Exceptional Strengthening Efficiency and Hardness of Ti/Mg-9Al-Zn-0.3Mn Matrix Composite

Abstract

1. Introduction

2. Experimental Procedure

2.1. Materials and Preparation

2.2. Microstructure and Properties Characterization

3. Results

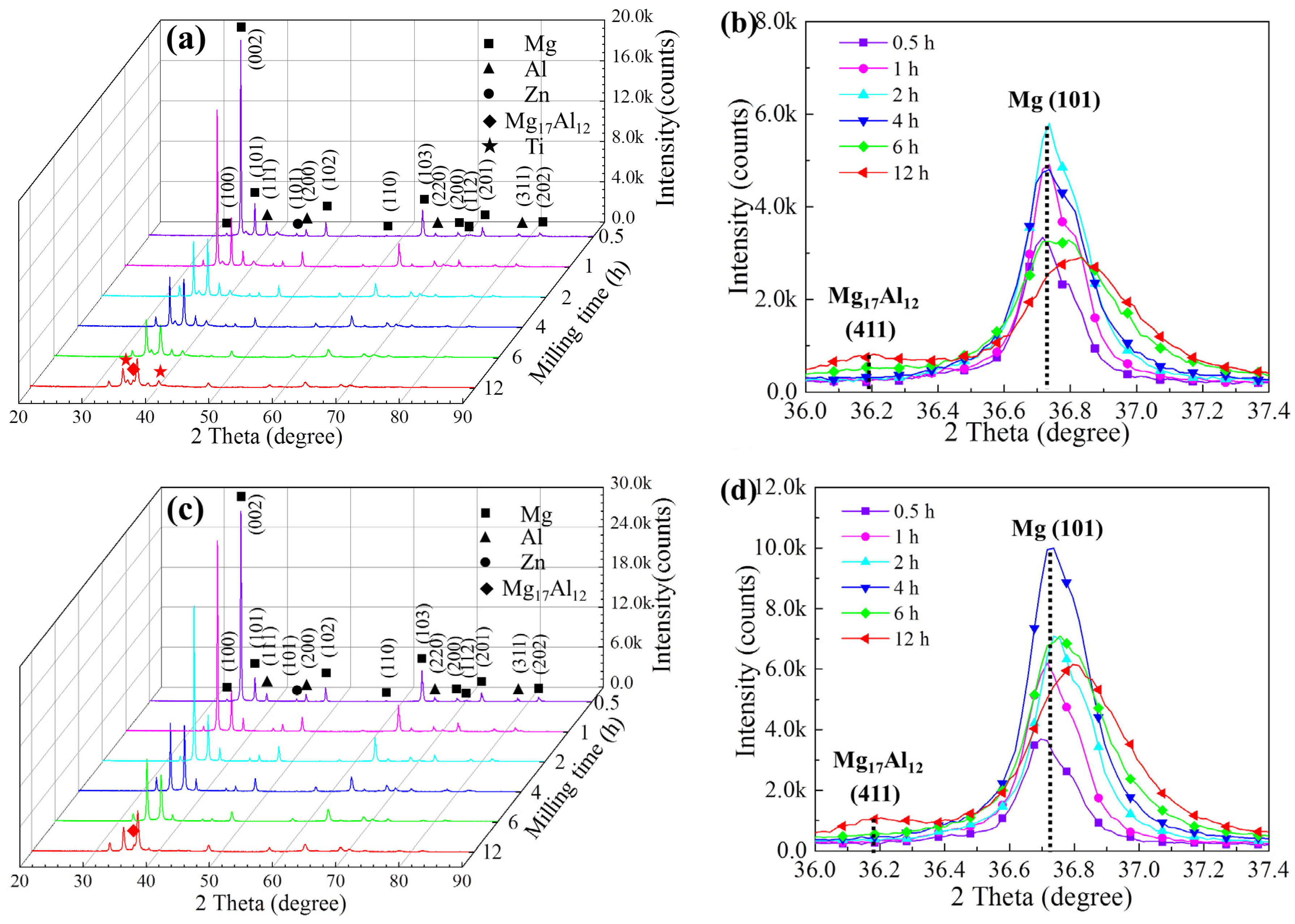

3.1. XRD Results

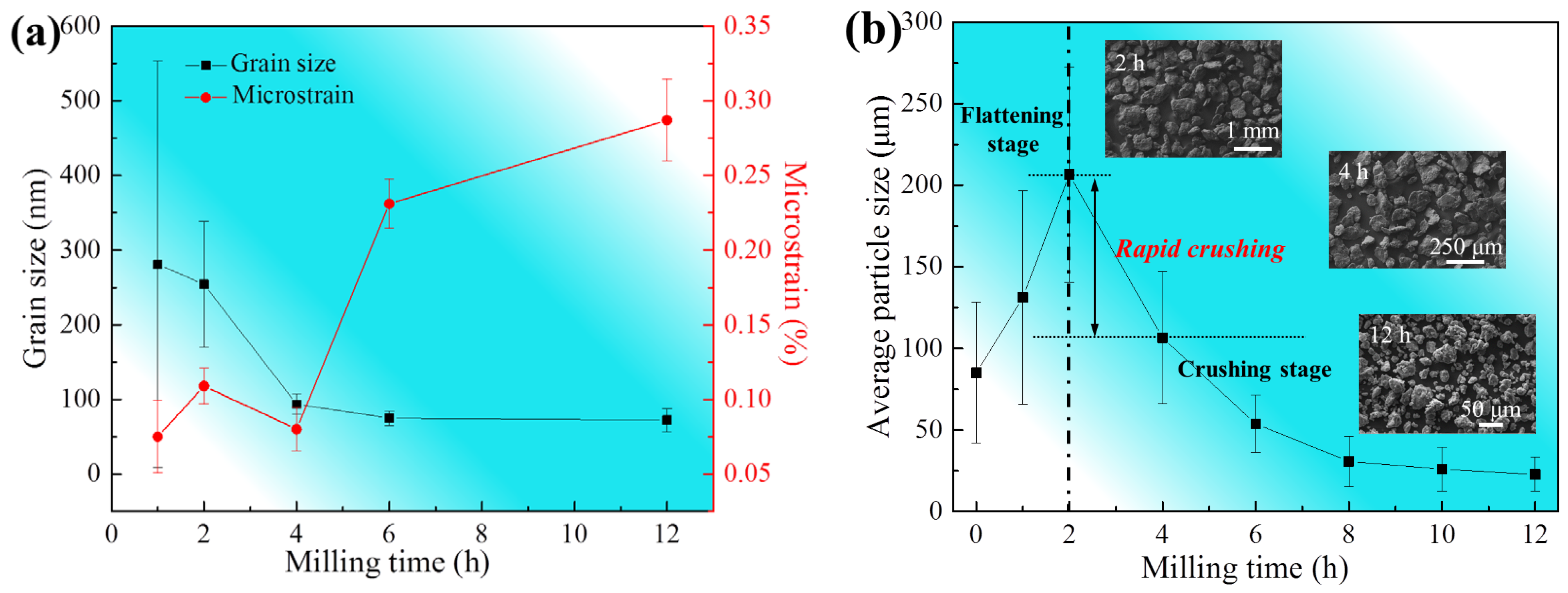

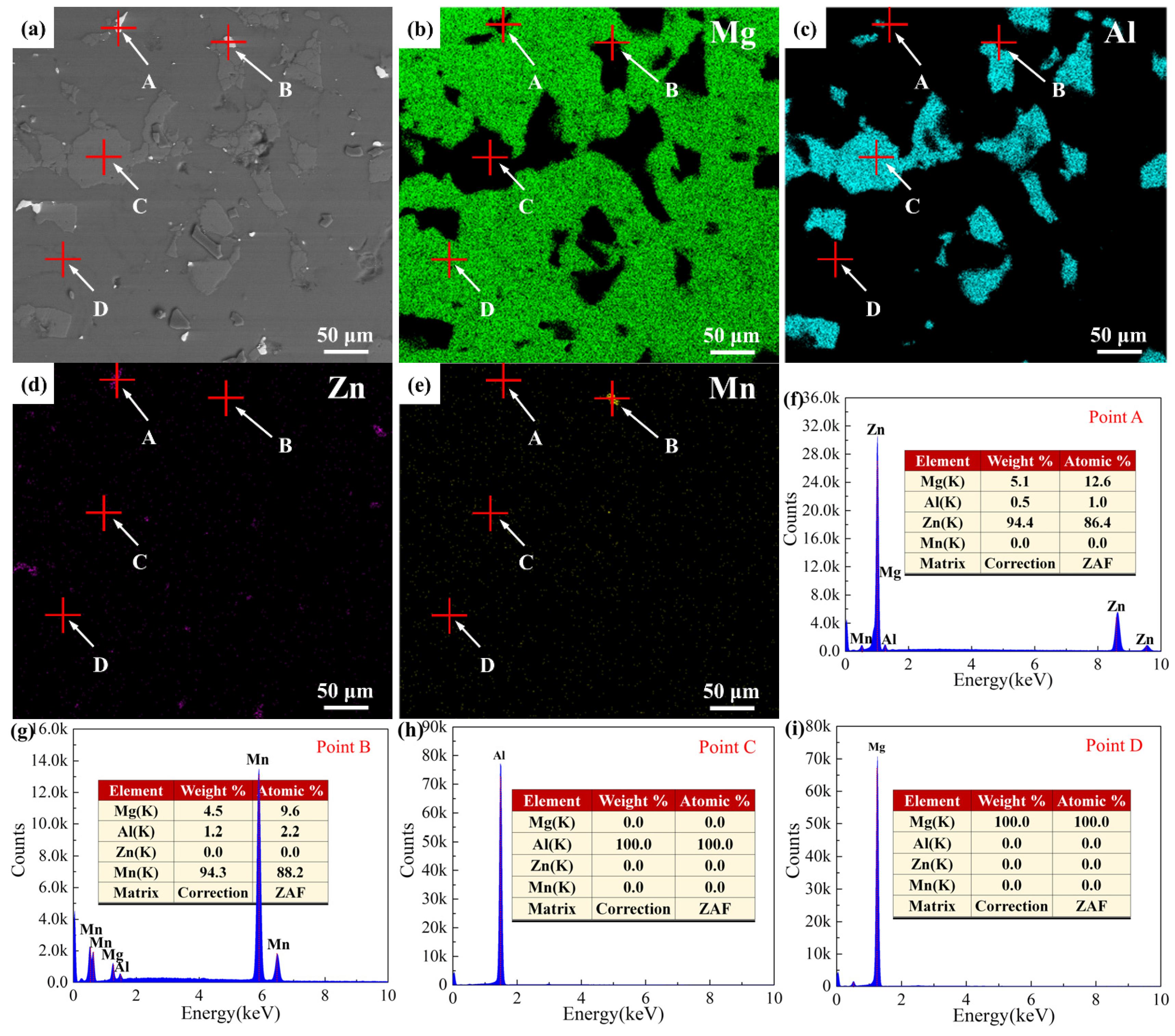

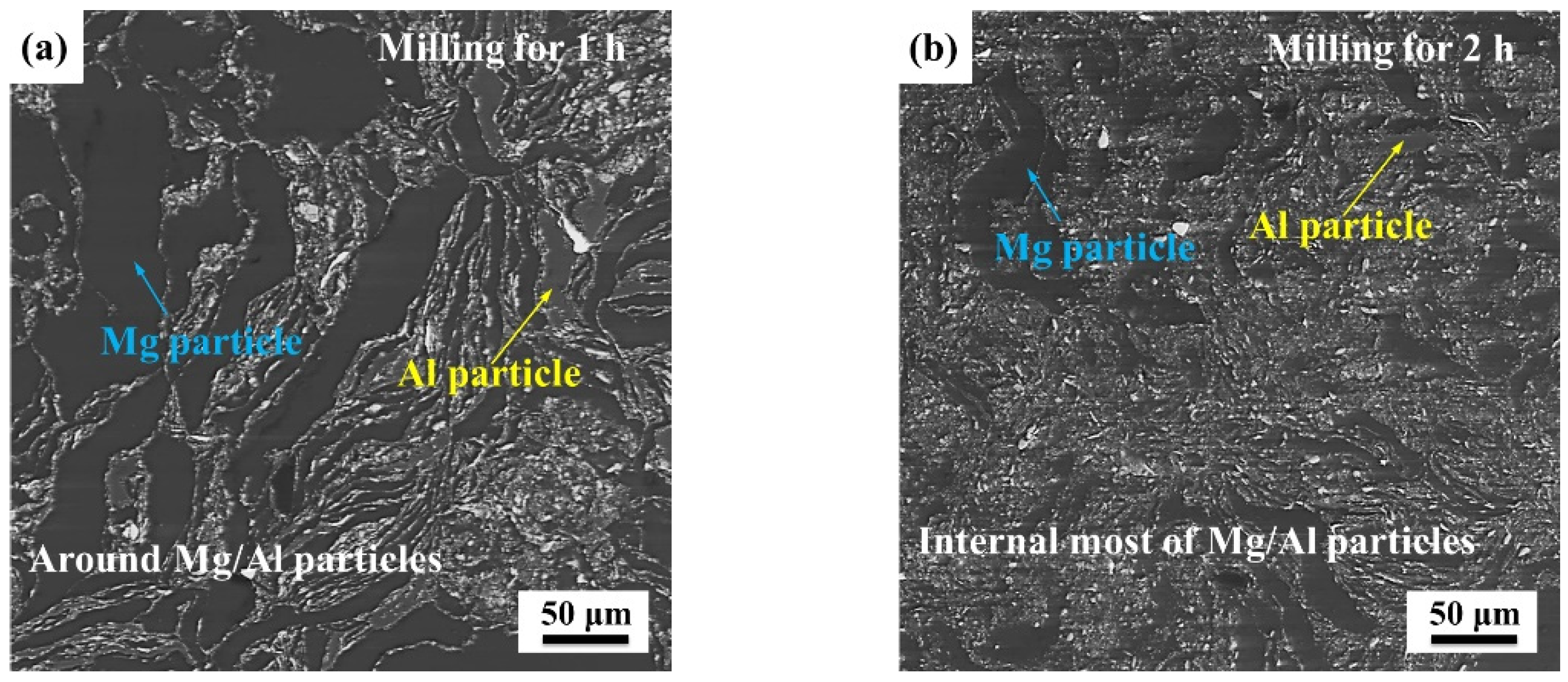

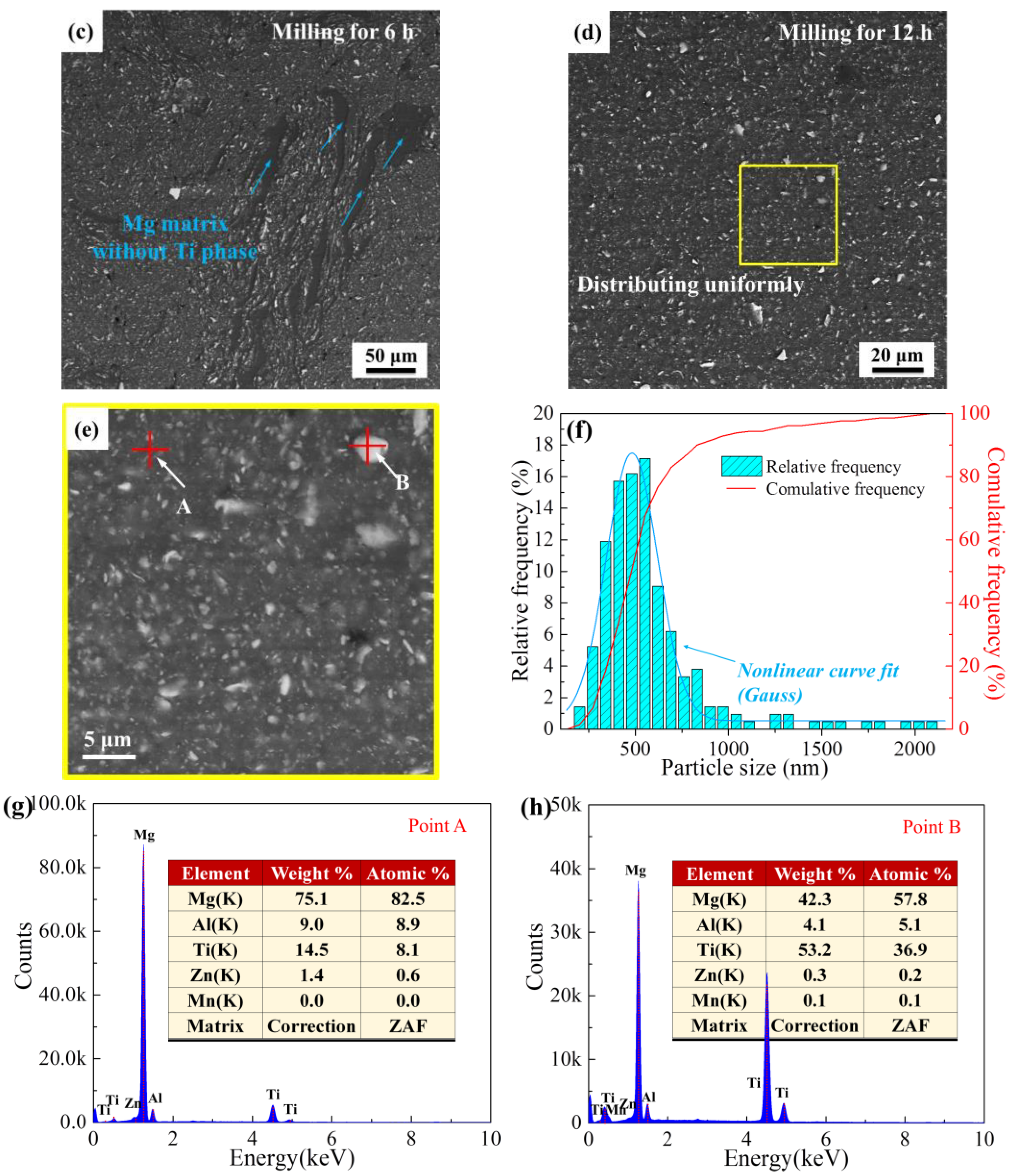

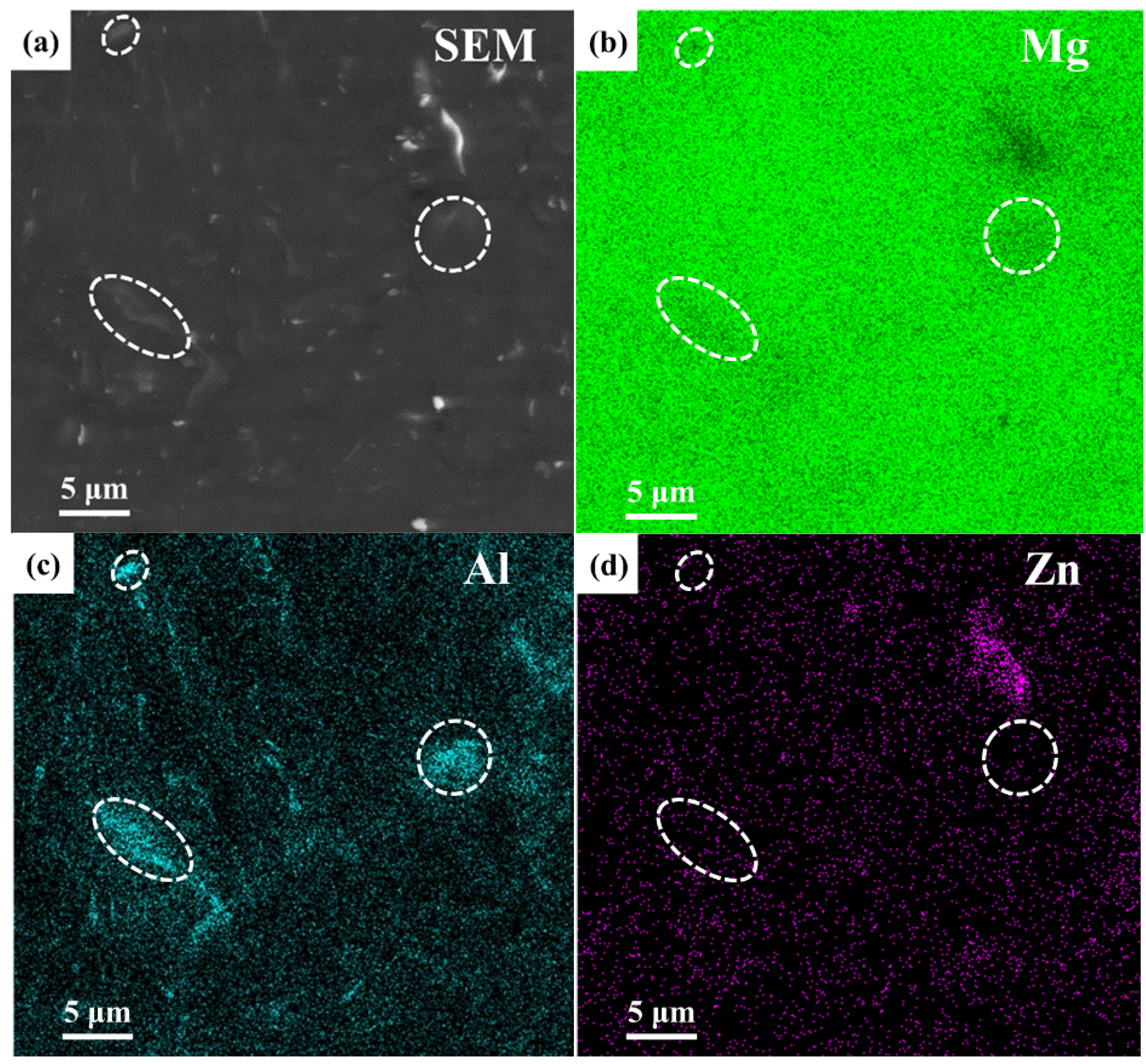

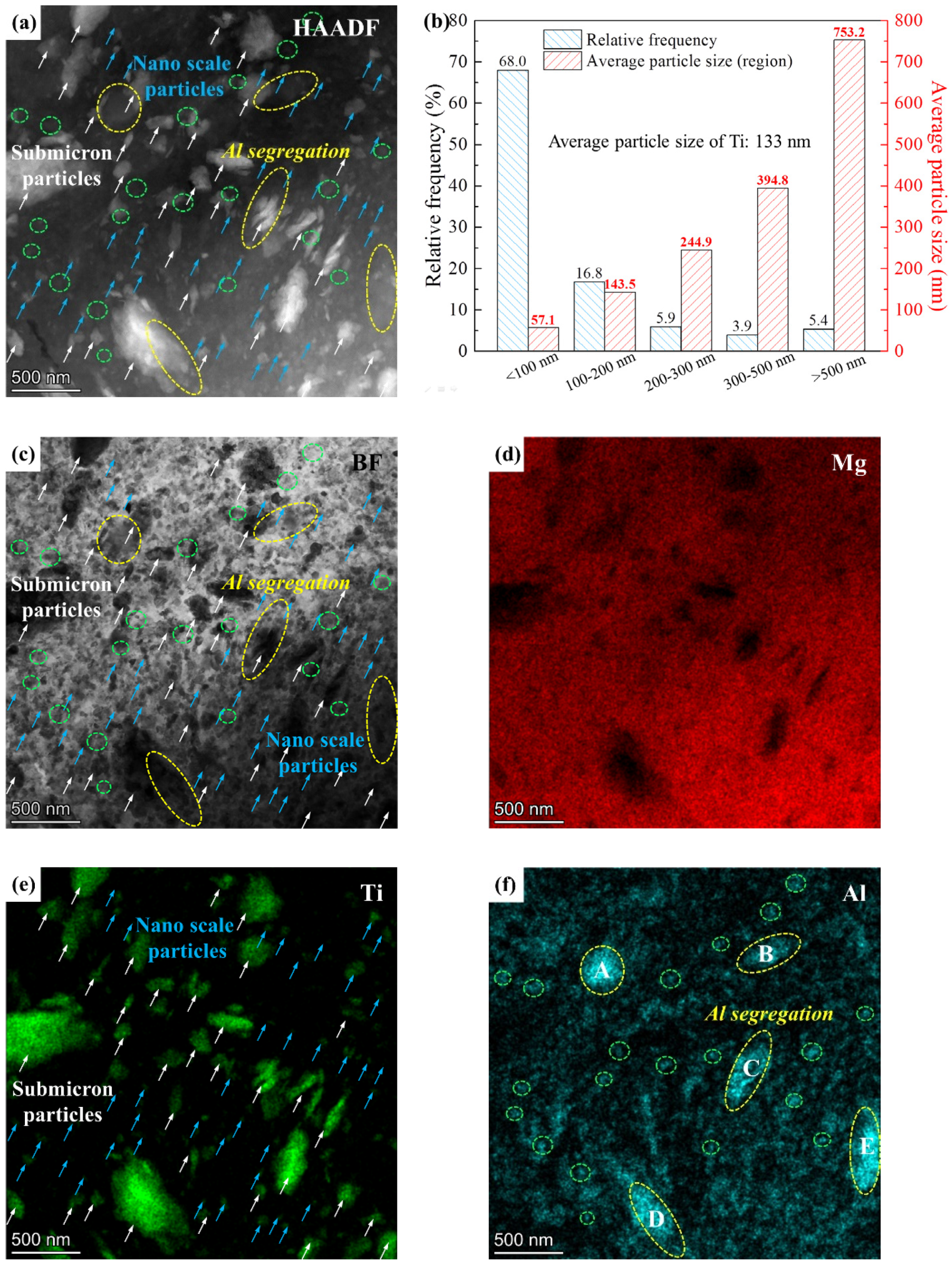

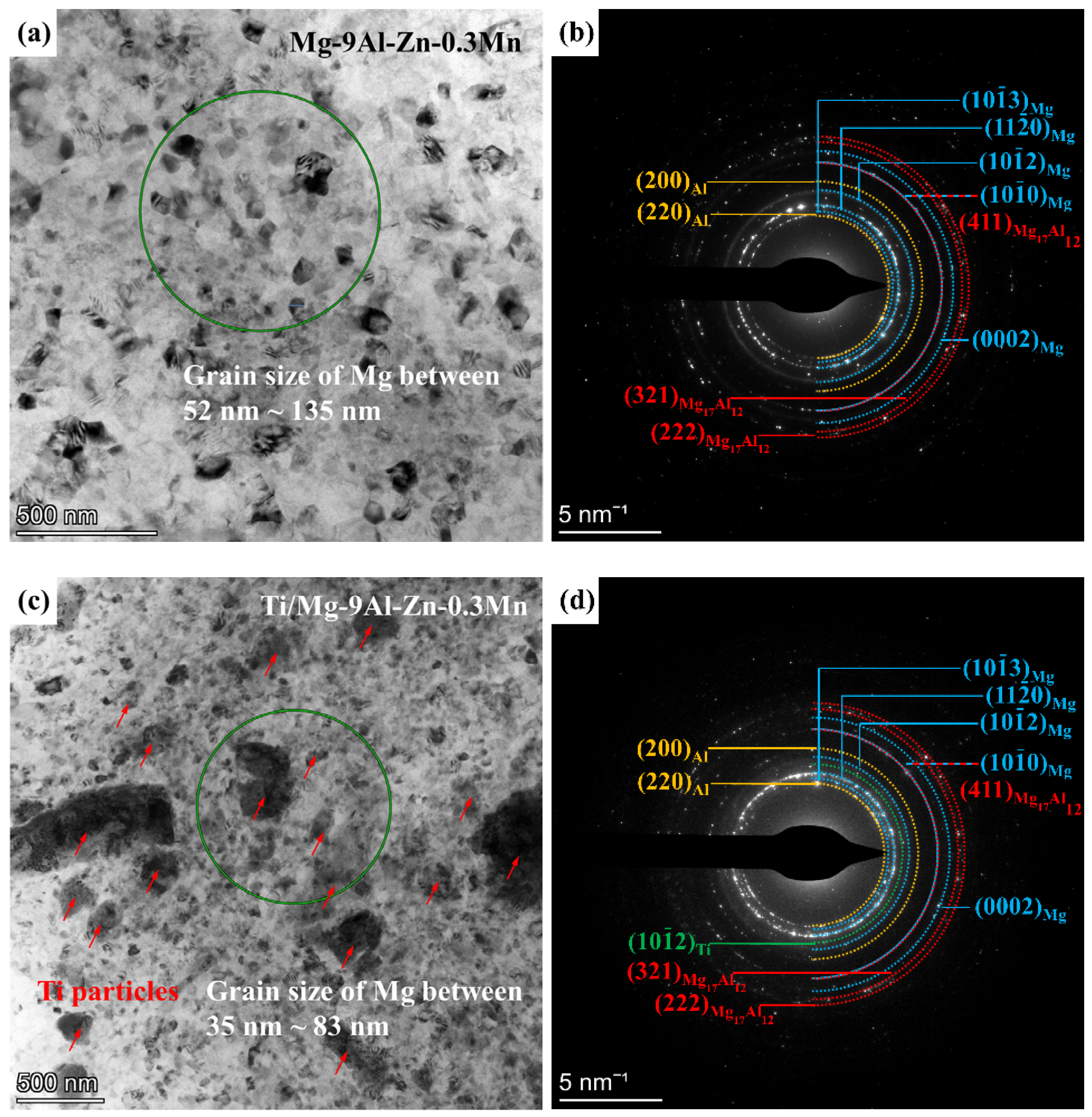

3.2. Microstructure Characterization

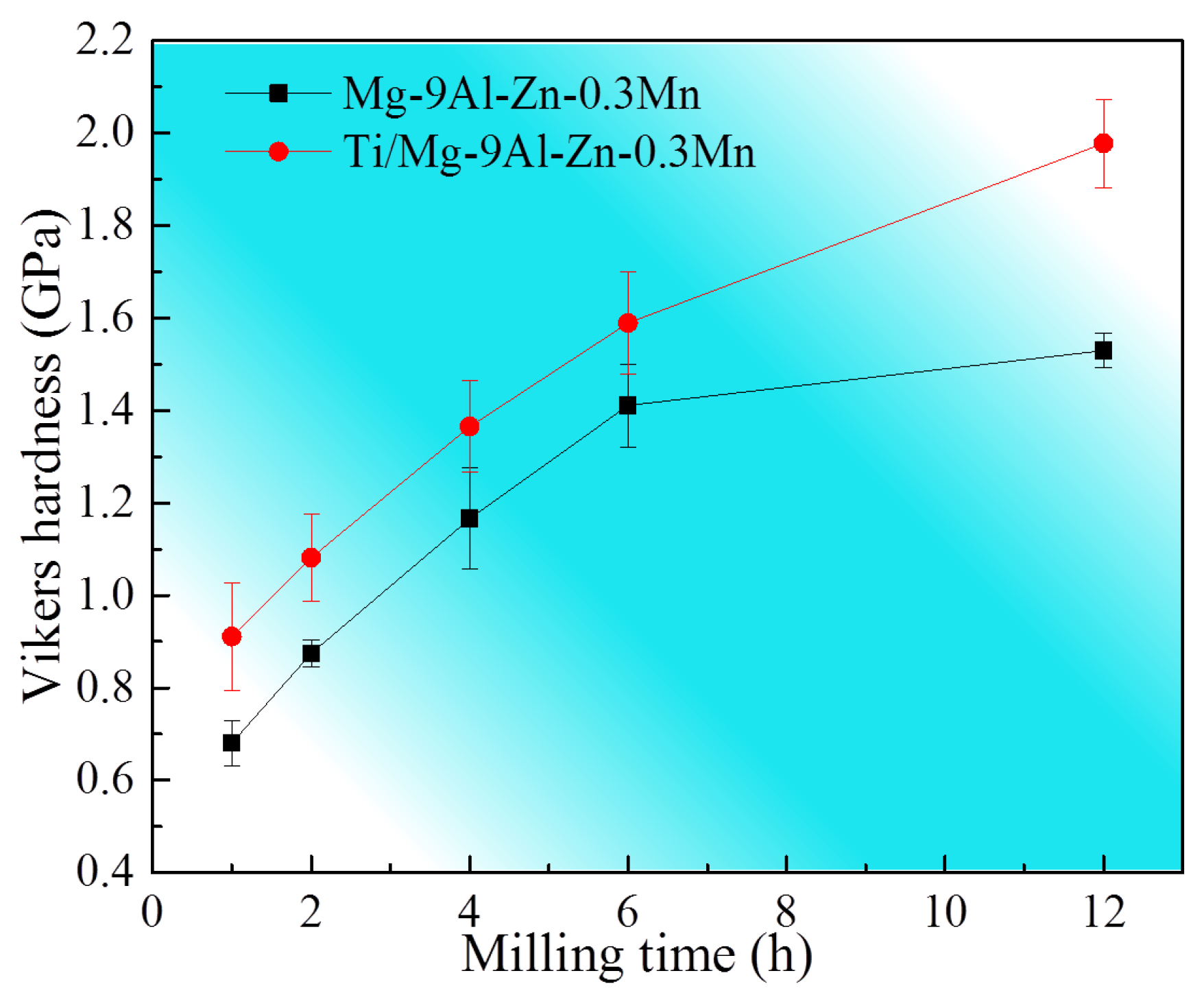

3.3. Mechanical Properties

4. Discussion

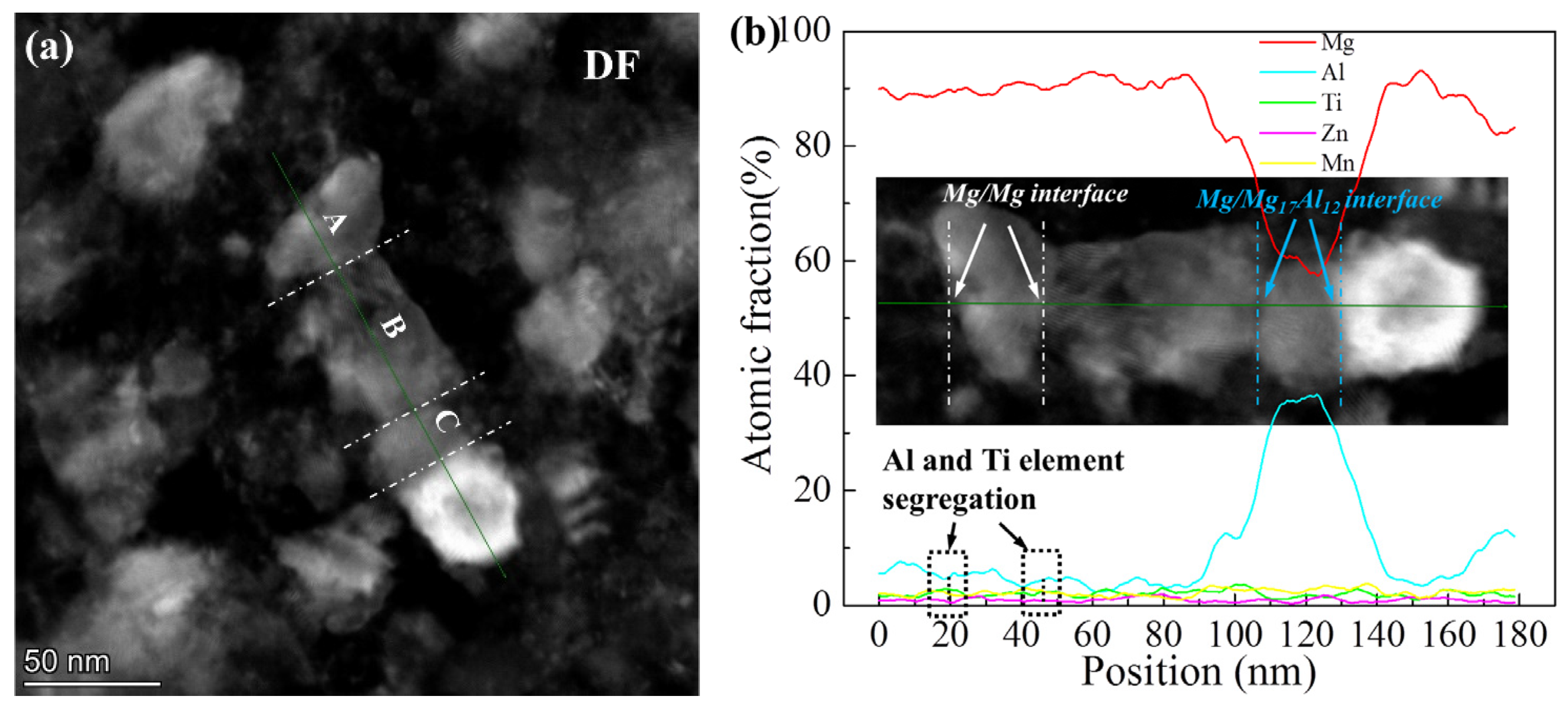

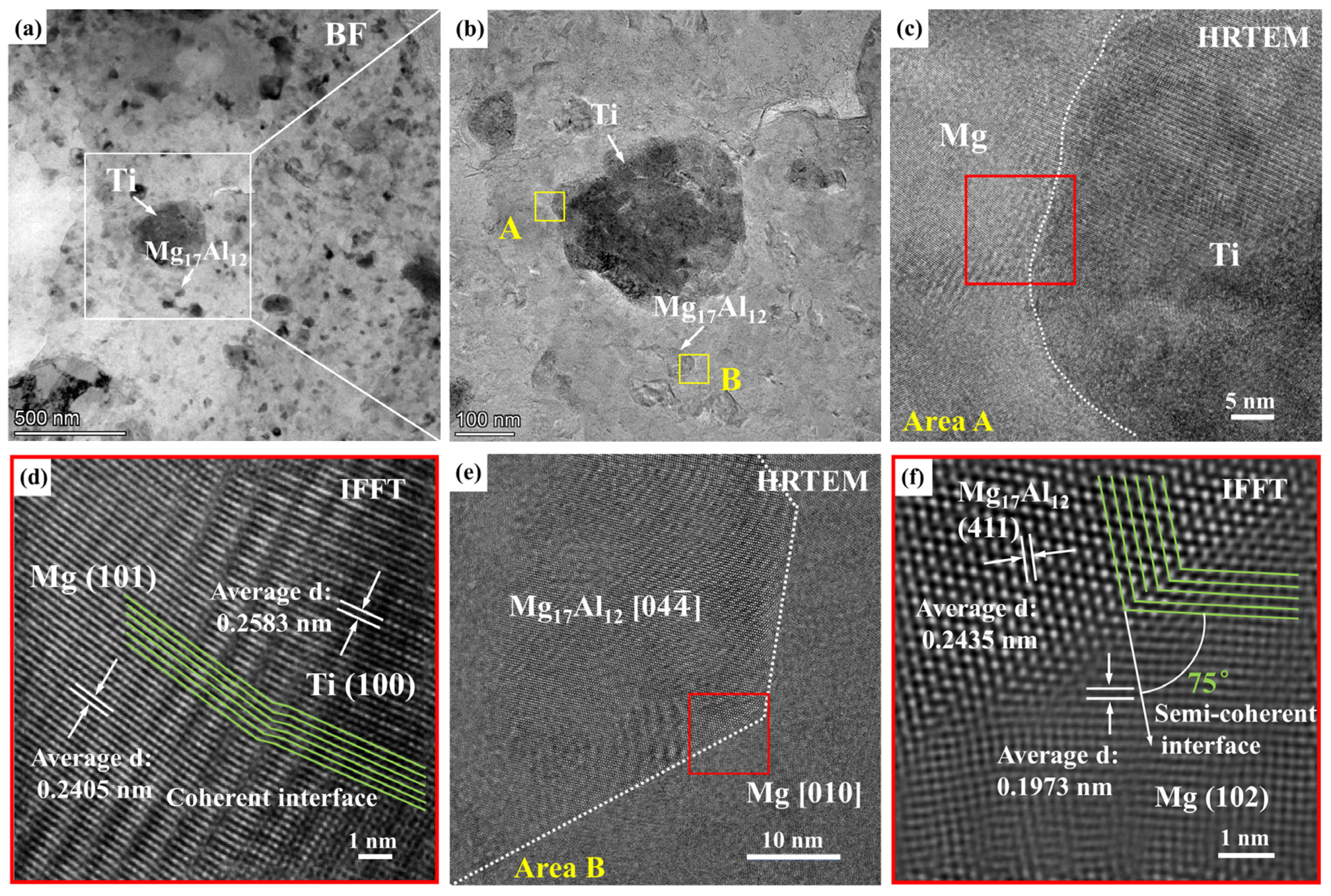

4.1. Interfacial Bonding Analysis

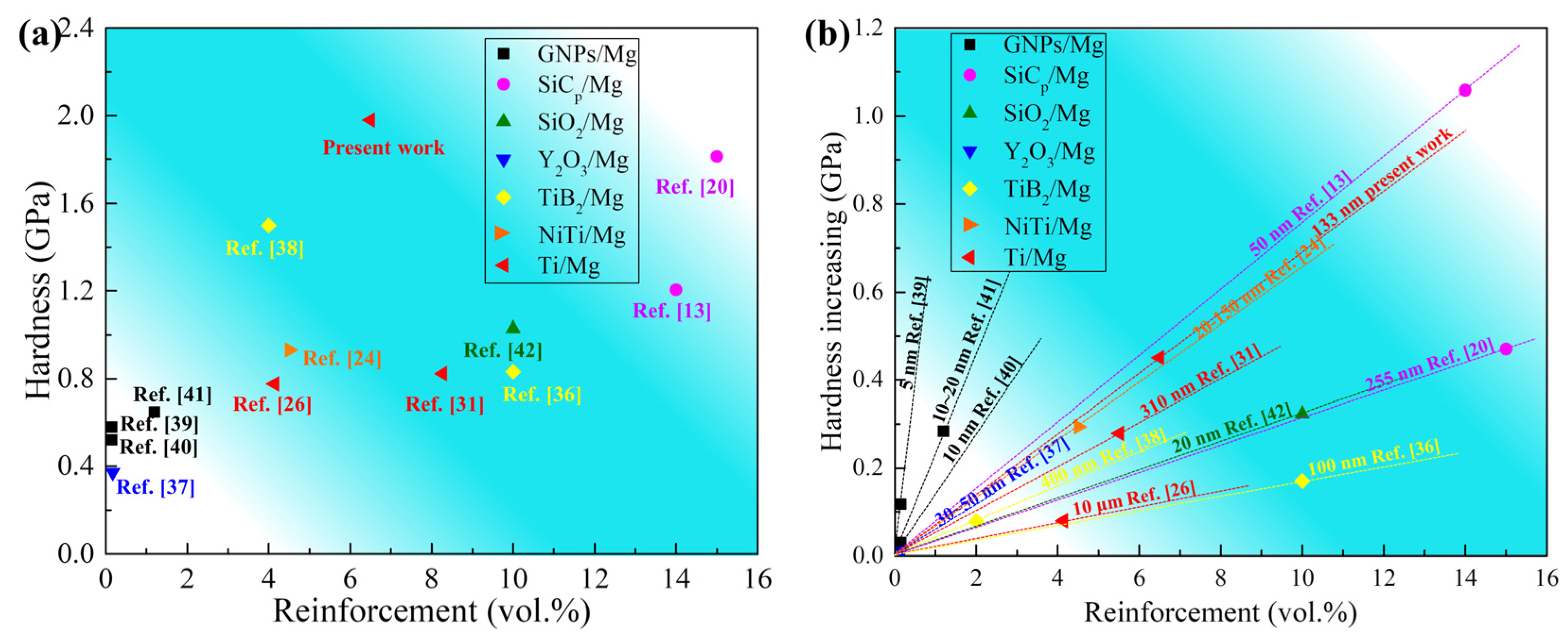

4.2. Strengthening Efficiency Analysis

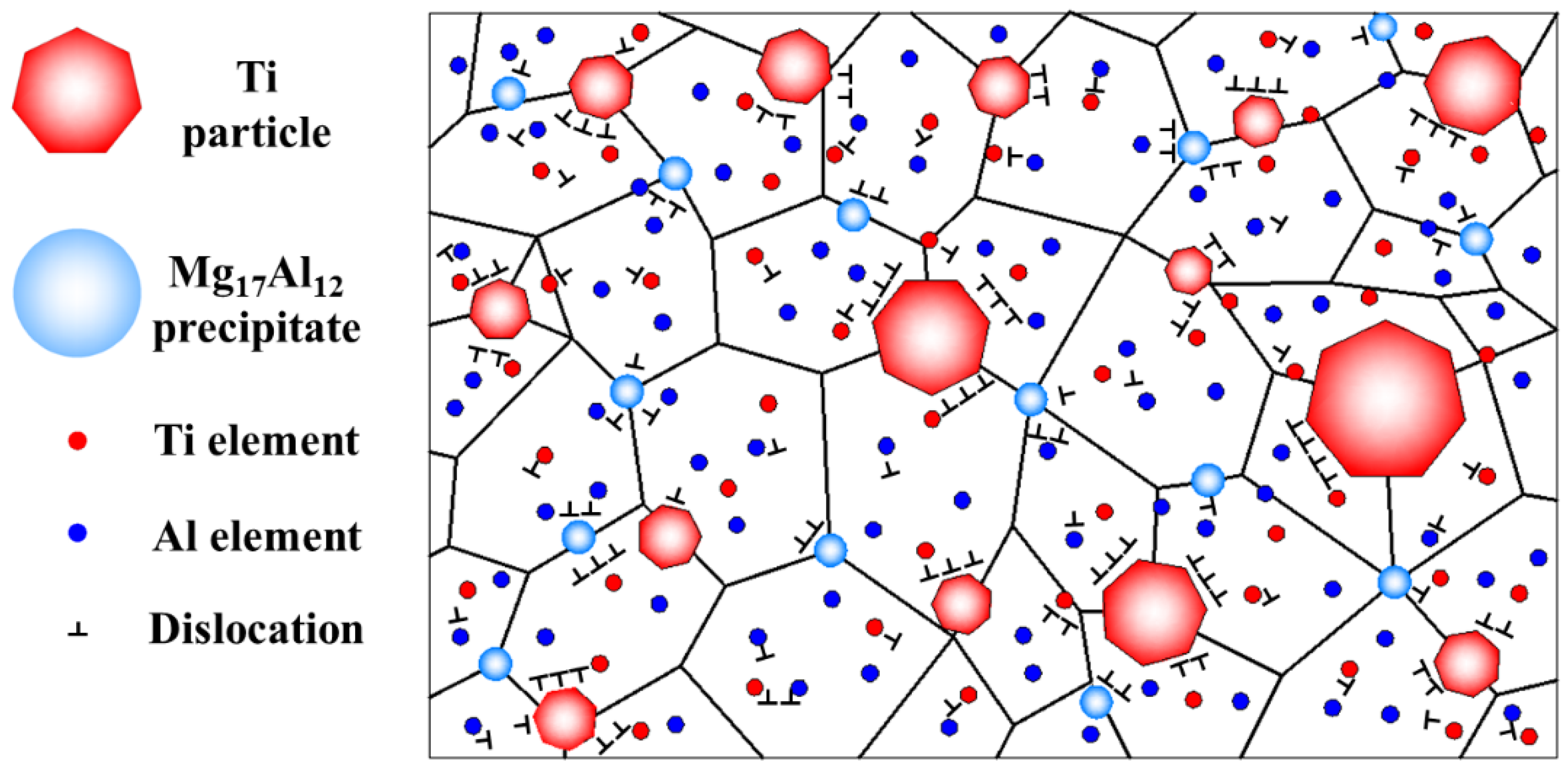

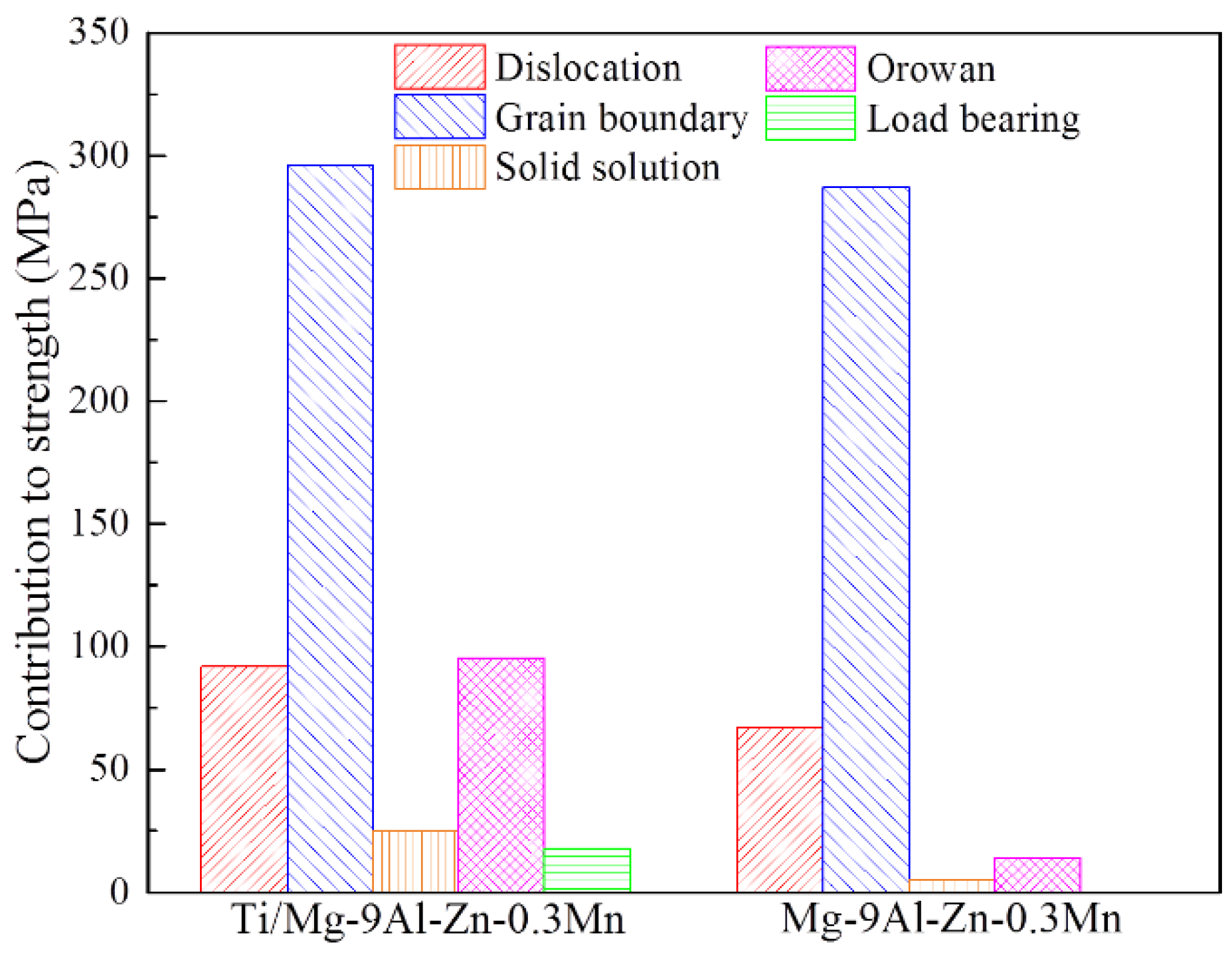

4.3. Strengthening Mechanisms

5. Conclusions

- (1)

- The NC Ti/Mg-9Al-Zn-0.3Mn composite was obtained. Submicron Ti particles and nano-scale Mg17Al12 precipitates were dispersed in the Mg matrix. A total of 68% of Ti particles were refined to nano-scale. The average grain size of the Mg matrix was ~72 nm. A Ti supersaturated Mg solid solution formed, and the solid solubility was 2.2 at.%.

- (2)

- The ultra-high hardness of MMCS was achieved. The hardness of the milled Mg-9Al-Zn-0.3Mn alloy and Ti/Mg-9Al-Zn-0.3Mn composite was 1.53 GPa and 1.98 GPa, respectively, 168% and 247% higher than the initial alloy. The tiny Ti particle was of excellent strengthening efficiency. The additional improvement of the composite was attributed to higher dislocation density, finer Mg grain and more nano-scale precipitates caused by submicron Ti dispersions.

- (3)

- A strong interfacial bonding was formed between the Mg matrix and second phase. A coherent interface of Ti/Mg was confirmed and the orientation relationship of the (101)Mg plane and (100)Ti plane inclined at 12°. A coherent interface between nano-scale Mg17Al12 and the Mg matrix was observed and the orientation relationship [044]Mg17Al12//[010]Mg was certified.

- (4)

- The strengthening mechanisms were systematically analyzed. Strengthening mechanisms were attributed to GBs strengthening, Orowan strengthening, dislocation strengthening, solid solution strengthening and load-bearing strengthening, accounting for 56.3%, 18.2%, 17.4%, 4.7% and 3.5%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hagihara, K.; Ueyama, R.; Yamasaki, M.; Kawamura, Y.; Nakano, T. Surprising increase in yield stress of Mg single crystal using long-period stacking ordered nanoplates. Acta Mater. 2021, 209, 116797. [Google Scholar] [CrossRef]

- Liu, F.; Xin, R.; Zhang, M.; Pérez-Prado, M.T.; Liu, Q. Evaluating the orientation relationship of prismatic precipitates generated by detwinning in Mg alloys. Acta Mater. 2020, 195, 263–273. [Google Scholar] [CrossRef]

- Ghosh, S.; Ganguly, S.; Maruthi, A.; Jana, S.; Remanan, S.; Das, P.; Das, T.K.; Ghosh, S.K.; Das, N.C. Micro-computed tomography enhanced cross-linked carboxylated acrylonitrile butadiene rubber with the decoration of new generation conductive carbon black for high strain tolerant electromagnetic wave absorber, Mater. Today Commun. 2020, 24, 100989. [Google Scholar] [CrossRef]

- Ghosh, S.; Das, P.; Ganguly, S.; Remanan, S.; Das, T.K.; Bhattacharyya, S.K.; Baral, J.; Das, A.K.; Laha, T.; Das, N.C. 3D-Enhanced, High-Performing, Super-hydrophobic and Electromagnetic-Interference Shielding Fabrics Based on Silver Paint and Their Use in Antibacterial Applications. Chem. Sel. 2019, 4, 11748–11754. [Google Scholar] [CrossRef]

- Sabat, R.K.; Brahme, A.P.; Mishra, R.K.; Inal, K.; Suwas, S. Ductility enhancement in Mg-0.2%Ce alloys. Acta Mater. 2018, 161, 246–257. [Google Scholar] [CrossRef]

- Wan, Y.; Tang, B.; Gao, Y.; Tang, L.; Sha, G.; Zhang, B.; Liang, N.; Liu, C.; Jiang, S.; Chen, Z.; et al. Bulk nanocrystalline high-strength magnesium alloys prepared via rotary swaging. Acta Mater. 2020, 200, 274–286. [Google Scholar] [CrossRef]

- Solomon, E.L.S.; Natarajan, A.R.; Roy, A.M.; Sundararaghavan, V.; van der Ven, A.; Marquis, E.A. Stability and strain-driven evolution of β′ precipitate in Mg-Y alloys. Acta Mater. 2019, 166, 148–157. [Google Scholar] [CrossRef]

- Sun, W.; He, Y.; Qiao, X.; Zhao, X.; Chen, H.; Gao, N.; Starink, M.J.; Zheng, M. Exceptional thermal stability and enhanced hardness in a nanostructured Mg-Gd-Y-Zn-Zr alloy processed by high pressure torsion. J. Magnes. Alloys 2022. [Google Scholar] [CrossRef]

- Zhou, H.; Lu, Y.; Deng, N.; Lu, Z.; Wang, G.; Gao, K.; Zhang, H.; Wang, X. Microstructure and mechanical properties of fine-grained TiB2/AZ31 composites prepared via powder metallurgy. J. Mater. Res. 2022, 37, 1520–1533. [Google Scholar] [CrossRef]

- Zhu, Z.H.; Nie, K.B.; Deng, K.K.; Han, J.G. Fabrication of biodegradable magnesium matrix composite with ultrafine grains and high strength by adding TiC nanoparticles to Mg-1.12Ca-0.84Zn-0.23Mn (at.%) alloy. Mater. Sci. Eng. C 2020, 107, 110360. [Google Scholar] [CrossRef]

- Saikrishna, N.; Reddy, G.P.K.; Munirathinam, B.; Dumpala, R.; Jagannatham, M.; Sunil, B.R. An investigation on the hardness and corrosion behavior of MWCNT/Mg composites and grain refined Mg. J. Magnes. Alloys 2018, 6, 83–89. [Google Scholar] [CrossRef]

- Penther, D.; Ghasemi, A.; Riedel, R.; Fleck, C.; Kamrani, S. Effect of SiC nanoparticles on manufacturing process, microstructure and hardness of Mg-SiC nanocomposites produced by mechanical milling and hot extrusion. Mater. Sci. Eng. A 2018, 738, 264–272. [Google Scholar] [CrossRef]

- Chen, L.; Xu, J.; Choi, H.; Pozuelo, M.; Ma, X.; Bhowmick, S.; Yang, J.; Mathaudhu, S.; Li, X. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature 2015, 528, 539–543. [Google Scholar] [CrossRef] [PubMed]

- Pan, H.; Qin, G.; Huang, Y.; Ren, Y.; Sha, X.; Han, X.; Liu, Z.; Li, C.; Wu, X.; Chen, H.; et al. Development of low-alloyed and rare-earth-free magnesium alloys having ultra-high strength. Acta Mater. 2018, 149, 350–363. [Google Scholar] [CrossRef]

- Sun, W.T.; Qiao, X.G.; Zheng, M.Y.; Zhao, X.J.; Chen, H.W.; Gao, N.; Starink, M.J. Achieving ultra-high hardness of nanostructured Mg-8.2Gd-3.2Y-1.0Zn-0.4Zr alloy produced by a combination of high pressure torsion and ageing treatment. Scr. Mater. 2018, 155, 21–25. [Google Scholar] [CrossRef]

- Liu, X.; Xu, R. Achieving ultra-high hardness of Mg-Sm-Ca alloy with the unique nanostructure. Mater. Sci. Eng. A 2021, 825, 141929. [Google Scholar] [CrossRef]

- Su, Q.; Wang, R.; Li, T.; Han, Y.; Hu, L.; Zhou, J.; Zhao, G.; Wang, X.; Yu, H. Effect of Ti addition on the thermal stability of nanocrystalline AZ61 Mg alloy. J. Alloys Compd. 2022, 905, 164266. [Google Scholar] [CrossRef]

- Cao, P.; Lu, L.; Lai, M.O. Grain growth and kinetics for nanocrystalline magnesium alloy produced by mechanical alloying. Mater. Res. Bull. 2001, 36, 981–988. [Google Scholar] [CrossRef]

- Yu, H.; Sun, Y.; Wan, Z.; Zhou, H.; Hu, L. Nanocrystalline Ti/AZ61 magnesium matrix composite: Evolution of microstructure and mechanical property during annealing treatment. J. Alloys Compd. 2018, 741, 231–239. [Google Scholar] [CrossRef]

- Su, S.; Zhou, J.; Tang, S.; Yu, H.; Su, Q.; Zhang, S. Synthesis of Nanocrystalline AZ91 Magnesium Alloy Dispersed with 15 vol.% Submicron SiC Particles by Mechanical Milling. Materials 2019, 12, 901. [Google Scholar] [CrossRef]

- Rahmany-Gorji, R.; Alizadeh, A.; Jafari, H. Microstructure and mechanical properties of stir cast ZX51/Al2O3p magnesium matrix composites. Mater. Sci. Eng. A 2016, 674, 413–418. [Google Scholar] [CrossRef]

- Shen, M.J.; Wang, X.J.; Zhang, M.F.; Hu, X.S.; Zheng, M.Y.; Wu, K. Fabrication of bimodal size SiCp reinforced AZ31B magnesium matrix composites. Mater. Sci. Eng. A 2014, 601, 58–64. [Google Scholar] [CrossRef]

- Cai, X.; Ding, S.; Li, Z.; Zhang, X.; Wen, K.; Xu, L.; Zhang, Y.; Shen, T. Mg-Ti composites fabricated by a novel one-step high-pressure sintering: The correlation between microstructures and mechanical properties. Compos. Part B-Eng. 2021, 215, 108743. [Google Scholar] [CrossRef]

- Razzaghi, M.; Kasiri-Asgarani, M.; Bakhsheshi-Rad, H.R.; Ghayour, H. Microstructure, mechanical properties, and in-vitro biocompatibility of nano- NiTi reinforced Mg–3Zn-0.5Ag alloy: Prepared by mechanical alloying for implant applications. Compos. Part B-Eng. 2020, 190, 107947. [Google Scholar] [CrossRef]

- Sun, S.; Deng, N.; Zhang, H.; He, L.; Zhou, H.; Han, B.; Gao, K.; Wang, X. Microstructure and mechanical properties of AZ31 magnesium alloy reinforced with novel sub-micron vanadium particles by powder metallurgy. J. Mater. Res. Technol. 2021, 15, 1789–1800. [Google Scholar] [CrossRef]

- Ye, J.; Li, J.; Luo, H.; Tan, J.; Chen, X.; Feng, B.; Zheng, K.; Pan, F. Effect of micron-Ti particles on microstructure and mechanical properties of Mg–3Al–1Zn based composites. Mater. Sci. Eng. A 2022, 833, 142526. [Google Scholar] [CrossRef]

- Dinaharan, I.; Zhang, S.; Chen, G.; Shi, Q. Titanium particulate reinforced AZ31 magnesium matrix composites with improved ductility prepared using friction stir processing. Mater. Sci. Eng. A 2020, 772, 138793. [Google Scholar] [CrossRef]

- Wu, B.; Li, J.; Ye, J.; Tan, J.; Liu, L.; Song, J.; Chen, X.; Pan, F. Work hardening behavior of Ti particle reinforced AZ91 composite prepared by spark plasma sintering. Vacuum 2021, 183, 109833. [Google Scholar] [CrossRef]

- Kondoh, K.; Kawakami, M.; Imai, H.; Umeda, J.; Fujii, H. Wettability of pure Ti by molten pure Mg droplets. Acta Mater. 2010, 58, 606–614. [Google Scholar] [CrossRef]

- Cai, X.C.; Song, J.; Yang, T.T.; Peng, Q.M.; Huang, J.Y.; Shen, T.D. A bulk nanocrystalline Mg–Ti alloy with high thermal stability and strength. Mater. Lett. 2018, 210, 121–123. [Google Scholar] [CrossRef]

- Yu, H.; Zhou, H.; Sun, Y.; Ren, L.; Wan, Z.; Hu, L. Microstructures and mechanical properties of ultrafine-grained Ti/AZ31 magnesium matrix composite prepared by powder metallurgy. Adv. Powder Technol. 2018, 29, 3241–3249. [Google Scholar] [CrossRef]

- Chen, L.; Peng, J.; Xu, J.; Choi, H.; Li, X. Achieving uniform distribution and dispersion of a high percentage of nanoparticles in metal matrix nanocomposites by solidification processing. Scr. Mater. 2013, 69, 634–637. [Google Scholar] [CrossRef]

- Yu, H.; Sun, Y.; Hu, L.; Wan, Z.; Zhou, H. The effect of Ti addition on microstructure evolution of AZ61 Mg alloy during mechanical milling. J. Alloys Compd. 2017, 704, 537–544. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, N.; Sha, G.; Ringer, S.P.; Starink, M.J. Microstructural evolution, strengthening and thermal stability of an ultrafine-grained Al–Cu–Mg alloy. Acta Mater. 2016, 109, 202–212. [Google Scholar] [CrossRef]

- Lutterotti, L.; Gialanella, S. X-ray diffraction characterization of heavily deformed metallic specimens. Acta Mater. 1998, 46, 101–110. [Google Scholar] [CrossRef]

- Xiao, P.; Gao, Y.; Yang, C.; Li, Y.; Huang, X.; Liu, Q.; Zhao, S.; Xu, F.; Gupta, M. Strengthening and toughening mechanisms of Mg matrix composites reinforced with specific spatial arrangement of in-situ TiB2 nanoparticles. Compos. Part B-Eng. 2020, 198, 108174. [Google Scholar] [CrossRef]

- Tun, K.S.; Gupta, M. Improving mechanical properties of magnesium using nano-yttria reinforcement and microwave assisted powder metallurgy method. Compos. Sci. Technol. 2007, 67, 2657–2664. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, C.; Han, B.; Qiu, J.; Qin, S.; Gao, K.; Liu, J.; Sun, S.; Zhang, H. Microstructures and Mechanical Properties of Nanocrystalline AZ31 Magnesium Alloy Powders with Submicron TiB2 Additions Prepared by Mechanical Milling. Crystals 2020, 10, 550. [Google Scholar] [CrossRef]

- Shahin, M.; Wen, C.; Munir, K.; Li, Y. Mechanical and corrosion properties of graphene nanoplatelet–reinforced Mg–Zr and Mg–Zr–Zn matrix nanocomposites for biomedical applications. J. Magnes. Alloys 2022, 10, 458–477. [Google Scholar] [CrossRef]

- Ramezanzade, S.; Ebrahimi, G.R.; Parizi, M.T.; Ezatpour, H.R. Synergetic effect of GNPs and MgOs on the mechanical properties of Mg–Sr–Ca alloy. Mater. Sci. Eng. A 2019, 761, 138025. [Google Scholar] [CrossRef]

- Chen, L.; Konishi, H.; Fehrenbacher, A.; Ma, C.; Xu, J.; Choi, H.; Xu, H.; Pfefferkorn, F.E.; Li, X. Novel nanoprocessing route for bulk graphene nanoplatelets reinforced metal matrix nanocomposites. Scr. Mater. 2012, 67, 29–32. [Google Scholar] [CrossRef]

- Lee, C.J.; Huang, J.C.; Hsieh, P.J. Mg based nano-composites fabricated by friction stir processing. Scr. Mater. 2006, 54, 1415–1420. [Google Scholar] [CrossRef]

- Zhang, P.; Li, S.X.; Zhang, Z.F. General relationship between strength and hardness. Mater. Sci. Eng. A 2011, 529, 62–73. [Google Scholar] [CrossRef]

- Sun, W.T.; Qiao, X.G.; Zheng, M.Y.; Xu, C.; Kamado, S.; Zhao, X.J.; Chen, H.W.; Gao, N.; Starink, M.J. Altered ageing behaviour of a nanostructured Mg-8.2Gd-3.8Y-1.0Zn-0.4Zr alloy processed by high pressure torsion. Acta Mater. 2018, 151, 260–270. [Google Scholar] [CrossRef]

- Starink, M.J.; Cheng, X.; Yang, S. Hardening of pure metals by high-pressure torsion: A physically based model employing volume-averaged defect evolutions. Acta Mater. 2013, 61, 183–192. [Google Scholar] [CrossRef]

- Wang, Y.; Choo, H. Influence of texture on Hall-Petch relationships in an Mg alloy. Acta Mater. 2014, 81, 83–97. [Google Scholar] [CrossRef]

- Schuh, C.A.; Nieh, T.G.; Iwasaki, H. The effect of solid solution W additions on the mechanical properties of nanocrystalline Ni. Acta Mater. 2003, 51, 431–443. [Google Scholar] [CrossRef]

- Zhou, H.; Hu, L.; Sun, H.; Chen, X. Synthesis of nanocrystalline Mg-based Mg–Ti composite powders by mechanical milling. Mater. Charact. 2015, 106, 44–51. [Google Scholar] [CrossRef]

- Goh, C.S.; Wei, J.; Lee, L.C.; Gupta, M. Properties and deformation behaviour of Mg–Y2O3 nanocomposites. Acta Mater. 2007, 55, 5115–5121. [Google Scholar] [CrossRef]

| Sample | Grain Size d (nm) | Microstrain ε (%) | Dislocation Density ρ (×1014 m−2) |

|---|---|---|---|

| Ti/Mg-9Al-Zn-0.3Mn composite | 72.0 | 0.287 | 4.3 |

| Mg-9Al-Zn-0.3Mn alloy | 91.1 | 0.196 | 2.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Han, Y.; Yu, H.; Su, Q.; Li, H.; Cheng, K.; Zhou, J.; Tang, S.; Ju, W. Exceptional Strengthening Efficiency and Hardness of Ti/Mg-9Al-Zn-0.3Mn Matrix Composite. Materials 2022, 15, 7075. https://doi.org/10.3390/ma15207075

Wang R, Han Y, Yu H, Su Q, Li H, Cheng K, Zhou J, Tang S, Ju W. Exceptional Strengthening Efficiency and Hardness of Ti/Mg-9Al-Zn-0.3Mn Matrix Composite. Materials. 2022; 15(20):7075. https://doi.org/10.3390/ma15207075

Chicago/Turabian StyleWang, Rongrong, Yejin Han, Huan Yu, Qian Su, Hang Li, Kaiming Cheng, Jixue Zhou, Shouqiu Tang, and Wei Ju. 2022. "Exceptional Strengthening Efficiency and Hardness of Ti/Mg-9Al-Zn-0.3Mn Matrix Composite" Materials 15, no. 20: 7075. https://doi.org/10.3390/ma15207075

APA StyleWang, R., Han, Y., Yu, H., Su, Q., Li, H., Cheng, K., Zhou, J., Tang, S., & Ju, W. (2022). Exceptional Strengthening Efficiency and Hardness of Ti/Mg-9Al-Zn-0.3Mn Matrix Composite. Materials, 15(20), 7075. https://doi.org/10.3390/ma15207075