Shear Strength Prediction Model for RC Exterior Joints Using Gene Expression Programming

Abstract

1. Introduction

2. Research Significance

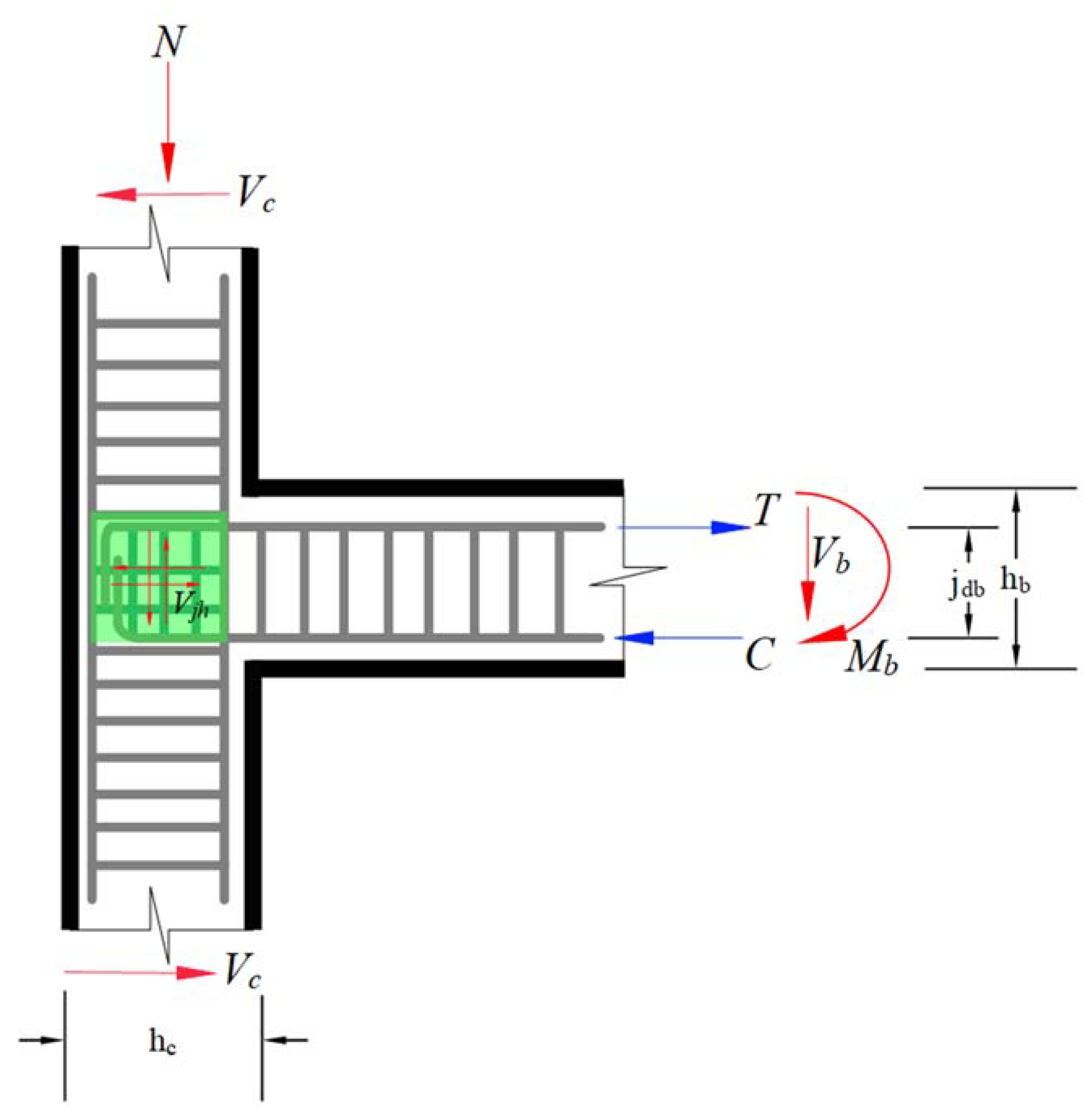

3. Basic Mechanics

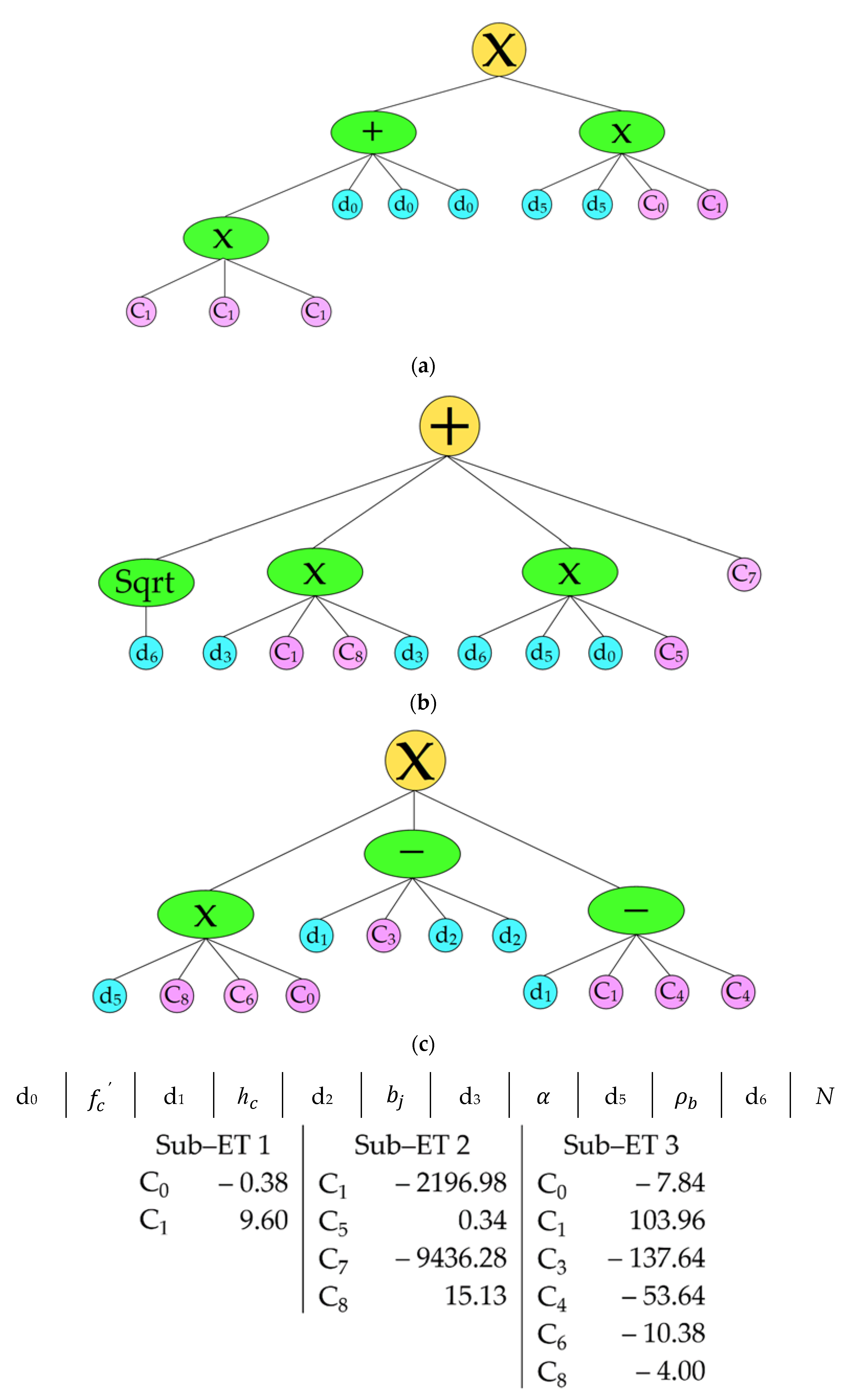

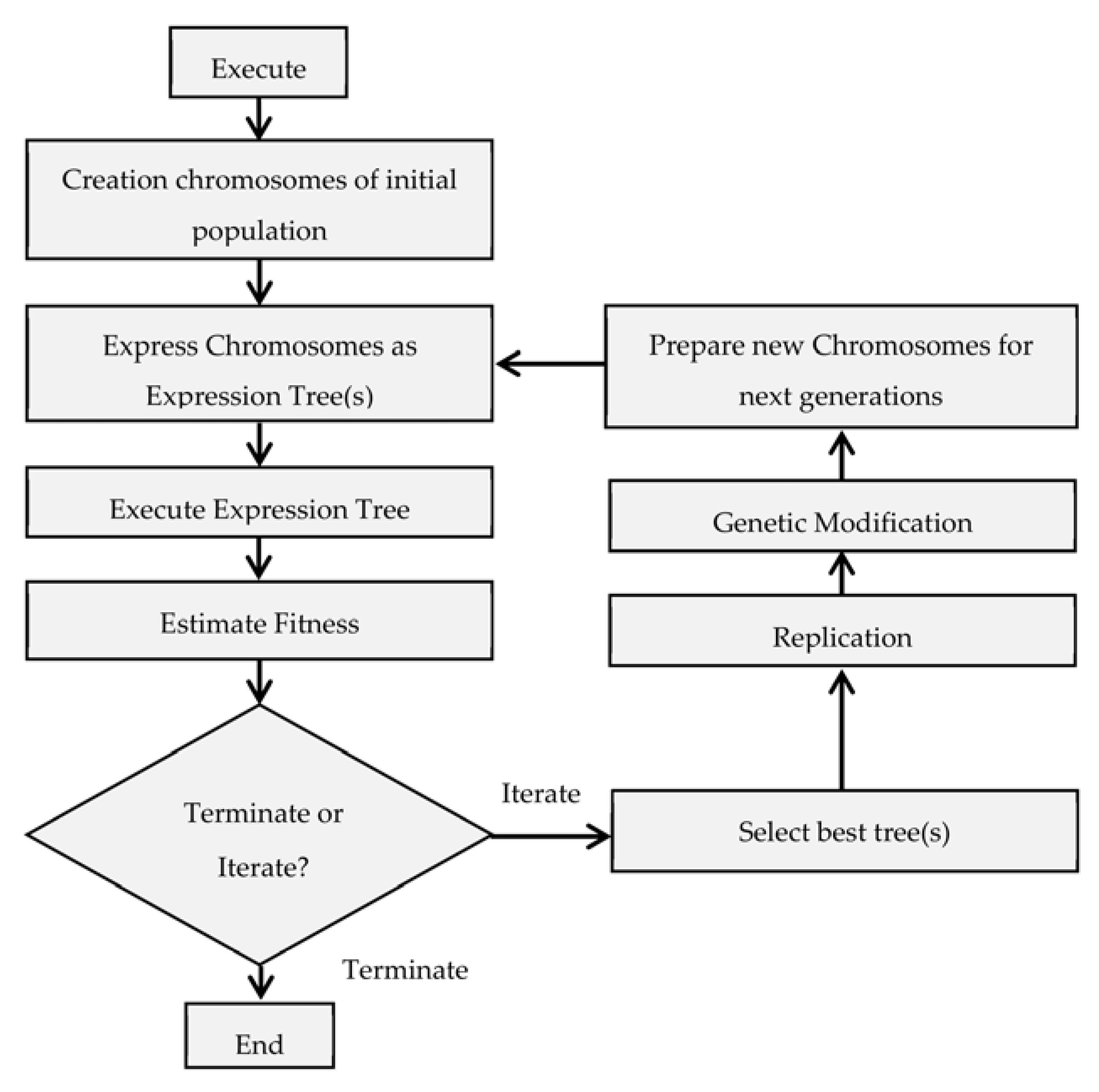

4. Fundamentals of Gene Expression Programming

Experimental Database

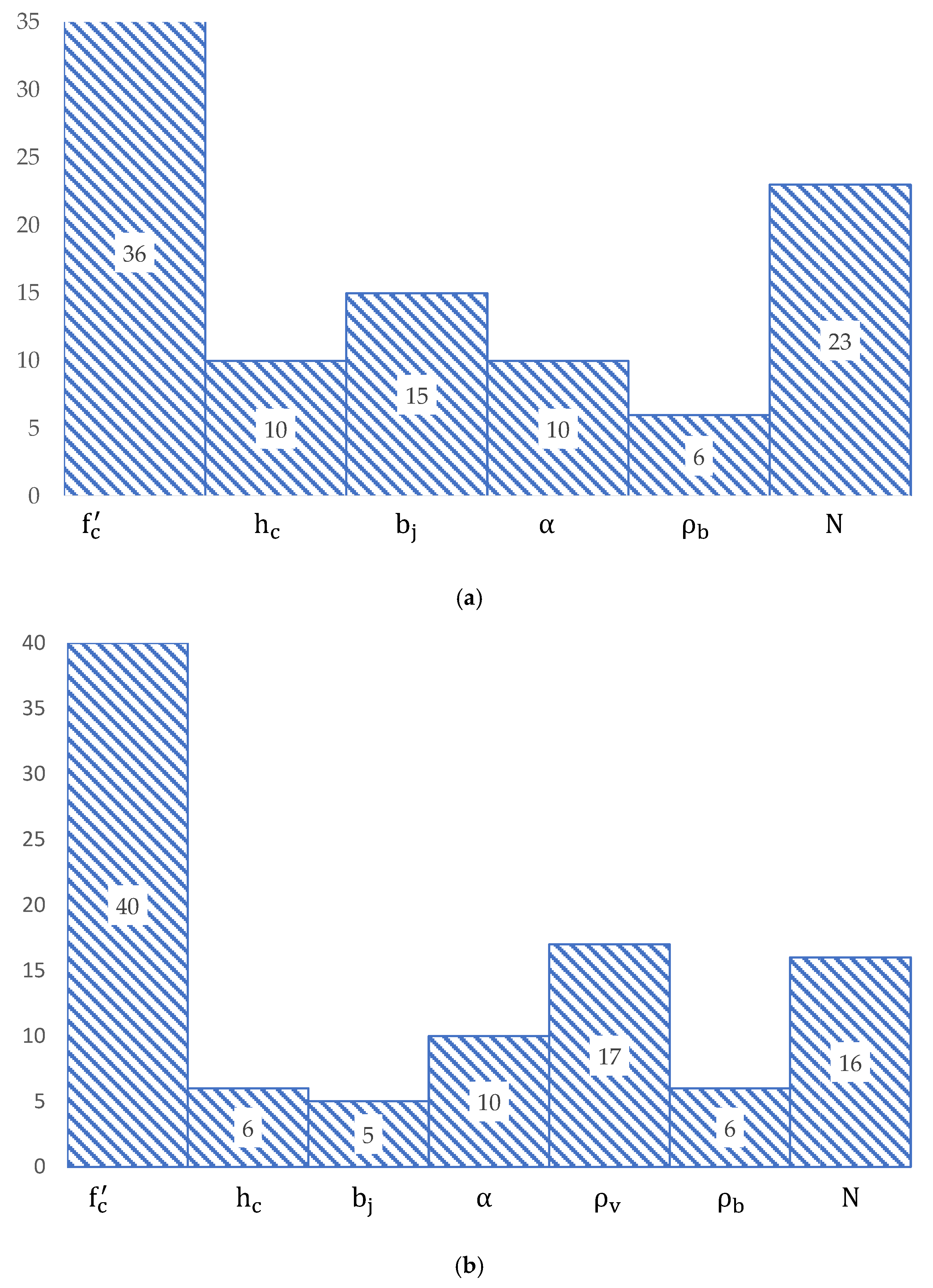

5. Proposed GEP Model for Estimating Joint Shear

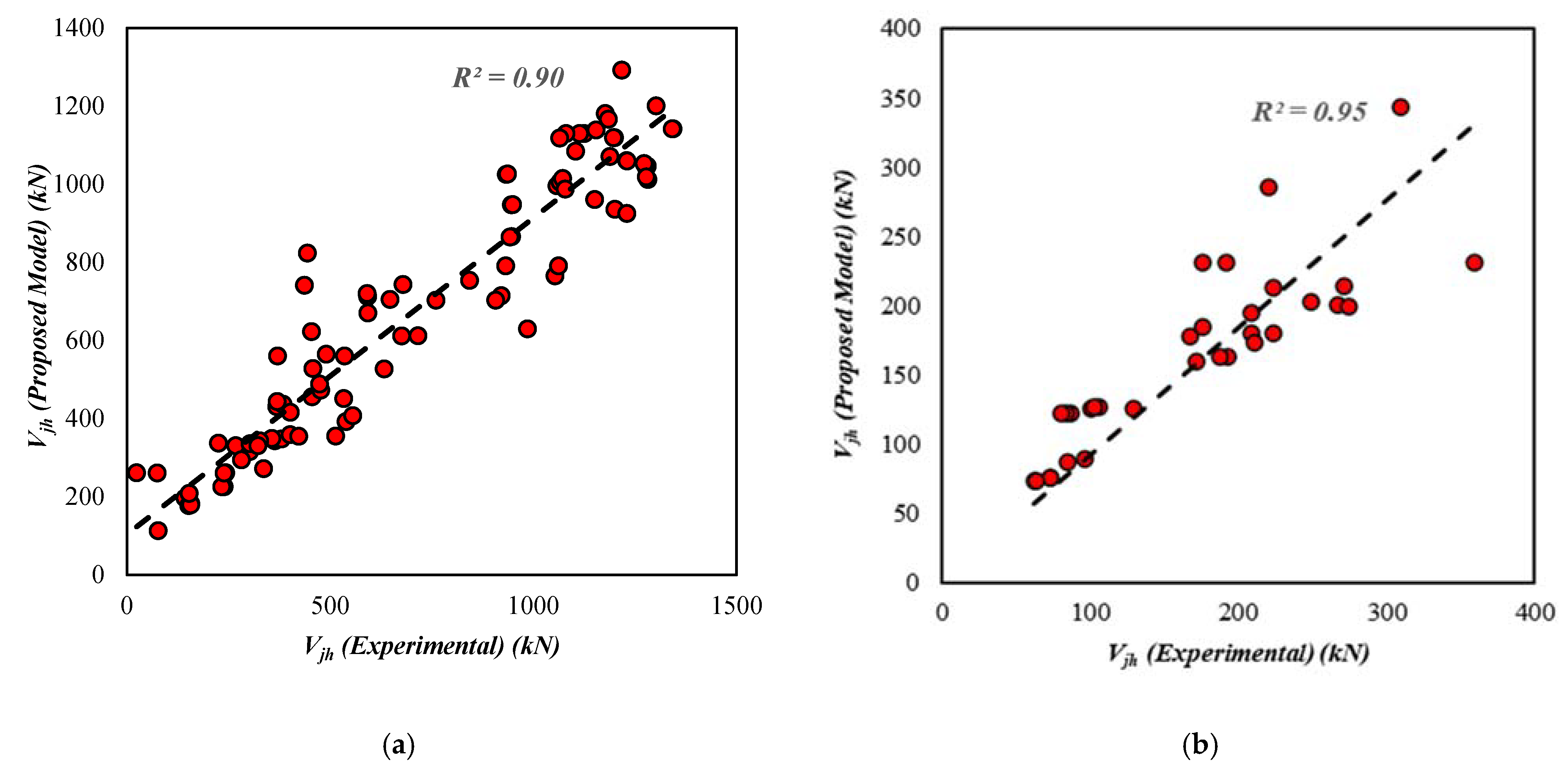

6. Statistical Validation of the Developed Model

7. Results and Discussions

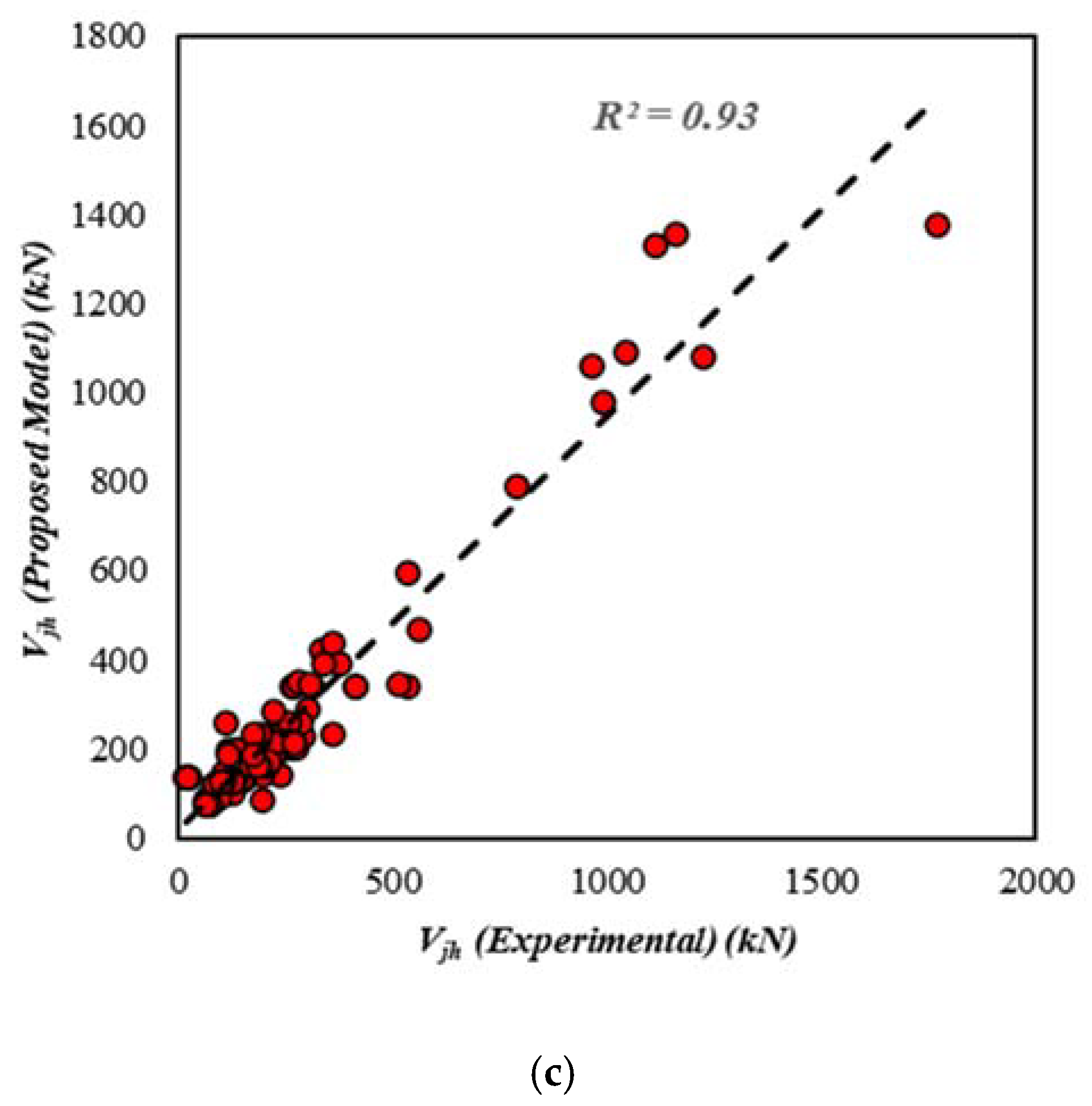

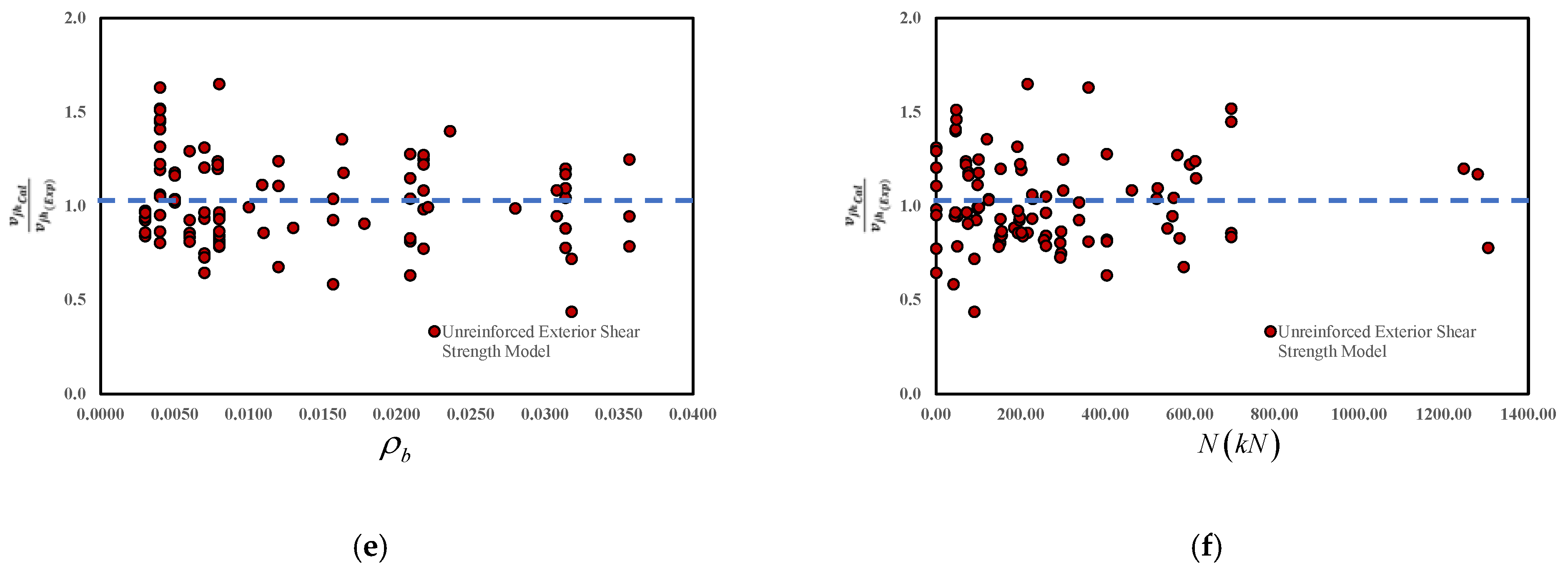

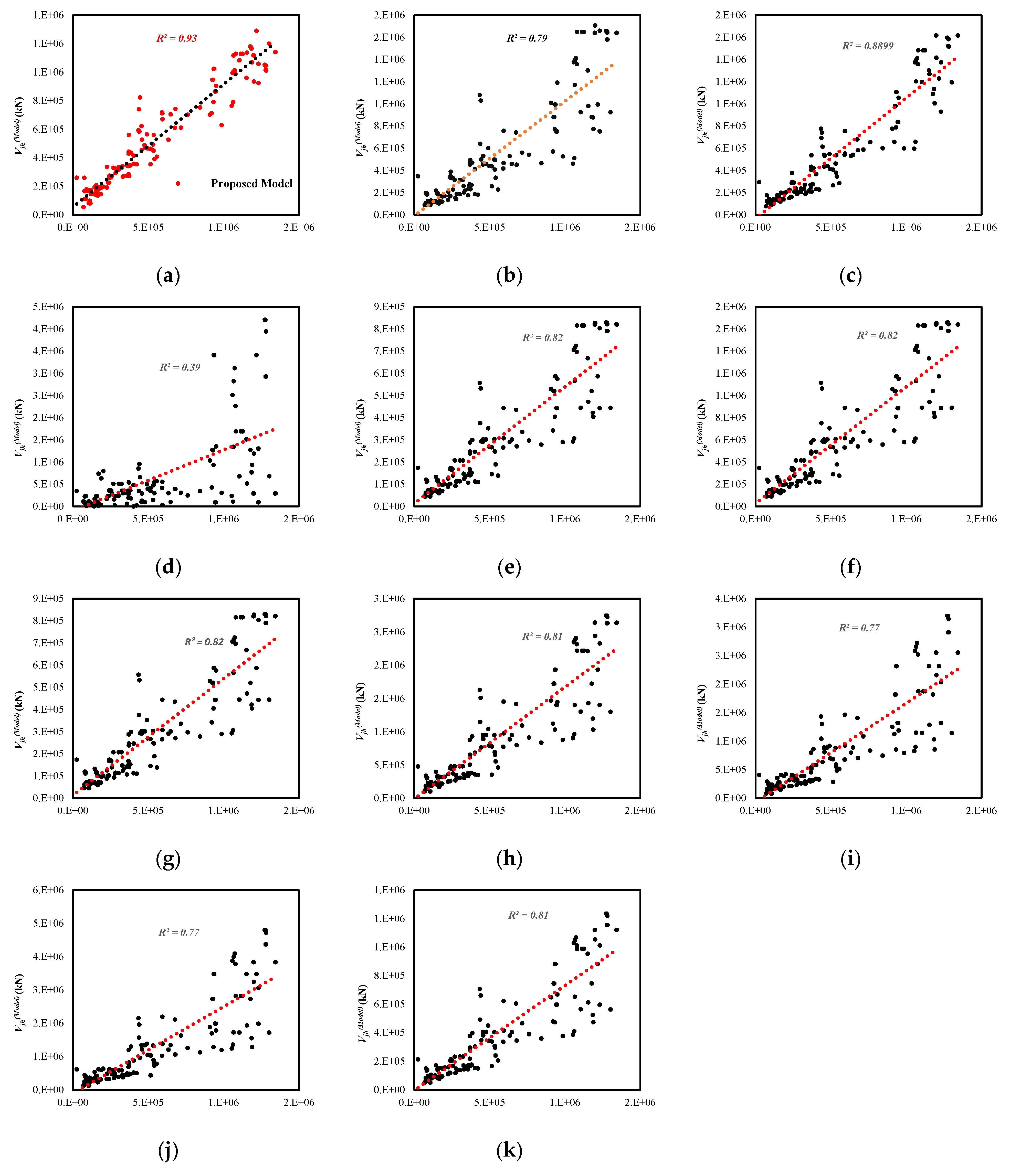

7.1. Shear Strength of the Unreinforced Exterior Joint

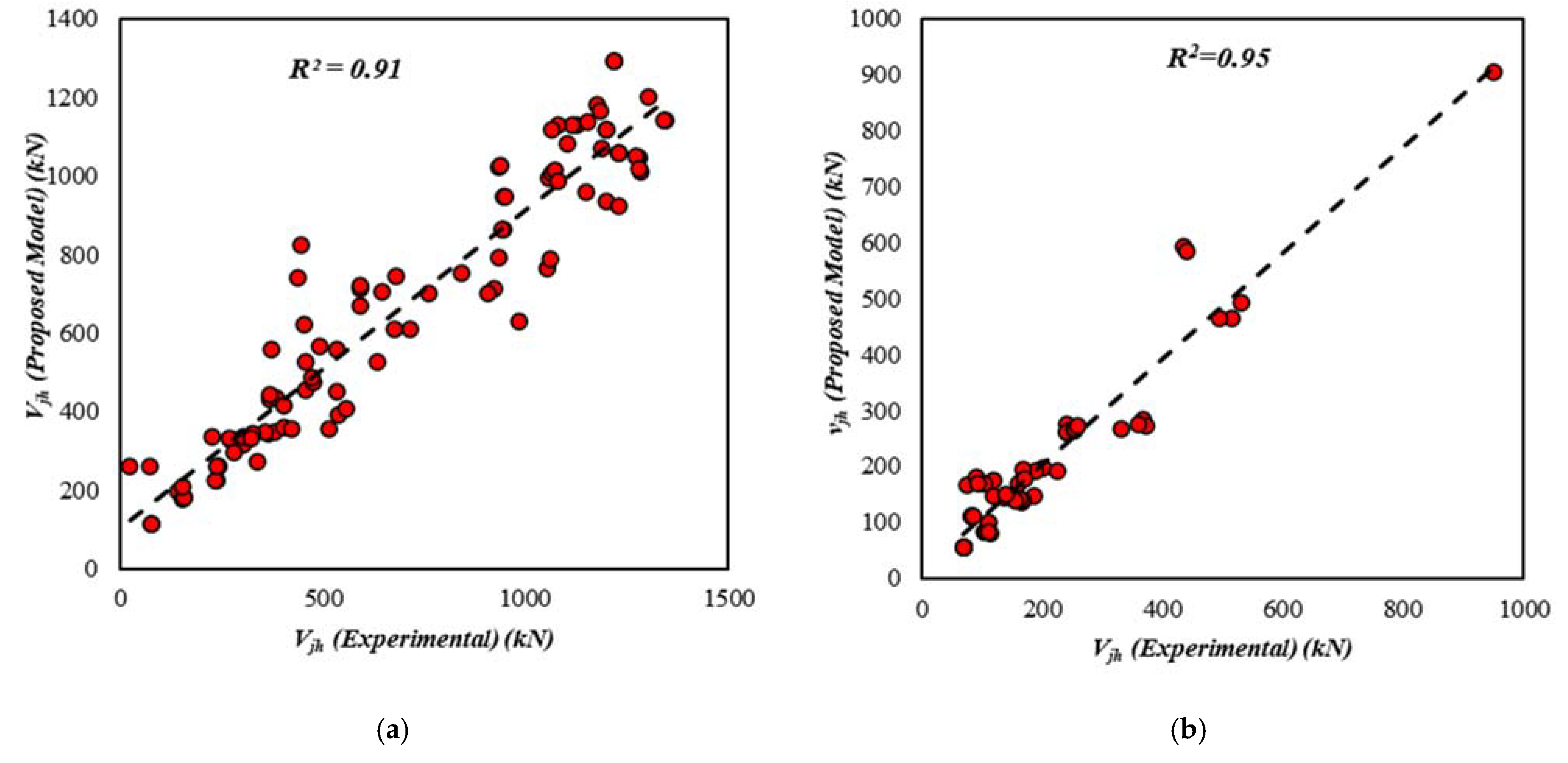

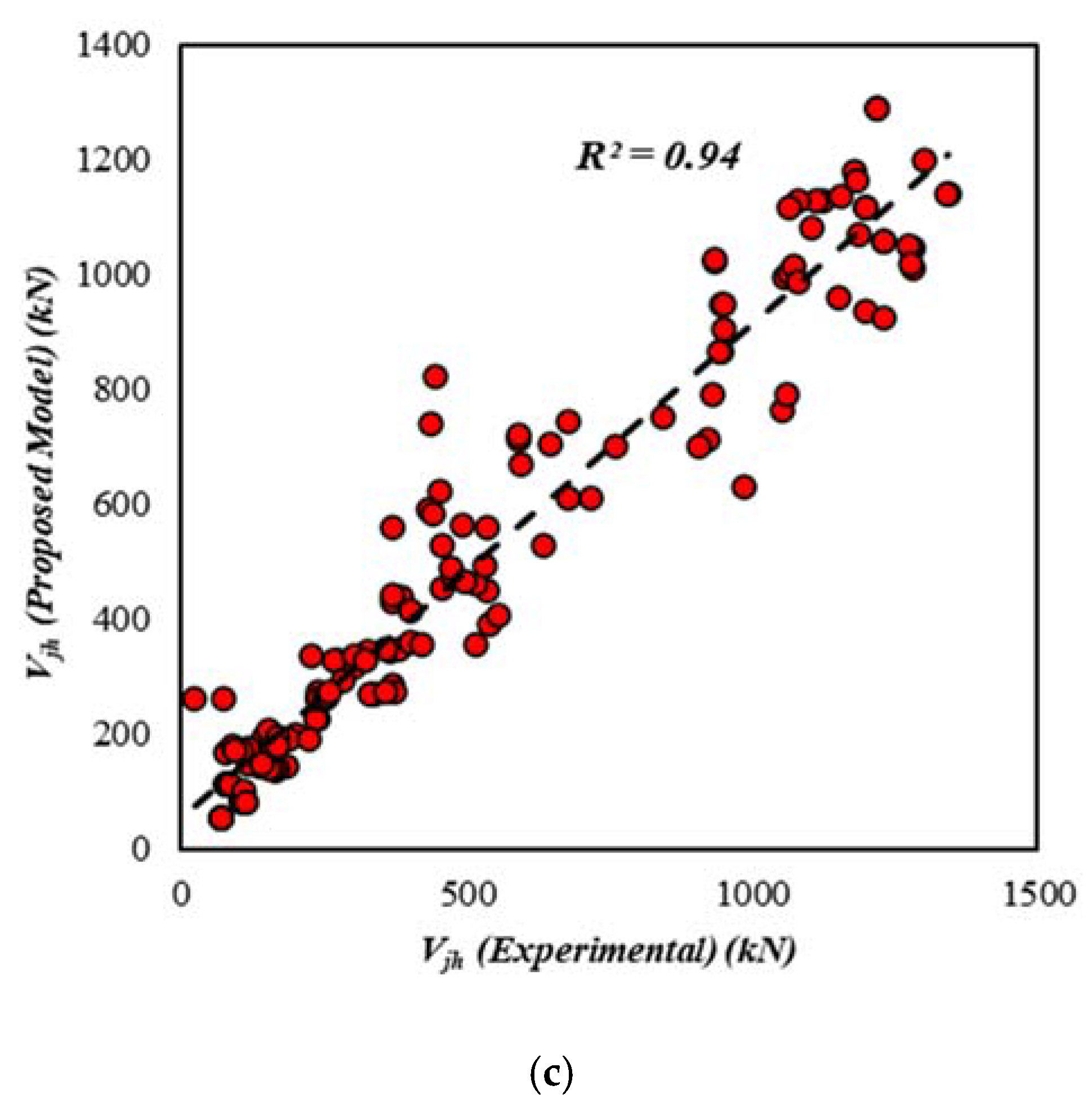

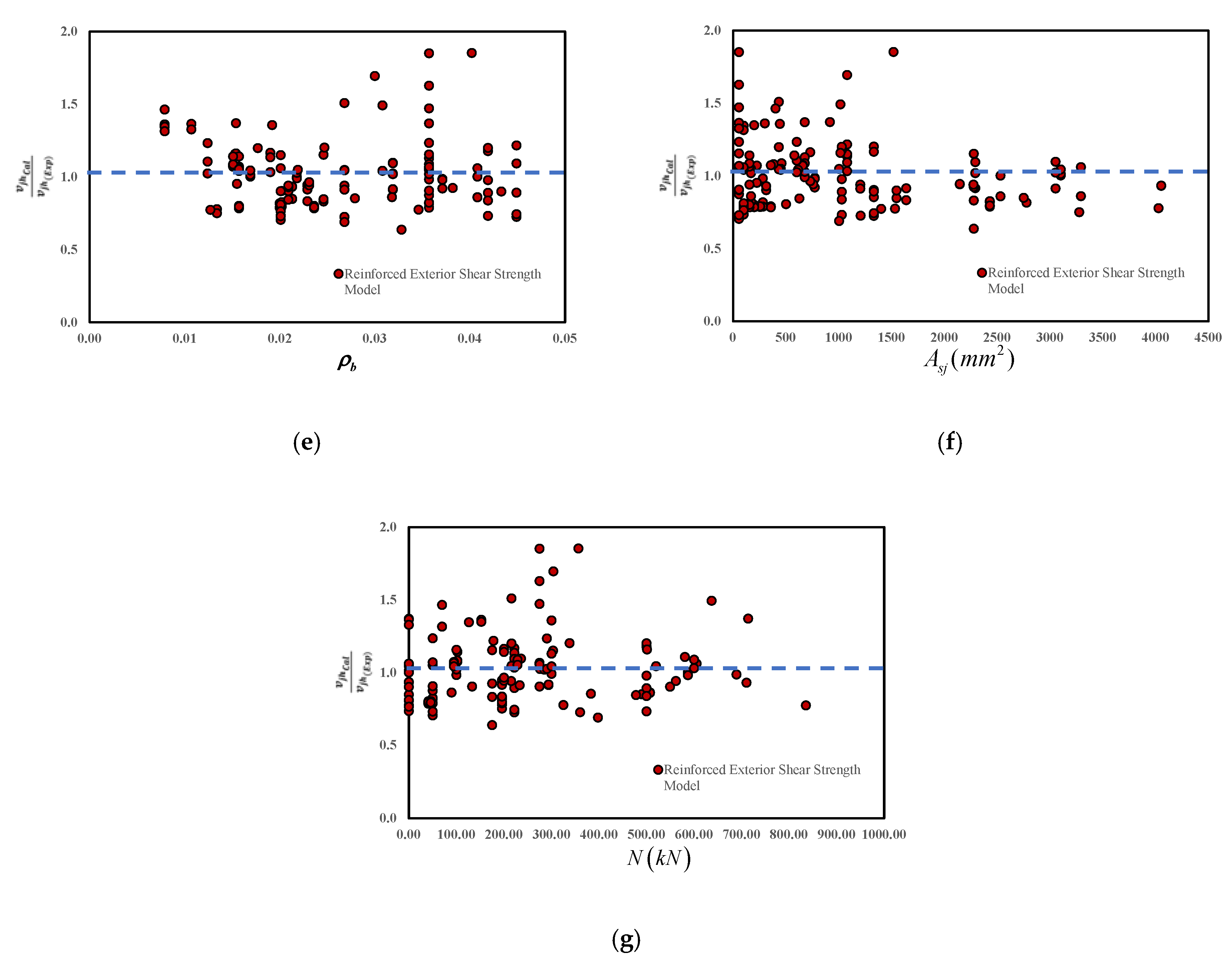

7.2. Shear Strength of the Reinforced Exterior Joint

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Vollum and Neman [24] | |

| Bakir and Boduroglu [4] | |

| Hegger et al. [25] | |

| Sarsam and Phipps [26] | |

| Parra-Montesinos and Wight [27] | |

| Kim et al. [28] | |

| Yasmin [46] | |

| ACI 352R-02 (2010) [22] | (MPa) (psi) |

| ASCE 41-17 [23] | |

| New Zealand design standard (NZS 3101-2006) [18] | |

| Chinese seismic standards (GB 50011:2010) [17] | |

| Eurocode 8 (EN 1998-1:2004) [19] | |

| Architectural Institute of Japan (AIJ) [20] |

Appendix B. Simple Example

| Authors and Year | Specimen Name | Cylinder Concrete Compressive Strength (MPa) | Joint Shear Reinforcement Area (mm2) | Column Depth (mm) | Joint Width (mm) | Joint Aspect Ratio | Beam Reinforcement Ratio | Experimental Joint Shear Strength (kN) | Predicted Joint Experimental Strength (kN) |

|---|---|---|---|---|---|---|---|---|---|

| BINDHU and JAYA 2008 [77] | A1 | 36.70 | 396.00 | 150.00 | 100.00 | 1.00 | 0.11 | 74.71 | 68.47 |

| T1 | 23.90 | 0.00 | 200.00 | 200.00 | 1.65 | 0.02 | 62.29 | 59.56 |

References

- Akguzel, U.; Pampanin, S. Effects of Variation of Axial Load and Bidirectional Loading on Seismic Performance of GFRP Retrofitted Reinforced Concrete Exterior Beam-Column Joints. J. Compos. Constr. 2010, 14, 94–104. [Google Scholar] [CrossRef]

- Akguzel, U.; Pampanin, S. Assessment and design procedure for the seismic retrofit of reinforced concrete beam-column joints using FRP composite materials. J. Compos. Constr. 2012, 16, 21–34. [Google Scholar] [CrossRef]

- Anderson, M.; Lehman, D.; Stanton, J. A cyclic shear stress-strain model for joints without transverse reinforcement. Eng. Struct. 2008, 30, 941–954. [Google Scholar] [CrossRef]

- Bakir, P.G.; Boduroğlu, H.M. A new design equation for predicting the joint shear strength of monotonically loaded exterior beam-column joints. Eng. Struct. 2002, 24, 1105–1117. [Google Scholar] [CrossRef]

- Lowes, L.N.; Altoontash, A. Modeling reinforced-concrete beam-column joints subjected to cyclic loading. J. Struct. Eng. 2003, 129, 1686–1697. [Google Scholar] [CrossRef]

- Mitra, N.; Lowes, L.N. Evaluation, calibration, and verification of a reinforced concrete beam–column joint model. J. Struct. Eng. 2007, 133, 105–120. [Google Scholar] [CrossRef]

- Pampanin, S.; Calvi, G.M.; Moratti, M. Seismic behaviour of RC beam-column joints designed for gravity loads. In Proceedings of the 12th European Conference on Earthquake Engineering, London, UK, 9–13 September 2002; Volume 726. [Google Scholar]

- Shafaei, J.; Nezami, S.A. Effect of different size of joint enlargement on seismic behavior of gravity load designed RC beam-column connections. Struct. Des. Tall Spec. Build. 2019, 28, e1653. [Google Scholar] [CrossRef]

- Wang, G.L.; Dai, J.G.; Teng, J.G. Shear strength model for RC beam-column joints under seismic loading. Eng. Struct. 2012, 40, 350–360. [Google Scholar] [CrossRef]

- Moretti, M.L.; Tassios, T.P.; Vintzileou, E. Behavior and Design of Corner Joints under Opening Bending Moment. ACI Struct. J. 2014, 111, 3–13. [Google Scholar]

- Hassan, W.M.; Moehle, J.P. Shear strength of exterior and corner beam-column joints without transverse reinforcement. ACI Struct. J. 2018, 115, 1719–1727. [Google Scholar] [CrossRef]

- De Risi, M.T.; Ricci, P.; Verderame, G.M. Modelling exterior unreinforced beam-column joints in seismic analysis of non-ductile RC frames. Earthq. Eng. Struct. Dyn. 2017, 46, 899–923. [Google Scholar] [CrossRef]

- Sezen, H.; Elwood, K.J.; Whittaker, A.S.; Mosalam, K.M.; Wallace, J.W.; Stanton, J.F. Structural Engineering Reconnaissance of the August 17, 1999 Earthquake: Kocaeli (Izmit), Turkey; Pacific Earthquake Engineering Research Center: Berkeley, CA, USA, 2000. [Google Scholar]

- Jimenez, J.I.; Villarreal, J.I.; Centeno, M.R.; Gonzalez, B.G.; Correa, J.J.G.; Acevedo, C.R.; Salazar, I.S. The Tehuacan, Mexico, earthquake of June 15, 1999. Seismol. Res. Lett. 1999, 70, 698–704. [Google Scholar] [CrossRef]

- Earthquake Engineering Research Institute. EERI Special Earthquake Report—November 1999; The Athens, Greece Earthquake of September 7, 1999; Earthquake Engineering Research Institute: Oakland, CA, USA, 1999. [Google Scholar]

- Javed, M.; Hussain, Z.; Naseer, A.; Muhammad, S.; Ahmed, I. First Report on the Kashmir Earthquake of October 8, 2005. Earthquake 2005. Available online: https://www.iitk.ac.in/nicee/RP/2005_KashmirEQ_EERI.pdf (accessed on 11 May 2022).

- NZS 3101.1&2:2006; Concrete Structures Standard. Standards New Zealand: Wellington, New Zealand, 2006; ISBN 9781776730902.

- EN 1998-1; Eurocode 8: Design of Structures for Earthquake Resistance—Part 1: General Rules, Seismic Actions and Rules for Buildings. CENEuropean Committeefor Standardization: Brussels, Belgium, 2004.

- Architectural Institute of Japan (AIJ). Structural Design Guidelines for Reinforced Concrete Buildings; Architectural Institute of Japan: Tokyo, Japan, 1999. [Google Scholar]

- ACI 318-19; Commentary on Building Code Requirements. American Concrete Institute: Farmington Hills, MI, USA, 2016; ISBN 9781945487118.

- Cagley, J.R.; LaFave, J.M.; Paultre, P.; Criswell, M.E.; Lee, D.D.; Saiidi, M.S.; French, C.E.; Leon, R.T.; Shahrooz, B.M.; Garcia, L.E.; et al. Recommendations for Design of Beam-Column Connections in Monolithic Reinforced Concrete Structures; 2010; Volume 2, Available online: https://www.academia.edu/32273471/Recommendations_for_Design_of_Beam_Column_Connections_in_Monolithic_Reinforced_Concrete_Structures (accessed on 11 May 2022).

- ASCE 41-17; Seismic Evaluation and Retrofit of Existing Buildings. American Society of Civil Engineers: Reston, VA, USA, 2017.

- Vollum, R.L.; Newman, J.B. The design of external, reinforced concrete beam-column joints. Struct. Eng. 1999, 77, 21–27. [Google Scholar]

- Hegger, J.; Sherif, A.; Roeser, W. Nonseismic Design of Beam-Column Joints. ACI Struct. J. 2003, 100, 654–664. [Google Scholar] [CrossRef]

- Sarsam, K.F.; Phipps, M.E.; Sarsam, K.F.; Phipps, M.E. The shear design of in situ reinforced concrete beam-column joints subjected to monotonic loading. Mag. Concr. Res. 1985, 37, 16–28. [Google Scholar] [CrossRef]

- Parra-Montesinos, G.J.; Wight, J.K. Prediction of Strength and Shear Distortion in R/C Beam-Column Joints. Am. Concr. Inst. Spec. Publ. 2002, 197, 191–214. [Google Scholar]

- Kim, J.; LaFave, J.M.; Song, J. Joint shear behaviour of reinforced concrete beam-column connections. Mag. Concr. Res. 2009, 61, 119–132. [Google Scholar] [CrossRef]

- Lynn, A.C.; Moehle, J.P.; Mahin, S.A.; Holmes, W.T. Seismic evaluation of existing reinforced concrete building columns. Earthq. Spectra 1996, 12, 715–739. [Google Scholar] [CrossRef]

- Ousalem, H.; Kabeyasawa, T.; Tasai, A.; Ohsugi, Y. Experimental study on seismic behavior of reinforced concrete columns under constant and variable axial loadings. Proc. Jpn. Concr. Inst. 2002, 24, 229–234. [Google Scholar]

- Sezen, H. Seismic Behavior and Modeling of Reinforced Concrete Building Columns; University of California at Berkeley: Berkeley, CA, USA, 2002. [Google Scholar]

- Elwood, K.; Moehle, J.P. Shake Table Tests and Analytical Studies on the Gravity Load Collapse of Reinforced Concrete Frames; University of California, Berkeley: Berkeley, CA, USA, 2003; ISBN PEER-2003/01. [Google Scholar]

- Elwood, K.J. Modelling failures in existing reinforced concrete columns. Can. J. Civ. Eng. 2004, 31, 846–859. [Google Scholar] [CrossRef]

- Elood, K.J.; Moehle, J.P. Axial capacity model for shear-damaged columns. ACI Struct. J. 2005, 102, 578–587. [Google Scholar] [CrossRef]

- Del Vecchio, C.; Del Zoppo, M.; Di Ludovico, M.; Verderame, G.M.; Prota, A. Comparison of available shear strength models for non-conforming reinforced concrete columns. Eng. Struct. 2017, 148, 312–327. [Google Scholar] [CrossRef]

- Elwood, K.J.; Moehle, J.P. Drift capacity of reinforced concrete columns with light transverse reinforcement. Earthq. Spectra 2005, 21, 71–89. [Google Scholar] [CrossRef]

- Priestley, M.J.N.; Verma, R.; Xiao, Y. Seismic Shear Strength of Reinforced Concrete Columns. J. Struct. Eng. 1994, 120, 2310–2329. [Google Scholar] [CrossRef]

- Ho, J.C.M.; Pam, H.J. Inelastic design of low-axially loaded high-strength reinforced concrete columns. Eng. Struct. 2003, 25, 1083–1096. [Google Scholar] [CrossRef]

- Moretti, M.; Tassios, T.P. Behaviour of short columns subjected to cyclic shear displacements: Experimental results. Eng. Struct. 2007, 29, 2018–2029. [Google Scholar] [CrossRef]

- Sezen, H.; Moehle, J.P. Shear Strength Model for Lightly Reinforced Concrete Columns. J. Struct. Eng. 2004, 130, 1692–1703. [Google Scholar] [CrossRef]

- Park, H.G.; Yu, E.J.; Choi, K.K. Shear-strength degradation model for RC columns subjected to cyclic loading. Eng. Struct. 2012, 34, 187–197. [Google Scholar] [CrossRef]

- Shin, M.; Lafave, J.M. Modeling of cyclic joint shear deformation contributions in RC beam-column connections to overall frame behavior. Struct. Eng. Mech. 2004, 18, 645–669. [Google Scholar] [CrossRef]

- Favvata, M.J.; Izzuddin, B.A.; Karayannis, C.G. Modelling exterior beam-column joints for seismic analysis of RC frame structures. Earthq. Eng. Struct. Dyn. 2008, 37, 1527–1548. [Google Scholar] [CrossRef]

- Wong, H.F. Shear Strength & Seismic Performance of Non-Seismically Designed RC BC Joints. 2005. Available online: https://hdl.handle.net/1783.1/2592 (accessed on 11 May 2022).

- Hakuto, S.; Park, R.; Tanaka, H. Effect of deterioration of bond of beam bars passing through interior beam-column joints on flexural strength and ductility. ACI Struct. J. 1999, 96, 858–864. [Google Scholar] [CrossRef]

- Murad, Y. Joint shear strength models for exterior RC beam-column connections exposed to biaxial and uniaxial cyclic loading. J. Build. Eng. 2020, 30, 101225. [Google Scholar] [CrossRef]

- Tariq, M.; Khan, A.; Ullah, A.; Shayanfar, J.; Niaz, M. Improved Shear Strength Prediction Model of Steel Fiber Reinforced Concrete Beams by Adopting Gene Expression Programming. Materials 2022, 15, 3758. [Google Scholar] [CrossRef]

- Tariq, M.; Khan, A.; Shayanfar, J.; Hanif, M.U.; Ullah, A. A regression model for predicting the shear strength of RC knee joint subjected to opening and closing moment. J. Build. Eng. 2021, 41, 102727. [Google Scholar] [CrossRef]

- Hassan, W.M. Analytical and Experimental Assessment of Seismic Vulnerability of Beam-Column Joints without Transverse Reinforcement in Concrete Buildings; University of California, Barkeley: Berkeley, CA, USA, 2011. [Google Scholar]

- Alva, G.M.S.; de Cresce El Debs, A.L.H.; El Debs, M.K. An experimental study on cyclic behaviour of reinforced concrete connections. Can. J. Civ. Eng. 2007, 34, 565–575. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Favvata, M.J.; Karayannis, C.G. Reinforced concrete beam-column joints with crossed inclined bars under cyclic deformations. Earthq. Eng. Struct. Dyn. 2008, 37, 881–897. [Google Scholar] [CrossRef]

- Chun, S.C.; Kim, D.Y. Evaluation of Mechanical Anchorage of Reinforcement by Exterior Beam-Column Joint Experiments. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004; p. 0326. [Google Scholar]

- Calvi, G.M.; Pampanin, G.M.S.; Magenes, G.; Pampanin, S. Studio Sperimentale sulla Risposta Sismica di Edifici a Telaio in Cemento Armato Progettati per Soli Carichi da Gravità; University of Canterbury: Christchurch, New Zealand, 2001. [Google Scholar]

- Chun, S.C.; Lee, S.H.; Kang, T.H.K.; Oh, B.; Wallace, J.W. Mechanical anchorage in exterior beam-column joints subjected to cyclic loading. ACI Struct. J. 2007, 104, 102–112. [Google Scholar] [CrossRef]

- Chutarat, N.; Aboutaha, R.S. Cyclic response of exterior reinforced concrete beam-column joints reinforced with headed bars—Experimental investigation. ACI Struct. J. 2003, 100, 259–264. [Google Scholar] [CrossRef]

- Pantelides, C.P.; Clyde, C.; Reaveley, L.D. Performance-based evaluation of reinforced concrete building exterior joints for seismic excitation. Earthq. Spectra 2002, 18, 449–480. [Google Scholar] [CrossRef]

- Durrani, A.J.; Zerbe, H.E. Seismic Resistance of R/C Exterior Connections with Floor Slab. J. Struct. Eng. 1987, 113, 1850–1864. [Google Scholar] [CrossRef]

- Ehsani, M.R.; Moussa, A.E.; Vallenilla, C.R. Comparison of Inelastic Behavior of Reinforced Ordinary- and High-Strength Concrete Frames. ACI Struct. J. 1987, 84, 161–169. [Google Scholar] [CrossRef]

- Ehsani, M.R.; Alameddine, F. Design recommendations for type 2 high-strength reinforced concrete connections. ACI Struct. J. 1991, 88, 277–291. [Google Scholar] [CrossRef]

- Ehsani, M.R.; Wight, J.K. Effect of Transverse Beams and Slab on Behavior of Reinforced Concrete Beam-To-Column Connections. Proc. J. Am. Concr. Inst. 1985, 82, 188–195. [Google Scholar]

- Ehsani, M.R.; Wight, J.K. Exterior reinforced concrete beam-to-column connections subjected to earthquake-type loading. Proc. J. Proc. 1985, 82, 492–499. [Google Scholar]

- Gençoǧlu, M.; Eren, I. An experimental study on the effect of steel fiber reinforced concrete on the behavior of the exterior beam-column joints subjected to reversal cyclic loading. Turk. J. Eng. Environ. Sci. 2002, 26, 493–502. [Google Scholar] [CrossRef]

- Hamil, S.J. Reinforced Concrete Beam-Column Connection Behaviour. Ph.D. Thesis, Durham University, Durham, UK, May 2000. [Google Scholar]

- Hakuto, S.; Park, R.; Tanaka, H. Seismic load tests on interior and exterior beam-column joints with substandard reinforcing details. ACI Struct. J. 2000, 97, 11–25. [Google Scholar] [CrossRef]

- Salim, I.B. The Influence of Concrete Strengths on the Behaviour of External Beam-Column Joints; Universiti Teknologi Malaysia: Skudai, Malaysia, 2007. [Google Scholar]

- Karayannis, C.G.; Chalioris, C.E.; Sirkelis, G.M. Local retrofit of exterior RC beam-column joints using thin RC jackets—An experimental study. Earthq. Eng. Struct. Dyn. 2008, 37, 727–746. [Google Scholar] [CrossRef]

- Karayannis, C.; Sirkelis, G. Response of columns and joints with spiral shear reinforcement. Comput. Methods Exp. Meas. 2005, 41, 455–463. [Google Scholar]

- Liu, C. Seismic Behaviour of Beam-Column Joint Subassemblies Reinforced with Steel Fibres; University of Canterbury: Christchurch, New Zealand, 2006. [Google Scholar]

- Pantelides, C.P.; Hansen, J.; Ameli, M.J.; Reaveley, L.D. Seismic performance of reinforced concrete building exterior joints with substandard details. J. Struct. Integr. Maint. 2017, 2, 1–11. [Google Scholar] [CrossRef]

- Scott, R.H. Intrinsic mechanisms in reinforced concrete beam-column connection behavior. ACI Struct. J. 1996, 93, 336–346. [Google Scholar] [CrossRef]

- Parker, D.E.; Bullman, P.J.M. Shear strength within reinforced concrete beam-column joints. Struct. Eng. 1997, 75, 53–57. [Google Scholar]

- Tsonos, A.G.; Tegos, I.A.; Penelis, G.G. Seismic resistance of type 2 exterior beam-column joints reinforced with inclined bars. ACI Struct. J. 1992, 89, 3–12. [Google Scholar] [CrossRef]

- Tsonos, A.G. Lateral load response of strengthened reinforced concrete beam-to-column joints. ACI Struct. J. 1999, 96, 46–56. [Google Scholar] [CrossRef]

- Tsonos, A.G. Cyclic load behaviour of reinforced concrete beam-column subassemblages of modern structures. WIT Trans. Built Environ. 2007, 81, 11. [Google Scholar]

- Alva, G.M.S. Theoretical-Experimental Study of the Behavior of Reinforced Concrete Frame Nodes Subjected to Cyclical Actions. Ph.D. Thesis, Universidade Federal de São Carlos, São Carlos, Brazil, 2004. [Google Scholar]

- Ridwan Reinforced Concrete Beam-Column Joints Strengthened in Shear with Embedded Bars; The University of Birmingham: Birmingham, UK, 2016.

- Bindhu, K.R.; Sukumar, P.M.; Jaya, K.P. Performance of exterior beam-column joints under seismic type loading. ISET J. Earthq. Technol. 2009, 46, 47–64. [Google Scholar]

- Vollum, R.L.; Newman, J.B. Strut and tie models for analysis/design of external beam-column joints. Mag. Concr. Res. 1999, 51, 415–425. [Google Scholar] [CrossRef]

- Paulay, T.; Priestly, M.J.N. Seismic Design of Reinforced Concrete and Masonry Buildings; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1992. [Google Scholar]

- Karayannis, C.G. Mechanics of external RC beam-column joints with rectangular spiral shear reinforcement: Experimental verification. Meccanica 2015, 50, 311–322. [Google Scholar] [CrossRef]

- Hwang, S.; Lee, H.; Wang, K. Seismic Design and Detailing of Exterior Reinforced Concrete Beam-Column Joints. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004; pp. 1–12. [Google Scholar]

- Hwang, S.J.; Lee, H.J.; Liao, T.F.; Wang, K.C.; Tsai, H.H. Role of hoops on shear strength of reinforced concrete beam-column joints. ACI Struct. J. 2005, 102, 445–453. [Google Scholar] [CrossRef]

- Kuang, J.S.; Wong, H.F. Effects of beam bar anchorage on beam-column joint behaviour. Proc. Inst. Civ. Eng. Struct. Build. 2006, 159, 115–124. [Google Scholar] [CrossRef]

- Shiohara, H.; Kusuhara, F. Benchmark test for validation of mathematical models for nonlinear and cyclic behaviour of R/C beam-column joints; Department of Architecture, Graduate School of Engineering, University of Tokyo: Tokyo, Japan, 2006. [Google Scholar]

- Masi, A.; Santarsiero, G.; Lignola, G.P.; Verderame, G.M. Study of the seismic behavior of external RC beam-column joints through experimental tests and numerical simulations. Eng. Struct. 2013, 52, 207–219. [Google Scholar] [CrossRef]

- Akguzel, U. Seismic Performance of FRP Retrofitted Exterior RC Beam-Column Joints under Varying Axial and Bidirectional Loading. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 2011. [Google Scholar]

- Halim, S.; Takahashi, S.; Ichinose, T.; Teshigawara, M.; Kamiya, T.; Fukuyama, H. Strength of beam-column joint in soft first story of RC buildings Part 2: Design equations. J. Adv. Concr. Technol. 2014, 12, 146–157. [Google Scholar] [CrossRef][Green Version]

- Antonopoulos, C.P.; Triantafillou, T.C. Experimental Investigation of FRP-Strengthened RC Beam-Column Joints. J. Compos. Constr. 2003, 7, 39–49. [Google Scholar] [CrossRef]

- Garcia, R.; Jemaa, Y.; Helal, Y.; Guadagnini, M.; Pilakoutas, K. Seismic Strengthening of Severely Damaged Beam-Column RC Joints Using CFRP. J. Compos. Constr. 2014, 18, 04013048. [Google Scholar] [CrossRef]

- Ghobarah, A.; El-Amoury, T. Seismic Rehabilitation of Deficient Exterior Concrete Frame Joints. J. Compos. Constr. 2005, 9, 408–416. [Google Scholar] [CrossRef]

- Shafaei, J.; Zareian, M.S.; Hosseini, A.; Marefat, M.S. Effects of joint flexibility on lateral response of reinforced concrete frames. Eng. Struct. 2014, 81, 412–431. [Google Scholar] [CrossRef]

- Shrestha, R.; Smith, S.T.; Samali, B. Strengthening RC beam-column connections with FRP strips. Proc. Inst. Civ. Eng. Struct. Build. 2009, 162, 323–334. [Google Scholar] [CrossRef]

- Melo, J.; Varum, H.; Rossetto, T.; Costa, A. Cyclic response of RC beam-column joints reinforced with plain bars: An experimental testing campaign. In Proceedings of the 15Wcee, Lisbon, Portugal, 24–28 September 2012; pp. 24–28. [Google Scholar]

- De Risi, M.T.; Ricci, P.; Verderame, G.M.; Manfredi, G. Experimental assessment of unreinforced exterior beam-column joints with deformed bars. Eng. Struct. 2016, 112, 215–232. [Google Scholar] [CrossRef]

- Yurdakul, Ö.; Avşar, Ö. Strengthening of substandard reinforced concrete beam-column joints by external post-tension rods. Eng. Struct. 2016, 107, 9–22. [Google Scholar] [CrossRef]

- Parvin, A.; Altay, S.; Yalcin, C.; Kaya, O. CFRP Rehabilitation of Concrete Frame Joints with Inadequate Shear and Anchorage Details. J. Compos. Constr. 2010, 14, 72–82. [Google Scholar] [CrossRef]

- Del Vecchio, C.; Di Ludovico, M.; Balsamo, A.; Prota, A.; Manfredi, G.; Dolce, M. Experimental Investigation of Exterior RC Beam-Column Joints Retrofitted with FRP Systems. J. Compos. Constr. 2014, 18, 04014002. [Google Scholar] [CrossRef]

- Kaya, O.; Yalcin, C.; Parvin, A.; Altay, S. Repairing Of Shear-Damaged Rc Joint Panel Zone Using Chemical Epoxy Injection Methodology. In Proceedings of the 14th World Conference on Earthquake Engineering (14WCEE), Beijing, China, 12–17 October 2008. [Google Scholar]

- Genesio, G. Seismic Assessment of RC Exterior Beam-Column Joints and Retrofit with Haunches Using Post-Installed Anchors; 2012; ISBN 9783981168242. Available online: https://elib.uni-stuttgart.de/handle/11682/489 (accessed on 11 May 2022).

- Helal, Y. Seismic Strengthening of Deficient Exterior RC Beam-Column Sub-Assemblages Using Post-Tensioned Metal Strips; University of Sheffield: Sheffield, UK, 2012. [Google Scholar]

- Kim, C.-G.; Eom, T.-S.; Park, H.-G.; Kim, T.-W. Seismic Performance of Lightly Reinforced Concrete Beam-Column Connections for Low-Rise Buildings. J. Archit. Inst. Korea Struct. Constr. 2016, 32, 19–30. [Google Scholar] [CrossRef]

- Ricci, P.; De Risi, M.T.; Verderame, G.M.; Manfredi, G. Experimental tests of unreinforced exterior beam-column joints with plain bars. Eng. Struct. 2016, 118, 178–194. [Google Scholar] [CrossRef]

- Kam, W.Y.P.S. Selective Weakening and Post-Tensioning for the Seismic Retrofit of Non-Ductile RC Frames. Ph. D. Thesis, University of Canterbury, Christchurch, New Zealand, 2010; p. 532. [Google Scholar]

- Pampanin, S.; Bolognini, D.; Pavese, A. Performance-Based Seismic Retrofit Strategy for Existing Reinforced Concrete Frame Systems Using Fiber-Reinforced Polymer Composites. J. Compos. Constr. 2007, 11, 211–226. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Alavi, A.H.; Yun, G.J. Nonlinear modeling of shear strength of SFRC beams using linear genetic programming. Struct. Eng. Mech. 2011, 38, 1–25. [Google Scholar] [CrossRef]

| Input Parameter | Range |

|---|---|

| (MPa) | |

| (mm2) | |

| (mm) | |

| Axial load in column (N) (kN) |

| Chromosomes | 100 |

| Head sizes | 10 |

| Linking function | Addition |

| Function set | |

| Gene | 3 |

| Rate of mutation | 0.0014 |

| Rate of inversion | 0.1 |

| Constants per gene | 10 |

| Lower/Upper bound of constants | –20/20 |

| One-point recombination rate | 0.0027 |

| Two-point recombination rate | 0.0027 |

| Gene recombination rate | 0.0027 |

| Gene transposition rate | 0.0027 |

| Author | AAE (%) | ||

|---|---|---|---|

| Mean | |||

| Vollum et al. [24] | 1.80 | 89.00 | 0.79 |

| Bakir et al. [4] | 1.20 | 45.10 | 0.88 |

| Montenious et al. [27] | 0.64 | 161.50 | 0.50 |

| Kim et al. [28] | 0.27 | 323.00 | 0.72 |

| ACI 352R-02 [22] | 0.61 | 126.90 | 0.73 |

| ASCE 41-17 [23] | 1.23 | 45.80 | 0.72 |

| EN 1998-1-2004 [18] | 0.49 | 174.40 | 0.75 |

| GB 50010-2011 [19] | 0.39 | 241.70 | 0.72 |

| NZS 3101-2006 [17 | 0.58 | 130.20 | 0.72 |

| AIJ (1999) [20] | 1.20 | 50.90 | 0.73 |

| Proposed | 1.20 | 38.00 | 0.93 |

| Author | AAE (%) | ||

|---|---|---|---|

| Mean | |||

| Vollum et al. [24] | 1.20 | 40.00 | 0.79 |

| Bakir et al. [4] | 1.20 | 30.10 | 0.89 |

| Montenious et al. [27] | 3.49 | 76.00 | 0.39 |

| Kim et al. [28] | 1.90 | 49.00 | 0.81 |

| ACI 352R-02 [22] | 0.95 | 43.00 | 0.82 |

| ASCE 41-17 [23] | 1.90 | 49.00 | 0.82 |

| EN 1998-1-2004 [18] | 0.66 | 84.00 | 0.81 |

| GB 50010-2011 [19] | 0.49 | 151.09 | 0.77 |

| NZS 3101-2006 [17 | 0.74 | 74.00 | 0.77 |

| AIJ (1999) [20] | 1.49 | 37.00 | 0.81 |

| Proposed | 1.10 | 25.0 | 0.94 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tariq, M.; Khan, A.; Ullah, A. Shear Strength Prediction Model for RC Exterior Joints Using Gene Expression Programming. Materials 2022, 15, 7076. https://doi.org/10.3390/ma15207076

Tariq M, Khan A, Ullah A. Shear Strength Prediction Model for RC Exterior Joints Using Gene Expression Programming. Materials. 2022; 15(20):7076. https://doi.org/10.3390/ma15207076

Chicago/Turabian StyleTariq, Moiz, Azam Khan, and Asad Ullah. 2022. "Shear Strength Prediction Model for RC Exterior Joints Using Gene Expression Programming" Materials 15, no. 20: 7076. https://doi.org/10.3390/ma15207076

APA StyleTariq, M., Khan, A., & Ullah, A. (2022). Shear Strength Prediction Model for RC Exterior Joints Using Gene Expression Programming. Materials, 15(20), 7076. https://doi.org/10.3390/ma15207076