Concrete Performance Attenuation of Mix Nano-SiO2 and Nano-CaCO3 under High Temperature: A Comprehensive Review

Abstract

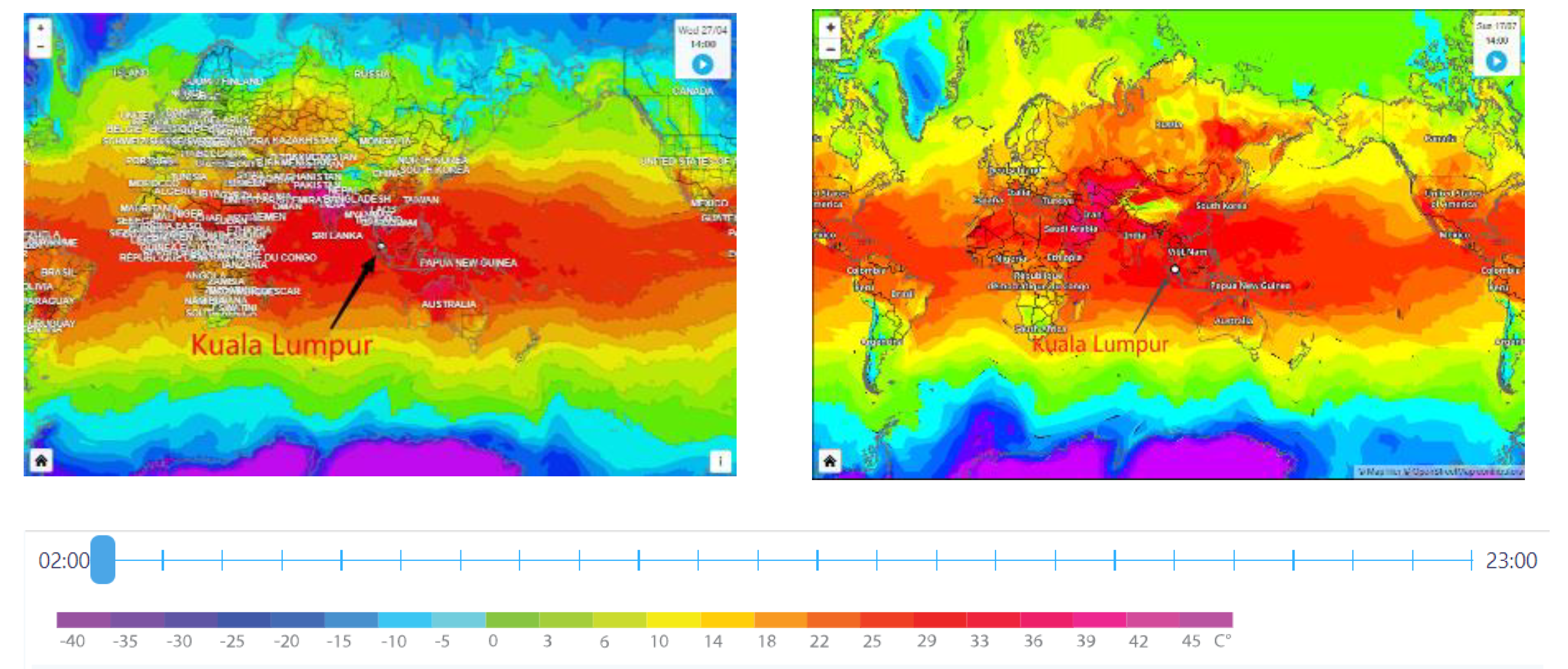

1. Introduction

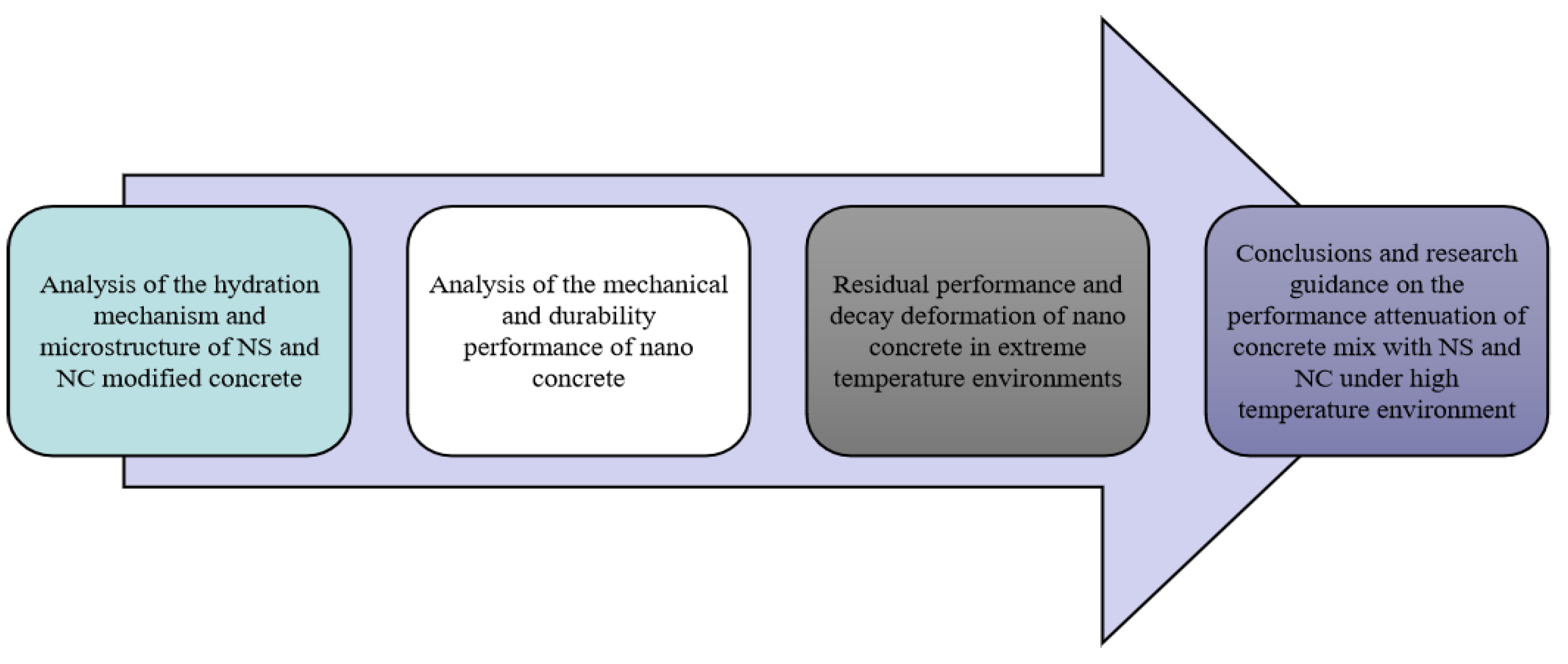

2. Research Methodology

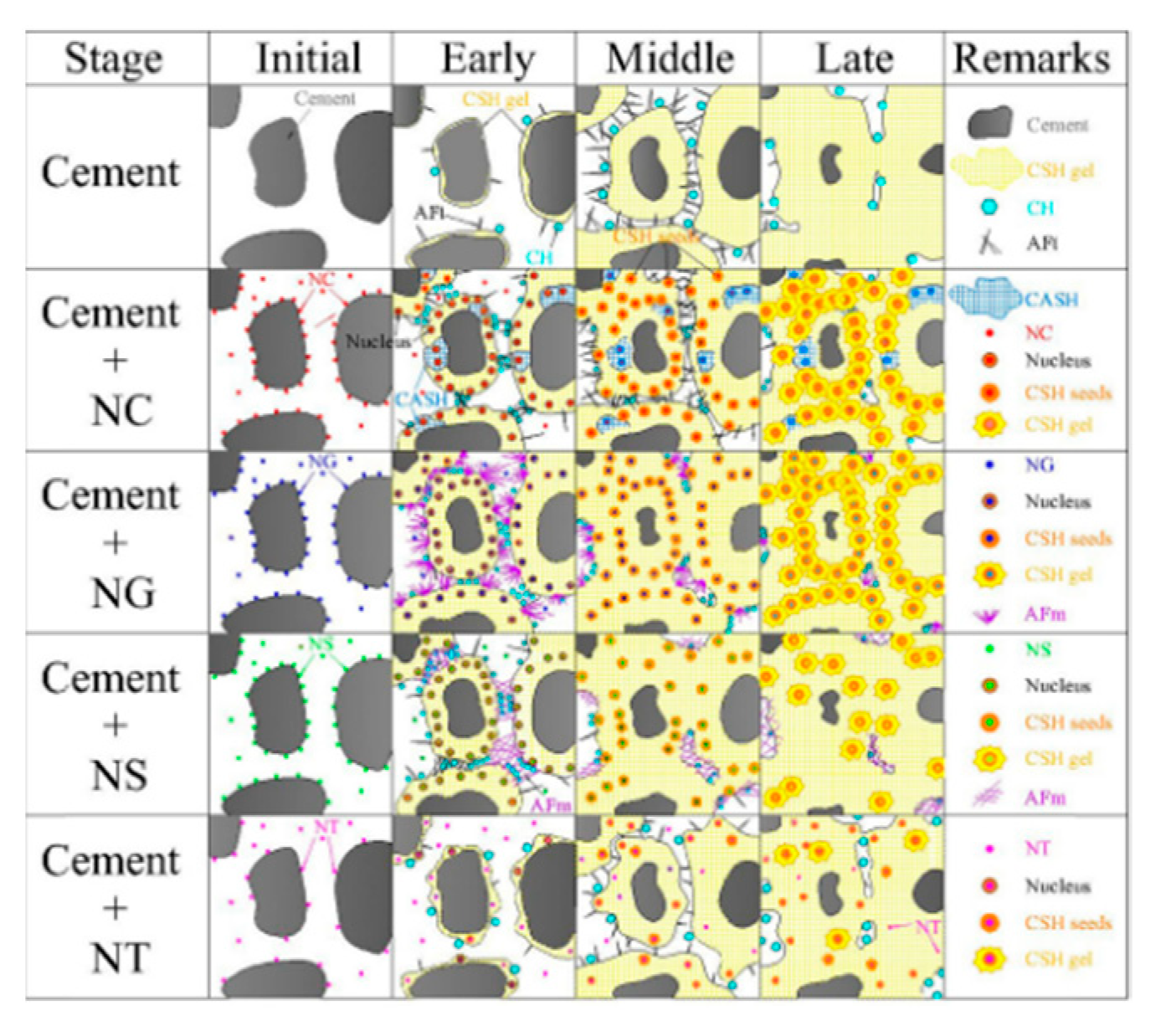

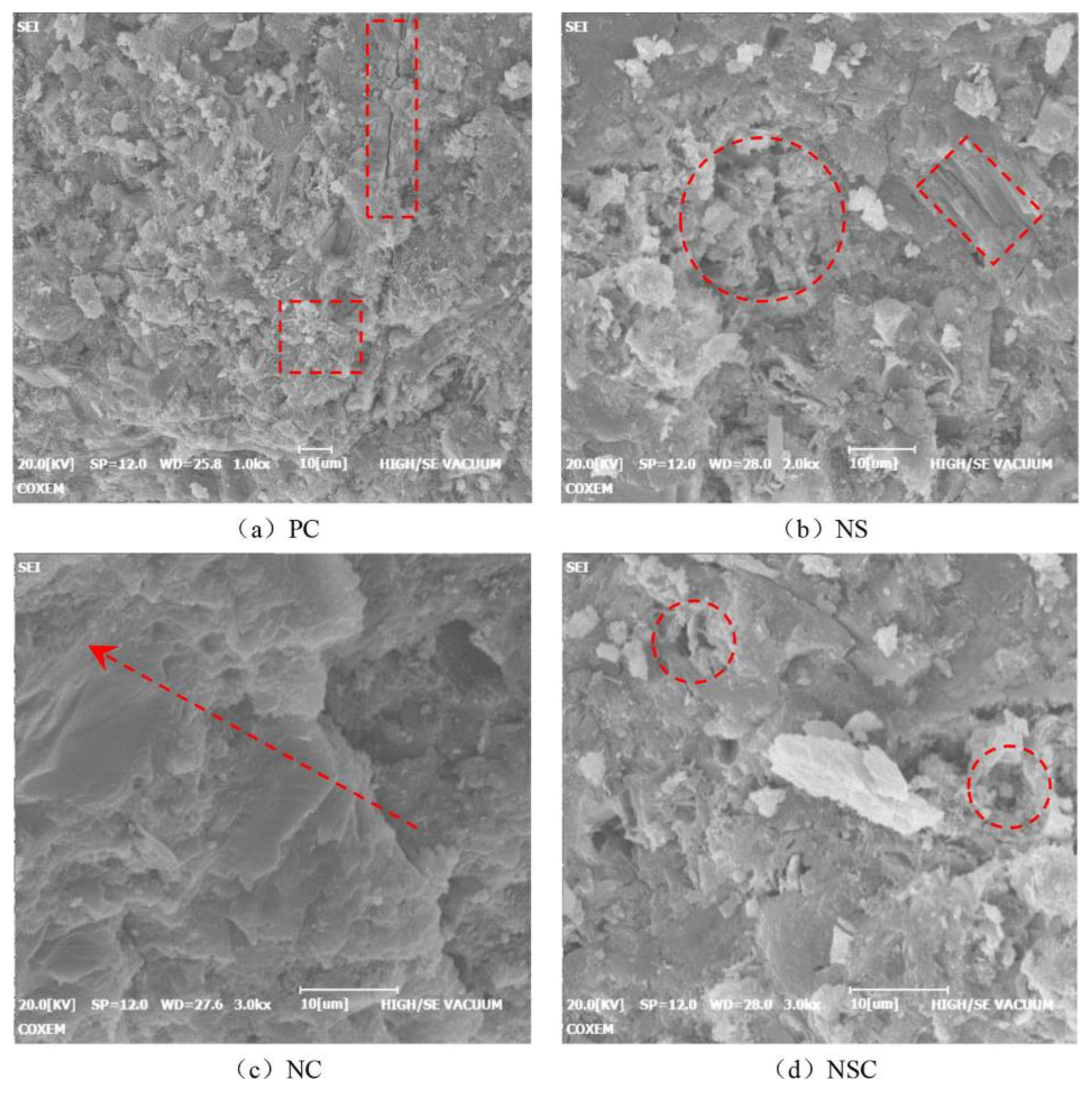

3. Nano-Modified Concrete

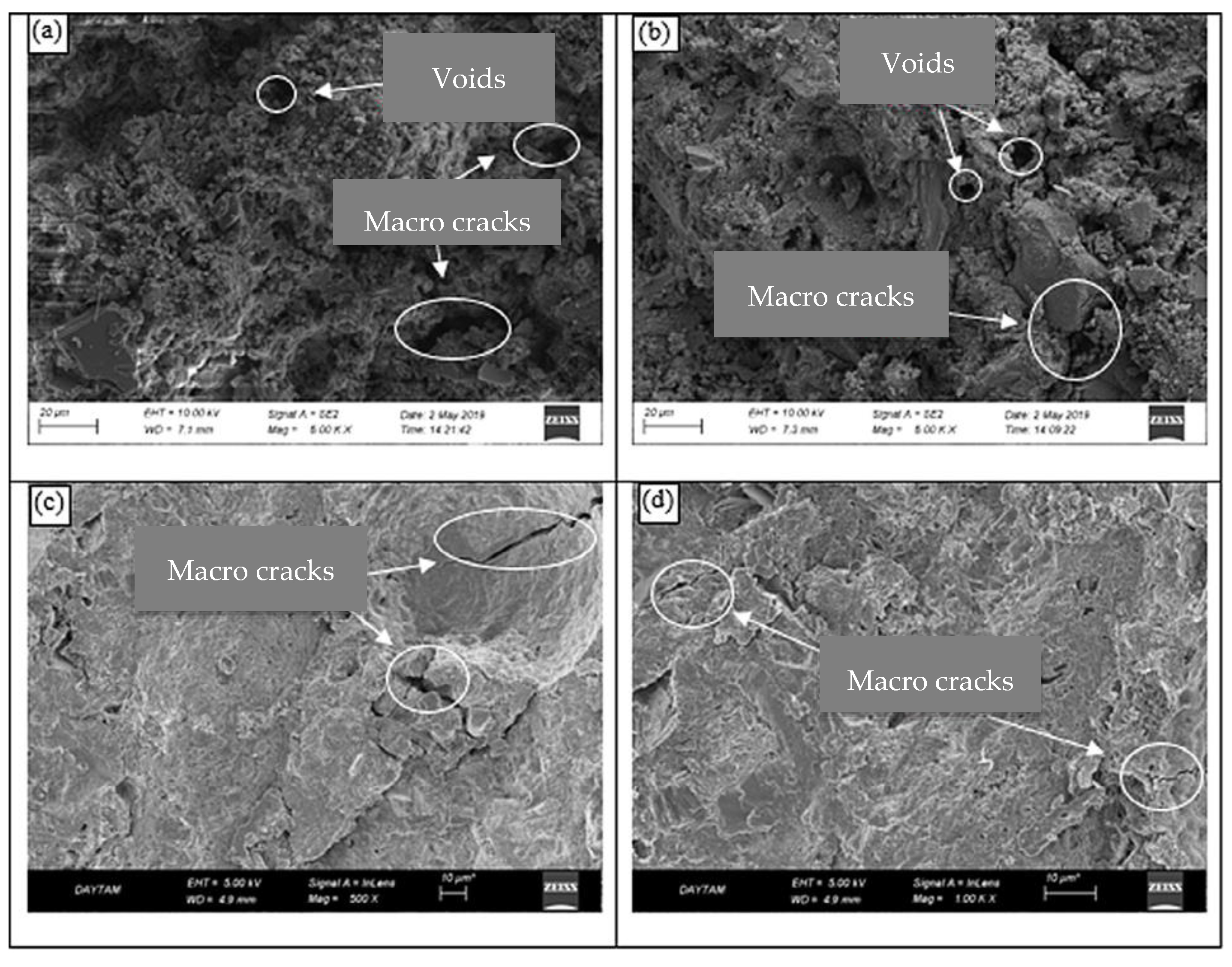

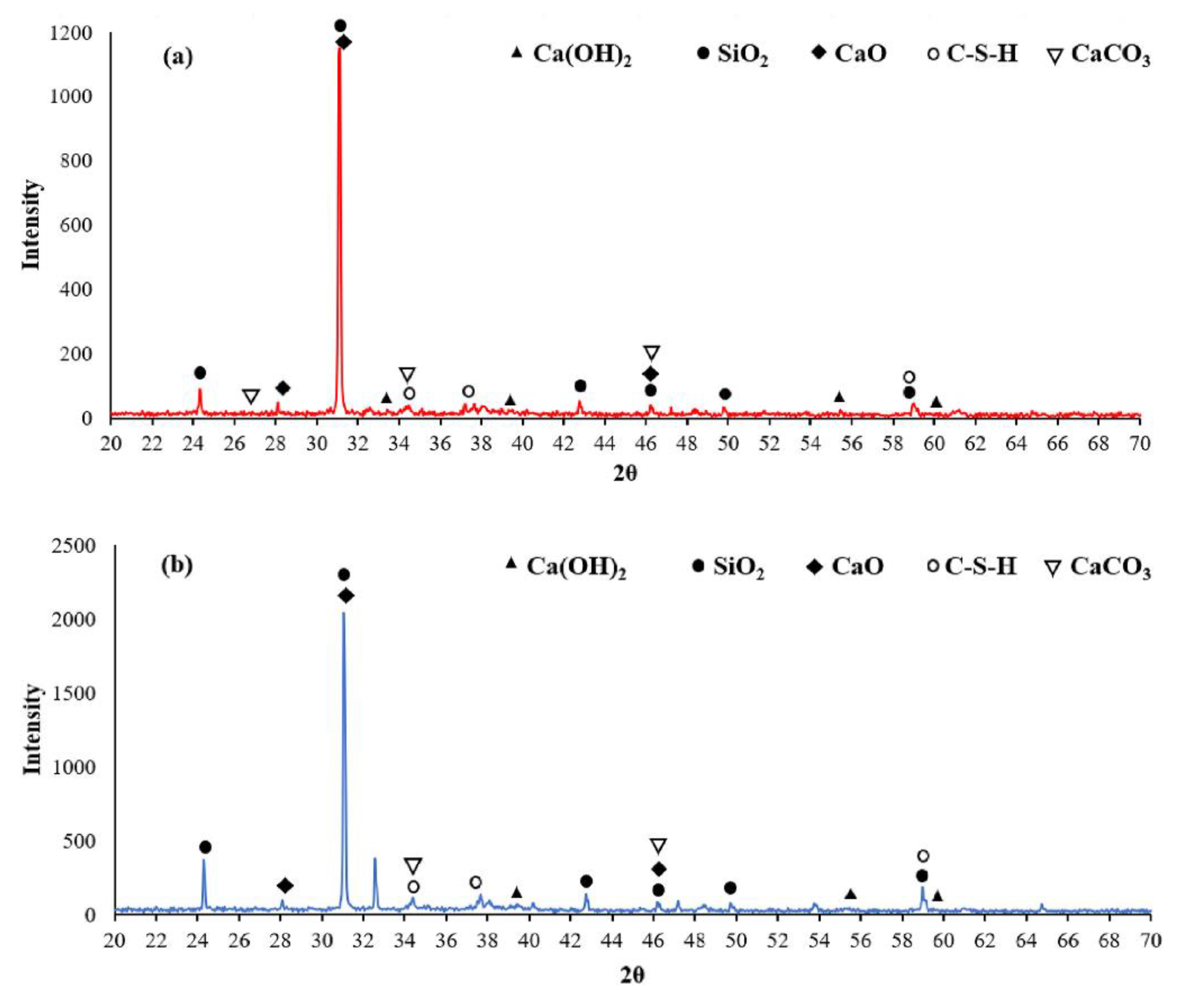

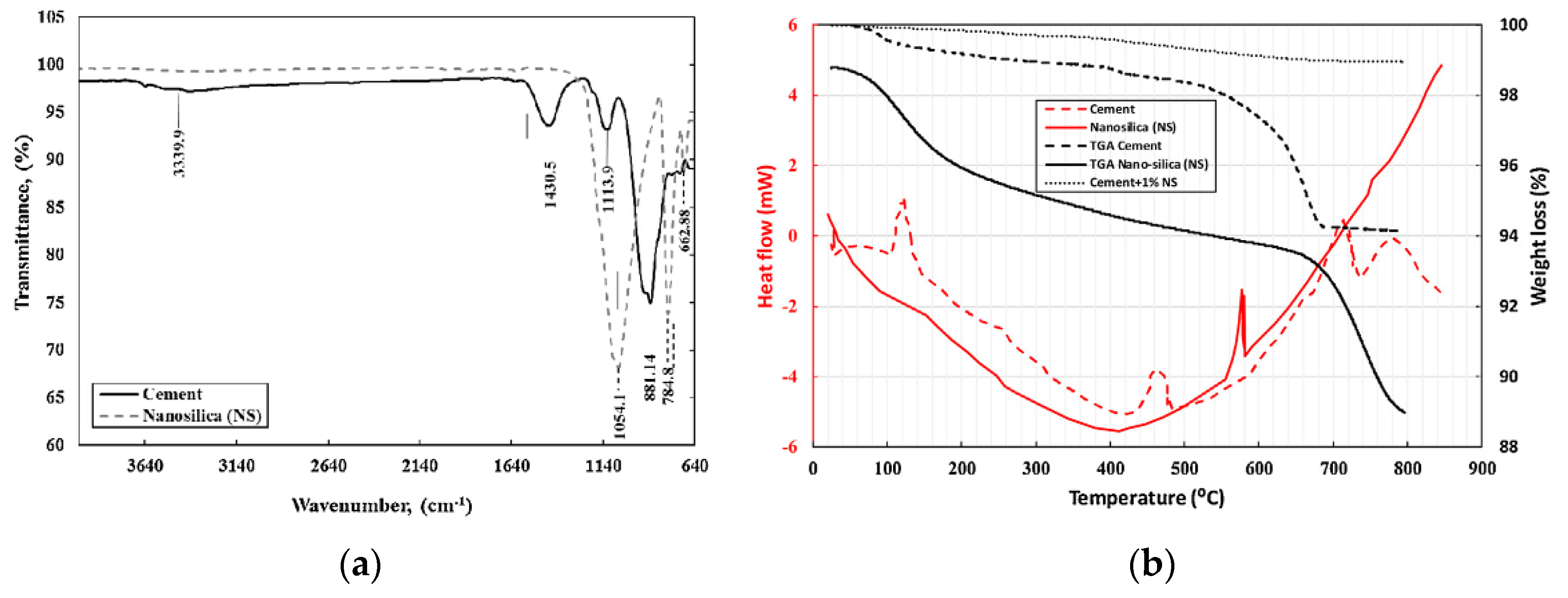

Microscopic Analysis

4. The Effect of Nano-SiO2and Nano-CaCO3on the Properties of Concrete

4.1. Rheological Properties

4.2. Mechanical Properties

4.3. Durability

5. Influence of Nano Concrete Properties under High-Temperature Environment

5.1. Residual Properties

5.2. Deformation Attenuation

6. Discussion

7. Conclusions

- Both NC and NS cause a hydration reaction within the concrete and at the same time fill the voids in the concrete, making the internal structure denser, as can be seen from the SEM, TGA and Infrared Spectroscopy Analysis.

- The mechanical properties of the concrete incorporated with the composite nanomaterial NC+NS are significantly enhanced, with a corresponding increase in mechanical properties under different high-temperature environments. The results of the review study show that concrete samples heated at different high temperatures such as 200 °C, 400 °C, 600 °C and 800 °C have higher strengths than the control concrete. The mechanical strength of the concrete does not change significantly in the 200 °C range, and the strength decreases from 200 °C to 600 °C. After high-temperature heating at 800 °C, the mechanical strength of concrete loses about 60%.

- The dense NC and NS materials reduce the water permeability, depth of carbonation and self-shrinkage of the concrete, contributing to the development of durability.

- Mixing of NC and NS materials can improve the thermal insulation of concrete structures, with NS having a more pronounced effect than NC. This facilitates the development and application of special insulation features for concrete.

- After continuous high temperatures, from 200 °C to 600 °C, the surface colour of NC and NS concrete gradually changes from grey to white, and from 600 °C to 1000 °C the colour gradually darkens to brown. The surface of the concrete starts to show obvious cracks at 600 °C and the concrete is more severely damaged at 800 °C, with the phenomenon of peeling of the skin. Concrete mixed with NC and NS has more severe appearance damage than normal concrete due to being denser and more closed, with temperatures exceeding 600 °C. In addition, the structural damage to the concrete is more severe as the time at high temperatures increases.

8. Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mostafa, S.A.; Faried, A.S.; Farghali, A.A.; El-Deeb, M.M.; Tawfik, T.A.; Majer, S.; Elrahman, M.A. Influence of Nanoparticles from Waste Materials on Mechanical Properties, Durability and Microstructure of UHPC. Materials 2020, 13, 4530. [Google Scholar] [CrossRef]

- Du, J.; Meng, W.; Khayat, K.H.; Bao, Y.; Guo, P.; Lyu, Z.; Abu-Obeidah, A.; Nassif, H.; Wang, H. New development of ultra-high-performance concrete (UHPC). Compos. Part B Eng. 2021, 224, 109220. [Google Scholar] [CrossRef]

- Abed, M.; Nemes, R.; Tayeh, B.A. Properties of self-compacting high-strength concrete containing multiple use of recycled aggregate. J. King Saud Univ.-Eng. Sci. 2020, 32, 108–114. [Google Scholar] [CrossRef]

- Wu, H.; Lin, X.; Zhou, A. A review of mechanical properties of fibre reinforced concrete at elevated temperatures. Cem. Concr. Res. 2020, 135, 106117. [Google Scholar] [CrossRef]

- Grzymski, F.; Musiał, M.; Trapko, T. Mechanical properties of fibre reinforced concrete with recycled fibres. Constr. Build. Mater. 2019, 198, 323–331. [Google Scholar] [CrossRef]

- Murcia, D.H.; Genedy, M.; Taha, M.R. Examining the significance of infill printing pattern on the anisotropy of 3D printed concrete. Constr. Build. Mater. 2020, 262, 120559. [Google Scholar] [CrossRef]

- Mo, Z.; Gao, X.; Su, A. Mechanical performances and microstructures of metakaolin contained UHPC matrix under steam curing conditions. Constr. Build. Mater. 2020, 268, 121112. [Google Scholar] [CrossRef]

- Fu, Q.; Bu, M.; Xu, W.; Chen, L.; Li, D.; He, J.; Kou, H.; Li, H. Comparative analysis of dynamic constitutive response of hybrid fibre-reinforced concrete with different matrix strengths. Int. J. Impact Eng. 2020, 148, 103763. [Google Scholar] [CrossRef]

- Das, S.; Sobuz, H.R.; Tam, V.W.; Akid, A.S.M.; Sutan, N.M.; Rahman, F.M. Effects of incorporating hybrid fibres on rheological and mechanical properties of fibre reinforced concrete. Constr. Build. Mater. 2020, 262, 120561. [Google Scholar] [CrossRef]

- Wang, X.; Yu, R.; Song, Q.; Shui, Z.; Liu, Z.; Wu, S.; Hou, D. Optimized design of ultra-high performance concrete (UHPC) with a high wet packing density. Cem. Concr. Res. 2019, 126, 105921. [Google Scholar] [CrossRef]

- Chu, S.; Kwan, A. A new bond model for reinforcing bars in steel fibre reinforced concrete. Cem. Concr. Compos. 2019, 104, 103405. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Wu, L.; Goto, K.; Najih, Y.M. Vulnerability of Structural Concrete to Extreme Climate Variances. Climate 2018, 6, 40. [Google Scholar] [CrossRef]

- Monteiro, H.; Moura, B.; Soares, N. Advancements in nano-enabled cement and concrete: Innovative properties and environmental implications. J. Build. Eng. 2022, 56, 104736. [Google Scholar] [CrossRef]

- Vishwakarma, V.; Uthaman, S. Environmental impact of sustainable green concrete. In Smart Nanoconcretes and Cement-Based Materials; Properties, Modelling and Applications Micro and Nano Technologies; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 241–255. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Ramli, M.Z. A comparative life cycle assessment (LCA) of concrete and steel-prefabricated prefinished volumetric construction structures in Malaysia. Environ. Sci. Pollut. Res. 2020, 27, 43186–43201. [Google Scholar] [CrossRef]

- Sohail, M.G.; Kahraman, R.; Ozerkan, N.G.; Alnuaimi, N.A.; Gencturk, B.; Dawood, M.; Belarbi, A. Reinforced Concrete Degradation in the Harsh Climates of the Arabian Gulf: Field Study on 30-to-50-Year-Old Structures. J. Perform. Constr. Facil. 2018, 32, 04018059. [Google Scholar] [CrossRef]

- Sohail, M.G.; Kahraman, R.; Al Nuaimi, N.; Gencturk, B.; Alnahhal, W. Durability characteristics of high and ultra-high performance concretes. J. Build. Eng. 2021, 33, 101669. [Google Scholar] [CrossRef]

- Hooton, R.D. Future directions for design, specification, testing, and construction of durable concrete structures. Cem. Concr. Res. 2019, 124, 105827. [Google Scholar] [CrossRef]

- Kardooni, R.; Yusoff, S.B.; Kari, F.B.; Moeenizadeh, L. Public opinion on renewable energy technologies and climate change in Peninsular Malaysia. Renew. Energy 2018, 116, 659–668. [Google Scholar] [CrossRef]

- Chong, C.H.; Tan, W.X.; Ting, Z.J.; Liu, P.; Ma, L.; Li, Z.; Ni, W. The driving factors of energy-related CO2 emission growth in Malaysia: The LMDI decomposition method based on energy allocation analysis. Renew. Sustain. Energy Rev. 2019, 115, 109356. [Google Scholar] [CrossRef]

- Jayaraj, V.J.; Avoi, R.; Gopalakrishnan, N.; Raja, D.B.; Umasa, Y. Developing a dengue prediction model based on climate in Tawau, Malaysia. Acta Trop. 2019, 197, 105055. [Google Scholar] [CrossRef]

- Raihan, A.; Tuspekova, A. Toward a sustainable environment: Nexus between economic growth, renewable energy use, forested area, and carbon emissions in Malaysia. Resour. Conserv. Recycl. Adv. 2022, 15, 200096. [Google Scholar] [CrossRef]

- Jindal, B.B.; Sharma, R. The effect of nanomaterials on properties of geopolymers derived from industrial by-products: A state-of-the-art review. Constr. Build. Mater. 2020, 252, 119028. [Google Scholar] [CrossRef]

- Wang, J.; Liu, M.; Wang, Y.; Zhou, Z.; Xu, D.; Du, P.; Cheng, X. Synergistic effects of nano-silica and fly ash on properties of cement-based composites. Constr. Build. Mater. 2020, 262, 120737. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Z.; Wang, J.; Zhou, Z.; Du, P.; Cheng, X. Synergistic effect of nano-silica and silica fume on hydration properties of cement-based materials. J. Therm. Anal. Calorim. 2020, 140, 2225–2235. [Google Scholar] [CrossRef]

- Liu, X.; Fang, T.; Zuo, J. Effect of Nano-Materials on Autogenous Shrinkage Properties of Cement Based Materials. Symmetry 2019, 11, 1144. [Google Scholar] [CrossRef]

- Morsy, M.; Shoukry, H.; Mokhtar, M.; Taha, N.A. Systematic investigation into mechanical strength, pore structure and microstructure of high performance concrete incorporating nano-hybrids. IOP Conf. Ser. Mater. Sci. Eng. 2020, 956, 012001. [Google Scholar] [CrossRef]

- Deboucha, W.; Sebaibi, N.; El Mendili, Y.; Fabien, A.; Alengaram, U.; Leklou, N.; Hamdadou, M.; Bourdot, A.; Gascoin, S. Reactivity Effect of Calcium Carbonate on the Formation of Carboaluminate Phases in Ground Granulated Blast Furnace Slag Blended Cements. Sustainability 2021, 13, 6504. [Google Scholar] [CrossRef]

- Zhao, Z.; Qi, T.; Zhou, W.; Hui, D.; Xiao, C.; Qi, J.; Zheng, Z. A review on the properties, reinforcing effects, and commercialization of nanomaterials for cement-based materials. Nanotechnol. Rev. 2020, 9, 303–322. [Google Scholar] [CrossRef]

- Poudyal, L.; Adhikari, K. Environmental sustainability in cement industry: An integrated approach for green and economical cement production. Resour. Environ. Sustain. 2021, 4, 100024. [Google Scholar] [CrossRef]

- Guler, S.; Türkmenoğlu, Z.F.; Ashour, A. Performance of single and hybrid nanoparticles added concrete at ambient and elevated temperatures. Constr. Build. Mater. 2020, 250, 118847. [Google Scholar] [CrossRef]

- Zhang, J.; Shen, C.; Diao, G. Application and Microstructure Properties of Nanomaterials in New Concrete Materials. J. Nanomater. 2022, 2022, 7396295. [Google Scholar] [CrossRef]

- Zhou, Y.; Zheng, S.; Huang, X.; Xi, B.; Huang, Z.; Guo, M. Performance enhancement of green high-ductility engineered cementitious composites by nano-silica incorporation. Constr. Build. Mater. 2021, 281, 122618. [Google Scholar] [CrossRef]

- Liu, R.; Xiao, H.; Liu, J.; Guo, S.; Pei, Y. Improving the microstructure of ITZ and reducing the permeability of concrete with various water/cement ratios using nano-silica. J. Mater. Sci. 2019, 54, 444–456. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, R.; Zhang, F.; Liu, M.; Li, H. Role of nano-SiO2 in improving the microstructure and impermeability of concrete with different aggregate gradations. Constr. Build. Mater. 2018, 188, 537–545. [Google Scholar] [CrossRef]

- Chu, S.; Li, L.; Kwan, A. Development of extrudable high strength fiber reinforced concrete incorporating nano calcium carbonate. Addit. Manuf. 2021, 37, 101617. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Thomas, B.S.; Hawileh, R.A.; Yang, J.; Jindal, B.B.; Ariyachandra, E. Influence of nano-TiO2, nano-Fe2O3, nanoclay and nano-CaCO3 on the properties of cement/geopolymer concrete. Clean. Mater. 2022, 4, 2772–3926. [Google Scholar] [CrossRef]

- Yonggui, W.; Shuaipeng, L.; Hughes, P.; Yuhui, F. Mechanical properties and microstructure of basalt fibre and nano-silica reinforced recycled concrete after exposure to elevated temperatures. Constr. Build. Mater. 2020, 247, 118561. [Google Scholar] [CrossRef]

- Long, G.; Li, Y.; Ma, C.; Xie, Y.; Shi, Y. Hydration kinetics of cement incorporating different nanoparticles at elevated temperatures. Thermochim. Acta 2018, 664, 108–117. [Google Scholar] [CrossRef]

- Saleh, A.N.; Attar, A.A.; Ahmed, O.K.; Mustafa, S.S. Improving the thermal insulation and mechanical properties of concrete using Nano-SiO2. Results Eng. 2021, 12, 100303. [Google Scholar] [CrossRef]

- Yuan, Y.; Li, S. Multiobjective Optimization Design of Green Building Energy Consumption Based on Inorganic Thermal Insulation Nanomaterials. Int. J. Anal. Chem. 2022, 6993034. [Google Scholar] [CrossRef]

- Avudaiappan, S.; Prakatanoju, S.; Amran, M.; Aepuru, R.; Saavedra Flores, E.I.; Das, R.; Gupta, R.; Fediuk, R.; Vatin, N. Experimental Investigation and Image Processing to Predict the Properties of Concrete with the Addition of Nano Silica and Rice Husk Ash. Crystals 2021, 11, 1230. [Google Scholar] [CrossRef]

- Meng, T.; Ying, K.; Yang, X.; Hong, Y. Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials. Nanotechnol. Rev. 2021, 10, 370–384. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, P.; Guo, W.; Bao, J.; Qu, C. Effect of Nano-CaCO3 on the Mechanical Properties and Durability of Concrete Incorporating Fly Ash. Adv. Mater. Sci. Eng. 2020, 2020, 7365862. [Google Scholar] [CrossRef]

- Yang, H.; Che, Y.; Leng, F. High volume fly ash mortar containing nano-calcium carbonate as a sustainable cementitious material: Microstructure and strength development. Sci. Rep. 2018, 8, 16439. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Xuan, D.; Sojobi, A.O.; Liu, S.; Chu, S.; Poon, C.S. Development of nano-silica treatment methods to enhance recycled aggregate concrete. Cem. Concr. Compos. 2021, 118, 103963. [Google Scholar] [CrossRef]

- Madhusudanan, S.; Amirtham, L.R.; Nallusamy, S. Symbiotic Outcomes of Potency and Microstructure on Nano Composite with Microsilica and Nanosilica Additives. J. Nano Res. 2019, 57, 105–116. [Google Scholar] [CrossRef]

- Thanmanaselvi, M.; Ramasamy, V. A study on durability characteristics of nano-concrete. Mater. Today Proc. 2021, 349, 2214–7853. [Google Scholar] [CrossRef]

- Wang, Z.-H.; Bai, E.-L.; Xu, J.-Y.; Du, Y.-H.; Zhu, J.-S. Effect of nano-SiO2 and nano-CaCO3 on the static and dynamic properties of concrete. Sci. Rep. 2022, 12, 907. [Google Scholar] [CrossRef] [PubMed]

- Bautista-Gutierrez, K.P.; Herrera-May, A.L.; Santamaría-López, J.M.; Honorato-Moreno, A.; Zamora-Castro, S.A. Recent Progress in Nanomaterials for Modern Concrete Infrastructure: Advantages and Challenges. Materials 2019, 12, 3548. [Google Scholar] [CrossRef]

- Gao, C.; Huang, L.; Yan, L.; Jin, R.; Chen, H. Mechanical properties of recycled aggregate concrete modified by nano-particles. Constr. Build. Mater. 2020, 241, 118030. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Łukowski, P.; Seul, C. Influence of Dispersing Method on the Quality of Nano-Admixtures Homogenization in Cement Matrix. Materials 2020, 13, 4865. [Google Scholar] [CrossRef] [PubMed]

- Faried, A.S.; Mostafa, S.A.; Tayeh, B.A.; Tawfik, T.A. Mechanical and durability properties of ultra-high performance concrete incorporated with various nano waste materials under different curing conditions. J. Build. Eng. 2021, 43, 102569. [Google Scholar] [CrossRef]

- Saleh, H.M.; El-Saied, F.A.; Salaheldin, T.A.; Hezo, A.A. Macro- and nanomaterials for improvement of mechanical and physical properties of cement kiln dust-based composite materials. J. Clean. Prod. 2018, 204, 532–541. [Google Scholar] [CrossRef]

- Li, W.; Wang, X.-C.; Xiong, L.; Huang, Z. Experimental Study on the Dry Shrinkage Properties of Nano Concrete Materials. J. Phys. Conf. Ser. 2020, 1605, 012157. [Google Scholar] [CrossRef]

- Rezania, M.; Panahandeh, M.; Razavi, S.; Berto, F. Experimental study of the simultaneous effect of nano-silica and nano-carbon black on permeability and mechanical properties of the concrete. Theor. Appl. Fract. Mech. 2019, 104, 102391. [Google Scholar] [CrossRef]

- Zhang, P.; Sha, D.; Li, Q.; Zhao, S.; Ling, Y. Effect of Nano Silica Particles on Impact Resistance and Durability of Concrete Containing Coal Fly Ash. Nanomaterials 2021, 11, 1296. [Google Scholar] [CrossRef]

- Behzadian, R.; Shahrajabian, H. Experimental Study of the Effect of Nano-silica on the Mechanical Properties of Concrete/PET Composites. KSCE J. Civ. Eng. 2019, 23, 3660–3668. [Google Scholar] [CrossRef]

- Yunchao, T.; Zheng, C.; Wanhui, F.; Yumei, N.; Cong, L.; Jieming, C. Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete. Nanotechnol. Rev. 2021, 10, 819–838. [Google Scholar] [CrossRef]

- Keshavarzian, F.; Saberian, M.; Li, J. Investigation on mechanical properties of steel fiber reinforced reactive powder concrete containing nano-SiO2: An experimental and analytical study. J. Build. Eng. 2021, 44, 102601. [Google Scholar] [CrossRef]

- Mohammed, A.; Rafiq, S.; Mahmood, W.; Noaman, R.; Al-Darkazali, H.; Ghafor, K.; Qadir, W. Microstructure characterizations, thermal properties, yield stress, plastic viscosity and compression strength of cement paste modified with nanosilica. J. Mater. Res. Technol. 2020, 9, 10941–10956. [Google Scholar] [CrossRef]

- Snehal, K.; Das, B.; Akanksha, M. Early age, hydration, mechanical and microstructure properties of nano-silica blended cementitious composites. Constr. Build. Mater. 2020, 233, 117212. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Thomas, B.S.; Hawileh, R.A.; Kabeer, K.S.A. Influence of nanomaterials on the workability and compressive strength of cement-based concrete. Mater. Today Proc. 2022, 65, 2073–2076. [Google Scholar] [CrossRef]

- Ahmed, N.Y.; Alkhafaji, F.F. Nano-Silica (SiO2) Contribution to Mechanical and Microstructural Characteristics of High Performance Concrete Pavement. J. Eng. Sustain. Dev. 2020, 24, 71–78. [Google Scholar] [CrossRef]

- Nooruddin, S.; Shah, S.; Hussaini, M.; Umair, S.; Belgar, A.; Patil, P.S. Strength of Nano Concrete using Nano Silica. Int. J. Eng. Res. Technol. 2019, 8, 408–418. [Google Scholar]

- Mugilvani, P.; Murugan, S.T.; Kaviya, B.; Sathishkumar, K. Experimental investigation on nano concrete. Int. J. Civ. Eng. Technol. 2019, 10, 907–912. [Google Scholar]

- Danielraj, R.C.; Aniruddha, D.; Parvati, T.; Joanna, P. Mechanical properties of sustainable nano concrete using optimized admixture. Mater. Today Proc. 2020, 45, 5953–5959. [Google Scholar] [CrossRef]

- Liu, R.; Xiao, H.; Geng, J.; Du, J.; Liu, M. Effect of nano-CaCO3 and nano-SiO2 on improving the properties of carbon fibre-reinforced concrete and their pore-structure models. Constr. Build. Mater. 2020, 244, 118297. [Google Scholar] [CrossRef]

- Durak, U.; Karahan, O.; Uzal, B.; Ilkentapar, S.; Atiş, C.D. Influence of nano SiO2 and nano CaCO3 particles on strength, workability, and microstructural properties of fly ash-based geopolymer. Struct. Concr. 2020, 22, 1–16. [Google Scholar] [CrossRef]

- Husain, N.; Ismail, N.N.; Ismail, K.M.; Syamsunur, D.; Taib, M.M. Development of high workability grout on semi rigid wearing course. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Selangor, Malaysia, 29–31 October 2019; Volume 512. [Google Scholar] [CrossRef]

- Nathaniel, O.; Sam, A.R.M.; Lim, N.H.A.S.; Adebisi, O.; Abdulkareem, M. Biogenic approach for concrete durability and sustainability using effective microorganisms: A review. Constr. Build. Mater. 2020, 261, 119664. [Google Scholar] [CrossRef]

- Yang, Z.; Tang, M.; Ji, X.; Hu, H.; Jiang, X.; Zhang, D. Improvement of impermeability and chemical resistance of concrete by nanocomposites. Chem. Eng. Trans. 2018, 66, 25–30. [Google Scholar] [CrossRef]

- Heikal, M.; Gawwad, H.A.; Ababneh, F. Positive impact performance of hybrid effect of nano-clay and silica nano-particles on composite cements. Constr. Build. Mater. 2018, 190, 508–516. [Google Scholar] [CrossRef]

- Wu, Z.; Khayat, K.H.; Shi, C.; Tutikian, B.F.; Chen, Q. Mechanisms underlying the strength enhancement of UHPC modified with nano-SiO2 and nano-CaCO3. Cem. Concr. Compos. 2021, 119, 103992. [Google Scholar] [CrossRef]

- Alomayri, T. Performance evaluation of basalt fiber-reinforced geopolymer composites with various contents of nano CaCO3. Ceram. Int. 2021, 47, 29949–29959. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.S.; Faraj, R.H.; Qaidi, S.M.; Mohammed, A.A. Compressive strength of geopolymer concrete modified with nano-silica: Experimental and modeling investigations. Case Stud. Constr. Mater. 2022, 16, 1–29. [Google Scholar] [CrossRef]

- AlKhatib, A.; Maslehuddin, M.; Al-Dulaijan, S.U. Development of high performance concrete using industrial waste materials and nano-silica. J. Mater. Res. Technol. 2020, 9, 6696–6711. [Google Scholar] [CrossRef]

- Wang, T.; Gong, J.; Chen, B.; Gong, X.; Guo, W.; Zhang, Y.; Li, F. Mechanical Properties and Shrinkage of Ultrahigh-Performance Concrete Containing Lithium Carbonate and Nano-Calcium Carbonate. Adv. Civ. Eng. 2021, 2021, 6646272. [Google Scholar] [CrossRef]

- Luan, C.; Zhou, Y.; Liu, Y.; Ren, Z.; Wang, J.; Yuan, L.; Du, S.; Zhou, Z.; Huang, Y. Effects of nano-SiO2, nano-CaCO3 and nano-TiO2 on properties and microstructure of the high content calcium silicate phase cement (HCSC). Constr. Build. Mater. 2022, 314, 125377. [Google Scholar] [CrossRef]

- Alhawat, M.; Ashour, A.; El-Khoja, A. Influence of using different surface areas of nano silica on concrete properties. In Proceedings of the AIP Conference Proceedings, Istanbul, Turkey, 24–26 April 2019; Volume 2146. [Google Scholar] [CrossRef]

- Zhan, Z. Research on the Renovation of Old Industrial Buildings Based on Nano-Modified Cement Materials. SAE Int. J. Mater. Manuf. 2020, 13, 151–159. [Google Scholar] [CrossRef]

- Nejad, F.M.; Tolouei, M.; Nazari, H.; Naderan, A. Effects of Calcium Carbonate Nanoparticles and Fly Ash on Mechanical and Permeability Properties of Concrete. Adv. Civ. Eng. Mater. 2018, 7, 651–668. [Google Scholar] [CrossRef]

- Assaedi, H.; Alomayri, T.; Kaze, C.R.; Jindal, B.B.; Subaer, S.; Shaikh, F.; Alraddadi, S. Characterization and properties of geopolymer nanocomposites with different contents of nano-CaCO3. Constr. Build. Mater. 2020, 252, 119137. [Google Scholar] [CrossRef]

- Safaei, B.; Davodian, E.; Fattahi, A.M.; Asmael, M. Calcium carbonate nanoparticles effects on cement plast properties. Microsyst. Technol. 2021, 27, 3059–3076. [Google Scholar] [CrossRef]

- Bhargavi, P.; Murali, K. An experimental study on partial replacement of cement with bagasse ASH in concrete mix. Int. J. Civ. Eng. Technol. 2018, 9, 175–184. [Google Scholar]

- El-Feky, M.S.; Youssef, P.; El-Tair, A.M.; Ibrahim, S.; Serag, M. Effect of nano silica addition on enhancing the performance of cement composites reinforced with nano cellulose fibers. AIMS Mater. Sci. 2019, 6, 864–883. [Google Scholar] [CrossRef]

- Liu, H.; Yu, Y.; Liu, H.; Jin, J.; Liu, S. Hybrid effects of nano-silica and graphene oxide on mechanical properties and hydration products of oil well cement. Constr. Build. Mater. 2018, 191, 311–319. [Google Scholar] [CrossRef]

- Ngo, V.-T.; Bui, T.-T.; Lam, T.-Q.; Nguyen, T.-T.; Nguyen, V.-H. Experimental Evaluation of Nano Silica Effects to High Performance Concrete Strength in Early Age. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Ulaanbaatar, Mongolia, 10–13 September 2020; Volume 869. [Google Scholar] [CrossRef]

- Evangelia, T.; Maria, S. Effect of nano-SiO2 and nano-CaO in autogenous Self-healing efficiency. Mater. Today Proc. 2021, 37, 4071–4077. [Google Scholar] [CrossRef]

- Fu, C.; Xie, C.; Liu, J.; Wei, X.; Wu, D. A Comparative Study on the Effects of Three Nano-Materials on the Properties of Cement-Based Composites. Materials 2020, 13, 857. [Google Scholar] [CrossRef]

- He, R.; Yang, Z.; Gan, V.J.; Chen, H.; Cao, D. Mechanism of nano-silica to enhance the robustness and durability of concrete in low air pressure for sustainable civil infrastructures. J. Clean. Prod. 2021, 321, 128783. [Google Scholar] [CrossRef]

- Diab, A.M.; Elyamany, H.E.; Elmoaty, A.E.M.A.; Sreh, M.M. Effect of nanomaterials additives on performance of concrete resistance against magnesium sulfate and acids. Constr. Build. Mater. 2019, 210, 210–231. [Google Scholar] [CrossRef]

- Mahdikhani, M.; Bamshad, O.; Shirvani, M.F. Mechanical properties and durability of concrete specimens containing nano silica in sulfuric acid rain condition. Constr. Build. Mater. 2018, 167, 929–935. [Google Scholar] [CrossRef]

- Li, C. Chloride permeability and chloride binding capacity of nano-modified concrete. J. Build. Eng. 2021, 41, 102419. [Google Scholar] [CrossRef]

- Al Ghabban, A.; Al Zubaidi, A.B.; Jafar, M.; Fakhri, Z. Effect of Nano SiO2 and Nano CaCO3 on The Mechanical Properties, Durability and flowability of Concrete. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Istanbul, Turkey, 8 August 2018; Volume 454. [Google Scholar] [CrossRef]

- Singh, L.; Ali, D.; Tyagi, I.; Sharma, U.; Singh, R.; Hou, P. Durability studies of nano-engineered fly ash concrete. Constr. Build. Mater. 2019, 194, 205–215. [Google Scholar] [CrossRef]

- Zhang, A.; Yang, W.; Ge, Y.; Du, Y.; Liu, P. Effects of nano-SiO2 and nano-Al2O3 on mechanical and durability properties of cement-based materials: A comparative study. J. Build. Eng. 2021, 34, 101936. [Google Scholar] [CrossRef]

- Maheswaran, S.; Murthy, A.R.; Kumar, V.R.; Karunanithi, A. Characterisation studies on the particle size effect of calcium carbonate in high-strength concrete. Mag. Concr. Res. 2021, 73, 661–673. [Google Scholar] [CrossRef]

- Hosan, A.; Shaikh, F.U.A. Compressive strength development and durability properties of high volume slag and slag-fly ash blended concretes containing nano-CaCO3. J. Mater. Res. Technol. 2021, 10, 1310–1322. [Google Scholar] [CrossRef]

- Yang, J. Effect of nano CaCO3 on durability of concrete. E3S Web Conf. 2020, 165, 03029. [Google Scholar] [CrossRef]

- Rad, T.A.; Tanzadeh, J.; Pourdada, A. Laboratory evaluation of self-compacting fiber-reinforced concrete modified with hybrid of nanomaterials. Constr. Build. Mater. 2020, 232, 117211. [Google Scholar] [CrossRef]

- Sujay, H.M.; Nair, N.A.; Rao, H.S.; Sairam, V. Experimental study on durability characteristics of composite fiber reinforced high-performance concrete incorporating nanosilica and ultra fine fly ash. Constr. Build. Mater. 2020, 262, 120738. [Google Scholar] [CrossRef]

- Kumar, K.S.J.; Rao, M.V.S.; Reddy, V.S.; Shrihari, S. Performance evaluation of nano-silica concrete. E3S Web Conf. 2020, 184, 01076. [Google Scholar] [CrossRef]

- Nayak, C.B.; Taware, P.P.; Jagadale, U.T.; Jadhav, N.A.; Morkhade, S.G. Effect of SiO2 and ZnO Nano-Composites on Mechanical and Chemical Properties of Modified Concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 46, 1237–1247. [Google Scholar] [CrossRef]

- Polat, R.; Qarluq, A.W.; Karagöl, F. Influence of singular and binary nanomaterials on the physical, mechanical and durability properties of mortars subjected to elevated temperatures and freeze–thaw cycles. Constr. Build. Mater. 2021, 295, 123608. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Thomas, B.S.; Hawileh, R.A.; Kabeer, K.S.A. Influence of nanomaterials on the water absorption and chloride penetration of cement-based concrete. Mater. Today Proc. 2022, 65, 2066–2069. [Google Scholar] [CrossRef]

- Huang, K.; Xie, J.; Wang, R.; Feng, Y.; Rao, R. Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete. Nanotechnol. Rev. 2021, 10, 304–317. [Google Scholar] [CrossRef]

- Zhu, P.; Xu, X.; Liu, H.; Liu, S.; Chen, C.; Jia, Z. Tunnel fire resistance of self-compacting concrete coated with SiO2 aerogel cement paste under 2.5 h HC fire loading. Constr. Build. Mater. 2020, 239, 117857. [Google Scholar] [CrossRef]

- Afzal, M.T.; Khushnood, R.A. Influence of carbon nano fibers (CNF) on the performance of high strength concrete exposed to elevated temperatures. Constr. Build. Mater. 2021, 268, 121108. [Google Scholar] [CrossRef]

- Wu, L.; Lu, Z.; Zhuang, C.; Chen, Y.; Hu, R. Mechanical Properties of Nano SiO2 and Carbon Fiber Reinforced Concrete after Exposure to High Temperatures. Materials 2019, 12, 3773. [Google Scholar] [CrossRef] [PubMed]

- Shah, A.; Sharma, U.; Roy, D.A.; Bhargava, P. Spalling behaviour of nano SiO2high strength concrete at elevated temperatures. In Proceedings of the MATEC Web of Conferences, Paris, France, 25–27 September 2013; Volume 6. [Google Scholar] [CrossRef]

- Elsayd, A.A.; Fathy, I.N. Experimental Study of Fire Effects on Compressive Strength of Normal-Strength Concrete Supported With Nanomaterials Additives. IOSR J. Mech. Civ. Eng. 2019, 16, 28–37. [Google Scholar]

- Gao, D.; Zhao, L.; Chen, G. Flexural behavior of fiber and nanoparticle reinforced concrete at high temperatures. Fire Mater. 2018, 42, 725–740. [Google Scholar] [CrossRef]

- Cao, M.; Yuan, X.; Ming, X.; Xie, C. Effect of High Temperature on Compressive Strength and Microstructure of Cement Paste Modified by Micro- and Nano-calcium Carbonate Particles. Fire Technol. 2022, 58, 1469–1491. [Google Scholar] [CrossRef]

- Abhilash, P.P.; Nayak, D.K.; Sangoju, B.; Kumar, R.; Kumar, V. Effect of nano-silica in concrete: A review. Constr. Build. Mater. 2021, 278, 122347. [Google Scholar] [CrossRef]

- Sikora, P.; Elrahman, M.A.; Stephan, D. The Influence of Nanomaterials on the Thermal Resistance of Cement-Based Composites—A Review. Nanomaterials 2018, 8, 465. [Google Scholar] [CrossRef] [PubMed]

- Laím, L.; Caetano, H.; Santiago, A. Review: Effects of nanoparticles in cementitious construction materials at ambient and high temperatures. J. Build. Eng. 2021, 35, 102008. [Google Scholar] [CrossRef]

- Ashwini, K.; Srinivasa Rao, P. Effect of elevated temperature on strength and durability properties of concrete using nano-silica and alccofine. Res. Eng. Struct. Mater. 2022, 8, 101–115. [Google Scholar] [CrossRef]

- Ashwini, K.; Rao, P.S. Behavior of concrete using alccofine and nano-silica under elevated temperature. Int. J. Adv. Technol. Eng. Explor. 2021, 8, 600–618. [Google Scholar] [CrossRef]

- Kantarci, F.; Türkmen, I.; Ekinci, E. Improving elevated temperature performance of geopolymer concrete utilizing nano-silica, micro-silica and styrene-butadiene latex. Constr. Build. Mater. 2021, 286, 122980. [Google Scholar] [CrossRef]

- Brzozowski, P.; Strzałkowski, J.; Rychtowski, P.; Wróbel, R.; Tryba, B.; Horszczaruk, E. Effect of Nano-SiO2 on the Microstructure and Mechanical Properties of Concrete under High Temperature Conditions. Materials 2022, 15, 166. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Chaopeng, X.; Ali, M. Experimental and analytical study of hybrid fiber reinforced concrete prepared with basalt fiber under high temperature. Fire Mater. 2022, 46, 205–226. [Google Scholar] [CrossRef]

- Mathews, M.E.; Kiran, T.; Naidu, V.C.H.; Jeyakumar, G.; Anand, N. Effect of high-temperature on the mechanical and durability behaviour of concrete. Mater. Today Proc. 2020, 42, 718–725. [Google Scholar] [CrossRef]

- Cao, M.; Ming, X.; Yin, H.; Li, L. Influence of high temperature on strength, ultrasonic velocity and mass loss of calcium carbonate whisker reinforced cement paste. Compos. Part B Eng. 2019, 163, 438–446. [Google Scholar] [CrossRef]

- Cao, M.; Li, L.; Yin, H.; Ming, X. Microstructure and Strength of Calcium Carbonate (CaCO3) Whisker Reinforced Cement Paste After Exposed to High Temperatures. Fire Technol. 2019, 55, 1983–2003. [Google Scholar] [CrossRef]

| Author | Year | Nanomaterials | Optimum Dosage (%) | Advance | Medium | Compressive Increase (%) | Splitting Increase (%) | Flexural Increase (%) | Influence Factor |

|---|---|---|---|---|---|---|---|---|---|

| [83] | 2020 | NC | 2.0 | Compressive, Flexural | NC | 57.1 | - | 58.7 | In total, 2.0% of NC particles have good cohesion to make the concrete denser, and 3.0% of NC agglomeration is severe and can lead to cracks. |

| [74] | 2021 | NC, NS | 3.2 | Compressive, Flexural | NS/NC + Steel fibres | 10 | - | 21 | The nucleation effect of nanomaterials and the development of an optimised internal organisation enhance the strength of concrete. The agglomeration of particles can occur in excessive amounts, weakening the interfacial transition zone. |

| [84] | 2021 | NC | 1.5 | Compressive, Splitting | NC | 25 | 20 | - | NC dosing above 1.5% will produce excessive hydration layers reducing strength. |

| [82] | 2018 | NC | 0.5 | Compressive, Splitting, Flexural | NC + Fly ash | 57.2 | 36.9 | 45.2 | NC reacts chemically with the elements in the cement paste, resulting in a significant increase in mechanical strength at 7 and 28 days. Greater modifying effect than the addition of fly ash. |

| [85] | 2018 | NS | 2.5 | Compressive, Splitting | NS | 8.4 | 104.2 | - | NS instead of cement mix concrete, smaller size fills the void of concrete to enhance the mechanical properties of the strength. |

| [81] | 2020 | NS | 2.0 | Compressive, Flexural | NS | 9.7 | - | 17.1 | Fine NS particles produce a hydration reaction that can be used for the restoration of old buildings. |

| [59] | 2021 | NS | 2.0 | Compressive, Splitting | NS + Silica fume | 15.7 | 31.5 | - | The volcanic ash effect of NS produces more C-S-H, making the interface transition zone dense and inhibiting the development of small cracks in concrete. |

| [86] | 2019 | NS | 1.5 | Compressive, Splitting | NS + Cellulose nano fibres | 39 | 49 | - | Transition zone between NS-modified cellulose nanofibres and gelling materials. |

| [87] | 2018 | NS | 1.5 | Compressive, Flexural | NS + Graphene oxide | 43.2 | - | 42 | NS particles are well dispersed and the hydration products resulting from the volcanic ash effect form a reticulated mix. |

| [58] | 2019 | NS | 3.0 | Compressive, Splitting, Flexural | NS + Polyethylene terephthalate | 30.0 | 27.0 | 9.0 | NS improves the interface transition zone between cement and PET aggregates. |

| [88] | 2020 | NS | 1.5 | Compressive, Splitting, Flexural | NS | - | - | 14.82 | Ultra-fine NS particles tighten the structure to produce more gel material. |

| [89] | 2020 | NS | 3.0 | Compressive | NS + Nano-CaO | 23.4 | - | - | NS modification has a denser microstructure and is accompanied by a self-healing ability. |

| [80] | 2019 | NS | 3.0 | Compressive | NS | 38 | - | - | The increase in strength is related to the water to glue ratio and the size of the NS particles, with the optimum range being between 2% and 5%. The hydrocolloid ratio increases as the voids become larger and the NS fills in the gaps. |

| [90] | 2020 | NS | 2.0 | Compressive, Flexural | NS | 23.1 | - | 14.91 | Promotes the hydration reaction of the cement, mixing 2.0% mass fraction of NS alone is the best result of the study. |

| [49] | 2022 | NS + NC | 2.0 | Compressive, Splitting, Flexural | NC, NS, NSC | 8.8 | 4 | 9.3 | NS optimises the void structure, NC makes the concrete structure denser and the effect of the two blends can synergistically improve dynamic and static mechanical properties. |

| Author | Year | Nanomaterials | Optimum Dosage (%) | Advance | Influence Factor |

|---|---|---|---|---|---|

| [49] | 2019 | NC | 3.0 | Water absorption and hydrochloric acid resistance | NC reacts with the aluminate phase to produce more hydration products, reducing the water absorption of the concrete and increasing the hydrochloric acid resistance. |

| [82] | 2018 | NC | 1.0 | Water absorption and depth of penetration | NC increases the microscopic nucleation during hydration and thus reduces the void ratio of the concrete. Used together with fly ash, it results in a denser microstructure. Compared to the previous author, no hydrochloric acid resistance experiments are tested and the dosing of NC can be reduced to 1.0%. |

| [99] | 2020 | NC | 1.0 | Water absorption, chloride penetration and drying shrinkage | The addition of 1% NC interfacial bonding is better, mixed with a certain amount of slag and fly ash, and hydration increases to obtain excellent durability properties. |

| [100] | 2020 | NC | 1.5 | Impermeability | The high activity of nanoparticles, the increased surface effect and the hydration reaction make the concrete dense and improve the impermeability. |

| [96] | 2019 | NS | 3.0 | Depth of carbonation | The additional hydration products reduce the depth of carbonation of the concrete and resist penetration and attack by harmful substances. |

| [101] | 2020 | NS | 3.0 | Water absorption | The volcanic ash effect and microfilling effect of NS reduce the water absorption of concrete. NS is a good promoter of the modification of basalt fibre concrete. |

| [102] | 2020 | NS | 3.0 | Porosity and chloride ion permeation | NS with ultra-fine fly ash reduces chloride ion permeability from 53.83% to 71.45%. Both increase the density of the concrete due to the smaller particles. The authors set NS admixture levels from 0% to 4.5% and tests yield an optimum value of 3.0% for resistance to chloride ion permeation. |

| [103] | 2020 | NS | 1.0 | Water absorption and porosity | NS is used as a filler to fill the density of the concrete and to fill the voids in the internal matrix. A 1.0% replacement cement will achieve the required result. |

| [104] | 2021 | NS | 0.75 | Hydrochloric acid resistance | The gel produced by NS with the gelling material contributes to the development of durable properties. The Zn(OH)2 produced in the hydration reaction is able to resist the ingress of moisture. |

| [105] | 2021 | NS | 2.5 | Porosity and freeze-thaw resistance | The authors confirm through microscopic experiments that NS reflects with calcium hydroxide, producing a large number of C-S-H gel structures, densifying the microstructure and reducing the void fraction. Compared to the previous authors’ conclusions, the NS-doping is increased to 2.5% in order to obtain the best freeze-thaw resistance. |

| [68] | 2020 | NS + NC | 1.0+3.0 | Impermeability | The addition of NS and NC gives the carbon fibre concrete greater durability and a lower water–cement ratio of 0.4 for water penetration properties. |

| [106] | 2022 | NS, NC | 2.0, 3.0 | Water absorption and chloride ion penetration | In total, 2% NS reduces the water absorption of concrete to 58% and 2% NS can reduce the water absorption of concrete to 65–70%. The main reason for this action is the hydration of the nanoparticles filling the tiny voids. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Syamsunur, D.; Wei, L.; Ahmed Memon, Z.; Surol, S.; Md Yusoff, N.I. Concrete Performance Attenuation of Mix Nano-SiO2 and Nano-CaCO3 under High Temperature: A Comprehensive Review. Materials 2022, 15, 7073. https://doi.org/10.3390/ma15207073

Syamsunur D, Wei L, Ahmed Memon Z, Surol S, Md Yusoff NI. Concrete Performance Attenuation of Mix Nano-SiO2 and Nano-CaCO3 under High Temperature: A Comprehensive Review. Materials. 2022; 15(20):7073. https://doi.org/10.3390/ma15207073

Chicago/Turabian StyleSyamsunur, Deprizon, Li Wei, Zubair Ahmed Memon, Salihah Surol, and Nur Izzi Md Yusoff. 2022. "Concrete Performance Attenuation of Mix Nano-SiO2 and Nano-CaCO3 under High Temperature: A Comprehensive Review" Materials 15, no. 20: 7073. https://doi.org/10.3390/ma15207073

APA StyleSyamsunur, D., Wei, L., Ahmed Memon, Z., Surol, S., & Md Yusoff, N. I. (2022). Concrete Performance Attenuation of Mix Nano-SiO2 and Nano-CaCO3 under High Temperature: A Comprehensive Review. Materials, 15(20), 7073. https://doi.org/10.3390/ma15207073