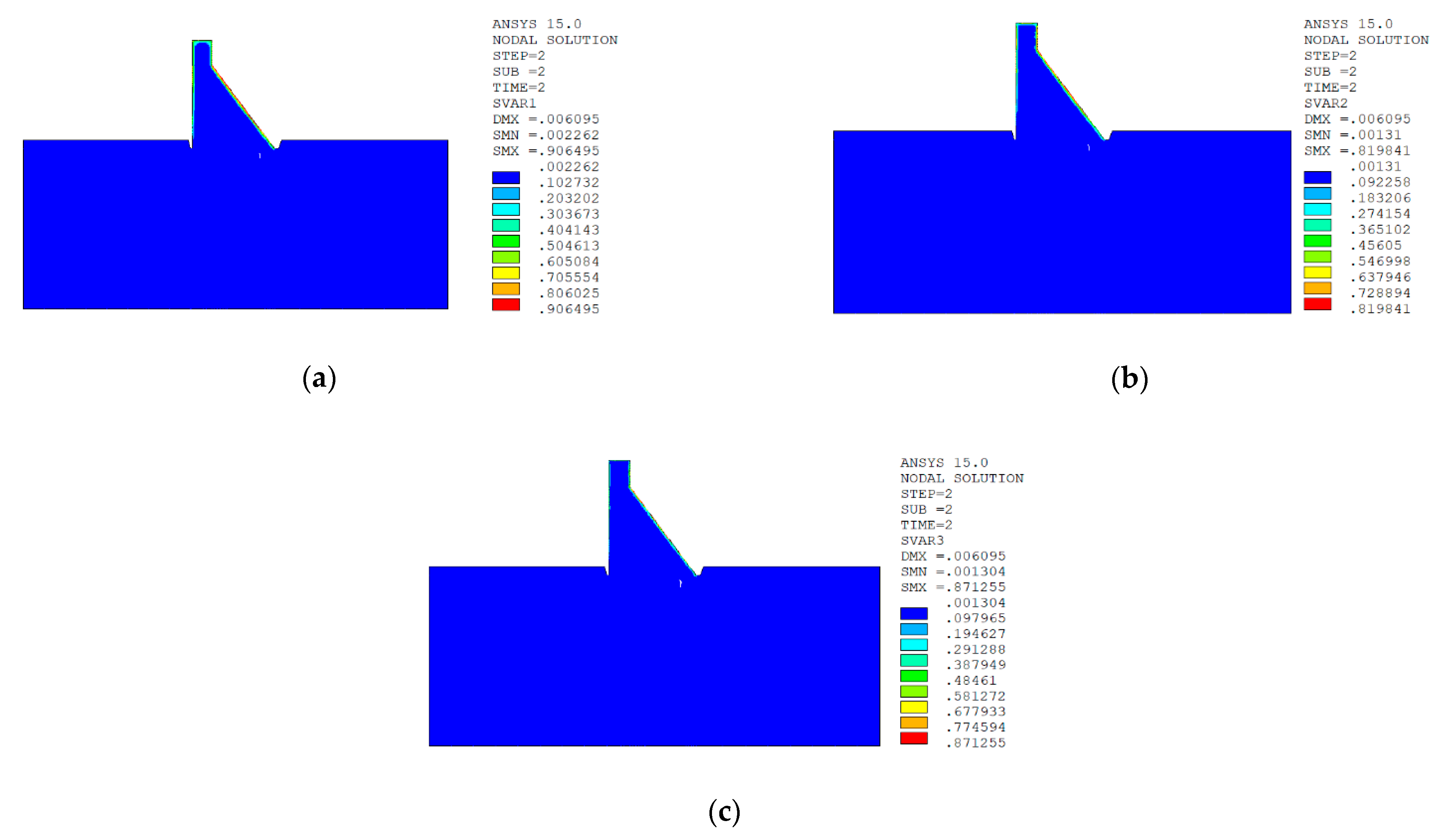

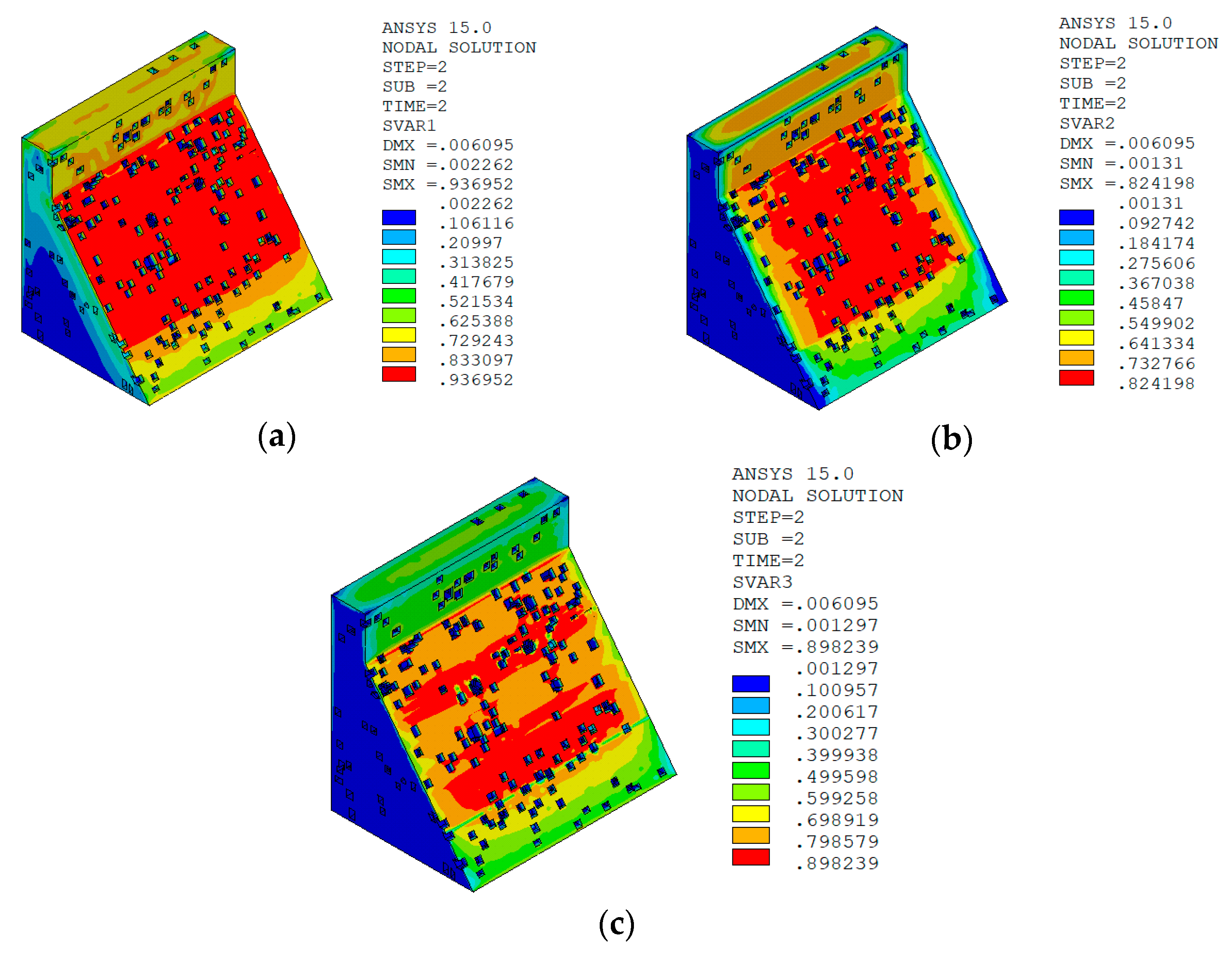

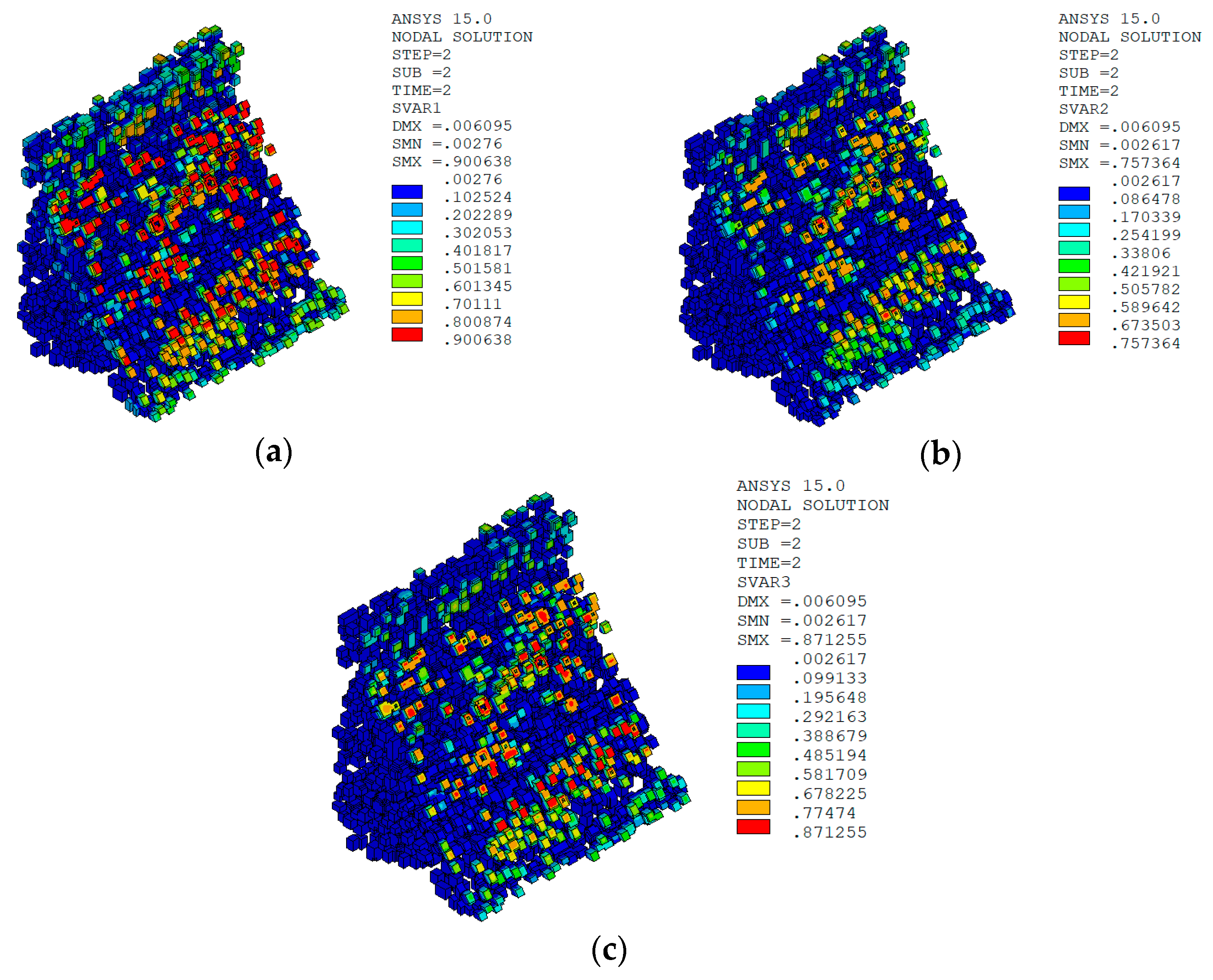

Normal Water Level + Sudden Temperature Drop

Normal Water Level + Sudden Temperature Rise

Result Analysis

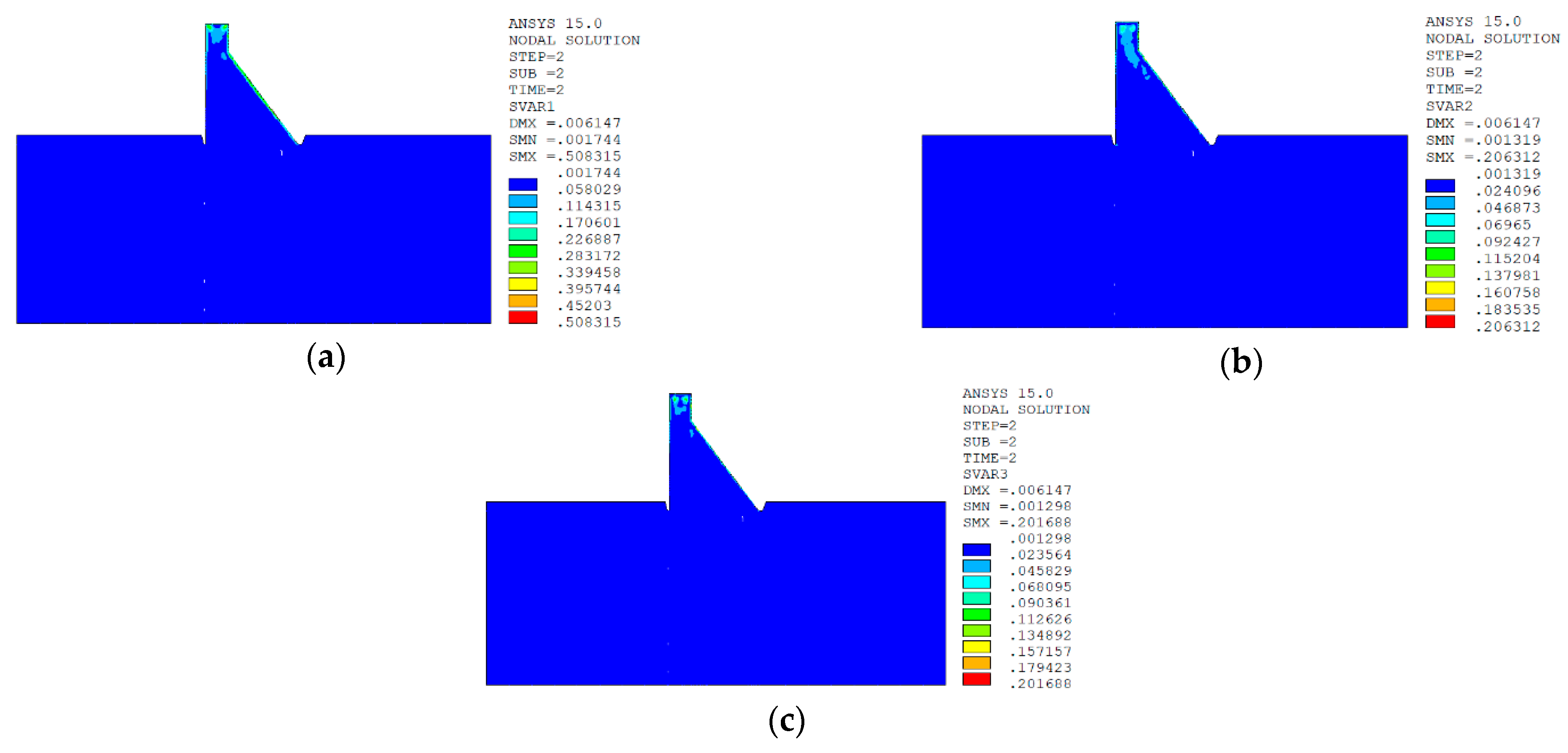

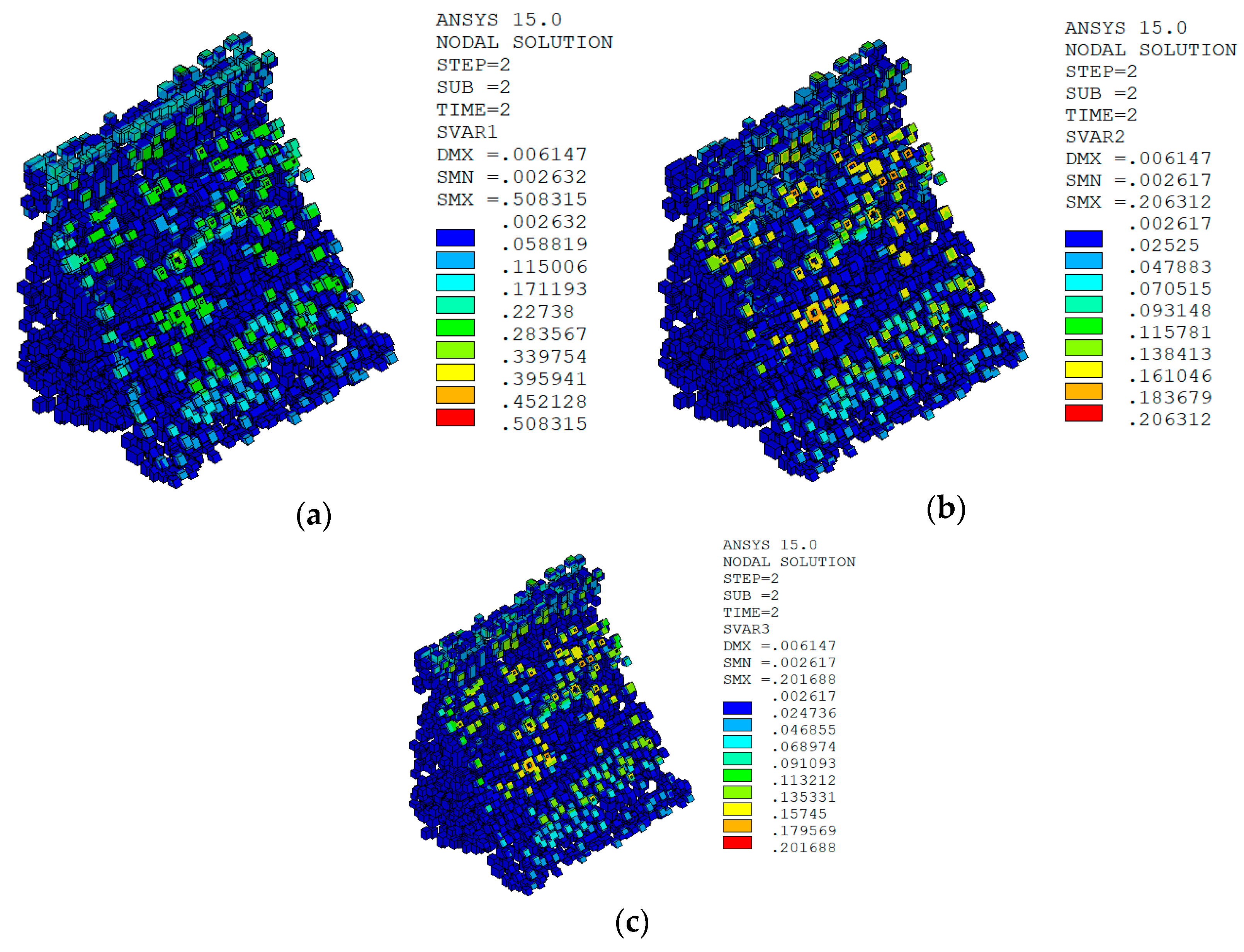

5.6.2. Calculation Results of Macro Model

Normal Water Level + Sudden Temperature Drop

Normal Water Level + Sudden Temperature Rise

Result Analysis

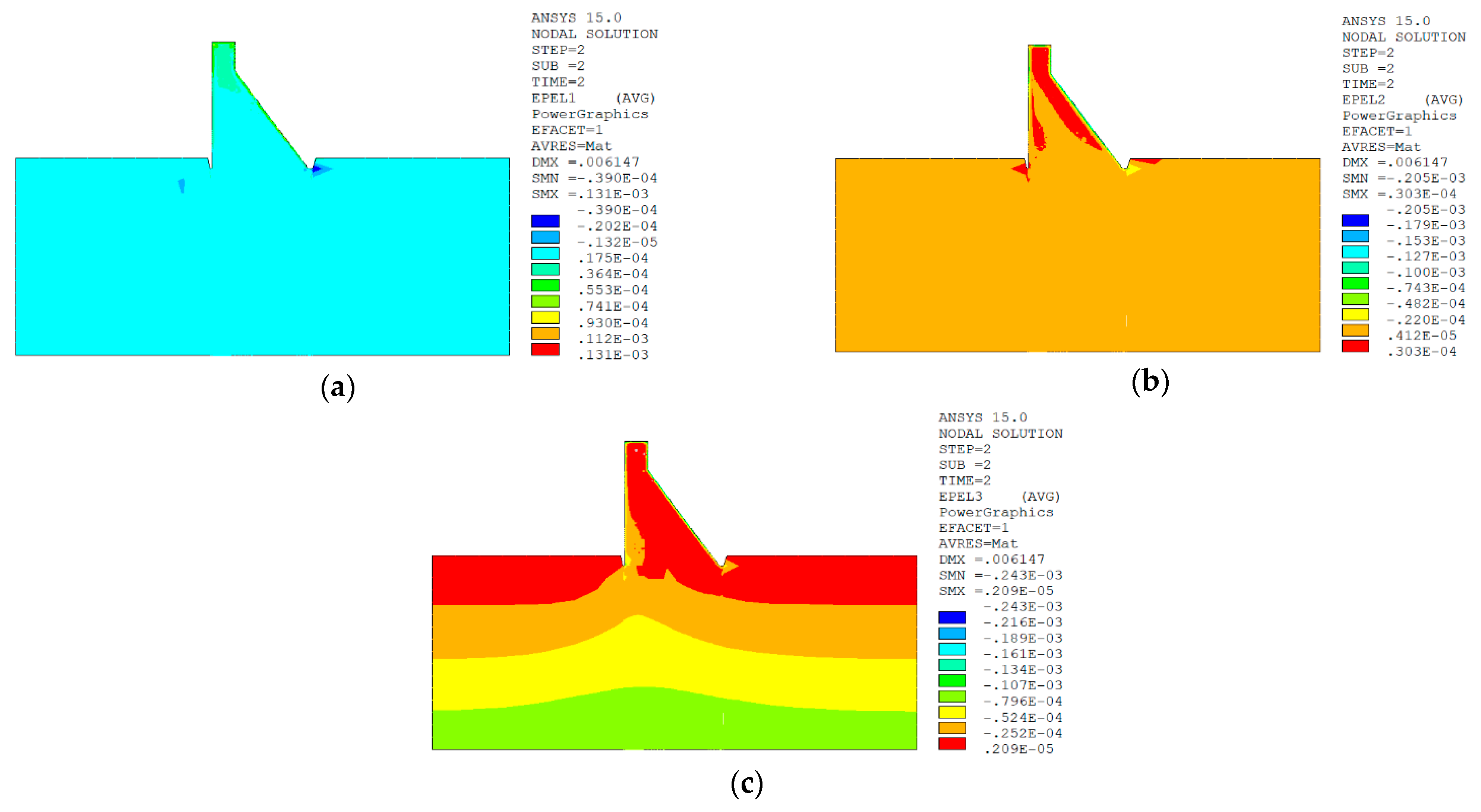

5.6.3. Comparative Analysis of Calculation Results

- Based on the damage calculation results, under the working condition of “normal water storage + sudden temperature drop”, the macro–meso model of the dam is constructed by using the aggregate placement method proposed in this paper, and when combined with the improved anisotropic temperature damage model in this paper, the calculated damage distribution of No. 9 non-overflow dam section of Shimantan dam conforms to the general law of concrete crack distribution on the surface of the dam body under the condition of sudden temperature drop. The damage distribution of the dam body calculated by the macro model combined with the bilinear damage model also conforms to the general law of the crack distribution of the dam surface concrete under the temperature drop condition. However, under the working condition of “normal water storage + sudden temperature rise”, the distribution of temperature damage calculated by the two methods is quite different. The damage distribution area calculated by the macro–meso model combined with the improved anisotropic temperature damage model in this paper is consistent with the distribution area of tensile strain, while the damage area calculated by the macro model combined with the bilinear damage model is quite different from the distribution area of tensile strain, and there is also a certain degree of damage in the compressive strain area. There are two through cracks in the No. 9 dam section of Shimantan dam that penetrate the upstream face, dam crest, and downstream face and are perpendicular to the dam axis. However, the results calculated by the macro model combined with the bilinear damage model indicate that the dam may produce longitudinal joints parallel to the dam axis in the middle of the downstream dam surface, which is not very consistent with the actual crack distribution.

- From the strain calculation results, when the macro model is used and combined with the bilinear damage model, the material partition is mainly completed by giving the corresponding material parameters to different dam blocks and bedrock. Due to the different elastic modulus and thermal conductivity of different materials, the deformation at the interface of different materials will be inconsistent, resulting in excessive strain gradient, Thus, the damage calculation results are inconsistent with the actual situation. When the macro–meso model is used and combined with the improved anisotropic temperature damage model in this paper, the material partition of dam concrete is mainly reflected by changing the aggregate content of the two- and three-graded concrete, while the material parameters are assigned to the aggregate, mortar, and ITZ respectively. Due to the randomness of aggregate distribution, there will be no excessive strain gradient at the interface of two- and three-graded concrete due to the different material properties of the two types of concrete, which will affect the calculation results of damage.

- From the perspective of the causes of the two through cracks in the No. 9 dam section of Shimantan dam, under the working condition of “normal water storage + sudden temperature drop”, large tensile stress and damage are generated on the dam surface calculated by the above two methods. From the perspective of damage, it is judged that the upstream and downstream surfaces of the dam body will produce macro cracks, which is consistent with the traditional strength theory; that is, when the temperature drops suddenly, it will lead to excessive tensile stress in the concrete on the dam surface, which leads to the generation of macroscopic cracks on the surface. Under the working condition of “normal water storage + sudden temperature rise”, small tensile stress and damage are generated in the dam body as calculated by the above two methods. From the perspective of traditional strength theory, since the tensile stress in the dam body does not exceed the tensile strength of concrete, the sudden temperature rise has little effect on the formation of cracks in concrete dams. However, from the perspective of damage mechanics, the formation of macro cracks is the result of the gradual accumulation of damage, and the damage of concrete materials is irreversible. Although the internal damage of the dam body caused by a rapid temperature rise process is small, if the dam experiences multiple sudden temperature rises, the damage inside the dam body may gradually accumulate until the dam forms macro cracks and finally fractures. It can be seen from the meteorological data that although the dam site area of Shimantan Dam belongs to the temperate monsoon climate, weather with rapid cooling in winter and rapid heating in summer often occurs. Based on the above analysis, this paper holds that under the condition that there is no obvious uneven settlement in the dam foundation, the cause of the two through cracks in the No. 9 non-overflow dam section of Shimantan dam is mainly due to the formation of surface macro cracks on the dam surface after the dam experiences a cold wave and rapid cooling, while after the next cold wave, the surface cracks develop towards the inside of the dam. However, the internal micro damage of the dam caused by the sudden temperature rise in summer leads to the deterioration of the performance of concrete materials. Under the intertwined influence of the sudden temperature drop, the internal micro damage continues to develop. After several cold and hot cycles of sudden temperature drops in winter and sudden temperature rises in summer, the internal damage of the dam gradually accumulates until the final formation of macro penetrating cracks.

6. Conclusions

- The 2D circular, polygonal, and elliptical random concrete aggregate models can be quickly generated by using the aggregate placement method proposed in this paper. For 3D problems, spherical, polyhedral, and ellipsoidal random aggregates can be generated in a very short time, which greatly improves the efficiency of random aggregate placement. Moreover, the proposed aggregate placement method can meet the modeling requirements of the 3D meso model of the large-scale concrete structure.

- Compared with the results of the macroscopic finite element model combined with the bilinear damage model, the temperature damage of the No.9 non-overflow dam section of the Shimantan dam calculated by using the macro–meso finite element model and the improved anisotropic temperature damage model is more consistent with the actual distribution of dam cracks, which shows that the proposed macro–meso finite element model and the improved anisotropic temperature damage model are reasonable and feasible. It provides a new way to simulate the temperature damage of mass concrete structures.

- The calculation results of the No. 9 non-overflow dam section of Shimantan dam show that the periodic rapid temperature drop in winter and the rapid temperature rise in summer are the main reasons for the temperature damage and cracks of Shimantan concrete gravity dam during the operation period. In the future dam operation process, permanent thermal insulation measures should be taken for the dam surface, and running water cooling measures can be taken for the dam surface in the high temperature season in summer.

- When assessing the structural safety of concrete dams, one should combine damage mechanics theory or fracture mechanics theory for auxiliary analysis and judgment, rather than relying solely on traditional strength theory to determine whether the dam will fracture under a specific load. When considering the effect of temperature load on the dam, besides the concrete damage on the surface of the dam caused by the sudden temperature drop, the internal damage of the dam caused by the rapid rise in temperature cannot be ignored.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Notation

| fracture constants; | |

| scalar damage variable; | |

| , | damage variables of mortar and ITZ in concrete; |

| , and | sieve size, target particle sizes and maximum aggregate diameter; |

| initial Young’s modulus; | |

| , , | elastic modulus of the aggregate, ITZ and mortar; |

| initial undamaged elastic stiffness matrix; | |

| damaged elastic stiffness matrix; | |

| fracture constants; | |

| , | tensile strength of the ITZ and mortar; |

| , | fracture energy of the ITZ and mortar; |

| second-order identity tensor; | |

| fourth-order damage-effect tensor; | |

| damage-effect matrix in the principal coordinate system of damage; | |

| damage-effect matrix in the global coordinate system; | |

| percentage of aggregate particles that pass through the sieve mesh size d; | |

| percentage of aggregate volume in total volume; | |

| radius of the aggregate particle; | |

| random variables in any interval [a, b]; | |

| random variables in the interval [0, 1]; | |

| coordinate-transformation matrix; | |

| temperature increment; | |

| thermal expansion coefficient of concrete; | |

| , , | thermal expansion coefficient of the aggregate, mortar and ITZ; |

| constraint coefficient; | |

| scalar strain; | |

| strain matrix; | |

| Poisson’s ratio; | |

| , | Poisson’s ratio of the aggregate and mortar; |

| , | scalar nominal and effective stress; |

| , | nominal and effective stress tensors; |

| , | nominal and effective stress matrixes; |

| second-order damage tensor; | |

| , | damage values of mortar and ITZ in the three principal strain directions;and |

| Macauley bracket. |

References

- Daoud, A.; Browning, J.; Meredith, P.G.; Mitchell, T.M. Microstructural Controls on Thermal Crack Damage and the Presence of a Temperature-Memory Effect During Cyclic Thermal Stressing of Rocks. Geophys. Res. Lett. 2020, 47, e2020GL088693. [Google Scholar] [CrossRef]

- Ghallab, A. Simulation of Cracking in High Concrete Gravity Dam Using the Extended Finite Elements by ABAQUS. Am. J. Mech. Appl. 2020, 8, 7–15. [Google Scholar] [CrossRef]

- Fu, Y.; Tan, Y.; Liu, C.; Pei, L.; Song, L. Research on concrete temperature control measures in deep hole area of super high arch dam. IOP Conf. Ser. Earth Environ. Sci. 2021, 826, 012035. [Google Scholar] [CrossRef]

- Sazonova, S.A.; Nikolenko, S.D.; Akamsina, N.V. Consideration of Temperature Stresses in the Calculation of Crack Formation in Concrete Massifs of Buildings. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1079, 032027. [Google Scholar] [CrossRef]

- Yu, H.; Li, S.; Liu, Y.; Chen, C. Study on temperature distribution due to freezing and thawing at the fengman concrete gravity dam. Therm. Sci. 2011, 15, S27–S32. [Google Scholar] [CrossRef]

- Yu, H.; Chen, S.; Jiang, Y.; Jin, S.; Bai, Q. Modelling thermal damage mechanism of dam in extremely frigid area by FEM. Mater. Res. Innov. 2014, 18, 978–981. [Google Scholar] [CrossRef]

- Zhenbo, W.; Yuanfeng, C.; Daoyuan, X.; Yupu, S. Simulating Calculation of Thermal Damage of Concrete Dams. J. China Three Gorges Univ. (Nat. Sci.) 2003, 25, 391–394. [Google Scholar]

- Zheng, S.; Lanfang, X.; Furong, N.; Honglu, X. Study on Temperature Damage of Mass Concrete Structures. Water Resour. Power 2018, 36, 109–112. [Google Scholar]

- Buttignol, T.E.T.; Bitencourt, L.A.G., Jr. A transient creep investigation applied to the mesoscopic analysis of plain concrete under uniaxial compression at high temperature. Fire Saf. J. 2021, 126, 103484. [Google Scholar] [CrossRef]

- Wu, T.; Wriggers, P. Multiscale diffusion-thermal-mechanical cohesive zone model for concrete. Comput. Mech. 2015, 55, 999–1016. [Google Scholar] [CrossRef]

- Zhou, W.; Zhao, C.; Liu, X.; Chang, X.; Feng, C. Mesoscopic simulation of thermo-mechanical behaviors in concrete under frost action. Constr. Build. Mater. 2017, 157, 117–131. [Google Scholar] [CrossRef]

- Chen, T.; Xiao, S. Three-dimensional mesoscale modeling of concrete with convex aggregate based on motion simulation. Constr. Build. Mater. 2021, 277, 122257. [Google Scholar] [CrossRef]

- Naderi, S.; Zhang, M. Meso-scale modelling of static and dynamic tensile fracture of concrete accounting for real-shape aggregates. Cem. Concr. Compos. 2020, 116, 103889. [Google Scholar] [CrossRef]

- Rodrigues, E.A.; Manzoli, O.L.; Bitencourt, L.A. 3D concurrent multiscale model for crack propagation in concrete. Comput. Methods Appl. Mech. Eng. 2020, 361, 112813. [Google Scholar] [CrossRef]

- Thilakarathna, P.S.M.; Baduge, K.S.K.; Mendis, P.; Vimonsatit, V.; Lee, H. Mesoscale modelling of concrete—A review of geometry generation, placing algorithms, constitutive relations and applications. Eng. Fract. Mech. 2020, 231, 106974. [Google Scholar] [CrossRef]

- Zhao, X.; Dong, Q.; Chen, X.; Xiao, Y.; Zheng, D. Fatigue damage numerical simulation of cement-treated base materials by discrete element method. Constr. Build. Mater. 2021, 276, 122142. [Google Scholar] [CrossRef]

- Chen, H.; Xu, B.; Mo, Y.L.; Zhou, T. Behavior of meso-scale heterogeneous concrete under uniaxial tensile and compressive loadings. Constr. Build. Mater. 2018, 178, 418–431. [Google Scholar] [CrossRef]

- Xu, W.; Chen, H.; Lv, Z. A 2D Elliptical Model of Random Packing for Aggregates in Concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2010, 25, 717–720. [Google Scholar] [CrossRef]

- Zhang, N.; Guo, X.; Zhu, B.; Guo, L. A mesoscale model based on Monte-Carlo method for concrete fracture behavior study. Sci. China Technol. Sci. 2012, 55, 3278–3284. [Google Scholar] [CrossRef]

- Su, X.T.; Yang, Z.J.; Liu, G.H. Monte Carlo simulation of complex cohesive fracture in random heterogeneous quasi-brittle materials: A 3D study. Int. J. Solids Struct. 2010, 47, 2336–2345. [Google Scholar] [CrossRef]

- Meng, Q.-X.; Lv, D.; Liu, Y. Mesoscale computational modeling of concrete-like particle-reinforced composites with non-convex aggregates. Comput. Struct. 2020, 240, 106349. [Google Scholar] [CrossRef]

- Ouyang, H.; Chen, X. 3D meso-scale modeling of concrete with a local background grid method. Constr. Build. Mater. 2020, 257, 119382. [Google Scholar] [CrossRef]

- Ma, H.; Wu, Z.; Yu, H.; Zhang, J.; Yue, C. Experimental and three-dimensional mesoscopic investigation of coral aggregate concrete under dynamic splitting-tensile loading. Mater. Struct. 2020, 53, 12. [Google Scholar] [CrossRef]

- Lin, J.; Chen, H.; Zhang, R.; Liu, L. Characterization of the wall effect of concrete via random packing of polydispersed superball-shaped aggregates. Mater. Charact. 2019, 154, 335–343. [Google Scholar] [CrossRef]

- Peng, C.; Feng, J.; Zhou, C.; Decheng, F. Investigation on statistical characteristics of asphalt concrete dynamic moduli with random aggregate distribution model. Constr. Build. Mater. 2017, 148, 723–733. [Google Scholar]

- Ma, H.; Wu, Z.; Zhang, J.; Yu, H.; Liang, L. Uniaxial compressive properties of ecological concrete: Experimental and three-dimensional (3D) mesoscopic investigation. Constr. Build. Mater. 2021, 278, 121034. [Google Scholar] [CrossRef]

- Luo, Q.; Wang, W.; Sun, Z.; Wang, B.; Xu, S. Statistical analysis of mesoscopic concrete with random elastic modulus. J. Build. Eng. 2021, 33, 101850. [Google Scholar] [CrossRef]

- Xu, J.; Zheng, C. Random generation of asphalt mixture mesostructure and thermal-mechanical coupling analysis at low temperature. Constr. Build. Mater. 2021, 280, 122537. [Google Scholar] [CrossRef]

- Kim, S.M.; Abu Al-Rub, R.K. Meso-scale computational modeling of the plastic-damage response of cementitious composites. Cem. Concr. Res. 2011, 41, 339–358. [Google Scholar] [CrossRef]

- Fang, J.; Pan, Y.; Dang, F.; Zhang, X.; Ren, J.; Li, N. Numerical Reconstruction Model and Simulation Study of Concrete Based on Damaged Partition Theory and CT Number. Materials 2019, 12, 4070. [Google Scholar] [CrossRef] [PubMed]

- Bin, F.; Yundong, M. Implementation of Two-dimensional Micro-mechanical Model of Tunnel Concrete Based on ANSYS Parametric Design Language(APDL). J. Libr. Inf. Sci. 2010, 20, 160–162. [Google Scholar]

- Qing, X.; Xiangsen, Z.; Zhicheng, C. Random aggregate model and mesomechanics analysis of concrete based on Ansys. Eng. J. Wuhan Univ. 2019, 52, 1035–1040+1047. [Google Scholar]

- Caifeng, W.; Xueqiang, M. Research on 3D random Aggregate generation method of concrete based on ANSYS. J. Henan Univ. Urban Constr. 2018, 27, 13–18. [Google Scholar]

- Ruiqi, G.; Yingxiong, X.; Xiangqiong, T. A fast hybrid realization method for three-dimensional concrete aggregate models. J. Civ. Environ. Eng. 2017, 39, 100–107. [Google Scholar]

- Zhenbo, W. Study of Damage for Concrete under Temperature; Hohai University: Nanjing, China, 2001. [Google Scholar]

- Lemaitre, J.L.; Chanboche, J.L. A Nonlinear Model of Creep-Fatigue Damage Cumulation and Interaction. In Proceedings of the TUTAM Symposium of Mechanics of Visco-Elasticity Media and Bodies, Gothenburg, Sweden, 2–6 September 1974; Springer: Berlin/Heidelberg, Germany, 1974. [Google Scholar]

- Grassl, P.; Jirásek, M. Plastic model with non-local damage applied to concrete. Int. J. Numer. Anal. Methods Geomech. 2006, 30, 71–90. [Google Scholar] [CrossRef]

- Cicekli, U.; Voyiadjis, G.Z.; Abu Al-Rub, R.K. A plasticity and anisotropic damage model for plain concrete. Int. J. Plast. 2007, 23, 1874–1900. [Google Scholar] [CrossRef]

- Jiao, Y.T.; Wang, B.; Shen, Z.Z. A New 3D Empirical Plastic and Damage Model for Simulating the Failure of Concrete Structure. Int. J. Concr. Struct. Mater. 2019, 13, 57. [Google Scholar] [CrossRef]

- Dabiri, H.; Kaviani, A.; Kheyroddin, A. Influence of reinforcement on the performance of non-seismically detailed RC beam-column joints. J. Build. Eng. 2020, 31, 101333. [Google Scholar] [CrossRef]

- Behnam, H.; Kuang, J.S.; Samali, B. Parametric finite element analysis of RC wide beam-column connections. Comput. Struct. 2018, 205, 28–44. [Google Scholar] [CrossRef]

- Zhuo, Z.; Zhanli, L.; Binbin, C.; Jianhui, L. Extended Finite Element Method; Tsinghua University Press: Beijing, China, 2012. [Google Scholar]

- Jianmei, C. Geometry-Dependent of R-Curve, Construction of Three Parameter Concrete R-Curve and Its Application; Dalian University of Technology: Dalian, China, 2020. [Google Scholar]

- Murakami, S. Continuum Damage Mechanics: A Continuum Mechanics Approach to the Analysis of Damage and Fracture; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Cordebois, J.P.; Sidoroff, F. Damage Induced Elastic Anisotropy; Springer: Dordrecht, The Netherlands, 1982. [Google Scholar]

- Carol, I.; Rizzi, E.; Willam, K. On the formulation of anisotropic elastic degradation. I. Theory based on a pseudo-logarithmic damage tensor rate. Int. J. Solids Struct. 2001, 38, 491–518. [Google Scholar] [CrossRef]

- Mozaffari, N.; Voyiadjis, G.Z. Phase field based nonlocal anisotropic damage mechanics model. Phys. D Nonlinear Phenom. 2015, 308, 11–25. [Google Scholar] [CrossRef]

- Pröchtel, P.; Häußler-Combe, U. On the dissipative zone in anisotropic damage models for concrete. Int. J. Solids Struct. 2008, 45, 4384–4406. [Google Scholar] [CrossRef][Green Version]

- Zhu, Y.; Cescotto, S. A fully coupled elasto-visco-plastic damage theory for anisotropic materials. Int. J. Solids Struct. 1995, 32, 1607–1641. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, Y.; Jin, Y. Effects of symmetrisation of net-stress tensor in anisotropic damage models. Int. J. Fract. 2001, 109, 345–363. [Google Scholar]

- Zhaoxiong, G. Temperature Control and Crack Prevention of Hydraulic Concrete; China Water&Power Press: Beijing, China, 1999. [Google Scholar]

- Bai, W.; Li, W.; Guan, J.; Wang, J.; Yuan, C. Research on the Mechanical Properties of Recycled Aggregate Concrete under Uniaxial Compression Based on the Statistical Damage Model. Materials 2020, 13, 3765. [Google Scholar] [CrossRef]

- Zili, Y.; Fuheng, M.; Yantao, J. Analysis of Temperature Effects of Shimantan RCC Gravity Dam. South-North Water Transf. Water Sci. Technol. 2013, 11, 61–69. [Google Scholar]

- Baant, Z.P.; Oh, B.H. Crack Band Theory for Fracture of Concrete. Mater. Struct. 1983, 16, 155–177. [Google Scholar] [CrossRef]

- Xinwei, T.; Yuande, Z.; Chuhan, Z. Concrete dam seismic analysis based on mesoscale damage mechanics. J. Hydroelectr. Eng. 2013, 32, 195–200+251. [Google Scholar]

- Longbang, Q.; Thirst, Y.; Dongqiang, X. Numerical analysis of macro-meso fractures in concrete gravity dams using extended finite element method. J. Hydroelectr. Eng. 2017, 36, 94–102. [Google Scholar]

- Jicheng, Q.; Jianfang, Z. Two Concrete Damage Models and Their Application. J. Hohai Univ. (Nat. Sci.) 1989, 3, 40–47. [Google Scholar]

- Fuheng, M.; Zhenzhong, S.; Zili, Y. Analysis Report on Prototype Observation Data of Shimantan Reservoir Dam in Henan Province; Nanjing Hydraulic Research Institute: Nanjing, China, 2012. [Google Scholar]

- Konglong, L. Meso-Numerical Simulation and Study on Size Effect of Compressive Strength of Recycled Concrete; Harbin Institute of Technology: Harbin, China, 2021. [Google Scholar]

- Xiaofang, L. Numerical Study on Fracture Damage of Steel Fiber Reinforced Concrete Based on Extended Finite Element Method; Zhengzhou University: Zhengzhou, China, 2019. [Google Scholar]

- Fangchao, S.; Jie, W.; Yanfen, H. Calculation and analysis of temperature damage of SMT gravity dam. Water Resour. Plan. Des. 2021, 12, 122–128+155. [Google Scholar]

| d0/mm | 40 | 20 | 5 |

|---|---|---|---|

| d0/dmax | 1 | 0.5 | 0.125 |

| Pc | 0.645 | 0.487 | 0.230 |

| Aggregate Radius/mm | 15 | 6.25 |

|---|---|---|

| Single aggregate area/mm2 | 706.5 | 122.66 |

| A/Ai | 31.85 | 183.43 |

| Parameter | Sign | Unit | Material | ||

|---|---|---|---|---|---|

| Mortar | Aggregate | ITZ | |||

| Density | Kg/m3 | 2151 | 2700 | 2360 | |

| Young’s Modulus | E | GPa | 21 | 60 | 20 |

| Poisson’s ratio | ν | - | 0.22 | 0.167 | 0.21 |

| Thermal Conductivity | λ | kJ/(m▪day▪°C) | 121 | 242 | 184 |

| Heat Capacity | c | kJ/(m▪°C) | 0.94 | 0.77 | 0.91 |

| Thermal Expansion Coefficient | α | 10−6/°C | 10 | 7 | 13 |

| Tension Strength | f | MPa | 1.66 | - | 1.02 |

| Fracture Energy | G | N/mm2 | 143 | - | 109.2 |

| Parameter | Sign | Unit | Material | |

|---|---|---|---|---|

| Bedrock | Micro-Expansion Concrete | |||

| Density | Kg/m3 | 2540 | 2400 | |

| Young’s Modulus | E | GPa | 13 | 25.5 |

| Poisson’s ratio | ν | - | 0.23 | 0.167 |

| Thermal Conductivity | λ | kJ/(m▪day▪°C) | 164.88 | 187.92 |

| Heat Capacity | c | kJ/(m▪°C) | 0.77 | 0.87 |

| Thermal Expansion Coefficient | α | 10−6/°C | 8 | 9 |

| Parameter | Sign | Unit | Material | |||

|---|---|---|---|---|---|---|

| Bedrock | Micro-Expansion Concrete | Two-Graded Concrete | Three-Graded Concrete | |||

| Density | Kg/m3 | 2540 | 2400 | 2351 | 2360 | |

| Young’s Modulus | E | GPa | 13 | 25.5 | 25.5 | 22 |

| Poisson’s ratio | ν | - | 0.23 | 0.167 | 0.167 | 0.167 |

| Thermal Conductivity | λ | kJ/(m▪day▪°C) | 164.88 | 187.92 | 184 | 184 |

| Heat Capacity | c | kJ/(m▪°C) | 0.77 | 0.87 | 0.94 | 0.94 |

| Thermal Expansion Coefficient | α | 10−6/°C | 7 | 8 | 5.8 | 6.7 |

| Tensile damage threshold strain | εtf | - | 1.2 × 10−4 | 6.84 × 10−5 | 6.84 × 10−5 | 6.18 × 10−5 |

| Tensile damage limit strain | εtu | - | 1.2 × 10−3 | 6.84 × 10−4 | 6.84 × 10−4 | 6.18 × 10−4 |

| Compressive damage threshold strain | εcf | - | 1.64 × 10−3 | 1.23× 10−3 | 1.23 × 10−3 | 1.16 × 10−3 |

| Compressive damage limit strain | εcu | - | 1.64 × 10−2 | 1.23 × 10−2 | 1.23 × 10−2 | 1.16 × 10−2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, Y.; Cheng, L.; Wang, N.; Wang, S.; Ma, L. Calculation and Analysis of Temperature Damage of Shimantan Concrete Gravity Dam Based on Macro–Meso Model. Materials 2022, 15, 7138. https://doi.org/10.3390/ma15207138

Jiao Y, Cheng L, Wang N, Wang S, Ma L. Calculation and Analysis of Temperature Damage of Shimantan Concrete Gravity Dam Based on Macro–Meso Model. Materials. 2022; 15(20):7138. https://doi.org/10.3390/ma15207138

Chicago/Turabian StyleJiao, Yantao, Liping Cheng, Ning Wang, Sizhe Wang, and Luyao Ma. 2022. "Calculation and Analysis of Temperature Damage of Shimantan Concrete Gravity Dam Based on Macro–Meso Model" Materials 15, no. 20: 7138. https://doi.org/10.3390/ma15207138

APA StyleJiao, Y., Cheng, L., Wang, N., Wang, S., & Ma, L. (2022). Calculation and Analysis of Temperature Damage of Shimantan Concrete Gravity Dam Based on Macro–Meso Model. Materials, 15(20), 7138. https://doi.org/10.3390/ma15207138