Tensile Strain Capacity Prediction Model of an X80 Pipeline with Improper Transitioning and Undermatched Girth Weld

Abstract

:1. Introduction

2. Characteristics and Properties of the Girth Weld

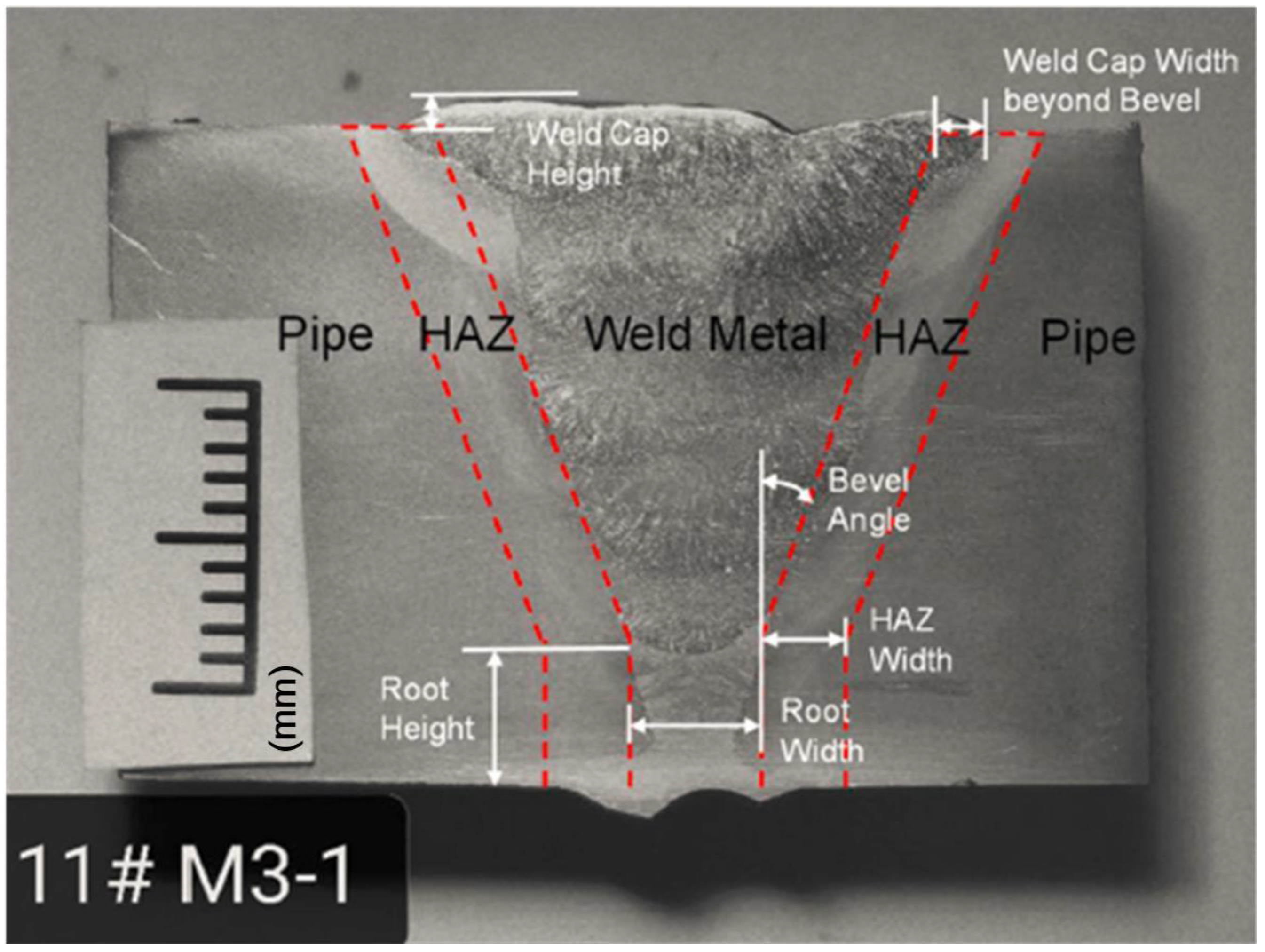

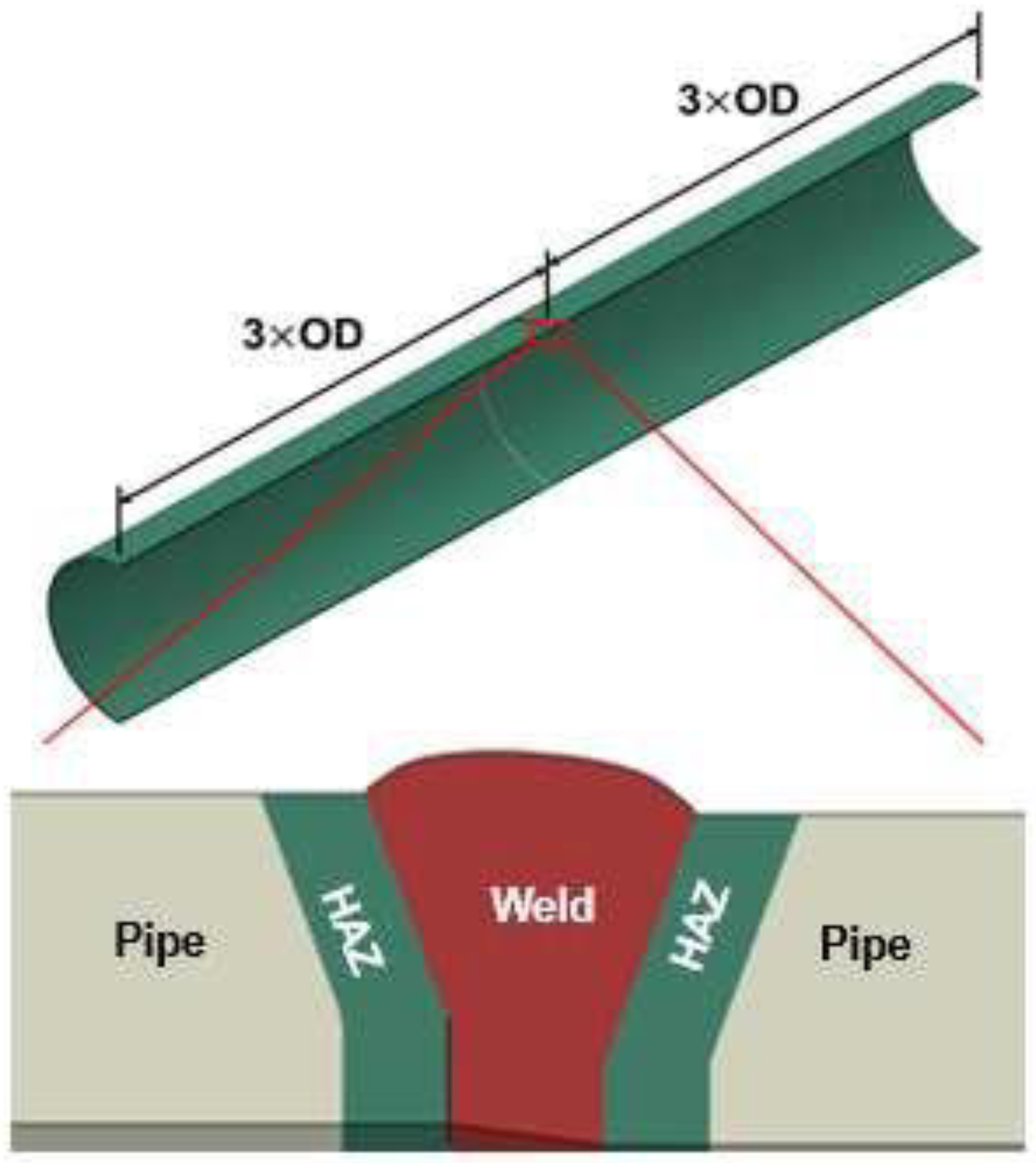

2.1. Girth Weld Profile and Material Zones

2.2. Material Properties in FEA Models

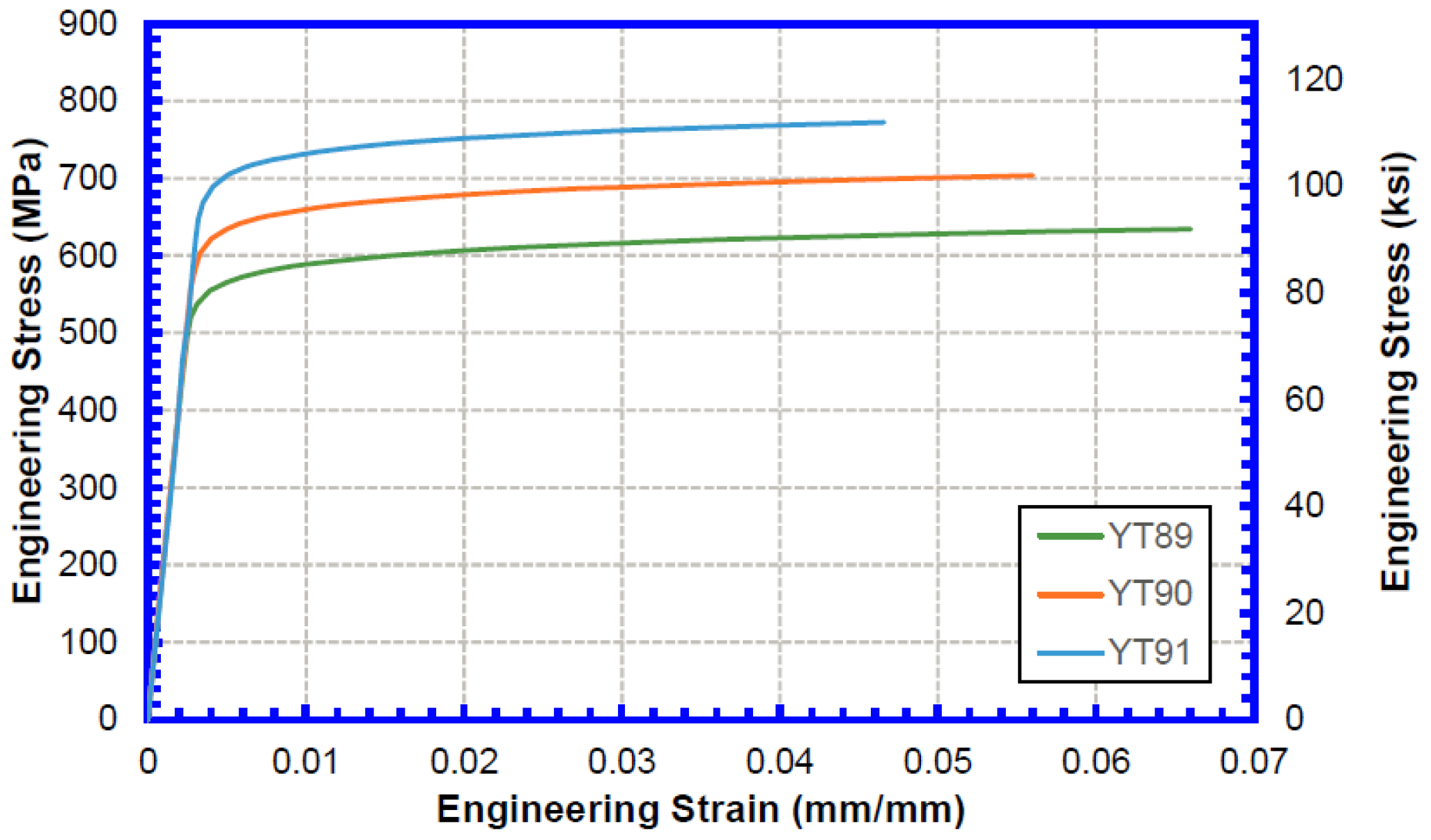

2.2.1. Linepipe Properties

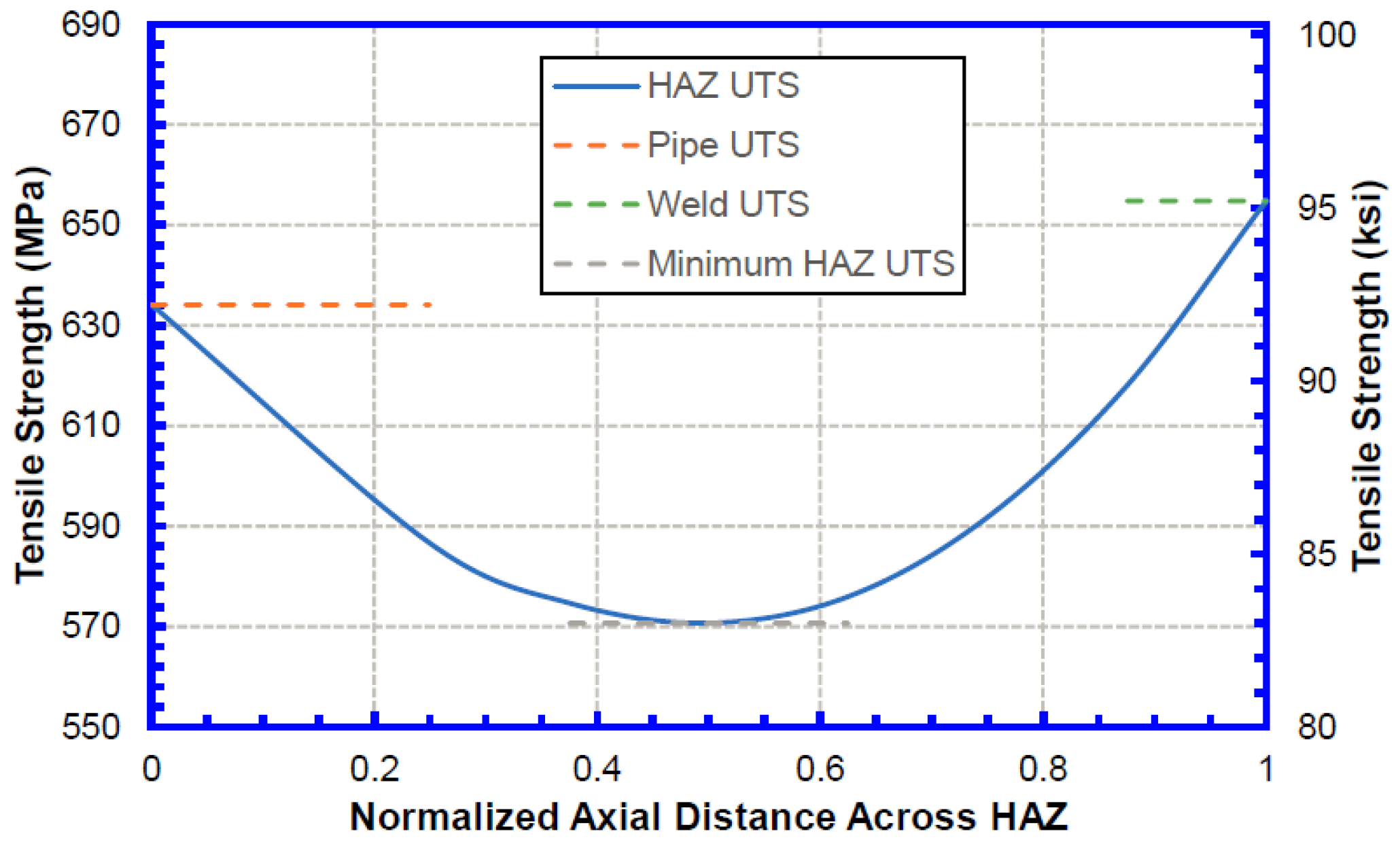

2.2.2. Heat-Affected Zone Properties

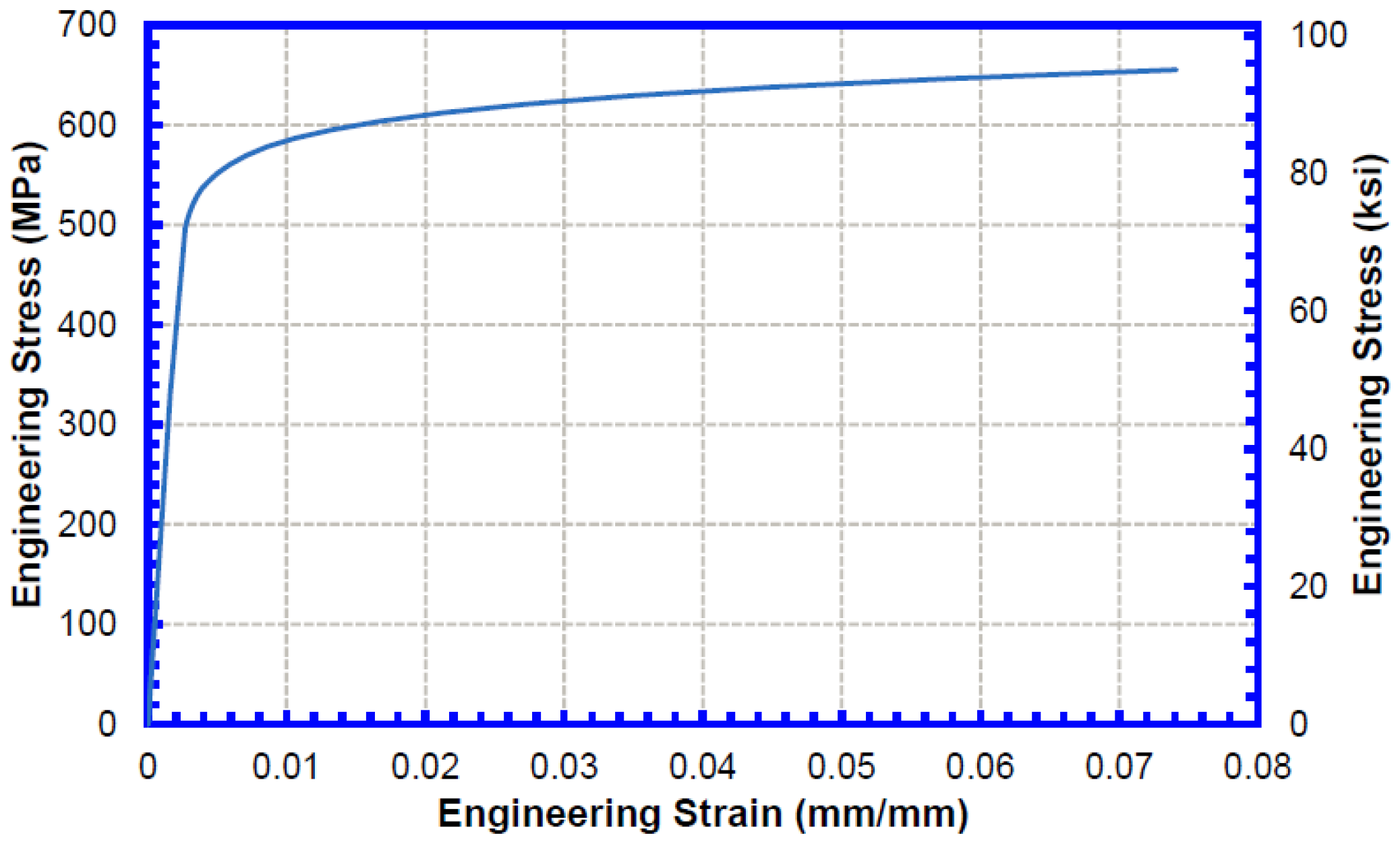

2.2.3. Deposited Weld Metal Properties

3. TSC Analysis

3.1. Summary of Conditions Analyzed

3.2. Finite Element Models

3.3. Analysis Procedure

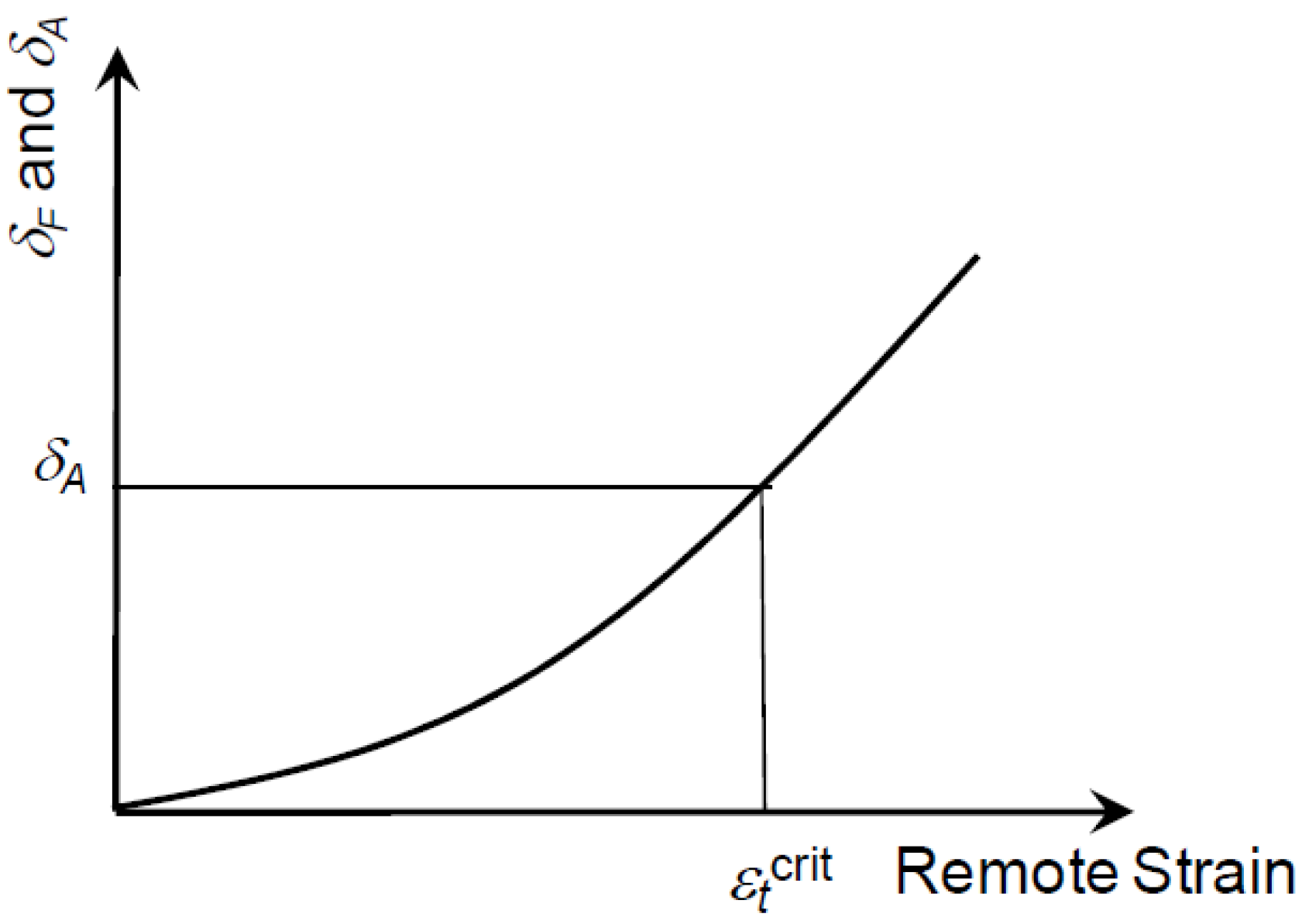

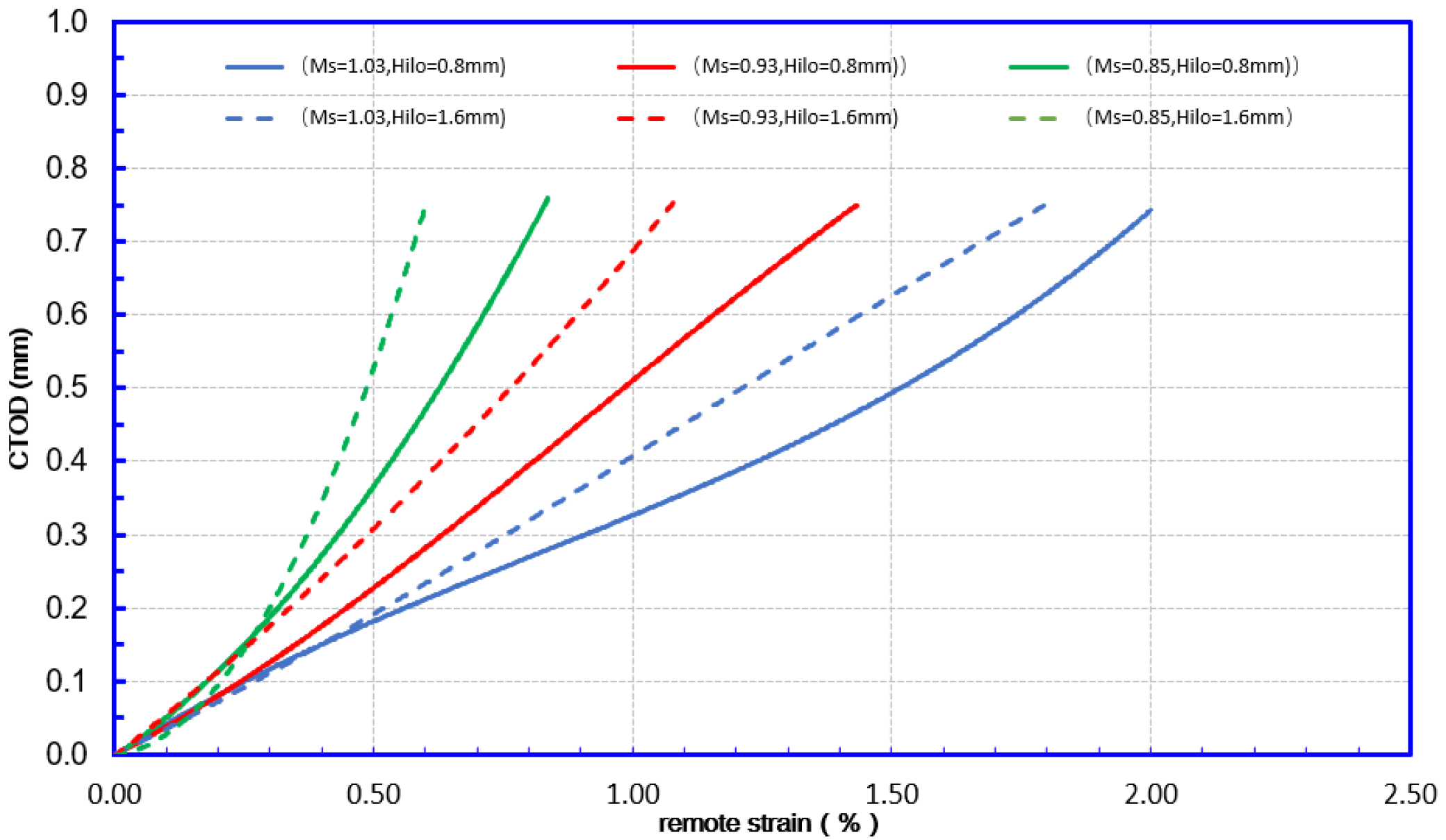

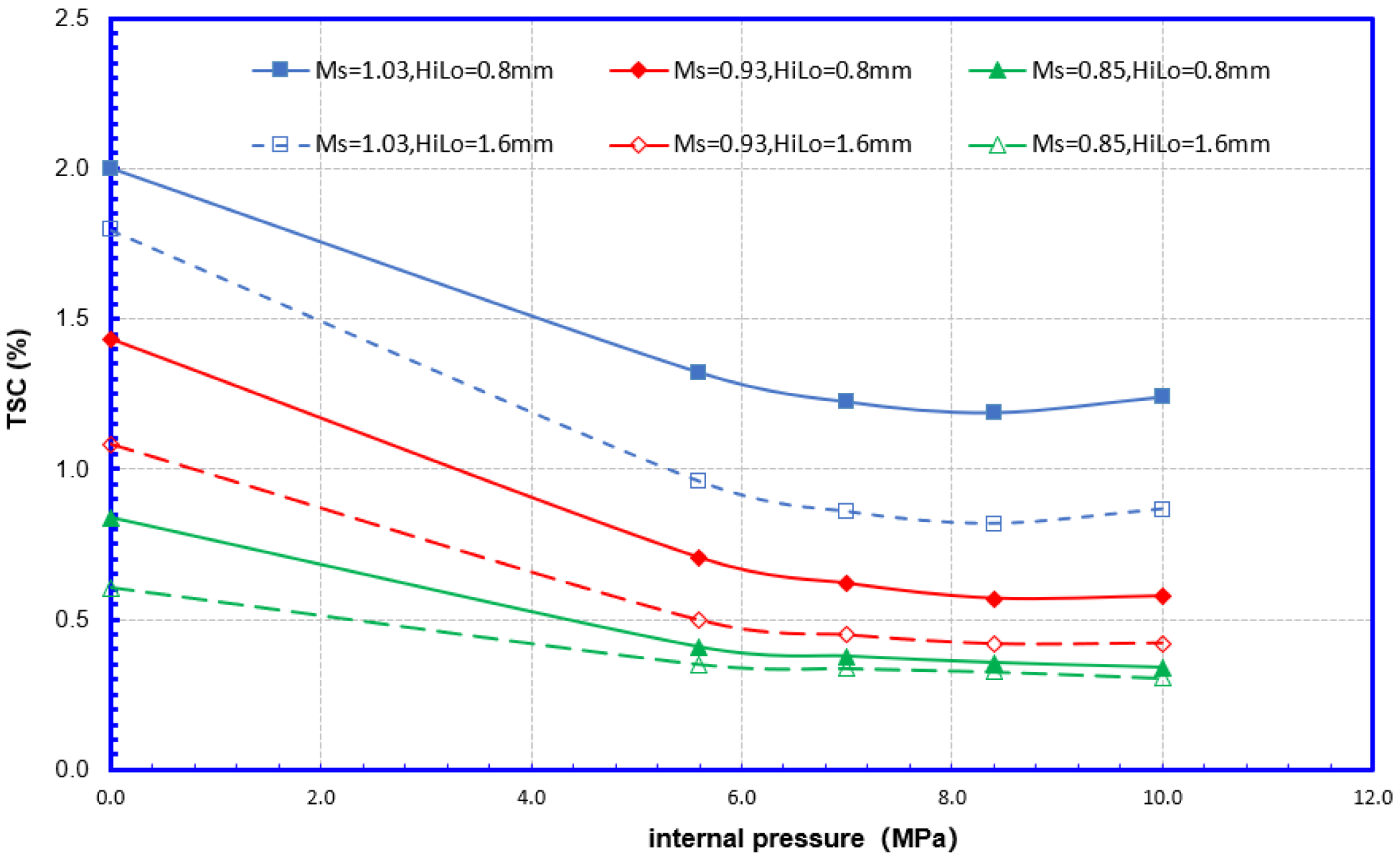

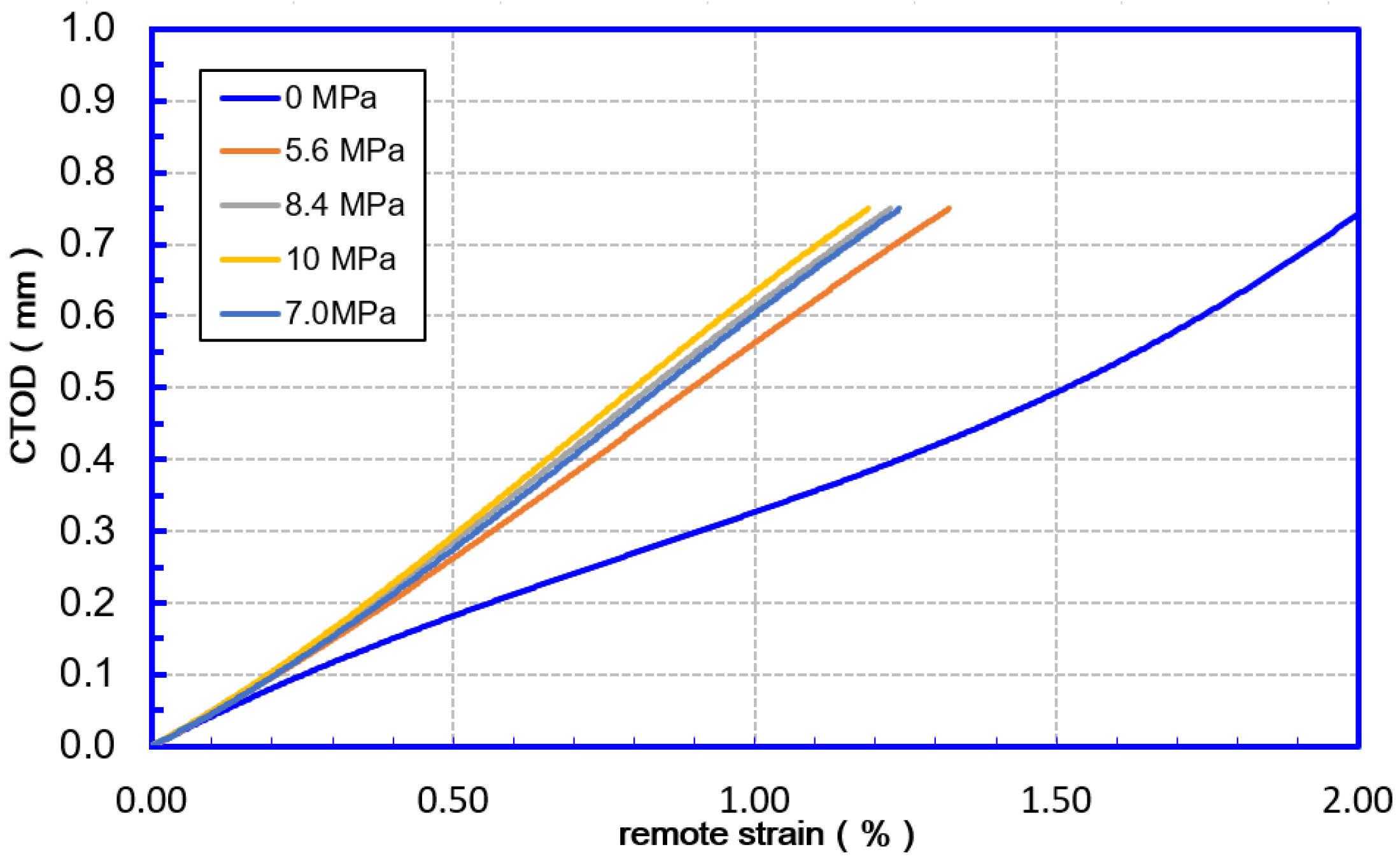

3.4. Summary of TSC under the Assessed Conditions

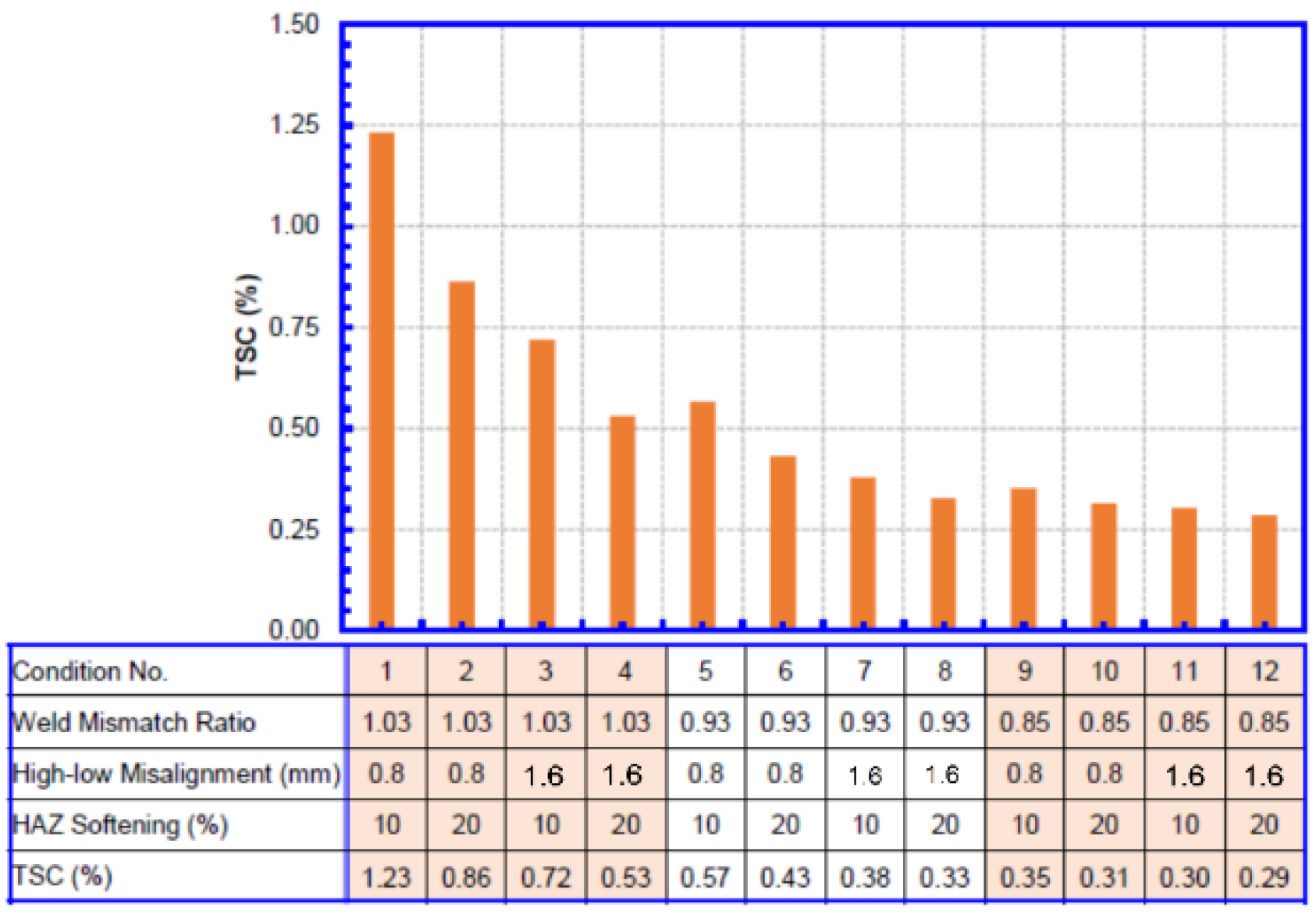

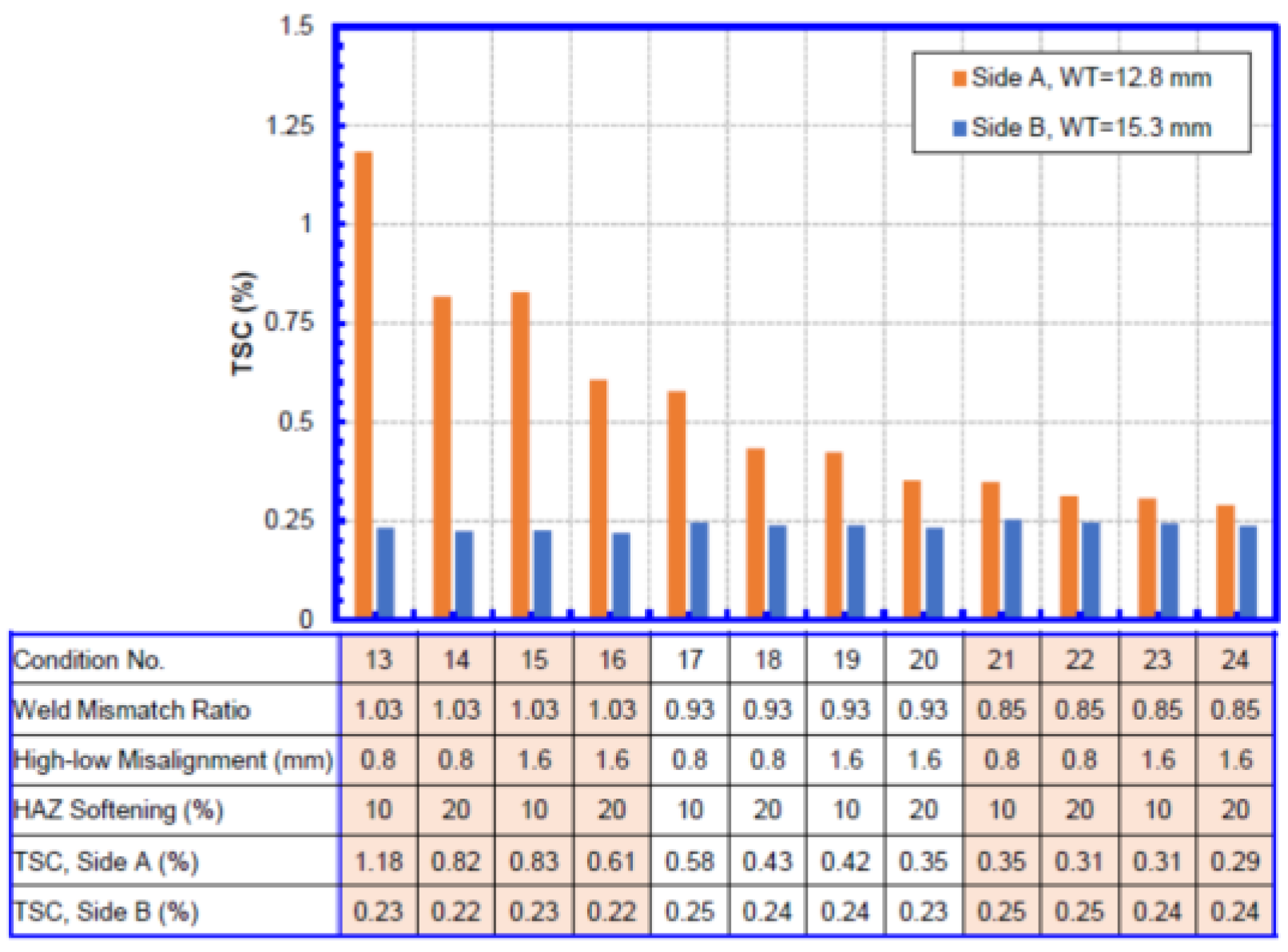

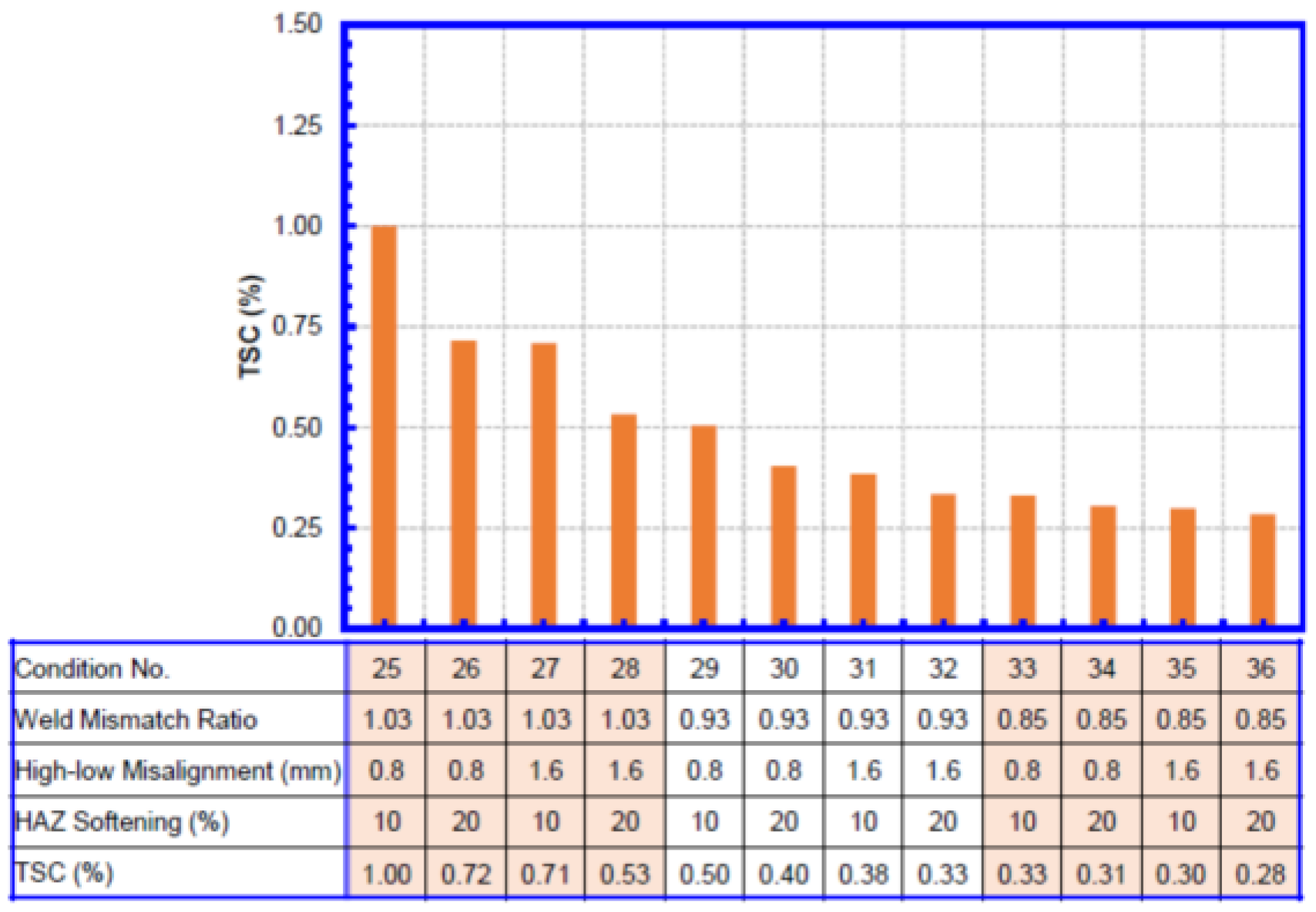

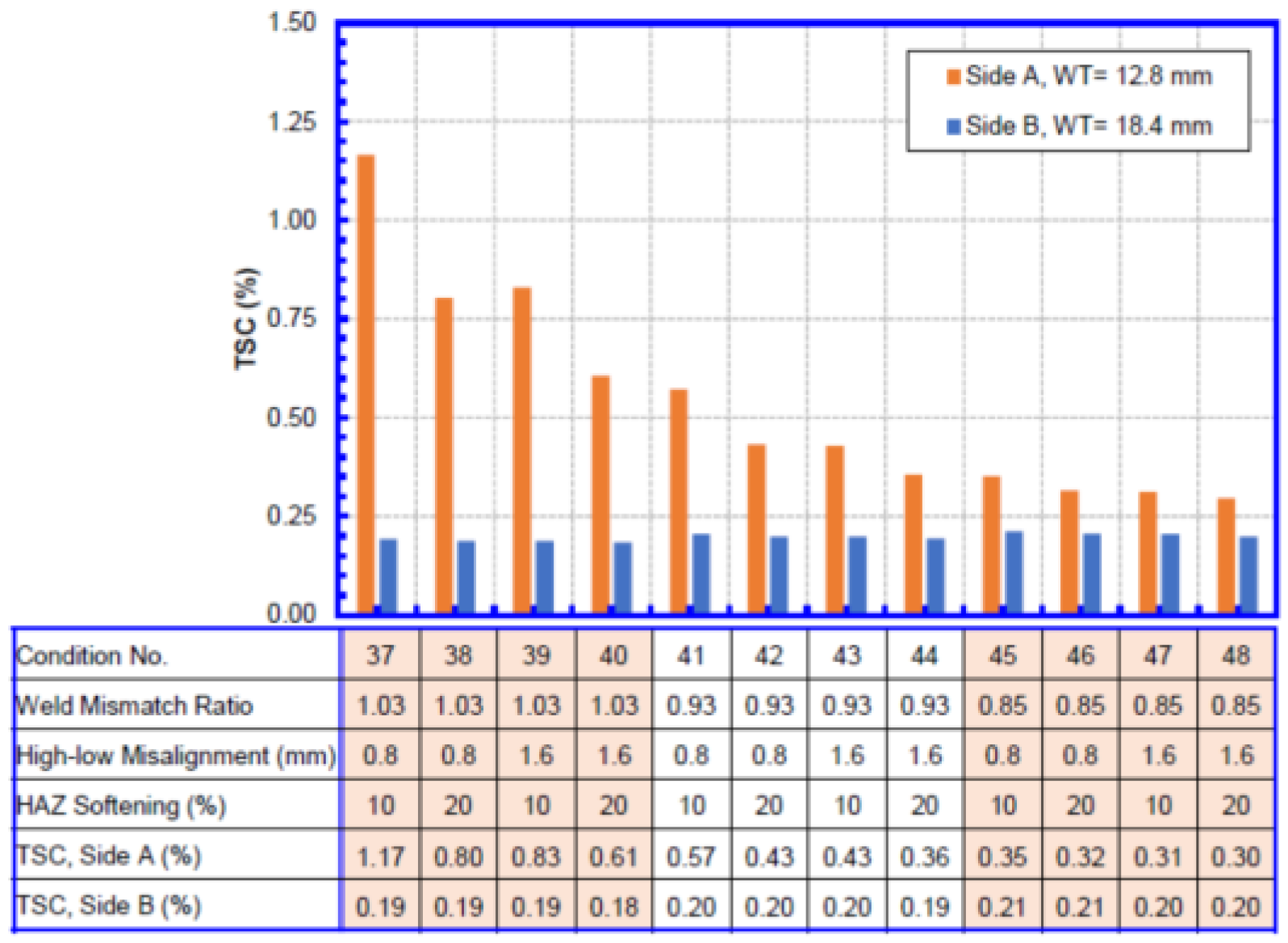

- A total of twelve conditions were listed, ordered by weld mismatch ratio, HAZ softening, and high–low misalignment.

- Cases 1–4, 5–8, and 9–12 correspond to the three weld mismatch levels, respectively. Weld mismatch can be seen to have a dominant impact on the TSC of the weld, with low weld strengths significantly reducing the overall TSC.

- Inside each mismatch group, the first two bars correspond to lower misalignment, and the second two bars correspond to higher misalignment. At higher weld mismatch ratio when the TSC is high, misalignment can be seen to have a significant impact on the TSC. The effect of misalignment is less pronounced when the mismatch ratio is low.

- At each misalignment level, the two bars represent the 10% and 20% HAZ softening conditions. Similar to the misalignment, the HAZ softening has a greater impact on the TSC when the weld mismatch ratio is relatively high.

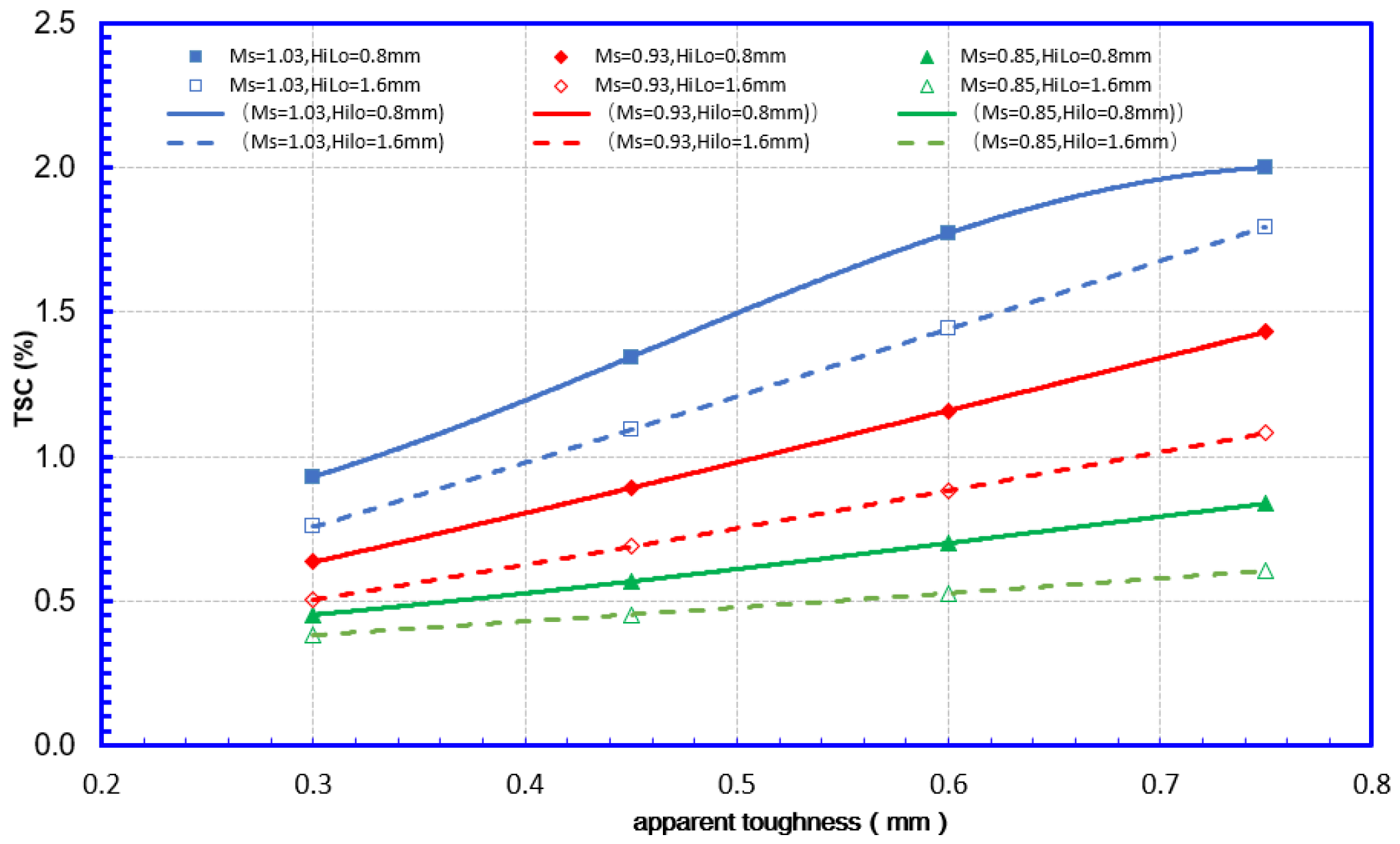

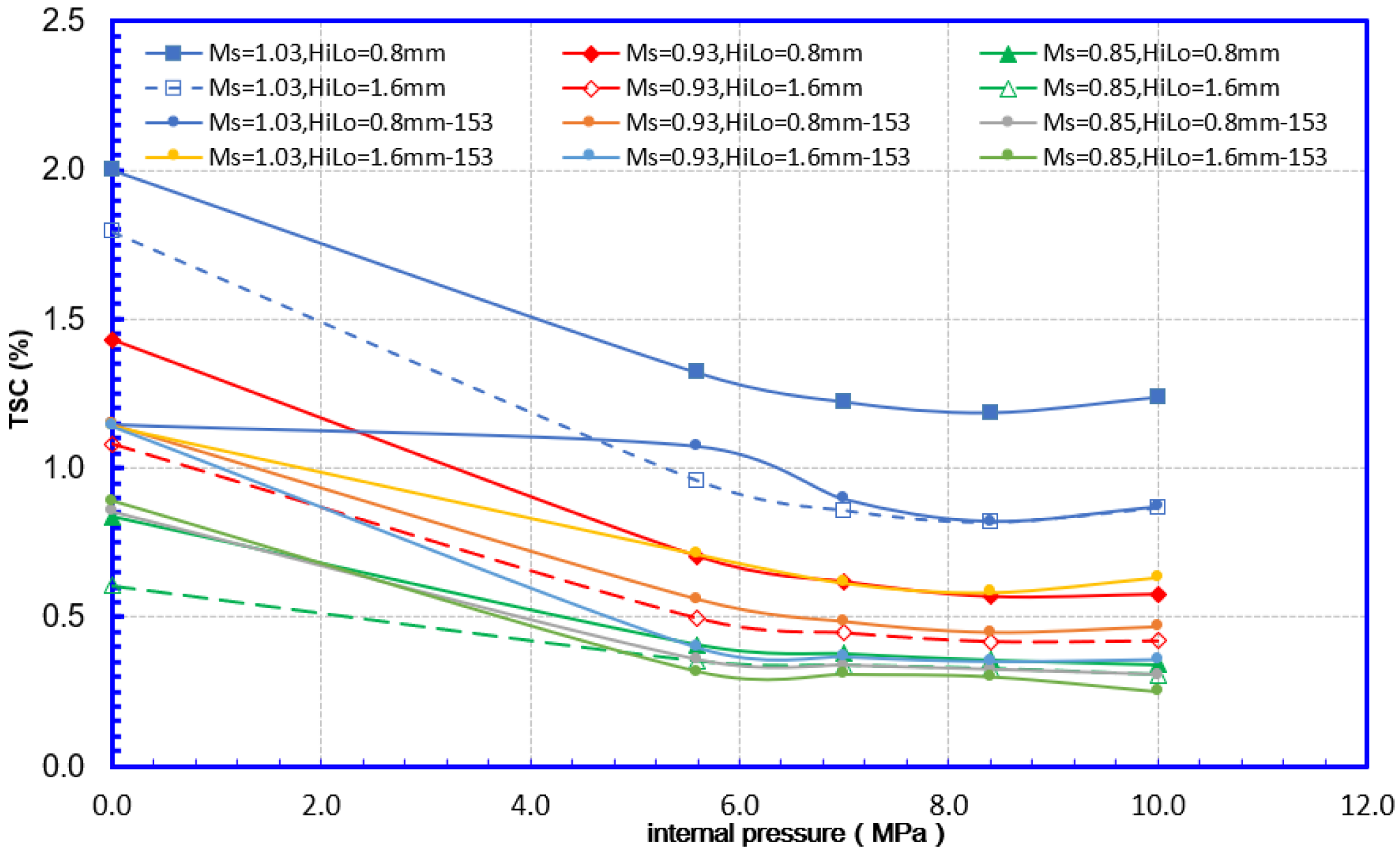

3.5. Sensitivity Analysis of Parameters

3.6. TSC Prediction

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Appendix A

| No. | Thickness (mm) | Weld Mismatch Ratio | High–Low Misalignment (mm) | HAZ Softening (%) | TSC (%) | TSC/Side B (%) |

|---|---|---|---|---|---|---|

| 1 | 18.4–18.4 | 1.03 | 0.8 | 10 | 1.23 | / |

| 2 | 18.4–18.4 | 1.03 | 0.8 | 20 | 0.86 | / |

| 3 | 18.4–18.4 | 1.03 | 2.2 | 10 | 0.72 | / |

| 4 | 18.4–18.4 | 1.03 | 2.2 | 20 | 0.53 | / |

| 5 | 18.4–18.4 | 0.93 | 0.8 | 10 | 0.57 | / |

| 6 | 18.4–18.4 | 0.93 | 0.8 | 20 | 0.43 | / |

| 7 | 18.4–18.4 | 0.93 | 2.2 | 10 | 0.38 | / |

| 8 | 18.4–18.4 | 0.93 | 2.2 | 20 | 0.33 | / |

| 9 | 18.4–18.4 | 0.85 | 0.8 | 10 | 0.35 | / |

| 10 | 18.4–18.4 | 0.85 | 0.8 | 20 | 0.31 | / |

| 11 | 18.4–18.4 | 0.85 | 2.2 | 10 | 0.3 | / |

| 12 | 18.4–18.4 | 0.85 | 2.2 | 20 | 0.29 | / |

| 13 | 12.8–15.3 | 1.03 | 0.8 | 10 | 1.18 | 0.23 |

| 14 | 12.8–15.3 | 1.03 | 0.8 | 20 | 0.82 | 0.22 |

| 15 | 12.8–15.3 | 1.03 | 1.6 | 10 | 0.83 | 0.23 |

| 16 | 12.8–15.3 | 1.03 | 1.6 | 20 | 0.61 | 0.22 |

| 17 | 12.8–15.3 | 0.93 | 0.8 | 10 | 0.58 | 0.25 |

| 18 | 12.8–15.3 | 0.93 | 0.8 | 20 | 0.43 | 0.24 |

| 19 | 12.8–15.3 | 0.93 | 1.6 | 10 | 0.42 | 0.24 |

| 20 | 12.8–15.3 | 0.93 | 1.6 | 20 | 0.35 | 0.23 |

| 21 | 12.8–15.3 | 0.85 | 0.8 | 10 | 0.35 | 0.25 |

| 22 | 12.8–15.3 | 0.85 | 0.8 | 20 | 0.31 | 0.25 |

| 23 | 12.8–15.3 | 0.85 | 1.6 | 10 | 0.31 | 0.24 |

| 24 | 12.8–15.3 | 0.85 | 1.6 | 20 | 0.29 | 0.24 |

| 25 | 12.8–12.8 | 1.03 | 0.8 | 10 | 1 | / |

| 26 | 12.8–12.8 | 1.03 | 0.8 | 20 | 0.72 | / |

| 27 | 12.8–12.8 | 1.03 | 1.6 | 10 | 0.71 | / |

| 28 | 12.8–12.8 | 1.03 | 1.6 | 20 | 0.53 | / |

| 29 | 12.8–12.8 | 0.93 | 0.8 | 10 | 0.5 | / |

| 30 | 12.8–12.8 | 0.93 | 0.8 | 20 | 0.4 | / |

| 31 | 12.8–12.8 | 0.93 | 1.6 | 10 | 0.38 | / |

| 32 | 12.8–12.8 | 0.93 | 1.6 | 20 | 0.33 | / |

| 33 | 12.8–12.8 | 0.85 | 0.8 | 10 | 0.33 | / |

| 34 | 12.8–12.8 | 0.85 | 0.8 | 20 | 0.31 | / |

| 35 | 12.8–12.8 | 0.85 | 1.6 | 10 | 0.3 | / |

| 36 | 12.8–12.8 | 0.85 | 1.6 | 20 | 0.28 | / |

| 37 | 12.8–18.4 | 1.03 | 0.8 | 10 | 1.17 | 0.19 |

| 38 | 12.8–18.4 | 1.03 | 0.8 | 20 | 0.8 | 0.19 |

| 39 | 12.8–18.4 | 1.03 | 1.6 | 10 | 0.83 | 0.19 |

| 40 | 12.8–18.4 | 1.03 | 1.6 | 20 | 0.61 | 0.18 |

| 41 | 12.8–18.4 | 0.93 | 0.8 | 10 | 0.57 | 0.2 |

| 42 | 12.8–18.4 | 0.93 | 0.8 | 20 | 0.43 | 0.2 |

| 43 | 12.8–18.4 | 0.93 | 1.6 | 10 | 0.43 | 0.2 |

| 44 | 12.8–18.4 | 0.93 | 1.6 | 20 | 0.36 | 0.19 |

| 45 | 12.8–18.4 | 0.85 | 0.8 | 10 | 0.35 | 0.21 |

| 46 | 12.8–18.4 | 0.85 | 0.8 | 20 | 0.32 | 0.21 |

| 47 | 12.8–18.4 | 0.85 | 1.6 | 10 | 0.31 | 0.2 |

| 48 | 12.8–18.4 | 0.85 | 1.6 | 20 | 0.3 | 0.2 |

References

- Leis, B. Vintage Pipelines. PHMSA R&D Forum. 2009. Available online: https://204.68.194.139/rd/mtgs/062409/BrianLeis.pdf (accessed on 8 October 2022).

- Wang, Y.-Y.; Rapp, S.; Horsley, D.; Warman, D.; Gianetto, J. Attributes of Modern Linepipes and Their Implications on Girth Weld Strain Capacity. In Proceedings of the 12th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2018. [Google Scholar]

- PHMSA DOT, Failure Investigation Report–Enterprise Products Operating, LLC: ATEX Ethane Pipeline Failure, Follansbee, West Virginia. 2016. Available online: https://www.ntsb.gov/investigations/AccidentReports/Pages/Reports.aspx (accessed on 8 October 2022).

- Hamat, W.A.W.; Ismail, W.M.M.W.; Ibrahim, K.A.; Zin, G.M.; Aris, N.S.M. High Strain Weld Solutions for Geohazard Active Environment. In Proceedings of the Conference on Asset Integrity Management-Pipeline Integrity Management Under Geohazard Conditions, Houston, TX, USA, 25–28 March 2019. [Google Scholar]

- Dot, P. Pipeline Safety: Potential Low and Variable Yield and Tensile Strength and Chemical Composition Properties in High Strength Line Pipe. Fed. Regist. 2009, 74, PHMSA–2009–0148. [Google Scholar]

- Canada Energy Regulator, Safety Advisory SA 2020-01-Girth Weld Area Strain-Induced Failures: Pipeline Design, Construction, and Operation Considerations, 2020, File OF-Surv-Gen 11. Available online: https://www.cer-rec.gc.ca/en/safety-environment/industry-performance/information-safety-advisories/safety-advisory/2020/safety-advisory-sa-2020-01-girth-weld-area-strain-induced-failures-pipeline-design-construction-operation-considerations.html (accessed on 8 October 2022).

- Wang, Y.Y.; Wang, B.; Liu, B.; Jia, D.; Gasunie, H. Strain Capacity of Vintage Girth Welds and Integrity Management Process. In Proceedings of the 22nd Joint Technical Meeting of APGA-EPRG-PRCI, Brisbane, Australia, 2 May 2019. [Google Scholar]

- Wang, Y.-Y.; Liu, M.; Zhang, F.; Horsley, D.; Nanney, S. Multi-Tier Tensile Strain Design Models for Strain-Based Design Part I–Fundamental Basis. In Proceedings of the 9th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2012. [Google Scholar]

- Liu, M.; Wang, Y.-Y.; Song, Y.; Horsley, D.; Nanney, S. Multi-Tier Tensile Strain Models for Strain-Based Design Part II–Development and Formulation of Tensile Strain Capacity Models. In Proceedings of the 9th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2012. [Google Scholar]

- Wang, Y.-Y.; Liu, M.; Song, Y. Tensile Strain Models for Strain-Based Design of Pipelines. In Proceedings of the ASME 2012 31st International Conference on Ocean, Offshore and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 July 2012. [Google Scholar]

- Sandivk, A.; Østby, E.; Naess, A.; Sigurdsson, G.; Thaulow, C. Fracture control–Offshore Pipelines: Probabilistic Fracture Assessment of Surface Cracked Ductile Pipelines Using Analytical Equations. In Proceedings of the 24th International Conference on Offshore Mechanics and Arctic Engineering, Halkidiki, Greece, 12–17 June 2005. [Google Scholar]

- Østby, E. New Strain-Based Fracture Mechanics Equations Including the Effects of Biaxial Loading, Mismatch And Misalignment. In Proceedings of the 24th International Conference on Offshore Mechanics and Arctic Engineering, Halkidiki, Greece, 12–17 June 2005. [Google Scholar]

- Fairchild, D.P.; Cheng, W.; Ford, S.J.; Minnaar, K.; Biery, N.E.; Kumar, A.; Nissley, N.E. Recent advances in curved wide plate testing and implications for strain-based design. In Proceedings of the 17th International Offshore and Polar Engineering Conference, Lisbon, Portugal, 1–6 July 2007. [Google Scholar]

- Kibey, S.; Issa, J.A.; Wang, X.; Minnaar, K. A Simplified, Parametric Equation for Prediction of Tensile Strain Capacity Welded Pipelines. In Proceedings of the Pipeline Technology Conference, Ostend, Belgium, 12–14 October 2009. [Google Scholar]

- Fairchild, D.; Kibey, S.; Tang, H.; Krishnan, V.; Macia, M.; Chen, W.; Wang, X. Continued Advancements Regarding Capacity Prediction of Strain-Based Pipelines. In Proceedings of the 9th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2012. [Google Scholar]

- Igi, S.; Suzuki, N. Tensile Strain Limits of X80 High-Strain Pipelines. In Proceedings of the 17th International Offshore and Polar Engineering Conference, Lisbon, Portugal, 1–7 July 2007. [Google Scholar]

- Igi, S.; Sakimoto, T.; Suzuki, N.; Muraoka, R.; Arakawa, T. Tensile Strain Capacity of X80 Pipeline Under Tensile Loading with Internal Pressure. In Proceedings of the 8th International Pipeline Conference, Calgary, AB, Canada, 27 September 2010. [Google Scholar]

- Verstraete, M.; Waele, W.; Denys, R.; Hertele, S. Pressure Correction Factor for Strain Capacity Predictions Based on Curved Wide Plate Testing. In Proceedings of the 9th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2012. [Google Scholar]

- Smith, S. Development of the BS 7910 Failure Assessment Diagram for Strain Based Design with Application to Pipelines. In Proceedings of the ASME 2012 31st International Conference on Ocean, Offshore, and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 July 2012. [Google Scholar]

- Cheaitani, M. Axial Misalignment in FAD-Based Fracture Assessment of Circumferential Girth Weld Flaws–Industrial Member Report 999. 2011. Available online: https://www.twi-global.com/what-we-do/research-and-technology/research-programmes/core-research-programme/report-abstracts/axial-misalignment-in-fad-based-fracture-assessment-of-circumferential-girth-weld-flaws-999-2011 (accessed on 8 October 2022).

- Wang, Y.Y.; Kotian, K.; Rapp, S. Effects of High-Low Misalignment on Girth Weld Integrity. In Proceedings of the International Pipeline Conference, Calgary, AB, Canada, 29 September 2014. [Google Scholar]

- American Petroleum Institute. API 1104: Welding of Pipelines and Related Facilities, 21st ed.; American Petroleum Institute: Washington, DC, USA, 2013. [Google Scholar]

- CSA Group. CSA Z662: Oil & Gas Pipeline Systems, 8th ed.; CSA Group: Toronto, ON, Canada, 2020. [Google Scholar]

- Denys, R.; De Waele, W.; Lefevre, A.; De Baets, P. Weld Strength Mismatch Effects on Plastic Straining Capacity of Axially Loaded Pipelines. In Proceedings of the 4th International Conference on Pipeline Technology, Ostend, Belgium, 9–13 May 2004. [Google Scholar]

- Pépin, A.; Tkaczyk, T.; O’Dowd, N.; Nikbin, K. Methodology for assessment of surface defects in undermatched pipeline girth welds. J. Press. Vessel. Technol. 2015, 137, 051402. [Google Scholar] [CrossRef]

- Moore, P.L.; Pisarski, H.G.; London, T. Validation of Methods to Determine CTOD from SENT Specimens. In Proceedings of the International Offshore & Polar Engineering Conference, Rhodes, Greece, 17–22 June 2012. [Google Scholar]

- Wang, B.; Liu, B.; Wang, Y.Y.; Huising, O.J. Estimation of Tensile Strain Capacity of Vintage Girth Welds. In Proceedings of the 13th International Pipeline Conference, Online, 28–30 September 2020. [Google Scholar]

| Welding Pass | Root Pass | Hot Pass | Fill Pass | Cap Pass |

|---|---|---|---|---|

| Type | AWS A5.1 E6010 | AWS A5.1 E6010 | AWS A5.29 E81T8-Ni2 | AWS A5.29 E81T8-Ni2 |

| Brand | BOHLER FOX CEL | BOHLER FOX CEL | Golden bridge JC30 | Golden bridge JC30 |

| Size | Φ4.0 mm | Φ4.0 mm | Φ2.0 mm | Φ2.0 mm |

| Welding position | 5G | 5G | 5G | 5G |

| Welding procedure | SMAW | SMAW | FCAW-S | FCAW-S |

| Position | Bevel Angle (Degree) | Weld Root Width (mm) | Weld Root Height (mm) | Weld Cap Width Beyond Bevel (mm) | Weld Cap Height (mm) | HAZ Width (mm) |

|---|---|---|---|---|---|---|

| GW1 | 20 | 4.2 | 4.6 | 1.4 | 1.0 | 2.7 |

| GW2 | 23 | 7.3 | 3.6 | 0.0 | 1.1 | 2.0 |

| GW3 | 16 | 5.6 | 1.9 | 2.8 | 3.0 | 2.1 |

| GW4 | 18 | 6.3 | 3.5 | 0.7 | 2.9 | 2.4 |

| GW5 | 20 | 3.2 | 3.4 | 0.0 | 1.6 | 2.2 |

| GW6 | 18 | 7.3 | 1.4 | 1.0 | 3.3 | 1.9 |

| GW7 | 26 | 5.6 | 2.8 | 0.0 | 1.8 | 4.0 |

| FEA Model | 20 | 5.6 | 3.2 | 0.0 | 2.0 | 4.0 |

| C | Si | Mn | P | S | Mo |

| 0.052 | 0.13 | 1.49 | 0.0079 | 0.0021 | 0.17 |

| Cr | Nb | V | Ni | Cu | Pcm |

| 0.036 | 0.051 | 0.0041 | 0.17 | 0.031 | 0.15 |

| Pipe YS (MPa) | Pipe UTS (MPa) | Pipe Y/T Ratio |

|---|---|---|

| 565 | 634 | 0.89 |

| 634 | 703 | 0.90 |

| 703 | 772 | 0.91 |

| Parameter | Conditions | Number of Conditions |

|---|---|---|

| Pipe | OD 1016 mm | 1 |

| Pipe WT | 18.4 mm + 18.4 mm 12.8 mm + 12.8 mm 12.8 mm + 15.3 mm 12.8 mm + 18.4 mm | 4 |

| Weld profiles | See Table 2 | 1 |

| Weld CTODA | 0.3, 0.45, 0.6, 0.75 | 4 |

| High–low misalignment | 1.6 mm or 0.8 mm | 2 |

| Flaw size | 25 mm × 4 mm | 1 |

| HAZ softening | 10%, 20% | 2 |

| Weld metal mismatchratio | 0.85, 0.93, 1.03 | 3 |

| Pressure | 0 MPa, 5.6 MPa, 7.0 MPa, 8.4 MPa, 10.0 MPa | 5 |

| Number of results | 960 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Dai, L.; Xuan, H.; Gao, X.; Yang, K.; Wang, L.; Chi, Q.; Huo, C. Tensile Strain Capacity Prediction Model of an X80 Pipeline with Improper Transitioning and Undermatched Girth Weld. Materials 2022, 15, 7134. https://doi.org/10.3390/ma15207134

Chen H, Dai L, Xuan H, Gao X, Yang K, Wang L, Chi Q, Huo C. Tensile Strain Capacity Prediction Model of an X80 Pipeline with Improper Transitioning and Undermatched Girth Weld. Materials. 2022; 15(20):7134. https://doi.org/10.3390/ma15207134

Chicago/Turabian StyleChen, Hongyuan, Lianshuang Dai, Heng Xuan, Xiongxiong Gao, Kun Yang, Lei Wang, Qiang Chi, and Chunyong Huo. 2022. "Tensile Strain Capacity Prediction Model of an X80 Pipeline with Improper Transitioning and Undermatched Girth Weld" Materials 15, no. 20: 7134. https://doi.org/10.3390/ma15207134

APA StyleChen, H., Dai, L., Xuan, H., Gao, X., Yang, K., Wang, L., Chi, Q., & Huo, C. (2022). Tensile Strain Capacity Prediction Model of an X80 Pipeline with Improper Transitioning and Undermatched Girth Weld. Materials, 15(20), 7134. https://doi.org/10.3390/ma15207134