Fly Ash-Based Geopolymer Composites: A Review of the Compressive Strength and Microstructure Analysis

Abstract

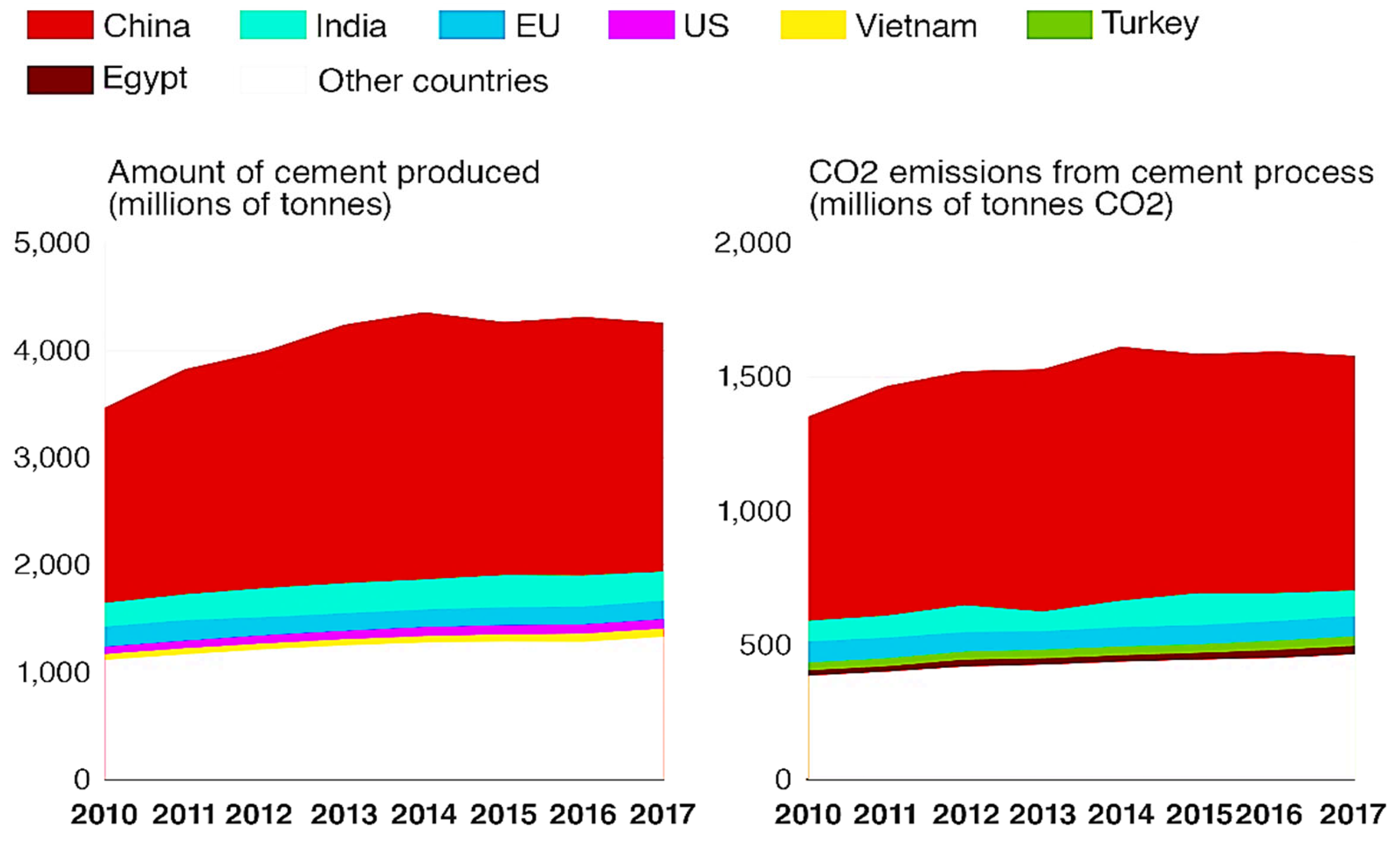

1. Introduction

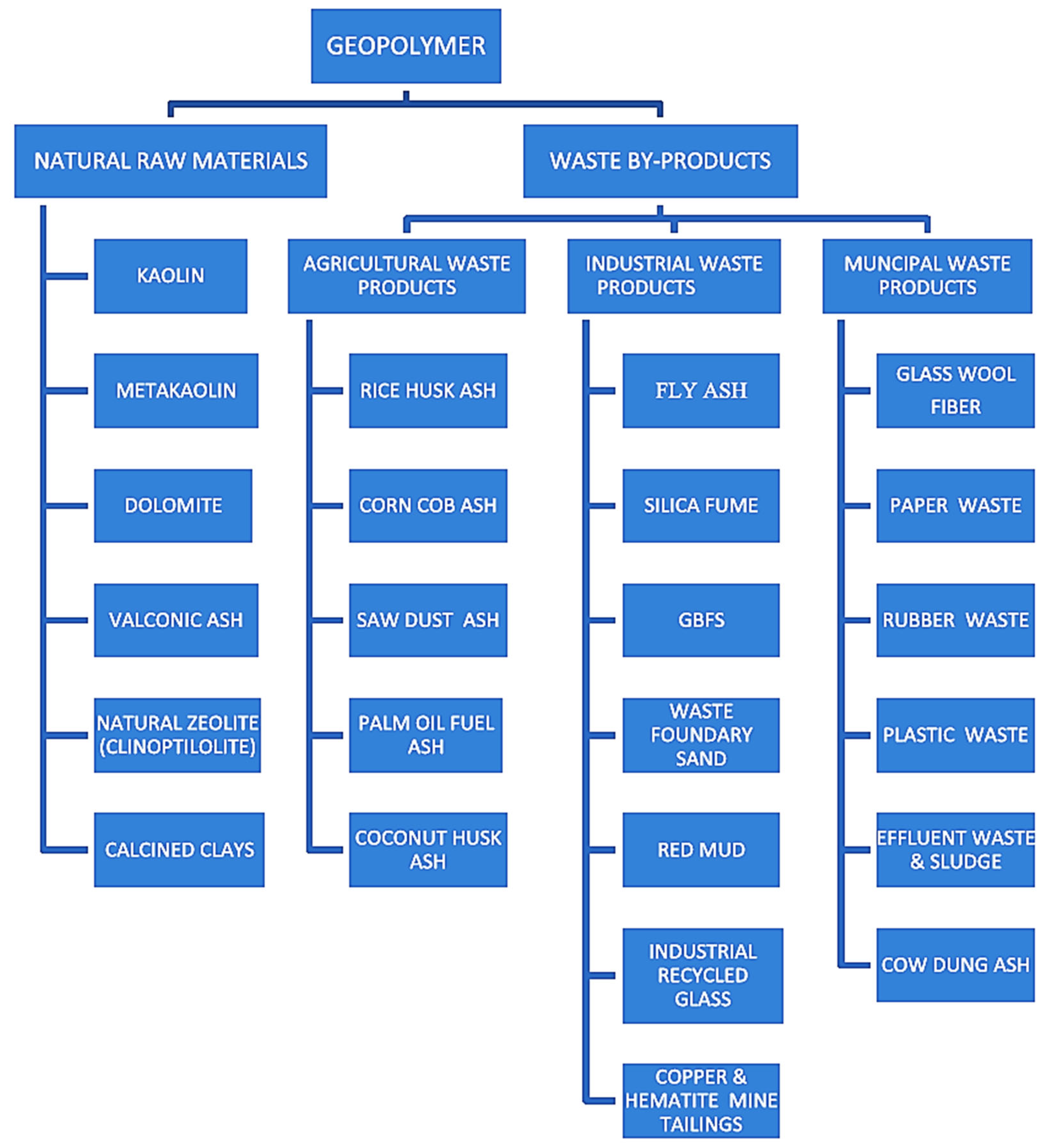

2. Significance of Study

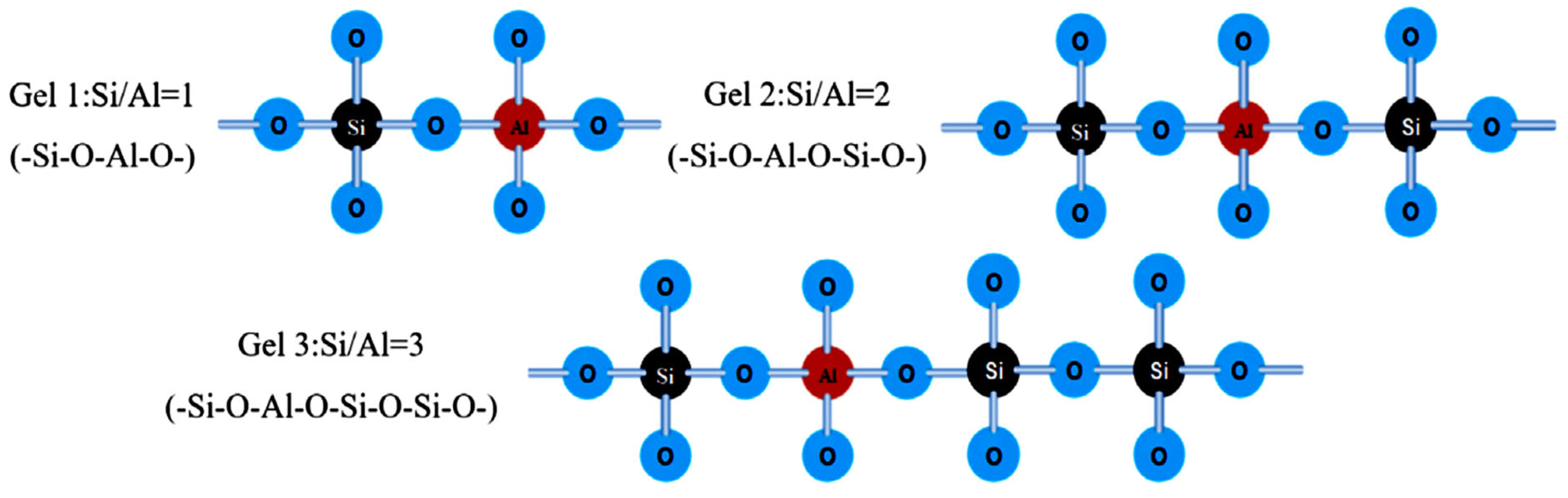

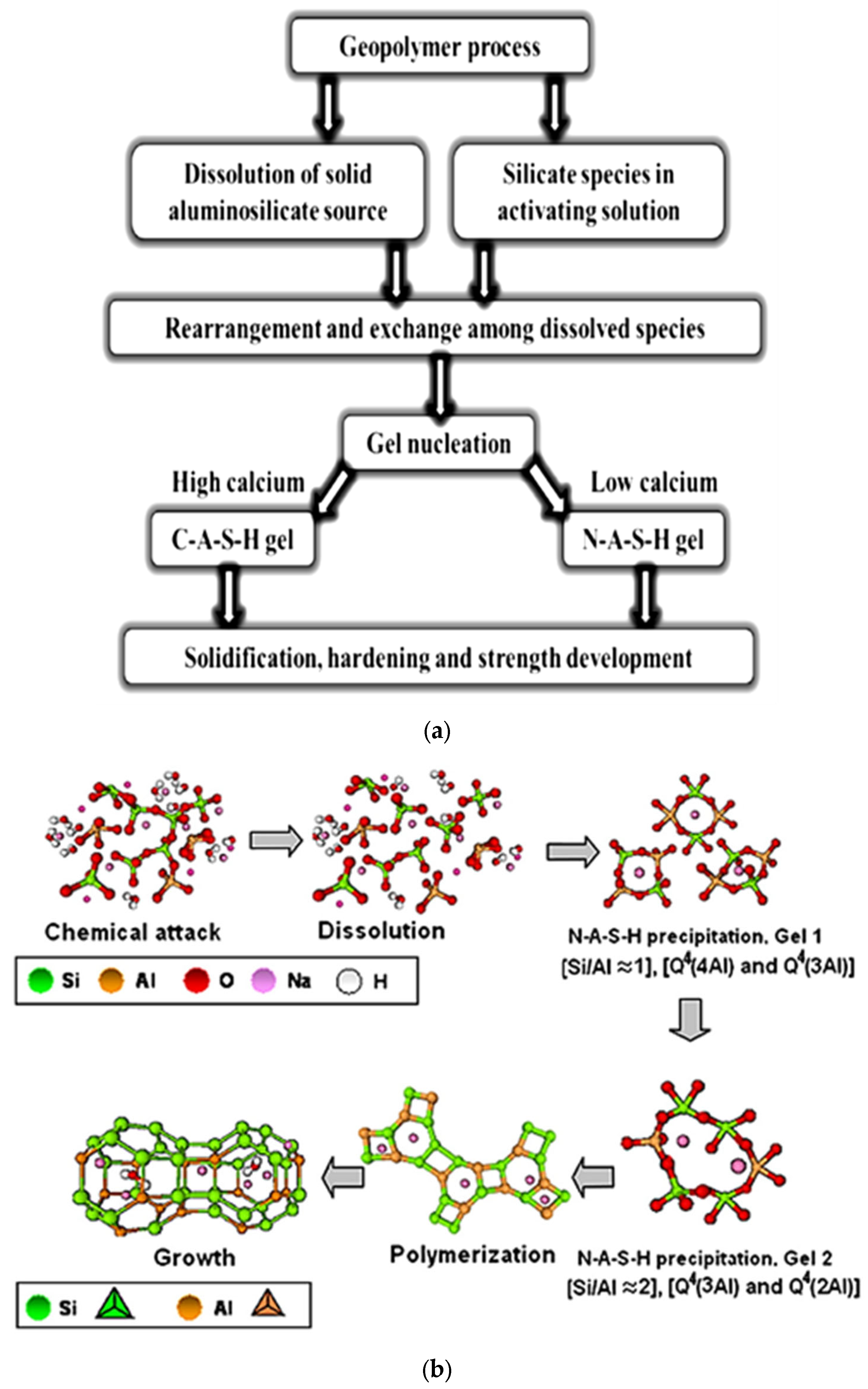

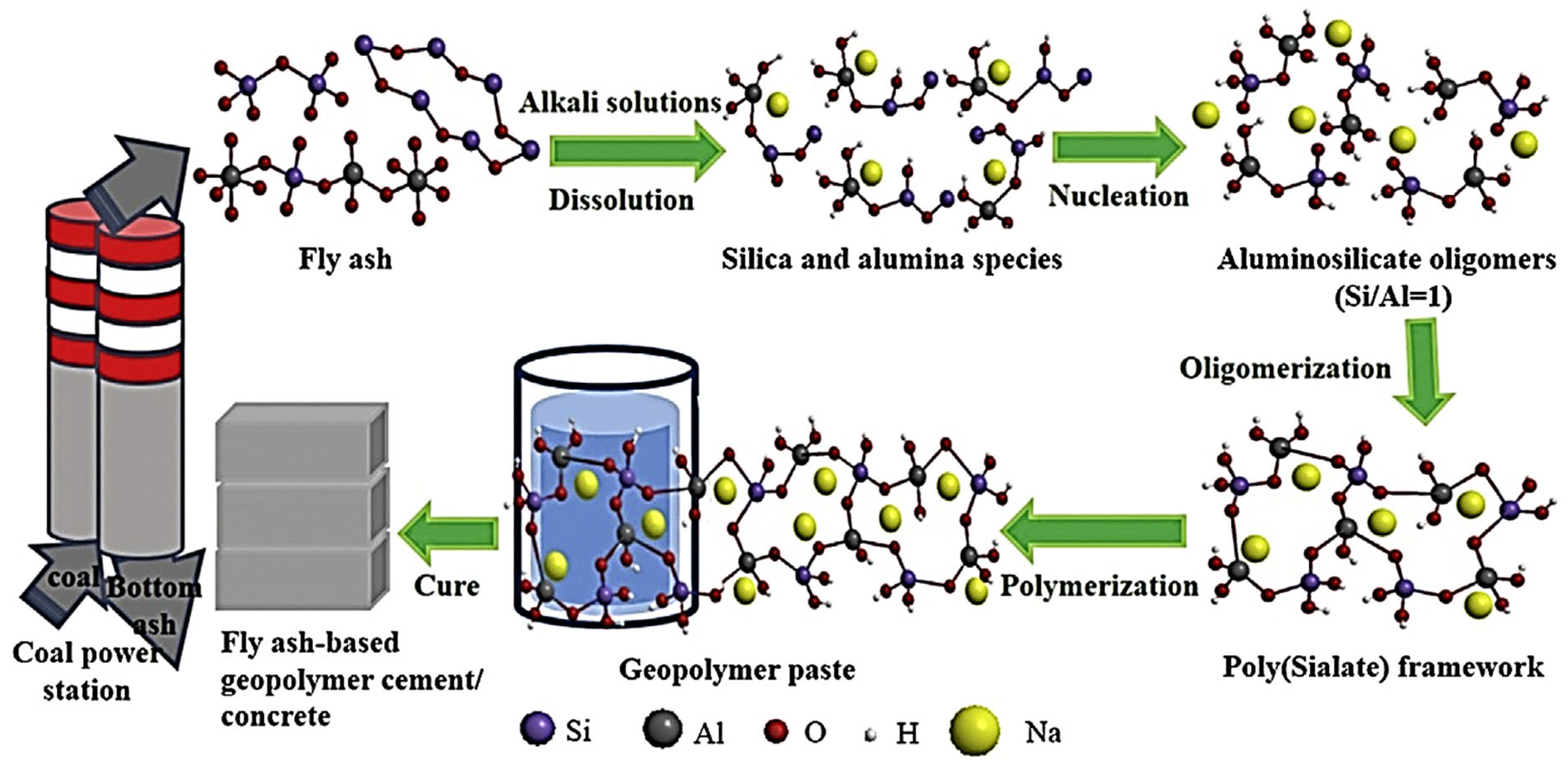

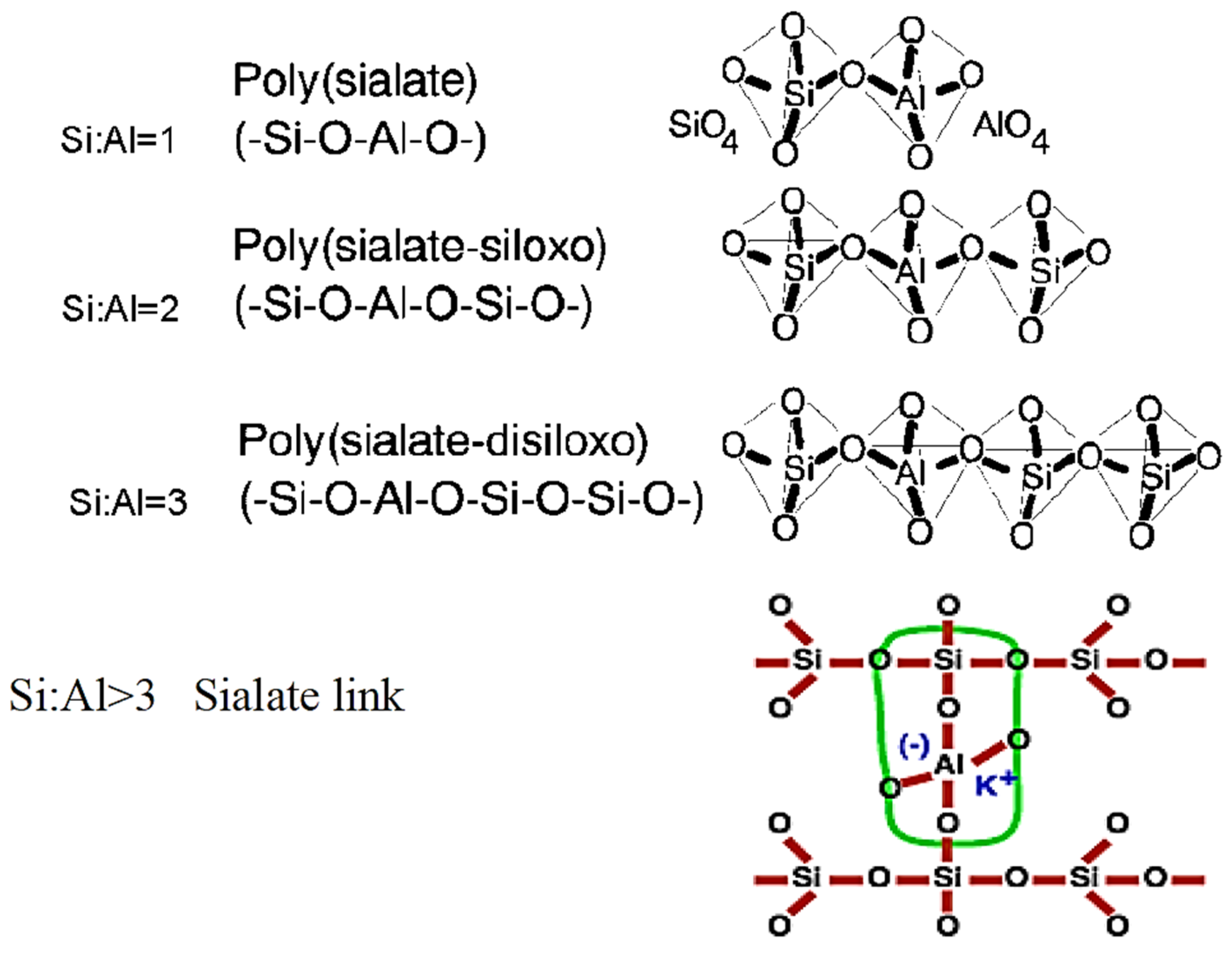

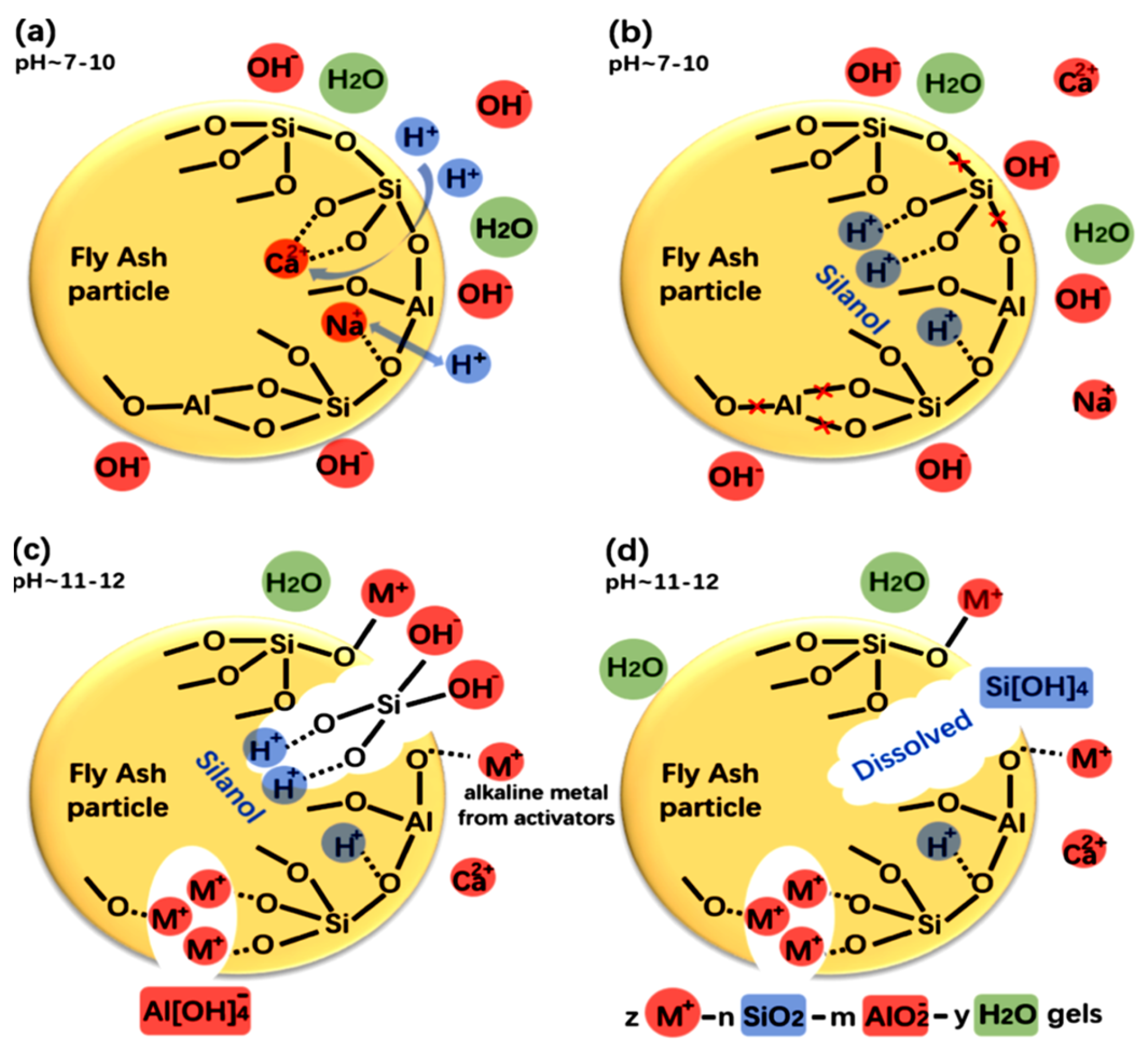

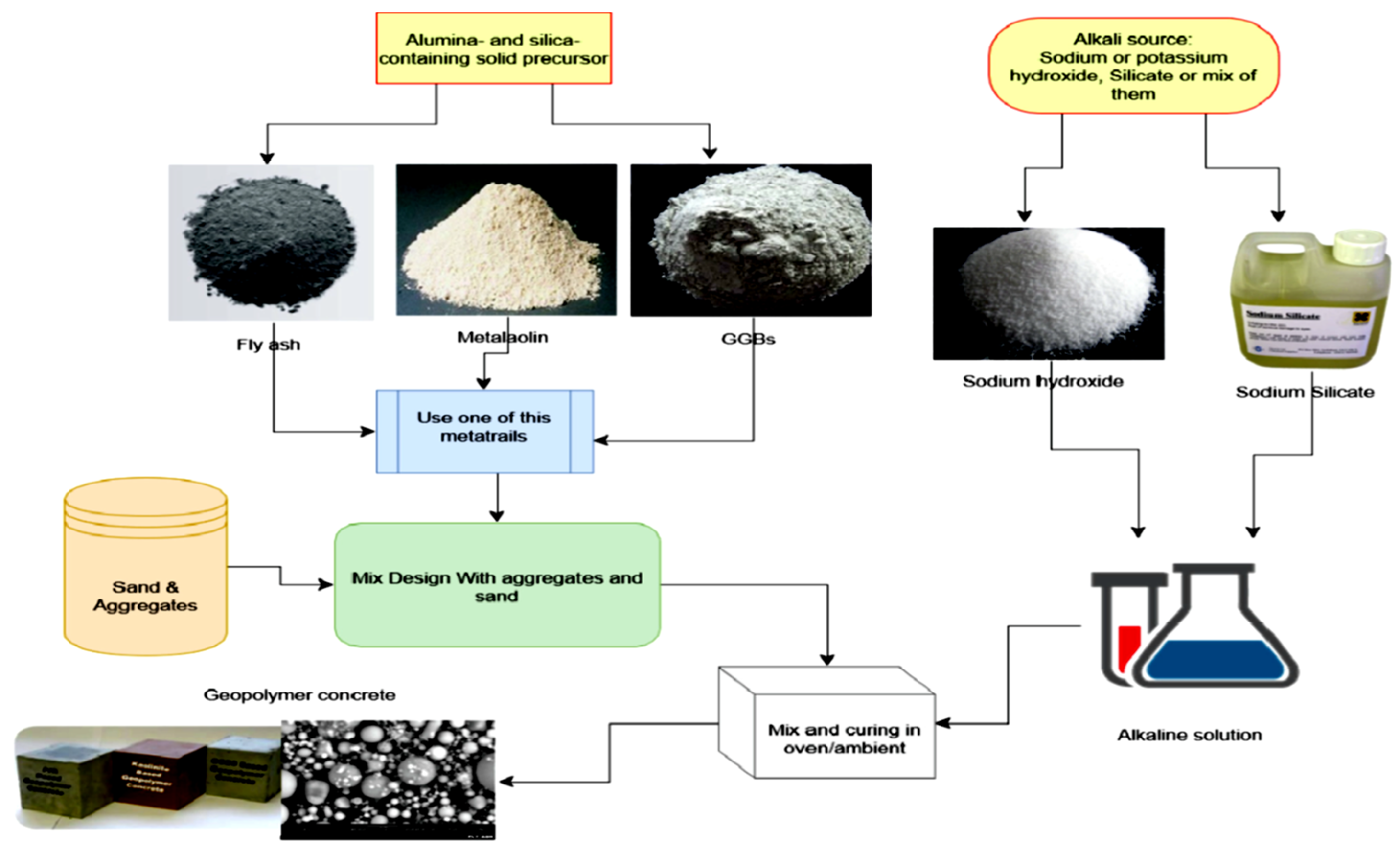

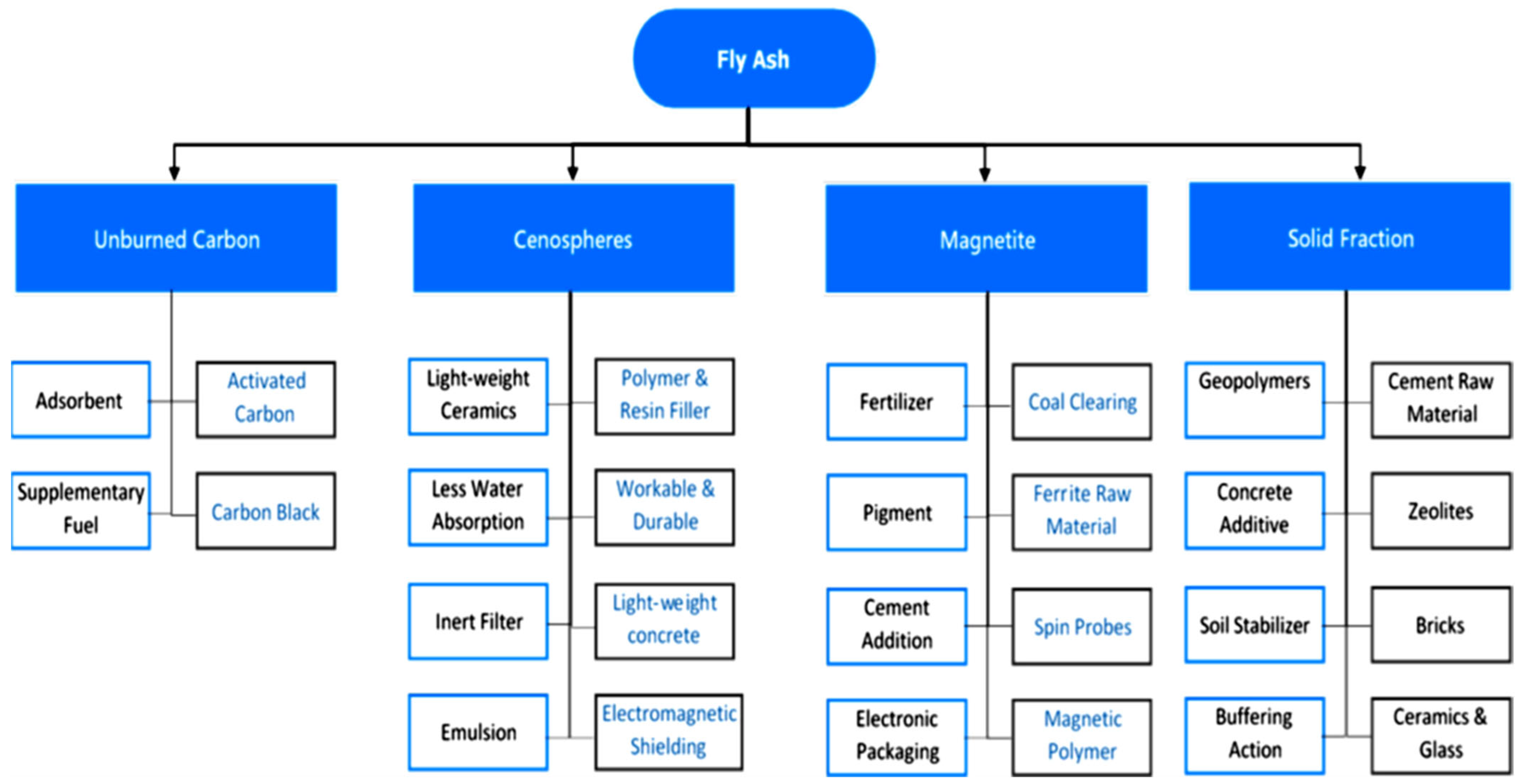

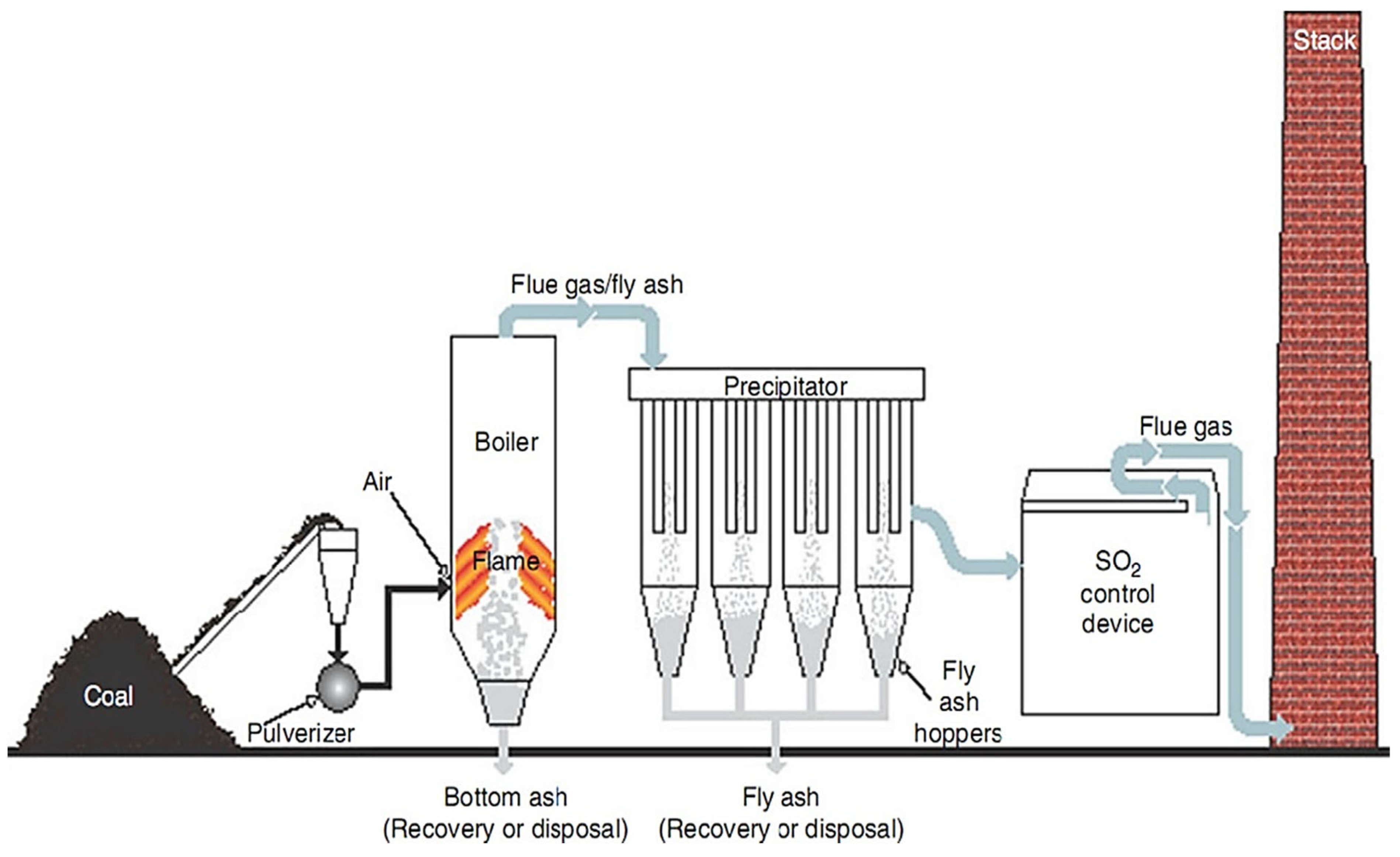

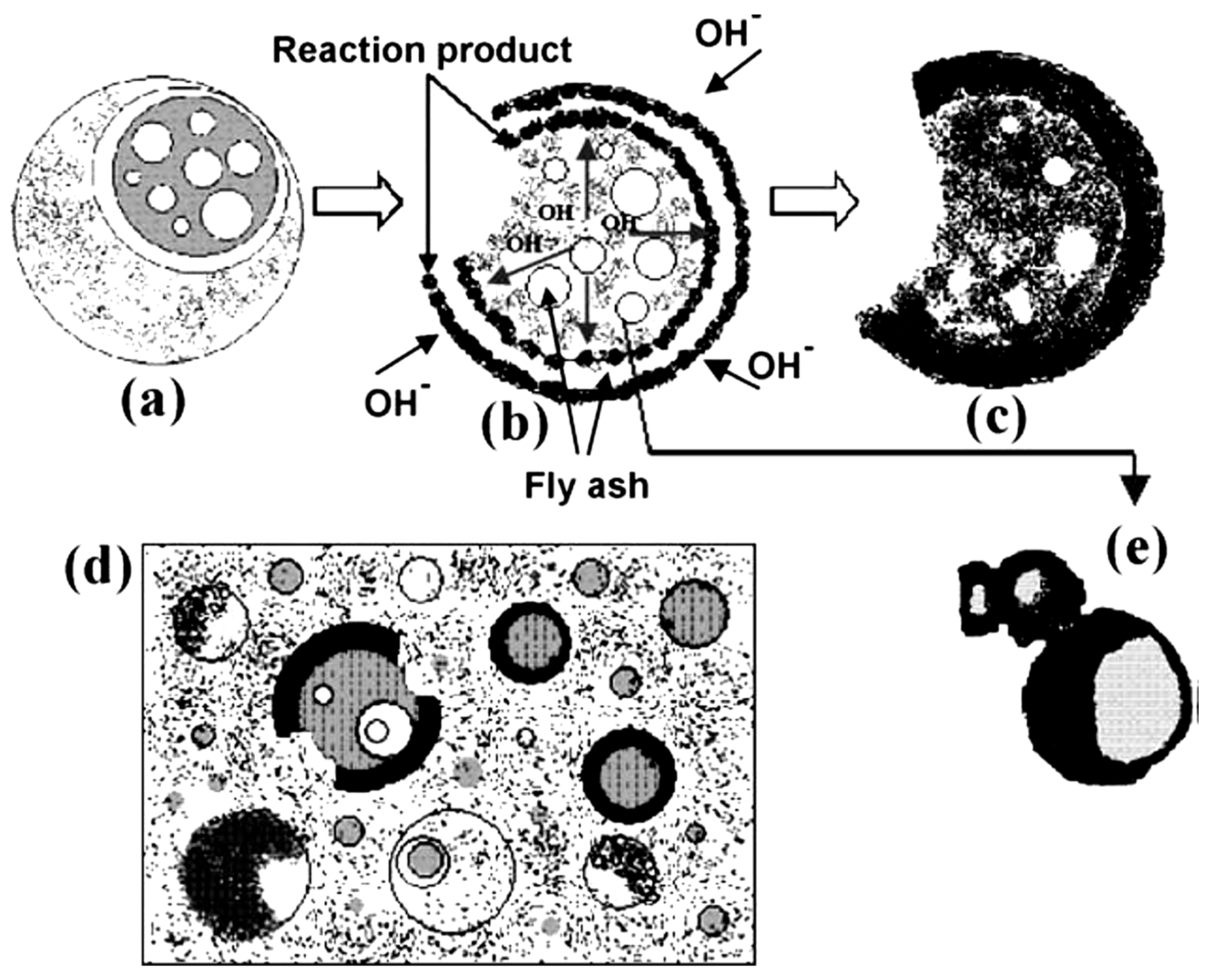

3. Geopolymerization

4. FA-GP Concrete

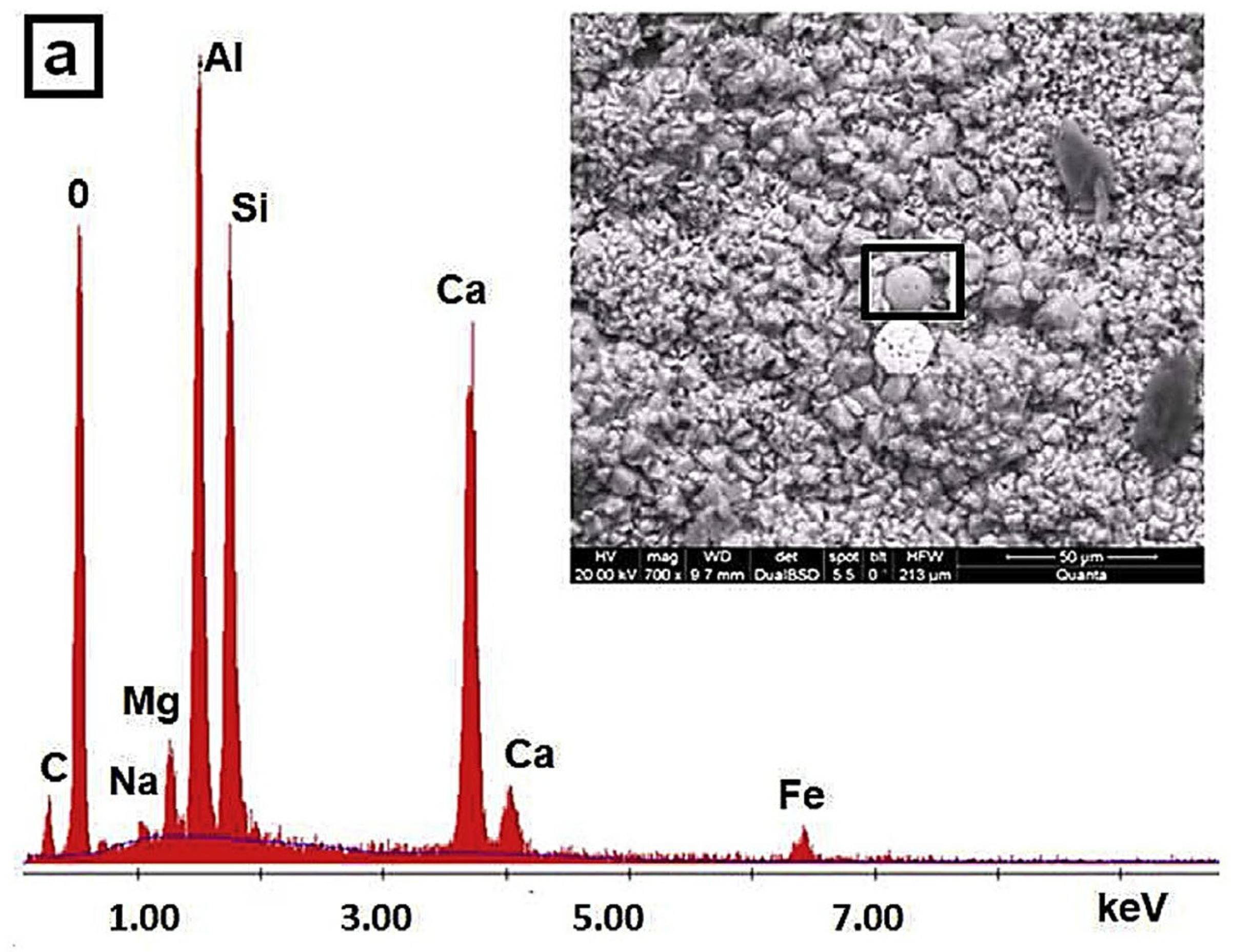

5. Chemical Composition of Binder Materials

| Material and Ref. | Composition (wt.%) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Fe2O3 | Al2O3 | CaO | Pb | Na2O | P2O5 | MnO | K2O | SO3 | MgO | SrO | TiO2 | CuO | Cl | LOI | |

| PC [93] | 19.0 | 3.20 | 4.68 | 66.8 | 26.8 | 0.09 | 0.08 | 0.19 | 1.17 | 3.00 | 0.81 | - | - | - | - | 2.48 |

| FA [94] | 48.8 | 10.20 | 27.00 | 6.20 | 86.0 | 0.37 | 1.20 | 0.15 | 0.85 | 0.22 | 1.40 | 0.16 | 1.30 | – | – | 1.70 |

| FA [95] | 61.8 | 4.11 | 28.05 | 0.87 | 94.0 | 0.40 | - | - | 0.82 | 1.32 | 0.38 | - | - | - | - | 0.49 |

| FA [96] | 49.0 | 3.00 | 31.00 | 5.00 | 83.0 | 4.00 | 1.00 | – | 1.00 | 0.00 | 3.00 | – | 2.00 | – | – | 0.00 |

| FA [93] | 50.7 | 8.80 | 28.80 | 2.38 | 88.3 | 0.84 | – | – | 2.40 | 0.30 | 1.39 | – | – | – | – | 3.79 |

| FA [97] | 26.4 | 30.13 | 9.25 | 21.6 | 65.7 | – | 0.67 | 0.27 | 2.58 | 1.30 | – | – | 3.07 | – | – | 3.02 |

| FA [98] | 53.5 | 7.47 | 28.80 | 1.55 | 89.7 | – | – | – | – | 0.14 | 0.81 | – | – | – | – | 3.11 |

| FA [99] | 64.9 | 5.69 | 26.64 | 0.33 | 97.3 | 0.49 | – | – | 0.25 | 0.33 | 0.85 | – | – | – | – | 0.45 |

| FA [100] | 17.5 | 12.43 | 36.37 | 10.5 | 66.3 | – | – | – | 1.77 | 1.39 | 3.05 | – | 0.88 | – | – | 1.19 |

| FA [101] | 54.7 | 5.15 | 27.28 | 5.31 | 87.1 | 0.43 | 1.12 | 0.10 | 1.00 | 1.01 | 1.10 | 0.36 | 1.82 | 0.01 | – | 6.80 |

| FA [102] | 27.3 | 2.01 | 50.85 | 5.41 | 80.2 | 0.04 | – | 0.02 | 0.33 | – | 0.28 | – | 2.12 | – | – | 7.74 |

| FA [103] | 50.6 | 6.35 | 18.96 | 14.1 | 75.9 | 0.69 | – | – | – | 0.74 | 3.12 | – | – | – | – | 0.17 |

| FA [71] | 57.6 | 5.80 | 28.90 | 0.20 | 92.3 | – | – | – | 0.90 | 0.20 | 0.90 | – | – | – | – | 3.60 |

| FA [104] | 63.1 | 3.07 | 24.88 | 2.58 | 91.0 | 0.71 | 0.17 | 0.05 | 2.01 | 0.18 | 0.61 | – | 0.96 | – | – | 1.45 |

| FA [105] | 66.5 | 3.54 | 22.47 | 1.64 | 92.5 | 0.58 | – | – | 1.75 | 0.10 | 0.65 | – | 0.88 | – | – | 1.66 |

| FA [106] | 51.1 | 12.50 | 25.70 | 4.30 | 89.3 | 0.80 | 0.90 | 0.20 | 0.70 | 0.20 | 1.50 | – | 1.30 | – | – | 0.60 |

| FA [107] | 47.8 | 14.09 | 28.00 | 3.81 | 89.9 | 0.41 | 1.81 | 0.21 | 0.62 | 0.27 | 0.93 | – | 1.99 | – | – | 0.43 |

| FA [108] | 54.4 | 8.14 | 27.72 | 1.29 | 90.3 | 0.67 | – | – | – | 0.11 | – | – | – | – | – | 4.11 |

| FA [109] | 52.7 | 5.92 | 18.05 | 12.9 | 76.7 | 1.11 | – | 0.14 | 2.09 | 1.76 | 3.86 | – | 1.01 | – | – | 1.60 |

| FA [110] | 58.4 | 4.19 | 23.80 | 7.32 | 86.3 | 1.43 | – | – | 1.02 | 0.44 | 1.11 | – | – | – | – | 0.50 |

| FA [111] | 35.8 | 17.31 | 15.05 | 17.1 | 68.2 | 1.58 | 0.30 | – | 3.12 | 5.94 | 2.34 | – | – | – | – | 0.10 |

| FA [112] | 50.8 | 6.82 | 23.15 | 6.87 | 80.8 | 1.29 | 1.14 | – | 2.14 | 1.24 | 1.70 | 0.19 | 1.01 | – | – | 0.55 |

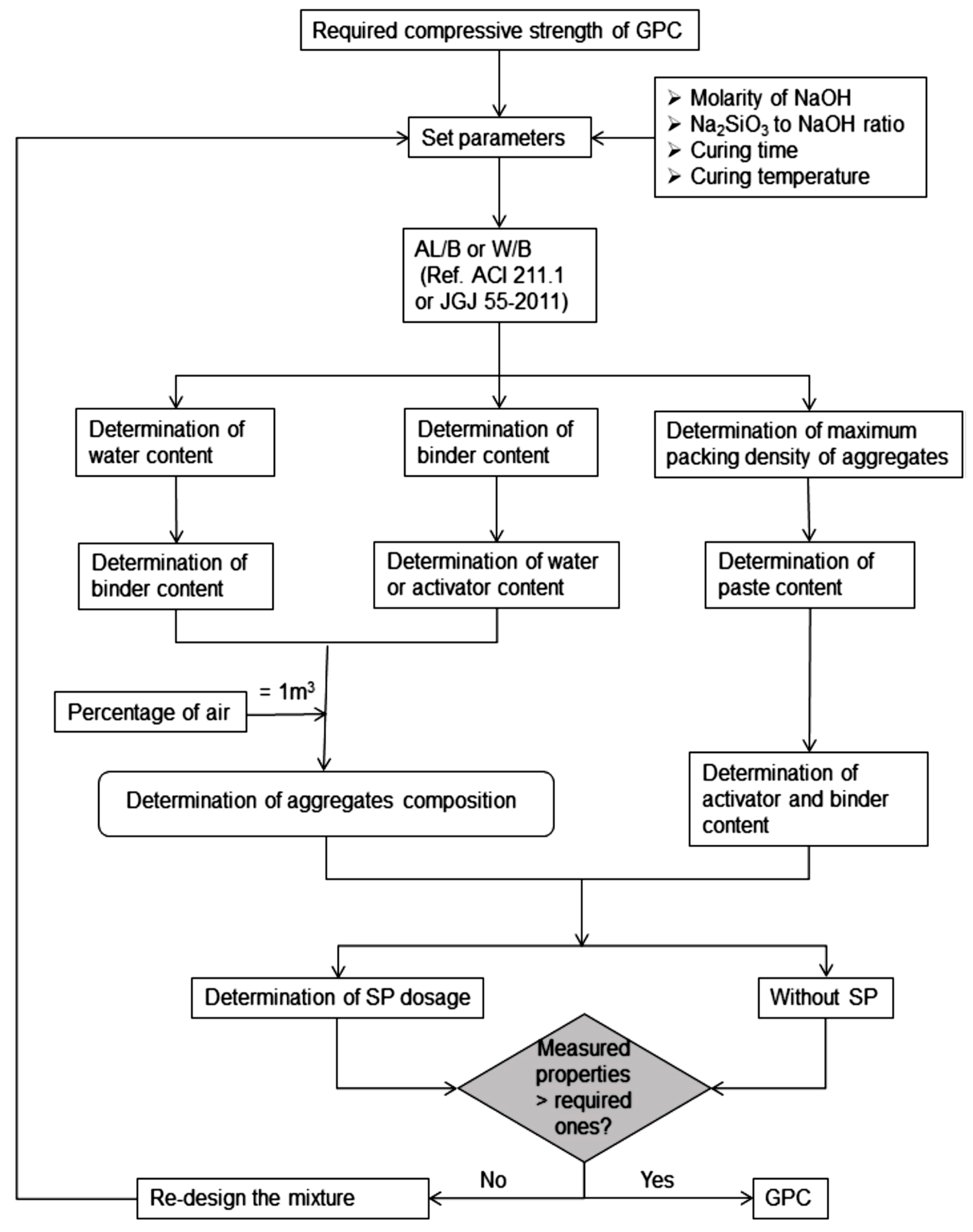

6. Mix Design of GP Concrete

| Ref. | FA (Kg/m3) | Aggregates (kg/m3) | Alkaline Activator (AA) (kg/m3) | NaOH Molarity (M) | Added Water (kg/m3) | Curing Conditions | Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Fine | Coarse | Na2SiO3 (SS) | NaOH (SH) | Temperature (C) | Time (h) | |||||

| [142] | 450 | 500 | 1150 | 162 | 108 | 16 | 24 | 24 | 24 | 38.4 |

| 450 | 500 | 1150 | 162 | 108 | 12 | 24 | 24 | 24 | 41.4 | |

| 450 | 500 | 1150 | 162 | 108 | 8 | 24 | 24 | 24 | 40.0 | |

| [143] | 400 | 651 | 1209 | 114.3 | 45.7 | 14 | 22 | 22 | 24 | 26.7 |

| [144] | 349 | 620 | 1221 | 194 | 12 | 13.3 | 23 | 24 | 41.7 | |

| [145] | 225 | 627 | 1164 | 112.5 | 45 | 14 | 24 | 24 | 24 | 41.1 |

| [146] | 400 | 548 | 1164 | 160 | 80 | 24 | 24 | 24 | 47.0 | |

| 300 | 623 | 1323 | 108 | 72 | 24 | 24 | 24 | 39.0 | ||

| [147] | 400 | 554 | 1293 | 113 | 45 | 14 | 100 | 100 | 24 | 33.5 |

| [148] | 400 | 850 | 950 | 143 | 57.0 | 12 | 40 | 70 | 24 | 53.5 |

| 400 | 850 | 950 | 143 | 57.0 | 12 | 48 | 60 | 48 | 44.8 | |

| 400 | 850 | 950 | 143 | 57.0 | 12 | 60 | 70 | 24 | 37.3 | |

| 400 | 850 | 950 | 143 | 57.0 | 12 | 80 | 70 | 24 | 22.6 | |

| [90] | 400 | 658 | 1222 | 84 | 56.0 | 14 | 0.0 | 20–23 | 27.0 | |

| 400 | 658 | 1222 | 100 | 40.0 | 14 | 0.0 | 20–23 | 72 | 25.0 | |

| [124] | 408 | 647 | 1201 | 103 | 41.0 | 14 | 0.0 | 90 | 24 | 89.0 |

| 408 | 554 | 1294 | 103 | 41.0 | 14 | 21.3 | 30 | 24 | 32.0 | |

| [142] | 476 | 554 | 1294 | 120 | 48.0 | 14 | 0.0 | 60 | 24 | 68.0 |

| 408 | 647 | 1201 | 103 | 41.0 | 8.0 | 0.0 | 60 | 24 | 63.0 | |

| 476 | 554 | 1294 | 120 | 48.0 | 8.0 | 0.0 | 60 | 24 | 57.0 | |

| 408 | 647 | 1201 | 103 | 55.4 | 8.0 | 0.0 | 75 | 24 | 44.0 | |

| 408 | 647 | 1201 | 103 | 41.0 | 10 | 7.5 | 60 | 24 | 45.0 | |

| 408 | 554 | 1294 | 103 | 41.0 | 14 | 0.0 | 60 | 24 | 44.0 | |

| 408 | 647 | 1201 | 103 | 41.0 | 14 | 17.6 | 60 | 24 | 43.0 | |

| 408 | 647 | 1201 | 103 | 41.0 | 12 | 14.4 | 60 | 24 | 42.0 | |

| 408 | 554 | 1294 | 103 | 51.5 | 14 | 16.5 | 60 | 24 | 42.0 | |

| 408 | 554 | 1294 | 103 | 51.5 | 14 | 16.5 | 60 | 24 | 41.0 | |

| 408 | 554 | 1294 | 103 | 51.5 | 14 | 16.5 | 60 | 24 | 41.0 | |

| 408 | 554 | 1294 | 103 | 41.0 | 14 | 16.5 | 60 | 24 | 40.0 | |

| 408 | 647 | 1201 | 103 | 41.0 | 16 | 26.5 | 60 | 24 | 40.0 | |

| 408 | 647 | 1201 | 103 | 41.0 | 14 | 20.7 | 90 | 4 | 37.0 | |

| 408 | 554 | 1294 | 103 | 51.5 | 14 | 16.5 | 60 | 24 | 36.0 | |

| 408 | 554 | 1294 | 103 | 41.0 | 14 | 10.7 | 30 | 24 | 35.0 | |

| 408 | 554 | 1246 | 103 | 41.0 | 8.0 | 20 | 60 | 18 | 29.0 | |

| 408 | 554 | 1080 | 103 | 41.0 | 8.0 | 20 | 60 | 18 | 29.0 | |

| 408 | 554 | 1243 | 103 | 41.0 | 8.0 | 20 | 60 | 18 | 25.0 | |

| [127] | 408 | 616 | 1232 | 103 | 41.0 | 14 | 0.0 | 60 | 24 | 66.8 |

| 408 | 616 | 1232 | 103 | 41.0 | 8.0 | 0.0 | 60 | 24 | 55.0 | |

| 408 | 616 | 1232 | 103 | 41.0 | 10 | 7.5 | 60 | 24 | 52.0 | |

| 408 | 616 | 1232 | 103 | 41.0 | 12 | 14.4 | 60 | 24 | 51.0 | |

| 408 | 616 | 1232 | 103 | 41.0 | 16 | 26.5 | 60 | 24 | 48.0 | |

| 408 | 616 | 1232 | 103 | 41.0 | 14 | 20.7 | 60 | 24 | 45.0 | |

| 408 | 616 | 1232 | 103 | 41.0 | 14 | 10.6 | 60 | 24 | 35.0 | |

| 408 | 616 | 1232 | 103 | 55.4 | 8.0 | 0.0 | 60 | 24 | 33.0 | |

| 408 | 616 | 1232 | 103 | 41.0 | 14 | 21.3 | 60 | 24 | 32.0 | |

| 408 | 616 | 1232 | 103 | 48.0 | 14 | 0.0 | 60 | 24 | 28.0 | |

| [94] | 350 | 645 | 1200 | 103 | 41.0 | 8.0 | 35 | 80 | 24 | 20.0 |

| [149] | 420 | 750 | 1125 | 100.0 | 40.0 | 16 | 0.0 | 100 | 24 | 70.5 |

| 400 | 535 | 1356 | 128.6 | 51.5 | 16 | 12.7 | 100 | 24 | 52.0 | |

| 380. | 540 | 1233 | 141.3 | 56.5 | 16 | 14.6 | 100 | 24 | 49.0 | |

| 405 | 545 | 1235 | 132.4 | 52.9 | 16 | 28.0 | 100 | 24 | 46.0 | |

| 400 | 540 | 1265 | 105.7 | 42.3 | 16 | 24.3 | 100 | 24 | 44.0 | |

| 309 | 648 | 1204 | 59.0 | 27.7 | 10 | 83.7 | 100 | 24 | 42.0 | |

| 254 | 694 | 1290 | 48.5 | 22.8 | 10 | 68.7 | 100 | 24 | 36.8 | |

| 365 | 602 | 1118 | 73.0 | 34.3 | 10 | 103.5 | 100 | 24 | 35.3 | |

| [150] | 408 | 554 | 1294 | 103 | 41.0 | 14 | 22.5 | 60 | 24 | 36.0 |

| 350 | 645 | 1200 | 103 | 41.0 | 8.0 | 35 | 60 | 24 | 48.0 | |

| [134] | 400 | 850 | 950 | 144 | 57.0 | 12 | 48 | 60 | 24–96 | 48.5 |

| 408 | 554 | 1294 | 103 | 41.0 | 8.0 | 0.0 | 60 | 24–96 | 56.0 | |

| [151] | 428 | 623 | 1177 | 102.9 | 68.6 | 14 | 28.5 | 20–23 | 72 | 28.6 |

| [152] | 400 | 651 | 1209 | 114.3 | 45.7 | 12 | 0.0 | 60–90 | 24–96 | 26.0 |

| [125] | 406 | 643 | 1194 | 102.0 | 41.0 | 14 | 26.8 | 70 | 12 | 37.0 |

| 424 | 623 | 1177 | 91.0 | 36.4 | 14 | 16.0 | 70 | 12 | 54.9 | |

| 462 | 599 | 1153 | 132.2 | 52.9 | 14 | 21.2 | 75 | 24 | 49.6 | |

| 461 | 623 | 1177 | 92.3 | 46.2 | 14 | 18.6 | 75 | 24 | 42.5 | |

| 498 | 599 | 1153 | 89.7 | 59.8 | 14 | 26.5 | 60 | 24 | 39.9 | |

| 444 | 623 | 1177 | 111.1 | 44.4 | 14 | 18.6 | 60 | 24 | 38.7 | |

| 480 | 599 | 1153 | 112.0 | 56.0 | 14 | 23.7 | 70 | 12 | 37.1 | |

| 408 | 623 | 1177 | 85.9 | 57.2 | 14 | 24.5 | 75 | 24 | 35.7 | |

| 394 | 647 | 1201 | 105.1 | 52.6 | 14 | 21.5 | 60 | 24 | 29.7 | |

| [153] | 408 | 554 | 1294 | 103 | 41.0 | 16 | 22.5 | 60 | 24 | 45.0 |

| 404 | 640 | 1195 | 102 | 41.0 | 16 | 20 | 60 | 24 | 50.0 | |

| [154] | 408 | 647 | 1201 | 93 | 62.0 | 14 | 4.0 | 60 | 4–96 | 32.0 |

| 408 | 554 | 1294 | 103 | 41.0 | 8.0 | 0.0 | 60 | 4–96 | 58.0 | |

7. Compressive Strength

| Ref. | Main Source Material | Additives | Remarks |

|---|---|---|---|

| [226] | FA | CAC | Increases strength by providing an additional supply of Al and Ca. |

| [227] | FA | Water glass | Increased CS because of higher Si dosage. The recommended dose is 15 g/100 mL. |

| [228] | FA | GBFS | With an M ratio of 0.96 SiO2/Na2O and raw materials of 70% GGBFS and 30% FA, CSs of 48 MPa were attained. |

| [226] | FA | GBFS | Compressive strength and Ms improve when GBFS dosage increases resulting from the production of more C-S-H. |

| [229] | High-calcium FA | PC | A GP composite with a more homogeneous and dense structure than concrete was created. |

| [197] | Low-calcium FA | GGBF, POFA | The addition of 30% POFA and 70% GGBS to FA-GP concrete produced a CS of 67 MPa. POFA dosages above 33% reduce CS. |

| [230] | FA | Superplasticizer | A high superplasticizer dose increases CS. |

| [231] | FA | Chitosan biopolymer | The introduction of N-carboxymethyl chitosan substantially improved tensile strength and resulted in a minor increase in CS. |

| [180] | FA | GGBFS | Slag inclusion in the raw material can improve the CS of GP mixtures, with a slag/FA dosage ratio of 0.8, providing the maximum strength. |

| [232] | FA | Sulfate of calcium and sodium, calcium chloride, and sucrose | Sucrose substantially slows down the ultimate setting time. All admixtures help to improve CS. |

| [233] | FA | GBFS, GCS | GCS partial replacement resulted in higher CS than GBFS partial replacement. |

| [234] | FA | Red mud | After 120 days, there is a decrease in CS. Localization of heavy metals within permitted levels. |

| [150] | FA | Incinerated rice husk ash | At an optimal dosage of 7%, addition resulted in an increase in compressive and bond strength. |

| [235] | FA | Nano-silica | The use of 6.0% nano-silica as a substitute caused improved mechanical properties. |

| [236] | FA | Aluminum-rich waste | A 2.5% admixture of dried powdered and calcined aluminum-rich waste gave early high strength of 34 MPa, but the CS dropped after that. |

| Ref. | Precursor | Curing Regime | Remarks |

|---|---|---|---|

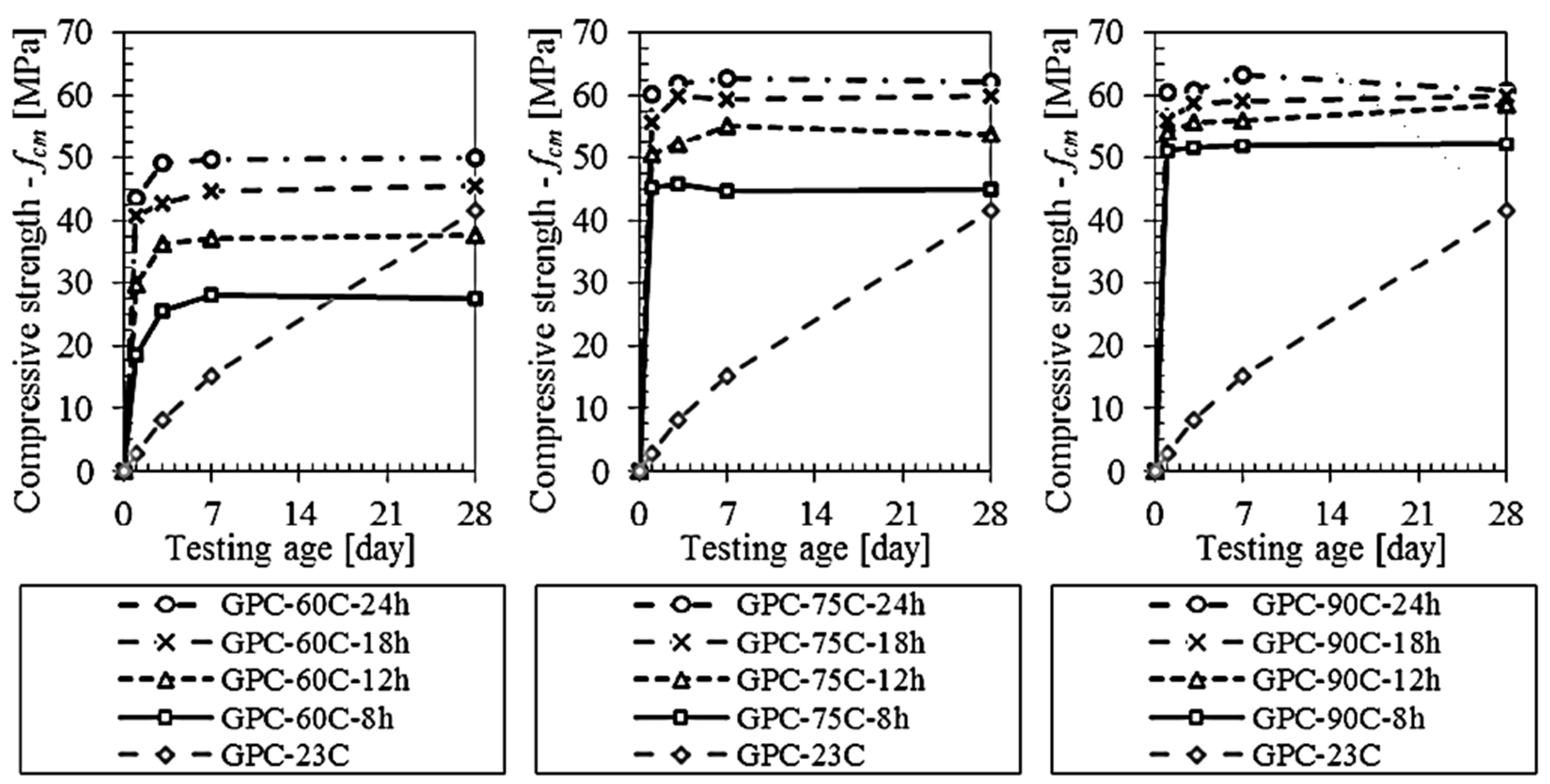

| [237] | FA | Curing temperatures between 66 °C and 85 °C | Curing at 85 °C for 24 h resulted in much greater strength than curing at 66 °C. Over time, the rate of growth in strength dropped after 24 h. |

| [167] | Class C FA | I: 62 °C for 24 h; II: 23 °C at room temperature. | The early strength of HCGC is influenced by higher curing temperatures. Compressive strength increases rapidly over the first 7 days and then gradually increases for the next 28 days. |

| [212] | FA/silica fume | I: 96 °C (8 h); II: 96 °C (2 h) then 150 °C (6 h) dry oven; III: 96 °C (2 h) then 96 °C (6 h) steam | 50–102 MPa for I; 28–57 MPa for II. The greatest results were obtained with III: 35–77 MPa, covering with 95 °C, and stream curing. |

| [234] | FA slag | I: 26 °C (28 days); II: 26 °C (48 h) followed by 60 °C (4 h) | The second curing regime, which was longer in length and followed by high-temperature treatment, resulted in enhanced strength. |

| [167] | FA | 85 °C (5 h–7 days) | Strength increases when curing time is extended. Sealed curing aids in the development of strength while also preventing early carbonation. |

| [238] | FA | 26 °C (16 h–672 h); 41 °C (72 h) to 336 h; 60 °C (16 h–120 h); and 85 °C (1 h–6 h). | 85 °C for 6 h is equivalent to 25 °C for 100 h. The strength of the K-based GP was reduced as the curing temperature increased. |

| [239] | FA | I: 21 days at 20 °C with an initial cure at 70 °C; II: 24 h at 20 °C with an initial cure at 70 °C. | Technique II has a higher CS than method I. |

| [220] | 85% FA and 15% kaolin | 6 h, 12 h, 24 h, and 48 h for temperatures of 30 °C, 50 °C, and 70 °C. | Curing at a greater temperature for a brief time has a positive influence on strength (a couple of hours). Structure deterioration with prolonged exposure to high temperatures. |

| [240] | FA | 24 h at 65 °C; 5 min in the microwave. After 66 °C curing for 3 h, 6 h, and 12 h, curing at room temp | The optimal curing time was 5 min in a microwave at 65 °C for 6 h. |

| [241] | FA | 1 h of pre-curing followed by 24 h of curing at 25, 40, and 60 °C. | Curing at 60 °C is ideal (for 7- and 28-day strength) |

| [200] | FA | 24 h, followed by 36 h in the oven (50–90 °C). | Curing in an oven at 80 °C is ideal. |

| [242] | FA | Room temperature for 9–12 h, then salt water, normal water, and sealed curing environment. | The sealed state produced the best outcomes, followed by salt water and the least effective water cure. |

| Ref. | Precursors | Precursor Gradation | Main Constants | Compressive Strength (MPa) | Remarks |

|---|---|---|---|---|---|

| [243] | FA | 100% GFA (1.45 m2/g) | Na2SiO3 with a silicate modulus of 2.5. | 6.79 | With the addition of finer binder content, the CS of 28 days is increased. |

| 25% OFA (0.395 m2/g) + 75% GFA | 4.65 | ||||

| 50% GFA and 50% OFA | 3.85 | ||||

| 25% GFA and 75% OFA | 3.84 | ||||

| [244] | FA | 365 m2/kg | NaOH dosage of 13 M, Na2SiO3/NaOH ratio of 3, Sol/FA ratio of 0.35, curing time of 7 h at 110 °C | 21.85 | With increasing fineness, there is a substantial rise in CS after 28 days. |

| 440 m2/kg | 29.7 | ||||

| 612 m2/kg | 42.29 | ||||

| [245] | FA | d50 = 32.24 µm and fineness 2110 cm2/g 525 m2/kg | Alkali sol with a dosage of 13 M was utilized, and the L/S ratio was 0.35 after 4 h of curing at 90 °C. | 40 62 | With an increase in fineness, CS and workability improve after 28 days. |

| 444 m2/kg | 57.62 | ||||

| 365 m2/kg | 39.22 | ||||

| [246] | FA | X10 = 0.12 µm, X99 = 3.66 µm, | Na2SiO3/NaOH ratio of 0.4 and activator to FA ratio of 0.45%. | 9.5 | With an increase in fineness, there is a substantial rise in the CS of mortar after 28 days. |

| X10 = 0.08 µm, X99 = 0.64 µm, | 15.5 | ||||

| X10 = 0.04 µm, X99 = 0.37 µm, | 19.3 | ||||

| [200] | FA, RHBA | FA 75 µm + RHBA 90 µm | Curing at 80 °C for 36 h with a NaOH dosage of 12 M. | 34 | With an increase in fineness, there is a substantial rise in the 28-day CS of mortar. |

| FA 75 µm + RHBA 7 µm | 44 | ||||

| FA 3 µm + RHBA 90 µm | 52.6 | ||||

| FA 3 µm + RHBA 7 µm | 59.1 | ||||

| [205] | FA, RHA | 5.1% retained on sieve 325 of RHA | As-received FA, Na2SO3/NaOH ratio = 4, 60 °C for 48 h. | 34.5 | Increased fineness resulted in an overall enhancement in CS after 28 days. |

| 1.1% retained on sieve 325 of RHA | 43 | ||||

| [204] | BA | d50 = 15.8µm and fineness 5100 cm2/g | Curing at 75 °C for 48 h with a Na2SO3/NaOH ratio of 1.5 and a NaOH dosage of 10 M. | 64.5 | With a rise in fineness, the CS of mortar increases in 28 days. |

| d50 = 24.4 µm and fineness 3500 cm2/g | 48 | ||||

| [158] | BA | Particle size of 15.7 µm | Liquid alkaline/ash ratios of 0.429–0.709, Na2SiO3/NaOH ratios of 0.67–1.5, and 7.5–12.5 M NaOH. | 24–58 | Grinding boosts reactivity and lowers porosity in BA particles, resulting in reasonably high workability and CS of 28 days. |

8. Microstructure (Ms)

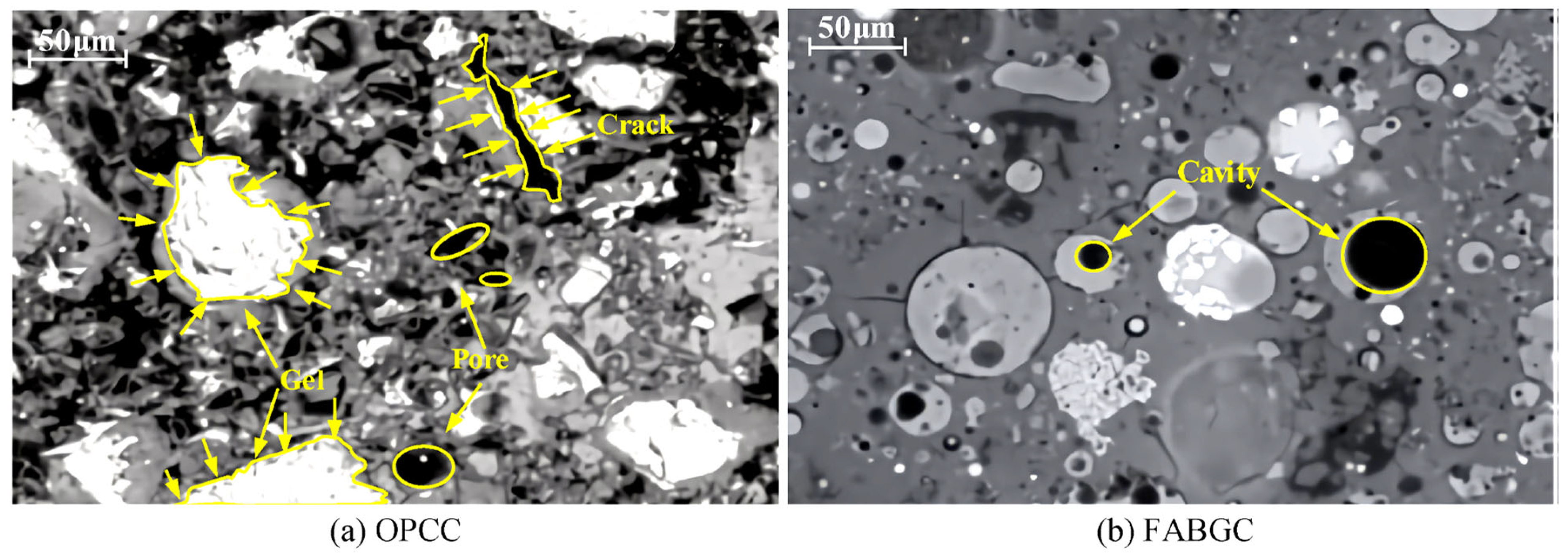

8.1. Scanning Electron Microscopy (SEM)

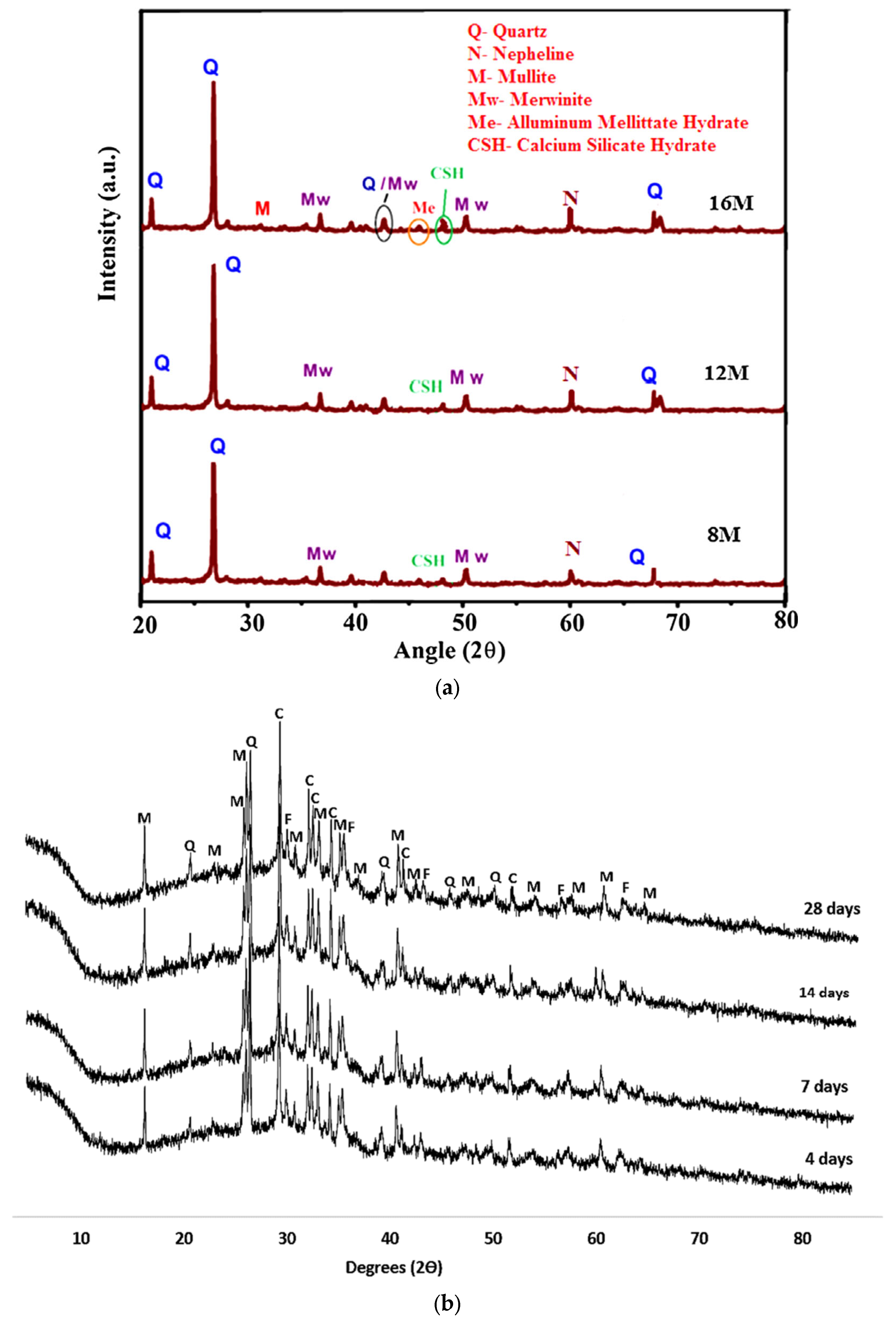

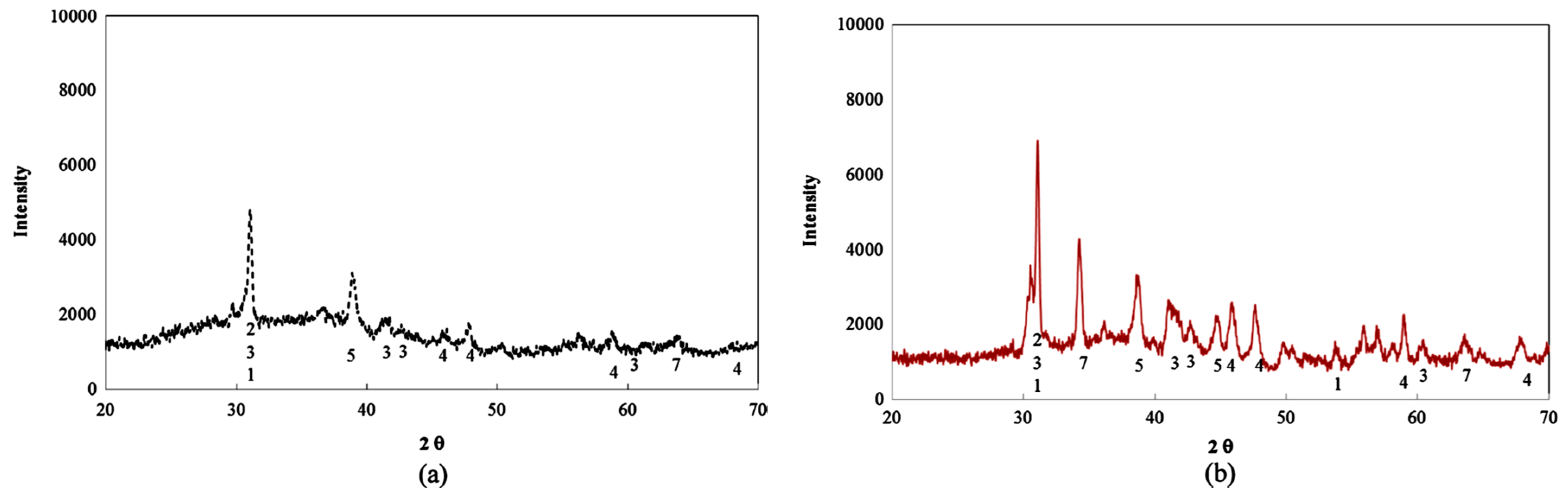

8.2. Wide-Angle X-ray Properties

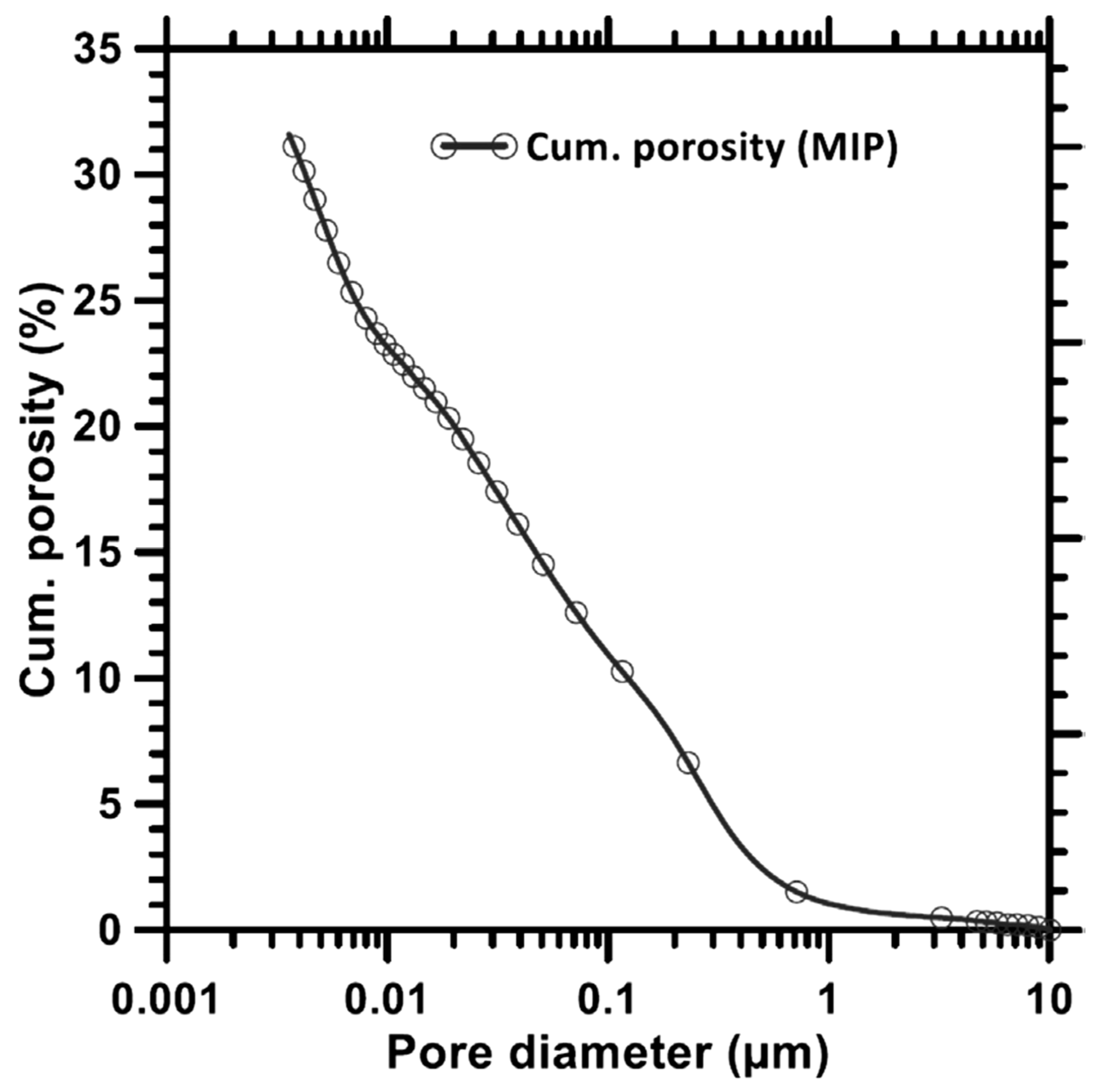

8.3. Mercury Intrusion Porosimetry (MIP)

8.4. GP Concrete and PC Ms Comparison

9. Challenges for Solid Wastes in Geopolymer

10. Conclusions

- The recommended S/A ratio for producing GPs of appropriate strength varies depending on the nature and content of the raw material. S/A ratios of 2–2.5 (class F FA) and 2.5–3.5 (class C FA) were determined to be optimal. The influence of Al and Si on setting and hardening characteristics in high-Ca FA is substantial.

- The conventional AAs, a combination of NaOH and Na2SiO3, are very good and economically viable alkali activating sols. Microstructural investigations revealed that GP concrete prepared with a lower NaOH to Na2SiO3 ratio reacts more efficiently because of the large surface area available for reaction and binding without being clogged by excess water. However, the hydroxyl groups tend to condense when specimens are heated to high temperatures.

- FA-ITZ GP concrete consists of gel, pores, fissures, and unreacted FA particles. N-A-S-H gel can improve the strength of the ITZ by promoting the combination of the aggregate interface and the GP matrix. As a result, FA-GP concrete has nearly no obvious weak ITZ near the aggregate.

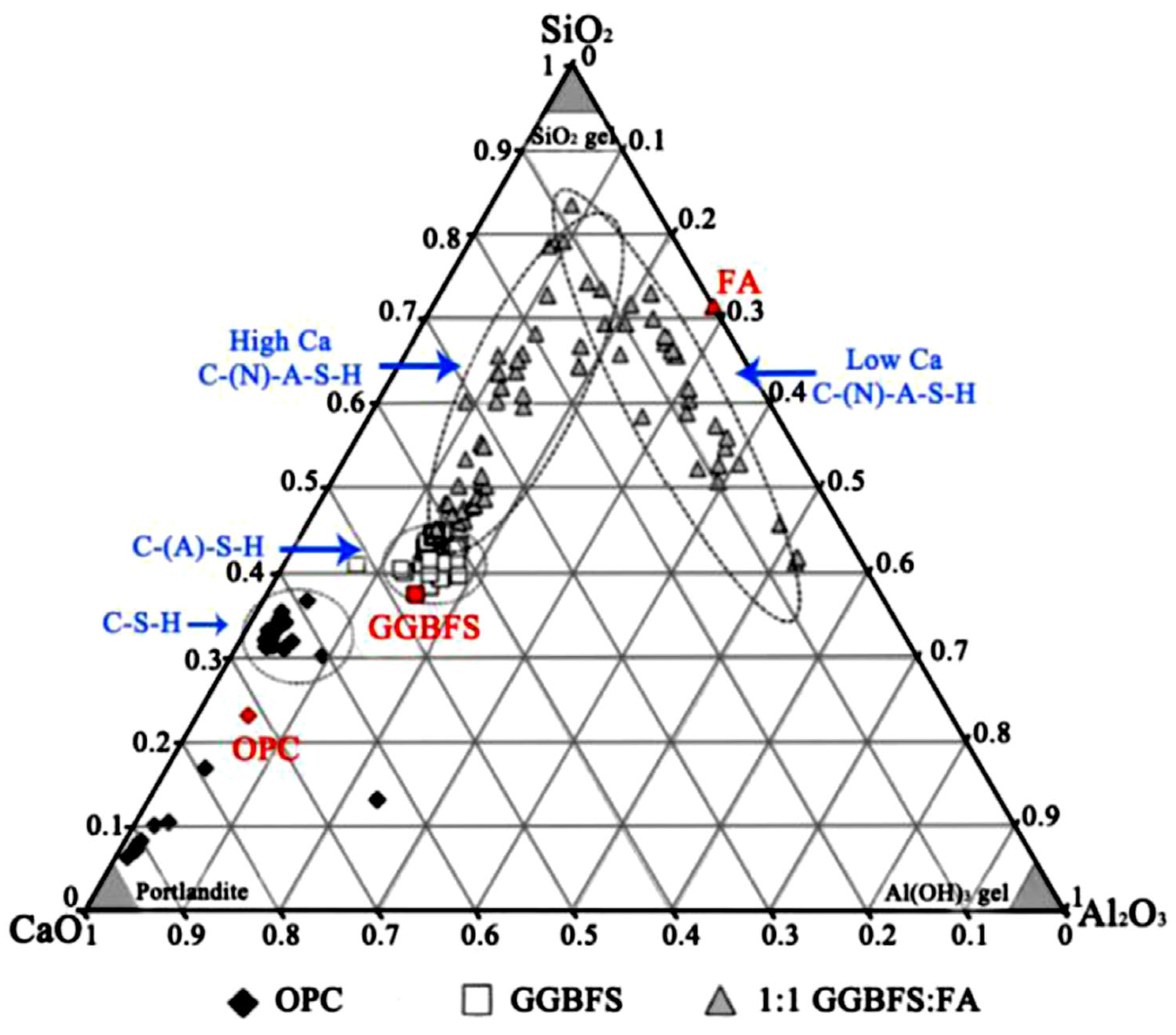

- The existence of C-S-H gel, as well as GP gel, improves the mechanical and Ms characteristics of precursors either having high Ca or mixed with Ca components.

- When it comes to GP synthesis, the criticality of precursor oxide dosage cannot be overstated. In general, the Si oxide content should be between 45% and 55%, the Al dosage should be between 22% and 28%, and the FeCO2 and CaO content should be between 15% and 20%.

- The experiment using MIP analysis reveals that extending the curing duration of GP specimens is useful in minimizing pores. The increased geopolymerization limits the connection between the pores, leading to a denser pattern. Furthermore, FA particles and gel may be used to refine the pores in FA-GP concrete. As a result, FA-GP concrete gel pores and capillary pores are concentrated in the tiny pore-size region. However, it is worth noting that the silicon content of the AA plays an essential role in the refining of the FA-GP concrete pore structure.

- It was found that increasing the fineness leads to an increase in the reaction rate and therefore requires a minus time of heating to achieve strength, as it was found that more than 60 MPa can achieve the strength of GP concrete by increasing the fineness of the precursor material.

- FA-GP concrete with a compact and denser structure shows high mechanical strength and good efflorescence that make it an ideal choice for the construction industry and has been effectively used in precast industries. Moreover, there is an enormous possibility of utilizing high-Ca GP as a restorative material.

11. Recommendations

- Currently, the findings of relevant investigations on the Ms of FA-GP concrete are discordant in several respects. For example, the conclusions on forming a new crystalline phase prior to and during the AA reaction of FA are inconsistent. As a result, additional systematic and in-depth research is required to prove this substance’s usefulness with greater certainty. Additionally, advanced analytical techniques such as micro- or nano-analysis and nuclear magnetic resonance must be employed.

- Suitable guidelines for the selection of aggregate contents in FA-GP concrete should be developed. It is also critical to develop design procedures for each substantial predecessor. Furthermore, the usage of dune sands, fibers, marble dust, date ash, and other materials as precursors should be investigated.

- Detailed investigations, such as those relating to the derivation and modeling of reaction kinetics under different treatment and production circumstances of the developing class of GP raw material, such as blended GPs and biomass ash GPs, are needed.

- GP binders need a high pH and heat curing. As a result, efforts are needed to create a room-temperature-cured one-component GP system that uses solid activators rather than alkaline sols in order to gain widespread acceptability in the field.

- FA-GP concrete should be given more functionality instead of using it as an alternative cement only. FA-GP concrete with biomass has the potential for development as a new class of lightweight fireproof composites.

- Lastly, more research is needed to evaluate the cost of GP concrete compared to that of standard concrete. Furthermore, contradictory findings regarding the embodied energy and carbon footprint of GPs in comparison to traditional Portland cement must be addressed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmed, H.U.; Mohammed, A.S.; Qaidi, S.M.A.; Faraj, R.H.; Sor, N.H.; Mohammed, A.A. Compressive strength of geopolymer concrete composites: A systematic comprehensive review, analysis and modeling. Eur. J. Environ. Civ. Eng. 2022, 1–46. [Google Scholar] [CrossRef]

- Ahmad, J.; Kontoleon, K.J.; Majdi, A.; Naqash, M.T.; Deifalla, A.F.; Ben Kahla, N.; Isleem, H.F.; Qaidi, S.M.A. A Comprehensive Review on the Ground Granulated Blast Furnace Slag (GGBS) in Concrete Production. Sustainability 2022, 14, 8783. [Google Scholar] [CrossRef]

- Saeed, A.; Najm, H.M.; Hassan, A.; Qaidi, S.; Sabri, M.M.S.; Mashaan, N.S. A Comprehensive Study on the Effect of Regular and Staggered Openings on the Seismic Performance of Shear Walls. Buildings 2022, 12, 1293. [Google Scholar] [CrossRef]

- Elsheikh, A. Bistable Morphing Composites for Energy-Harvesting Applications. Polymers 2022, 14, 1893. [Google Scholar] [CrossRef] [PubMed]

- Qaidi, S. Behaviour of Concrete Made of Recycled Waste PET and Confined with CFRP Fabrics. Master’s Thesis, University of Duhok, Duhok, Iraq, 2021. [Google Scholar]

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Arshad, S.; Sharif, M.B.; Irfan-Ul-Hassan, M.; Khan, M.; Zhang, J.-L. Efficiency of Supplementary Cementitious Materials and Natural Fiber on Mechanical Performance of Concrete. Arab. J. Sci. Eng. 2020, 45, 8577–8589. [Google Scholar] [CrossRef]

- Cao, M.; Khan, M. Effectiveness of multiscale hybrid fiber reinforced cementitious composites under single degree of freedom hydraulic shaking table. Struct. Concr. 2021, 22, 535–549. [Google Scholar] [CrossRef]

- Cao, M.; Khan, M.; Ahmed, S. Effectiveness of Calcium Carbonate Whisker in Cementitious Composites. Period. Polytech. Civ. Eng. 2020, 64, 265–275. [Google Scholar] [CrossRef]

- A Miller, S.; Horvath, A.; Monteiro, P.J.M. Readily implementable techniques can cut annual CO2 emissions from the production of concrete by over 20%. Environ. Res. Lett. 2016, 11, 074029. [Google Scholar] [CrossRef]

- Miller, S.A.; Moore, F.C. Climate and health damages from global concrete production. Nat. Clim. Chang. 2020, 10, 439–443. [Google Scholar] [CrossRef]

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; De-Prado-Gil, J.; Qaidi, S.M.A.; Brahmia, A. Effects of waste glass and waste marble on mechanical and durability performance of concrete. Sci. Rep. 2021, 11, 21525. [Google Scholar] [CrossRef] [PubMed]

- Gollakota, A.R.; Volli, V.; Shu, C.-M. Progressive utilisation prospects of coal fly ash: A review. Sci. Total Environ. 2019, 672, 951–989. [Google Scholar] [CrossRef] [PubMed]

- Amran, Y.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Xiao, R.; Polaczyk, P.; Zhang, M.; Jiang, X.; Zhang, Y.; Huang, B.; Hu, W. Evaluation of Glass Powder-Based Geopolymer Stabilized Road Bases Containing Recycled Waste Glass Aggregate. Transp. Res. Rec. J. Transp. Res. Board 2020, 2674, 22–32. [Google Scholar] [CrossRef]

- Ng, C.; Alengaram, U.J.; Wong, L.S.; Mo, K.H.; Jumaat, M.Z.; Ramesh, S. A review on microstructural study and compressive strength of geopolymer mortar, paste and concrete. Constr. Build. Mater. 2018, 186, 550–576. [Google Scholar] [CrossRef]

- Albidah, A.S. Effect of partial replacement of geopolymer binder materials on the fresh and mechanical properties: A review. Ceram. Int. 2021, 47, 14923–14943. [Google Scholar] [CrossRef]

- Raj, M.K.A.; Muthusamy, S.; Panchal, H.; Ibrahim, A.M.M.; Alsoufi, M.S.; Elsheikh, A.H. Investigation of mechanical properties of dual-fiber reinforcement in polymer composite. J. Mater. Res. Technol. 2022, 18, 3908–3915. [Google Scholar] [CrossRef]

- Kamal, A.; Ashmawy, M.; Shanmugan, S.; Algazzar, A.M.; Elsheikh, A.H. Fabrication techniques of polymeric nanocomposites: A comprehensive review. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 236, 4843–4861. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Panchal, H.; Shanmugan, S.; Muthuramalingam, T.; El-Kassas, A.; Ramesh, B. Recent progresses in wood-plastic composites: Pre-processing treatments, manufacturing techniques, recyclability and eco-friendly assessment. Clean. Eng. Technol. 2022, 8, 100450. [Google Scholar] [CrossRef]

- Assi, L.; Carter, K.; Deaver, E.; Anay, R.; Ziehl, P. Sustainable concrete: Building a greener future. J. Clean. Prod. 2018, 198, 1641–1651. [Google Scholar] [CrossRef]

- Assi, L.N.; Carter, K.; Deaver, E.; Ziehl, P. Review of availability of source materials for geopolymer/sustainable concrete. J. Clean. Prod. 2020, 263, 121477. [Google Scholar] [CrossRef]

- Van Jaarsveld, J.G.S.; van Deventer, J.S.J.; Lukey, G.C. The characterisation of source materials in fly ash-based geopolymers. Mater. Lett. 2003, 57, 1272–1280. [Google Scholar] [CrossRef]

- Ahmad, J.; Majdi, A.; Elhag, A.B.; Deifalla, A.F.; Soomro, M.; Isleem, H.F.; Qaidi, S. A Step towards Sustainable Concrete with Substitution of Plastic Waste in Concrete: Overview on Mechanical, Durability and Microstructure Analysis. Crystals 2022, 12, 944. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.A.; Rafiq, S.; Mohammed, A.S.; Mosavi, A.; Sor, N.H.; Qaidi, S.M.A. Compressive Strength of Sustainable Geopolymer Concrete Composites: A State-of-the-Art Review. Sustainability 2021, 13, 13502. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.S.; Faraj, R.H.; Qaidi, S.M.; Mohammed, A.A. Compressive strength of geopolymer concrete modified with nano-silica: Experimental and modeling investigations. Case Stud. Constr. Mater. 2022, 16, e01036. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Barbosa, V.F.; MacKenzie, K. Thermal behaviour of inorganic geopolymers and composites derived from sodium polysialate. Mater. Res. Bull. 2003, 38, 319–331. [Google Scholar] [CrossRef]

- Phair, J.; Van Deventer, J. Effect of silicate activator pH on the leaching and material characteristics of waste-based inorganic polymers. Miner. Eng. 2001, 14, 289–304. [Google Scholar] [CrossRef]

- Najm, H.M.; Nanayakkara, O.; Sabri, M.M.S. Destructive and Non-Destructive Evaluation of Fibre-Reinforced Concrete: A Comprehensive Study of Mechanical Properties. Materials 2022, 15, 4432. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Improvement in concrete behavior with fly ash, silica-fume and coconut fibres. Constr. Build. Mater. 2019, 203, 174–187. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Optimization of concrete stiffeners for confined brick masonry structures. J. Build. Eng. 2020, 32, 101689. [Google Scholar] [CrossRef]

- Rodgers, L. Climate change: The massive CO2 emitter you may not know about. BBC News 2018, 17, 2018. [Google Scholar]

- Farhan, K.Z.; Johari, M.A.M.; Demirboğa, R. Assessment of important parameters involved in the synthesis of geopolymer composites: A review. Constr. Build. Mater. 2020, 264, 120276. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Use of geopolymer concrete for a cleaner and sustainable environment—A review of mechanical properties and microstructure. J. Clean. Prod. 2019, 223, 704–728. [Google Scholar] [CrossRef]

- Mohajerani, A.; Suter, D.; Jeffrey-Bailey, T.; Song, T.; Arulrajah, A.; Horpibulsuk, S.; Law, D. Recycling waste materials in geopolymer concrete. Clean Technol. Environ. Policy 2019, 21, 493–515. [Google Scholar] [CrossRef]

- Ahmed, S.N.; Sor, N.H.; Ahmed, M.A.; Qaidi, S.M. Thermal conductivity and hardened behavior of eco-friendly concrete incorporating waste polypropylene as fine aggregate. Mater. Today Proc. 2022, 57, 818–823. [Google Scholar] [CrossRef]

- Aslam, F.; Zaid, O.; Althoey, F.; Alyami, S.H.; Qaidi, S.M.A.; de Prado Gil, J.; Martínez-García, R. Evaluating the influence of fly ash and waste glass on the characteristics of coconut fibers reinforced concrete. Struct. Concrete, 2022; early view. [Google Scholar] [CrossRef]

- Ryu, G.S.; Lee, Y.B.; Koh, K.T.; Chung, Y.S. The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Constr. Build. Mater. 2013, 47, 409–418. [Google Scholar] [CrossRef]

- Sreevidya, V. Investigations on the Flexural Behaviour of Ferro Geopolymer Composite Slabs; Anna University: Tamil Nadu, India, 2014. [Google Scholar] [CrossRef]

- Emad, W.; Mohammed, A.S.; Bras, A.; Asteris, P.G.; Kurda, R.; Muhammed, Z.; Hassan, A.; Qaidi, S.M.; Sihag, P. Metamodel techniques to estimate the compressive strength of UHPFRC using various mix proportions and a high range of curing temperatures. Constr. Build. Mater. 2022, 349, 128737. [Google Scholar] [CrossRef]

- Faraj, R.H.; Ahmed, H.U.; Rafiq, S.; Sor, N.H.; Ibrahim, D.F.; Qaidi, S.M. Performance of Self-Compacting mortars modified with Nanoparticles: A systematic review and modeling. Clean. Mater. 2022, 4, 100086. [Google Scholar] [CrossRef]

- He, X.; Yuhua, Z.; Qaidi, S.; Isleem, H.F.; Zaid, O.; Althoey, F.; Ahmad, J. Mine tailings-based geopolymers: A comprehensive review. Ceram. Int. 2022, 48, 24192–24212. [Google Scholar] [CrossRef]

- Maglad, A.M.; Zaid, O.; Arbili, M.M.; Ascensão, G.; Șerbănoiu, A.A.; Grădinaru, C.M.; García, R.M.; Qaidi, S.M.A.; Althoey, F.; de Prado-Gil, J. A Study on the Properties of Geopolymer Concrete Modified with Nano Graphene Oxide. Buildings 2022, 12, 1066. [Google Scholar] [CrossRef]

- Mansi, A.; Sor, N.H.; Hilal, N.; A Qaidi, S.M. The Impact of Nano Clay on Normal and High-Performance Concrete Characteristics: A Review. In Proceedings of the 2nd International Conference of Al-Esraa University College for Engineering Sciences (ICAUC_ES 2021), Baghdad, Iraq, 3–4 November 2021; p. 012085. [Google Scholar]

- Martínez-García, R.; Jagadesh, P.; Zaid, O.; Șerbănoiu, A.A.; Fraile-Fernández, F.J.; de Prado-Gil, J.; Qaidi, S.M.A.; Grădinaru, C.M. The Present State of the Use of Waste Wood Ash as an Eco-Efficient Construction Material: A Review. Materials 2022, 15, 5349. [Google Scholar] [CrossRef] [PubMed]

- Qaidi, S. Ultra-high-performance fiber-reinforced concrete (UHPFRC): A mini-review of the challenges. ScienceOpen Preprints 2022, preprints. [Google Scholar]

- Qaidi, S. Ultra-high-performance fiber-reinforced concrete: Applications. Preprints 2022. [Google Scholar] [CrossRef]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics—Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Dwivedi, A.; Jain, M.K. Fly ash–waste management and overview: A Review. Recent Res. Sci. Technol. 2014, 6, 1. [Google Scholar]

- Amran, M.; Debbarma, S.; Ozbakkaloglu, T. Fly ash-based eco-friendly geopolymer concrete: A critical review of the long-term durability properties. Constr. Build. Mater. 2021, 270, 121857. [Google Scholar] [CrossRef]

- Ranjbar, N.; Kuenzel, C. Cenospheres: A review. Fuel 2017, 207, 1–12. [Google Scholar] [CrossRef]

- Arnett, D.K.; Blumenthal, R.S.; Albert, M.A.; Buroker, A.B.; Goldberger, Z.D.; Hahn, E.J.; Himmelfarb, C.D.; Khera, A.; Lloyd-Jones, D.; McEvoy, J.W.; et al. 2019 ACC/AHA Guideline on the Primary Prevention of Cardiovascular Disease: A Report of the American College of Cardiology/American Heart Association Task Force on Clinical Practice Guidelines. Circulation 2019, 140, e596–e646. [Google Scholar] [CrossRef]

- Nanayakkara, O.; Najm, H.M.; Sabri, M.M.S. Effect of Using Steel Bar Reinforcement on Concrete Quality by Ultrasonic Pulse Velocity Measurements. Materials 2022, 15, 4565. [Google Scholar] [CrossRef] [PubMed]

- Qaidi, S.M.A. PET-Concrete; University of Duhok: Duhok, Iraq, 2021. [Google Scholar]

- Davidovits, J. Geopolymers and geopolymeric materials. J. Therm. Anal. 1989, 35, 429–441. [Google Scholar] [CrossRef]

- Purdon, A. The action of alkalis on blast-furnace slag. J. Soc. Chem. Ind. 1940, 59, 191–202. [Google Scholar]

- Shi, C.; Roy, D.; Krivenko, P. Alkali-Activated Cements and Concretes; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Provis, J.L.; Van Deventer, J.S. Alkali Activated Materials: State-of-the-Art Report; RILEM TC 224-AAM; Springer Science & Business Media: Dordrecht, The Netherlands, 2013. [Google Scholar]

- Pacheco-Torgal, E.; Labrincha, J.; Leonelli, C.; Palomo, A.; Chindaprasit, P. Handbook of Alkali-Activated Cements, Mortars and Concretes; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Khan, M.; Cao, M.; Ai, H.; Hussain, A. Basalt Fibers in Modified Whisker Reinforced Cementitious Composites. Period. Polytech. Civ. Eng. 2022, 66, 344–354. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Ali, M. Experimental and Empirical Study of Basalt Fibber Reinforced Concrete; Building Tomorrow’s Society: Fredericton, NB, Canada, 2018; Paper ID–MA39_0610035833. [Google Scholar]

- Khan, M.; Cao, M.; Chu, S.; Ali, M. Properties of hybrid steel-basalt fiber reinforced concrete exposed to different surrounding conditions. Constr. Build. Mater. 2022, 322, 126340. [Google Scholar] [CrossRef]

- Provis, J.L.; van Deventer, J.S.J. Geopolymerisation kinetics. 2. Reaction kinetic modelling. Chem. Eng. Sci. 2007, 62, 2318–2329. [Google Scholar] [CrossRef]

- Provis, J.L.; van Deventer, J.S.J. Geopolymerisation kinetics. 1. In situ energy-dispersive X-ray diffractometry. Chem. Eng. Sci. 2007, 62, 2309–2317. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Properties of fresh and hardened fly ash/slag based geopolymer concrete: A review. J. Clean. Prod. 2020, 270, 122389. [Google Scholar] [CrossRef]

- Qaidi, S.M.A. PET-Concrete Confinement with CFRP; University of Duhok: Duhok, Iraq, 2021. [Google Scholar]

- Qaidi, S.M.A. Ultra-High-Performance Fiber-Reinforced Concrete: Principles and Raw Materials; University of Duhok: Duhok, Iraq, 2022. [Google Scholar]

- Singh, J.; Singh, S.P. Geopolymerization of solid waste of non-ferrous metallurgy—A review. J. Environ. Manag. 2019, 251, 109571. [Google Scholar] [CrossRef] [PubMed]

- Shi, C.; Jimenez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Liu, M.Y.J.; Alengaram, U.J.; Santhanam, M.; Jumaat, M.Z.; Mo, K.H. Microstructural investigations of palm oil fuel ash and fly ash based binders in lightweight aggregate foamed geopolymer concrete. Constr. Build. Mater. 2016, 120, 112–122. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, R.; Jiang, X.; Li, W.; Zhu, X.; Huang, B. Effect of particle size and curing temperature on mechanical and microstructural properties of waste glass-slag-based and waste glass-fly ash-based geopolymers. J. Clean. Prod. 2020, 273, 122970. [Google Scholar] [CrossRef]

- Gupta, V.; Pathak, D.K.; Siddique, S.; Kumar, R.; Chaudhary, S. Study on the mineral phase characteristics of various Indian biomass and coal fly ash for its use in masonry construction products. Constr. Build. Mater. 2019, 235, 117413. [Google Scholar] [CrossRef]

- Hashmi, A.F.; Shariq, M.; Baqi, A.; Haq, M. Optimization of fly ash concrete mix—A solution for sustainable development. Mater. Today Proc. 2020, 26, 3250–3256. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Hussain, A.; Chu, S. Effect of silica-fume content on performance of CaCO3 whisker and basalt fiber at matrix interface in cement-based composites. Constr. Build. Mater. 2021, 300, 124046. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Effectiveness of hybrid steel-basalt fiber reinforced concrete under compression. Case Stud. Constr. Mater. 2022, 16, e00941. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Hybrid fiber concrete with different basalt fiber length and content. Struct. Concr. 2021, 23, 346–364. [Google Scholar] [CrossRef]

- Yin, K.; Ahamed, A.; Lisak, G. Environmental perspectives of recycling various combustion ashes in cement production—A review. Waste Manag. 2018, 78, 401–416. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Ishida, T.; Gu, R. A study of the influence of crystal component on the reactivity of low-calcium fly ash in alkaline conditions based on SEM-EDS. Constr. Build. Mater. 2020, 243, 118227. [Google Scholar] [CrossRef]

- Yilmaz, G. Structural characterization of glass–ceramics made from fly ash containing SiO2–Al2O3–Fe2O3–CaO and analysis by FT-IR–XRD–SEM methods. J. Mol. Struct. 2012, 1019, 37–42. [Google Scholar] [CrossRef]

- Qaidi, S.M.A. Ultra-High-Performance Fiber-Reinforced Concrete: Mixture Design; University of Duhok: Duhok, Iraq, 2022. [Google Scholar]

- Qaidi, S.M.A. Ultra-High-Performance Fiber-Reinforced Concrete: Hydration and Microstructure; University of Duhok: Duhok, Iraq, 2022. [Google Scholar]

- Qaidi, S.M.A. Ultra-High-Performance Fiber-Reinforced Concrete: Fresh Properties; University of Duhok: Duhok, Iraq, 2022. [Google Scholar] [CrossRef]

- Chou, M.I.M. Fly Ash, Encyclopedia of Sustainability Scienc and Technology; Springer New York: New York, NY, USA, 2012; pp. 3820–3843. [Google Scholar]

- Davidovits, J. 30 years of successes and failures in geopolymer applications. Market trends and potential breakthroughs. In Geopolymer 2002 Conference; Geopolymer Institute: Saint-Quentin, France; Melbourne, VC, Australia, 2002; p. 29. [Google Scholar]

- Dimas, D.; Giannopoulou, I.; Panias, D. Polymerization in sodium silicate solutions: A fundamental process in geopolymerization technology. J. Mater. Sci. 2009, 44, 3719–3730. [Google Scholar] [CrossRef]

- He, J.; Zhang, J.; Yu, Y.; Zhang, G. The strength and microstructure of two geopolymers derived from metakaolin and red mud-fly ash admixture: A comparative study. Constr. Build. Mater. 2012, 30, 80–91. [Google Scholar] [CrossRef]

- Kriven, W.M.; Bell, J.L.; Gordon, M. Microstructure and Microchemistry of Fully-Reacted Geopolymers and Geopolymer Matrix Composites. Ceram. Trans. 2003, 153, 227–250. [Google Scholar]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Mallicoat, S.W.; Kriven, W.M.; van Deventer, J.S.J. Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloids Surf. A Physicochem. Eng. Asp. 2005, 269, 47–58. [Google Scholar] [CrossRef]

- Zhuang, X.Y.; Chen, L.; Komarneni, S.; Zhou, C.H.; Tong, D.S.; Yang, H.M.; Yu, W.H.; Wang, H. Fly ash-based geopolymer: Clean production, properties and applications. J. Clean. Prod. 2016, 125, 253–267. [Google Scholar] [CrossRef]

- Kamseu, E.; Alzari, V.; Nuvoli, D.; Sanna, D.; Lancellotti, I.; Mariani, A.; Leonelli, C. Dependence of the geopolymerization process and end-products to the nature of solid precursors: Challenge of the sustainability. J. Clean. Prod. 2021, 278, 123587. [Google Scholar] [CrossRef]

- Ren, B.; Zhao, Y.; Bai, H.; Kang, S.; Zhang, T.; Song, S. Eco-friendly geopolymer prepared from solid wastes: A critical review. Chemosphere 2021, 267, 128900. [Google Scholar] [CrossRef] [PubMed]

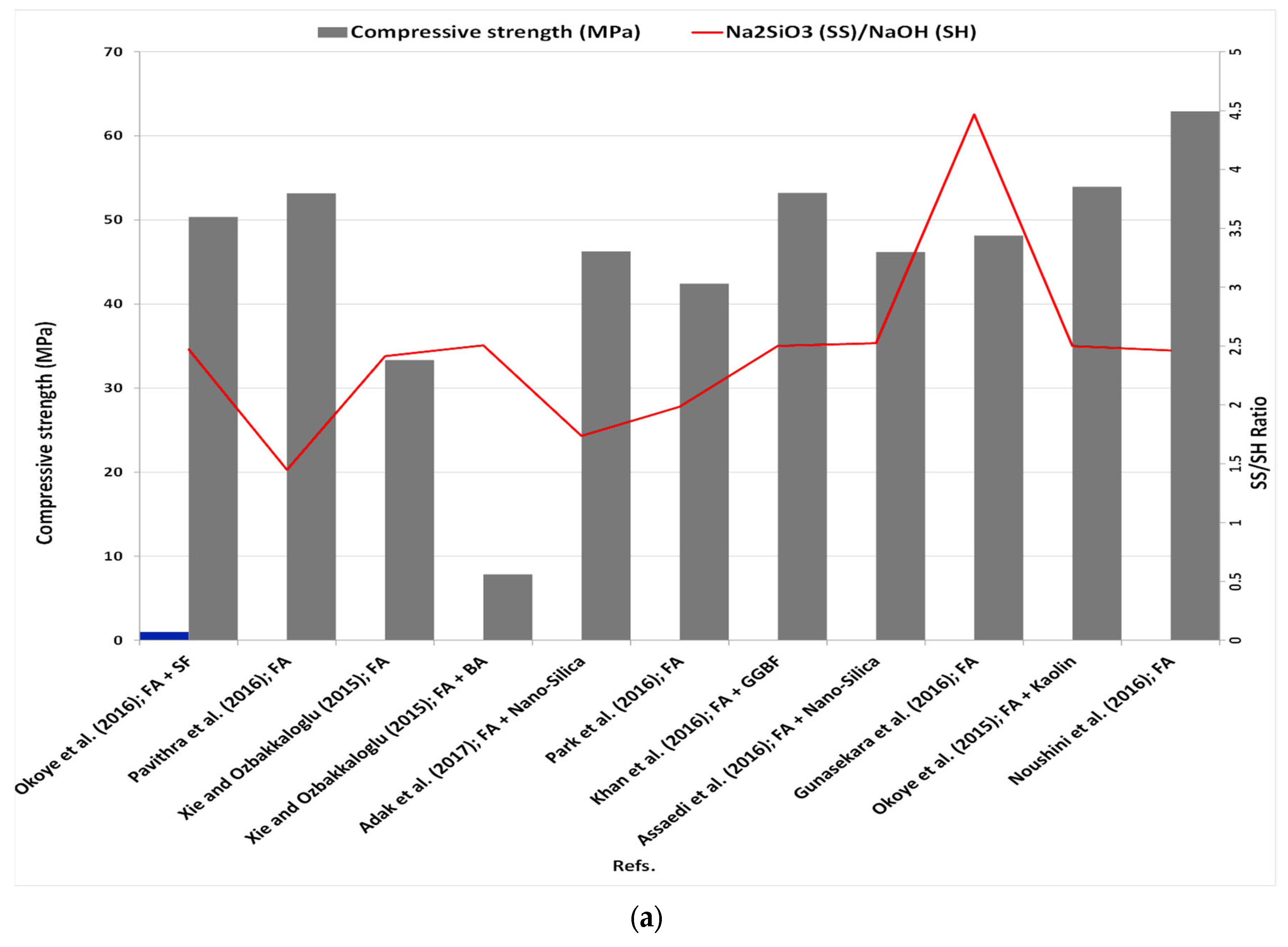

- Okoye, F.; Durgaprasad, J.; Singh, N. Effect of silica fume on the mechanical properties of fly ash based-geopolymer concrete. Ceram. Int. 2016, 42, 3000–3006. [Google Scholar] [CrossRef]

- Kong, D.L.; Sanjayan, J.G. Effect of elevated temperatures on geopolymer paste, mortar and concrete. Cem. Concr. Res. 2010, 40, 334–339. [Google Scholar] [CrossRef]

- Pavithra, P.; Reddy, M.S.; Dinakar, P.; Rao, B.H.; Satpathy, B.; Mohanty, A. A mix design procedure for geopolymer concrete with fly ash. J. Clean. Prod. 2016, 133, 117–125. [Google Scholar] [CrossRef]

- Xie, T.; Ozbakkaloglu, T. Behavior of low-calcium fly and bottom ash-based geopolymer concrete cured at ambient temperature. Ceram. Int. 2015, 41, 5945–5958. [Google Scholar] [CrossRef]

- Abdulkareem, O.A.; Al Bakri, A.M.; Kamarudin, H.; Nizar, I.K.; Saif, A.A. Effects of elevated temperatures on the thermal behavior and mechanical performance of fly ash geopolymer paste, mortar and lightweight concrete. Constr. Build. Mater. 2014, 50, 377–387. [Google Scholar] [CrossRef]

- Assi, L.; Ghahari, S.; Deaver, E.; Leaphart, D.; Ziehl, P. Improvement of the early and final compressive strength of fly ash-based geopolymer concrete at ambient conditions. Constr. Build. Mater. 2016, 123, 806–813. [Google Scholar] [CrossRef]

- Adak, D.; Sarkar, M.; Mandal, S. Structural performance of nano-silica modified fly-ash based geopolymer concrete. Constr. Build. Mater. 2017, 135, 430–439. [Google Scholar] [CrossRef]

- Embong, R.; Kusbiantoro, A.; Shafiq, N.; Nuruddin, M.F. Strength and microstructural properties of fly ash based geopolymer concrete containing high-calcium and water-absorptive aggregate. J. Clean. Prod. 2016, 112, 816–822. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Alengaram, U.J.; Metselaar, H.S.C.; Jumaat, M.Z. Compressive strength and microstructural analysis of fly ash/palm oil fuel ash based geopolymer mortar under elevated temperatures. Constr. Build. Mater. 2014, 65, 114–121. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.; Luo, W.; Zhou, W. Effects of adding nano-TiO2 on compressive strength, drying shrinkage, carbonation and microstructure of fluidized bed fly ash based geopolymer paste. Constr. Build. Mater. 2016, 106, 115–125. [Google Scholar] [CrossRef]

- Park, Y.; Abolmaali, A.; Kim, Y.H.; Ghahremannejad, M. Compressive strength of fly ash-based geopolymer concrete with crumb rubber partially replacing sand. Constr. Build. Mater. 2016, 118, 43–51. [Google Scholar] [CrossRef]

- Assaedi, H.; Shaikh, F.U.A.; Low, I.M. Influence of mixing methods of nano silica on the microstructural and mechanical properties of flax fabric reinforced geopolymer composites. Constr. Build. Mater. 2016, 123, 541–552. [Google Scholar] [CrossRef]

- Khan, M.; Castel, A.; Akbarnezhad, A.; Foster, S.; Smith, M. Utilisation of steel furnace slag coarse aggregate in a low calcium fly ash geopolymer concrete. Cem. Concr. Res. 2016, 89, 220–229. [Google Scholar] [CrossRef]

- Leong, H.Y.; Ong, D.E.L.; Sanjayan, J.; Nazari, A. Suitability of Sarawak and Gladstone fly ash to produce geopolymers: A physical, chemical, mechanical, mineralogical and microstructural analysis. Ceram. Int. 2016, 42, 9613–9620. [Google Scholar] [CrossRef]

- Gunasekara, C.; Law, D.; Setunge, S. Long term permeation properties of different fly ash geopolymer concretes. Constr. Build. Mater. 2016, 124, 352–362. [Google Scholar] [CrossRef]

- Zeng, S.; Wang, J. Characterization of mechanical and electric properties of geopolymers synthesized using four locally available fly ashes. Constr. Build. Mater. 2016, 121, 386–399. [Google Scholar] [CrossRef]

- Huiskes, D.M.A.; Keulen, A.; Yu, Q.L.; Brouwers, H.J.H. Design and performance evaluation of ultra-lightweight geopolymer concrete. Mater. Des. 2016, 89, 516–526. [Google Scholar] [CrossRef]

- Das, S.; Yang, P.; Singh, S.S.; Mertens, J.C.; Xiao, X.; Chawla, N.; Neithalath, N. Effective properties of a fly ash geopolymer: Synergistic application of X-ray synchrotron tomography, nanoindentation, and homogenization models. Cem. Concr. Res. 2015, 78, 252–262. [Google Scholar] [CrossRef]

- Tho-In, T.; Sata, V.; Boonserm, K.; Chindaprasirt, P. Compressive strength and microstructure analysis of geopolymer paste using waste glass powder and fly ash. J. Clean. Prod. 2018, 172, 2892–2898. [Google Scholar] [CrossRef]

- Pilehvar, S.; Cao, V.D.; Szczotok, A.M.; Carmona, M.; Valentini, L.; Lanzón, M.; Pamies, R.; Kjøniksen, A.-L. Physical and mechanical properties of fly ash and slag geopolymer concrete containing different types of micro-encapsulated phase change materials. Constr. Build. Mater. 2018, 173, 28–39. [Google Scholar] [CrossRef]

- Jindal, B.B. Feasibility study of ambient cured geopolymer concrete—A review. Adv. Concr. Constr. 2018, 6, 387. [Google Scholar]

- Hussein, O.H.; Ibrahim, A.M.; Abd, S.M.; Najm, H.M.; Shamim, S.; Sabri, M.M.S. Hybrid Effect of Steel Bars and PAN Textile Reinforcement on Ductility of One-Way Slab Subjected to Bending. Molecules 2022, 27, 5208. [Google Scholar] [CrossRef]

- Najm, H.M.; Ahmad, S. The effect of metallic and non-metallic fiber on the mechanical properties of waste ceramic concrete. Innov. Infrastruct. Solut. 2021, 6, 1–15. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete Containing Waste Glass as an Environmentally Friendly Aggregate: A Review on Fresh and Mechanical Characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef] [PubMed]

- Pimraksa, K.; Chindaprasirt, P.; Rungchet, A.; Sagoe-Crentsil, K.; Sato, T. Lightweight geopolymer made of highly porous siliceous materials with various Na2O/Al2O3 and SiO2/Al2O3 ratios. Mater. Sci. Eng. A 2011, 528, 6616–6623. [Google Scholar] [CrossRef]

- Khan, M.; Lao, J.; Dai, J.-G. Comparative study of advanced computational techniques for estimating the compressive strength of UHPC. J. Asian Concr. Fed. 2022, 8, 51–68. [Google Scholar] [CrossRef]

- Khan, M.; Rehman, A.; Ali, M. Efficiency of silica-fume content in plain and natural fiber reinforced concrete for concrete road. Constr. Build. Mater. 2020, 244, 118382. [Google Scholar] [CrossRef]

- Khan, U.A.; Jahanzaib, H.M.; Khan, M.; Ali, M. Improving the Tensile Energy Absorption of High Strength Natural Fiber Reinforced Concrete with Fly-Ash for Bridge Girders. In Key Engineering Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2018; Volume 765, pp. 335–342. [Google Scholar] [CrossRef]

- Parvez, I.; Shen, J.; Khan, M.; Cheng, C. Modeling and Solution Techniques Used for Hydro Generation Scheduling. Water 2019, 11, 1392. [Google Scholar] [CrossRef]

- Al Bakri, A.M.; Kamarudin, H.; Bnhussain, M.; Nizar, I.K.; Rafiza, A.; Zarina, Y. The processing, characterization, and properties of fly ash based geopolymer concrete. Rev. Adv. Mater. Sci. 2012, 30, 90–97. [Google Scholar]

- Songpiriyakij, S.; Kubprasit, T.; Jaturapitakkul, C.; Chindaprasirt, P. Compressive strength and degree of reaction of biomass- and fly ash-based geopolymer. Constr. Build. Mater. 2010, 24, 236–240. [Google Scholar] [CrossRef]

- Hardjito, D.; Rangan, B.V. Development and Properties of Low-Calcium Fly Ash-Based Geopolymer Concrete; Research Report GC 1; Faculty of Engineering Curtin University of Technology: Perth, Australia, 2005. [Google Scholar]

- Olivia, M.; Nikraz, H. Properties of fly ash geopolymer concrete designed by Taguchi method. Mater. Des. 2012, 36, 191–198. [Google Scholar] [CrossRef]

- Luhar, I.; Luhar, S. A Comprehensive Review on Fly Ash-Based Geopolymer. J. Compos. Sci. 2022, 6, 219. [Google Scholar] [CrossRef]

- Wallah, S.; Rangan, B.V. Low-Calcium Fly Ash-Based Geopolymer Concrete: Long-Term Properties; Faculty of Engineering Curtin University of Technology: Perth, Australia, 2006. [Google Scholar]

- Lee, N.; Jang, J.; Lee, H. Shrinkage characteristics of alkali-activated fly ash/slag paste and mortar at early ages. Cem. Concr. Compos. 2014, 53, 239–248. [Google Scholar] [CrossRef]

- Kuenzel, C.; Neville, T.; Donatello, S.; Vandeperre, L.; Boccaccini, A.; Cheeseman, C. Influence of metakaolin characteristics on the mechanical properties of geopolymers. Appl. Clay Sci. 2013, 83-84, 308–314. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhu, H.; Zhou, C.; Wang, H. Geopolymer from kaolin in China: An overview. Appl. Clay Sci. 2016, 119, 31–41. [Google Scholar] [CrossRef]

- Joseph, B.; Mathew, G. Behavior of Geopolymer Concrete Exposed to Elevated Temperatures. Ph.D Thesis, Cochin University of Science and Technology, Koch, India, 2015. [Google Scholar]

- Ramujee, K.; PothaRaju, M. Mechanical Properties of Geopolymer Concrete Composites. Mater. Today Proc. 2017, 4, 2937–2945. [Google Scholar] [CrossRef]

- Collins, F.; Sanjayan, J. Early Age Strength and Workability of Slag Pastes Activated by NaOH and Na2CO3. Cem. Concr. Res. 1998, 28, 655–664. [Google Scholar] [CrossRef]

- June, J. Geopolymer Concrete with Fly Ash. In Proceedings of the Second International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2019; p. 1493, ISBN 978-1-4507-1490-7. Available online: http://www.claisse.info/Proceedings.htm (accessed on 1 August 2022).

- Ferdous, W.; Manalo, A.; Khennane, A.; Kayali, O. Geopolymer concrete-filled pultruded composite beams—Concrete mix design and application. Cem. Concr. Compos. 2015, 58, 1–13. [Google Scholar] [CrossRef]

- Anuradha, R.; Sreevidya, V.; Venkatasubramani, R.; Rangan, B.V. Modified guidelines for geopolymer concrete mix design using Indian standard. Asian J. Civ. Eng. 2012, 13, 353–364. [Google Scholar]

- Lokuge, W.; Wilson, A.; Gunasekara, C.; Law, D.W.; Setunge, S. Design of fly ash geopolymer concrete mix proportions using Multivariate Adaptive Regression Spline model. Constr. Build. Mater. 2018, 166, 472–481. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R.; Singh, B.P.; Aggoun, S.; Łagód, G.; Barnat-Hunek, D. Influence of various parameters on strength and absorption properties of fly ash based geopolymer concrete designed by Taguchi method. Constr. Build. Mater. 2017, 150, 817–824. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications. Geopolymer Institute, 5th ed.; Institut Géopolymère, Geopolymer Institute: Saint-Quentin, France, 2008; ISBN 9782954453118. [Google Scholar]

- Phoo-Ngernkham, T.; Phiangphimai, C.; Damrongwiriyanupap, N.; Hanjitsuwan, S.; Thumrongvut, J.; Chindaprasirt, P. A Mix Design Procedure for Alkali-Activated High-Calcium Fly Ash Concrete Cured at Ambient Temperature. Adv. Mater. Sci. Eng. 2018, 2018, 2460403. [Google Scholar] [CrossRef]

- Li, N.; Shi, C.; Zhang, Z.; Wang, H.; Liu, Y. A review on mixture design methods for geopolymer concrete. Compos. Part B Eng. 2019, 178, 107490. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Chindaprasirt, P. Influence of recycled aggregate on fly ash geopolymer concrete properties. J. Clean. Prod. 2016, 112, 2300–2307. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef]

- Noushini, A.; Castel, A.; Aldred, J.; Rawal, A. Chloride diffusion resistance and chloride binding capacity of fly ash-based geopolymer concrete. Cem. Concr. Compos. 2020, 105, 103290. [Google Scholar] [CrossRef]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N. Experimental Investigation on the Effect of Corrosion on the Bond Between Reinforcing Steel Bars and Fibre Reinforced Geopolymer Concrete. Structures 2018, 14, 251–261. [Google Scholar] [CrossRef]

- Al-Azzawi, M.; Yu, T.; Hadi, M.N. Factors Affecting the Bond Strength Between the Fly Ash-based Geopolymer Concrete and Steel Reinforcement. Structures 2018, 14, 262–272. [Google Scholar] [CrossRef]

- Okoye, F.N.; Prakash, S.; Singh, N.B. Durability of fly ash based geopolymer concrete in the presence of silica fume. J. Clean. Prod. 2017, 149, 1062–1067. [Google Scholar] [CrossRef]

- Memon, F.; Nuruddin, F.; Shafiq, N. Compressive strength and workability characteristics of low-calcium fly ash-based self-compacting geopolymer concrete. Int. J. Civ. Environ. Eng. 2011, 3, 72–78. [Google Scholar]

- Joseph, B.; Mathew, G. Influence of aggregate content on the behavior of fly ash based geopolymer concrete. Sci. Iran. 2012, 19, 1188–1194. [Google Scholar] [CrossRef]

- Kusbiantoro, A.; Nuruddin, M.F.; Shafiq, N.; Qazi, S.A. The effect of microwave incinerated rice husk ash on the compressive and bond strength of fly ash based geopolymer concrete. Constr. Build. Mater. 2012, 36, 695–703. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Use of OPC to improve setting and early strength properties of low calcium fly ash geopolymer concrete cured at room temperature. Cem. Concr. Compos. 2015, 55, 205–214. [Google Scholar] [CrossRef]

- Nuruddin, M.F.; Qazi, S.A.; Kusbiantoro, A.; Shafiq, N. Utilisation of waste material in geopolymeric concrete. Proc. Inst. Civ. Eng. Constr. Mater. 2011, 164, 315–327. [Google Scholar] [CrossRef]

- Rahman, M.; Sarker, P. Geopolymer concrete columns under combined axial load and biaxial bending. In Proceedings of the CONCRETE 2011 Conference, Perth, Australia, 12 October 2011. [Google Scholar]

- Rangan, B. Geopolymer concrete for environmental protection. Indian Concr. J. 2014, 88, 41–59. [Google Scholar]

- Görhan, G.; Kürklü, G. The influence of the NaOH solution on the properties of the fly ash-based geopolymer mortar cured at different temperatures. Compos. Part B Eng. 2014, 58, 371–377. [Google Scholar] [CrossRef]

- Ahmari, S.; Zhang, L. Production of eco-friendly bricks from copper mine tailings through geopolymerization. Constr. Build. Mater. 2012, 29, 323–331. [Google Scholar] [CrossRef]

- Somna, K.; Jaturapitakkul, C.; Kajitvichyanukul, P.; Chindaprasirt, P. NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel 2011, 90, 2118–2124. [Google Scholar] [CrossRef]

- Sathonsaowaphak, A.; Chindaprasirt, P.; Pimraksa, K. Workability and strength of lignite bottom ash geopolymer mortar. J. Hazard. Mater. 2009, 168, 44–50. [Google Scholar] [CrossRef] [PubMed]

- Anuar, K.; Ridzuan, A.; Ismail, S. Strength characteristic of geopolymer concrete containing recycled concrete aggregate. Int. J. Civ. Environ. Eng. 2011, 11, 59–62. [Google Scholar]

- Posi, P.; Teerachanwit, C.; Tanutong, C.; Limkamoltip, S.; Lertnimoolchai, S.; Sata, V.; Chindaprasirt, P. Lightweight geopolymer concrete containing aggregate from recycle lightweight block. Mater. Des. 2013, 52, 580–586. [Google Scholar] [CrossRef]

- Sata, V.; Wongsa, A.; Chindaprasirt, P. Properties of pervious geopolymer concrete using recycled aggregates. Constr. Build. Mater. 2013, 42, 33–39. [Google Scholar] [CrossRef]

- Shi, X.S.; Wang, Q.Y.; Zhao, X.L.; Collins, F. Discussion on Properties and Microstructure of Geopolymer Concrete Containing Fly Ash and Recycled Aggregate. Adv. Mater. Res. 2012, 450, 1577–1583. [Google Scholar] [CrossRef]

- Qaidi, S.M.A. Ultra-High-Performance Fiber-Reinforced Concrete: Applications; University of Duhok: Duhok, Iraq, 2022. [Google Scholar] [CrossRef]

- Qaidi, S.M.; Atrushi, D.S.; Mohammed, A.S.; Ahmed, H.U.; Faraj, R.H.; Emad, W.; Najm, H.M. Ultra-high-performance geopolymer concrete: A review. Constr. Build. Mater. 2022, 346, 128495. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mahmood, L.J.; Muhammad, M.A.; Faraj, R.H.; Qaidi, S.M.; Sor, N.H.; Mohammed, A.S.; Mohammed, A.A. Geopolymer concrete as a cleaner construction material: An overview on materials and structural performances. Clean. Mater. 2022, 5, 100111. [Google Scholar] [CrossRef]

- De Vargas, A.S.; Dal Molin, D.C.C.; Vilela, A.C.F.; Silva, F.J.D.; Pavão, B.; Veit, H. The effects of Na2O/SiO2 molar ratio, curing temperature and age on compressive strength, morphology and microstructure of alkali-activated fly ash-based geopolymers. Cem. Concr. Compos. 2011, 33, 653–660. [Google Scholar] [CrossRef]

- Criado, M.; Palomo, A.; Fernández-Jiménez, A. Alkali activation of fly ashes. Part 1: Effect of curing conditions on the carbonation of the reaction products. Fuel 2005, 84, 2048–2054. [Google Scholar] [CrossRef]

- Rattanasak, U.; Chindaprasirt, P. Influence of NaOH solution on the synthesis of fly ash geopolymer. Miner. Eng. 2009, 22, 1073–1078. [Google Scholar] [CrossRef]

- De Silva, P.; Sagoe-Crenstil, K.; Sirivivatnanon, V. Kinetics of geopolymerization: Role of Al2O3 and SiO2. Cem. Concr. Res. 2007, 37, 512–518. [Google Scholar] [CrossRef]

- North, M.R.; Swaddle, T.W. Kinetics of Silicate Exchange in Alkaline Aluminosilicate Solutions. Inorg. Chem. 2000, 39, 2661–2665. [Google Scholar] [CrossRef] [PubMed]

- Lizcano, M.; Kim, H.S.; Basu, S.; Radovic, M. Mechanical properties of sodium and potassium activated metakaolin-based geopolymers. J. Mater. Sci. 2012, 47, 2607–2616. [Google Scholar] [CrossRef]

- Ma, Y.; Hu, J.; Ye, G. The pore structure and permeability of alkali activated fly ash. Fuel 2013, 104, 771–780. [Google Scholar] [CrossRef]

- Qaidi, S. Ultra-High-Performance Geopolymer Concrete. Part 1: Manufacture Approaches; University of Duhok: Duhok, Iraq, 2022. [Google Scholar] [CrossRef]

- Qaidi, S. Ultra-High-Performance Geopolymer Concrete. Part 2: Applications; University of Duhok: Duhok, Iraq, 2022. [Google Scholar] [CrossRef]

- Mijarsh, M.; Johari, M.M.; Ahmad, Z.A. Synthesis of geopolymer from large amounts of treated palm oil fuel ash: Application of the Taguchi method in investigating the main parameters affecting compressive strength. Constr. Build. Mater. 2014, 52, 473–481. [Google Scholar] [CrossRef]

- Phoo-ngernkham, T.; Chindaprasirt, P.; Sata, V.; Hanjitsuwan, S.; Hatanaka, S. The effect of adding nano-SiO2 and nano-Al2O3 on properties of high calcium fly ash geopolymer cured at ambient temperature. Mater. Des. 2014, 55, 58–65. [Google Scholar] [CrossRef]

- Rattanasak, U.; Chindaprasirt, P.; Suwanvitaya, P. Development of high volume rice husk ash alumino silicate composites. Int. J. Miner. Met. Mater. 2010, 17, 654–659. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Wang, Y.C.; Xu, D.L.; Li, S. Mechanical performance and hydration mechanism of geopolymer composite reinforced by resin. Mater. Sci. Eng. A 2010, 527, 6574–6580. [Google Scholar] [CrossRef]

- MacKenzie, K.J.; Komphanchai, S.; Vagana, R. Formation of inorganic polymers (geopolymers) from 2:1 layer lattice aluminosilicates. J. Eur. Ceram. Soc. 2008, 28, 177–181. [Google Scholar] [CrossRef]

- Yang, T.; Yao, X.; Zhang, Z.; Wang, H. Mechanical property and structure of alkali-activated fly ash and slag blends. J. Sustain. Cem. Mater. 2012, 1, 167–178. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R.; Mehrotra, S.P. Influence of granulated blast furnace slag on the reaction, structure and properties of fly ash based geopolymer. J. Mater. Sci. 2010, 45, 607–615. [Google Scholar] [CrossRef]

- Shi, C.; Day, R.L. Early strength development and hydration of alkali-activated blast furnace slag/fly ash blends. Adv. Cem. Res. 1999, 11, 189–196. [Google Scholar] [CrossRef]

- Puertas, F.; Fernández-Jiménez, A. Mineralogical and microstructural characterisation of alkali-activated fly ash/slag pastes. Cem. Concr. Compos. 2003, 25, 287–292. [Google Scholar] [CrossRef]

- Sata, V.; Jaturapitakkul, C.; Kiattikomol, K. Influence of pozzolan from various by-product materials on mechanical properties of high-strength concrete. Constr. Build. Mater. 2007, 21, 1589–1598. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Buranasing, R.; Jaturapitakkul, C.; Chindaprasirt, P. Influence of rice husk–bark ash on mechanical properties of concrete containing high amount of recycled aggregates. Constr. Build. Mater. 2008, 22, 1812–1819. [Google Scholar] [CrossRef]

- Rajaokarivony-Andriambololona, Z.; Thomassin, J.H.; Baillif, P.; Touray, J.C. Experimental hydration of two synthetic glassy blast furnace slags in water and alkaline solutions (NaOH and KOH 0.1 N) at 40 °C: Structure, composition and origin of the hydrated layer. J. Mater. Sci. 1990, 25, 2399–2410. [Google Scholar] [CrossRef]

- Teoreanu, I. The interaction mechanism of blast-furnace slags with water. The role of the activating agents. IL Cem. 1991, 2, 91–97. [Google Scholar]

- Bernal, S.A.; Provis, J.L.; Walkley, B.; San Nicolas, R.; Gehman, J.D.; Brice, D.G.; Kilcullen, A.R.; Duxson, P.; Van Deventer, J.S. Gel nanostructure in alkali-activated binders based on slag and fly ash, and effects of accelerated carbonation. Cem. Concr. Res. 2013, 53, 127–144. [Google Scholar] [CrossRef]

- Singh, G.B.; Subramaniam, K.V. Evaluation of sodium content and sodium hydroxide molarity on compressive strength of alkali activated low-calcium fly ash. Cem. Concr. Compos. 2017, 81, 122–132. [Google Scholar] [CrossRef]

- Yang, C.; Gupta, R. Prediction of the Compressive Strength from Resonant Frequency for Low-Calcium Fly Ash–Based Geopolymer Concrete. J. Mater. Civ. Eng. 2018, 30, 04018050. [Google Scholar] [CrossRef]

- Helmuth, R.; Stark, D.; Diamond, S.; Moranville-Regourd, M. Alkali-silica reactivity: An overview of research. Contract 1993, 100, 202. [Google Scholar]

- Schmücker, M.; MacKenzie, K. Microstructure of sodium polysialate siloxo geopolymer. Ceram. Int. 2005, 31, 433–437. [Google Scholar] [CrossRef]

- Temuujin, J.; Van Riessen, A.; Williams, R. Influence of calcium compounds on the mechanical properties of fly ash geopolymer pastes. J. Hazard. Mater. 2009, 167, 82–88. [Google Scholar] [CrossRef]

- Temuujin, J.; Van Riessen, A. Effect of fly ash preliminary calcination on the properties of geopolymer. J. Hazard. Mater. 2009, 164, 634–639. [Google Scholar] [CrossRef]

- Yip, C.K.; Lukey, G.C.; Provis, J.L.; van Deventer, J.S. Effect of calcium silicate sources on geopolymerisation. Cem. Concr. Res. 2008, 38, 554–564. [Google Scholar] [CrossRef]

- He, J.; Jie, Y.; Zhang, J.; Yu, Y.; Zhang, G. Synthesis and characterization of red mud and rice husk ash-based geopolymer composites. Cem. Concr. Compos. 2013, 37, 108–118. [Google Scholar] [CrossRef]

- Islam, A.; Alengaram, U.J.; Jumaat, M.Z.; Bashar, I.I. The development of compressive strength of ground granulated blast furnace slag-palm oil fuel ash-fly ash based geopolymer mortar. Mater. Des. 2014, 56, 833–841. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Behnia, A.; Alengaram, U.J.; Jumaat, M.Z. Compressive strength and microstructural analysis of fly ash/palm oil fuel ash based geopolymer mortar. Mater. Des. 2014, 59, 532–539. [Google Scholar] [CrossRef]

- Khater, H. Effect of Calcium on Geopolymerization of Aluminosilicate Wastes. J. Mater. Civ. Eng. 2012, 24, 92–101. [Google Scholar] [CrossRef]

- Nazari, A.; Bagheri, A.; Riahi, S. Properties of geopolymer with seeded fly ash and rice husk bark ash. Mater. Sci. Eng. A 2011, 528, 7395–7401. [Google Scholar] [CrossRef]

- Qaidi, S. Ultra-High-Performance Geopolymer Concrete. Part 3: Environmental Parameters; University of Duhok: Duhok, Iraq, 2022. [Google Scholar]

- Qaidi, S. Ultra-High-Performance Geopolymer Concrete. Part 4: Mix Design Methods; University of Duhok: Duhok, Iraq, 2022. [Google Scholar]

- Qaidi, S. Ultra-High-Performance Geopolymer Concrete. Part 5: Fresh Properties; University of Duhok: Duhok, Iraq, 2022. [Google Scholar]

- Sata, V.; Sathonsaowaphak, A.; Chindaprasirt, P. Resistance of lignite bottom ash geopolymer mortar to sulfate and sulfuric acid attack. Cem. Concr. Compos. 2012, 34, 700–708. [Google Scholar] [CrossRef]

- Detphan, S.; Chindaprasirt, P. Preparation of fly ash and rice husk ash geopolymer. Int. J. Miner. Metall. Mater. 2009, 16, 720–726. [Google Scholar]

- Duxson, P.; Provis, J.L. Designing Precursors for Geopolymer Cements. J. Am. Ceram. Soc. 2008, 91, 3864–3869. [Google Scholar] [CrossRef]

- Li, Z.; Xu, G.; Shi, X. Reactivity of coal fly ash used in cementitious binder systems: A state-of-the-art overview. Fuel 2021, 301, 121031. [Google Scholar] [CrossRef]

- Okoye, F.; Durgaprasad, J.; Singh, N. Mechanical properties of alkali activated flyash/Kaolin based geopolymer concrete. Constr. Build. Mater. 2015, 98, 685–691. [Google Scholar] [CrossRef]

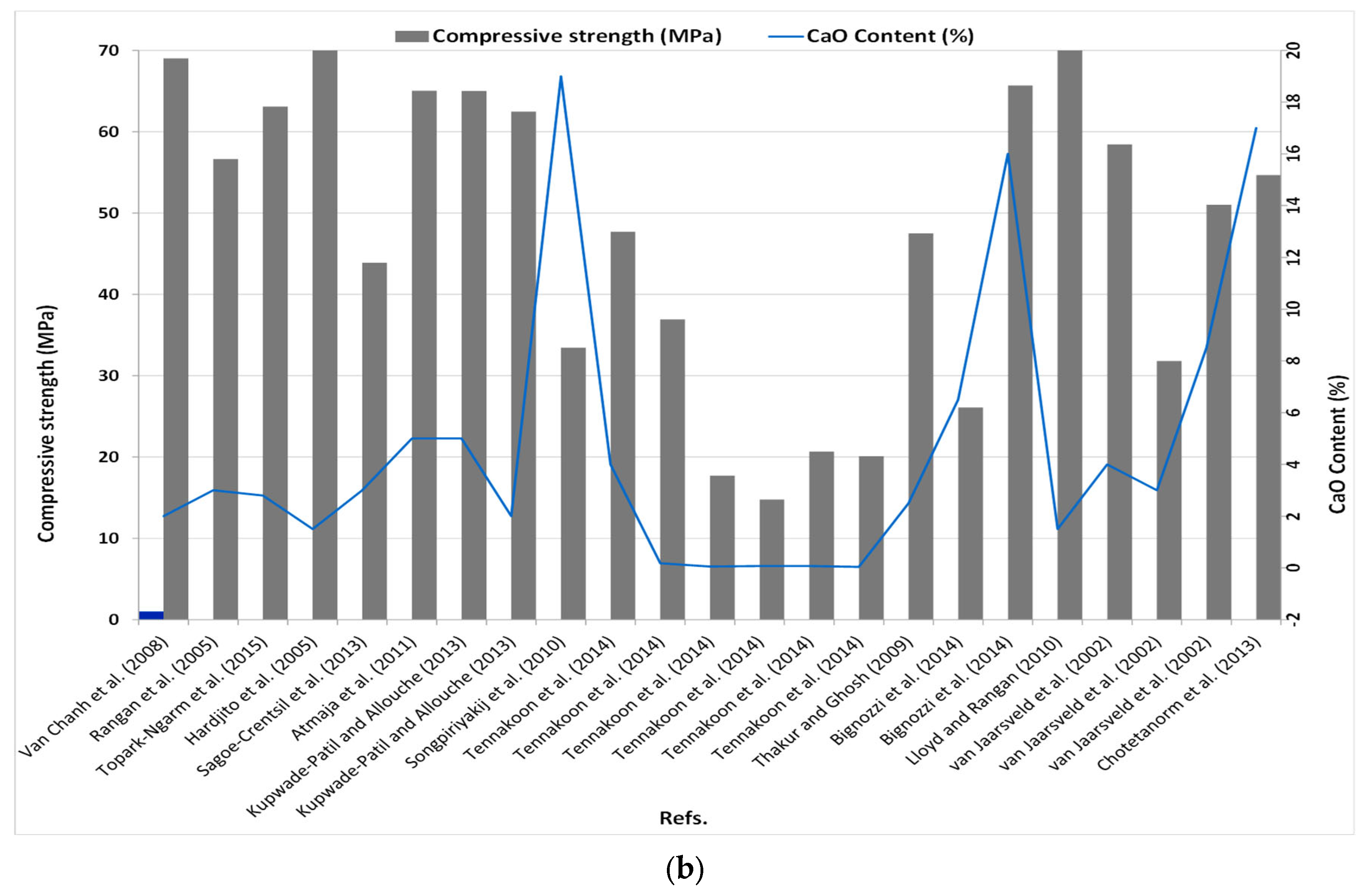

- Van Chanh, N.; Trung, B.D.; Van Tuan, D. Recent research geopolymer concrete. In Proceedings of the 3rd ACF International Conference-ACF/VCA, HCM City, Vietnam, 11–13 November 2008; pp. 235–241. [Google Scholar]

- Rangan, B.V.; Hardjito, D.; Wallah, S.E.; Sumajouw, D.M. Studies on fly ash-based geopolymer concrete. In Proceedings of the World Congress Geopolymer, Saint Quentin, France, 28 June–1 July 2005; pp. 133–137. [Google Scholar]

- Topark-Ngarm, P.; Chindaprasirt, P.; Sata, V. Setting Time, Strength, and Bond of High-Calcium Fly Ash Geopolymer Concrete. J. Mater. Civ. Eng. 2015, 27, 04014198. [Google Scholar] [CrossRef]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.J.; Rangan, B.V. Fly Ash-Based Geopolymer Concrete. Aust. J. Struct. Eng. 2005, 6, 77–86. [Google Scholar] [CrossRef]

- Sagoe-Crentsil, K.; Brown, T.; Taylor, A. Drying shrinkage and creep performance of geopolymer concrete. J. Sustain. Cem.-Based Mater. 2013, 2, 35–42. [Google Scholar] [CrossRef]

- Atmaja, L.; Fansuri, H.; Maharani, A. Crystalline phase reactivity in the synthesis of fly ash-based geopolymer. Indones. J. Chem. 2011, 11, 90–95. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; Allouche, E.N. Impact of Alkali Silica Reaction on Fly Ash-Based Geopolymer Concrete. J. Mater. Civ. Eng. 2013, 25, 131–139. [Google Scholar] [CrossRef]

- Tennakoon, C.; Shayan, A.; Sagoe-Crentsil, K.; Sanjayan, J. Importance of reactive SiO2, AlO3 and Na2O in geopolymer formation. In Proceedings of the 9th Austroads Bridge Conference, Sydney, Australia, 22–24 October 2014. [Google Scholar]

- Thakur, R.N.; Ghosh, S. Effect of mix composition on compressive strength and microstructure of fly ash based geopolymer composites. ARPN J. Eng. Appl. Sci. 2009, 4, 68–74. [Google Scholar]

- Bignozzi, M.C.; Manzi, S.; Natali, M.E.; Rickard, W.D.; van Riessen, A. Room temperature alkali activation of fly ash: The effect of Na2O/SiO2 ratio. Constr. Build. Mater. 2014, 69, 262–270. [Google Scholar] [CrossRef]

- Lloyd, N.; Rangan, V. Geopolymer concrete with fly ash. In Proceedings of the Second International Conference on Sustainable Construction Materials and Technologies, UWM Center for By-Products Utilization, Ancona, Italy, 28 June 2010; pp. 1493–1504. [Google Scholar]

- Van Jaarsveld, J.G.S.; van Deventer, J.S.; Lukey, G.C. The effect of composition and temperature on the properties of fly ash- and kaolinite-based geopolymers. Chem. Eng. J. 2002, 89, 63–73. [Google Scholar] [CrossRef]

- Chotetanorm, C.; Chindaprasirt, P.; Sata, V.; Rukzon, S.; Sathonsaowaphak, A. High-Calcium Bottom Ash Geopolymer: Sorptivity, Pore Size, and Resistance to Sodium Sulfate Attack. J. Mater. Civ. Eng. 2013, 25, 105–111. [Google Scholar] [CrossRef]

- Qaidi, S. Ultra-High-Performance Geopolymer Concrete. Part 6: Mechanical Properties; University of Duhok: Duhok, Iraq, 2022. [Google Scholar]

- Qaidi, S. Ultra-High-Performance Geopolymer Concrete. Part 7: Mechanical Performance Correlation; University of Duhok: Duhok, Iraq, 2022. [Google Scholar]

- Qaidi, S. Ultra-High-Performance Geopolymer Concrete. Part 8: Dynamic Behavior; University of Duhok: Duhok, Iraq, 2022. [Google Scholar]

- Bernal, S.A.; Provis, J.L. Durability of Alkali-Activated Materials: Progress and Perspectives. J. Am. Ceram. Soc. 2014, 97, 997–1008. [Google Scholar] [CrossRef]

- Phoo-Ngernkham, T.; Maegawa, A.; Mishima, N.; Hatanaka, S.; Chindaprasirt, P. Effects of sodium hydroxide and sodium silicate solutions on compressive and shear bond strengths of FA–GBFS geopolymer. Constr. Build. Mater. 2015, 91, 1–8. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass in the geopolymer preparation. Mechanical and microstructural characterization. J. Clean. Prod. 2015, 90, 397–408. [Google Scholar] [CrossRef]

- Ding, Y.-C.; Cheng, T.-W.; Dai, Y.-S. Application of geopolymer paste for concrete repair. Struct. Concr. 2017, 18, 561–570. [Google Scholar] [CrossRef]

- Phoo-Ngernkham, T.; Sata, V.; Hanjitsuwan, S.; Ridtirud, C.; Hatanaka, S.; Chindaprasirt, P. High calcium fly ash geopolymer mortar containing Portland cement for use as repair material. Constr. Build. Mater. 2015, 98, 482–488. [Google Scholar] [CrossRef]

- Demie, S.; Nuruddin, M.F.; Shafiq, N. Effects of micro-structure characteristics of interfacial transition zone on the compressive strength of self-compacting geopolymer concrete. Constr. Build. Mater. 2013, 41, 91–98. [Google Scholar] [CrossRef]

- Li, Z.; Chen, R.; Zhang, L. Utilization of chitosan biopolymer to enhance fly ash-based geopolymer. J. Mater. Sci. 2013, 48, 7986–7993. [Google Scholar] [CrossRef]

- Rattanasak, U.; Pankhet, K.; Chindaprasirt, P. Effect of chemical admixtures on properties of high-calcium fly ash geopolymer. Int. J. Miner. Met. Mater. 2011, 18, 364–369. [Google Scholar] [CrossRef]

- Nath, S.; Kumar, S. Influence of iron making slags on strength and microstructure of fly ash geopolymer. Constr. Build. Mater. 2013, 38, 924–930. [Google Scholar] [CrossRef]

- Zhang, M.; Zhao, M.; Zhang, G.; Mann, D.; Lumsden, K.; Tao, M. Durability of red mud-fly ash based geopolymer and leaching behavior of heavy metals in sulfuric acid solutions and deionized water. Constr. Build. Mater. 2016, 124, 373–382. [Google Scholar] [CrossRef]

- Adak, D.; Sarkar, M.; Mandal, S. Effect of nano-silica on strength and durability of fly ash based geopolymer mortar. Constr. Build. Mater. 2014, 70, 453–459. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U.; Vongvoradit, P.; Jenjirapanya, S. Thermal treatment and utilization of Al-rich waste in high calcium fly ash geopolymeric materials. Int. J. Miner. Met. Mater. 2012, 19, 872–878. [Google Scholar] [CrossRef]

- Palomo, A.; Grutzeck, M.W.; Blanco, M.T. Alkali-activated fly ashes: A cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Andini, S.; Cioffi, R.; Colangelo, F.; Grieco, T.; Montagnaro, F.; Santoro, L. Coal fly ash as raw material for the manufacture of geopolymer-based products. Waste Manag. 2008, 28, 416–423. [Google Scholar] [CrossRef]

- Temuujin, J.; Williams, R.; van Riessen, A. Effect of mechanical activation of fly ash on the properties of geopolymer cured at ambient temperature. J. Mater. Process. Technol. 2009, 209, 5276–5280. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U.; Taebuanhuad, S. Resistance to acid and sulfate solutions of microwave-assisted high calcium fly ash geopolymer. Mater. Struct. 2012, 46, 375–381. [Google Scholar] [CrossRef]

- Ridtirud, C.; Chindaprasirt, P.; Pimraksa, K. Factors affecting the shrinkage of fly ash geopolymers. Int. J. Miner. Met. Mater. 2011, 18, 100–104. [Google Scholar] [CrossRef]

- Giasuddin, H.M.; Sanjayan, J.G.; Ranjith, P. Strength of geopolymer cured in saline water in ambient conditions. Fuel 2013, 107, 34–39. [Google Scholar] [CrossRef]

- Zelinkova, M.; Ondova, M. Effect of Fly Ash Fineness on Sorption Properties of Geopolymers Based On Liquid Glass. Int. J. Civ. Environ. Eng. 2015, 9, 583–587. [Google Scholar]

- Shinde, P.; Patankar, S.; Sayyad, A. Investigation on effects of fineness of flyash and alkaline ratio on mechanical properties of geopolymer concrete. Res. Eng. Struct. Mater. 2018, 4, 61–71. [Google Scholar] [CrossRef]

- Jamkar, S.; Ghugal, Y.; Patankar, S. Effect of fly ash fineness on workability and compressive strength of geopolymer concrete. Indian Concr. J. 2013, 87, 57–61. [Google Scholar]

- Firdaus; Yunus, I.; Rosidawani, D. Contribution of Fineness Level of Fly Ash to the Compressive Strength of Geopolymer Mortar. MATEC Web Conf. 2017, 103, 01026. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A.; Criado, M. Microstructure development of alkali-activated fly ash cement: A descriptive model. Cem. Concr. Res. 2005, 35, 1204–1209. [Google Scholar] [CrossRef]

- He, P.; Jia, D.; Wang, M.; Zhou, Y. Thermal evolution and crystallization kinetics of potassium-based geopolymer. Ceram. Int. 2011, 37, 59–63. [Google Scholar] [CrossRef]

- Qaidi, S. Ultra-High-Performance Geopolymer Concrete. Part 9: Strain Hardening; University of Duhok: Duhok, Iraq, 2022. [Google Scholar] [CrossRef]

- Mohammed, H.; Ahmed, S. Mechanical performance evaluation of concrete with waste coarse ceramic aggregate. In Smart Cities—Opportunities and Challenges; Springer: Singapore, 2020; pp. 593–605. [Google Scholar] [CrossRef]

- Abdulkareem, O.A.; Ramli, M. Optimization of Alkaline Activator Mixing and Curing Conditions for A fly Ash-Based Geopolymer Paste System. Mod. Appl. Sci. 2015, 9, 61. [Google Scholar] [CrossRef]

- Villa, C.; Pecina, E.; Torres, R.; Gómez, L. Geopolymer synthesis using alkaline activation of natural zeolite. Constr. Build. Mater. 2010, 24, 2084–2090. [Google Scholar] [CrossRef]

- Noushini, A.; Aslani, F.; Castel, A.; Gilbert, R.I.; Uy, B.; Foster, S. Compressive stress-strain model for low-calcium fly ash-based geopolymer and heat-cured Portland cement concrete. Cem. Concr. Compos. 2016, 73, 136–146. [Google Scholar] [CrossRef]

- Karthik, A.; Sudalaimani, K.; Vijayakumar, C.; Saravanakumar, S. Effect of bio-additives on physico-chemical properties of fly ash-ground granulated blast furnace slag based self-cured geopolymer mortars. J. Hazard. Mater. 2018, 361, 56–63. [Google Scholar] [CrossRef]

- Alomayri, T. Experimental study of the microstructural and mechanical properties of geopolymer paste with nano material (Al2O3). J. Build. Eng. 2019, 25, 100788. [Google Scholar] [CrossRef]

- Prabha, V.; Revathi, V. Geopolymer Mortar Incorporating High Calcium Fly Ash and Silica Fume. Arch. Civ. Eng. 2019, 65, 3–16. [Google Scholar] [CrossRef]

- Cai, J.; Pan, J.; Li, X.; Tan, J.; Li, J. Electrical resistivity of fly ash and metakaolin based geopolymers. Constr. Build. Mater. 2020, 234, 117868. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Vongsvivut, J. Interfacial chemistry of a fly ash geopolymer and aggregates. J. Clean. Prod. 2019, 231, 980–989. [Google Scholar] [CrossRef]

- Fu, Q.; Xu, W.; Zhao, X.; Bu, M.; Yuan, Q.; Niu, D. The microstructure and durability of fly ash-based geopolymer concrete: A review. Ceram. Int. 2021, 47, 29550–29566. [Google Scholar] [CrossRef]

- Lloyd, R.R.; Provis, J.L.; van Deventer, J.S.J. Microscopy and microanalysis of inorganic polymer cements. 1: Remnant fly ash particles. J. Mater. Sci. 2009, 44, 608–619. [Google Scholar] [CrossRef]

- Qaidi, S. Ultra-High-Performance Geopolymer Concrete. Part 11: Microstructural Properties; University of Duhok: Duhok, Iraq, 2022. [Google Scholar] [CrossRef]

- Parveen; Singhal, D.; Junaid, M.T.; Jindal, B.B.; Mehta, A. Mechanical and microstructural properties of fly ash based geopolymer concrete incorporating alccofine at ambient curing. Constr. Build. Mater. 2018, 180, 298–307. [Google Scholar] [CrossRef]

- Aligizaki, K.K. Pore Structure of Cement-Based Materials: Testing, Interpretation and Requirements; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Puertas, F.; Palacios, M.; Manzano, H.; Dolado, J.S.; Rico, A.; Rodríguez, J. A model for the C-A-S-H gel formed in alkali-activated slag cements. J. Eur. Ceram. Soc. 2011, 31, 2043–2056. [Google Scholar] [CrossRef]

- Najm, H.M.; Ahmad, S.; Khan, R.A. Mechanical and Microstructural Analysis of Waste Ceramic Optimal Concrete Reinforced by Hybrid Fibers Materials: A Comprehensive Study. J. Archit. Environ. Struct. Eng. Res. 2022, 5, 11–33. [Google Scholar] [CrossRef]

- Najm, H.M.; Nanayakkara, O.; Ahmad, M.; Sabri Sabri, M.M. Mechanical Properties, Crack Width, and Propagation of Waste Ceramic Concrete Subjected to Elevated Temperatures: A Comprehensive Study. Materials 2022, 15, 2371. [Google Scholar] [CrossRef]

- Najm, H.M.; Nanayakkara, O.; Ahmad, M.; Sabri Sabri, M.M. Colour Change of Sustainable Concrete Containing Waste Ceramic and Hybrid Fibre: Effect of Temperature. Materials 2022, 15, 2174. [Google Scholar] [CrossRef]

- Najm, H.M.; Ahmad, S. Effect of elevated temperatures exposure on the mechanical properties of waste ceramic concrete reinforced with hybrid fibers materials. Sigma J. Eng. Nat. Sci. 2021; in press. [Google Scholar]

- Najm, H.M.; Ahmad, S. The Use of Waste Ceramic Optimal Concrete for A Cleaner and Sustainable Environment—A Case Study of Mechanical Properties. Civ. Environ. Eng. Rep. 2022, 32, 85–102. [Google Scholar]

- Najm, H.M.; Ahmad, S.; Submitter, Y. Artificial Neural Networks for Evaluation & Prediction of the Mechanical Properties of Waste Ceramic Optimal Concrete Exposed to Elevated Temperature. SSRN 2021. [Google Scholar] [CrossRef]

| FAs | Origin | Characteristic | Mineral Phases | Potential of Products | Potential for Geopolymerization |

|---|---|---|---|---|---|

| 1. Pozzolanic (sialic) | Highly ranked fuels, bituminous with detrital quartz, kaolinite, illite, mica, k-feldspars | Maximum values of fine fraction, true density | Viscous melt (glass), minimum values of crystallization | Dense and porous GP pastes | Good activation but with a low rate of high dissolution pH of alkaline sol |

| 2. Active low pozzolanic, calsialic, ferrisialic, ferricalsialic | Variable rank of fuel but mostly liquid with carbonates, sulfates, sulfides, detrital silicates | Maximum values of the water-soluble fraction | Oxyhydrosydes, sulfates, carb, and actives silicates | Porous matrix paste | Aam low alkaline sol and pH |

| 3. Ferrisialic inert (sialic), calsialic | Variable rank of fuels, bituminous and sub-bituminous | High content of original infused quartz, max true density, min of water-soluble elements | Mullite and quartz | Dense and less porous composites | Low dissolution rate, high pH |

| 4. Ferricalsialic | Low-rank fuels, lignites, bituminous gypsum, ferrite, calcite, dolomite | Max bulk density | Fe, Mg, Na phases | Porous product paste | High dissolution rate, poor polymerization |